The gas turbine cooling system is an important industrial process control problem which is widely studied by scholars [

1,

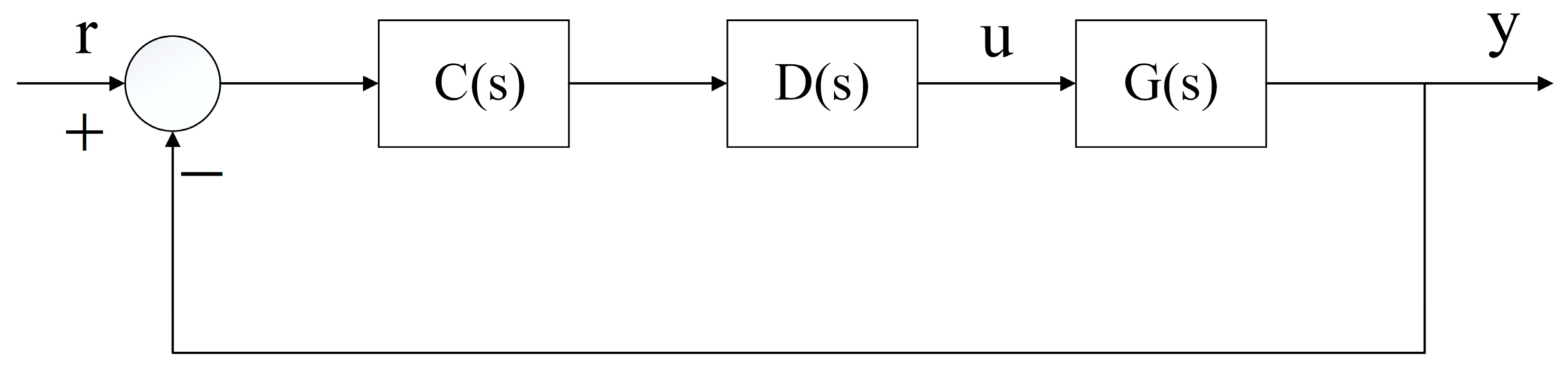

2]. Most gas turbine cooling system in steamships rely on secondary water circulation and a heat exchanger. The control accuracy of the gas turbine cooling system studied in this paper mostly depends on the on-site staff who adjust the opening of valves and rotation speed of the motor according to experience. There are problems such as a low working efficiency, low control accuracy, long adjustment time, unstable output variables, etc. The system has certain shortcomings in rapidity, accuracy and safety. In order to solve these problems caused by the manual operation of the gas turbine cooling system, it is necessary to adopt the automatic control system to realize the accuracy control of the load inlet flow, load inlet temperature and main pipe pressure. The gas turbine cooling system is an MIMO complex system. Due to the large number of controlled variables in an MIMO system, it is necessary to add multiple control loops to control it, which leads to a certain coupling phenomenon among variables [

3,

4] which will reduce the performance of the system, making the gas turbine cooling system complex and even difficult to control. Variables have nonlinear strong coupling characteristics, and need to be decoupled. Traditional decoupling methods are mainly divided into static decoupling and dynamic decoupling. The design of the static decoupler requires some harsh conditions, such as ensuring the system is closed-loop stable, the closed-loop transfer function matrix is nonsingular and the diagonal constant matrix is in a steady state. Once the complex industrial system has a strong nonlinearity or the model has a relatively large error, it is often difficult to obtain a good control performance [

5,

6]. A dynamic decoupler provides model information to the decoupling process and the decoupling compensator acts directly on the controlled object, which can obtain a better control performance and meet the design requirements of a nonlinear MIMO system controller [

7,

8]. The controllers of the gas turbine cooling system are proportional–integral–derivative (PID) controllers. Since there are three controlled variables of the gas turbine cooling system and three corresponding PID controllers, it is a challenge for the parameters setting of the PID controllers. It is a good method to introduce the optimization algorithm to optimize the parameters of the PID controller. Optimization algorithms have developed rapidly. The common optimization algorithms have particle swarm optimization (PSO) [

9], genetic algorithm (GA) [

10], simulated annealing (SA) [

11], etc. Reference [

12] pointed out that when solving complex problems, particle swarm optimization shows a poor local search ability and a slow convergence speed. Reference [

13] pointed out that when the controller needs to set a large number of parameters (five), the complexity of the genetic algorithm is too high and the performance is relatively ill-behaved. References [

14,

15,

16] improved the particle swarm optimization algorithm to speed up the convergence speed of the algorithm and improve the accuracy of the convergence results. Reference [

17] proposed an improved genetic algorithm PID control aiming at the problem that PID tuning methods cannot deal with the complex process of non-linearity, time-varying, coupling and the uncertainty of the parameters and structure in time. Reference [

18] improved the passive web optimization, which is more applied to the PID controller parameters setting for a DC motor. The physics based multi-verse optimizer (MVO) has emerged in recent years [

19]. Black hole, white hole, wormhole exchange and expansion are similar to the cross operation of the genetic algorithm, and the best universe is obtained by updating. It was originally used to deal with the single objective and continuous optimization problems. Although the MVO has been improved, there are still some limitations for the gas turbine cooling system. The dingo optimization algorithm (DOA) [

20] simulated four behaviors of African wild dog hunting: the siege, chase, scavenging and survival. When applied to the parameters optimization of the PID controller, it performs well in overshoot and transient time, but its performance in peak time is not as good as that of the artificial bee colony (ABC) [

21].

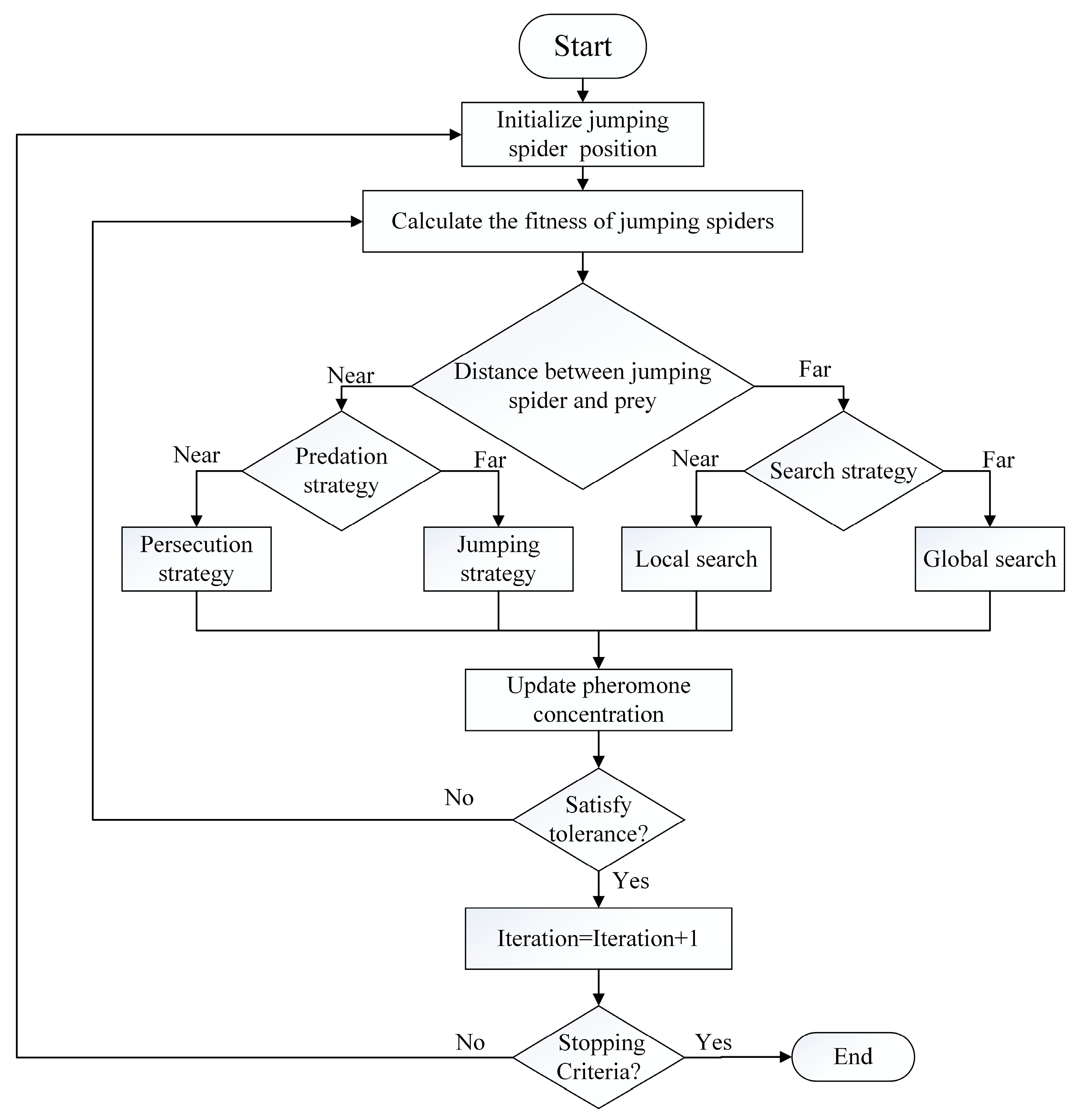

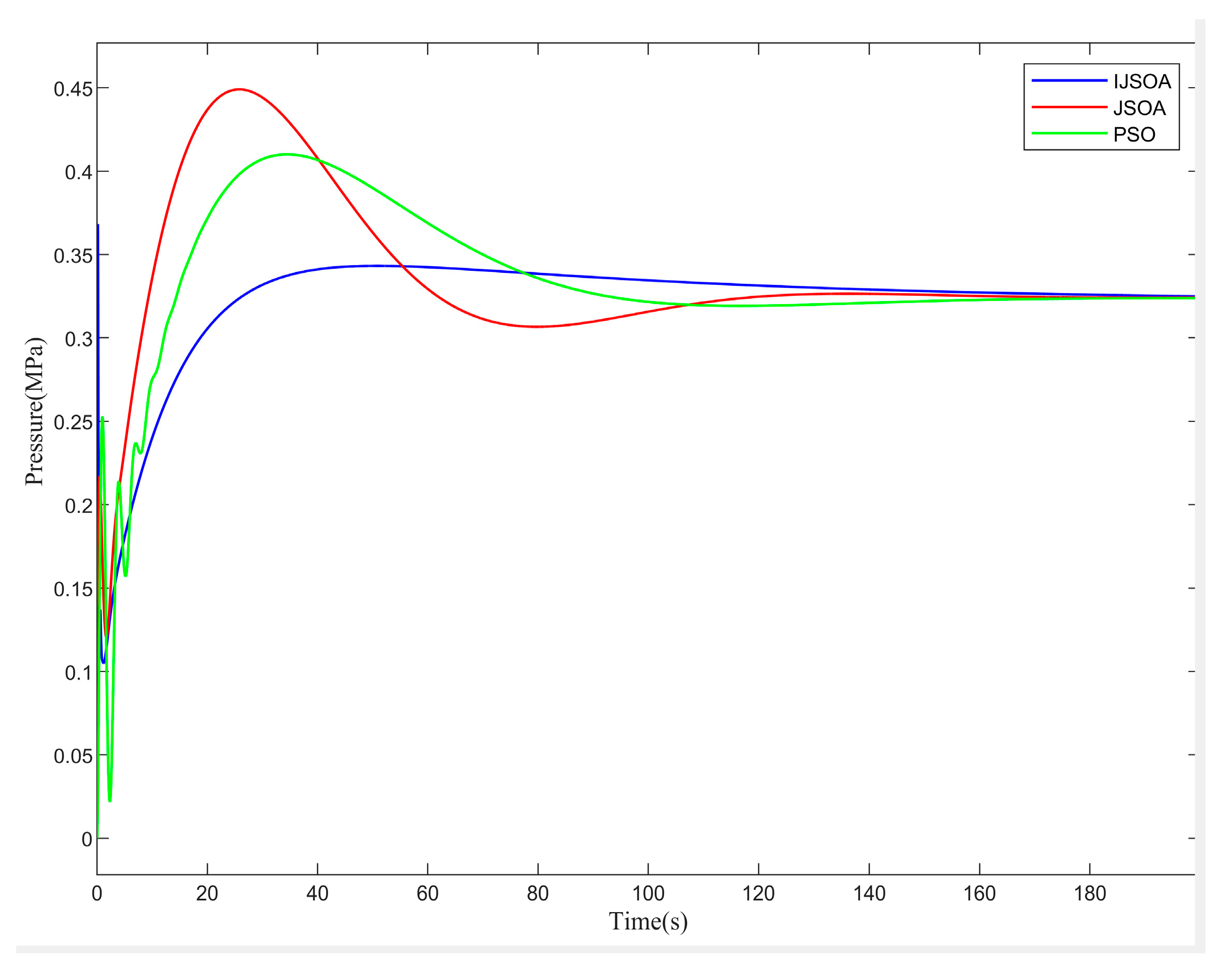

The jumping spider optimization algorithm (JSOA) [

22] is a new intelligent optimization algorithm which was proposed in 2021. It has the characteristics of fast convergence and a strong optimization ability. The objective function selected in the literature is the reference function, and it is proved that in the unimodal function, the jumping spider optimization algorithm performs better than other optimization algorithms such as the chaos game optimization (CGO) and Archimedes optimization algorithm (AOA). However, when applied to the gas turbine cooling system, the performance and overshoot of the jumping spider optimization algorithm are unacceptable. This is unfavorable to the stability and service life of the gas turbine cooling system, and is not applicable to the MIMO control system represented by the gas turbine cooling system. The genetic algorithm within the DTC shows a very good robustness in speed and torque by reducing torque ripples and suppressing overshoots [

23]. Reference [

24] proposed an optimized genetic algorithm to automatically tune the PI regulator in the model reference adaptive system based on several execution sequences. The results prove that this strategy can enhance speed and tracking performance while guaranteeing an excellent behavior of the overshoot and rejection time. The parallel mechanism potential of the genetic algorithm is not fully utilized, which is also a potential research direction. In Reference [

25], the central chord architecture was considered, and the performance characteristics were obtained by using gray wolf optimization (GWO) and the flower pollination algorithm (FPA). Reference [

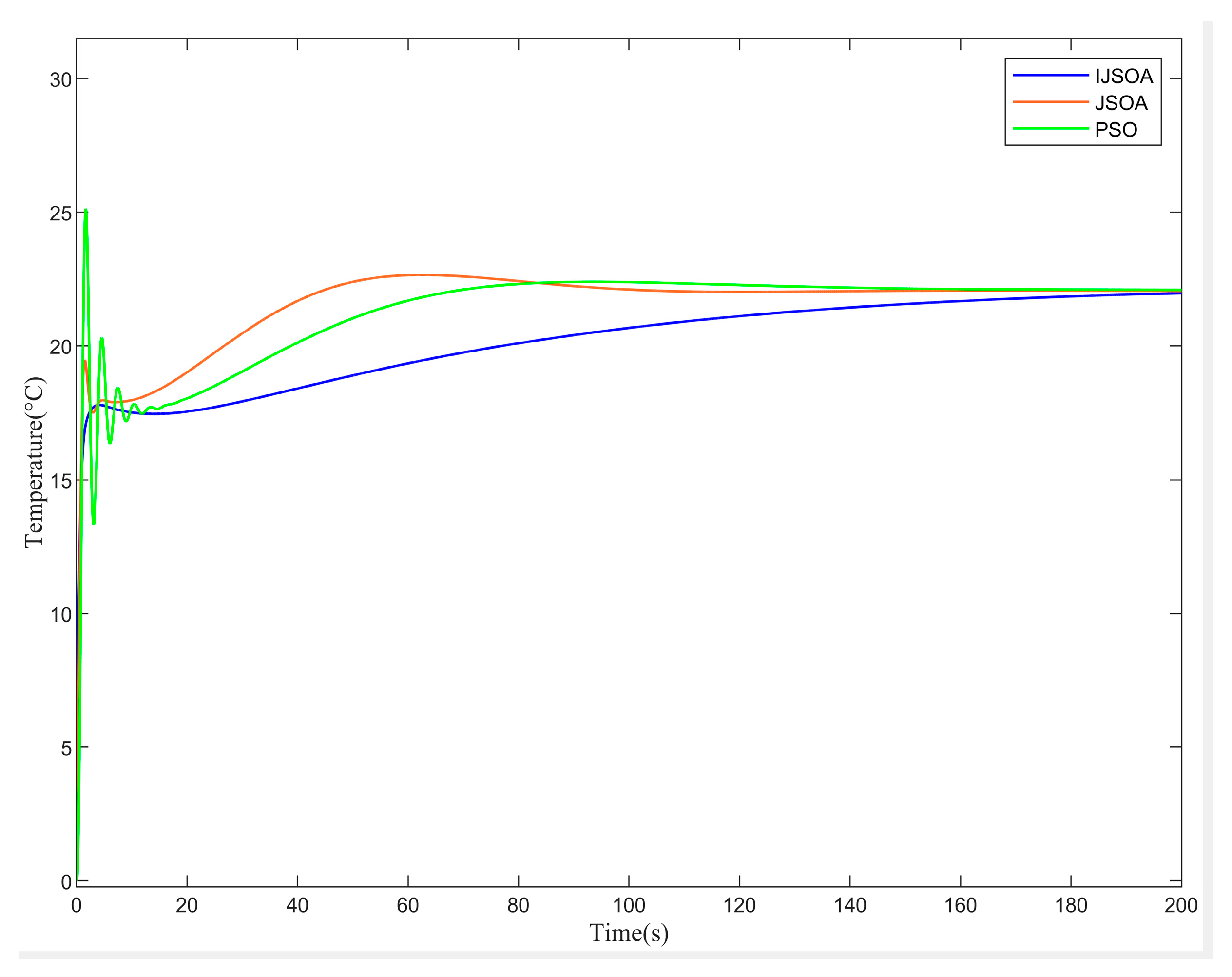

26] proposed a new maximum power point tracking (MPPT) framework for photovoltaic (PV) systems, which was based on the remora optimization algorithm (ROA) under standard and partial shadow conditions. In view of the limitations of the application of the above optimization algorithm in the gas turbine cooling system, in this paper the pheromone model of the JSOA and jumping cycle strategy are improved. An intelligent PID controller based on the improved jumping spider optimization algorithm is proposed. The gas turbine cooling system is developed through the improved jumping spider optimization algorithm to solve the temperature, flow and pressure real-time control.

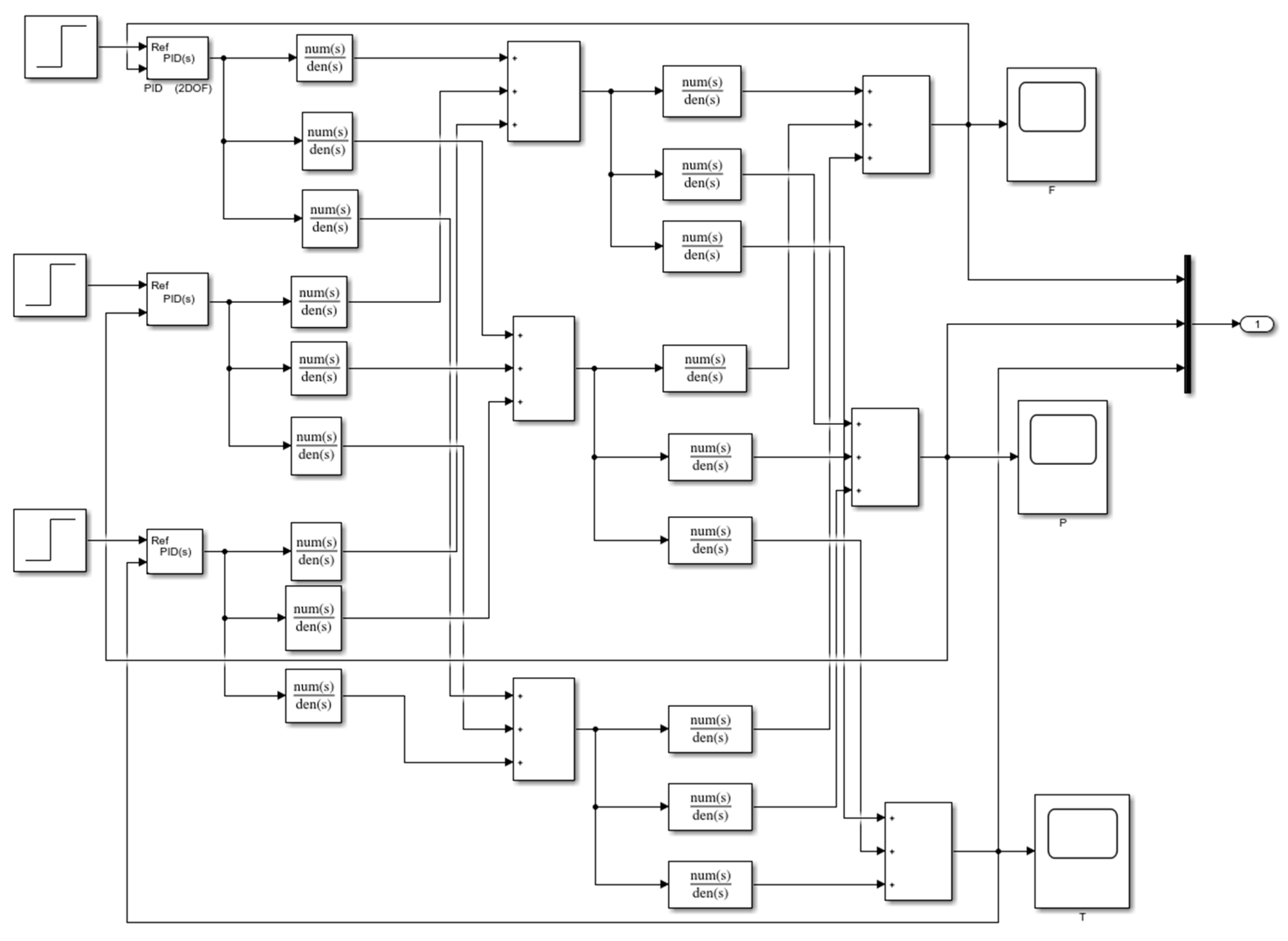

In the second section, the working principle of the gas turbine cooling system is introduced and the decoupling device is designed. In

Section 2.2 and

Section 2.3, the coupling relationship of the gas turbine cooling system is analyzed and the system mathematical model is obtained through system identification; the simulation block diagram of the three input and three output decoupling control system is established by the diagonal matrix decoupling method. In the third section, the principle of the JSOA and IJSOA are introduced.

Section 3.2 improves the pheromone model of the JSOA to overcome the limitations of the JSOA in an MIMO system. Due to the complexity of the JSOA optimization strategy, a jumping out of the loop strategy is designed to speed up the algorithm running time. In the fourth section, PSO, the JSOA and IJSOA are applied to the controller parameter tuning of the gas turbine cooling system, respectively, and the simulation results are obtained.