Fatigue Analysis of Dozer Push Arms under Tilt Bulldozing Conditions

Abstract

:1. Introduction

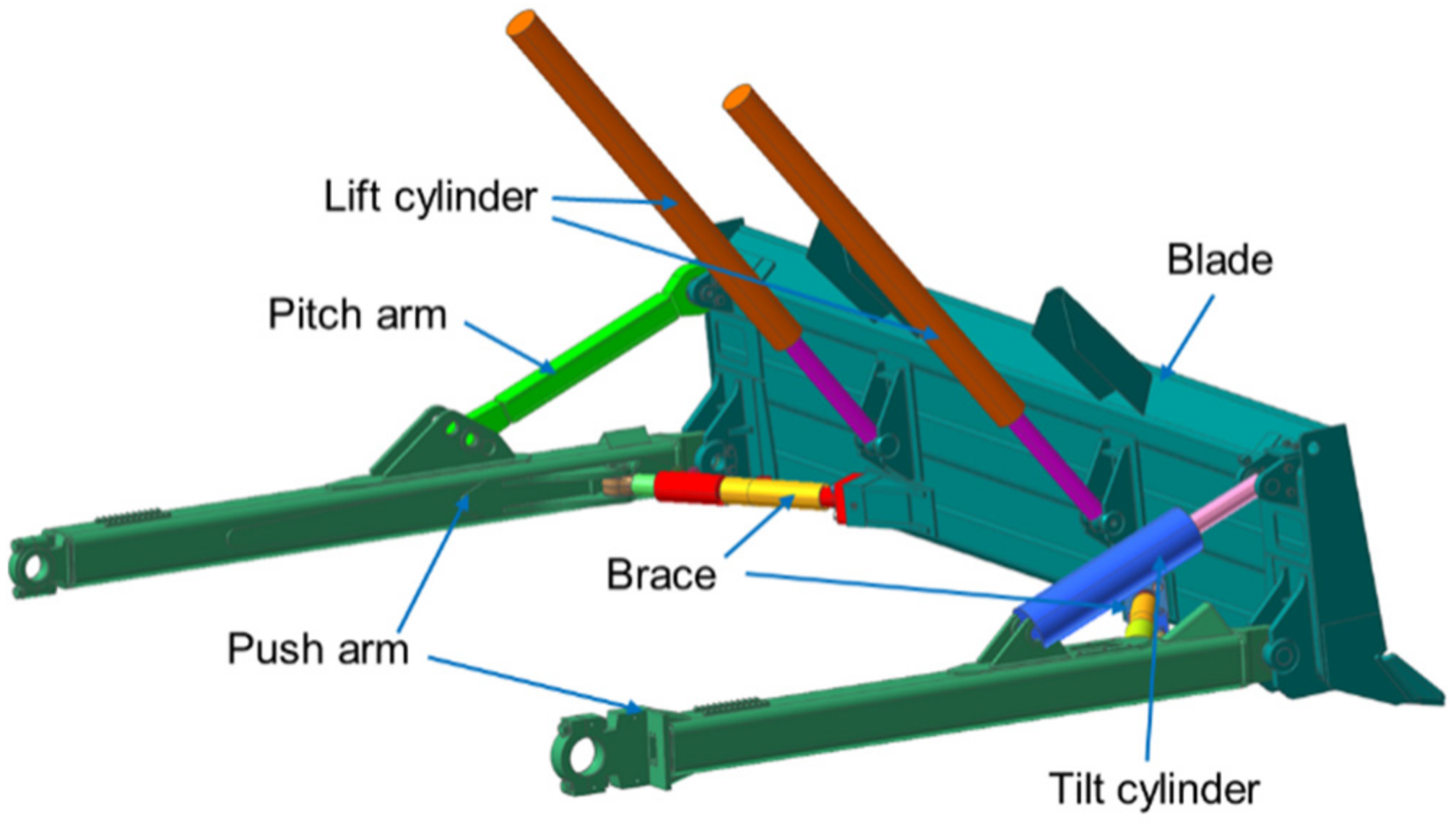

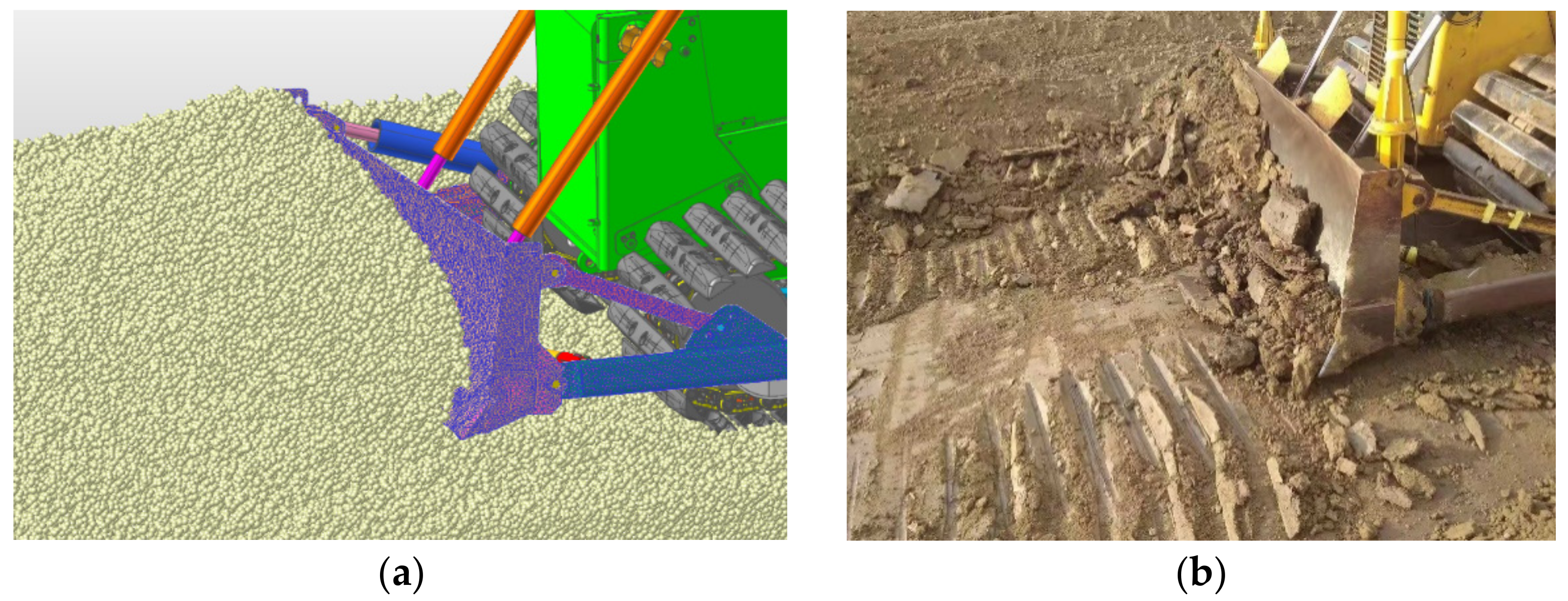

2. Simulation Model

2.1. Dozer Dynamic Model

2.2. Soil Model

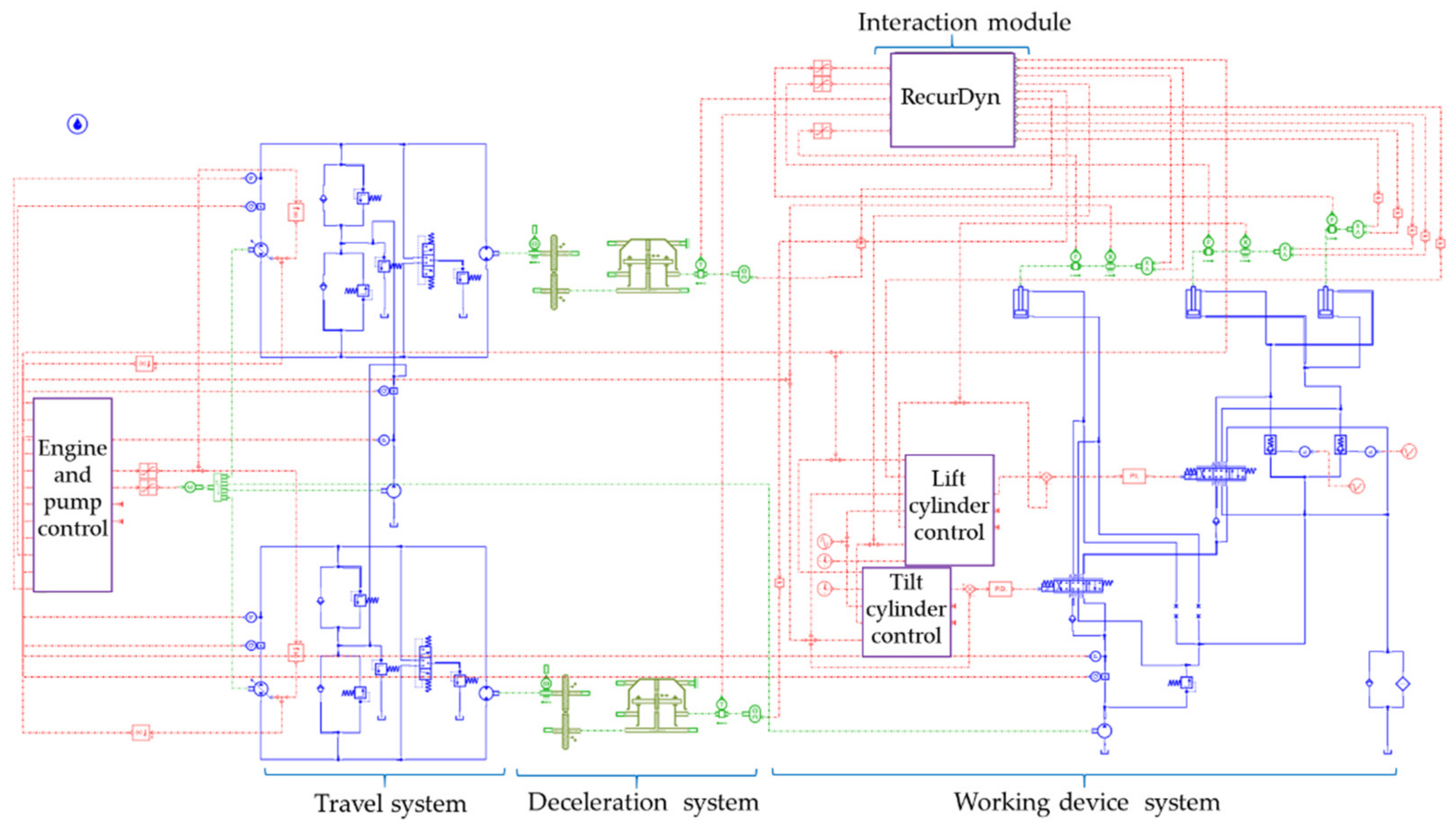

2.3. Control System Model

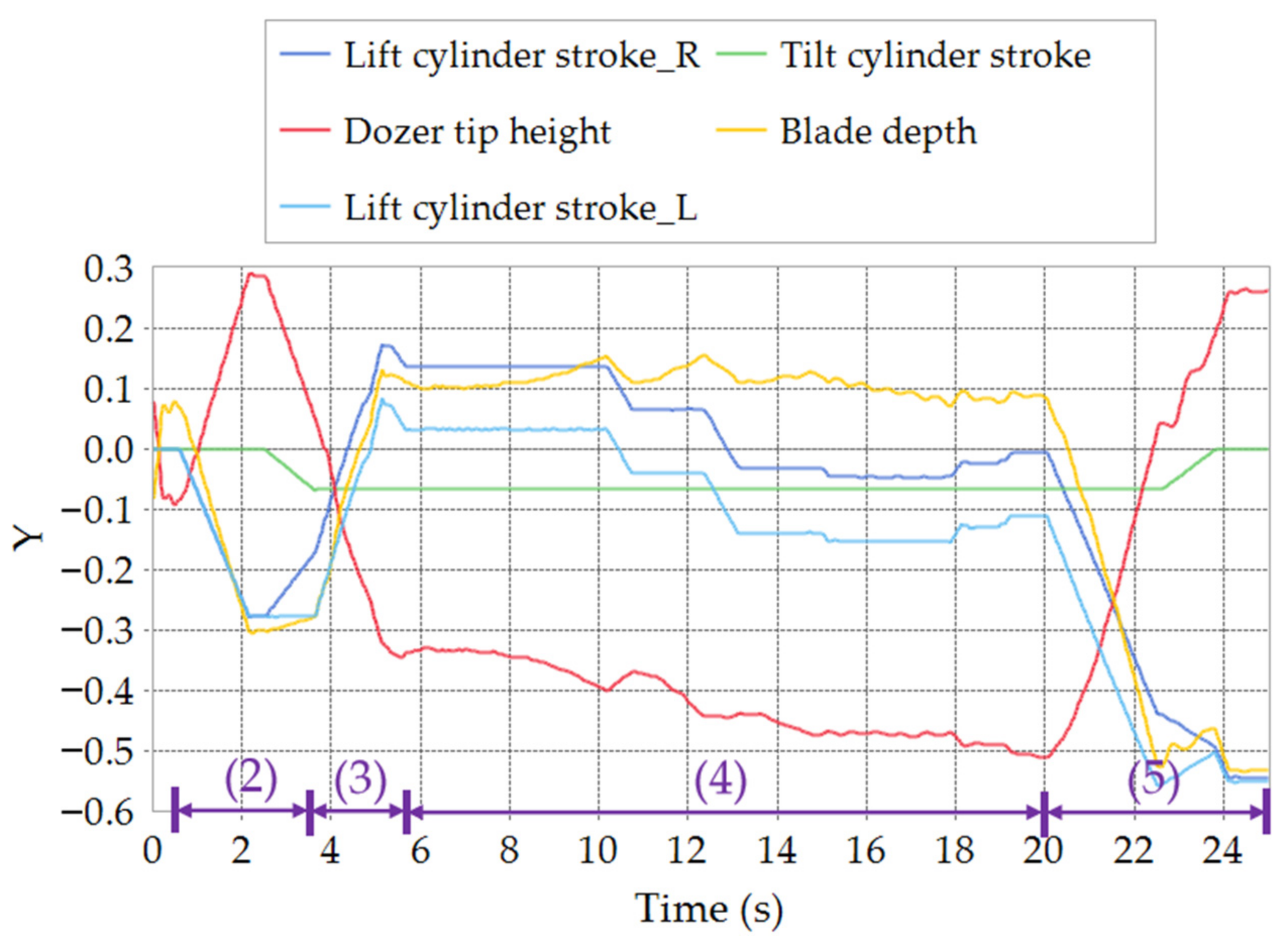

- (1)

- Initial stage. All the oil cylinders remain stationary to ensure the stability of the system within the first 0.5 s;

- (2)

- Blade lifting and tilting stage. The lift cylinders retract at the speed of 0.2 m/s to lift the blade. Then, the lift cylinders remain stationary as the blade is 0.3 m above the ground. Subsequently, the tilt cylinder retracts at a speed of 0.2 m/s to make the blade tilt right to its maximum inclination;

- (3)

- Soil cutting stage. The lift cylinders extend at a speed of 0.25 m/s to lower the blade for cutting soil. Then the lift cylinders remain stationary to collect the soil as the blade depth (distance from the ground to the middle of the blade lower edge) reaches 0.13 m;

- (4)

- Soil collection stage. The movement of the lift cylinders is controlled according to the real-time detected blade depth and the slip rate, such that the soil can be collected within the target depth range, i.e., 0.08 m to 0.16 m, and within the specified slip rate range, i.e., less than 0.3. The speed of the lift cylinders is 0.13 m/s;

- (5)

- Soil unloading stage. The lift cylinders retract at a speed of 0.5 m/s for unloading the soil, as the simulation time is greater than 20 s. When the blade is lifted, the right tip is 0.03 m above the ground and the tilt cylinder retracts at the speed of 0.3 m/s to rotate the blade back.where represents slip rate of the dozer track, and are angular velocity of sprocket and forward speed of the dozer, respectively, and is pitch radius of the sprocket.

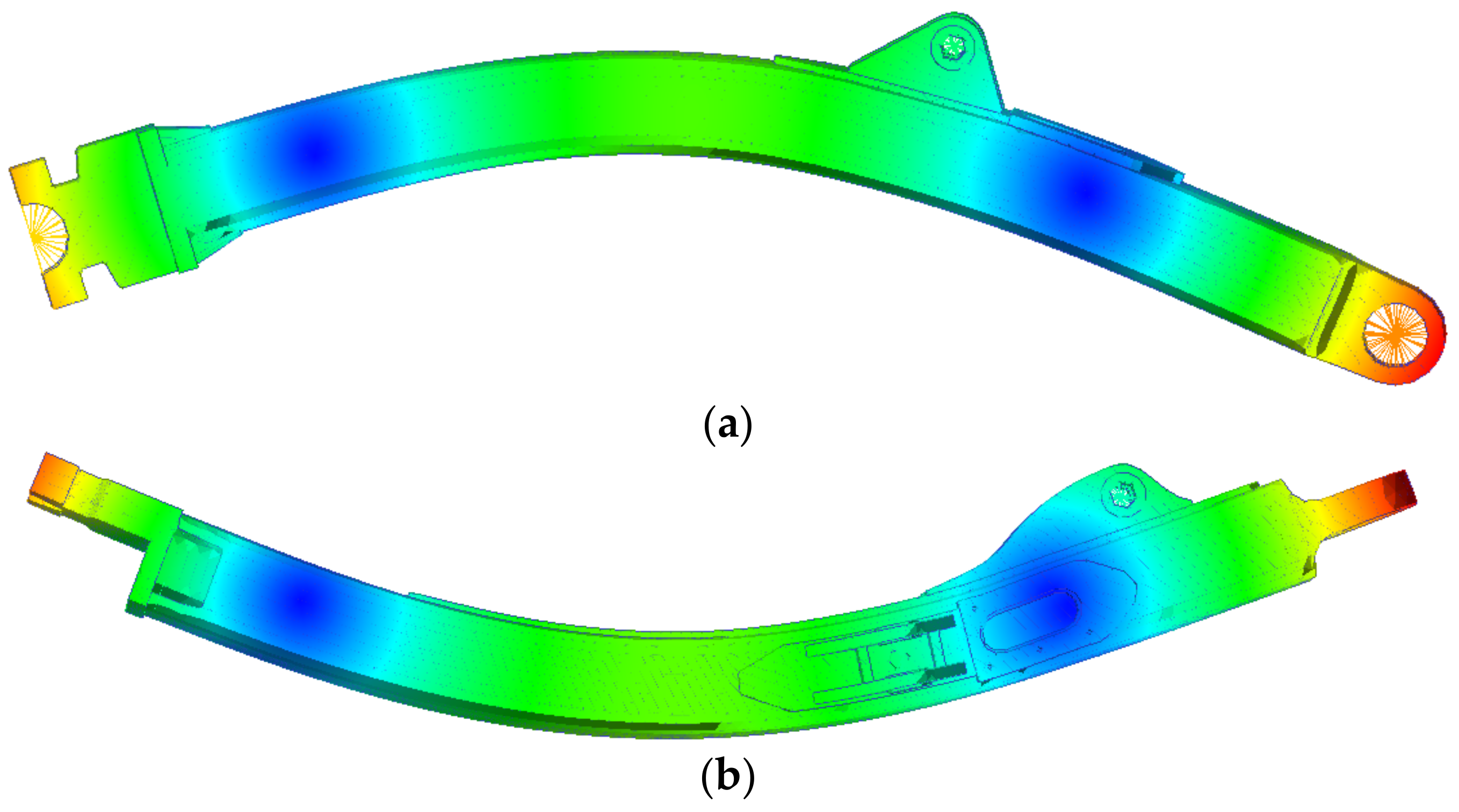

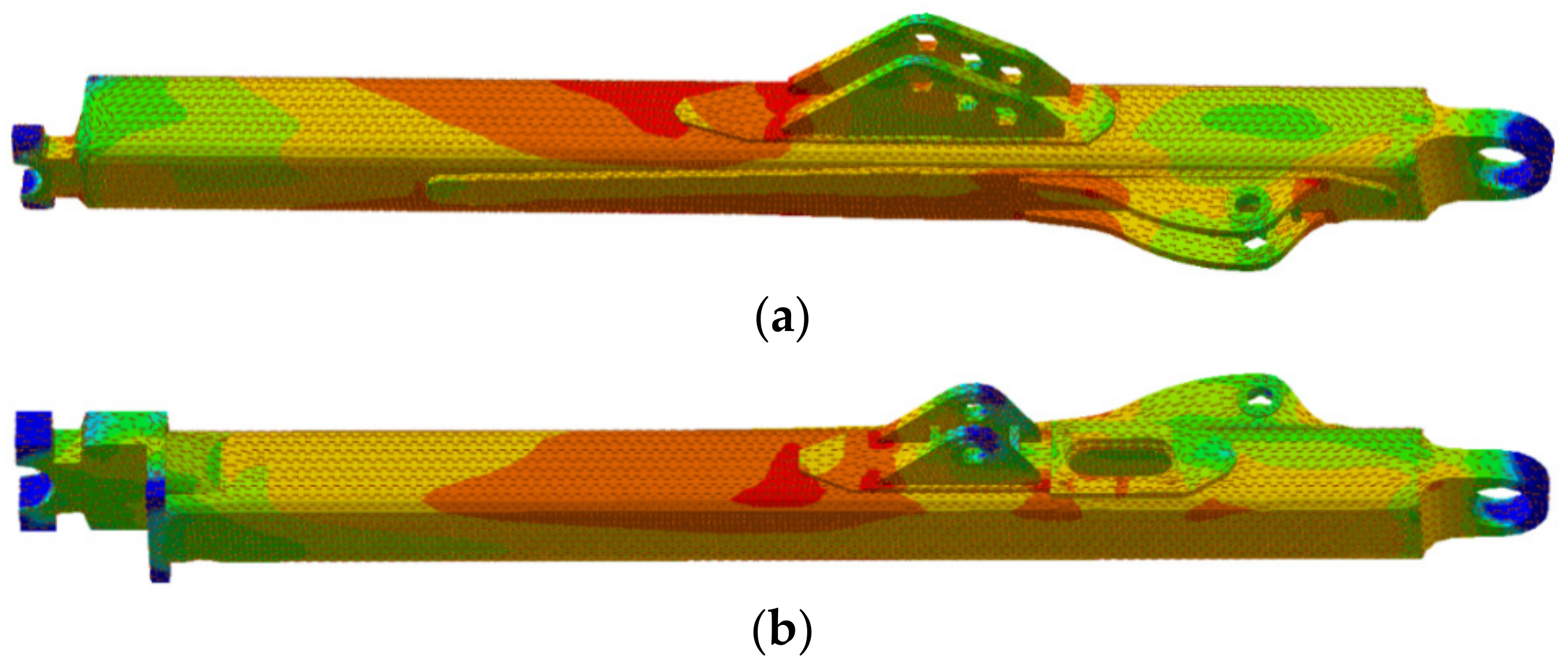

3. Fatigue Analysis

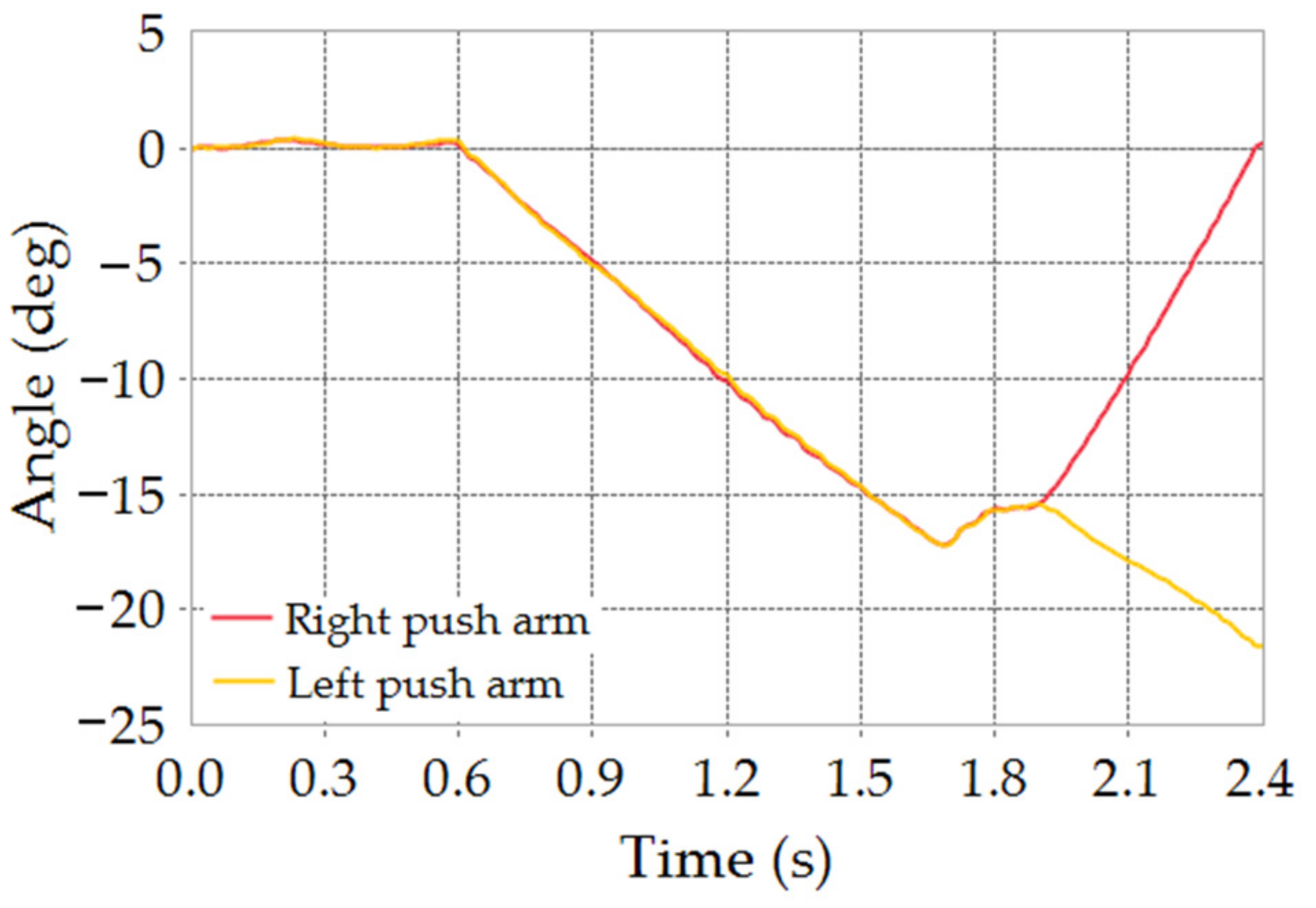

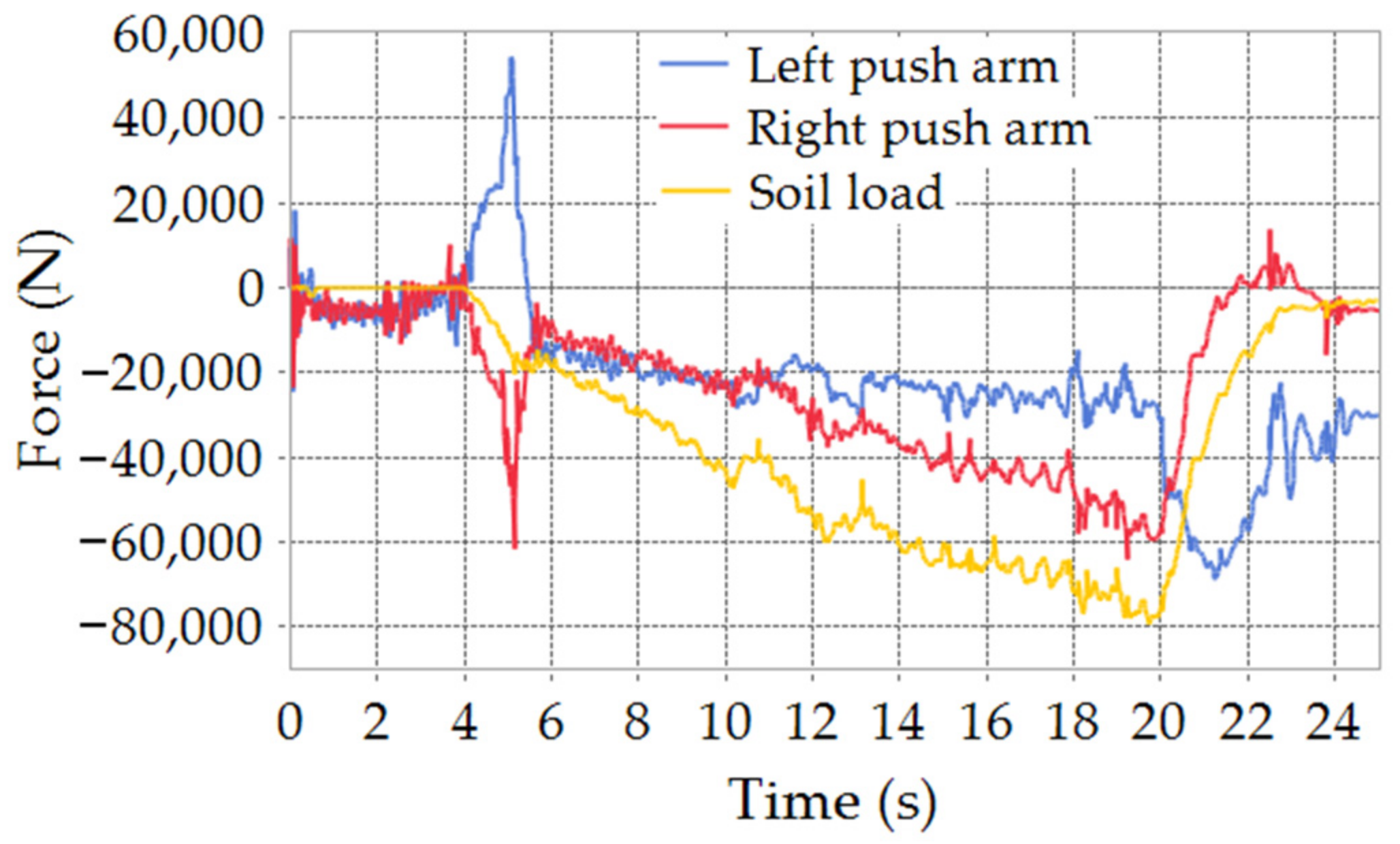

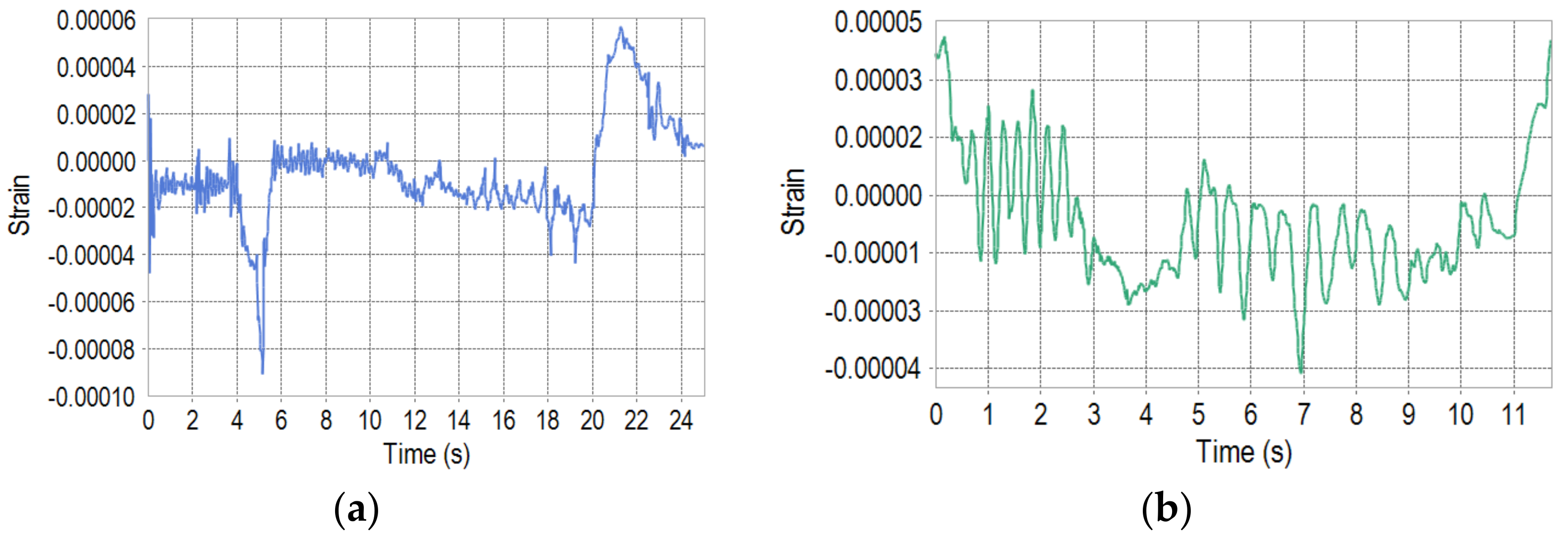

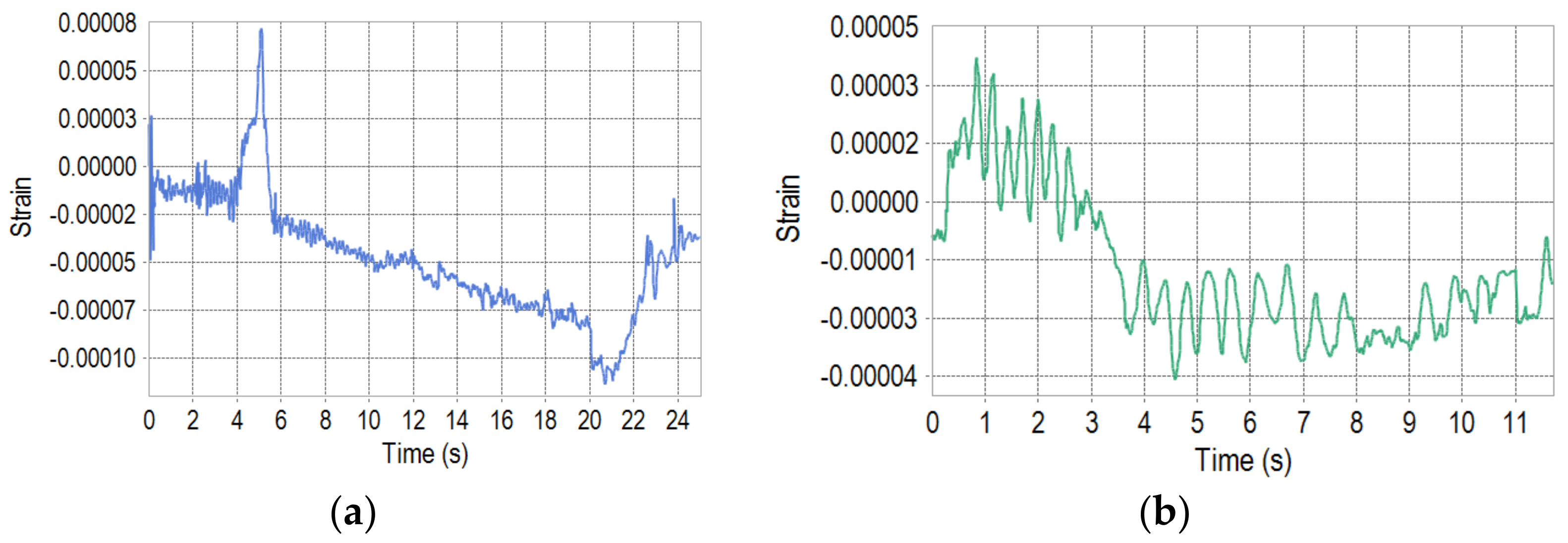

3.1. Co-Simulation Results

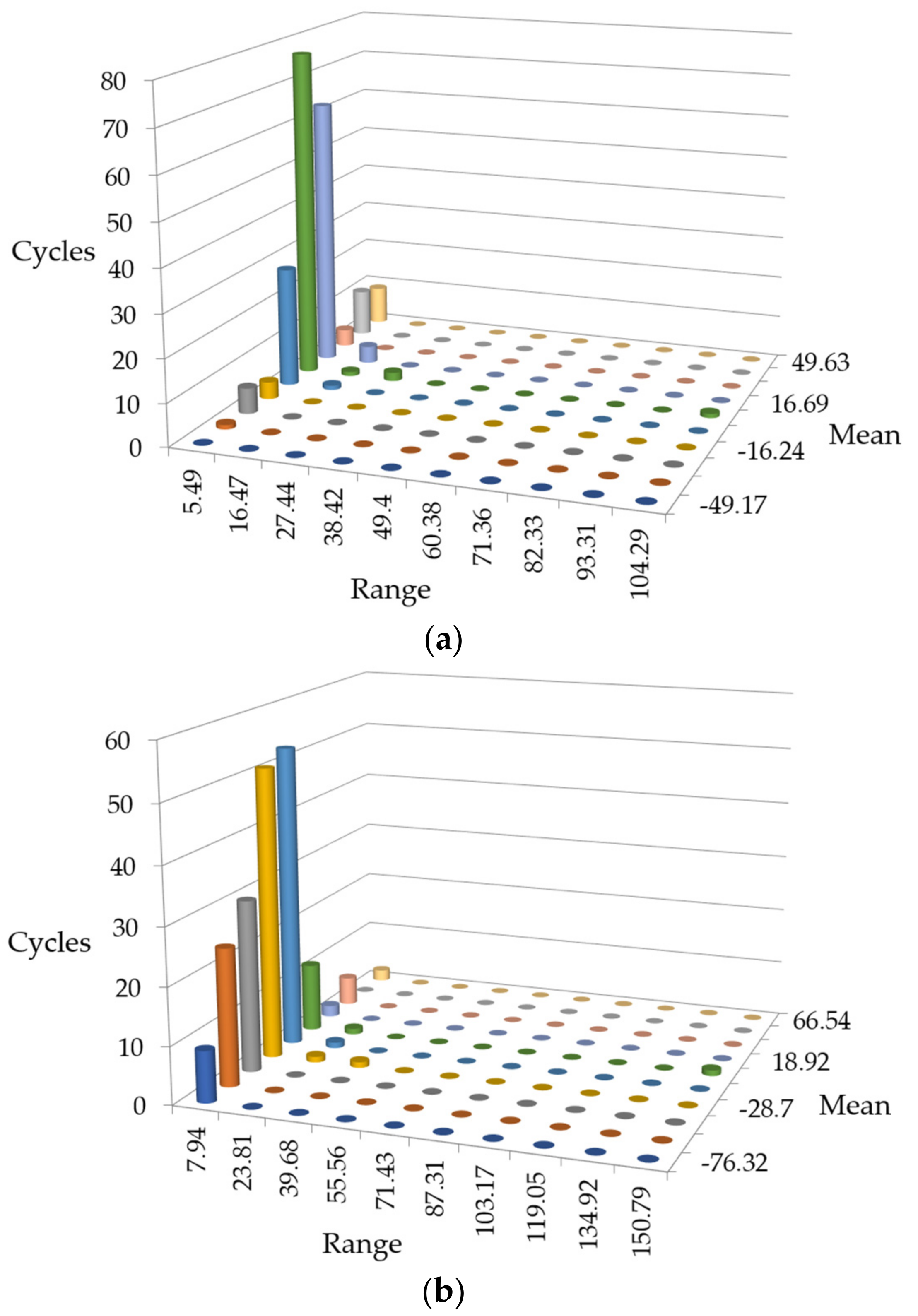

3.2. Rain Flow Counting

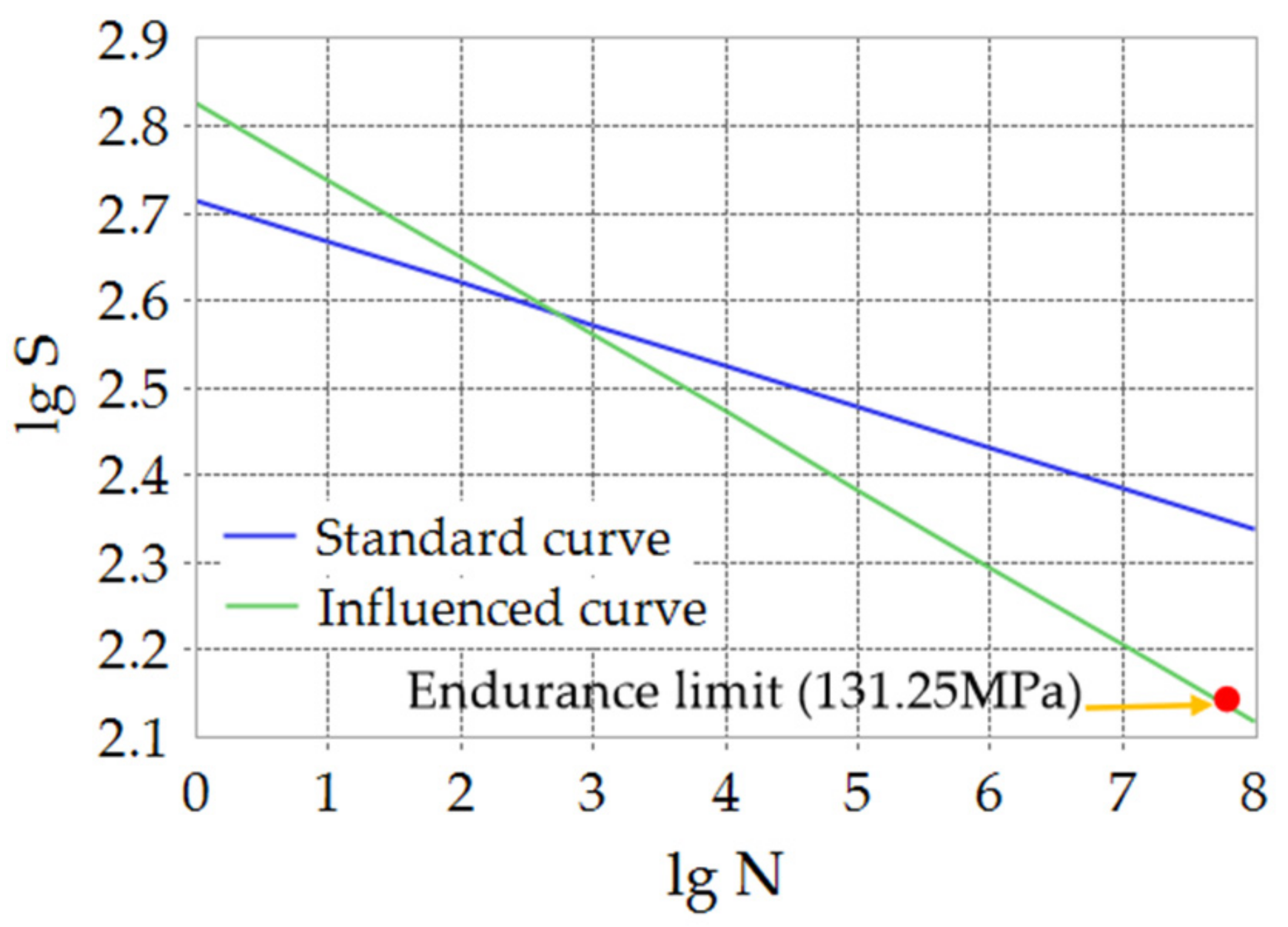

3.3. S-N Curve

3.4. Fatigue Life Calculation

4. Experimental Verification

5. Conclusions

- (1)

- The soil loads acting on the dozer components are calculated based on the established dozer dynamic model and soil model. The soil loads acting on the blade are accurately transferred to the push arms;

- (2)

- Considering the influence of the hydraulic pressure on the forces of push arms, a control system model of the dozer is established, which can accomplish the working-mode control actually realized by driver in combination with the electronic and hydraulic systems;

- (3)

- The push arms are analyzed in an integrated dozer system, which circumvents the inaccuracy involved in imposing simplified constraint forces;

- (4)

- The stress–time histories of the push arms are obtained under the complete tilt bulldozing conditions based on RecurDyn–EDEM–AMESim co-simulation, which effectively circumvents the deficiency of static fatigue analysis methods with specific boundary conditions and loading histories;

- (5)

- The overall damage of the push arms is analyzed by using Palmgren–Miner criterion, and the fatigue lives of the most damaged positions are predicted instead of predicting the lives of specified positions according to experience in traditional methods;

- (6)

- The stresses and fatigue lives of the left and right push arms under tilt bulldozing conditions are compared. It is concluded that the service lives of the left and right push arms are 39381.89 h and 7317.84 h, respectively, with a maximum bulldozing resistance of 78888 N. The service life of the right push arm is 81.42% shorter than that of the left push arm.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Geng, L.; Luo, G.; Zhang, Z.; Yang, X.; Wu, D. Fatigue life analysis and structure performance improvement of bulldozer working device based on ANSYS. In Proceedings of the 2017 IEEE 3rd Information Technology and Mechatronics Engineering Conference (ITOEC), Chongqing, China, 3–5 October 2017. [Google Scholar]

- Choi, K.; Cho, J. Durability Study on Damage at the Front Side of Bulldozer due to Fatigue Load by Using Finite Element Method. Int. Inf. Inst. (Tokyo) Inf. 2017, 20, 3593–3601. [Google Scholar]

- Ding, Q.X.; Tian, Y.C.; Chen, J.; Chen, J.W.; Hui, K.L.; Yin, H.W. Estimation of Fatigue Life for Hydraulic Excavator Boom under All Operating States. Adv. Mater. Res. 2011, 199–200, 463–469. [Google Scholar] [CrossRef]

- Zhao, H.; Wang, G.; Wang, H.; Bi, Q.; Li, X. Fatigue life analysis of crawler chain link of excavator. Eng. Fail. Anal. 2017, 79, 737–748. [Google Scholar] [CrossRef]

- Wu, Z.Y.; Gao, Y.D.; Xu, Z.; Wang, S.F. Modeling and Simulation of Tracked Vehicle Based on Pro/E and RecurDyn. In Proceedings of the 5th International Conference on Advanced Design and Manufacturing Engineering, Shenzhen, China, 19–20 September 2015. [Google Scholar] [CrossRef] [Green Version]

- Cleary, P.W. DEM modelling of particulate flow in a screw feeder. Prog. Comput. Fluid Dyn. Int. J. 2007, 7, 128–138. [Google Scholar] [CrossRef]

- Bischoff, M.; Onate, E.; Owen, D.R.J.; Ramm, E. A discrete element model for cohesive soil. In Proceedings of the III International Conference on Particle-Based Methods: Fundamentals and applications (PARTICLES 2013), Stuttgart, Germany, 18–20 September 2013. [Google Scholar]

- Tsuji, T.; Nakagawa, Y.; Matsumoto, N.; Kadono, Y.; Takayama, T.; Tanaka, T. 3-D DEM simulation of cohesive soil-pushing behavior by bulldozer blade. J. Terramechanics 2012, 49, 37–47. [Google Scholar] [CrossRef]

- Li, X.; Duan, C.; Bai, K.; Yao, Z. Operating Performance of Pure Electric Loaders with Different Types of Motors Based on Simulation Analysis. Energies 2021, 14, 617. [Google Scholar] [CrossRef]

- Shin, Y.J.; Jeong, J.S.; Jun, C.W.; Sohn, J.H. Interacting analysis between wheel and sand particles based on DEM and its validation with experiments. J. Mech. Sci. Technol. 2020, 34, 4537–4544. [Google Scholar] [CrossRef]

- Cheng, K.; Zhang, J.; Dai, Q.L.; Wang, P.Y.; Zhang, J. Modeling and Simulation of Hybrid Hydraulic Excavator Based on AMESim. Appl. Mech. Mater. 2010, 29–32, 2071–2075. [Google Scholar] [CrossRef]

- Park, S.H.; Alam, K.; Jeong, Y.M.; Chang, D.L.; Yang, S.Y. Modeling and simulation of hydraulic system for a wheel loader using AMESim. In Proceedings of the ICCAS-SICE, Fukuoka, Japan, 18–21 August 2009. [Google Scholar]

- Xu, F.; Liu, X.; Chen, W.; Zhou, C.; Cao, B. Modeling and co-simulation based on Adams and AMESim of pivot steering system. J. Eng. 2018, 2019, 392–396. [Google Scholar] [CrossRef]

- Bin, X.S.C. Modelling and stability investigation of a rigid flexible coupling system. Acta Mech. Sin. 1997, 4, 56–64. [Google Scholar]

- Hong, J. Advances in dynamics of rigid-flexible coupling system. J. Dyn. Control. 2004, 2, 3–8. [Google Scholar]

- Selech, J.; Ulbrich, D.; Włodarczyk, K.; Staszak, Ż.; Marcinkiewicz, J.; Romek, D.; Baran, B. A working design of a bulldozer blade as additional equipment of a compaction drum roller. In Proceedings of the MATEC Web of Conferences, Wuhan, China, 22–24 October 2019; p. 04005. [Google Scholar] [CrossRef]

- Jeong, H.; Yu, J.; Lee, D. Track HM Design for Dynamic Analysis of 4-tracked Vehicle on Rough Terrain Using Recurdyn. Trans. Korean Soc. Mech. Eng. A 2021, 45, 275–283. [Google Scholar] [CrossRef]

- Gummer, A.; Sauer, B. Modeling planar slider-crank mechanisms with clearance joints in RecurDyn. Multibody Syst. Dyn. 2014, 31, 127–145. [Google Scholar] [CrossRef]

- Pan, L.; Zhu, X.; Li, Y.; Guan, T. Lightweight design of an electric tricycle frame considering dynamic stress in driving conditions. Int. J. Automot. Technol. 2021, 22, 1075–1085. [Google Scholar] [CrossRef]

- Rusiński, E.; Harnatkiewicz, P.; Kowalczyk, M.; Moczko, P. Examination of the causes of a bucket wheel fracture in a bucket wheel excavator. Eng. Fail. Anal. 2010, 17, 1300–1312. [Google Scholar] [CrossRef]

- Khulief, Y.; Mohiuddin, M. On the dynamic analysis of rotors using modal reduction. Finite Elem. Anal. Des. 1997, 26, 41–55. [Google Scholar] [CrossRef]

- Li, L.; Du, B.; Li, J.S.; Chen, S.; Yang, F.; Qi, D. Simulation Analysis of Centroid Offset of Electric Drive Bulldozer Based on Recur Dyn. DEStech Transactions on Computer Science and Engineering. 2018. Available online: https://www.destechpub.com/product/destech-transactions-computer-science-engineering/ (accessed on 15 November 2021).

- LU, J.; Wei, L.; Zhao, T. Dynamic simulation of tracked vehicle turning at high speed based on RecurDyn. Mod. Mach. 2008, 1, 13–15. [Google Scholar]

- Choi, J.; Ryu, H.; Bae, D.; Huh, G.; Park, D. Dynamic track tension of high mobility tracked vehicles. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Pittsburgh, PA, USA, 9–12 September 2001; pp. 61–67. [Google Scholar]

- Idelsohn, S.R.; Onate, E.; Del Pin, F. The particle finite element method: A powerful tool to solve incompressible flows with free-surfaces and breaking waves. Int. J. Numer. Methods Eng. 2004, 61, 964–989. [Google Scholar] [CrossRef] [Green Version]

- Oñate, E.; Celigueta, M.A.; Idelsohn, S.R.; Salazar, F.; Suárez, B. Possibilities of the particle finite element method for fluid–soil–structure interaction problems. Comput. Mech. 2011, 48, 307. [Google Scholar] [CrossRef]

- Stomakhin, A.; Schroeder, C.; Chai, L.; Teran, J.; Selle, A. A material point method for snow simulation. ACM Trans. Graph. (TOG) 2013, 32, 102. [Google Scholar]

- Al-Kafaji, I. Formulation of a Dynamic Material Point Method (MPM) for Geomechanical Problems; Institute of Geotechnical Engineering, University of Stuttgart: Stuttgart, Germany, 2013. [Google Scholar] [CrossRef]

- Ucgul, M.; Fielke, J.M.; Saunders, C. Defining the effect of sweep tillage tool cutting edge geometry on tillage forces using 3D discrete element modelling. Inf. Processing Agric. 2015, 2, 130–141. [Google Scholar] [CrossRef] [Green Version]

- Tekeste, M.Z.; Way, T.R.; Syed, Z.; Schafer, R.L. Modeling soil-bulldozer blade interaction using the discrete element method (DEM). J. Terramechanics 2020, 88, 41–52. [Google Scholar] [CrossRef]

- Richter, C.; Roessler, T.; Otto, H.; Katterfeld, A. Coupled discrete element and multibody simulation, part I implementation, verification and validation—ScienceDirect. Powder Technol. 2020, 379, 494–504. [Google Scholar] [CrossRef]

- Engineers, S.o.A. SAE J1099. Rev. 2002. Available online: https://www.docin.com/p-1750860016.html (accessed on 15 November 2021).

- Zinchenko, A.; Baiul, K.; Krot, P.; Khudyakov, A.; Vashchenko, S.; Banasiewicz, A.; Wróblewski, A. Materials Selection and Design Options Analysis for a Centrifugal Fan Impeller in a Horizontal Conveyor Dryer. Materials 2021, 14, 6696. [Google Scholar] [CrossRef]

- Glinka, G.; Kam, J. Rainflow counting algorithm for very long stress histories. Int. J. Fatigue 1987, 9, 223–228. [Google Scholar] [CrossRef]

- Dharmadhikari, S.; Bhattacharya, C.; Ray, A.; Basak, A. A Data-Driven Framework for Early-Stage Fatigue Damage Detection in Aluminum Alloys Using Ultrasonic Sensors. Machines 2021, 9, 211. [Google Scholar] [CrossRef]

- Fisher, J.W.; Kulak, G.L.; Smith, I.F. A Fatigue Primer for Structural Engineers; National Steel Bridge Alliance, American Institute of Steel Construction: Chicago, IL, USA, 1998. [Google Scholar]

- Tamas, K. The role of bond and damping in the discrete element model of soil-sweep interaction. Biosyst. Eng. 2018, 169, 57–70. [Google Scholar] [CrossRef]

| Yield Stress (MPa) | Ultimate Stress (MPa) | Fatigue Strength Coefficient | Fatigue Strength Exponent | Fatigue Ductility Coefficient | Fatigue Ductility Exponent | Cyclic Strength Coefficient | Cyclic Strength Hardening Exponent |

|---|---|---|---|---|---|---|---|

| 357 | 490 | 536 | −0.047 | 4.118 | −0.883 | 481 | 0.049 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, L.; Guan, X.; Luan, X.; Huang, Y.; Zhang, R.; Choi, J.-H.; Zhu, X. Fatigue Analysis of Dozer Push Arms under Tilt Bulldozing Conditions. Machines 2022, 10, 38. https://doi.org/10.3390/machines10010038

Pan L, Guan X, Luan X, Huang Y, Zhang R, Choi J-H, Zhu X. Fatigue Analysis of Dozer Push Arms under Tilt Bulldozing Conditions. Machines. 2022; 10(1):38. https://doi.org/10.3390/machines10010038

Chicago/Turabian StylePan, Longye, Xianglong Guan, Xingwei Luan, Yajun Huang, Ruwei Zhang, Jin-Hwan Choi, and Xiangqian Zhu. 2022. "Fatigue Analysis of Dozer Push Arms under Tilt Bulldozing Conditions" Machines 10, no. 1: 38. https://doi.org/10.3390/machines10010038

APA StylePan, L., Guan, X., Luan, X., Huang, Y., Zhang, R., Choi, J.-H., & Zhu, X. (2022). Fatigue Analysis of Dozer Push Arms under Tilt Bulldozing Conditions. Machines, 10(1), 38. https://doi.org/10.3390/machines10010038