Steam Gasification in a Fluidized Bed with Various Methods of In-Core Coal Treatment

Abstract

1. Introduction

2. Methods and Materials

2.1. Experiment

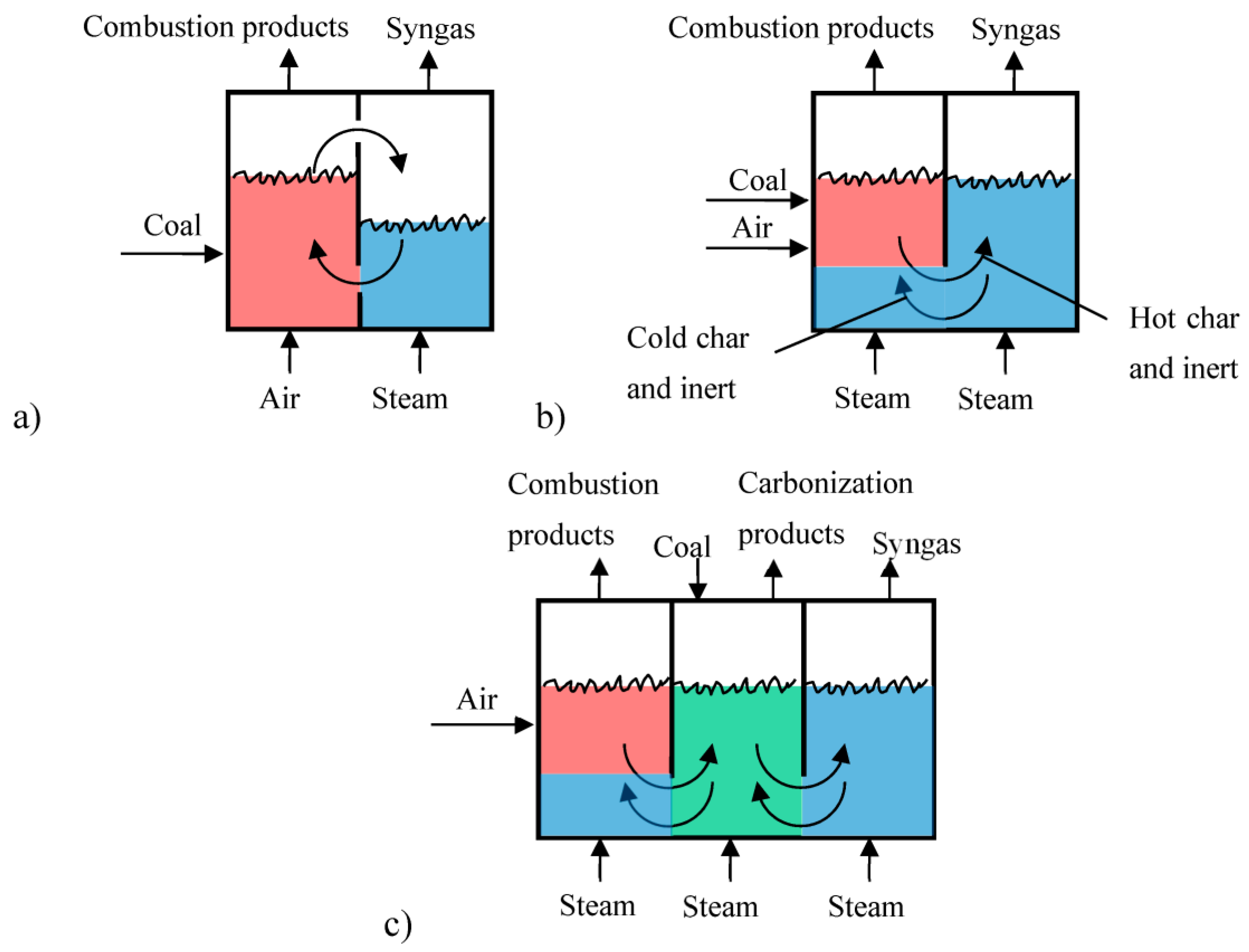

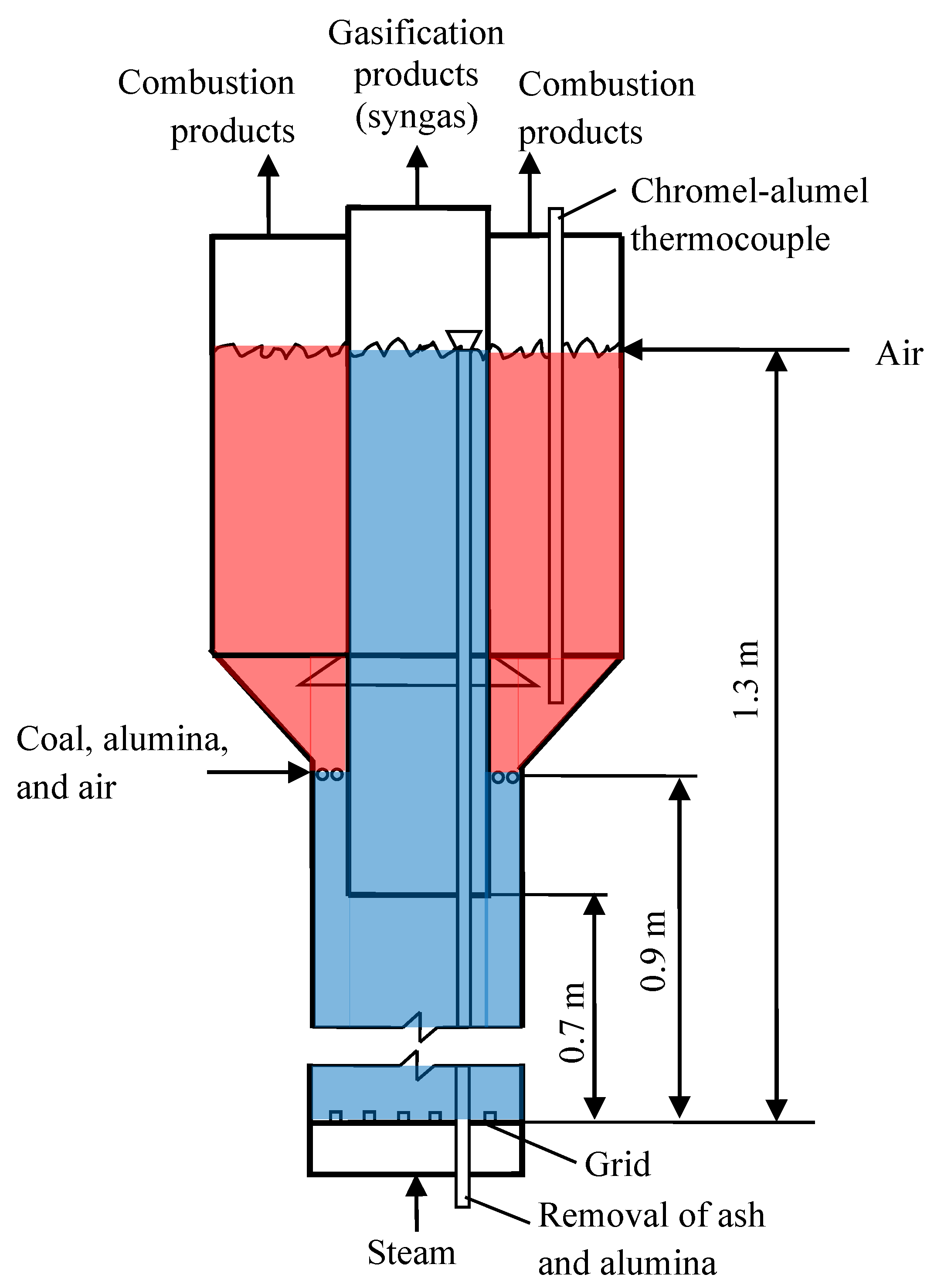

2.1.1. SDFB-II

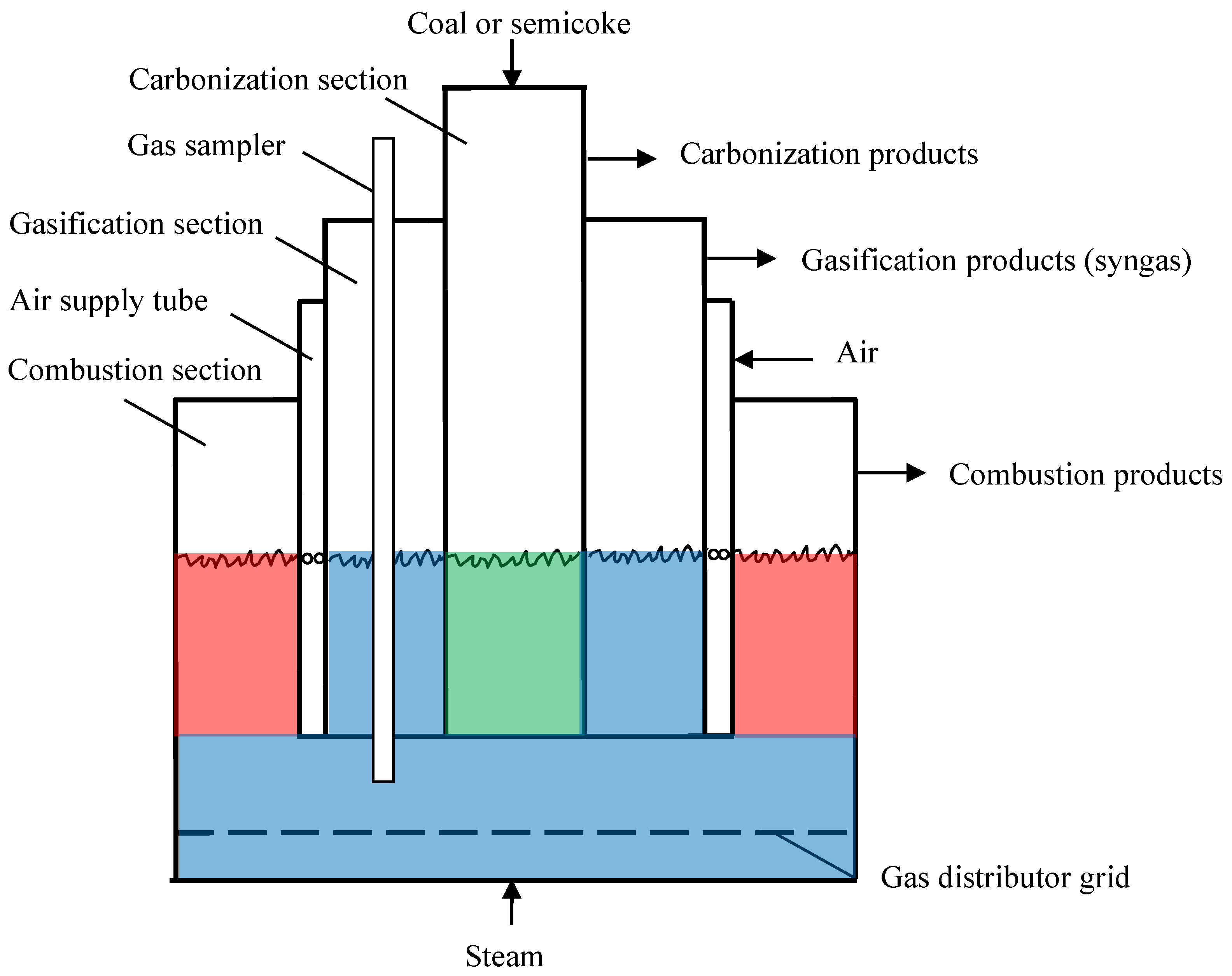

2.1.2. STFB-II

2.2. Modelling

3. Results and Discussion

3.1. Statistical Evaluation of Results

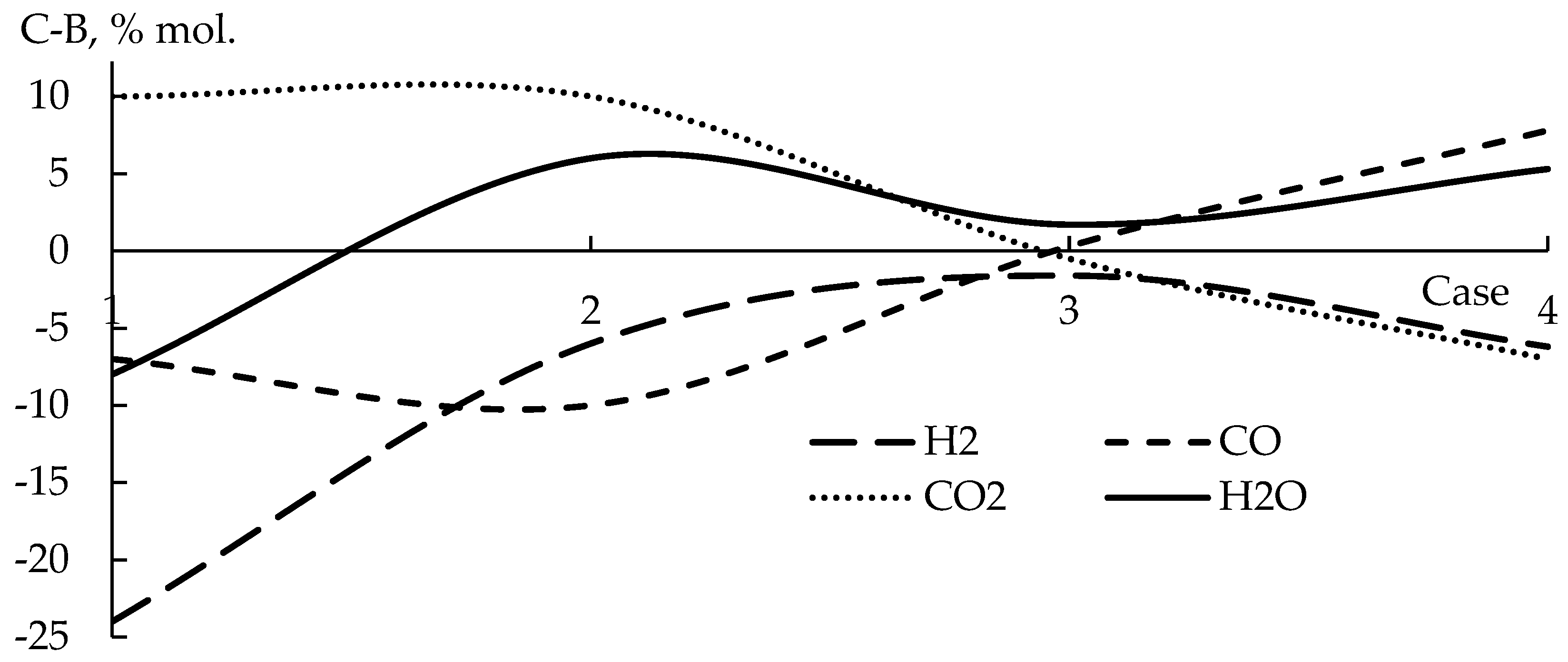

3.2. Dominant Reactions and Their Ratio

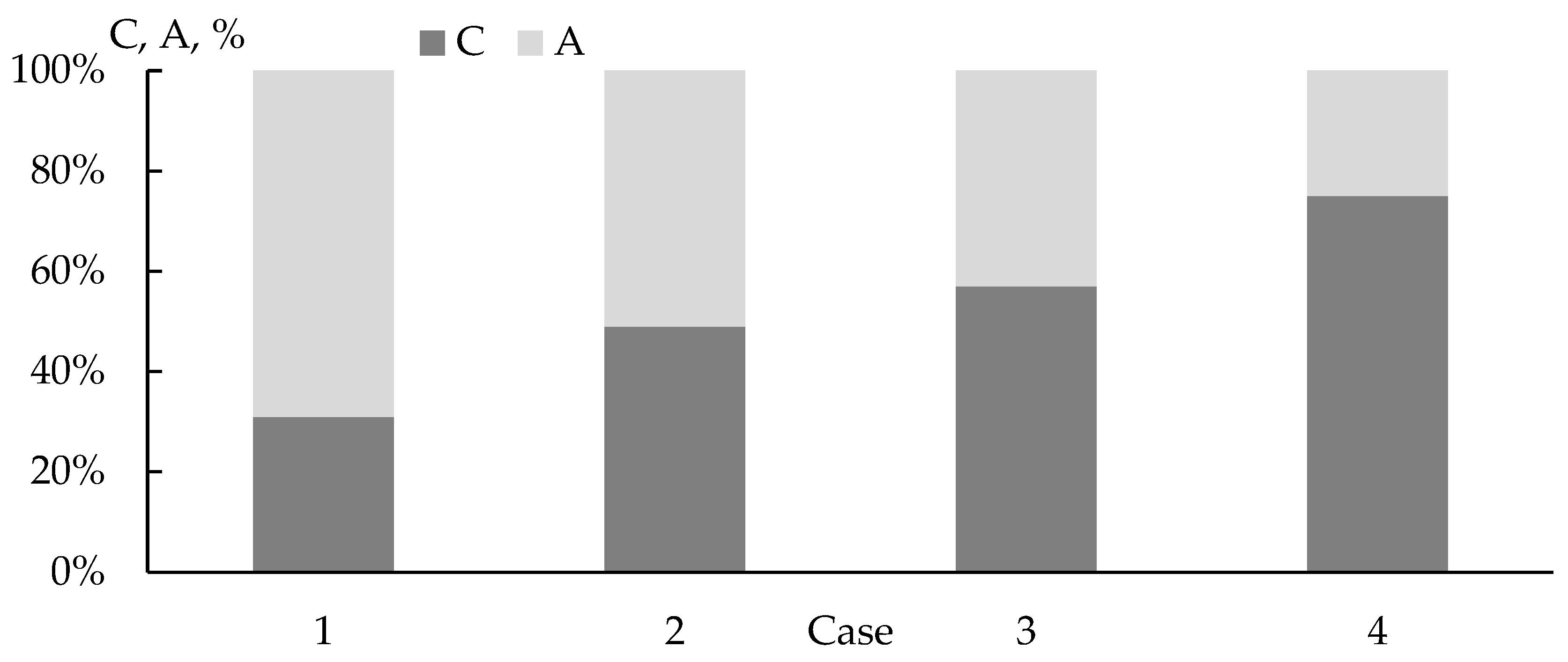

3.3. Char Composition

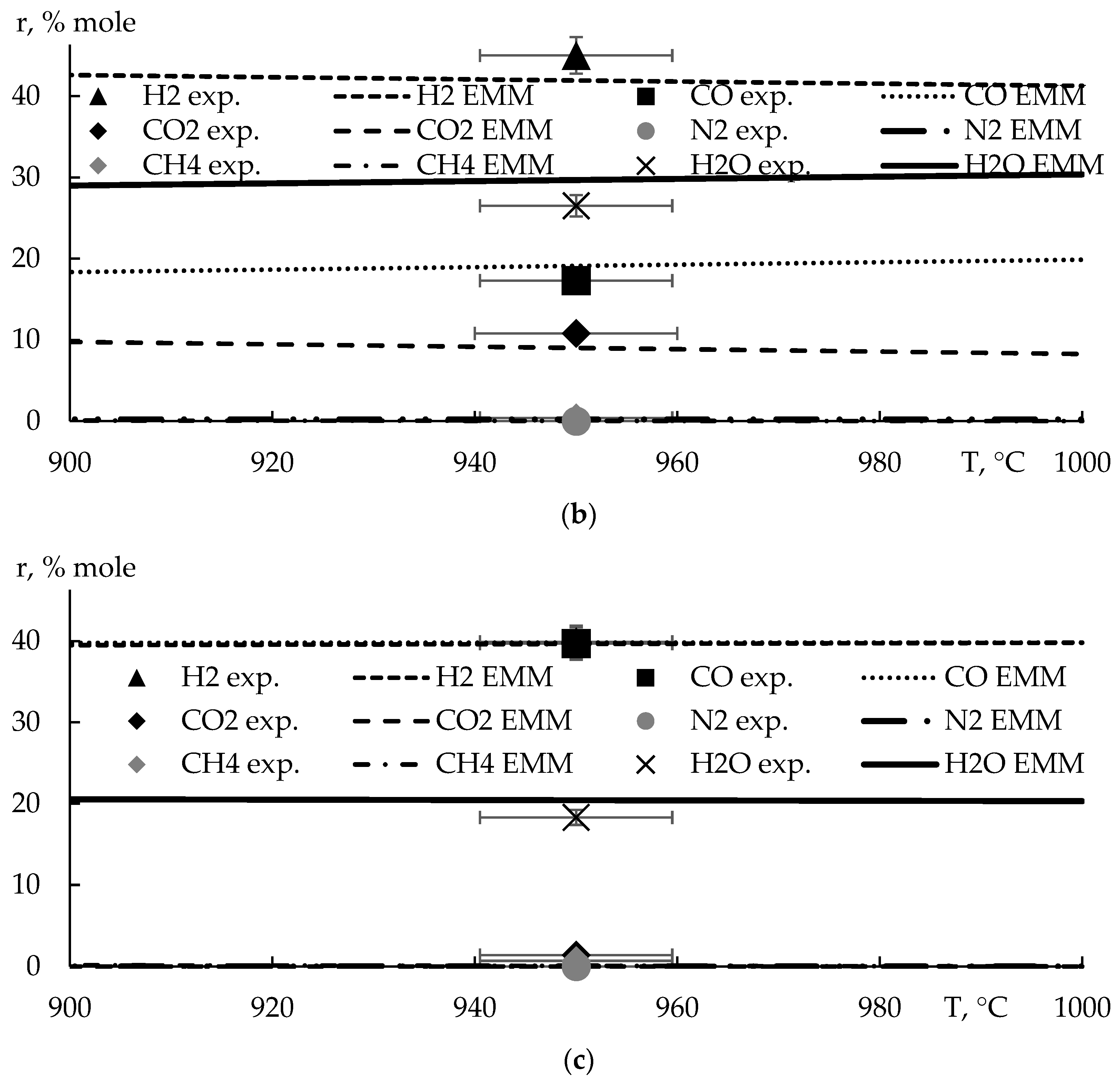

3.4. Temperature Influence

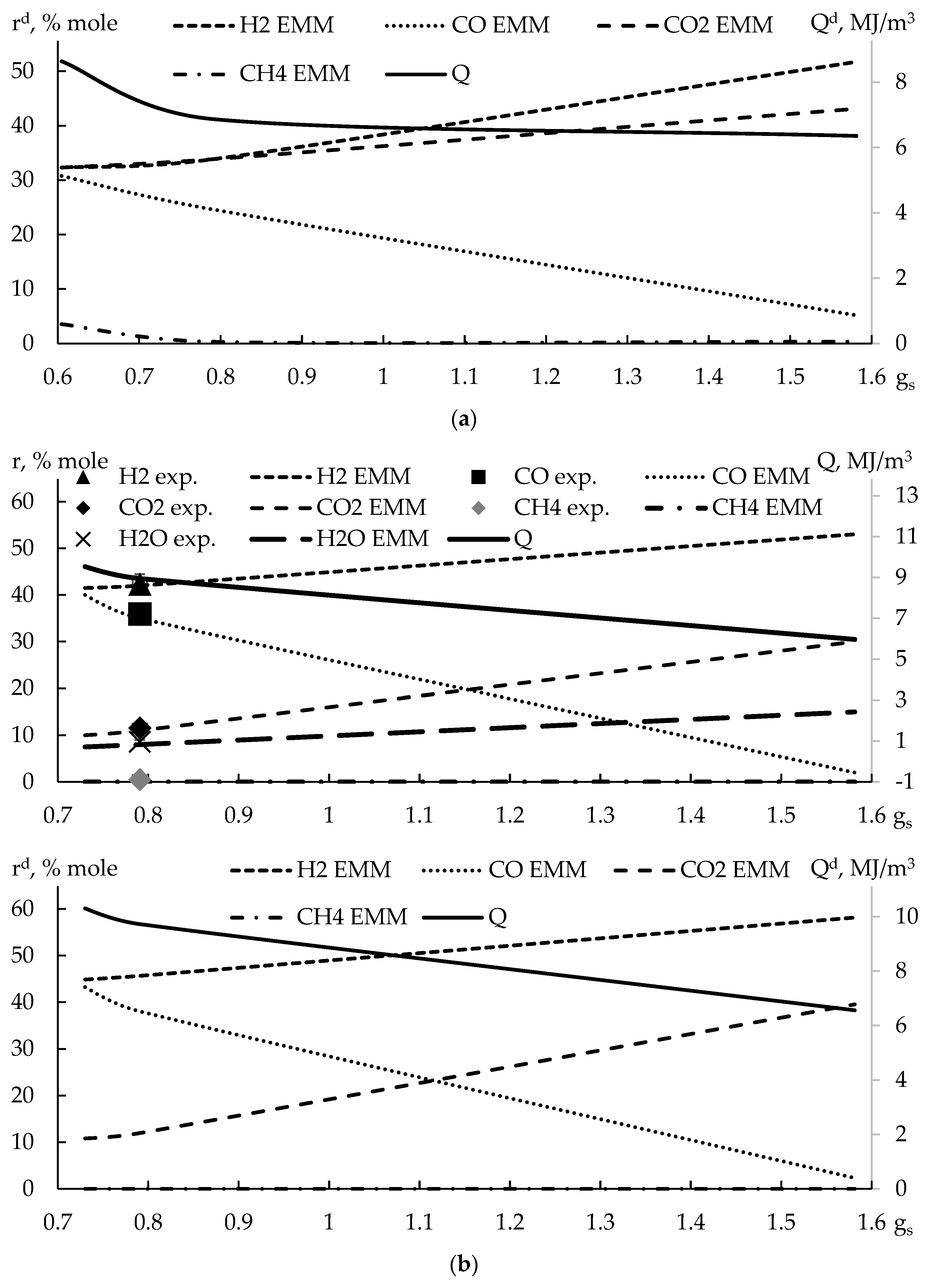

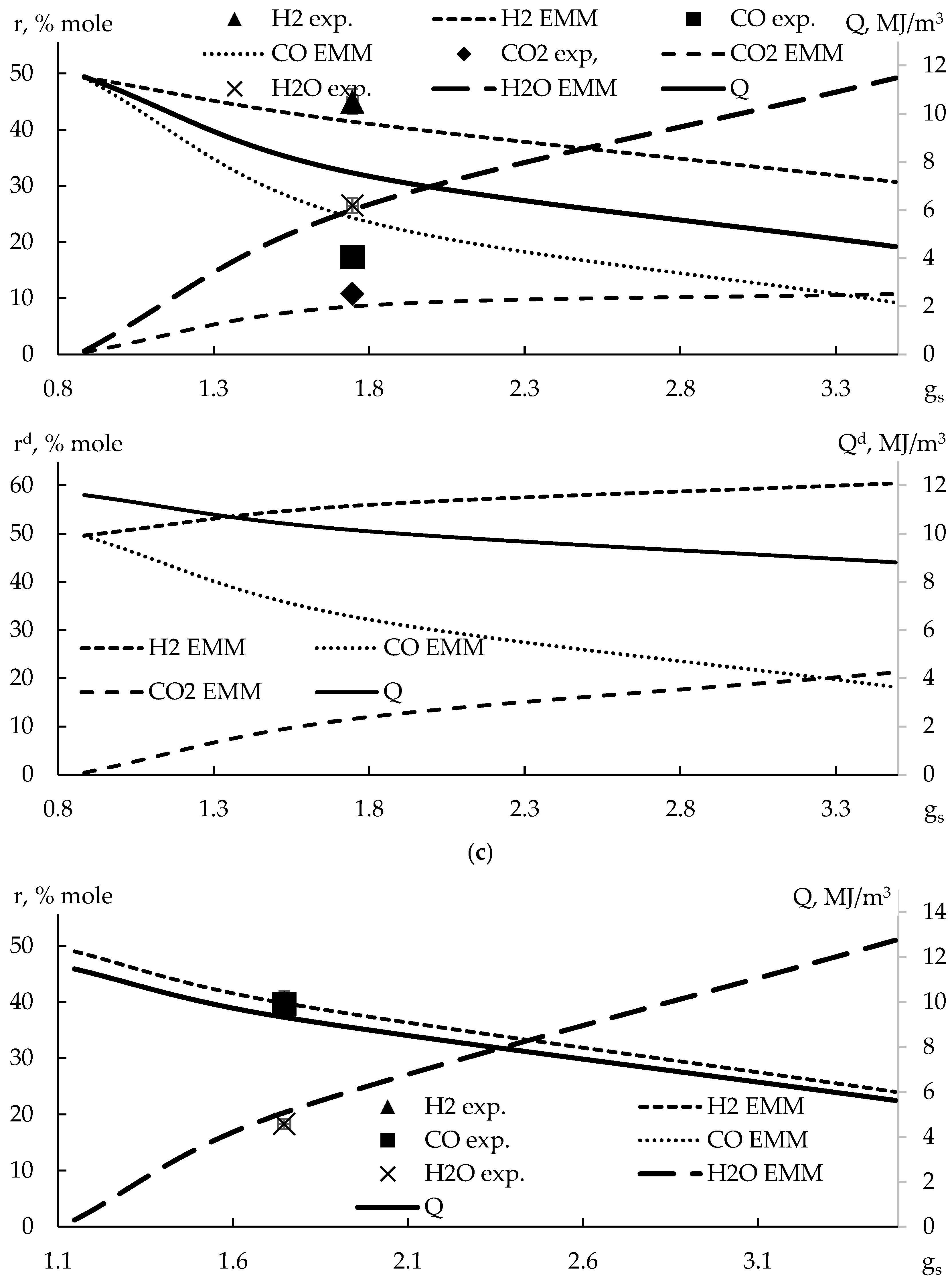

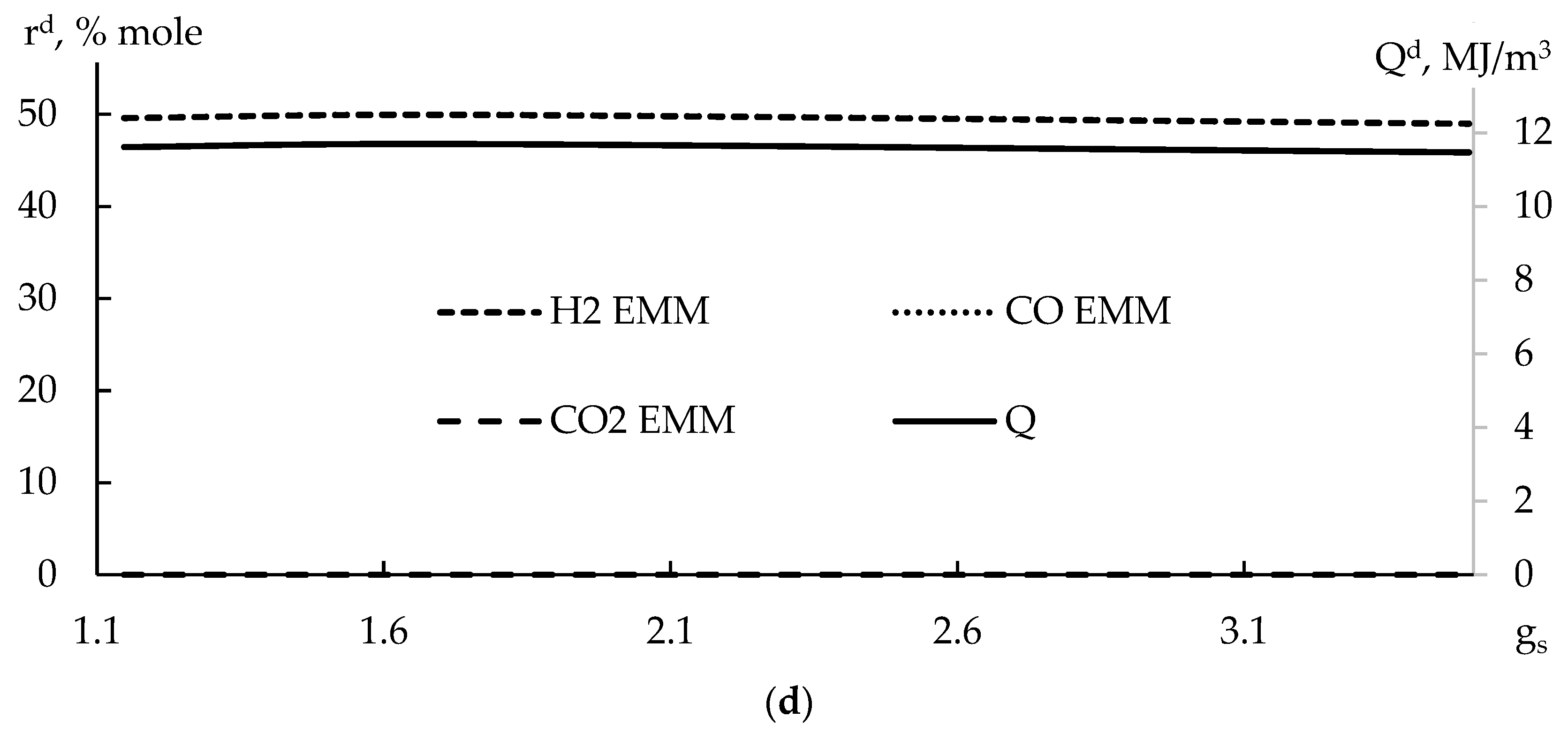

3.5. Steam Flow Rate Influence

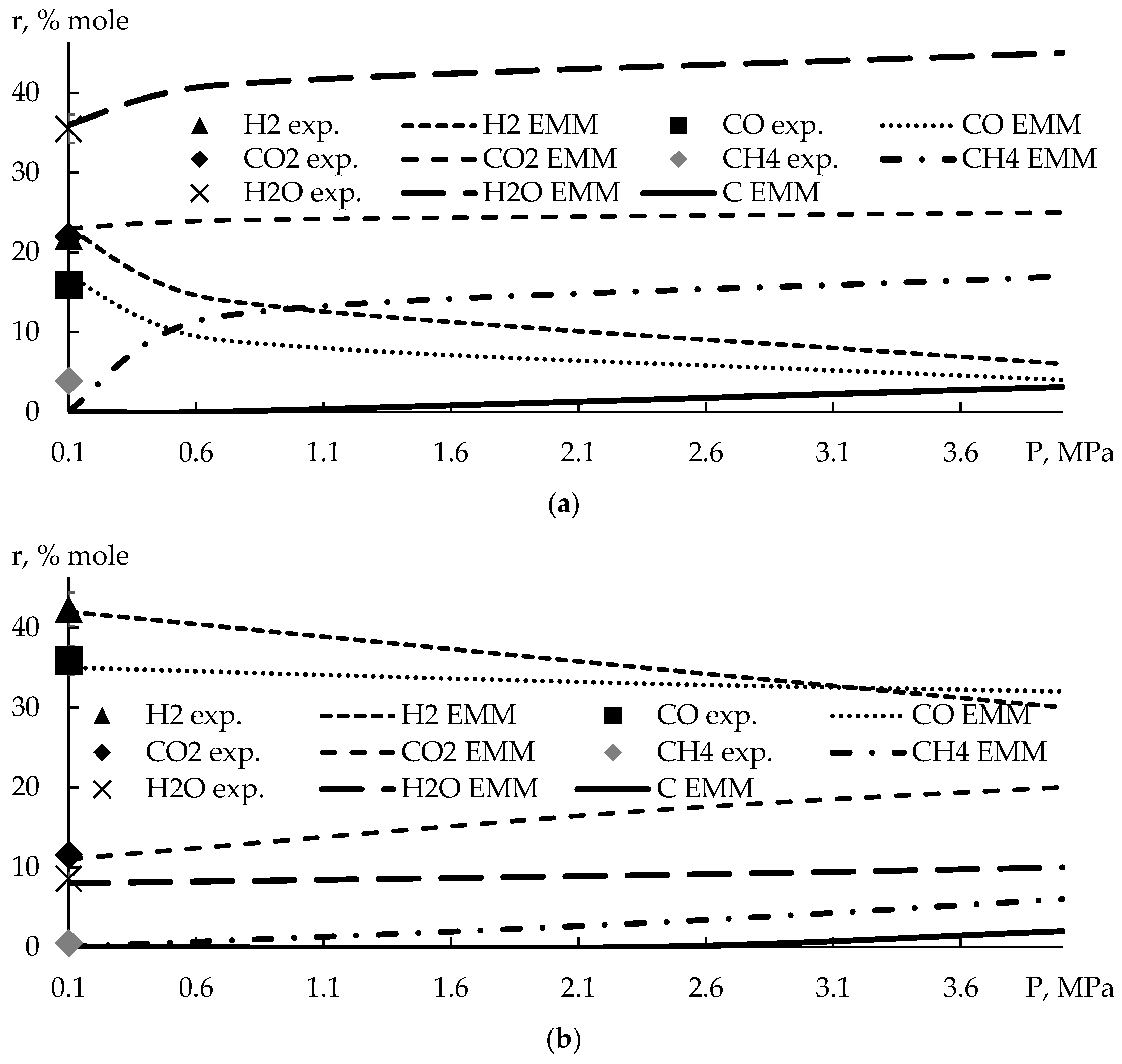

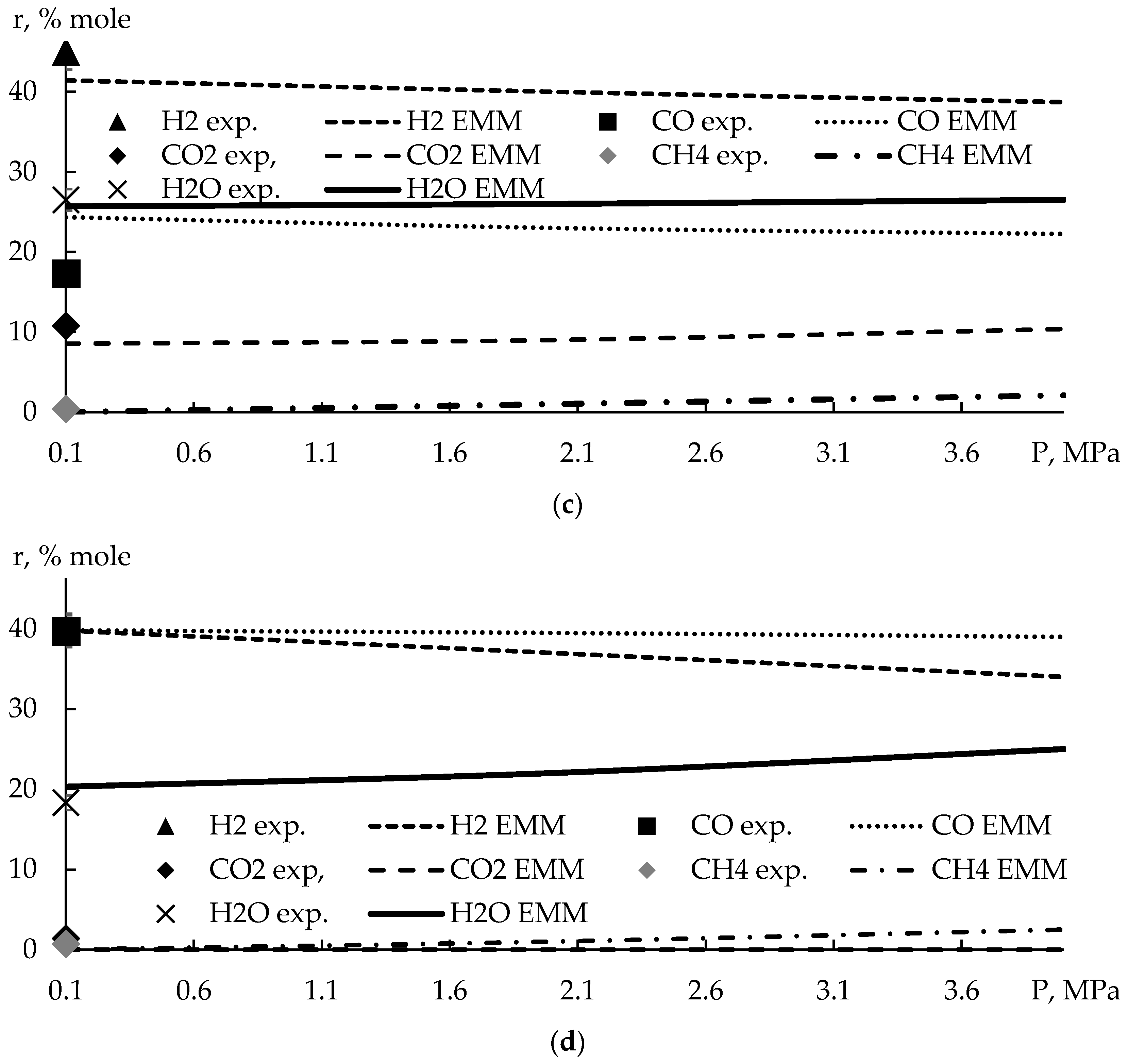

3.6. Pressure Influence

3.7. Comparison with Literature Data

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| D | gasifier diameter, m |

| d | gasification section diameter, m |

| gs | dimensionless steam consumption, kg of steam/kg of fuel |

| P | pressure, Pa |

| Q | heating value, MJ/m3 |

| R0 | universal gas constant, J/(mol K) |

| r | volume concentration, % |

| S | entropy J/(kg K) |

| T | temperature, °C |

| ug | superficial gas velocity, m/s |

| umf | minimum fluidization gas velocity, m/s |

| BFB | bubbling fluidized bed |

| CFB | circulating fluidized bed |

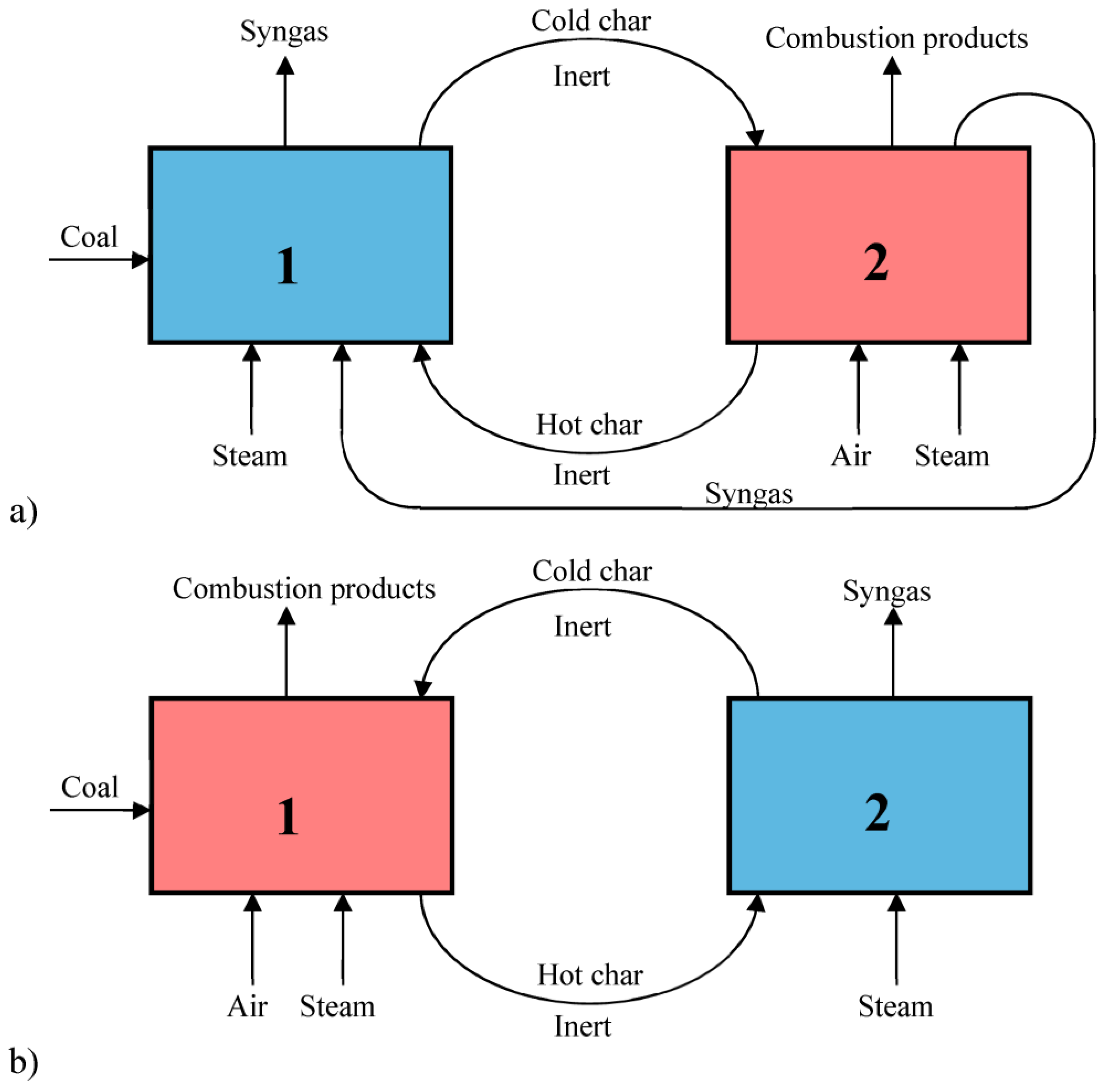

| DFB | double-vessel fluidized bed |

| EMM | entropy maximization method |

| FB | fluidized bed |

| FFB | fast fluidized bed |

| IGCC | integrated gasification combined cycle |

| SFB | single-vessel fluidized bed |

| SDFB | two-section fluidized bed |

| STFB | three-section fluidized bed |

| WGSR | water gas shift reaction |

References

- Karl, J.; Pröll, T. Steam gasification of biomass in dual fluidized bed gasifier: A review. Renew. Sustain. Energy Rev. 2018, 98, 64–78. [Google Scholar] [CrossRef]

- Schilling, H.-D.; Bonn, B.; Kraus, U. Coal Gasification; Graham and Trotman: London, UK, 1981; p. 175. [Google Scholar]

- Wang, D.; Li, S.; He, S.; Gao, L. Coal to substitute natural gas based on combined coal-steam gasification and one-step methanation. Appl. Energy 2019, 240, 851–859. [Google Scholar] [CrossRef]

- Chavan, P.; Datta, S.; Saha, S.; Sahu, G.; Sharma, T. Influence of high ash indian coals in fluidized bed gasification under different operating conditions. Solid Fuel Chem. 2012, 46, 108–113. [Google Scholar] [CrossRef]

- Shevyrev, S.A.; Mazheiko, N.E.; Yakutin, S.K.; Strizhak, P.A. Investigation of characteristics of gas and coke residue for the regime of quasi- and non-stationary steam gasification of coal in a fluidized bed: Part 1. Energy 2022, 251, 123938. [Google Scholar] [CrossRef]

- Aigner, I.; Pfeifer, C.; Hofbauer, H. Co-gasification of coal and wood in a dual fluidized bed gasifier. Fuel 2011, 90, 2404–2412. [Google Scholar] [CrossRef]

- Kern, S.; Pfeifer, C.; Hofbauer, H. Gasification of lignite in a dual fluidized bed gasifier—Influence of bed material particles size and the amount of steam. Fuel Process. Technol. 2013, 111, 1–13. [Google Scholar] [CrossRef]

- Barco-Burgos, J.; Carles-Bruno, J.; Eicker, U.; Saldana-Robles, A.L.; Alcantar-Camarena, V. Hydrogen-rich syngas production from palm kernel shells (PKS) biomass on a downdraft allothermal gasifier using steam as a gasifying agent. Energy Convers. Manag. 2021, 245, 114592. [Google Scholar] [CrossRef]

- Feng, J.; Yan, S.; Zhang, R.; Gu, S.; Qu, X.; Bi, J. Characteristics of Co–Ca catalyzed coal hydrogasification in a mixture of H2 and CO2 atmosphere. Fuel 2022, 324, 124486. [Google Scholar] [CrossRef]

- Li, B.; Lyu, Z.; Zhu, J.; Han, M.; Sun, Z. Study on the operating parameters of the 10 kW SOFC-CHP system with syngas. Int. J. Coal Sci. Technol. 2021, 8, 500–509. [Google Scholar] [CrossRef]

- Antonelli, J.; Lindino, C.A.; Bariccatti, R.A.; Souza, S.N.M.; Lenz, A.M. Lead adsorption and subsequent gasification with Pinus elliottii waste. Manag. Environ. Qual. Int. J. 2017, 28, 839–850. [Google Scholar] [CrossRef]

- Dubinin, A.M.; Shcheklein, S.E. Mini coal-fired CHP plant on the basis of synthesis gas generator (CO+H2) and electrochemical current generator. Int. J. Hydrog. Energy 2017, 42, 26048–26058. [Google Scholar] [CrossRef]

- Dubinin, A.M.; Tuponogov, V.G.; Kagramanov, Y.A. Air-based coal gasification in a two-chamber gas reactor with circulating fluidized bed. Therm. Eng. 2017, 64, 46–52. [Google Scholar] [CrossRef]

- Valin, S.; Bedel, L.; Guillaudeau, J.; Thiery, S.; Ravel, S. CO2 as a substitute of steam or inert transport gas in a fluidised bed for biomass gasification. Fuel 2016, 177, 288–295. [Google Scholar] [CrossRef]

- Pletka, R.; Brown, R.C.; Smeenk, J. Indirectly heated biomass gasifcation using a latent heat ballast—1: Experimental evaluations. Biomass Bioenergy 2001, 20, 297–305. [Google Scholar] [CrossRef]

- Murakami, T.; Xu, G.; Suda, T.; Matsuzawa, Y.; Tani, H.; Fujimori, T. Some process fundamentals of biomass gasification in dual fluidized bed. Fuel 2007, 86, 244–255. [Google Scholar] [CrossRef]

- Puig-Arnavat, M.; Bruno, J.C.; Coronas, A. Review and analysis of biomass gasification models. Renew. Sustain. Energy Rev. 2010, 14, 2841–2851. [Google Scholar] [CrossRef]

- Kobayashi, N.; Tanaka, M.; Piao, G.; Kobayashi, J.; Hatano, S.; Itaya, Y.; Mori, S. High temperature air-blown woody biomass gasification model for the estimation of an entrained down-flow gasifier. Waste Manag. 2009, 29, 245–251. [Google Scholar] [CrossRef]

- Biagini, E.; Barontini, F.; Tognotti, L. Development of a bi-equilibrium model for biomass gasification in a downdraft bed reactor. Bioresour. Technol. 2016, 201, 156–165. [Google Scholar] [CrossRef]

- Liao, C.; Summers, M.; Seiser, R.; Cattolica, R.; Herz, R. Simulation of a pilot-scale dual-fluidized-bed gasifier for biomass. Environ. Prog. Sustain. Energy 2014, 33, 732–736. [Google Scholar] [CrossRef]

- Detournay, M.; Hemati, M.; Andreux, R. Biomass steam gasification in fluidized bed of inert or catalytic particles: Comparison between experimental results and thermodynamic equilibrium predictions. Powder Technol. 2011, 208, 558–567. [Google Scholar] [CrossRef]

- Agu, C.E.; Pfeifer, C.; Eikeland, M.; Tokheim, L.-A.; Moldestad, B.M.E. Detailed One-Dimensional Model for Steam-Biomass Gasification in a Bubbling Fluidized Bed. Energy Fuels 2019, 33, 7385–7397. [Google Scholar] [CrossRef]

- Nguyen, N.M.; Alobaid, F.; Epple, B. Process Simulation of Steam Gasification of Torrefied Woodchips in a Bubbling Fluidized Bed Reactor Using Aspen Plus. Appl. Sci. 2021, 11, 2877. [Google Scholar] [CrossRef]

- Valin, S.; Ravel, S.; Pons de Vincent, P.; Thiery, S.; Miller, H.; Defoort, F.; Grateau, M. Fluidised Bed Gasification of Diverse Biomass Feedstocks and S. Blends—An Overall Performance Study. Energies 2020, 13, 3706. [Google Scholar] [CrossRef]

- Leckner, B. Developments in fluidized bed conversion of solid fuels. Therm. Sci. 2016, 20, S1–S18. [Google Scholar] [CrossRef]

- Midilli, A.; Kucuk, H.; Topal, M.E.; Akbulut, U.; Dincer, I. A comprehensive review on hydrogen production from coal gasification: Challenges and Opportunities. Int. J. Hydrog. Energy 2021, 46, 25385–25412. [Google Scholar] [CrossRef]

- Li, G.; Liu, Z.; Liu, F.; Weng, Y.; Ma, S.; Zhang, Y. Thermodynamic analysis and techno-economic assessment of synthetic natural gas production via ash agglomerating fluidized bed gasification using coal as fuel. Int. J. Hydrog. Energy 2020, 45, 27359–27368. [Google Scholar] [CrossRef]

- Datta, S.; Sarkar, P.; Chavan, P.D.; Saha, S.; Sahu, G.; Sinha, A.K.; Saxena, V.K. Agglomeration behavior of high ash Indian coals in fluidized bed gasification pilot plant. Appl. Therm. Eng. 2015, 86, 222–228. [Google Scholar] [CrossRef]

- Ogi, T.; Nakanishi, M.; Fukuda, Y.; Matsumoto, K. Gasification of oil palm residues (empty fruit bunch) in an entrained-flow gasifier. Fuel 2013, 104, 28–35. [Google Scholar] [CrossRef]

- Messerle, V.E.; Ustimenko, A.B.; Lavrichshev, O.A. Comparative study of coal plasma gasification: Simulation and experiment. Fuel 2016, 164, 172–179. [Google Scholar] [CrossRef]

- Uhm, H.S.; Na, Y.H.; Hong, Y.C.; Shin, D.H.; Cho, C.H. Production of hydrogen-rich synthetic gas from low-grade coals by microwave steam-plasmas. Int. J. Hydrog. Energy 2014, 39, 4351–4355. [Google Scholar] [CrossRef]

- Hong, Y.C.; Lee, S.J.; Shin, D.H.; Kim, Y.J.; Lee, B.J.; Cho, S.Y.; Chang, H.S. Syngas production from gasification of brown coal in a microwave torch plasma. Energy 2012, 47, 36–40. [Google Scholar] [CrossRef]

- Dubinin, A.M.; Munts, V.A.; Baskakov, A.P.; Choinzonov, B.L. Gasification of Irsha-Borodino coal in a fluidized-bed reactor. Solid Fuel Chem. 1983, 17, 117–120. [Google Scholar]

- Dubinin, A.M.; Tuponogov, V.G.; Filippov, D.V. Determining maximum capacity of an autothermal fluidized-bed gas generator. Therm. Eng. 2009, 56, 421–425. [Google Scholar] [CrossRef]

- Messerle, V.E.; Ustimenko, A.B.; Lavrichshev, O.A. Plasma coal conversion including mineral mass utilization. Fuel 2017, 203, 877–883. [Google Scholar] [CrossRef]

- Qiu, P.; Du, C.; Liu, L.; Chen, L. Hydrogen and syngas production from catalytic steam gasification of char derived from ion-exchangeable Na- and Ca-loaded coal. Int. J. Hydrog. Energy 2018, 43, 12034–12048. [Google Scholar] [CrossRef]

- Kriengsak, S.N.; Buczynski, R.; Gmurczyk, J.; Gupta, A.K. Hydrogen production by high-temperature steam gasification of biomass and coal. Environ. Eng. Sci. 2009, 26, 739–744. [Google Scholar] [CrossRef]

- Kunii, D.; Levenspiel, O. Fluidization Engineering, 2nd ed.; Butterworth-Heinemann: Waltham, MA, USA, 1991; p. 490. [Google Scholar]

- Wang, X.; Li, Y.; Zhang, W.; Zhao, J.; Wang, Z. Simultaneous SO2 and NO removal by pellets made of carbide slag and coal char in a bubbling fluidized-bed reactor. Process Saf. Environ. Prot. 2020, 134, 83–94. [Google Scholar] [CrossRef]

- Pérez-Astray, A.; Adánez-Rubio, I.; Mendiara, T.; Izquierdo, M.; Abad, A.; Gayán, P.; de Diego, L.; García-Labiano, F.; Adánez, J. Comparative study of fuel-N and tar evolution in chemical looping combustion of biomass under both iG-CLC and CLOU modes. Fuel 2019, 236, 598–607. [Google Scholar] [CrossRef]

- Ding, N.; Zhang, C.; Luo, C.; Zheng, Y.; Liu, Z. Effect of hematite addition to CaSO4 oxygen carrier in chemical looping combustion of coal char. RSC Adv. 2015, 5, 56362–56376. [Google Scholar] [CrossRef]

- Mondal, S.; Sinha, K.; Aikat, K.; Halder, G. Adsorption thermodynamics and kinetics of ranitidine hydrochloride onto superheated steam activated carbon derived from mung bean husk. J. Environ. Chem. Eng. 2015, 3, 187–195. [Google Scholar] [CrossRef]

- Gorokhovski, M.; Karpenko, E.I.; Lockwood, F.C.; Messerle, V.E.; Trusov, B.G.; Ustimenko, A.B. Plasma technologies for solid fuels: Experiment and theory. J. Energy Inst. 2005, 78, 157–171. [Google Scholar] [CrossRef]

- Chase, M.W.; Davies, C.A.; Downey, J.R.; Frurip, D.J.; McDonald, R.A.; Syverud, A.N. JANAF thermochemical tables. J. Phys. Chem. Ref. Data 1985, 14 (Suppl. 1), 535. [Google Scholar]

- Rambush, N.E. Modern Gas Producers; Benn Bros. Ltd.: London, UK, 1923; p. 545. [Google Scholar]

- Mayerhofer, M.; Mitsakis, P.P.; Meng, X.; de Jong, W.; Hartmut Spliethoff, H.; Gaderer, M. Influence of pressure; temperature and steam on tar and gas in allothermal fluidized bed gasification. Fuel 2012, 99, 204–209. [Google Scholar] [CrossRef]

- Praks, P.; Lampart, M.; Praksová, R.; Brkić, D.; Kozubek, T.; Najser, J. Selection of Appropriate Symbolic Regression Models Using Statistical and Dynamic System Criteria: Example of Waste Gasification. Axioms 2022, 11, 463. [Google Scholar] [CrossRef]

- Yang, Q.; Peng, X. A Fast Calculation Method for Sensitivity Analysis Using Matrix Decomposition Technique. Axioms 2023, 12, 179. [Google Scholar] [CrossRef]

| No. | Gasifier | Fuel | Reagent | P, MPa | T, °C | Syngas Composition | Qd, MJ/m3 | Ref | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Section 1 | Section 2 | H2 | CO | CO2 | CH4 | |||||||

| 1 | DFB–II, allothermal, 2 vessels, lab scale | Brown coal | Pyrolysis gas coal | Steam | 4 | 742/790 | 57.5 | 19.8 | 20.8 | 1.9 | 12.9 (10.6 (gas 1) | [2] |

| 2 | DFB-II, allothermal, lab scale | Brown coal | Steam coal | Pyrolysis gas /steam | 4 | 660/666 | 67.1 | 3 | 28.3 | 1.6 | 9.58 | [2] |

| 3 | “Cogas”, TFB-II, 5 vessels, autothermal, pilot scale | Bituminous coal subbitumious coal | Generator gas coal | Steam (Section 2) air (Section 3) | 0.1 | 300–800 800 800–900 | 49.5 | 32.5 | 15.6 | 0 | 9.44 | [2] |

| 4 | Agglomerating, DFB-I, autothermal, 2 vessels, pilot scale | Bituminous coal | Steam coal | Air | 0.8 | 850–930 1100 | 47.9–66.2 | 0–38.6 | 3.3–28.2 | 1.6–1.9 | up to 10 | [2] |

| 5 | “Westinghouse”, TFB-I, 2 vessels, 3 sections, autothermal, pilot scale | Coal | Generator gas + coal (Section 1) generator gas + char (Section 2) | Steam/air (3rd section, vessel 2) | 1.1–1.7 | 700–900 (vessel1) 1000–1100 (vessel 2) | 14.4 | 19.2 | 9.4 | 2.8 | 5.2 (vessel 1) | [2] |

| 6 | DFB-II, 2 vessels, allothermal, catalytic (Na(OH)2), lab scale | Coal | N2, Ar coal | Steam | 0.1 | 700 800 900 | 57 56 55 | 8 10 18 | 32 30 25 | 3 3 3 | - | [36] |

| 7 | DFB-II, 2 vessels, allothermal, lab scale | Coal D SS | Steam coal | Steam | 0.1 | 750 850 950 750 850 950 | 61.2 58.7 57.8 61 62.5 60 | 14.7 16.2 19 16 15 19.1 | 15.6 17.1 19.4 12 10.2 12.9 | 4.7 8.1 2.9 2.1 2.4 3.7 | - | [5] |

| 8 | SFB-I, 1 vessel, autothermal, pilot scale | Anthracite | Steam/O2 coal | 2.5 | 995 | 38.49 | 26.35 | 23.6 | 4.89 | - | [27] | |

| 9 | SFB-I, 1 vessel, autothermal, pilot scale | Coal | Steam/air coal | 0.1 | 950 | 15–20 | 15–20 | 10–12 | 1–2 | - | [28] | |

| 10 | Fixed bed, 2 vessels, allothermal, lab scale | Bituminous coal | Pyrolysis gas coal | Steam | 0.1 | 950 1000 1100 | 59.6 52.5 52.9 | 22.4 37.6 39.6 | 16.00 8.18 5.3 | 1.33 1.19 0.77 | - | [3] |

| 11 | Plasma gasifier, lab scale | Brown coal | Steam coal | - | 2427–3177 | 46.8–51 | 39.3–46 | 0 | 0 | - | [35] | |

| 12 | Plasma gasifier, lab scale | Bituminous coal | Steam/air air coal | - | 3077–3577 2417–2577 | 17.0–61.2 16.8–17.9 | 21.5–45.8 32.4–38.1 | 0 | 0 | - | [30] | |

| 13 | Microwave, plasma gasifier, pilot scale | Brown coal | Steam coal | - | 1640 | 39.8 | 32 | 18.2 | 0 | - | [31] | |

| 14 | Microwave plasma gasifier lab scale | Brown coal | Steam/air coal | - | 5727 | 36–49 | 19–24 | 24–46 | 0 | - | [32] | |

| 15 | TFB-II, 1 vessel, 3 sections, autothermal lab scale | Bituminous coal | Steam coal (Section 1) | steam/air ĸoĸc (Section 2) steam char (Section 3) | 0.1 | 925–950 * | 58.9–75.3 | 13.2–29.6 | 6.9–14.7 | 0–4.5 | 9.7–11.5 | [33] |

| Semicoke | Steam semicoke (Section 1) | steam/air semicoke (Section 2) steam semicoke (Section 3) | 0.1 | 925–950 ** | 47.5–48.6 | 47.1–48.8 | 1.8–4.7 | 0.7–0.8 | 11.7 | |||

| 16 | DFB-II, 1 vessel, 2 sections, autothermal lab scale | Bituminous coal | Steam/air coal (Section 1) | Steam char (Section 2) | 0.1 | 700– 1000 *** | 22.2– 42.8 | 15.9– 36.1 | 11.9–22.1 | 0.4–4.1 | 9.0– 10.4 | [34] |

| 17 | Fixed bed, 1 vessel, Allothermal, lab scale | Bituminous coal | Steam coal | - | ~0.1 | 900–1200 | 28–58 | 19–29 | 42–17 | 10–1 | 220–230 kJ/mol | [37] |

| Parameter | Coal | Semicoke | Ash | |

|---|---|---|---|---|

| LHV, MJ/kg | 22.676 | 26.857 | Slagging start temperature, °C | 950 |

| Wr, % | 7.11 | 2.51 | SiO2, % | 46.8 |

| Ar, % | 13.39 | 14.41 | Al2O3, % | 12.9 |

| Cdaf, % | 71.26 | 90.48 | TiO2, % | 0.6 |

| Hdaf, % | 4.88 | 1.81 | Fe2O3, % | 7.9 |

| Ndaf, % | 1.21 | 0.97 | CaO, % | 25.8 |

| Odaf, % | 22.26 | 6.74 | MgO, % | 5 |

| Sdaf, % | 0.39 | - | K2O, % | 0.5 |

| Vdaf, % | 48.89 | 10.46 | Na2O, % | 0.5 |

| Parameter | SDFB-II | STFB-II |

|---|---|---|

| Gasifier diameter | 0.28 m | 0.18 m |

| Bed height | 1.3 m | 1.0 m |

| Bed temperature | 7000–1000 °C | 925–950 °C |

| Gasification section diameter | 0.134–0.213 m | 0.08/0.03 m |

| Coal mean particle diameter | 1 × 10−3 m | 1.2 × 10−3 m |

| Density of coal | 1250 kg/m3 | 1250 kg/m3 |

| Coke bed concentration | 0.6 kg on 1 kg of mixture | 0.12 kg on 1 kg of mixture |

| Alumina average particle diameter | 0.5 × 10−3 m | 0.32 × 10−3 m |

| Alumina density | 3900 kg/m3 | 3900 kg/m3 |

| Alumina minimum fluidization velocity | 0.294 m/s | 0.127 m/s |

| Air flow rate | 30–100 m3/h | 20–30 m3/h |

| Steam flow rate | 17 kg/h | 4.4 kg/h |

| Steam velocity | 0.4 m/s | 0.28 m/s |

| Parameter | Case 1 | Case 2 | Case 3 | Case 4 |

|---|---|---|---|---|

| Gasifier | SDFB-II | STFB-II | ||

| Fuel | Coal | Semicoke | ||

| Temperature. °C | 700 | 1000 | 950 | |

| Component | Case 1 | Case 2 | Case 3 | Case 4 |

|---|---|---|---|---|

| H2 | 22.0 | 42.3 | 45 | 39.9 |

| CO | 15.9 | 35.9 | 17.3 | 39.7 |

| CO2 | 21.9 | 11.5 | 10.8 | 1.4 |

| CH4 | 3.9 | 0.5 | 0.4 | 0.7 |

| N2 | 0.3 | 0.1 | 0 | 0 |

| H2O | 35.5 | 8.6 | 26.5 | 18.3 |

| O2 | - | - | - | - |

| r, % | Case 1 | Case 2 | Case 3 | Case 4 | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | Exp. | A | B | C | Exp. | A | B | C | Exp. | A | B | C | Exp. | |

| H2 | 47 | 47 | 23 | 22.0 | 51 | 49 | 43 | 42.3 | 42 | 43 | 41.4 | 45 | 47 | 46 | 39.8 | 39.9 |

| CO | 29 | 24 | 17 | 15.9 | 38 | 46 | 36 | 35.9 | 20 | 24 | 24.3 | 17.3 | 16 | 32 | 39.8 | 39.7 |

| CO2 | 9 | 13 | 23 | 21.9 | 4 | 2 | 12 | 11.5 | 9 | 9 | 8.5 | 10.8 | 7 | 7 | 0 | 1.4 |

| CH4 | 3 | 1 | 1 | 3.9 | 0 | 0 | 0 | 0.49 | 0 | 0 | 0 | 0.4 | 0 | 0 | 0 | 0.7 |

| N2 | 0 | 0 | 0 | 0.3 | 0 | 0 | 0 | 0.14 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| H2O | 9 | 15 | 7 | 35.5 | 7 | 3 | 9 | 8.59 | 29 | 24 | 25.7 | 26.5 | 16 | 15 | 20.3 | 18.3 |

| Case 1 | Case 2 | Case | Case 4 | |

|---|---|---|---|---|

| K | 1/2.45 | 1/1.18 | 1/1 | 1/0 |

| Temperature, °C | ||||

|---|---|---|---|---|

| 700 | 800 | 900 | 1000 | |

| K | 2.45/1 | 2.02/1 | 1.61/1 | 1.18/1 |

| No. | Gasifier | Fuel | gs, kg/kg of Fuel | P, MPa | T, °C | Dry Syngas Composition | Qd, MJ/m3 | |||

|---|---|---|---|---|---|---|---|---|---|---|

| H2 | CO | CO2 | CH4 | |||||||

| 1 | Entrained-flow [29] | Oil palm residues | 1–8.4 | 0.1 | 1000 | 42–55 | 25–12 | 14–25 | 6–5 | 9.9–9.2 |

| 2 | Fixed bed [8] | Palm kernel shells | 0.85 | 0.1 | 850 | 48.2 | 28.2 | 15.9 | 7.6 | 11.5 |

| 3 | Fluidized bed [46] | Wood | 0.83–1.2 | 0.1 | 840 | 45.8–48.2 | 21.1–19.9 | 19.2–19.4 | 6.9–5.9 | 10.1–9.8 |

| 750 | 38.3–44.3 | 22.2–17.9 | 20.7–22 | 8–6.6 | 9.8–9.4 | |||||

| 1.2 | 0.1–0.25 | 44.3–45 | 17.9–11.8 | 22–26.6 | 6.6–9 | 9.4–9.6 | ||||

| 4 | Case 1 (before optimization/after optimization) | Subbituminous coal | 0.79/0.61 | 0.1 | 700 | 34/32 | 25/31 | 34/32 | 0.3/3.5 | 6.9/8.6 |

| 5 | Case 2 (before optimization/after optimization) | Subbituminous coal | 0.79/0.73 | 0.1 | 1000 | 46/45 | 38/43 | 12/11 | 0/0 | 9.7/10.3 |

| 6 | Case 3 (before optimization/after optimization) | Subbituminous coal | 1.7/0.9 | 0.1 | 950 | 56/50 | 33/49 | 1/0 | 0/0 | 10.1/11.6 |

| 7 | Case 4 (before optimization/after optimization) | Semicoke | 1.7/1.1 | 0.1 | 950 | 50/50 | 50/50 | 0/0 | 0/0 | 11.6/11.6 |

| No. | Gasifier | H2/CO | H2/CO2 | CO/CO2 | Qd, MJ/m3 | Gas Type (from Section 3.1) |

|---|---|---|---|---|---|---|

| 1 | DFB-II, allothermal, 2 vessels, lab scale [2] | 2.9 | 2.8 | 1 | 10.6 | 2 |

| 2 | DFB-II, allothermal, lab scale [2] | 22.4 | 2.4 | 0.1 | 9.58 | 1 |

| 3 | “Cogas”, TFB–II, 5 vessls, autothermal, pilot scale [2] | 1.5 | 3.2 | 2.1 | 9.44 | 3 |

| 4 | Agglomerating, DFB-I, autothermal, 2 vessels, pilot scale [2] | - | 14.5 | 0 | 10 | 2 |

| 5 | “Westinghouse”, TFB-I, 2 vessels, 3 sections autothermal, pilot scale [2] | 0.75 | 1.5 | 2.1 | 5.2 | 1 |

| 6 | DFB-II, 2 vessels, allothermal, catalytic (Na(OH)2), lab scale [36] | 7.1 | 1.7 | 0.25 | 7.1 | 2 |

| 7 | DFB-II, 2 vessels, allothermal, lab scale [5] | 4.2 | 3.9 | 0.9 | 11.2 | 2 |

| 8 | Case 1 (before optimization/after optimization) | 1.4/1 | 1/1 | 0.7/1 | 6.8/7.3 | 2/1 |

| 9 | Case 2 (before optimization/after optimization) | 1.2/1 | 3.8/4 | 3.2/4 | 9.8/10.3 | 2/3 |

| 10 | Case 3 (before optimization/after optimization) | 1.7/1 | 56/- | 33/- | 10.2/11.6 | 2/3 |

| 11 | Case 4 (before optimization/after optimization) | 1/1 | -/- | -/- | 11.7/11.7 | 3/3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abaimov, N.; Ryzhkov, A.; Tuponogov, V.; Simbiriatin, L.; Dubinin, A.; Ding, L.; Alekseenko, S. Steam Gasification in a Fluidized Bed with Various Methods of In-Core Coal Treatment. Axioms 2023, 12, 587. https://doi.org/10.3390/axioms12060587

Abaimov N, Ryzhkov A, Tuponogov V, Simbiriatin L, Dubinin A, Ding L, Alekseenko S. Steam Gasification in a Fluidized Bed with Various Methods of In-Core Coal Treatment. Axioms. 2023; 12(6):587. https://doi.org/10.3390/axioms12060587

Chicago/Turabian StyleAbaimov, Nikolay, Alexander Ryzhkov, Vladimir Tuponogov, Leonid Simbiriatin, Alexey Dubinin, Lu Ding, and Sergey Alekseenko. 2023. "Steam Gasification in a Fluidized Bed with Various Methods of In-Core Coal Treatment" Axioms 12, no. 6: 587. https://doi.org/10.3390/axioms12060587

APA StyleAbaimov, N., Ryzhkov, A., Tuponogov, V., Simbiriatin, L., Dubinin, A., Ding, L., & Alekseenko, S. (2023). Steam Gasification in a Fluidized Bed with Various Methods of In-Core Coal Treatment. Axioms, 12(6), 587. https://doi.org/10.3390/axioms12060587