Thermo-Optical Measurements and Simulation in a Fibre-Optic Circuit Using an Extrinsic Fabry–Pérot Interferometer under Pulsed Laser Heating

Abstract

1. Introduction

- –

- Thermal radiation of a heated body;

- –

- Temperature dependence of the refractive index;

- –

- Temperature change of the absorption coefficient;

- –

- Temperature change of the reflection coefficient as a result of changes in refraction and absorption, as well as thermal deformation of the surface.

2. Materials and Methods

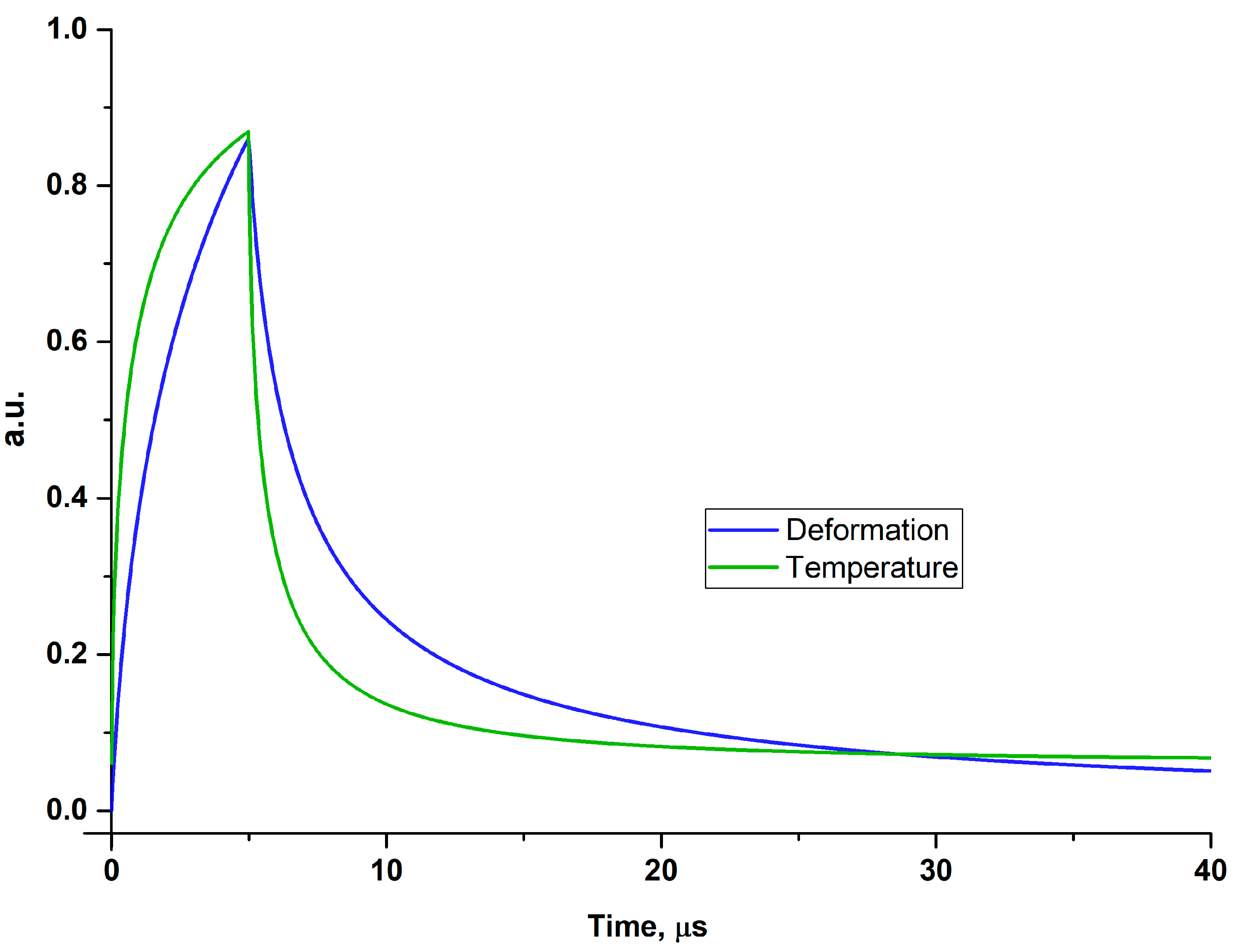

2.1. Thermal Mirror and Interferometry Method

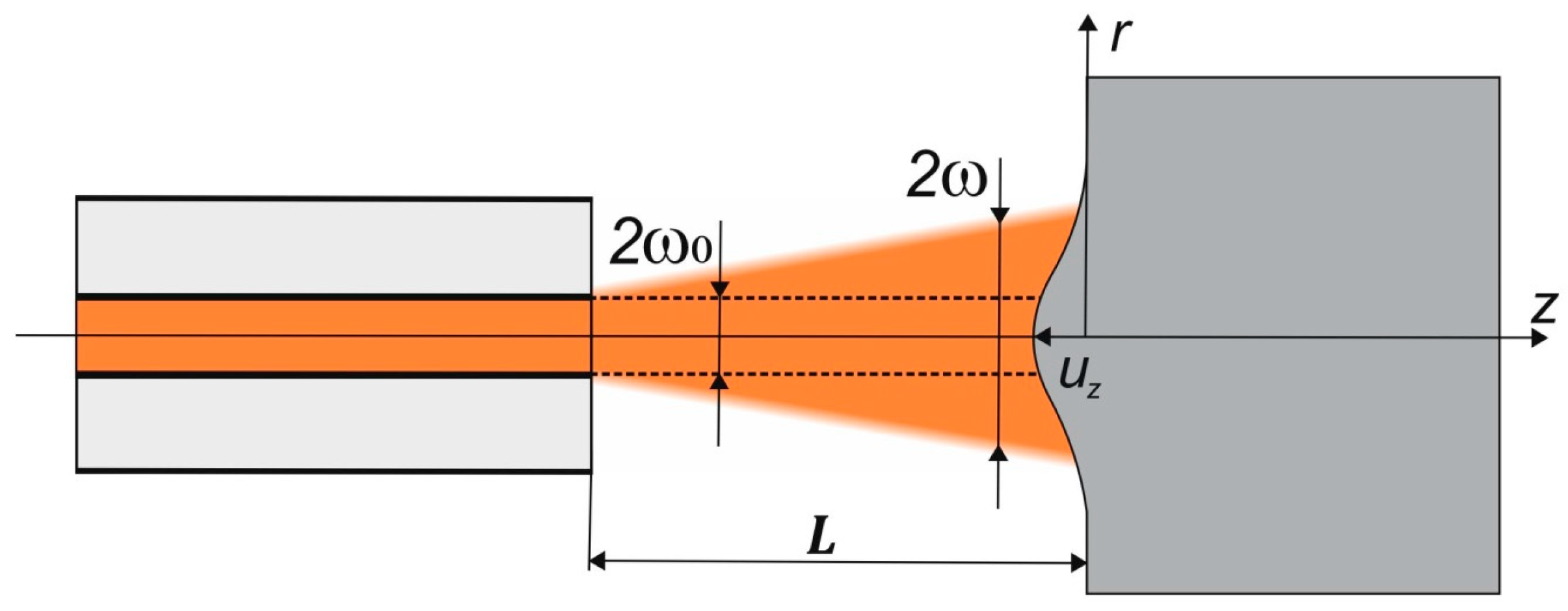

2.2. Interferometer

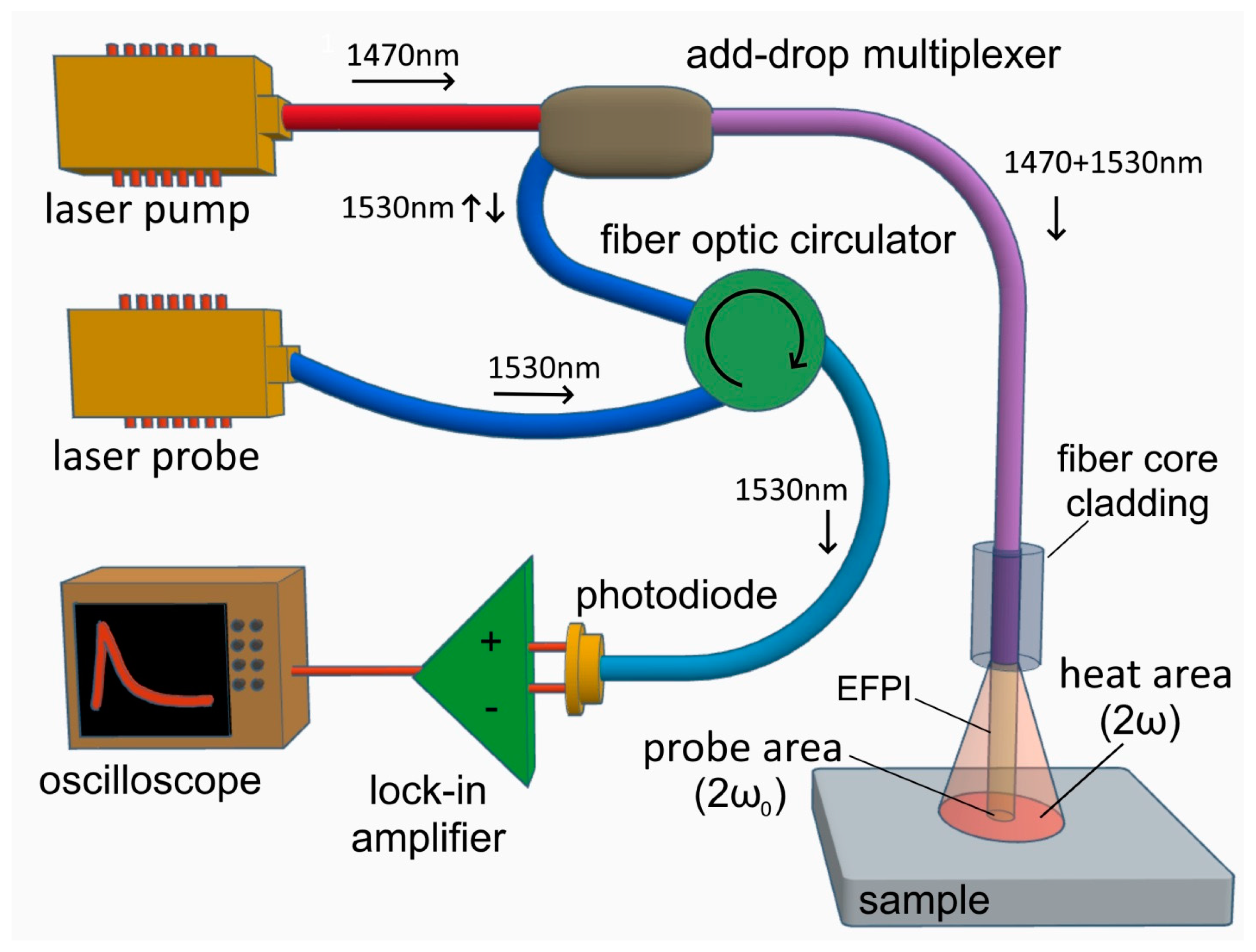

2.3. Laser Surface Heating Control Unit with Fibre-Optic EFPI

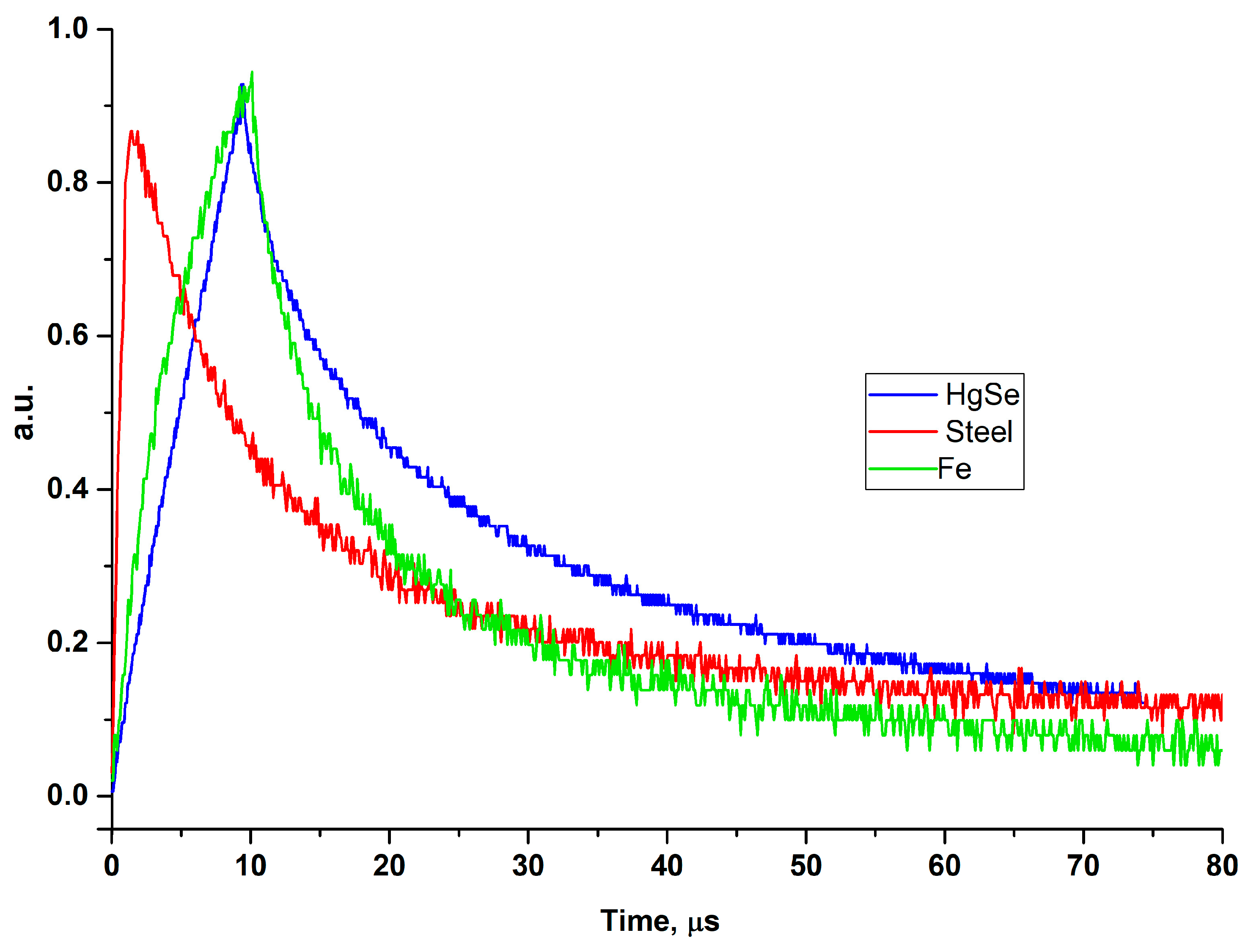

3. Results

Experimental Section

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

List of Symbols and Abbreviations

| Definition | |

| Subscripts | |

| A | Aperture |

| p | Pressure |

| d | Duration |

| r | Radiation |

| T | Thermal |

| z | z-axis direction |

| Variables and functions | |

| αT | Coefficient of linear thermal expansion |

| β | Variable of integration |

| δ | Delta function |

| η | Attenuation coefficient of the radiation intensity |

| λ | Wavelength of the probing radiation |

| ν | Poisson’s ratio |

| π | π number |

| ρ0 | Density of the material |

| τ | Characteristic thermal time |

| τd | Duration of the radiation pulse |

| φ | Phase shift of the radiation reflected from the sample |

| ω | Radius of the Gaussian light beam |

| ω0 | Half diameter of the mode spot of the light guide |

| a | Thermal diffusivity |

| cp | Specific heat capacity |

| E | Pulse energy |

| E0 | Absorbed pulse energy |

| F | Heating source function |

| f | Normalised dependence of the pulse amplitude on time |

| I | Gaussian power distribution |

| Ir | Radiation intensity in time at the EFPI output |

| I0 | Initial radiation intensity at the EFPI input |

| L | Interferometer gap size |

| L0 | Rayleigh beam length |

| NA | Fibre core numerical aperture |

| n | Refractive index of the medium in the interferometer gap |

| R | Average reflection coefficient |

| r | Radial distance from heating centre |

| T | Temperature change |

| t | Time |

| t′ | Variable of integration |

| Δt | Integration time |

| u0 | Quasi-one-dimensional mode amplitude |

| uz | Normal thermal deformations along heated surface |

| W | Local surface heat source |

| Abbreviations | |

| DFB | Distributed feedback laser diode |

| EFPI | External Fabry–Pérot interferometer |

References

- Kennedy, D.; Xue, Y.; Mihaylova, M. Current and Future Applications of Surface Engineering. Eng. J. 2005, 59, 287–292. [Google Scholar]

- Kannatey-Asibu, E. Laser surface modification. In Principles of Laser Materials Processing, 2nd ed.; Wiley: Hoboken, NJ, USA, 2023; pp. 568–616. [Google Scholar]

- Kwok, C.T. Pulsed laser surface treatment of multilayer gold-nickel-copper (Au/Ni/Cu) coatings to improve the corrosion resistance of components in electronics. In Laser Surface Modification of Alloys for Corrosion and Erosion Resistance; Kwok, C.T., Ed.; Elsevier Science: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Orazi, L.; Rota, A.; Reggiani, B. Experimental investigation on a novel approach for laser surface hardening modelling. Int. J. Mech. Mater. Eng. 2021, 16, 2. [Google Scholar] [CrossRef]

- Malinauskas, M.; Žukauskas, A.; Hasegawa, S.; Hayasaki, Y.; Mizeikis, V.; Buividas, R.; Juodkazis, S. Ultrafast laser processing of materials: From science to industry. Light Sci. Appl. 2016, 5, e16133. [Google Scholar] [CrossRef] [PubMed]

- Shugaev, M.V.; He, M.; Levy, Y.; Mazzi, A.; Miotello, A.; Bulgakova, N.M.; Zhigilei, L.V. Laser-Induced Thermal Processes: Heat Transfer, Generation of Stresses, Melting and Solidification, Vaporization, and Phase Explosion. In Handbook of Laser Micro—And Nano-Engineering; Sugioka, K., Ed.; Springer: Cham, Switzerland, 2020; pp. 83–163. [Google Scholar] [CrossRef]

- Starostin, A.A.; Shangin, V.V.; Lonchakov, A.T.; Kotov, A.N.; Bobin, S.B. Laser Pump Probe Fiber Optic Technique for Characterization of Near Surface Layers of Solids: Development and Application Prospects for Studying Semiconductors and Weyl Semimetals. Annal. der Physik. 2020, 532, 1900586–1900593. [Google Scholar] [CrossRef]

- Lipnyagov, E.V.; Gurashkin, A.L.; Starostin, A.A.; Skripov, P.V. Going to Spontaneous Boiling-Up Onset. J. Eng. Thermophys. 2018, 27, 307–318. [Google Scholar] [CrossRef]

- Kotov, A.N.; Gurashkin, A.L.; Starostin, A.A.; Skripov, P.V. Low-Energy Activation of Superheated N-pentane Booling-Up by Laser Pulse at the Fiber-Liquid Interface. Interfacial Phenom. Heat Transf. 2022, 10, 15–23. [Google Scholar] [CrossRef]

- Zhu, J.; Wu, X.; Lattery, D.M.; Zheng, W.; Xi, W. The Ultrafast Laser Pump-Probe Technique for Thermal Characterization of Materials with Micro/nanostructures. Nanoscale Microscale Thermophys. Eng. 2017, 21, 177–198. [Google Scholar] [CrossRef]

- Magunov, A.N. Laser Thermometry of Solids: State of the Art and Problems. Meas. Tech. 2002, 45, 173–181. [Google Scholar] [CrossRef]

- Hovell, T.; Petzing, J.; Justham, L.; Kinnell, P. From Light to Displacement: A Design Framework for Optimising Spectral-Domain Low-Coherence Interferometric Sensors for In Situ Measurement. Appl. Sci. 2020, 10, 8590. [Google Scholar] [CrossRef]

- Escola, F.Z.; Kunik, D.; Martinez, O.E.; Mingolo, N. Photothermal Microscopy. Procedia Mater. Sci. 2015, 8, 665–673. [Google Scholar] [CrossRef]

- Proskurnin, M.A.; Khabibullin, V.R.; Usoltseva, L.O.; Vyrko, E.A.; Mikheev, I.V.; Volkov, D.S. Photothermal and optoacoustic spectroscopy: State of the art and prospects. Phys.-Uspekhi 2022, 65, 270–312. [Google Scholar] [CrossRef]

- Capeloto, O.A.; Lukasievicz, G.V.B.; Zanuto, V.S.; Herculano, L.S.; Souza Filho, N.E.; Novatski, A.; Malacarne, L.C.; Bialkowski, S.E.; Baesso, M.L.; Astrath, N.G.C. Pulsed photothermal mirror technique: Characterization of opaque materials. Appl. Opt. 2014, 53, 7985–7991. [Google Scholar] [CrossRef] [PubMed]

- Marcano, A.; Gwanmesia, G.; Workie, B. Photothermal Mirror Method for the Study of Thermal Diffusivity and Thermo-Elastic Properties of Opaque Solid Materials. Int. J. Thermophys. 2017, 38, 136. [Google Scholar] [CrossRef]

- Sato, F.; Malacarne, L.C.; Pedreira, P.R.B.; Belancon, M.P.; Mendes, R.S.; Baesso, M.L.; Astrath, N.G.C.; Shen, J. Time-resolved thermal mirror method: A theoretical study. J. Appl. Phys. 2008, 104, 053520. [Google Scholar] [CrossRef]

- Flizikowski, G.A.S.; Anghinoni, B.; Rohling, J.H.; Belançon, M.P.; Mendes, R.S.; Baesso, M.L.; Malacarne, L.C.; Požar, T.; Bialkowski, S.E.; Astrath, N.G.C. Influence of edge effects on laser-induced surface displacement of opaque materials by photothermal interferometry. J. Appl. Phys. 2020, 128, 044509. [Google Scholar] [CrossRef]

- Vintsents, S.V.; Dmitriev, S.G.; Shagimuratov, O.G. Instantaneous profiles of quasistatic deformations and displacements of solid surfaces during local laser irradiation. Phys. Solid State 1996, 38, 552–557. [Google Scholar]

- Vintsents, S.V.; Dmitriev, S.G.; Spiridonov, K.I. Quasi-one-dimensional thermal deformation and displacement of the surface of a solid in a pulsed laser beam. Phys. Solid State 1997, 39, 1985–1988. [Google Scholar] [CrossRef]

- Huang, Y.W.; Tao, J.; Huang, X.G. Research Progress on F-P Interference—Based Fiber-Optic Sensors. Sensors 2016, 16, 1424. [Google Scholar] [CrossRef]

- Liokumovich, L.; Markvart, A.; Ushakov, N. Utilization of extrinsic Fabry-Perot interferometers with spectral interferometric interrogation for microdisplacement measurement. J. Electron. Sci. Technol. 2020, 18, 100030. [Google Scholar] [CrossRef]

- Jiang, Y.; Ding, W. Recent developments in fiber optic spectral white-light interferometry. Photonic Sens. 2011, 1, 62–71. [Google Scholar] [CrossRef]

- Lee, B.H.; Kim, Y.H.; Park, K.S.; Eom, J.B.; Kim, M.J.; Rho, B.S.; Choi, H.Y. Interferometric Fiber Optic Sensors. Sensors 2012, 12, 2467–2486. [Google Scholar] [CrossRef] [PubMed]

- Ushakov, N.; Liokumovich, L. Resolution limits of extrinsic Fabry—Perot interferometric displacement sensors utilizing wavelength scanning interrogation. Appl. Opt. 2014, 53, 5092–5099. [Google Scholar] [CrossRef] [PubMed]

- Chin, K.K.; Sun, Y.; Feng, G.; Georgiou, G.E.; Guo, K.; Niver, E.; Roman, H.; Noe, K. Fabry-Perot diaphragm fiber-optic sensor. Appl. Opt. 2007, 46, 7614–7619. [Google Scholar] [CrossRef] [PubMed]

- Liokumovich, L.B.; Ushakov, N.A.; Markvart, A.A.; Evdokimenko, E.Y. The spectral characteristic of a multilayer extrinsic fiber Fabry—Perot interferometer, St. Petersburg State Polytechnical University. J. Phys. Mat. 2022, 15, 129–146. [Google Scholar] [CrossRef]

- Zhukovsky, K. Operational Approach and Solutions of Hyperbolic Heat Conduction Equations. Axioms 2016, 5, 28. [Google Scholar] [CrossRef]

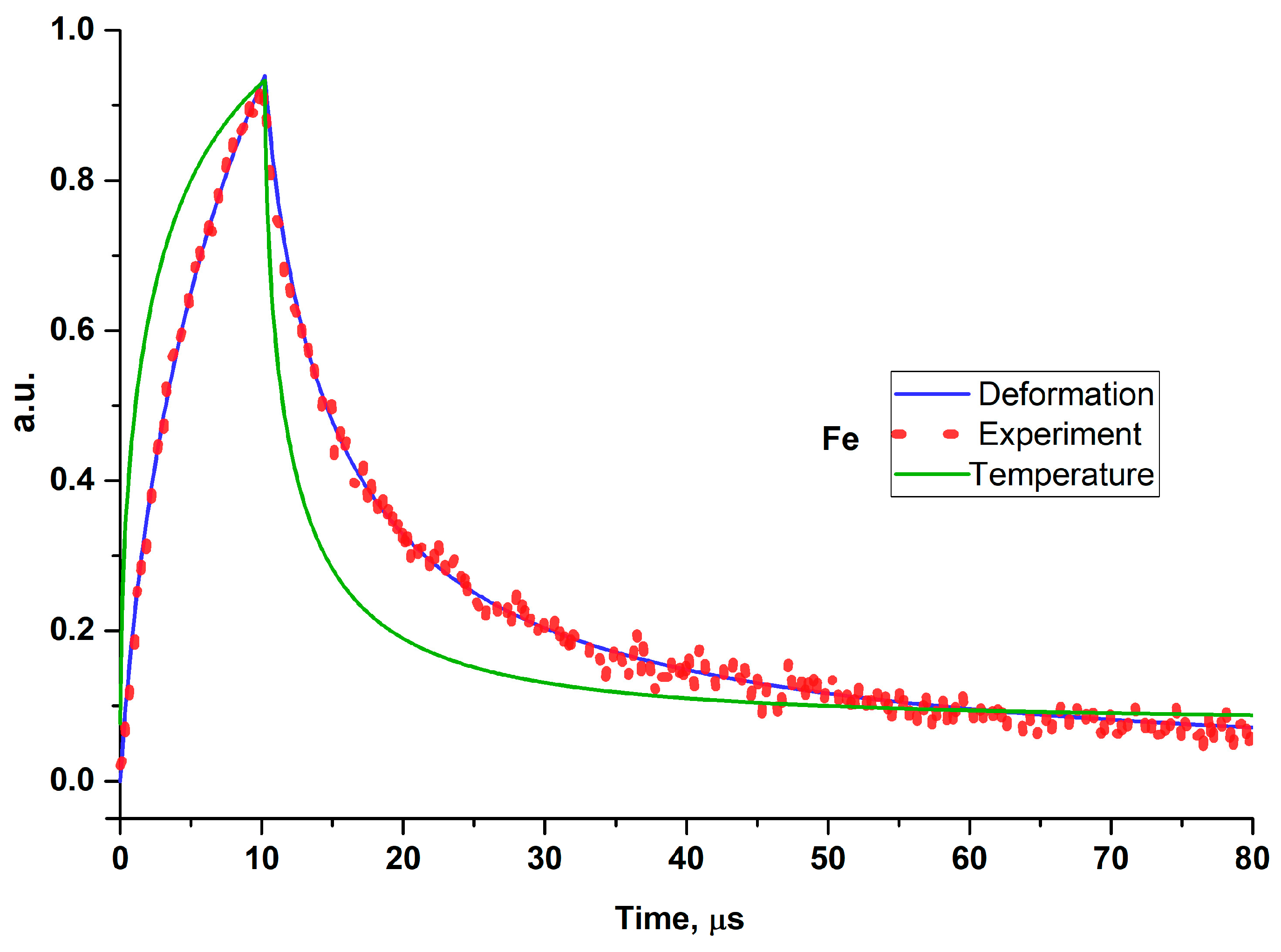

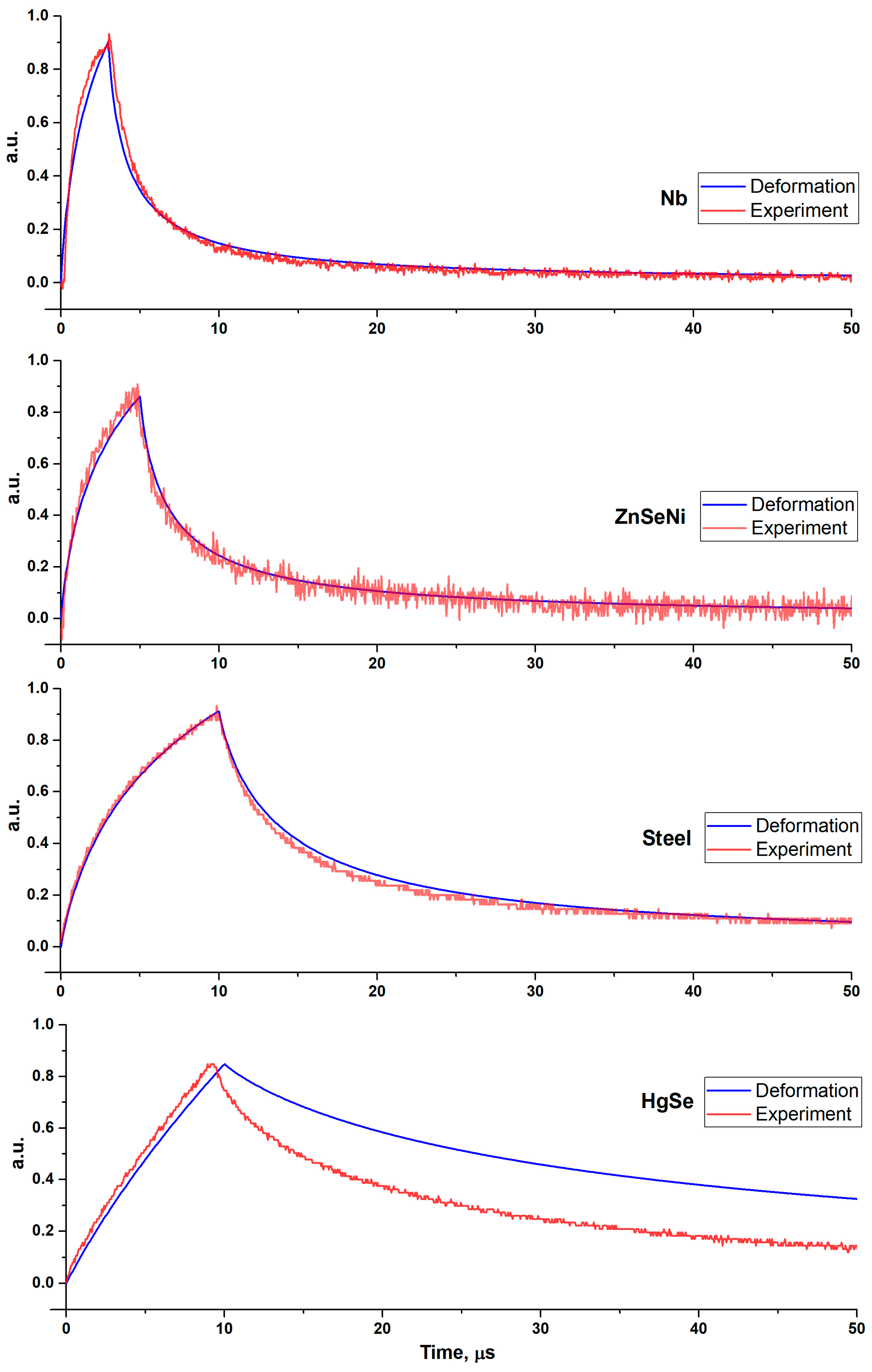

| Parameter | Nb | ZnSeNi | Steel | HgSe | Fe |

|---|---|---|---|---|---|

| Standard deviation, % | 2.192 | 3.341 | 1.593 | 8.935 | 2.068 |

| Pearson correlation coefficient | 0.9945 | 0.9856 | 0.9973 | 0.9062 | 0.9960 |

| Thermal diffusivity a, m2/s | 2.48·10−5 | 1.05·10−5 | 4·10−6 | 1.18·10−6 | 2.2·10−5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kotov, A.N.; Starostin, A.A.; Gorbatov, V.I.; Skripov, P.V. Thermo-Optical Measurements and Simulation in a Fibre-Optic Circuit Using an Extrinsic Fabry–Pérot Interferometer under Pulsed Laser Heating. Axioms 2023, 12, 568. https://doi.org/10.3390/axioms12060568

Kotov AN, Starostin AA, Gorbatov VI, Skripov PV. Thermo-Optical Measurements and Simulation in a Fibre-Optic Circuit Using an Extrinsic Fabry–Pérot Interferometer under Pulsed Laser Heating. Axioms. 2023; 12(6):568. https://doi.org/10.3390/axioms12060568

Chicago/Turabian StyleKotov, Artem N., Aleksandr A. Starostin, Vladimir I. Gorbatov, and Pavel V. Skripov. 2023. "Thermo-Optical Measurements and Simulation in a Fibre-Optic Circuit Using an Extrinsic Fabry–Pérot Interferometer under Pulsed Laser Heating" Axioms 12, no. 6: 568. https://doi.org/10.3390/axioms12060568

APA StyleKotov, A. N., Starostin, A. A., Gorbatov, V. I., & Skripov, P. V. (2023). Thermo-Optical Measurements and Simulation in a Fibre-Optic Circuit Using an Extrinsic Fabry–Pérot Interferometer under Pulsed Laser Heating. Axioms, 12(6), 568. https://doi.org/10.3390/axioms12060568