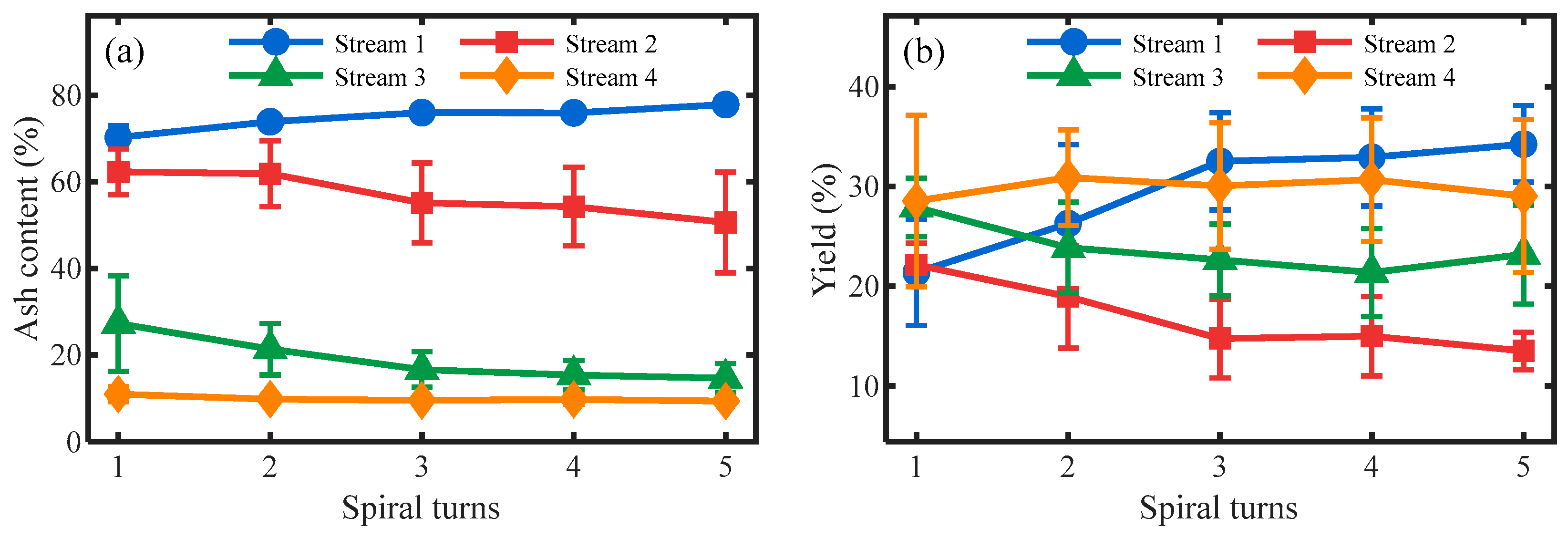

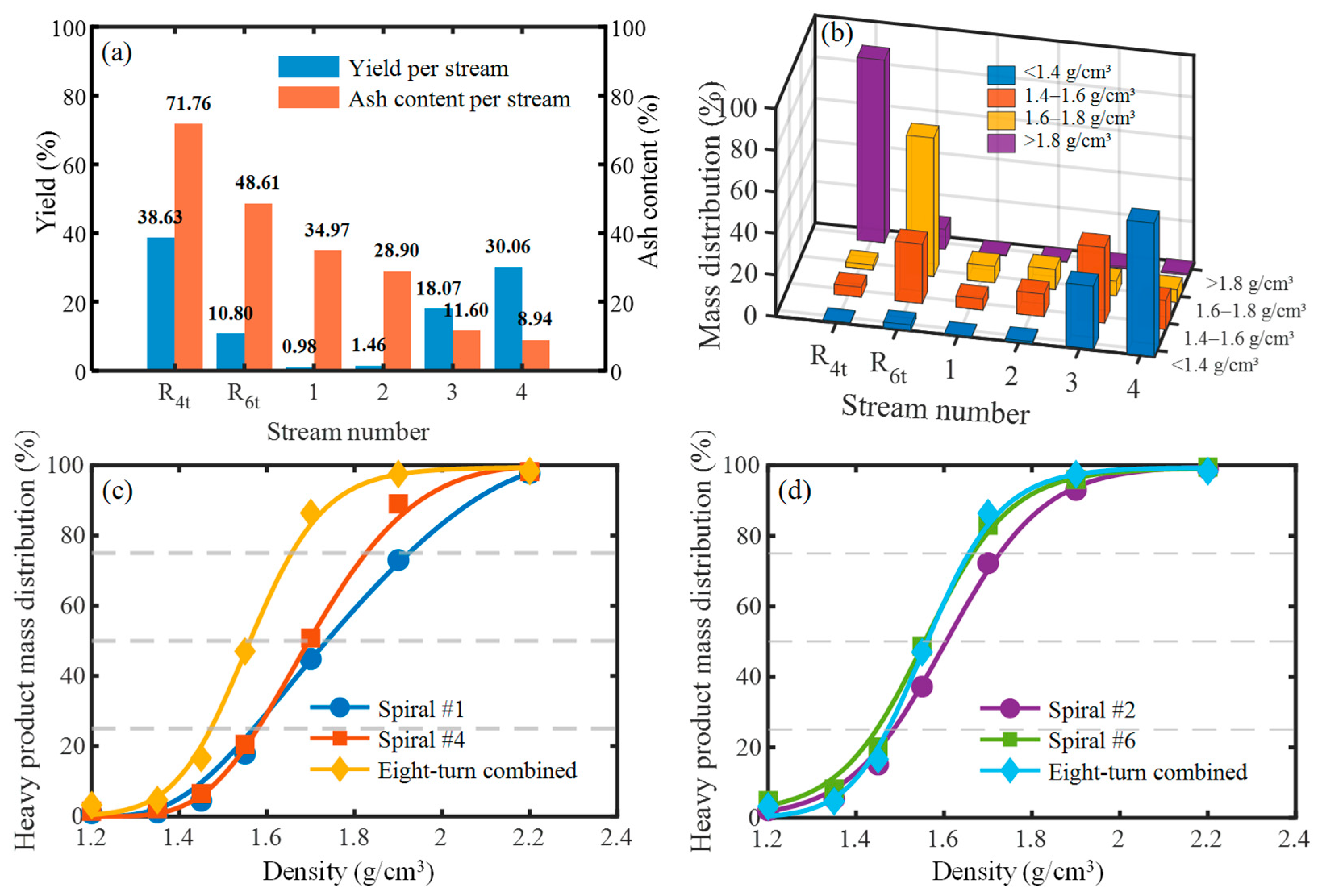

3.2.1. Ash Content, Yield and Particle Distribution During the Spiral Separation Process

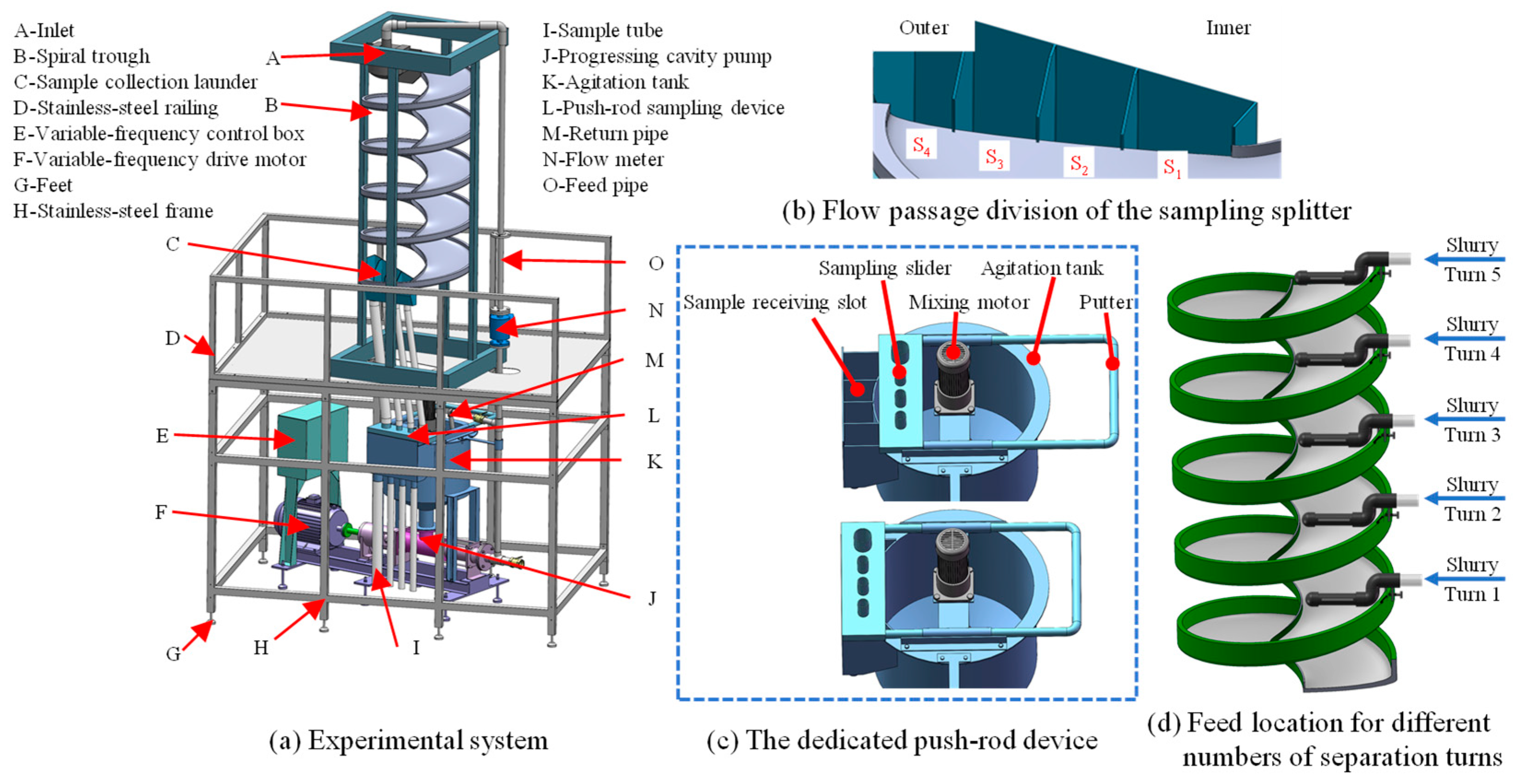

Figure 3 presents the evolution of ash content and solid yield across the radial sampling streams with increasing spiral turns, with the data points representing the average results from all six separators at the completion of each turn. As revealed in

Figure 3a, a pronounced radial heterogeneity in ash content was established after just one single separation turn, decreasing from 70% in the innermost stream (S

1) to 10% in the outermost stream (S

4). With further turns, the ash content of S

1 demonstrated a gradual increase from 70% to 78%. In contrast, the ash content in S

4 remained largely stable, exhibiting only a marginal decreasing trend. Conversely, streams S

2 and S

3 exhibited considerable ash content variations, both decreasing from 27% to 18% and from 60% to 52%, respectively.

Figure 3b illustrates the distinct evolutionary trends in solid yield across the radial sampling streams throughout the separation process. Following the first turn, the yield distribution was relatively concentrated, with values spanning a narrow range of 20–30% across all four streams (S

1 to S

4). As separation progressed, the yield of S

1 increased gradually, though the rate of increase moderated after the third turn. In contrast, the yield of S

4, while subject to minor fluctuations, exhibited an overall declining tendency. Similarly, streams S

2 and S

3 displayed comparable trends, with their yield gradually decreasing as the number of turns increased—a process characterized by a decelerating rate of decline beyond the third turn.

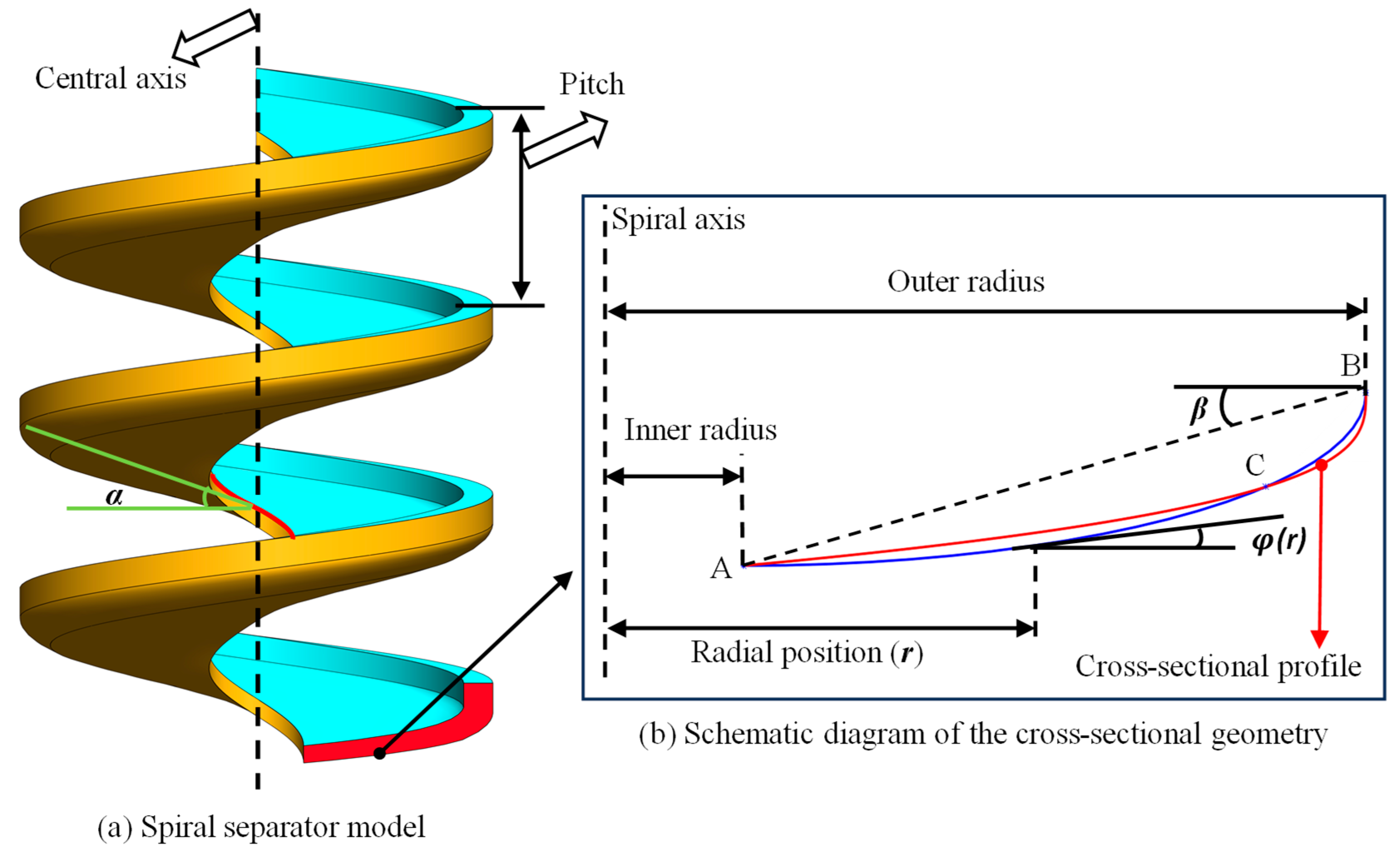

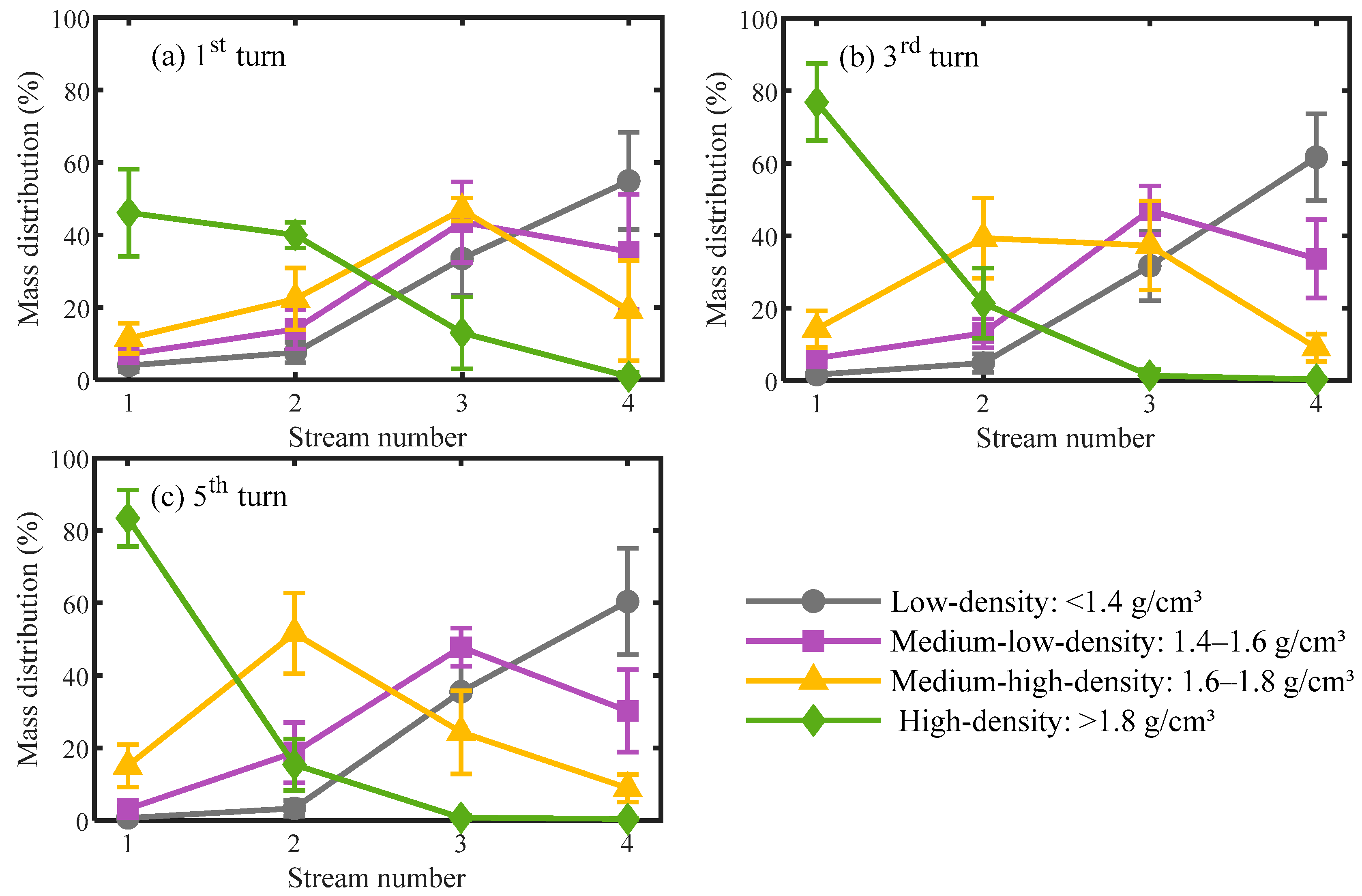

To gain deeper insights into particle migration dynamics,

Figure 4 shows the evolution of the mass distribution of different density fractions as the number of spiral turns increased, with the data points representing the average results from all six separators at the completion of each turn. As seen in

Figure 4a, high-density particles were primarily concentrated in stream S

1, with their mass distribution decreasing progressively across the radial direction toward the outer streams, leaving only negligible quantities in the outermost stream S

4. As separation progressed, the mass distribution of high-density particles in S

1 increased substantially. Conversely, a continuous decline was observed in streams S

2, S

3, and S

4. Owing to the initially low mass distribution of high-density particles in S

4, the subsequent reduction was less pronounced with additional turns. In contrast, the declines observed in S

2 and S

3 were more substantial. Specifically, in S

3, the mass distribution of high-density particles declined to a minimal level after the third turn, with no significant reduction thereafter. In S

2, however, the rate of decline diminished significantly after the third turn.

As presented in

Figure 4b, streams S

2 and S

3 served as the primary accumulation zones for medium-high-density particles. The dominant zone shifted from S

3 to S

2 after the third spiral turn. As separation progressed, the mass distribution of medium-high-density particles exhibited an increasing trend in both S

1 and S

2, with the latter demonstrating a more substantial increase. In contrast, the mass distribution in S

3 and S

4 decreased with additional turns, with a more marked reduction observed in S

3. After three turns, the mass distribution of medium-high-density particles in S

1 and S

4 stabilized, suggesting that an equilibrium state was approached in these streams. In contrast, streams S

2 and S

3 continued to undergo significant dynamic changes.

As shown in

Figure 4c, medium-low-density particles were primarily concentrated in streams S

3 and S

4. Throughout the separation process, the relative mass distribution of these particles across the streams maintained a consistent ranking: S

3 > S

4 > S

2 > S

1. The mass distribution of medium-low-density particles exhibited distinct evolutionary trends across the streams: a slight decrease in S

1 and S

4, minimal variation in S

3, and a pronounced increase in S

2 as separation progressed. Beyond three spiral turns, the mass distribution stabilized in S

1 and S

4, indicating the attainment of a steady state, whereas it continued to evolve dynamically in S

2 and S

3.

As demonstrated in

Figure 4d, low-density particles were primarily concentrated in streams S

3 and S

4. Throughout the separation process, their mass distribution consistently adhered to the sequence S

4 > S

3 > S

2 > S

1. A notable distribution shift occurred at the second spiral turn: the mass distribution of low-density particles increased substantially in S

4, while it decreased significantly across S

1 to S

3. Beyond this point, further spiral turns had negligible influence on the distribution of low-density particles.

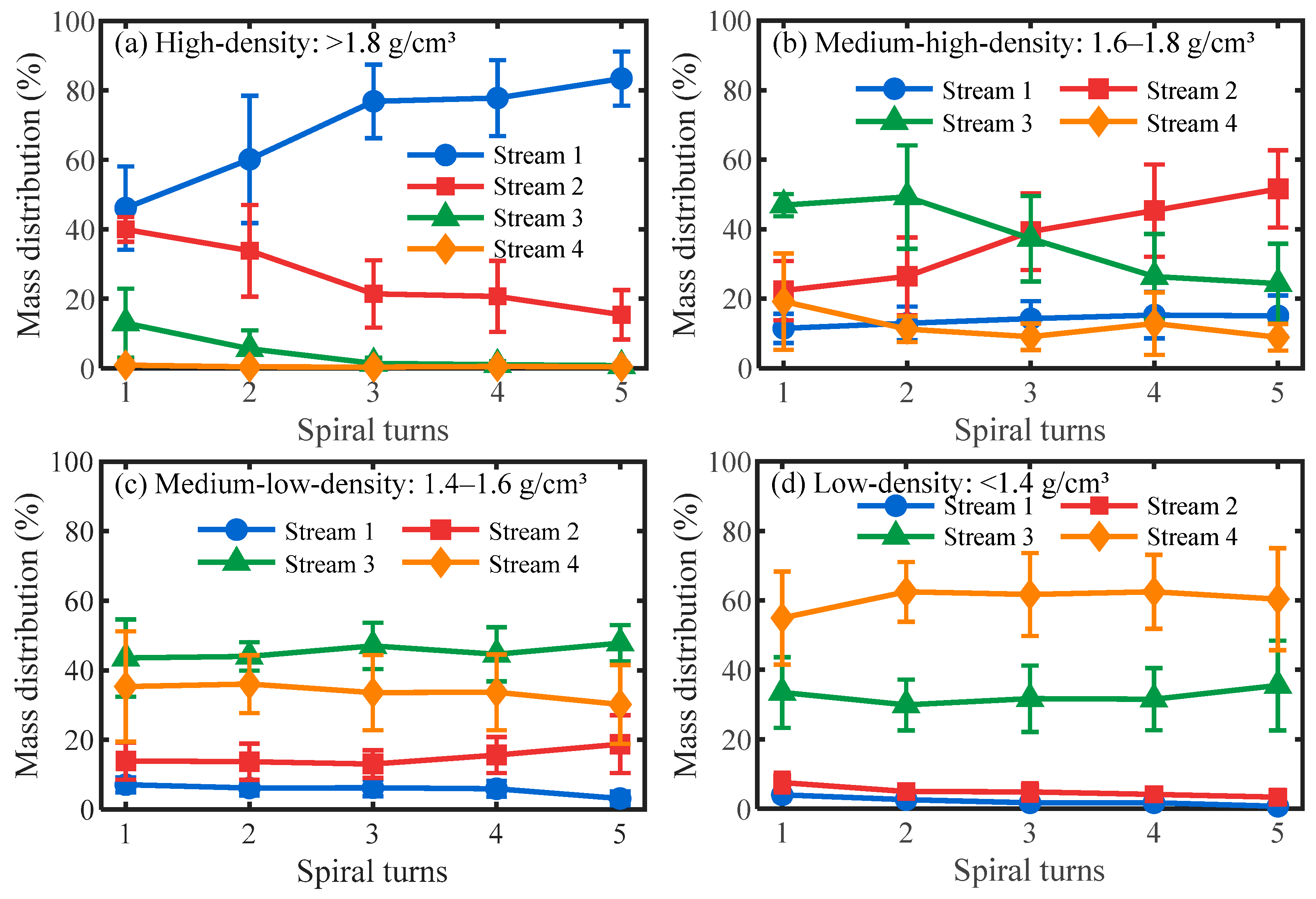

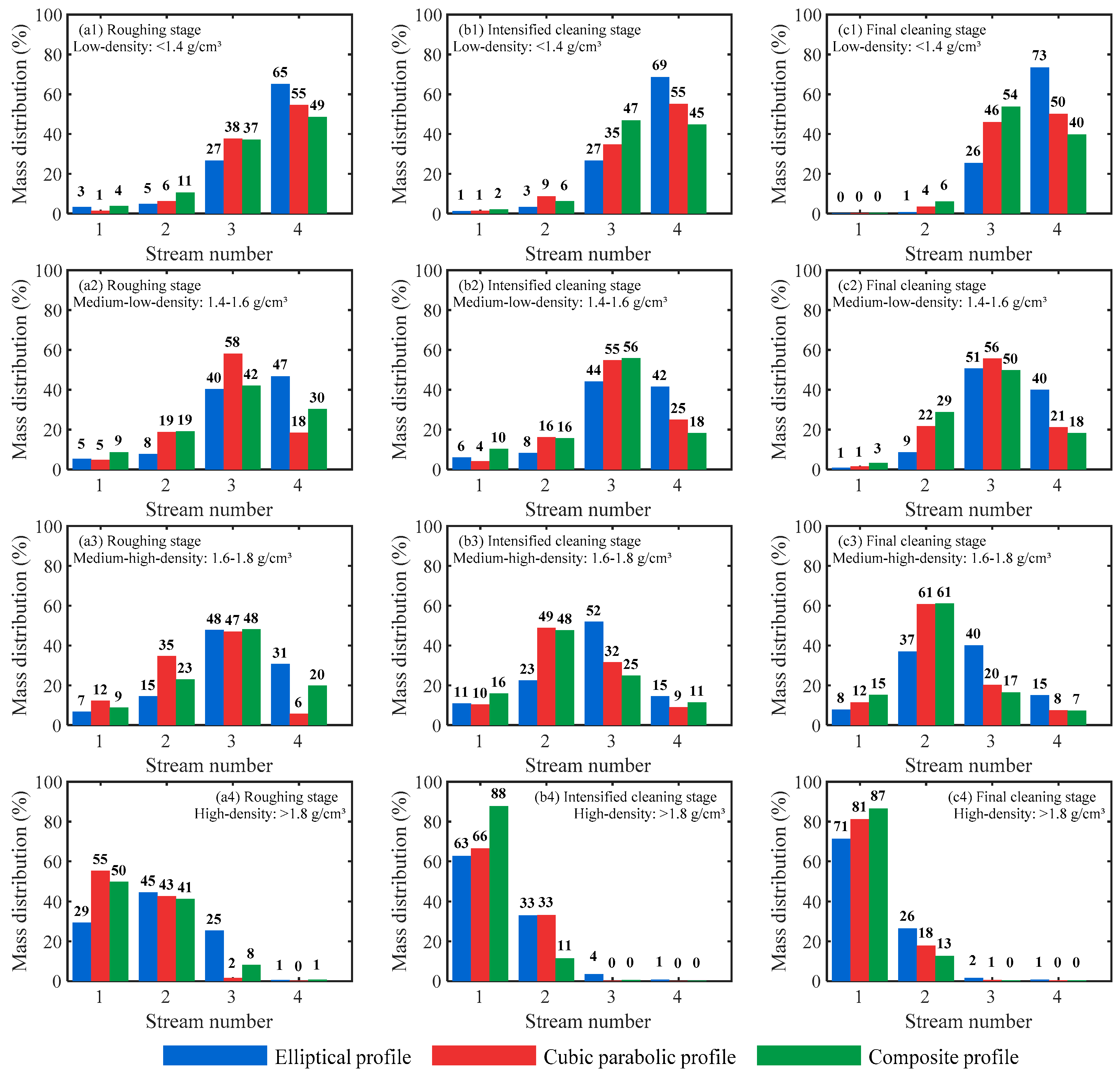

3.2.2. Particle Distribution Characteristics at 1st, 3rd, and 5th Spiral Turns

Based on the preceding analysis of

Figure 3 and

Figure 4, three key positions—corresponding to the completion of the 1st, 3rd, and 5th spiral turns—were identified. The radial distribution characteristics of particles at these three positions are further illustrated in

Figure 5, with the data points representing the average values from the six separators. As shown in

Figure 5a, after the first separation turn, high-density particles were predominantly concentrated in S

1, accounting for 45% of the mass distribution. Substantial proportions were also observed in S

2 (40%) and S

3 (18%). Medium-high-density particles form a distribution peak in S

3, constituting approximately 45% of the total. Medium-low-density particles showed a relatively uniform distribution overall, with slightly higher proportions in S

3 and S

4. Low-density particles were strongly concentrated in S

4, with their mass distribution in S

4 accounting for 55%, whereas this ratio in S

1 was only about 5%.

As shown in

Figure 5b, after two additional turns of separation, the mass distribution of high-density particles in S

1 increased markedly to approximately 80%. In contrast, their proportion in S

2 reduced substantially, while S

3 and S

4 contained negligible amounts of these particles. Concurrently, medium-high-density particles exhibited comparable mass distribution in S

2 and S

3, each accounting for approximately 40%. In S

1 and S

4, however, the corresponding proportions were considerably lower, at 18% and 14%, respectively. Medium-low-density particles were predominantly concentrated in streams S

3 and S

4, with respective mass distributions of 42% and 37%. Furthermore, the enrichment of low-density particles in the outermost stream (S

4) became more pronounced, reaching approximately 60%, in contrast to merely 5% in S

1.

As illustrated in

Figure 5c, following five separation turns, the innermost stream (S

1) was highly enriched with high-density particles, which accounted for 85% of its total mass distribution. In comparison, the mass distribution of high-density particles in S

2 was only about 15%, while virtually none were detected in S

3 and S

4. For medium-high-density particles, S

2 was the primary aggregation location, with mass distribution accounting for 50%. In addition, their mass distribution in S

3 and S

4 was relatively high, at 23% and 10%, respectively. Medium-low-density particles were chiefly concentrated in S

3, exhibiting a mass distribution of 42%. Substantial proportions were likewise present in S

2 (20%) and S

4 (35%). Meanwhile, the outermost stream (S

4) contained the highest concentration of low-density particles, constituting nearly 60% of the mass distribution.

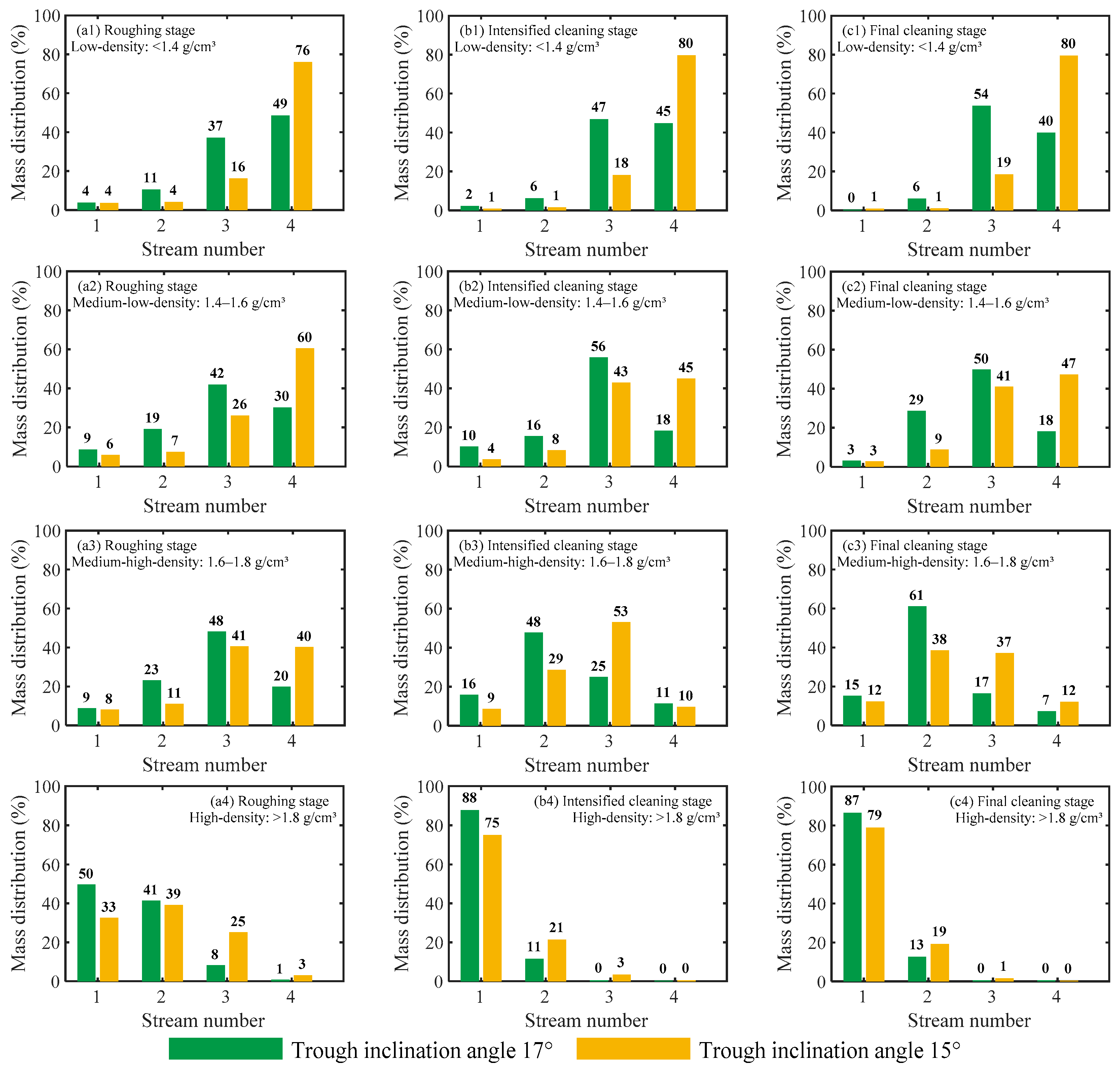

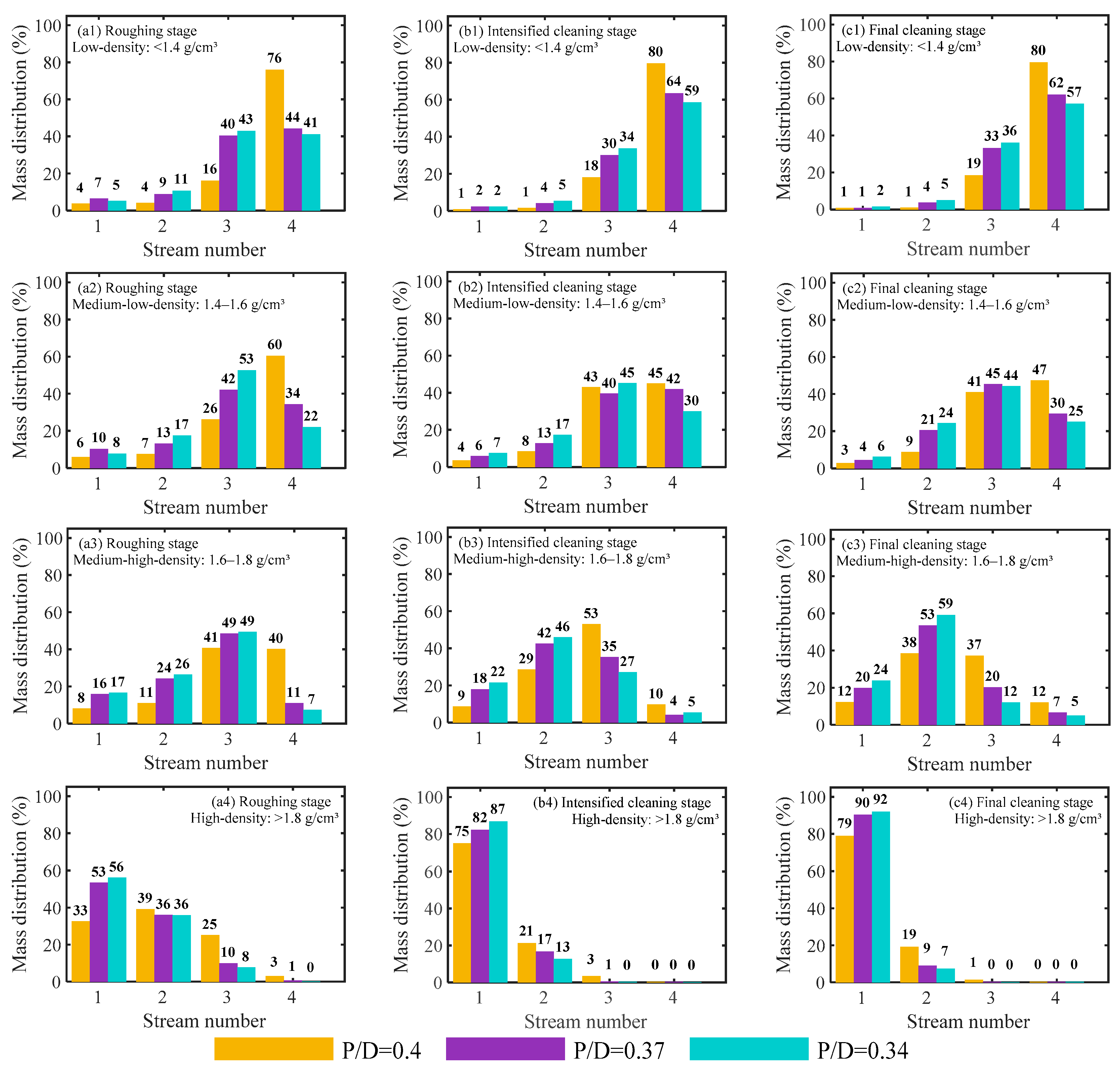

3.2.3. Stage Characteristics and Mechanism Explanation of the Separation Process

Based on a comprehensively analysis of the experimental results presented in

Figure 3,

Figure 4 and

Figure 5, the spiral separation process of coarse coal slime (1–0.25 mm) can be deconstructed into three sequential and functionally distinct stages according to its dynamic evolution characteristics: the Roughing Stage (1st turn), the Intensified Cleaning Stage (2nd–3rd turns), and the Final Cleaning Stage (4th–5th turns). The characteristics of each stage and their underlying dominant mechanisms are elaborated as follows:

- (1)

Roughing Stage (1st turn): Rapid stratification and light/heavy particle separation

Upon entering the spiral trough, particles undergo rapid separation between light and heavy fractions. High-density particles (>1.8 g/cm3) become significantly enriched in the innermost stream (S1, mass distribution ~45%), while low-density particles (<1.4 g/cm3) are quickly transported to the outermost stream (S4, mass distribution ~55%). In contrast, intermediate-density particles (1.4–1.8 g/cm3) exhibit a relatively broad distribution without forming distinct enrichment zones. This distribution pattern directly results in a pronounced radial ash gradient, decreasing sharply from ~70% in S1 to ~10% in S4.

The essence of this phenomenon lies in the high feed slurry velocity and the absence of a well-developed radial circulating flow upon entry into the spiral trough. During this stage, the pulp undergoes a rapid transition from inertia-dominated to spiral flow. Entering the trough with high initial kinetic energy, the slurry trajectory is initially governed by inertia, impacting the outer wall in an approximately straight line [

22,

25]. After deflection by the wall, the flow direction is gradually constrained to follow the spiral path downwards, and a radial secondary flow begins to develop, although it remains unstable in this nascent phase. Within this dynamic flow field, particles of different densities exhibit distinct migration behaviors due to differences in force mechanisms: High-density particles, owing to their significant density difference, effectively penetrate the flow film and settle onto the trough bottom. Once settled, the component of gravity along the inclined trough bottom becomes the dominant force, driving them to overcome fluid drag and slide continuously towards the inner region (S

1). Conversely, low-density particles are confined to the upper high-velocity flow layer, dominated by centrifugal force, and are rapidly transported to the outer region (S

4). For intermediate-density particles, the flow field conditions at this stage are unfavorable for precise separation. Due to intense pulp turbulence and the insufficient establishment of a stable secondary flow, these particles lack a sustained, directional radial driving force for separation. Consequently, they are primarily carried by the pulp, resulting in a broad and relatively uniform radial distribution.

- (2)

Intensified Cleaning Stage (2nd–3rd turns): Dynamic migration and precise separation of intermediate particles

This stage is crucial for determining the final separation efficiency. The particle distribution profile becomes noticeably “narrower” and “sharper” compared to the first turn. The enrichment of high-density particles in S

1 increases substantially to approximately 80%, and the concentration of low-density particles in S

4 consolidates to around 60%. The most critical feature is the intense redistribution of intermediate-density particles: medium-high-density particles (1.6–1.8 g/cm

3) show a clear inward migration trend, with their distribution gravity shifting from S

3 to S

2, while medium-low-density particles (1.4–1.6 g/cm

3) migrate outward (to S

3 and S

4). This dynamic process directly causes the significant changes in ash content observed in streams S

2 and S

3 in

Figure 3a.

Upon entering the Intensified Cleaning Stage, the flow field is fully developed, forming a stable secondary circulation [

27,

30]. The resulting flow pattern—outward in the upper layer and inward in the lower layer—provides the primary driving force for density-based separation. Benefiting from the pre-stratification and pre-separation in the roughing stage, the particle bed becomes more ordered and stable. In this environment, medium-high-density particles can continuously sink to regions near the trough bottom, where they are effectively captured by the strong inward-directed lower-layer flow and transported inward, eventually accumulating in S

2. Medium-low-density particles are predominantly transported by the outward-directed upper-layer flow, migrating towards the outer region alongside low-density particles. Because their density is higher than that of low-density particles, the balance point between centrifugal force and fluid drag is located further inward; thus, their migration distance is limited, and they primarily enrich in the S

3 stream.

- (3)

Final Cleaning Stage (4th–5th turns): Distribution stabilization and mismatch correction

In the final two turns (the spiral separator used in the experiment has 5 turns), the radial migration of particles across all density levels slows down significantly, and the separation trend according to density differences stabilizes. The concentration of high-density particles in S

1 reaches its peak of about 85%, and the distribution of low-density particles in S

4 also stabilizes around 60%. The distribution of intermediate-density particles becomes largely fixed: medium-high-density particles are primarily located in S

2, while medium-low-density particles are distributed in S

3 and S

4. Correspondingly, the ash content in all streams shows only minor fluctuations after the third turn (

Figure 3a), indicating that the separation process is essentially complete.

Entering the Final Cleaning Stage, the separation behavior of particles reaches or approaches a dynamic equilibrium. Most particles have found their respective equilibrium orbits within the resultant force field composed of centrifugal force, fluid drag, the gravity component, and bed support force. Macroscopic radial migration is markedly reduced. The role of the flow field at this stage is no longer to induce large-scale particle radial migration, but rather to maintain a stable force field environment. This allows the few residual mismatched particles—caused by inter-particle collisions or local turbulent disturbances in earlier stages—the opportunity to return to their theoretical equilibrium positions through low-intensity reciprocating motion. Simultaneously, this stable flow field ensures the efficient and non-interfering transport of the separated products to their respective collection zones. Therefore, although the kinetic activity is subdued, the Final Cleaning Stage is critical for achieving high final product purity and recovery rate; the quality of the separated products is ultimately established and consolidated here.