Investigations of MgO on Sintering Performance and Metallurgical Property of High-Chromium Vanadium-Titanium Magnetite

Abstract

1. Introduction

2. Experiment

2.1. Materials Analysis and Characteristic

2.2. Sinter Pot Test

2.3. Definition of Parameters

2.3.1. Vertical Sintering Speed

2.3.2. Productivity

2.3.3. Reduction Degradation Index

2.3.4. Reduction Index

2.3.5. Softening-Melting Properties

3. Results and Discussion

3.1. Sintering Performance

3.2. Mineral Composition and Microstructure

3.3. Metallurgical Property of HCVTM Sinter

3.4. Comprehensive Index

4. Conclusions

- (1)

- With MgO content increased from 2.7% to 3.5%, the yield and the productivity increased, while the VSS and the TI initially increased then decreased.

- (2)

- The mineral structure of the HCVTM sinter changed from a non-uniform state to a uniform state with increased MgO content. Most of the Mg2+ entered the magnetite lattice, while a small amount entered the perovskite and the calcium silicate.

- (3)

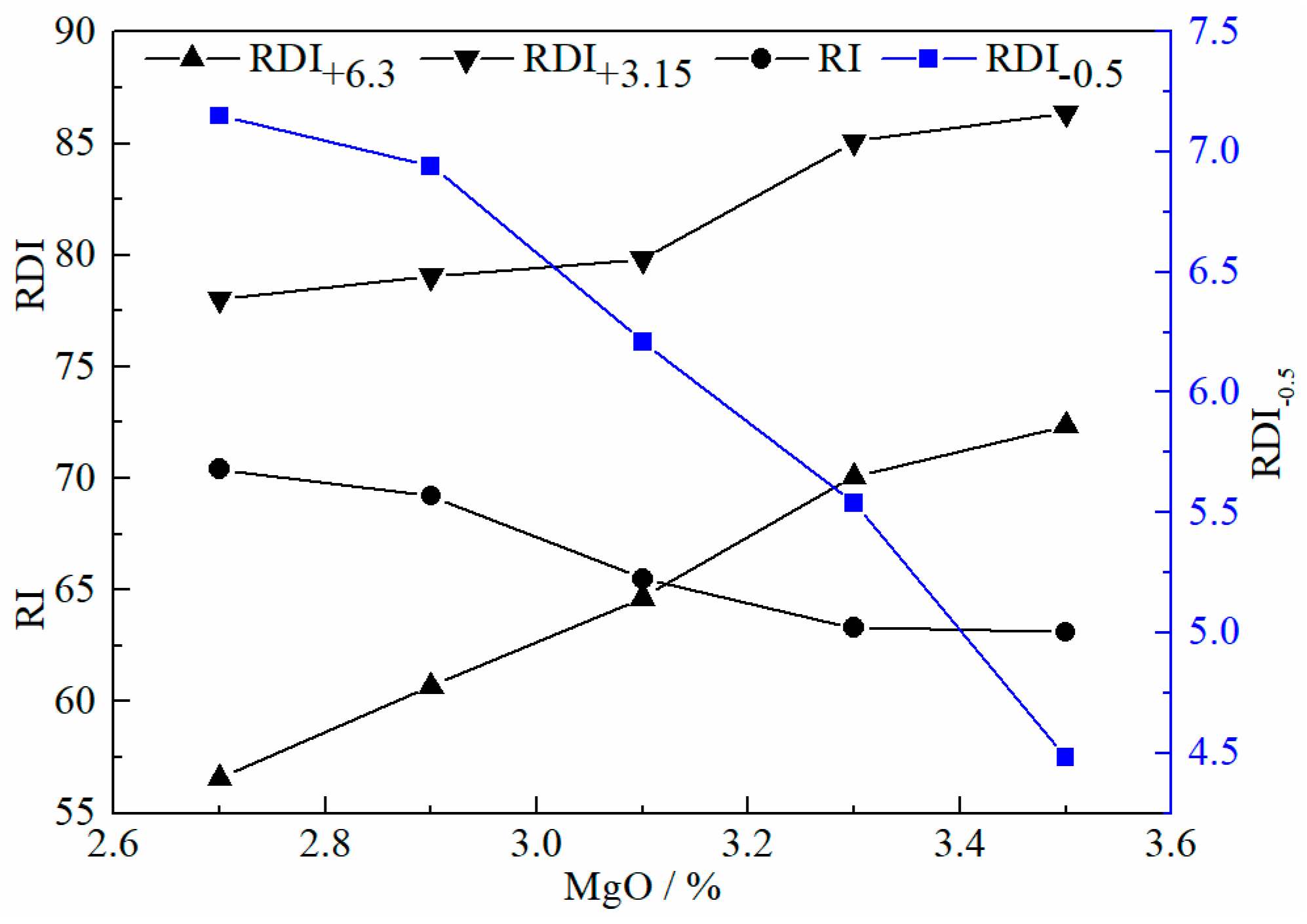

- With the increased MgO content, the RDI sinter increased while the RI decreased. Additionally, the sinter softening-melting properties were improved. According to the comprehensive index, the optimal recommended amount of MgO was 3.3%.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Takano, C.; Zambrano, A.P.; Nogueira, A.E.A.; Mourao, M.B.; Iguchi, Y. Chromites reduction reaction mechanisms in carbon-chromites composite agglomerates at 1773K. ISIJ Int. 2007, 47, 1585–1589. [Google Scholar] [CrossRef]

- Lu, C.; Zou, X.; Lu, X.; Xie, X.; Zheng, K.; Xiao, W.; Cheng, H.; Li, G. Reductive kinetics of Panzhihua ilmenite with hydrogen. Trans. Nonferrous Met. Soc. China 2016, 26, 3266–3273. [Google Scholar] [CrossRef]

- Wu, S.; Xu, H.; Tian, Y. Evaluation of lump ores for use in modern blast furnaces as part of mixed burden practice. Ironmak. Steelmak. 2013, 36, 19–23. [Google Scholar] [CrossRef]

- Liao, J.; Li, J.; Wang, X.; Zhang, Z. Influence of TiO2 and basicity on viscosity of Ti bearing slag. Ironmak Steelmak. 2012, 39, 133–139. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, L.; Wang, M.; Li, G.; Sui, Z. Dynamic oxidation of the Ti-bearing blast furnace slag. ISIJ Int. 2006, 46, 458–465. [Google Scholar] [CrossRef]

- Moskalyk, R.; Alfantazi, A. Processing of vanadium: A review. Miner Eng. 2003, 16, 793–805. [Google Scholar] [CrossRef]

- Chen, D.; Song, B.; Wang, L.; Qi, T.; Wang, Y.; Wang, W. Solid state reduction of Panzhihua titanomagnetite concentrates with pulverized coal. Miner. Eng. 2011, 24, 864–869. [Google Scholar] [CrossRef]

- Rocha, M.; Silva, A.; Mourao, M.; Kurauchi, M.; Takano, C. Fundamental aspects of sintering of chromites concentrates. Miner. Process. Extr. M. 2014, 123, 251–256. [Google Scholar] [CrossRef]

- Zhang, G.; Zhang, T.; Lv, G.; Zhang, Y.; Liu, Y.; Gang, X. Extraction of vanadium from LD converter slag by pressure leaching process with titanium white waste acid. Rare Metal Mat. Eng. 2015, 44, 1894–1898. [Google Scholar]

- Zhang, L.; Zhang, L.; Wang, M.; Li, G.; Sui, Z. Recovery of titanium compounds from molten Ti-bearing blast furnace slag under the dynamic oxidation condition. Miner. Eng. 2007, 20, 684–693. [Google Scholar] [CrossRef]

- Li, Q.; Huang, Z.Z.; Jiang, T.; Yang, Y.B.; Li, G.H. Effect of dolomite and serpentine on sinter quality and microstructure. Iron Steel 2006, 41, 10–14. [Google Scholar]

- Yu, S.R.; Yu, S.J.; Liu, Y.H.; Li, Y.M. Influence of MgO content on the sinter index and the metallurgical property. Angang Technol. 2008, 353, 23–26. [Google Scholar]

- Zhou, M.S.; Li, Y.R. Laboratory study on reasonable MgO content in the sinter of Anshan iron and steel group co. Sinter. Pelletizing 2005, 6, 1–4. [Google Scholar]

- Zhao, Z. Laboratory sintering study with adding dolomite fines. Sinter Pelletizing 2003, 28, 25–27. [Google Scholar]

- Yadav, U.S.; Pandey, B.D.; Das, B.K.; Jene, D. Influence of magnesia on sintering characteristics of iron ore. Ironmak. Steelmak. 2002, 29, 91–95. [Google Scholar] [CrossRef]

- Yang, L.X.; Davis, L. Assimilation and mineral formation during sintering for blends containing magnetite concentrate and hematite/pisolite sintering fines. ISIJ Int. 2007, 39, 239–245. [Google Scholar] [CrossRef][Green Version]

- Liu, Z.; Chu, M.; Wang, H.; Zhao, W.; Xue, X. Effect of MgO content in sinter on the softening-melting behavior of mixed burden made from chromium-bearing vanadium-titanium magnetite. Int. J. Miner. Metall. Mater. 2016, 23, 25–32. [Google Scholar] [CrossRef]

- Yang, S.T.; Tang, W.D.; Zhou, M.; Jiang, T.; Xue, X.X.; Zhang, W.J. Effect of dolomite on mineral composition and metallurgical properties of chromium-bearing vanadium-titanium magnetite sinter. Minerals 2017, 7, 210. [Google Scholar] [CrossRef]

- Umadevi, T.; Nelson, K.; Mahapatra, P.C.; Prabhu, M.; Ranjan, M. Influence of magnesia on iron ore sinter properties and productivity. Ironmak. Steelmak. 2009, 36, 515–520. [Google Scholar] [CrossRef]

- Gan, Q.; He, Q.; Wen, Y. Study on influence of MgO on mineral composition and metallurgical properties of V-bearing titaniferous magnetite sinter. Iron Steel 2008, 8, 7–11. [Google Scholar]

- Fan, X.H.; Li, W.Q.; Gan, M. Influence and mechanism of MgO on strength of high basicity sinter. J Cent. South Univ. (Sci. Technol.) 2012, 9, 3325–3330. [Google Scholar]

- Yang, S.T.; Zhou, M.; Jiang, T.; Wang, Y.J.; Xue, X.X. Effect of basicity on sintering behavior of low-titanium vanadium-titanium magnetite. Trans. Nonferrous Met. Soc. China 2015, 25, 2087–2094. [Google Scholar] [CrossRef]

- Tang, W.D.; Yang, S.T.; Cheng, G.J.; Gao, Z.X.; Yang, H.; Xue, X.X. Effect of TiO2 on the sintering behavior of chromium-bearing vanadium-titanium magnetite. Minerals 2018, 8, 263. [Google Scholar] [CrossRef]

- Pelton, A.D. Thermodynamic database development—Modeling and phase diagram calculations in oxide systems. Rare Met. 2006, 25, 473–480. [Google Scholar] [CrossRef]

- Trömel, G.; Koch, K.; Fix, W.; Großkurth, N. Magnesiumoxyds auf die gleichgewichte im system Fe–CaO–FeOn–SiO2 und auf die schwefelverteilung bei 1600 °C. Archiv für das Eisenhüttenwesen 1969, 40, 969–978. [Google Scholar] [CrossRef]

- Panigrahy, S.; Verstraeten, P.; Dilewijns, J. Influence of MgO addition on mineralogy of iron ore sinter. Metall. Mater. Trans. B 1984, 15, 23–32. [Google Scholar] [CrossRef]

- Long, H.; Yuan, X.; Liu, Z. Iron Ore Powder Sintering Principle and Process; Metallurgical Industry Press: Beijing, China, 2010. [Google Scholar]

- Zhou, M.; Yang, S.; Jiang, T.; Xue, X. Influence of MgO in form of magnesite on properties and mineralogy of high chromium, vanadium, titanium magnetite sinters. Ironmak. Steelmak. 2015, 42, 217–225. [Google Scholar] [CrossRef]

- Ma, J.Y.; Sun, X.W.; Sheng, S.X. Intensified smelting of vanadium and titanium magnetite in blast furnace. Iron Steel (China) 2000, 35, 4–8. [Google Scholar]

- Qie, J.M.; Zhang, C.X.; Li, X.P.; Guo, Y.H.; Wang, H.F.; Wu, S.L. Lower SO2 emissions in the sintering process utilizing the difference of sulphur contents of iron ores. ISIJ Inter. 2017, 12, 2115–2123. [Google Scholar] [CrossRef]

| Raw Materials | TFe | FeO | TiO2 | V2O5 | Cr2O3 | CaO | SiO2 | MgO | Al2O3 | P | S |

|---|---|---|---|---|---|---|---|---|---|---|---|

| HCVTM * | 56.45 | 28.05 | 11.01 | 1.32 | 0.55 | 0.63 | 2.66 | 2.54 | 2.42 | 0.01 | 0.34 |

| Gas-ash | 32.39 | 1.79 | 0.25 | 0.16 | 5.16 | 5.95 | 1.79 | 2.69 | 0.07 | 0.17 | |

| Magnetic powder | 0.14 | 0.03 | 29.4 | 2.58 | 20.65 | 0.90 | |||||

| Ordinary Magnetite | 63.79 | 28.35 | 0.89 | 0.06 | 0.02 | 0.38 | 7.15 | 0.38 | 1.25 | 0.02 | 0.05 |

| Dolomite | 28.97 | 7.77 | 20.2 | 1.16 | |||||||

| Quicklime | 60.80 | 3.42 | 2.87 | 1.11 |

| Item | Fixed Carbon | Volatile | Organic Compounds | Ash | ∑ | ||||

|---|---|---|---|---|---|---|---|---|---|

| CaO | SiO2 | MgO | Al2O3 | others | |||||

| Coke | 76.90 | 0.559 | 1.48 | 1.35 | 6.4 | 0.28 | 4.18 | 8.85 | 100.00 |

| Coal | 85.40 | 0.147 | 1.35 | 0.74 | 4.6 | 0.18 | 3.35 | 4.23 | 100.00 |

| Point | Fe | Si | Al | Mg | Ti | V | Cr | O |

|---|---|---|---|---|---|---|---|---|

| A | 69.88 | 0.39 | 0.54 | 0.54 | 16.54 | 0.59 | 0.42 | 11.09 |

| B | 38.21 | - | - | 1.38 | 34.38 | 0.26 | 0.43 | 25.34 |

| C | - | 14.83 | 12.77 | 20.86 | - | - | - | 51.54 |

| Number | ω(MgO)/% | Mixed Sinter Raw Materials (100 %)/wt % | CaO/SiO2 | ω(C)/% | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| HCVTM | Magnetite | Return Mine | Gas Ash | Magnetic Powder | Quick-Lime | Dolo-Mite | ||||

| 1 | 2.7 | 35.0 | 30 | 20 | 1 | 1 | 11.6 | 1.5 | 1.9 | 5.0 |

| 2 | 2.9 | 34.2 | 30 | 20 | 1 | 1 | 11.3 | 2.5 | 1.9 | 5.0 |

| 3 | 3.1 | 33.1 | 30 | 20 | 1 | 1 | 11.3 | 3.6 | 1.9 | 5.0 |

| 4 | 3.3 | 32.8 | 30 | 20 | 1 | 1 | 10.5 | 4.7 | 1.9 | 5.0 |

| 5 | 3.5 | 32.2 | 30 | 20 | 1 | 1 | 10.1 | 5.7 | 1.9 | 5.0 |

| Item | Parameter | Item | Parameter |

|---|---|---|---|

| Sinter pot height | 700 mm | Sinter pot inner diameter | 320 mm |

| Sintering weight | 100 kg | Pelletizing time | 10 min |

| Ignition temperature | 1050 °C | Ignition time | 2 min |

| Ignition pressure | 8.0 kPa | Exhausting pressure | 12.0 kPa |

| ω(MgO)/% | zi1 | zi2 | zi3 | zi4 | zi5 | zi6 | fi | Fi = fi − f1 + 100 |

|---|---|---|---|---|---|---|---|---|

| 2.7 | 17.10 | 2.30 | 84.00 | 52.02 | 78.02 | 70.4 | 1032.70 | 100 |

| 2.9 | 18.10 | 2.41 | 84.80 | 47.52 | 79.05 | 69.2 | 1034.24 | 101.53 |

| 3.1 | 18.56 | 2.54 | 85.70 | 49.36 | 79.82 | 65.5 | 1040.53 | 107.82 |

| 3.3 | 20.40 | 2.71 | 86.30 | 55.12 | 85.09 | 63.3 | 1077.91 | 145.21 |

| 3.5 | 19.88 | 2.69 | 86.40 | 48.70 | 86.38 | 63.1 | 1061.97 | 129.26 |

| Rj | 3.30 | 0.41 | 2.40 | 7.60 | 8.36 | 7.3 | ||

| Wj | 5 | 25 | 10 | 20 | 20 | 20 | ||

| ωj | 1.52 | 60.98 | 4.17 | 2.63 | 2.39 | 2.74 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Yang, S.; Tang, W.; Xue, X. Investigations of MgO on Sintering Performance and Metallurgical Property of High-Chromium Vanadium-Titanium Magnetite. Minerals 2019, 9, 324. https://doi.org/10.3390/min9050324

Zhang L, Yang S, Tang W, Xue X. Investigations of MgO on Sintering Performance and Metallurgical Property of High-Chromium Vanadium-Titanium Magnetite. Minerals. 2019; 9(5):324. https://doi.org/10.3390/min9050324

Chicago/Turabian StyleZhang, Liheng, Songtao Yang, Weidong Tang, and Xiangxin Xue. 2019. "Investigations of MgO on Sintering Performance and Metallurgical Property of High-Chromium Vanadium-Titanium Magnetite" Minerals 9, no. 5: 324. https://doi.org/10.3390/min9050324

APA StyleZhang, L., Yang, S., Tang, W., & Xue, X. (2019). Investigations of MgO on Sintering Performance and Metallurgical Property of High-Chromium Vanadium-Titanium Magnetite. Minerals, 9(5), 324. https://doi.org/10.3390/min9050324