Swell–Shrink Behavior of Rubberized Expansive Clays during Alternate Wetting and Drying

Abstract

:1. Introduction

2. Materials

2.1. Expansive Clay

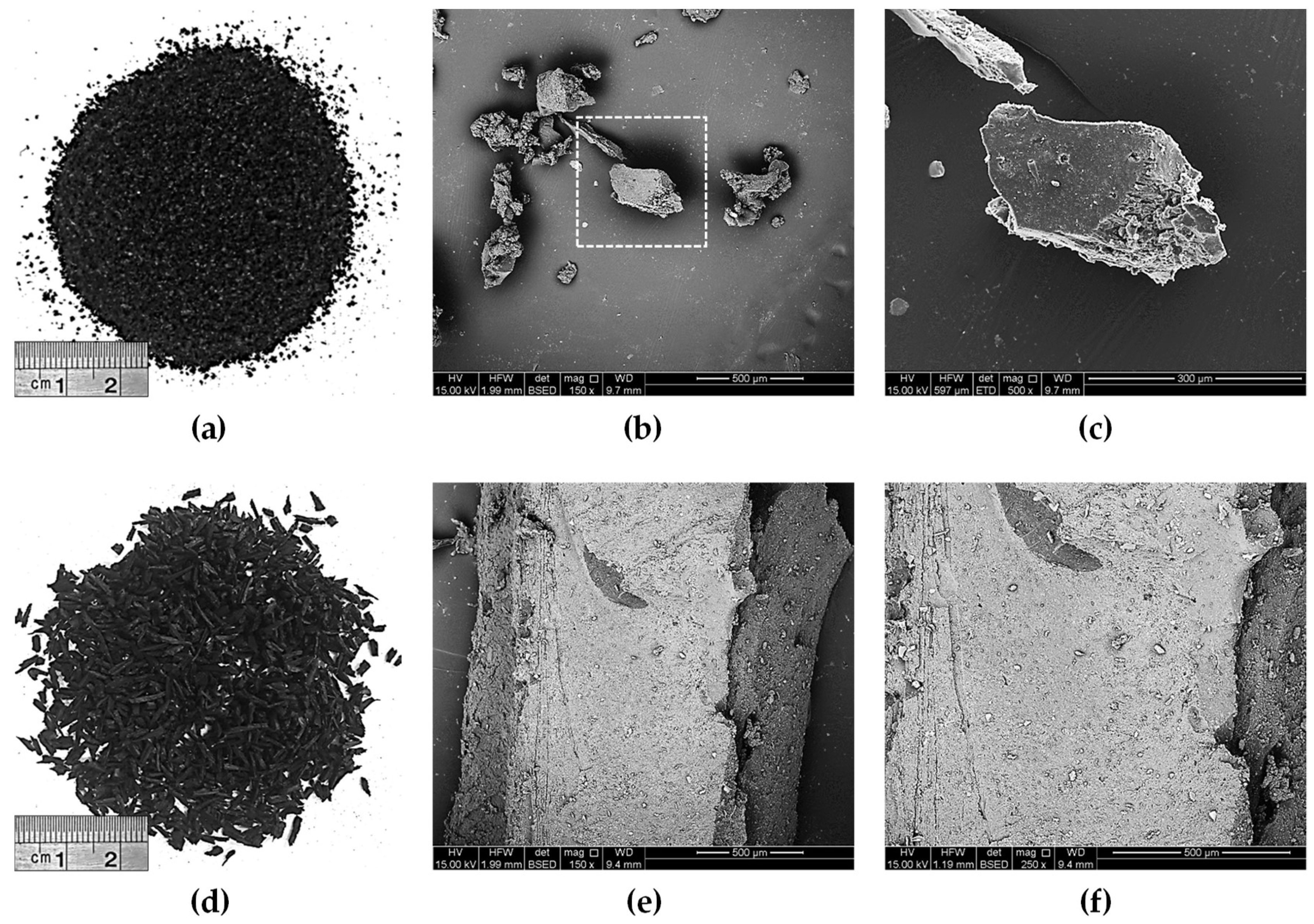

2.2. Recycled Tire Rubbers

3. Experimental Methodologies

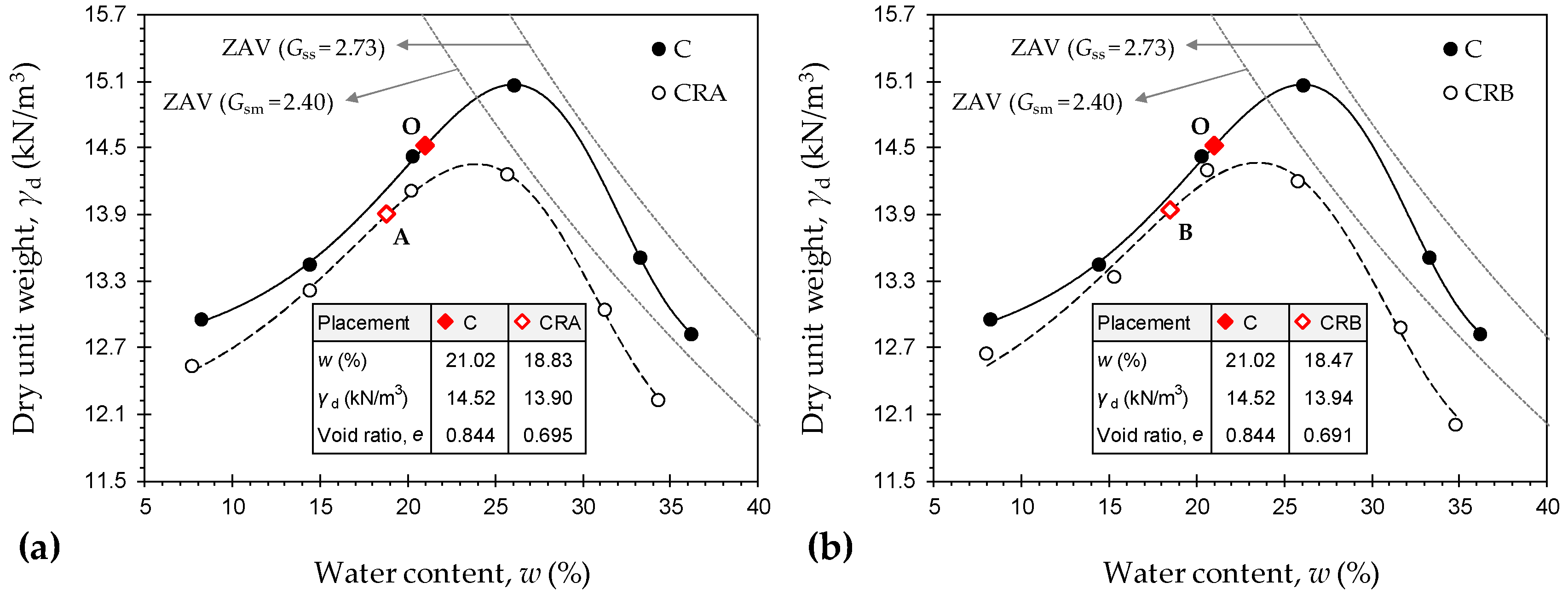

3.1. Compaction Studies and Sample Preparations

3.2. Cyclic Wetting–Drying Test

3.3. Microstructure Analysis

4. Results and Discussion

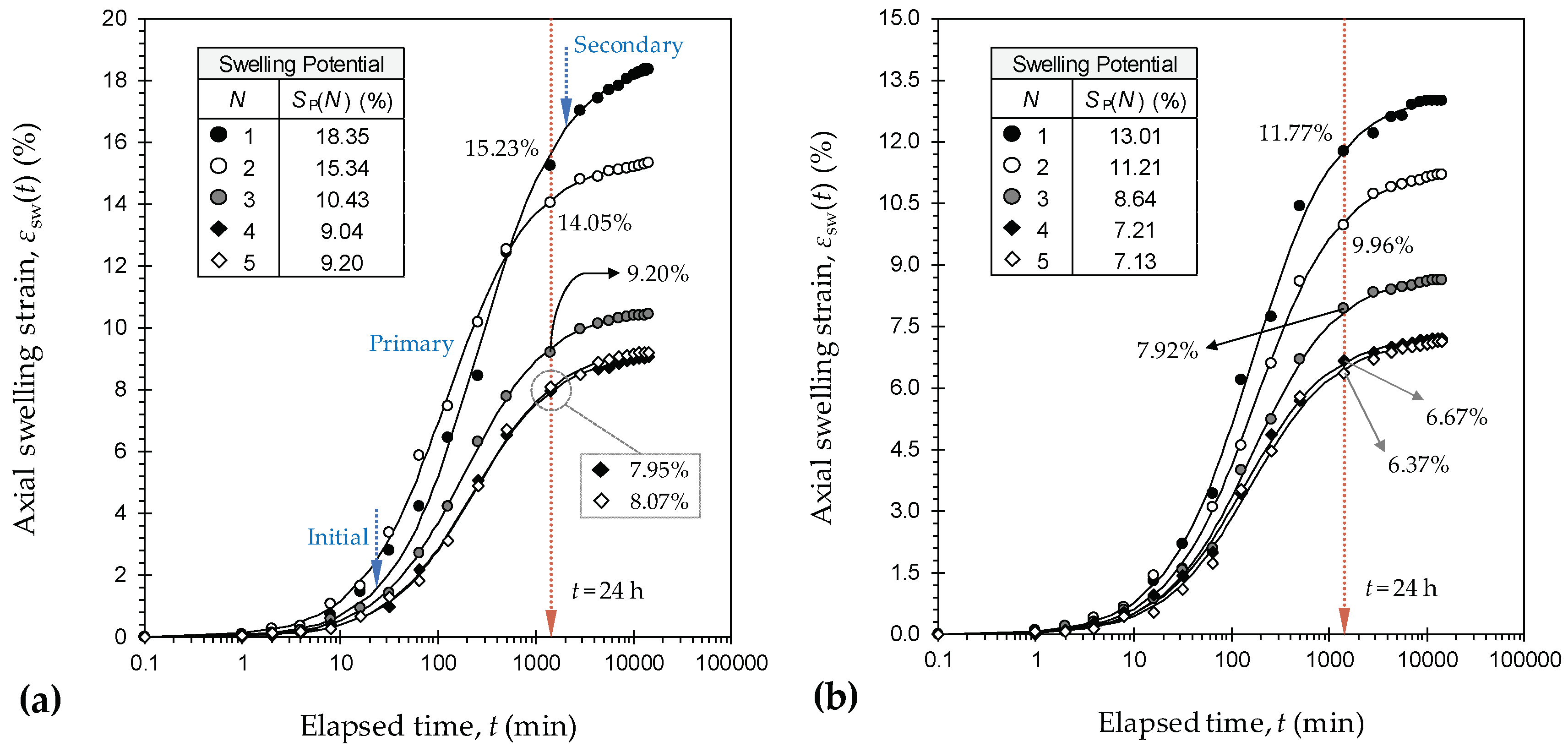

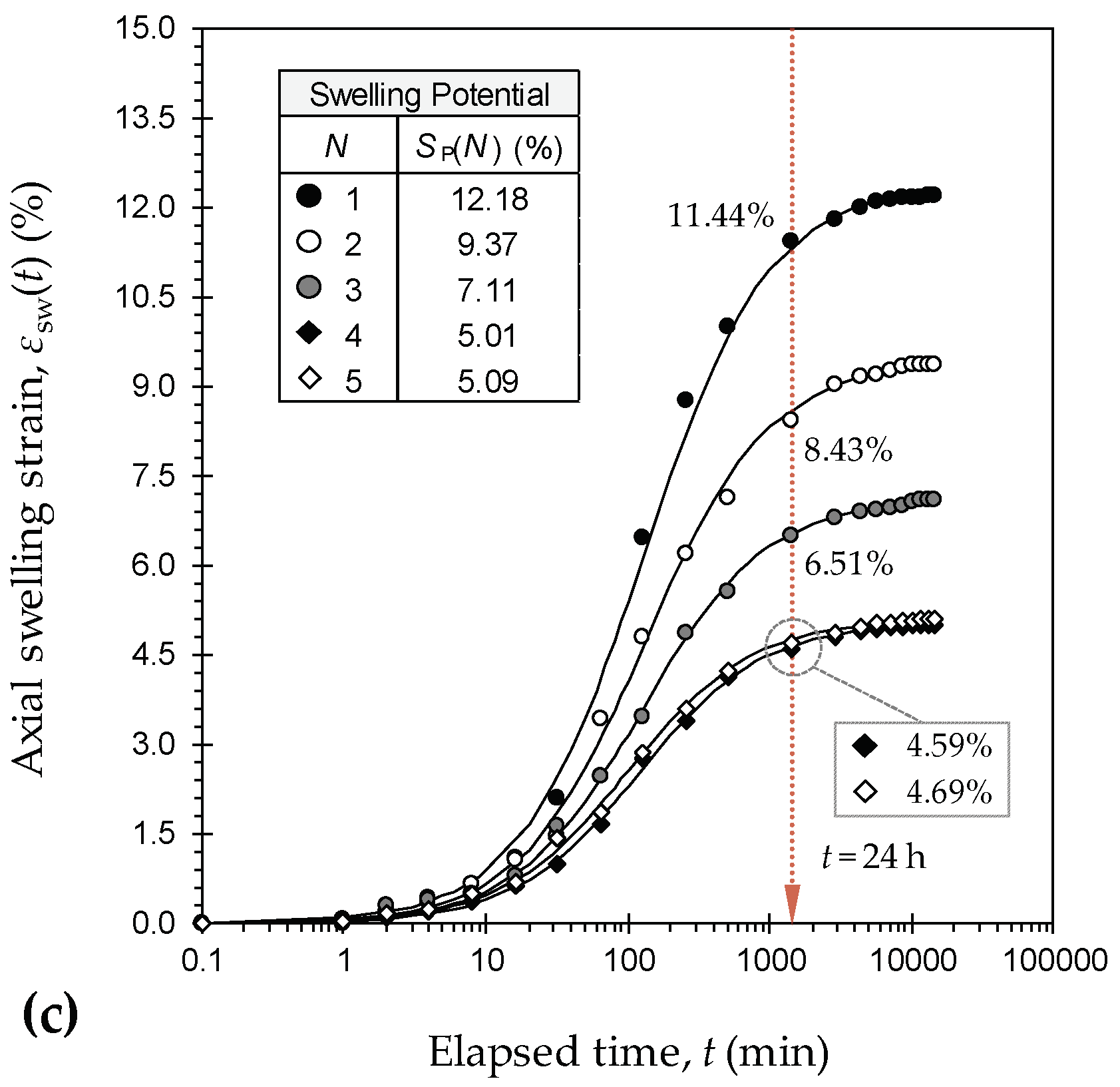

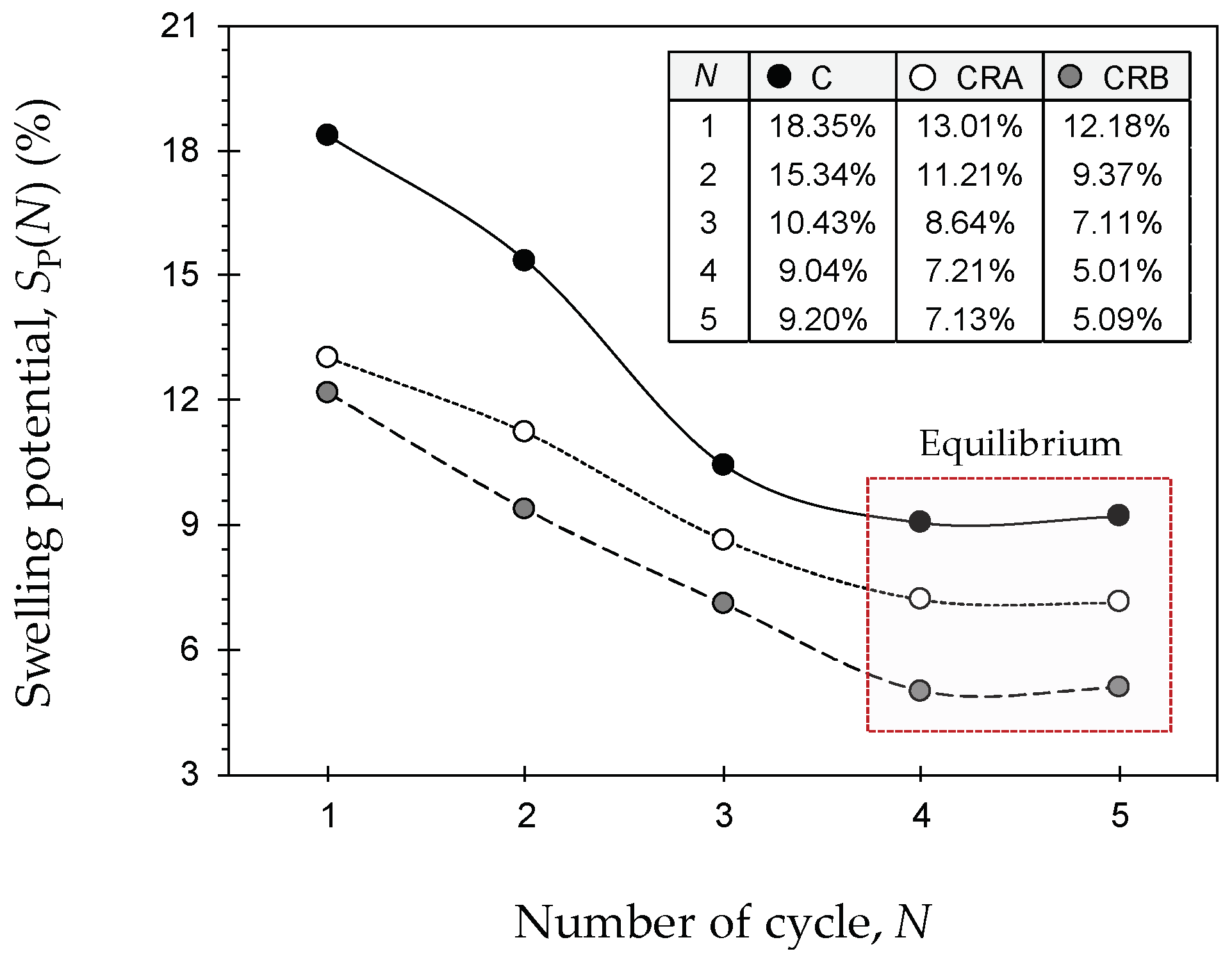

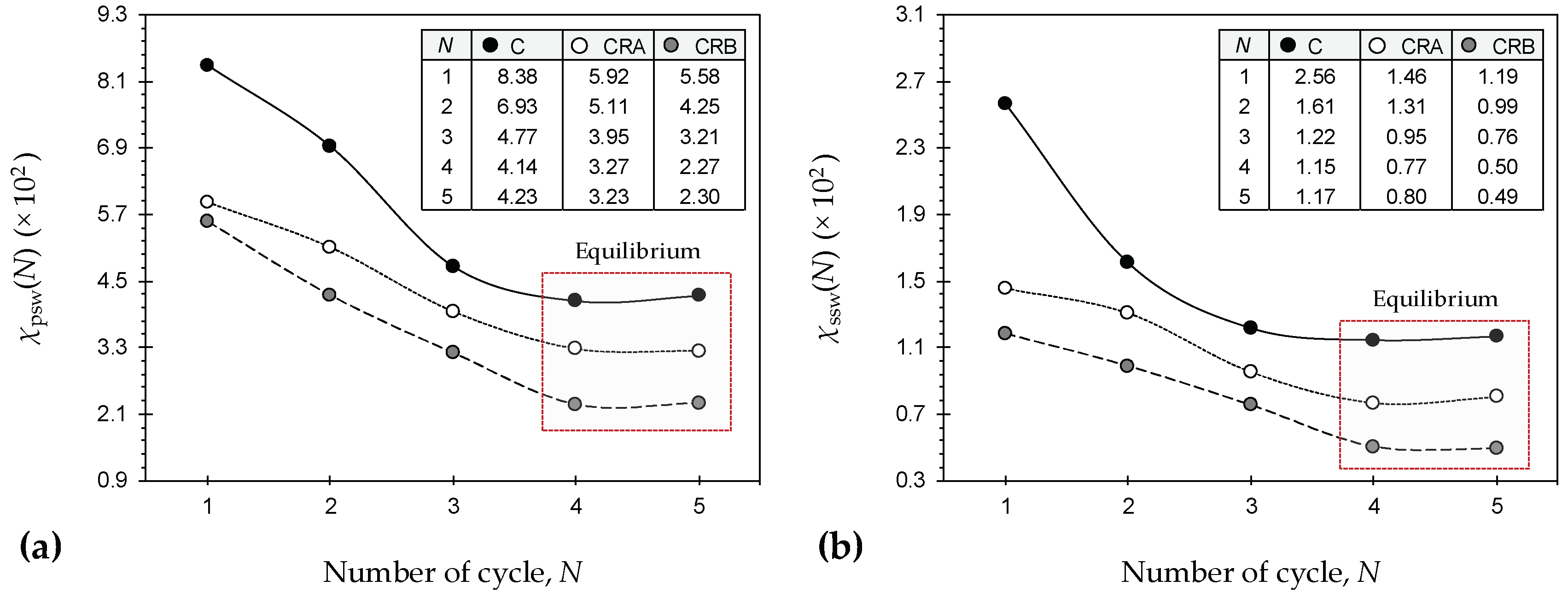

4.1. Swelling Characteristics

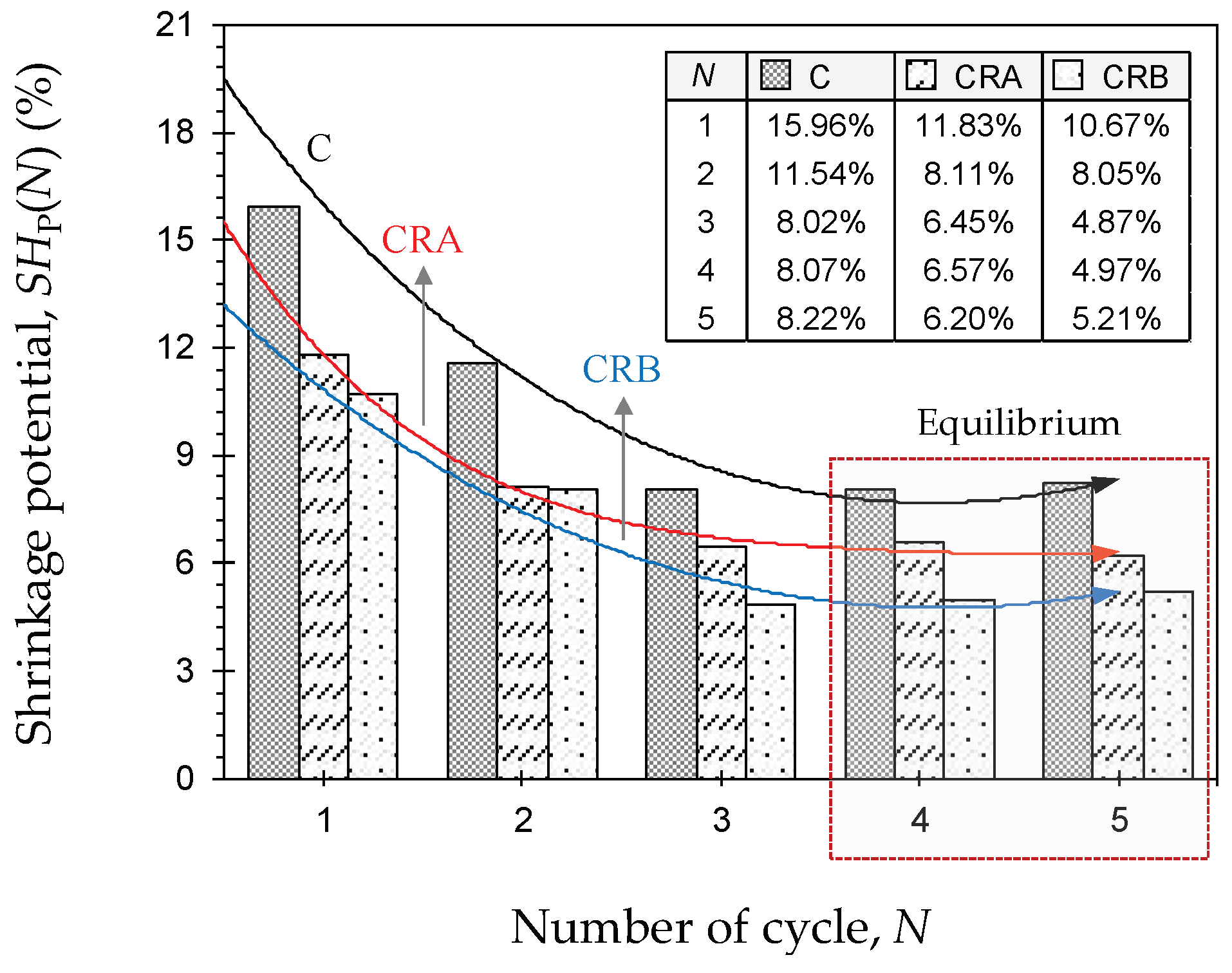

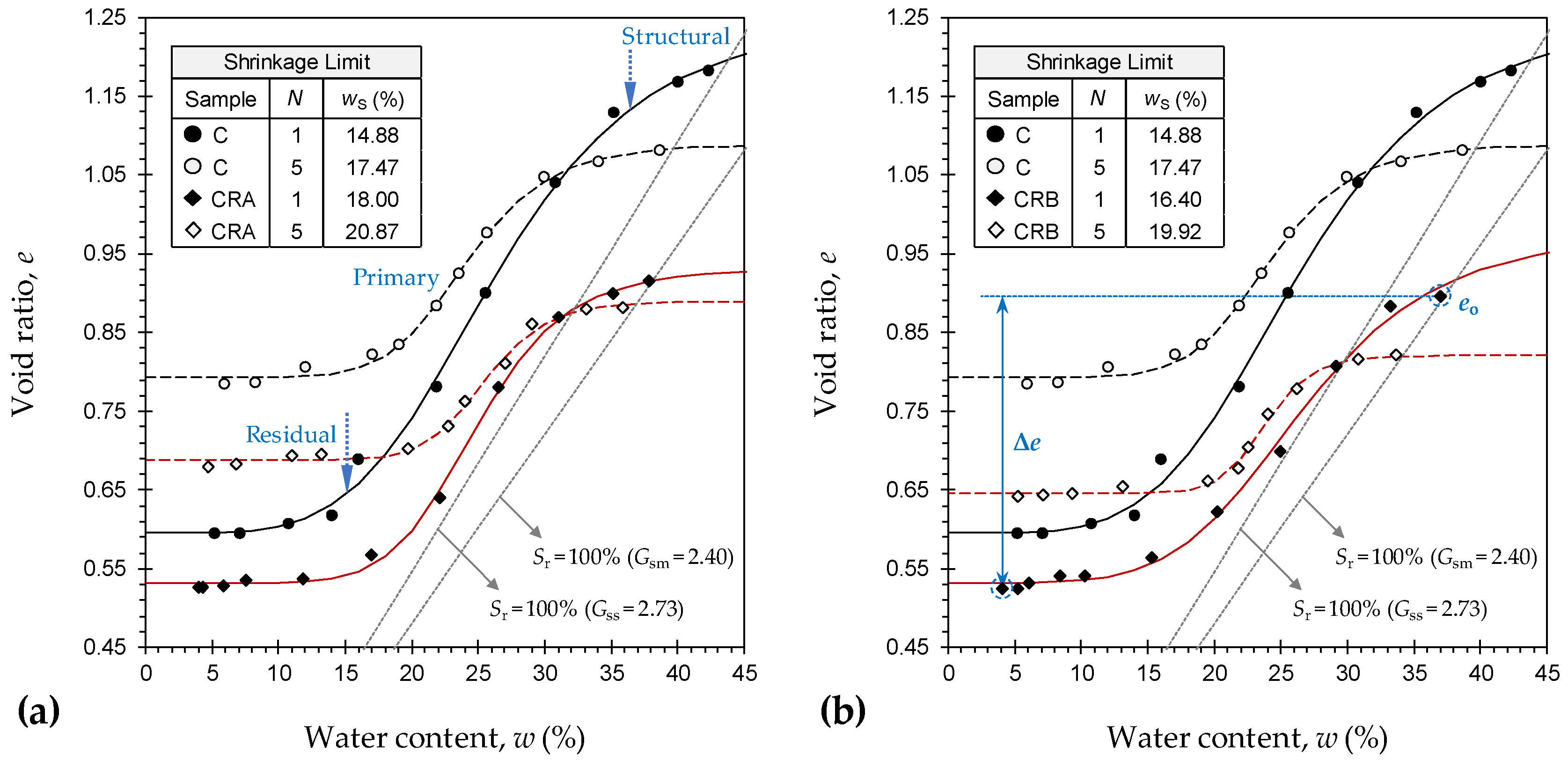

4.2. Shrinkage Characteristics

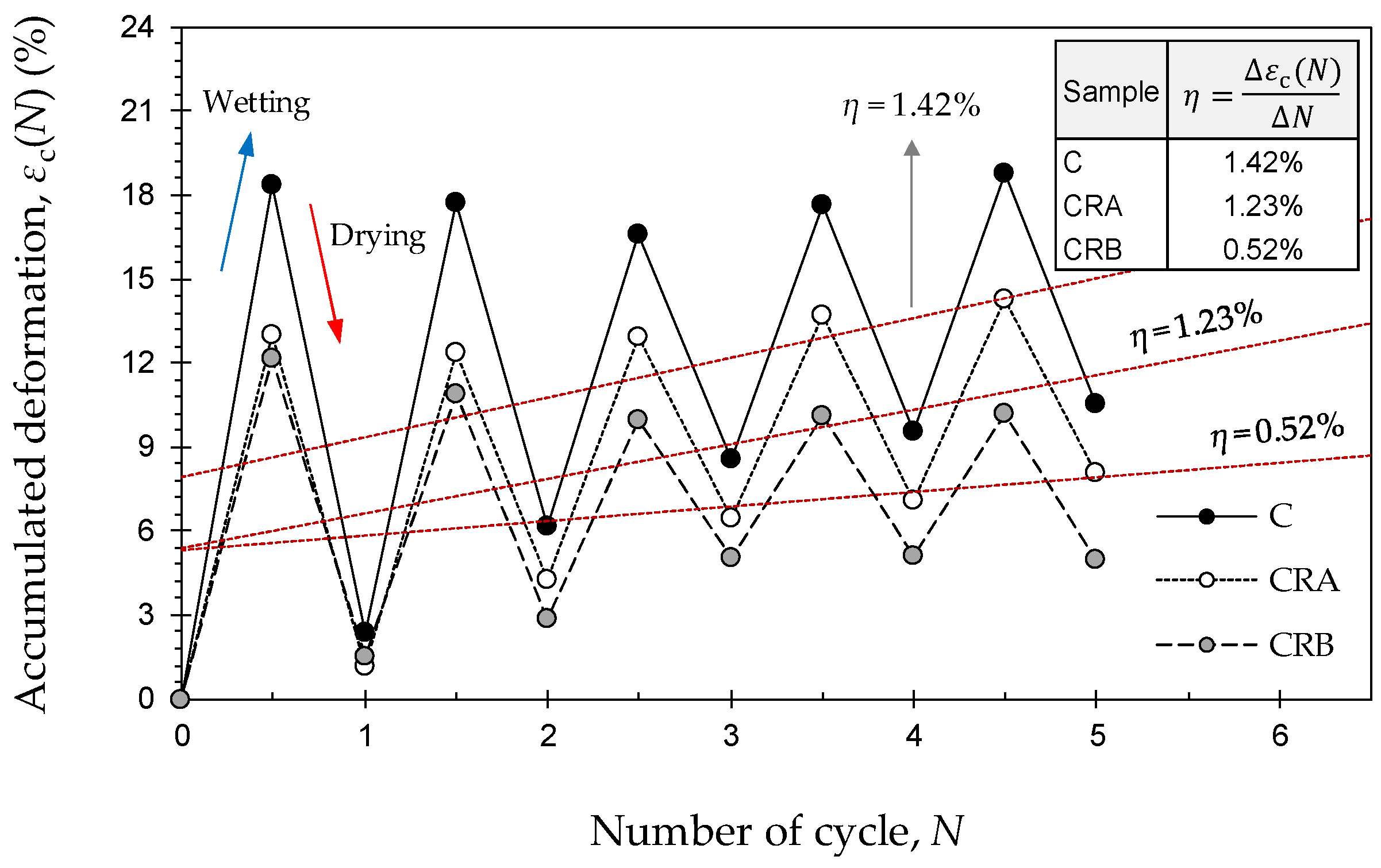

4.3. Swell–Shrink Patterns

- η > 0: The magnitude of incurred swelling is greater than that of shrinkage, and as such, the accumulated deformation is expansive. Quite clearly, the greater the magnitude of η, the higher the expansive tendency.

- η < 0: The magnitude of incurred shrinkage is greater than that of swelling, and as such, the accumulated deformation is contractive. In this case, the greater the magnitude of η, the higher the tendency for contraction.

- η = 0: The magnitude of incurred swelling and shrinkage are on par with each other, and as such, the accumulated deformation is neutral and hence desirable for minimizing free surface ground movements.

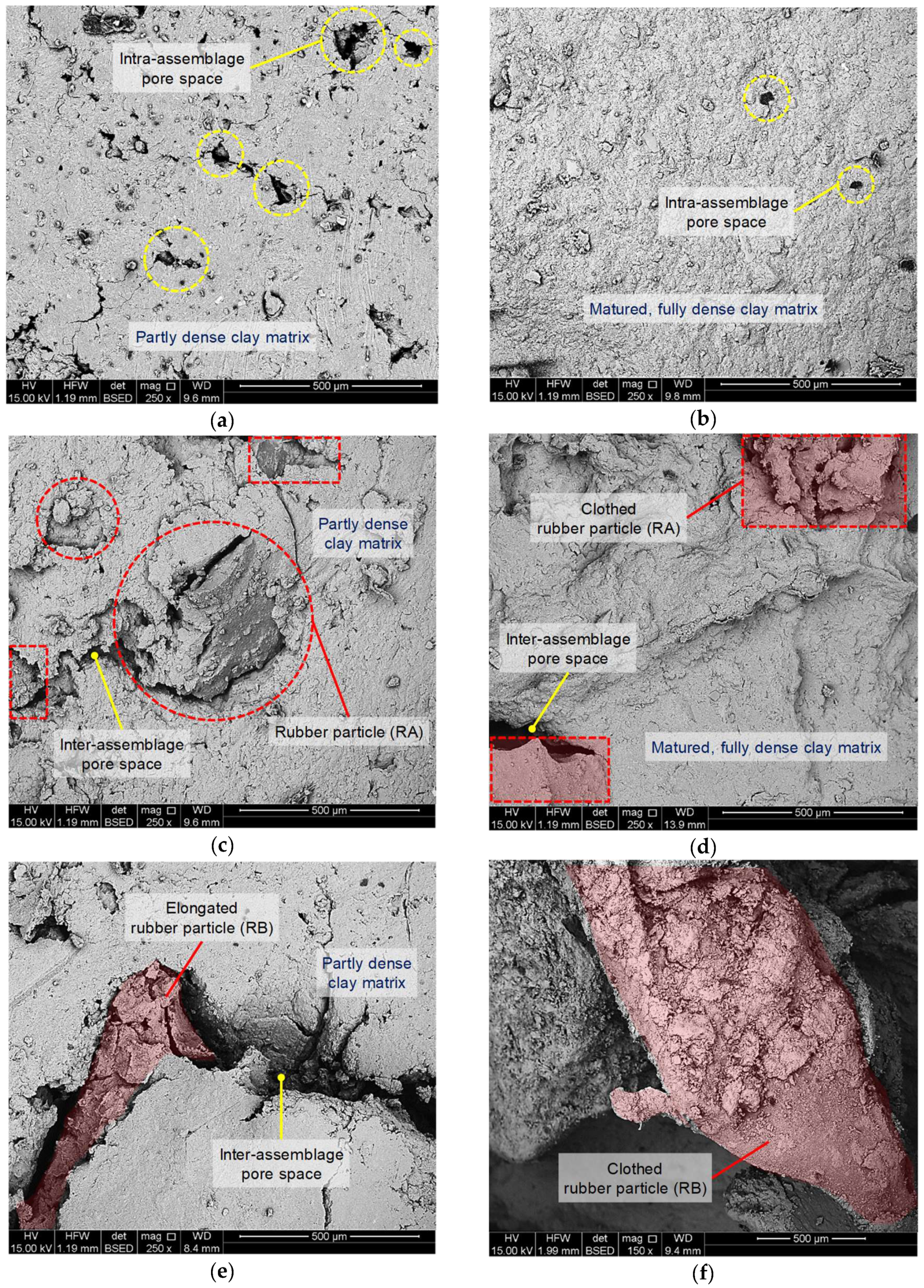

4.4. Amending Mechanisms and Fabric Evolution

- Increase in non-expansive content: The swell–shrink capacity is primarily a function of the soil’s expansive clay content, implying that the lower the expansive clay content, the lower the tendency for swelling and shrinkage. The rubber inclusions substitute a fraction of the expansive clay content with non-plastic, hydrophobic rubber particles, thereby leading to a decrease in the swell–shrink capacity.

- Frictional resistance generated as a result of soil–rubber contact: The frictional resistance is a function of the soil–rubber contact area, with greater contact levels offering a higher resistance to bear the swell–shrink forces. Consequently, this amending mechanism can be ascribed to the rubber content, and potentially the rubber size or surface area (not shape). For any given rubber content, the coarser the rubber particles (or the lower the rubber’s specific surface area), the greater the achieved contact level (or interface) between the rubber particles and the soil grains, and thus the higher the generated frictional resistance against swelling and shrinkage (compare CRB with CRA in Figure 4 and Figure 6).

- Mechanical interlocking of rubber particles and soil grains: Mechanical interlocking is achieved during sample preparation (or compaction), and induces matrix adhesion by immobilizing the soil grains against swell–shrink movements. Quite clearly, the more effective the achieved mechanical interlocking, the higher the resistance to swelling and shrinkage. Consequently, this amending mechanism is in line with the rubber content, and more importantly the rubber shape (not size or surface area). As opposed to the granular form factor of RA, the particles of RB are rather fiber-shaped or elongated (see Figure 1), and thus favor a more pronounced mechanical interlocking by entwining within the matrix and immobilizing the soil grains against swell–shrink movements with increased efficiency (compare CRB with CRA in Figure 4 and Figure 6).

5. Conclusions

- Alternate wetting and drying led to the reconstruction of the soil/soil–rubber microstructure by way of inducing aggregation and cementation of the soil grains. The greater the number of applied cycles, the lower the swelling and shrinkage potentials, both following a monotonically decreasing trend, with the rubberized blends holding a notable advantage over the virgin soil. The tendency for reduction, however, was found to be in favor of a larger rubber size, thus signifying a rubber size/shape-dependent amending mechanism.

- The axial swelling strain–time data (time in logarithmic scale) developed into an S-shaped curve, and thus suggested three phases during swell evolvement, namely, initial, primary, and secondary swelling. As a result of cyclic wetting–drying and/or rubber inclusion, the swell–time locus encountered a major downward shift, thereby indicating a capacity to counteract the heave in both magnitude and time.

- The void ratio–water content shrinkage data also developed into an S-shaped curve, and thus suggested three phases during shrink evolvement, namely, structural, primary, and residual shrinkage. As a result of cyclic wetting–drying and/or rubber inclusion, the shrinkage curve encountered a major vertical dilation, thus indicating a reduced tendency for shrinkage. Furthermore, alternate wetting and drying and/or rubber inclusion led to a notable increase in the shrinkage limit, whereas the effect of rubber size/shape was found to be marginal.

- The rubber inclusions led to a notable decrease in the magnitude of the accumulated axial deformation during successive wetting–drying cycles. The swell–shrink patterns/paths indicated an expansive accumulated deformation for the virgin soil, whereas the rubberized blends, particularly the one blended with the rubber of coarser category, manifested a relatively neutral accumulated deformation, thereby corroborating the rubber’s capacity to counteract the heave and/or settlement incurred by alternate wetting and drying.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Jones, L.D.; Jefferson, I. Expansive soils. In ICE Manual of Geotechnical Engineering: Volume I; Burland, J., Chapman, T., Brown, M., Skinner, H., Eds.; ICE Publishing: London, UK, 2012; pp. 413–441. ISBN 9780727757081. [Google Scholar] [CrossRef]

- Soltani, A.; Deng, A.; Taheri, A.; Mirzababaei, M. Rubber powder–polymer combined stabilization of South Australian expansive soils. Geosynth. Int. 2018, 25, 304–321. [Google Scholar] [CrossRef]

- Soltani, A.; Taheri, A.; Khatibi, M.; Estabragh, A.R. Swelling potential of a stabilized expansive soil: A comparative experimental study. Geotech. Geol. Eng. 2017, 35, 1717–1744. [Google Scholar] [CrossRef]

- Estabragh, A.R.; Rafatjo, H.; Javadi, A.A. Treatment of an expansive soil by mechanical and chemical techniques. Geosynth. Int. 2014, 21, 233–243. [Google Scholar] [CrossRef]

- Onyejekwe, S.; Ghataora, G.S. Soil stabilization using proprietary liquid chemical stabilizers: Sulphonated oil and a polymer. Bull. Eng. Geol. Environ. 2015, 74, 651–665. [Google Scholar] [CrossRef]

- Alazigha, D.P.; Indraratna, B.; Vinod, J.S.; Ezeajugh, L.E. The swelling behaviour of lignosulfonate-treated expansive soil. Proc. Inst. Civ. Eng. Ground Improv. 2016, 169, 182–193. [Google Scholar] [CrossRef]

- Soltani, A.; Deng, A.; Taheri, A.; Mirzababaei, M. A sulphonated oil for stabilisation of expansive soils. Int. J. Pavement Eng. 2017. [Google Scholar] [CrossRef]

- Mirzababaei, M.; Arulrajah, A.; Horpibulsuk, S.; Soltani, A.; Khayat, N. Stabilization of soft clay using short fibers and poly vinyl alcohol. Geotext. Geomembr. 2018, 46, 646–655. [Google Scholar] [CrossRef]

- Zhang, J.; Soltani, A.; Deng, A.; Jaksa, M.B. Mechanical performance of jute fiber-reinforced micaceous clay composites treated with ground-granulated blast-furnace slag. Materials 2019, 12, 576. [Google Scholar] [CrossRef]

- Al-Omari, R.R.; Hamodi, F.J. Swelling resistant geogrid—A new approach for the treatment of expansive soils. Geotext. Geomembr. 1991, 10, 295–317. [Google Scholar] [CrossRef]

- Al-Akhras, N.M.; Attom, M.F.; Al-Akhras, K.M.; Malkawi, A.I.H. Influence of fibers on swelling properties of clayey soil. Geosynth. Int. 2008, 15, 304–309. [Google Scholar] [CrossRef]

- Viswanadham, B.V.S.; Phanikumar, B.R.; Mukherjee, R.V. Swelling behaviour of a geofiber-reinforced expansive soil. Geotext. Geomembr. 2009, 27, 73–76. [Google Scholar] [CrossRef]

- Phanikumar, B.R.; Singla, R. Swell–consolidation characteristics of fibre-reinforced expansive soils. Soils Found. 2016, 56, 138–143. [Google Scholar] [CrossRef]

- Soltani, A.; Deng, A.; Taheri, A. Swell‒compression characteristics of a fiber-reinforced expansive soil. Geotext. Geomembr. 2018, 46, 183–189. [Google Scholar] [CrossRef]

- Mirzababaei, M.; Miraftab, M.; Mohamed, M.; McMahon, P. Impact of carpet waste fibre addition on swelling properties of compacted clays. Geotech. Geol. Eng. 2013, 31, 173–182. [Google Scholar] [CrossRef]

- Arulrajah, A.; Mohammadinia, A.; D’Amico, A.; Horpibulsuk, S. Effect of lime kiln dust as an alternative binder in the stabilization of construction and demolition materials. Constr. Build. Mater. 2017, 152. [Google Scholar] [CrossRef]

- Kua, T.A.; Arulrajah, A.; Mohammadinia, A.; Horpibulsuk, S.; Mirzababaei, M. Stiffness and deformation properties of spent coffee grounds based geopolymers. Constr. Build. Mater. 2017, 138, 79–87. [Google Scholar] [CrossRef]

- Mirzababaei, M.; Mohamed, M.; Arulrajah, A.; Horpibulsuk, S.; Anggraini, V. Practical approach to predict the shear strength of fibre-reinforced clay. Geosynth. Int. 2018, 25, 50–66. [Google Scholar] [CrossRef]

- Phummiphan, I.; Horpibulsuk, S.; Rachan, R.; Arulrajah, A.; Shen, S.L.; Chindaprasirt, P. High calcium fly ash geopolymer stabilized lateritic soil and granulated blast furnace slag blends as a pavement base material. J. Hazard. Mater. 2018, 341, 257–267. [Google Scholar] [CrossRef]

- Soltani, A.; Deng, A.; Taheri, A.; Mirzababaei, M.; Nikraz, H. Interfacial shear strength of rubber-reinforced clays: A dimensional analysis perspective. Geosynth. Int. 2019. [Google Scholar] [CrossRef]

- Edil, T.; Bosscher, P. Engineering properties of tire chips and soil mixtures. Geotech. Test. J. 1994, 17, 453–464. [Google Scholar] [CrossRef]

- Foose, G.J.; Benson, C.H.; Bosscher, P.J. Sand reinforced with shredded waste tires. J. Geotech. Eng. 1996, 122, 760–767. [Google Scholar] [CrossRef]

- Al-Tabbaa, A.; Blackwell, O.; Porter, S.A. An investigation into the geotechnical properties of soil–tyre mixtures. Environ. Technol. 1997, 18, 855–860. [Google Scholar] [CrossRef]

- Lee, J.H.; Salgado, R.; Bernal, A.; Lovell, C.W. Shredded tires and rubber sand as lightweight backfill. J. Geotech. Geoenviron. Eng. 1999, 125, 132–141. [Google Scholar] [CrossRef]

- Zornberg, J.G.; Cabral, A.R.; Viratjandr, C. Behaviour of tire shred–sand mixtures. Can. Geotech. J. 2004, 41, 227–241. [Google Scholar] [CrossRef]

- Al-Tabbaa, A.; Aravinthan, T. Natural clay–shredded tire mixtures as landfill barrier materials. Waste Manag. 1998, 18, 9–16. [Google Scholar] [CrossRef]

- Cokca, E.; Yilmaz, Z. Use of rubber and bentonite added fly ash as a liner material. Waste Manag. 2004, 24, 153–164. [Google Scholar] [CrossRef]

- Seda, J.H.; Lee, J.C.; Carraro, J.A.H. Beneficial use of waste tire rubber for swelling potential mitigation in expansive soils. In Geo-Denver 2007: Soil Improvement (GSP 172); Schaefer, V.R., Filz, G.M., Gallagher, P.M., Sehn, A.L., Wissmann, K.J., Eds.; ASCE: Denver, CO, USA, 2007; pp. 1–9. [Google Scholar] [CrossRef]

- Patil, U.; Valdes, J.R.; Evans, T.M. Swell mitigation with granulated tire rubber. J. Mater. Civ. Eng. 2011, 23, 721–727. [Google Scholar] [CrossRef]

- Trouzine, H.; Bekhiti, M.; Asroun, A. Effects of scrap tyre rubber fibre on swelling behaviour of two clayey soils in Algeria. Geosynth. Int. 2012, 19, 124–132. [Google Scholar] [CrossRef]

- Kalkan, E. Preparation of scrap tire rubber fiber–silica fume mixtures for modification of clayey soils. Appl. Clay Sci. 2013, 80–81, 117–125. [Google Scholar] [CrossRef]

- Cabalar, A.F.; Karabash, Z.; Mustafa, W.S. Stabilising a clay using tyre buffings and lime. Road Mater. Pavement Des. 2014, 15, 872–891. [Google Scholar] [CrossRef]

- Srivastava, A.; Pandey, S.; Rana, J. Use of shredded tyre waste in improving the geotechnical properties of expansive black cotton soil. Geomech. Geoengin. 2014, 9, 303–311. [Google Scholar] [CrossRef]

- Signes, C.H.; Garzón-Roca, J.; Fernández, P.M.; Torre, M.E.G.; Franco, R.I. Swelling potential reduction of Spanish argillaceous marlstone Facies Tap soil through the addition of crumb rubber particles from scrap tyres. Appl. Clay Sci. 2016, 132–133, 768–773. [Google Scholar] [CrossRef]

- Mukherjee, K.; Mishra, A.K. The impact of scrapped tyre chips on the mechanical properties of liner materials. Environ. Process. 2017, 4, 219–233. [Google Scholar] [CrossRef]

- Yadav, J.S.; Tiwari, S.K. A study on the potential utilization of crumb rubber in cement treated soft clay. J. Build. Eng. 2017, 9, 177–191. [Google Scholar] [CrossRef]

- Yadav, J.S.; Tiwari, S.K. Effect of waste rubber fibres on the geotechnical properties of clay stabilized with cement. Appl. Clay Sci. 2017, 149, 97–110. [Google Scholar] [CrossRef]

- Mukherjee, K.; Mishra, A.K. Hydraulic and mechanical characteristics of compacted sand–bentonite: Tyre chips mix for its landfill application. Environ. Dev. Sustain. 2018. [Google Scholar] [CrossRef]

- Soltani, A.; Deng, A.; Taheri, A.; Sridharan, A. Swell–shrink–consolidation behavior of rubber-reinforced expansive soils. Geotech. Test. J. 2018. [Google Scholar] [CrossRef]

- Zhang, R.; Yang, H.; Zheng, J. The effect of vertical pressure on the deformation and strength of expansive soil during cyclic wetting and drying. In Unsaturated Soils 2006: Proceedings of the Fourth International Conference on Unsaturated Soils; Miller, G.A., Zapata, C.E., Houston, S.L., Fredlund, D.G., Eds.; ASCE: Carefree, AZ, USA, 2006; pp. 894–905. [Google Scholar] [CrossRef]

- Dif, A.; Bluemel, W. Expansive soils under cyclic drying and wetting. Geotech. Test. J. 1991, 14, 96–102. [Google Scholar] [CrossRef]

- Al-Homoud, A.S.; Basma, A.A.; Malkawi, A.I.H.; Al-Bashabsheh, M.A. Cyclic swelling behaviour of clays. J. Geotech. Eng. 1995, 121, 562–565. [Google Scholar] [CrossRef]

- Subba Rao, K.S. Swell–shrink behaviour of expansive Soils—Geotechnical challenges. Indian Geotech. J. 2000, 30, 1–68. [Google Scholar]

- Tripathy, S.; Subba Rao, K.S.; Fredlund, D.G. Water content–void ratio swell–shrink paths of compacted expansive soils. Can. Geotech. J. 2002, 39, 938–959. [Google Scholar] [CrossRef]

- Tripathy, S.; Subba Rao, K.S. Cyclic swell–shrink behaviour of a compacted expansive soil. Geotech. Geol. Eng. 2009, 27, 89–103. [Google Scholar] [CrossRef]

- Estabragh, A.R.; Parsaei, B.; Javadi, A.A. Laboratory investigation of the effect of cyclic wetting and drying on the behaviour of an expansive soil. Soils Found. 2015, 55, 304–314. [Google Scholar] [CrossRef]

- Zhao, N.F.; Ye, W.M.; Chen, Y.G.; Chen, B.; Cui, Y.J. Investigation on swelling–shrinkage behavior of unsaturated compacted GMZ bentonite on wetting–drying cycles. Bull. Eng. Geol. Environ. 2019, 78, 617–627. [Google Scholar] [CrossRef]

- Estabragh, A.R.; Soltani, A.; Javadi, A.A. Effect of pore water chemistry on the behaviour of a kaolin–bentonite mixture during drying and wetting cycles. Eur. J. Environ. Civ. Eng. 2018. [Google Scholar] [CrossRef]

- Guney, Y.; Sari, D.; Cetin, M.; Tuncan, M. Impact of cyclic wetting–drying on swelling behavior of lime-stabilized soil. Build. Environ. 2007, 42, 681–688. [Google Scholar] [CrossRef]

- Yazdandoust, F.; Yasrobi, S.S. Effect of cyclic wetting and drying on swelling behavior of polymer-stabilized expansive clays. Appl. Clay Sci. 2010, 50, 461–468. [Google Scholar] [CrossRef]

- Kalkan, E. Impact of wetting–drying cycles on swelling behavior of clayey soils modified by silica fume. Appl. Clay Sci. 2011, 52, 345–352. [Google Scholar] [CrossRef]

- Estabragh, A.R.; Pereshkafti, M.R.S.; Parsaei, B.; Javadi, A.A. Stabilised expansive soil behaviour during wetting and drying. Int. J. Pavement Eng. 2013, 14, 418–427. [Google Scholar] [CrossRef]

- Alazigha, D.P.; Vinod, J.S.; Indraratna, B.; Heitor, A. Potential use of lignosulfonate for expansive soil stabilisation. Environ. Geotech. 2018. [Google Scholar] [CrossRef]

- Sridharan, A.; Nagaraj, H.B. Compressibility behaviour of remoulded, fine-grained soils and correlation with index properties. Can. Geotech. J. 2000, 37, 712–722. [Google Scholar] [CrossRef]

- Prakash, K.; Sridharan, A. Free swell ratio and clay mineralogy of fine-grained soils. Geotech. Test. J. 2004, 27, 220–225. [Google Scholar] [CrossRef]

- Yadav, J.S.; Tiwari, S.K. The impact of end-of-life tires on the mechanical properties of fine-grained soil: A Review. Environ. Dev. Sustain. 2017. [Google Scholar] [CrossRef]

- Sivapullaiah, P.V.; Sridharan, A.; Stalin, V.K. Swelling behaviour of soil–bentonite mixtures. Can. Geotech. J. 1996, 33, 808–814. [Google Scholar] [CrossRef]

- Day, R.W. Geotechnical and Foundation Engineering: Design and Construction, 1st ed.; McGraw-Hill: New York, NY, USA, 1999; ISBN 0071341382. [Google Scholar]

- Sridharan, A.; Gurtug, Y. Swelling behaviour of compacted fine-grained soils. Eng. Geol. 2004, 72, 9–18. [Google Scholar] [CrossRef]

- Haines, W.B. The volume-changes associated with variations of water content in soil. J. Agric. Sci. 1923, 13, 296–310. [Google Scholar] [CrossRef]

- Cornelis, W.M.; Corluy, J.; Medina, H.; Díaz, J.; Hartmann, R.; van Meirvenne, M.; Ruiz, M.E. Measuring and modelling the soil shrinkage characteristic curve. Geoderma 2006, 137, 179–191. [Google Scholar] [CrossRef]

- Thyagaraj, T.; Thomas, S.R.; Das, A.P. Physico-chemical effects on shrinkage behavior of compacted expansive clay. Int. J. Geomech. 2017, 17, 06016013:1–06016013:11. [Google Scholar] [CrossRef]

- Sridharan, A.; Prakash, K. Mechanism controlling the shrinkage limit of soils. Geotech. Test. J. 1998, 21, 240–250. [Google Scholar] [CrossRef]

- Sridharan, A.; Prakash, K. Shrinkage limit of soil mixtures. Geotech. Test. J. 2000, 23, 3–8. [Google Scholar] [CrossRef]

| Source | wL (%) 1 | IP (%) 2 | USCS 3 | Rubber | Rubber Size (mm) | Rubber Content (%) | Binder(s) |

|---|---|---|---|---|---|---|---|

| [26] | 34 | 12 | CL 4 | Shreds | 1–4; 4–8 | 6–15 (M) | — |

| [27] | - | - | - | Crumbs | 0.08–0.85 | 1–10 (M) | Bentonite |

| [28] | 52 | 34 | CH 5 | Shreds | 2–6.7 | 30 (V) | — |

| [29] | 81 | 58 | CH | Crumbs | 0.075–0.85 | 20–36 (V) | — |

| [30] | 45 | 22 | CI 6 | Fibers | 5–30 (L) | 10–50 (M) | — |

| [30] | 133 | 83 | CH | Fibers | 5–30 (L) | 10–50 (M) | — |

| [31] | 72 | 37 | MH 7 | Fibers | 5–10 (L), 0.25–1.25 (W) | 1–4 (M) | Silica fume |

| [32] | 50 | 27 | CI | Buffings | 0.6–4.75 | 5–15 (M) | Lime |

| [33] | 61 | 32 | CH | Shreds | 0.075–2; 2–4.75 | 5–50 (M) | — |

| [34] | 52 | 28 | CH | Crumbs | 0.08–2 | 2.5–25 (M) | — |

| [35] | 32 | - | - | Chips | 2–4.75 | 5–15 (M) | — |

| [36] | 34 | 9 | CI | Crumbs | 0.8–2 | 2.5–10 (M) | Cement |

| [37] | 34 | 9 | CI | Fibers | 10–15 (L), 2–3 (W) | 2.5–10 (M) | Cement |

| [38] | - | - | - | Chips | 2–4.75 | 5–15 (M) | — |

| [2] | 78 | 56 | CH | Crumbs | 0.075–1.18 | 10–30 (M) | PAM 8 |

| [39] | 60 | 33 | CH | Crumbs | 0.075–1.18 | 5–30 (M) | — |

| [39] | 60 | 33 | CH | Buffings | 1.18–4.75 | 5–30 (M) | — |

| Properties | Value | Standard Designation |

|---|---|---|

| Specific gravity, Gss | 2.73 | ASTM D854–14 |

| Clay [<2 μm] (%) | 52.80 | ASTM D422–07 |

| Silt [2–75 μm] (%) | 46.16 | ASTM D422–07 |

| Fine sand [0.075–0.425 mm] (%) | 1.04 | ASTM D422–07 |

| Liquid limit, wL (%) | 59.60 | AS 1289.3.9.1–15 |

| Plastic limit, wP (%) | 27.28 | AS 1289.3.2.1–09 |

| Plasticity index, IP (%) 1 | 32.32 | AS 1289.3.3.1–09 |

| Linear shrinkage, LS (%) | 8.19 | AS 1289.3.4.1–08 |

| Shrinkage index, IS (%) 2 | 51.41 | Sridharan and Nagaraj [54] |

| USCS classification | CH | ASTM D2487–11 |

| Free swell ratio, FSR 3 | 2.91 | Prakash and Sridharan [55] |

| Degree of expansivity | High | Prakash and Sridharan [55] |

| Optimum water content, wopt (%) | 26.00 | ASTM D698–12 |

| Maximum dry unit weight, γdmax (kN/m3) | 15.07 | ASTM D698–12 |

| Unconfined compressive strength, qu (kPa) 4 | 112.62 | ASTM D2166–16 |

| Splitting tensile strength, qs (kPa) 4 | 13.57 | ASTM C496–17 |

| Properties | Crumbs (RA) | Buffings (RB) |

|---|---|---|

| Specific gravity (at 20 °C), Gsr | 1.09 | 1.09 |

| Particle diameter D10 (mm) | 0.182 | 1.077 |

| Particle diameter D30 (mm) | 0.334 | 1.370 |

| Particle diameter D60 (mm) | 0.513 | 1.682 |

| Particle diameter D90 (mm) | 0.864 | 2.105 |

| Coefficient of uniformity, Cu 1 | 2.81 | 1.56 |

| Coefficient of curvature, Cc 2 | 1.20 | 1.04 |

| USCS classification 3 | SP 4 | SP |

| Water adsorption (%) | <4 | <4 |

| Softening point (°C) | 170 | 170 |

| Solubility in water | Insoluble | Insoluble |

| Resistance to acid/alkaline | Excellent | Excellent |

| Styrene–butadiene copolymer (wt %) | 55 | 55 |

| Carbon black (wt %) | 25–35 | 25–35 |

| Acetone extract (wt %) | 5–20 | 5–20 |

| Zinc oxide (wt %) | 2–3 | 2–3 |

| Sulphur (wt %) | 1–3 | 1–3 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Soltani, A.; Deng, A.; Taheri, A.; Mirzababaei, M.; Vanapalli, S.K. Swell–Shrink Behavior of Rubberized Expansive Clays during Alternate Wetting and Drying. Minerals 2019, 9, 224. https://doi.org/10.3390/min9040224

Soltani A, Deng A, Taheri A, Mirzababaei M, Vanapalli SK. Swell–Shrink Behavior of Rubberized Expansive Clays during Alternate Wetting and Drying. Minerals. 2019; 9(4):224. https://doi.org/10.3390/min9040224

Chicago/Turabian StyleSoltani, Amin, An Deng, Abbas Taheri, Mehdi Mirzababaei, and Sai K. Vanapalli. 2019. "Swell–Shrink Behavior of Rubberized Expansive Clays during Alternate Wetting and Drying" Minerals 9, no. 4: 224. https://doi.org/10.3390/min9040224

APA StyleSoltani, A., Deng, A., Taheri, A., Mirzababaei, M., & Vanapalli, S. K. (2019). Swell–Shrink Behavior of Rubberized Expansive Clays during Alternate Wetting and Drying. Minerals, 9(4), 224. https://doi.org/10.3390/min9040224