Fabrication and Thermal Properties of Capric Acid/Calcinated Iron Tailings/Carbon Nanotubes Composite as Form-Stable Phase Change Materials for Thermal Energy Storage

Abstract

1. Introduction

2. Experiment

2.1. Material

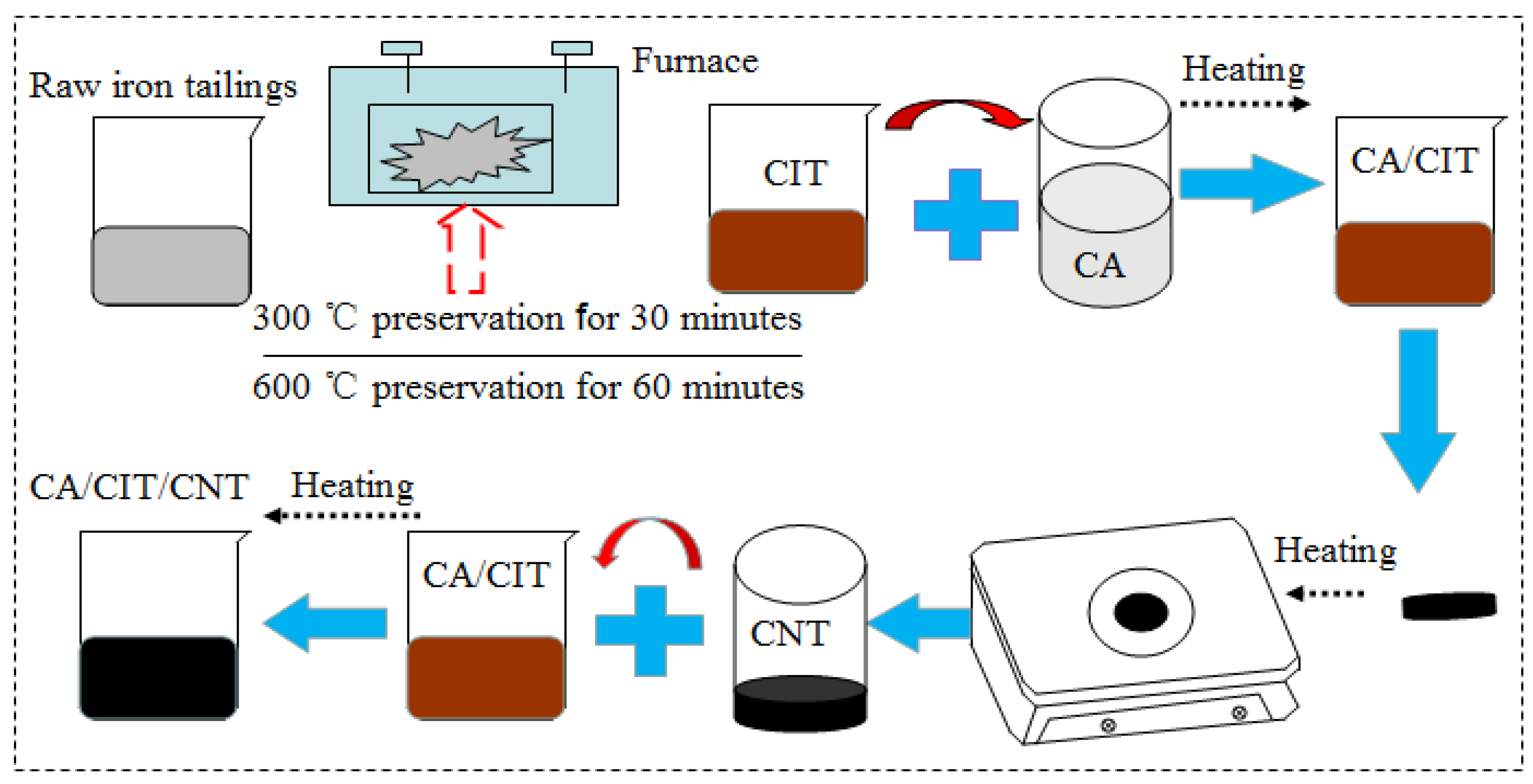

2.2. Preparation of FSPCM

2.3. Characterization of FSPCM

3. Results and Discussion

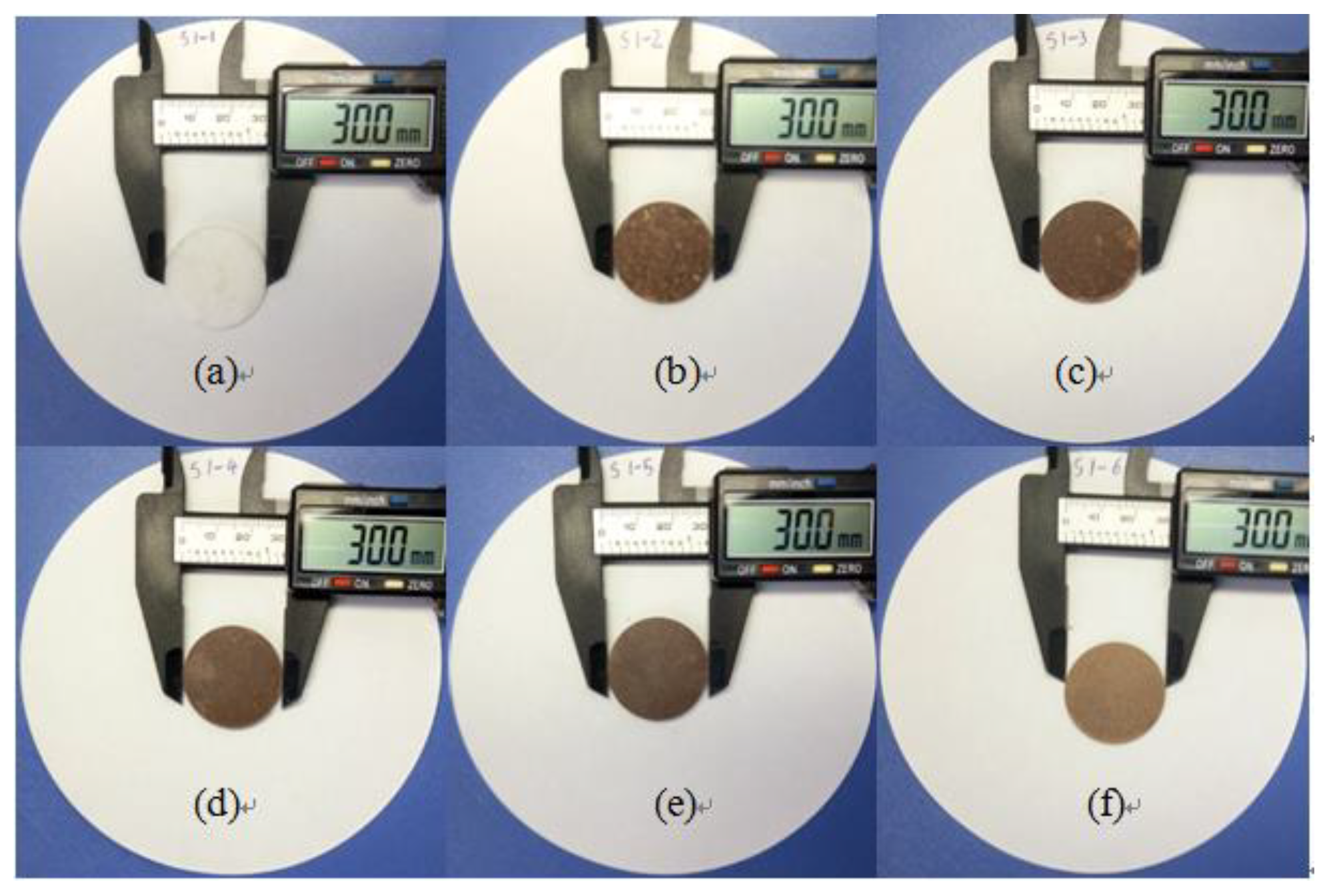

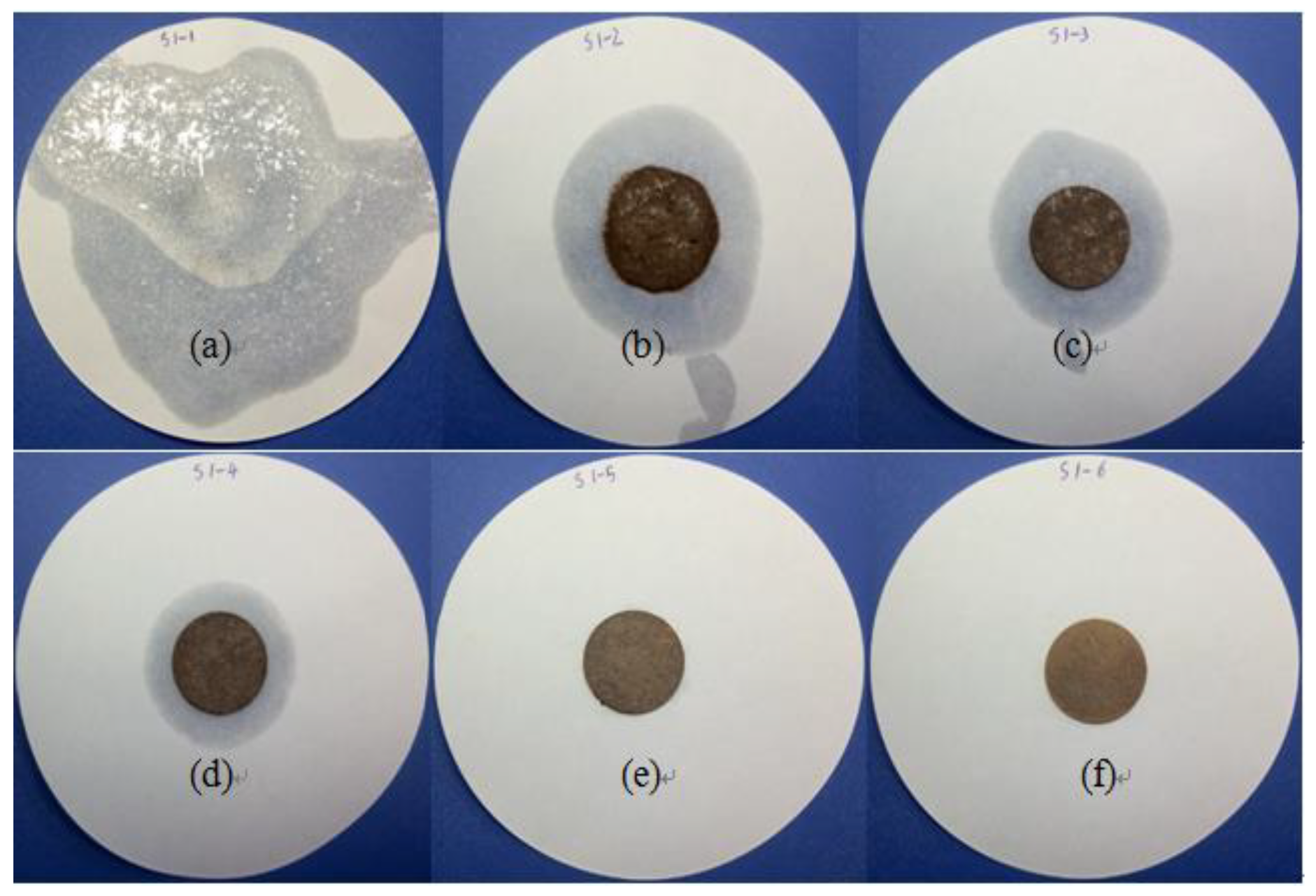

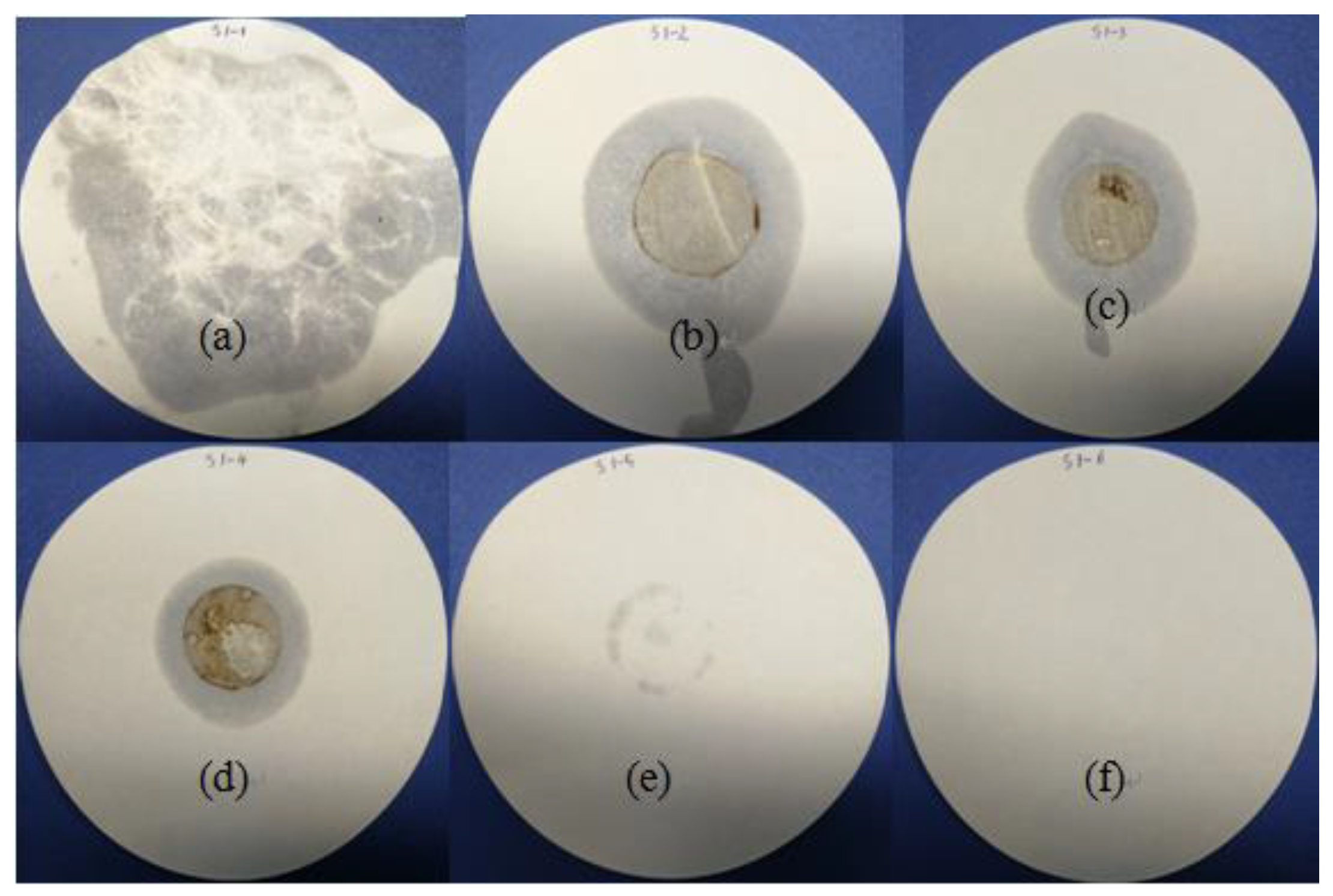

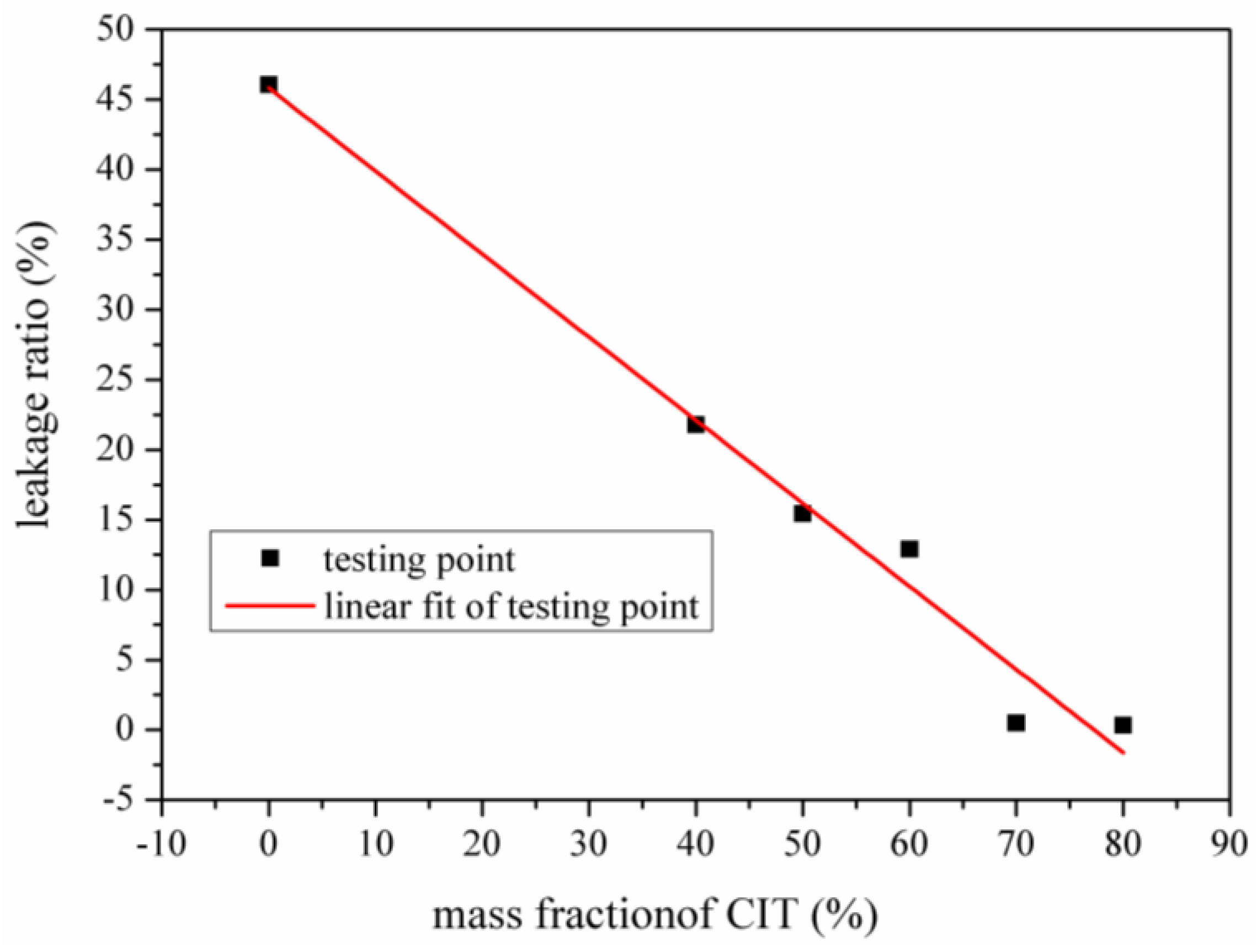

3.1. The Leakage Tests of CA/CIT/CNT Composites

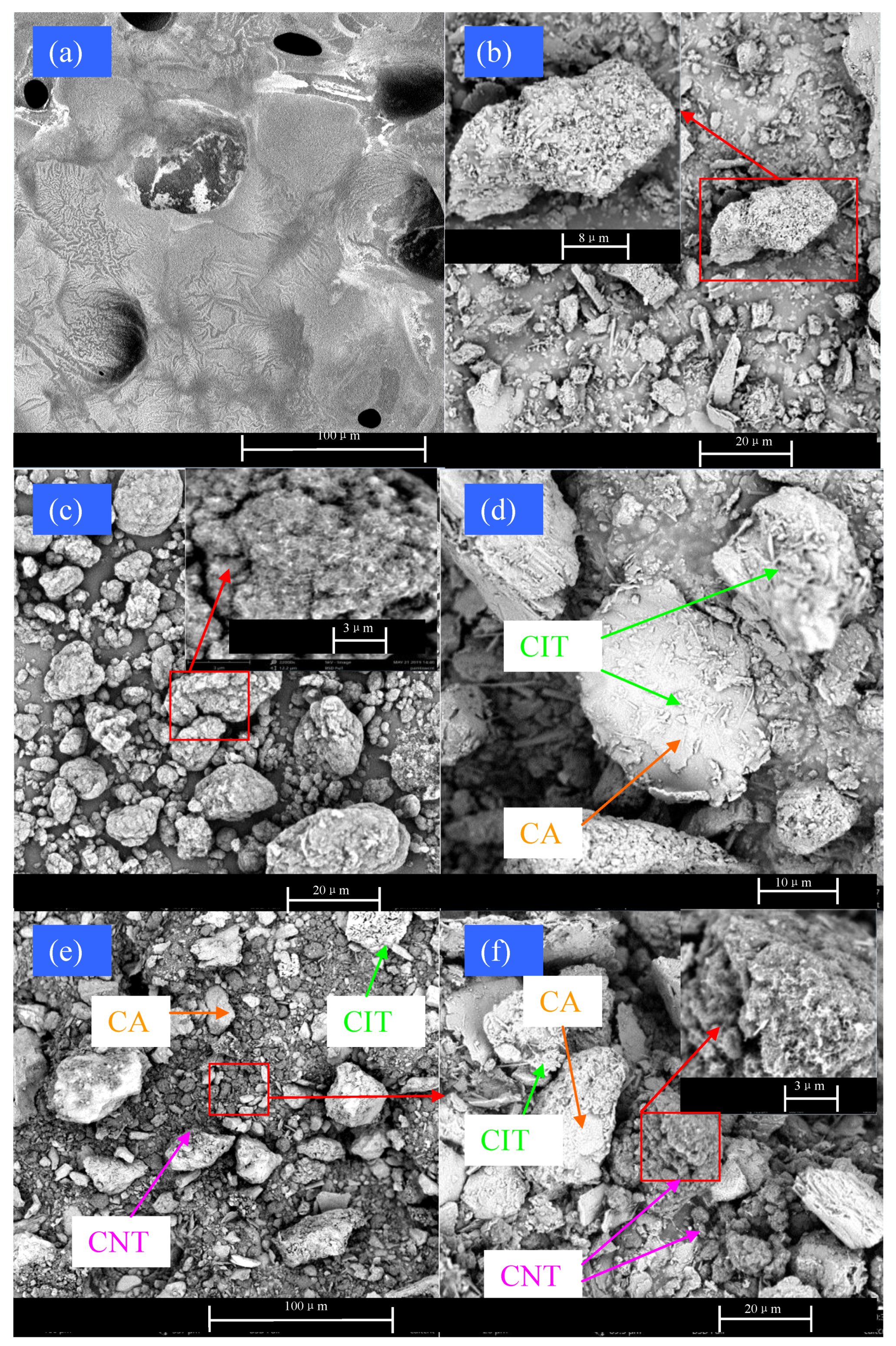

3.2. Morphology of the CA, CIT, CNT, CA/CIT, and CA/CIT/CNT Composites

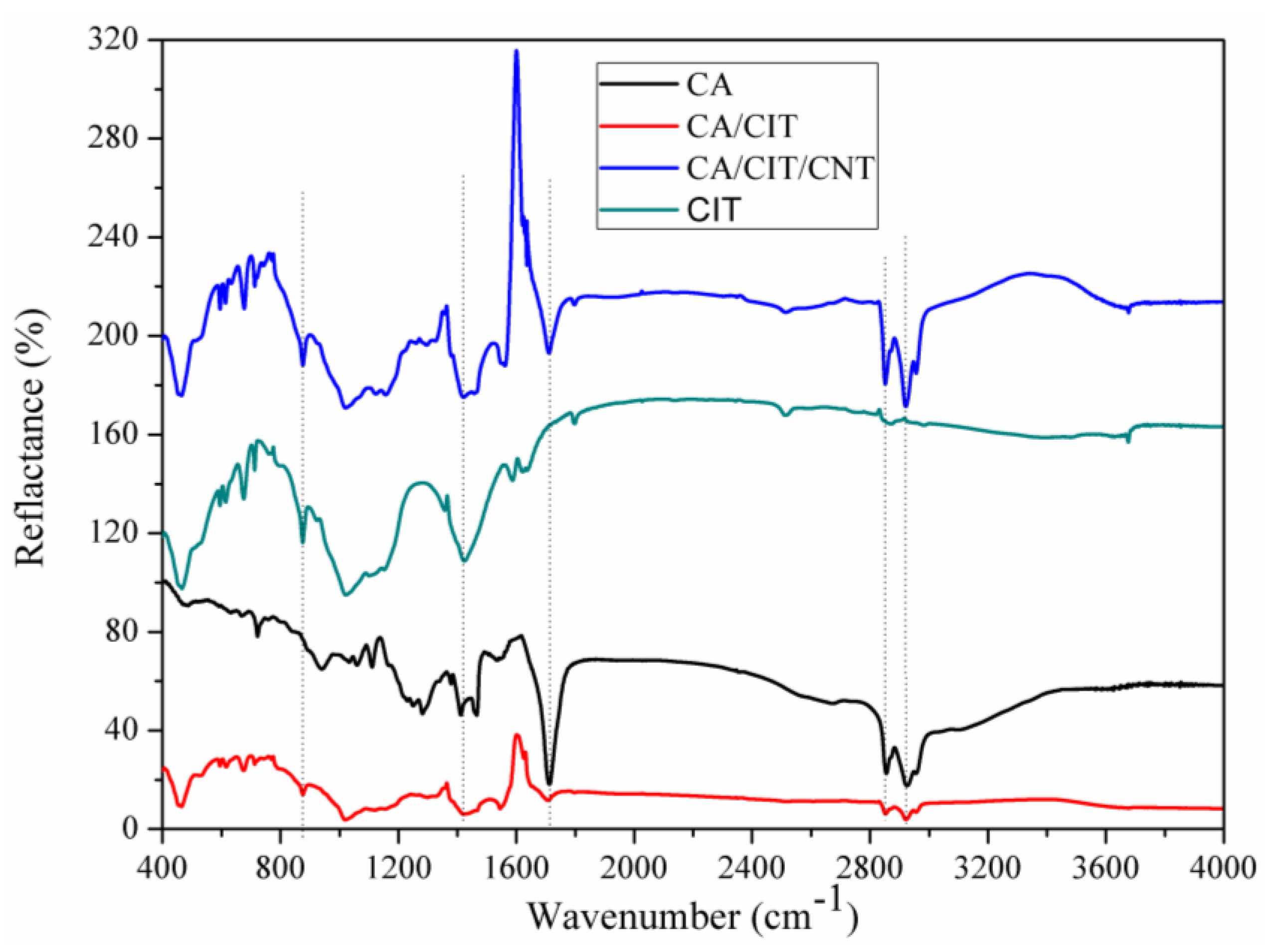

3.3. Chemical Compatibility of the CA/CIT/CNT Composites

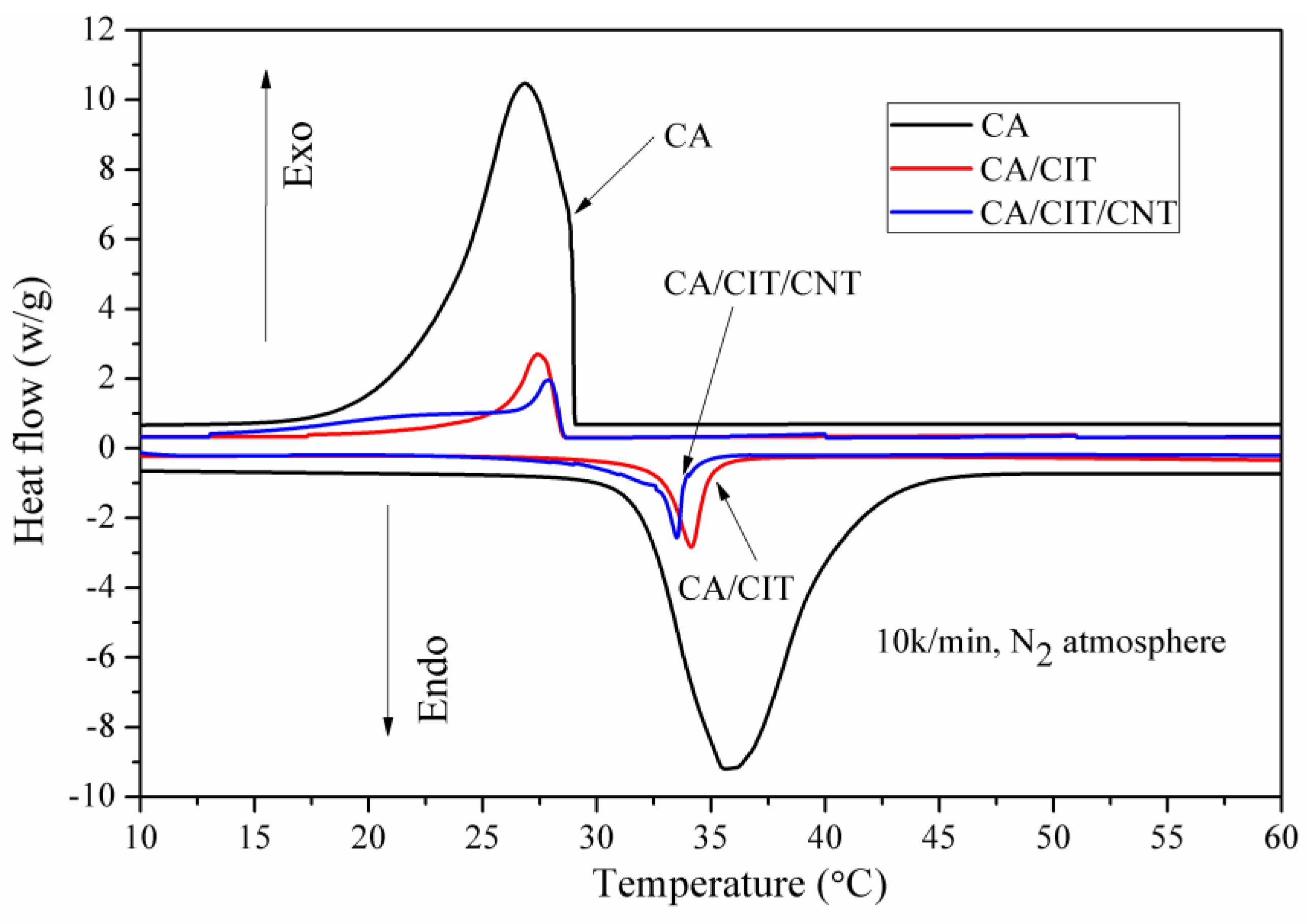

3.4. Thermal Properties of the CA/CIT/CNT FSPCMs

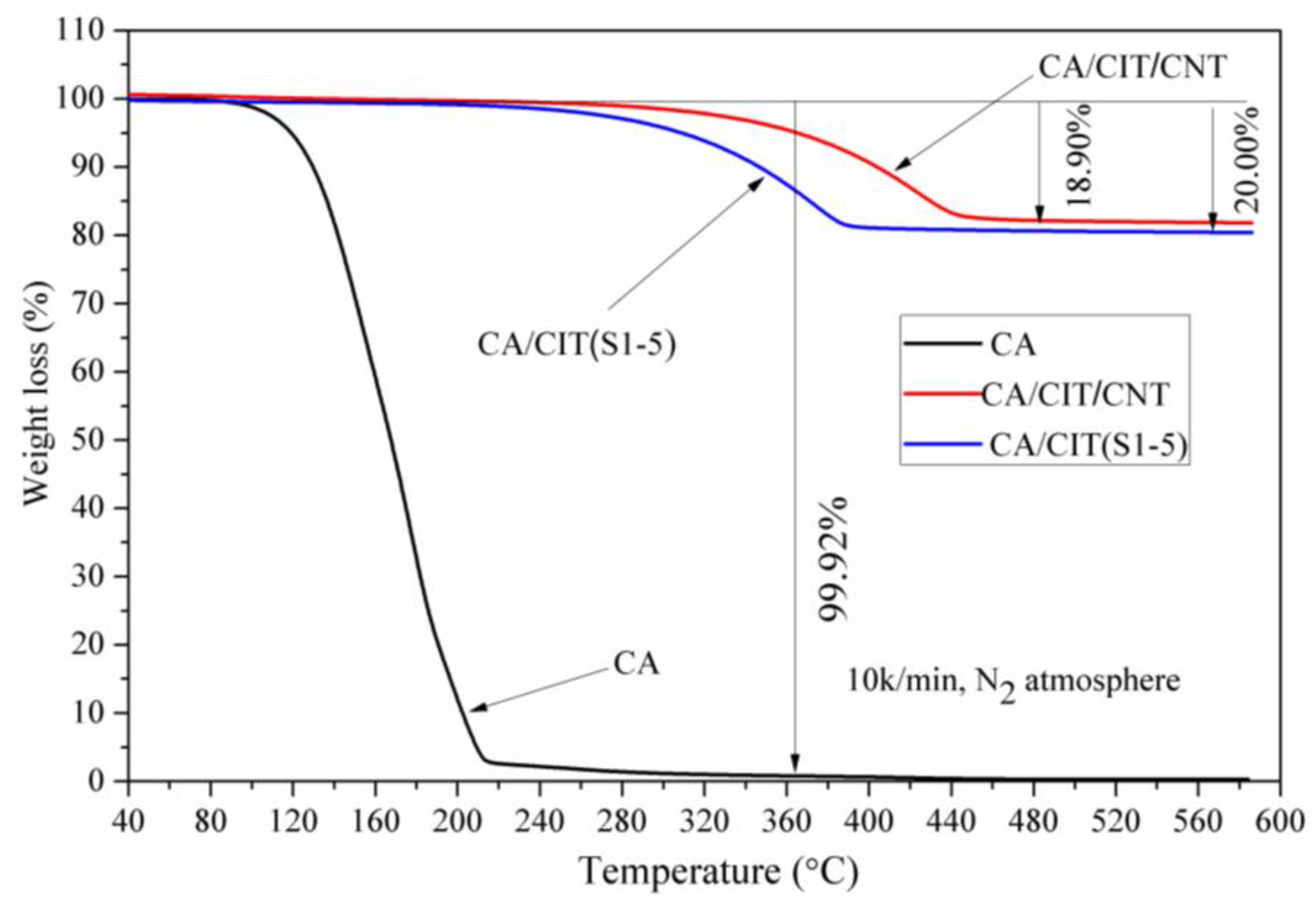

3.5. Thermal Stability of the CA/CIT/CNT FSPCMs

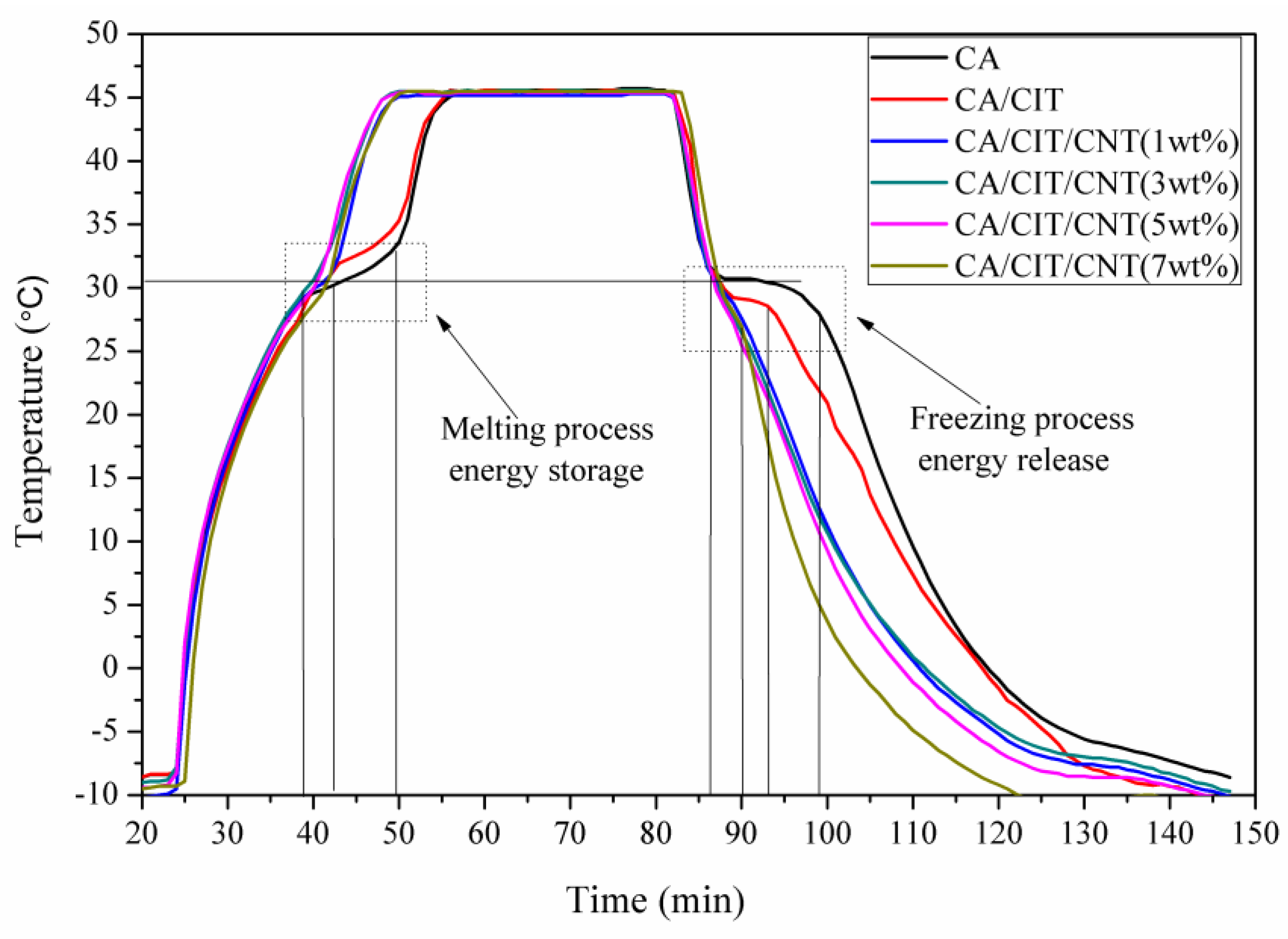

3.6. Thermal Storage/Release Performance of the CA/CIT/CNT FSPCMs

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Li, M.; Mu, B. Effect of different dimensional carbon materials on the properties and application of phase change materials: A review. Appl. Energy 2019, 242, 695–715. [Google Scholar] [CrossRef]

- Sharma, R.K.; Ganesan, P.; Tyagi, V.V.; Metselaar, H.S.C.; Sandaran, S.C. Developments in organic solid–liquid phase change materials and their applications in thermal energy storage. Energy Convers. Manag. 2015, 95, 193–228. [Google Scholar] [CrossRef]

- Su, X.; Jia, S.; Lv, G.; Yu, D. A unique strategy for polyethylene glycol/hybrid carbon foam phase change materials: Morphologies, thermal properties, and energy storage behavior. Materials 2018, 11, 2011. [Google Scholar] [CrossRef]

- Said, M.A.; Hamdy, H. Effect of using nanoparticles on the performance of thermal energy storage of phase change material coupled with air-conditioning unit. Energy Convers. Manag. 2018, 171, 903–916. [Google Scholar] [CrossRef]

- Irsyad, M.; Suwono, A.; Indartono, Y.S.; Pasek, A.D.; Pradipta, M.A. Phase change materials development from salt hydrate for application as secondary refrigerant in air-conditioning systems. Sci. Technol. Built Environ. 2017, 24, 90–96. [Google Scholar] [CrossRef]

- Arshad, A.; Ali, H.M.; Ali, M.; Manzur, S. Thermal performance of phase change material (PCM) based pin-finned heat sinks for electronics devices: Effect of pin thickness and PCM volume fraction. Appl. Therm. Eng. 2017, 112, 143–155. [Google Scholar] [CrossRef]

- Liang, Z.; Xing, Y.; Wang, Z.; Xin, L. The passive thermal management system for electronic device using low-melting-point alloy as phase change material. Appl. Therm. Eng. 2017, 125, 317–327. [Google Scholar]

- Bakan, G.; Gerislioglu, B.; Dirisaglik, F.; Jurado, Z.; Sullivan, L.; Dana, A.; Lam, C.; Gokirmak, A.; Silva, H. Extracting the temperature distribution on a phase-change memory cell during crystallization. J. Appl. Phys. 2016, 120, 164504. [Google Scholar] [CrossRef]

- Gerislioglu, B.; Ahmadivand, A.; Karabiyik, M.; Sinha, R.; Pala, N. VO2-based reconfigurable antenna platform with addressable microheater matrix. Adv. Electron. Mater. 2017, 3, 1700170. [Google Scholar] [CrossRef]

- Michel, A.K.U.; Chigrin, D.N.; Mass, T.W.; Schoenauer, K.; Salinga, M.; Wuttig, M.; Taubner, T. Using low-loss phase-change materials for mid-infrared antenna resonance tuning. Nano Lett. 2013, 13, 3470–3475. [Google Scholar] [CrossRef]

- Xu, H.; Romagnoli, A.; Jia, Y.S.; Py, X. Application of material assessment methodology in latent heat thermal energy storage for waste heat recovery. Appl. Energy 2017, 187, 281–290. [Google Scholar] [CrossRef]

- Dal Magro, F.; Xu, H.; Nardin, G.; Romagnoli, A. Application of high temperature phase change materials for improved efficiency in waste-to-energy plants. Waste Manag. 2018, 73, 322–331. [Google Scholar] [CrossRef] [PubMed]

- Tong, X.; Xiong, X. A parametric investigation on energy-saving effect of solar building based on double phase change material layer wallboard. Int. J. Photoenergy 2018, 2018, 1–8. [Google Scholar] [CrossRef]

- Aketouane, Z.; Malha, M.; Bruneau, D.; Bah, A.; Michel, B.; Asbik, M.; Ansari, O. Energy savings potential by integrating phase change material into hollow bricks: The case of moroccan buildings. Build. Simul. 2018, 11, 1109–1122. [Google Scholar] [CrossRef]

- Yi, S.; Sun, S.; Deng, Y.; Feng, S. Preparation of composite thermochromic and phase-change materials by the sol–gel method and its application in textiles. J. Text. Inst. 2014, 106, 1071–1077. [Google Scholar] [CrossRef]

- Iqbal, K.; Khan, A.; Sun, D.; Ashraf, M.; Rehman, A.; Safdar, F.; Basit, A.; Maqsood, H. Phase change materials, their synthesis and application in textiles—A review. J. Text. Inst. 2019, 110, 625–638. [Google Scholar] [CrossRef]

- Reyes, A.; Vásquez, J.; Pailahueque, N.; Mahn, A. Effect of drying using solar energy and phase change material on kiwifruit properties. Dry. Technol. 2018, 37, 232–244. [Google Scholar] [CrossRef]

- Liu, Z.; Chen, Z.; Fei, Y. Microencapsulated phase change material modified by graphene oxide with different degrees of oxidation for solar energy storage. Sol. Energy Mater. Sol. Cells 2018, 174, 453–459. [Google Scholar] [CrossRef]

- Bicer, A.; Sari, A. Synthesis and thermal energy storage properties of xylitol pentastearate and xylitol pentapalmitate as novel solid-liquid PCMs. Sol. Energy Mat. Sol. Cells 2012, 102, 125–130. [Google Scholar] [CrossRef]

- Karaipekli, A.; BicEr, A.; Sari, A.; Tyagi, V. Thermal characteristics of expanded perlite/paraffin composite phase change material with enhanced thermal conductivity using carbon nanotubes. Energy Convers. Manag. 2017, 134, 373–381. [Google Scholar] [CrossRef]

- Zhang, H.; Gao, X.; Chen, C.; Xu, T.; Fang, Y.; Zhang, Z. A capric–palmitic–stearic acid ternary eutectic mixture/expanded graphite composite phase change material for thermal energy storage. Compos. Part A Appl. Sci. Manuf. 2016, 87, 138–145. [Google Scholar] [CrossRef]

- Ates, M.; Caliskan, S.; Gazi, M. A ternary nanocomposites of graphene/TiO2/polypyrrole for energy storage applications. Fuller. Nanotub. Carbon Nanostructures 2018, 26, 631–642. [Google Scholar] [CrossRef]

- Benmoussa, D.; Molnar, K.; Hannache, H.; Cherkaoui, O. Development of thermo-regulating fabric using microcapsules of phase change material. Mol. Cryst. Liq. Cryst. 2015, 627, 163–169. [Google Scholar] [CrossRef]

- Sobolciak, P.; Karkri, M.; Al-Maadeed, M.; Krupa, I. Thermal characterization of phase change materials based on linear low-density polyethylene, paraffin wax and expanded graphite. Renew. Energy 2016, 88, 372–382. [Google Scholar] [CrossRef]

- Liu, S.; Han, L.; Xie, S.; Jia, Y.; Sun, J.; Jing, Y.; Zhang, Q. A novel medium-temperature form-stable phase change material based on dicarboxylic acid eutectic mixture/expanded graphite composites. Sol. Energy 2017, 143, 22–30. [Google Scholar] [CrossRef]

- Ramakrishnan, S.; Wang, X.; Sanjayan, J. Thermal enhancement of paraffin/hydrophobic expanded perlite granular phase change composite using graphene nanoplatelets. Energy Build. 2018, 169, 206–215. [Google Scholar] [CrossRef]

- Sari, A. Fabrication and thermal characterization of kaolin-based composite phase change materials for latent heat storage in buildings. Energy Build. 2015, 96, 193–200. [Google Scholar] [CrossRef]

- Liu, S.; Yang, H. Composite of coal-series kaolinite and capric-lauric acid as form-stable phase-change material. Energy Technol. 2015, 3, 77–83. [Google Scholar] [CrossRef]

- Jeong, S.; Jeon, J.; Chung, O.; Kim, S.; Kim, S. Evaluation of PCM/diatomite composites using exfoliated graphite nanoplatelets (xGnP) to improve thermal properties. J. Therm. Anal. Calorim. 2013, 114, 689–698. [Google Scholar] [CrossRef]

- Liu, Z.; Hu, D.; Lv, H.; Zhang, Y.; Wu, F.; Shen, D.; Fu, P. Mixed mill-heating fabrication and thermal energy storage of diatomite/paraffin phase change composite incorporated gypsum-based materials. Appl. Therm. Eng. 2017, 118, 703–713. [Google Scholar] [CrossRef]

- Karaipekli, A.; Sarı, A. Preparation, thermal properties and thermal reliability of eutectic mixtures of fatty acids/expanded vermiculite as novel form-stable composites for energy storage. J. Ind. Eng. Chem. 2010, 16, 767–773. [Google Scholar] [CrossRef]

- Ramakrishnan, S.; Wang, X.; Sanjayan, J.; Wilson, J. Assessing the feasibility of integrating form-stable phase change material composites with cementitious composites and prevention of pcm leakage. Mater. Lett. 2017, 192, 88–91. [Google Scholar] [CrossRef]

- Dong, Z.; Meizhu, C.; Quantao, L.; Jiuming, W.; Jinxuan, H. Preparation and thermal properties of molecular-bridged expanded graphite/polyethylene glycol composite phase change materials for building energy conservation. Materials 2018, 11, 818. [Google Scholar]

- Wang, F.; Xie, Z.; Liang, J.; Fang, B.; Piao, Y.; Hao, M.; Wang, Z. Tourmaline-Modified FeMnTiOx Catalysts for Improved Low-Temperature NH3-SCR Performance. Environ. Sci. Technol. 2019, 53, 6989–6996. [Google Scholar] [CrossRef]

- Zhang, S.; Xue, X.; Liu, X.; Duan, P.; Yang, H.; Jiang, T.; Wang, D.; Liu, R. Current situation and comprehensive utilization of iron ore tailing resources. J. Min. Sci. 2006, 42, 403–408. [Google Scholar] [CrossRef]

- Li, C.; Sun, H.; Yi, Z.; Li, L. Innovative methodology for comprehensive utilization of iron ore tailings: Part 2: The residues after iron recovery from iron ore tailings to prepare cementitious material. J. Hazard. Mater. 2010, 174, 78–83. [Google Scholar] [CrossRef]

- Li, C.; Sun, H.; Bai, J.; Li, L. Innovative methodology for comprehensive utilization of iron ore tailings: Part 1. The recovery of iron from iron ore tailings using magnetic separation after magnetizing roasting. J. Hazard. Mater. 2010, 174, 71–77. [Google Scholar] [CrossRef]

- Lv, P.; Liu, C.; Rao, Z. Review on clay mineral-based form-stable phase change materials: Preparation, characterization and applications. Renew. Sustain. Energy Rev. 2017, 68, 707–726. [Google Scholar] [CrossRef]

- Song, X.; Cai, Y.; Huang, C.; Gu, Y.; Zhang, J.; Qiao, H.; Wei, Q. Cu nanoparticles improved thermal property of form-stable phase change materials made with carbon nanofibers and LA-MA-SA eutectic mixture. J. Nanosci. Nanotechnol. 2018, 18, 2723–2731. [Google Scholar] [CrossRef]

- Han, J.; Liu, S. Myristic acid-hybridized diatomite composite as a shape-stabilized phase change material for thermal energy storage. RSC Adv. 2017, 7, 22170–22177. [Google Scholar] [CrossRef]

- Yang, Y.; Pang, Y.; Liu, Y.; Guo, H. Preparation and thermal properties of polyethylene glycol/expanded graphite as novel form-stable phase change material for indoor energy saving. Mater. Lett. 2018, 216, 220–223. [Google Scholar] [CrossRef]

- Amin, M.; Putra, N.; Kosasih, E.; Prawiro, E.; AchmadLuanto, R.; Mahlia, T. Thermal properties of beeswax/graphene phase change material as energy storage for building applications. Appl. Therm. Eng. 2017, 112, 273–280. [Google Scholar] [CrossRef]

- Li, M.; Guo, Q.; Nutt, S. Carbon nanotube/paraffin/montmorillonite composite phase change material for thermal energy storage. Sol. Energy 2017, 146, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Sari, A.; Bicer, A.; Al-Sulaiman, F.; Karaipekli, A.; Tyagi, V. Diatomite/CNTs/PEG composite PCMs with shape-stabilized and improved thermal conductivity: Preparation and thermal energy storage properties. Energy Build. 2018, 164, 166–175. [Google Scholar] [CrossRef]

- Wen, R.; Zhang, X.; Huang, Z.; Fang, M.; Liu, Y.; Wu, X.; Min, X.; Gao, W.; Huang, S. Preparation and thermal properties of fatty acid/diatomite form-stable composite phase change material for thermal energy storage. Sol. Energy Mater. Sol. Cells 2018, 178, 273–279. [Google Scholar] [CrossRef]

- Li, X.; Chen, H.; Liu, L.; Lu, Z.; Sanjayan, J.; Duan, W. Development of granular expanded perlite/paraffin phase change material composites and prevention of leakage. Sol. Energy 2016, 137, 179–188. [Google Scholar] [CrossRef]

- Lv, P.; Liu, C.; Rao, Z. Experiment study on the thermal properties of paraffin/kaolin thermalenergy storage form-stable phase change material. Appl. Energy 2016, 182, 475–487. [Google Scholar] [CrossRef]

- Gu, X.; Peng Liu, P.; Liang Bian, L.; He, H. Enhanced thermal conductivity of palmitic acid/mullite phase change composite with graphite powder for thermal energy storage. Renew. Energy 2019, 138, 833–841. [Google Scholar] [CrossRef]

- Gu, X.; Liu, P.; Liu, C.; Peng, L.; He, H. A novel form-stable phase change material of palmitic acid-carbonized pepper straw for thermal energy storage. Mater. Lett. 2019, 248, 12–15. [Google Scholar] [CrossRef]

- Gu, X.; Liu, P.; Bian, L.; Peng, L.; Liu, Y.; He, H. Mullite stabilized palmitic acid as phase change materials for thermal energy storage. Minerals 2018, 8, 440. [Google Scholar] [CrossRef]

- Sarı, A.; Karaipekli, A. Thermal properties and thermal reliability of capric acid/expanded perlite composite for thermal energy storage. Mater. Chem. Phys. 2008, 109, 459–464. [Google Scholar] [CrossRef]

- Mei, D.; Zhang, B.; Liu, R.; Zhang, Y.; Liu, J. Preparation of capric acid/halloysite nanotube composite as form-stable phase change material for thermal energy storage. Sol. Energy Mater. Sol. Cells 2011, 95, 2772–2777. [Google Scholar] [CrossRef]

- Karaipekli, A.; Sari, A. Capric–myristic acid/vermiculite composite as form-stable phase change material for thermal energy storage. Sol. Energy 2009, 83, 323–332. [Google Scholar] [CrossRef]

- Shilei, L.; Neng, Z.; Guohui, F. Eutectic mixtures of capric acid and lauric acid applied in building wallboards for heat energy storage. Energy Build. 2006, 38, 708–711. [Google Scholar] [CrossRef]

- Feldman, D.; Banu, D.; Hawes, D. Development and application of organic phase change mixtures in thermal storage gypsum wallboard. Sol. Energy Mater. Sol. Cells 1995, 36, 147–157. [Google Scholar] [CrossRef]

- Karaman, S.; Karaipekli, A.; Sari, A.; Bicer, A. Polyethylene glycol (PEG)/diatomite composite as a novel form-stable phase change material for thermal energy storage. Sol. Energy Mater. Sol. Cells 2011, 95, 1647–1653. [Google Scholar] [CrossRef]

- Hawes, D.; Feldman, D.; Banu, D. Latent heat storage in building materials. Energy Build. 1993, 20, 77–86. [Google Scholar] [CrossRef]

- Memon, S.; Liao, W.; Yang, S.; Cui, H.; Shah, S. Development of composite PCMs by incorporation of paraffin into various building materials. Materials 2015, 8, 499–518. [Google Scholar] [CrossRef]

- Biçer, A.; Sarı, A. New kinds of energy-storing building composite PCMs for thermal energy storage. Energy Convers. Manag. 2013, 69, 148–156. [Google Scholar] [CrossRef]

- Sari, A.; Karaipekli, A.; Kaygusuz, K. Capric acid and myristic acid for latent heat thermal energy storage. Energy Sources Part A 2008, 30, 1498–1507. [Google Scholar] [CrossRef]

- Feldman, D.; Banu, D. DSC analysis for the evaluation of an energy storing wallboard. Thermochim. Acta 1996, 272, 243–251. [Google Scholar] [CrossRef]

- Fang, G.; Li, H.; Cao, L.; Shan, F. Preparation and thermal properties of form-stable palmitic acid/active aluminum oxide composites as phase change materials for latent heat storage. Mater. Chem. Phys. 2012, 137, 558–564. [Google Scholar] [CrossRef]

- Liu, P.; Gu, X.; Bian, L.; Cheng, X.; Peng, L.; He, H. Thermal properties and enhanced thermal conductivity of capric acid/diatomite/carbon nanotube composites as form-stable phase change materials for thermal energy storage. ACS Omega 2019, 4, 2964–2972. [Google Scholar] [CrossRef]

| Material | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | K2O + Na2O | Others |

|---|---|---|---|---|---|---|---|

| Iron tailings | 31.98 | 6.49 | 10.23 | 30.77 | 13.84 | 1.64 | 5.05 |

| CIT | 33.97 | 7.23 | 10.59 | 31.14 | 13.91 | 1.66 | 1.50 |

| Diatomite | 97.91 | 1.04 | 0.65 | - | 0.05 | 0.12 | 0. 23 |

| Perlite | 74.6 | 13.1 | 0.83 | 0.83 | 0.19 | 7.87 | 2.58 |

| Properties | CA | CNT |

|---|---|---|

| CAS number | 334-48-5 | 308068-56-6 |

| Chemical formula | C10H20O2 | - |

| Molecular weight | 172.26 | - |

| Purity (%) | 98.5 | 91% |

| Melting point (°C) | 31.4 °C | 3550 °C |

| Solidifying point (°C) | ≥29.0 °C | - |

| Thermal conductivity (w/(m∙k)) | - | 2860 |

| Step | Sample | The Composition Ratio of the CA/CIT Composites | Leakage Ratio (%) | Leakage Area of the Sample (cm2) |

|---|---|---|---|---|

| 1 | S1-1 | Pure CA | 46.07 | 72.35 |

| 1 | S1-2 | 50% CA + 50% CIT | 21.80 | 39.57 |

| 1 | S1-3 | 40% CA + 60% CIT | 15.43 | 26.41 |

| 1 | S1-4 | 30% CA + 70% CIT | 12.89 | 18.85 |

| 1 | S1-5 | 20% CA + 80% CIT | 0.50 (negligible) | (Missing) |

| 1 | S1-6 | 10% CA + 90% CIT | 0.33 (negligible) | 0 |

| Item | Melting Temperature (°C) | Solidifying Temperature (°C) | Latent Heat of Melting (J/g) | Latent Heat of Solidifying (J/g) | References |

|---|---|---|---|---|---|

| Capric-myristic acid (20 wt.%)/VMT | 19.8 | 17.1 | 27.46 | 31.42 | [53] |

| Capric-myristic acid (20 wt.%)/VMT + EG (2 wt.%) | 19.7 | 17.1 | 26.9 | (Missing) | [53] |

| Capric-lauric acid (26 wt.%)/gypsum | 19.11 | (Missing) | 35.24 | (Missing) | [54] |

| Dodecanol (25–30 wt.%)/gypsum | 20.0 | 21.0 | 17.0 | (Missing) | [55,56] |

| Propyl palmitate (25–30 wt.%)/gypsun | 19.0 | 16.0 | 40.0 | [55,56] | |

| Capric-lauric acid (25–30 wt.%) + fire retardant/gypsum | 17.0 | 21.0 | 28.0 | (Missing) | [57] |

| Paraffin (18 wt.%)/kaolin | 23.9 | 26.3 | 27.9 | (Missing) | [58] |

| Xylitol pentalaurate (19 wt.%)/cement | 44.07 | 41.08 | 31.09 | 27.36 | [59] |

| Xylitol pentalaurate (20 wt.%)/gypsum | 40.44 | 39.53 | 31.77 | 29.47 | [59] |

| Capric-palmitic acid (25 wt.%)/gypsum wallboard | 21.12 | 21.46 | 36.23 | 38.28 | [60] |

| Emerest 2326 (25.7 wt.%)/gypsum | 16.32 | 19.7 | 34.77 | 33.97 | [61] |

| PA (25 wt.%)/active aluminum oxide | 74.13 | 59.57 | 28.56 | 17.53 | [62] |

| S1-5 (CA 20 wt.% + CIT 80 wt.%) | 30.73 | 28.98 | 25.14 | 23.05 | This study |

| CA/CIT/CNT (CA20 wt.% + CIT 80 wt.%/CNT 5 wt.%) | 29.70 | 28.09 | 22.69 | 21.17 | This study |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, P.; Gu, X.; Zhang, Z.; Shi, J.; Rao, J.; Bian, L. Fabrication and Thermal Properties of Capric Acid/Calcinated Iron Tailings/Carbon Nanotubes Composite as Form-Stable Phase Change Materials for Thermal Energy Storage. Minerals 2019, 9, 648. https://doi.org/10.3390/min9110648

Liu P, Gu X, Zhang Z, Shi J, Rao J, Bian L. Fabrication and Thermal Properties of Capric Acid/Calcinated Iron Tailings/Carbon Nanotubes Composite as Form-Stable Phase Change Materials for Thermal Energy Storage. Minerals. 2019; 9(11):648. https://doi.org/10.3390/min9110648

Chicago/Turabian StyleLiu, Peng, Xiaobin Gu, Zhikai Zhang, Jianping Shi, Jun Rao, and Liang Bian. 2019. "Fabrication and Thermal Properties of Capric Acid/Calcinated Iron Tailings/Carbon Nanotubes Composite as Form-Stable Phase Change Materials for Thermal Energy Storage" Minerals 9, no. 11: 648. https://doi.org/10.3390/min9110648

APA StyleLiu, P., Gu, X., Zhang, Z., Shi, J., Rao, J., & Bian, L. (2019). Fabrication and Thermal Properties of Capric Acid/Calcinated Iron Tailings/Carbon Nanotubes Composite as Form-Stable Phase Change Materials for Thermal Energy Storage. Minerals, 9(11), 648. https://doi.org/10.3390/min9110648