On the Use of Sodium Chloride and Calcined Diatomite Sludge as Additives to Improve the Engineering Properties of Bricks Made with a Clay Earth from Jun (Granada, Spain)

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials, Additives, Preparation, and Firing of the Test Samples

2.2. Analytical Techniques

2.1.1. Chemical and Mineralogical Characterization

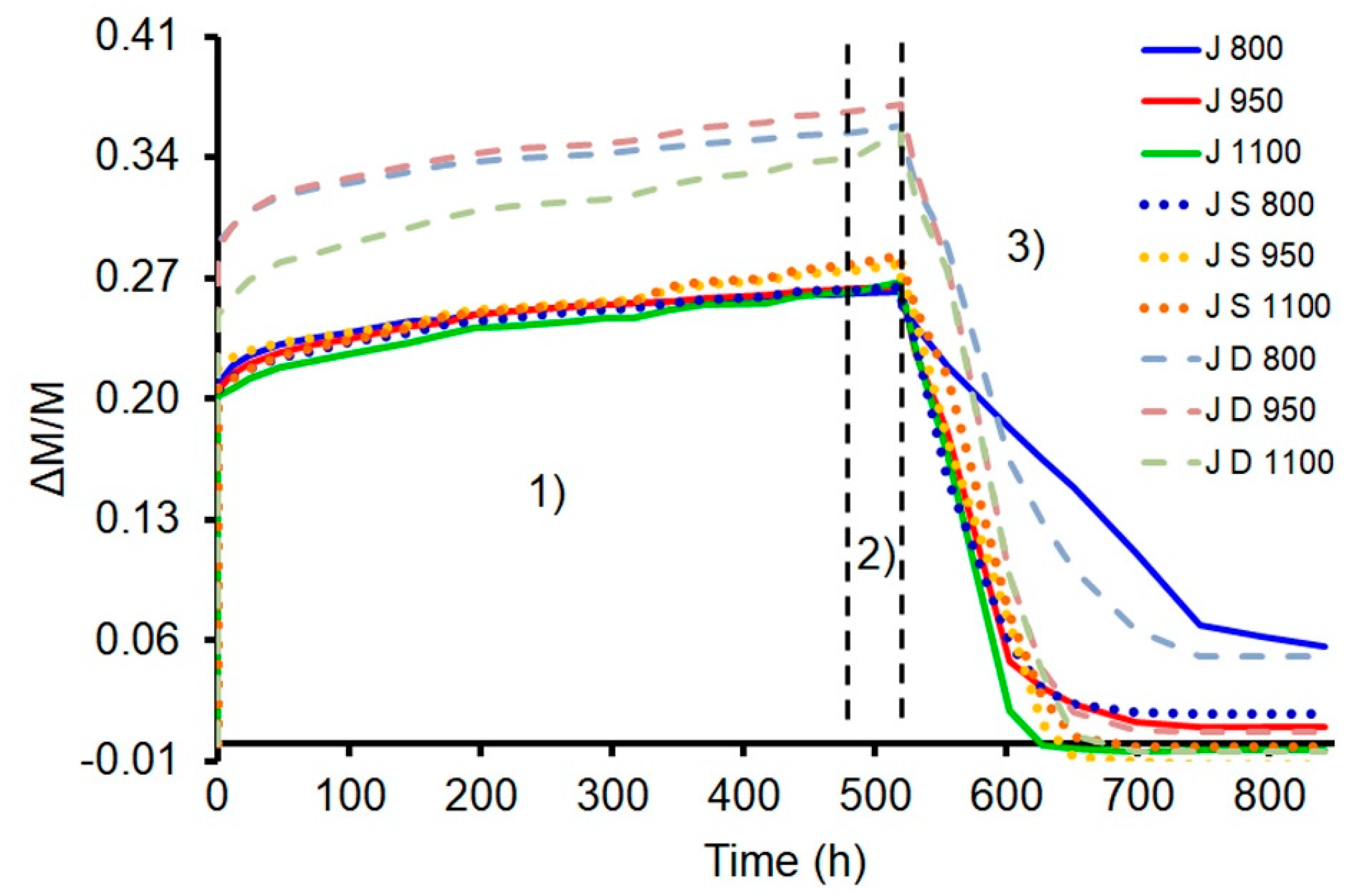

2.1.2. Physical Characterization

3. Results

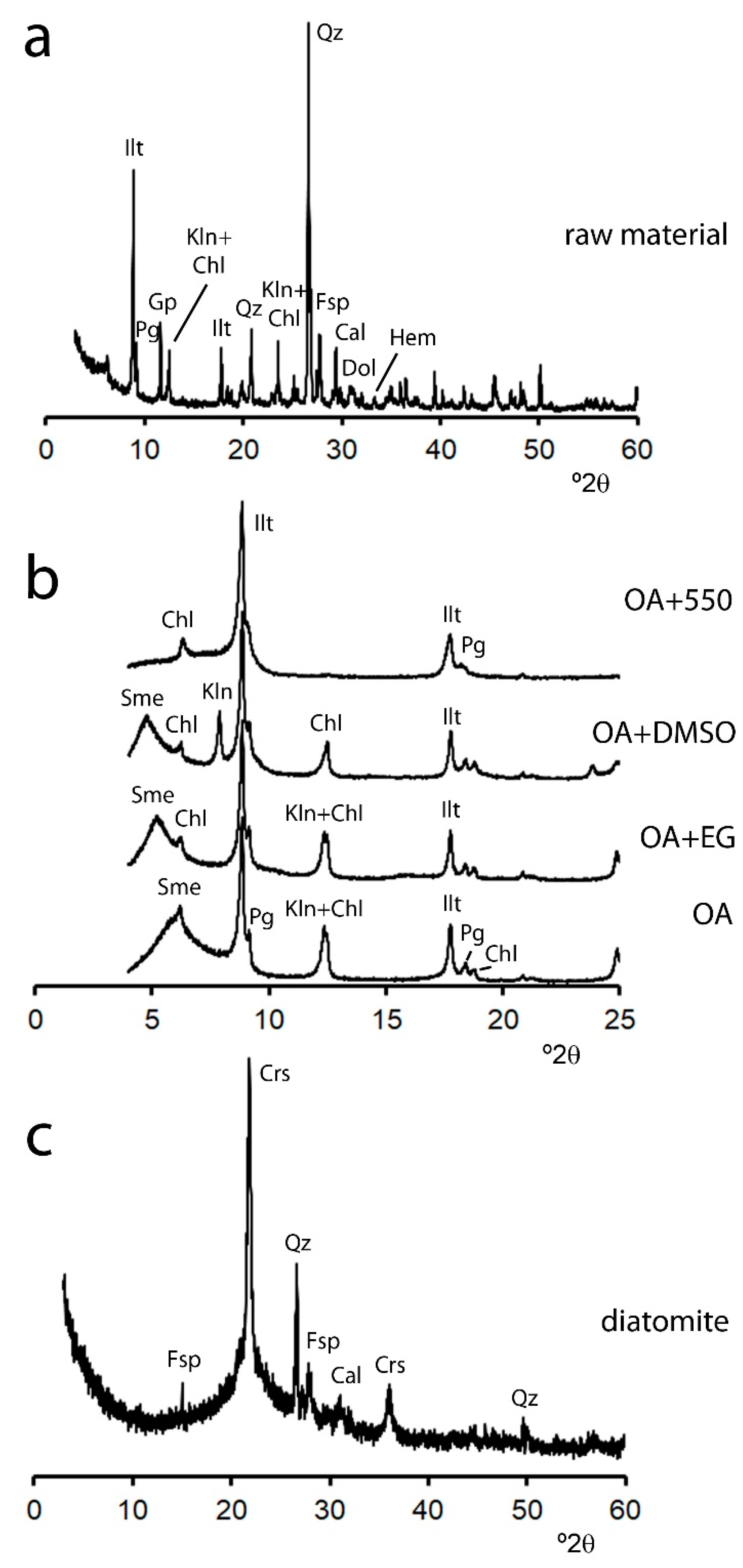

3.1. Raw Materials and Additives

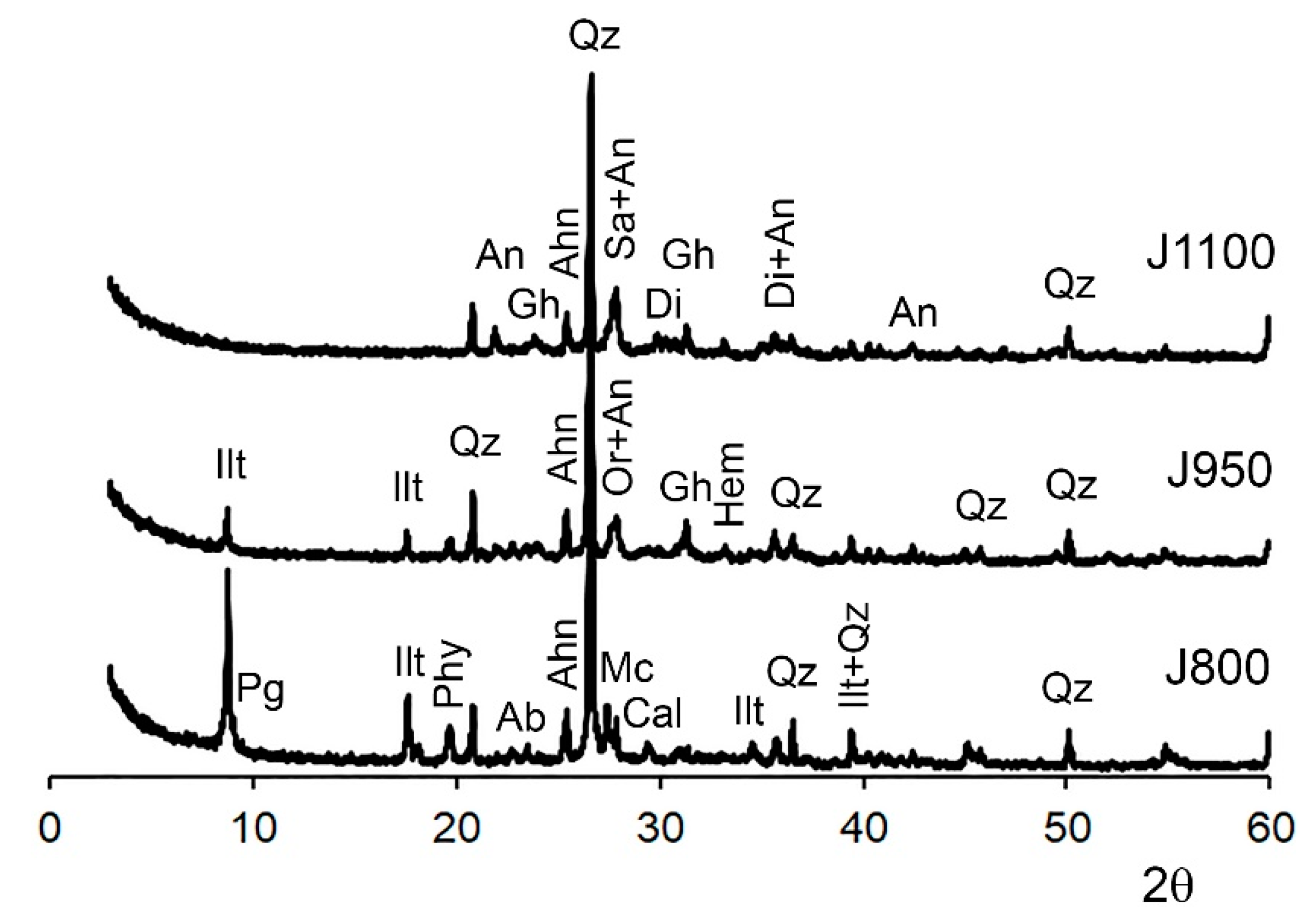

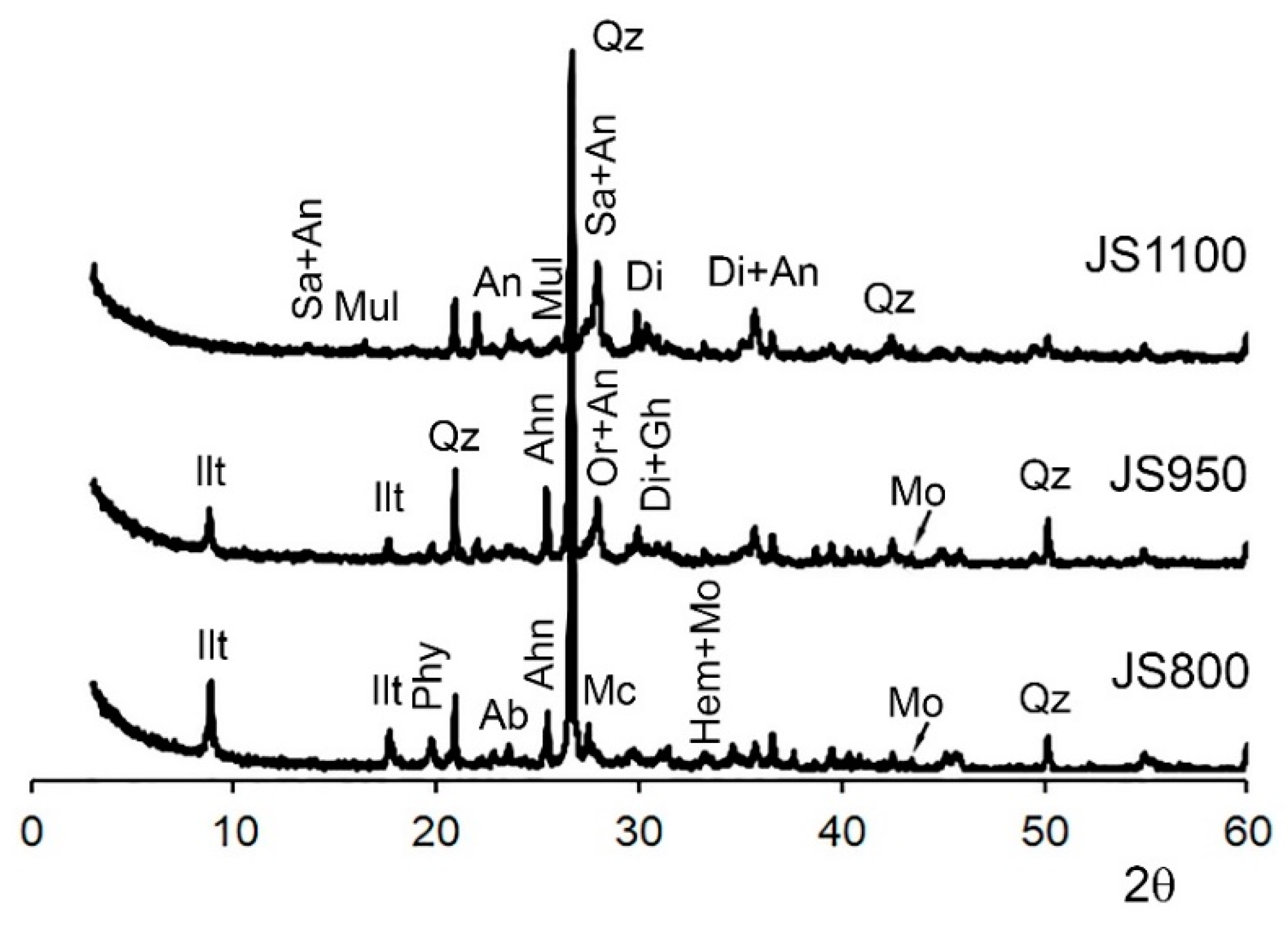

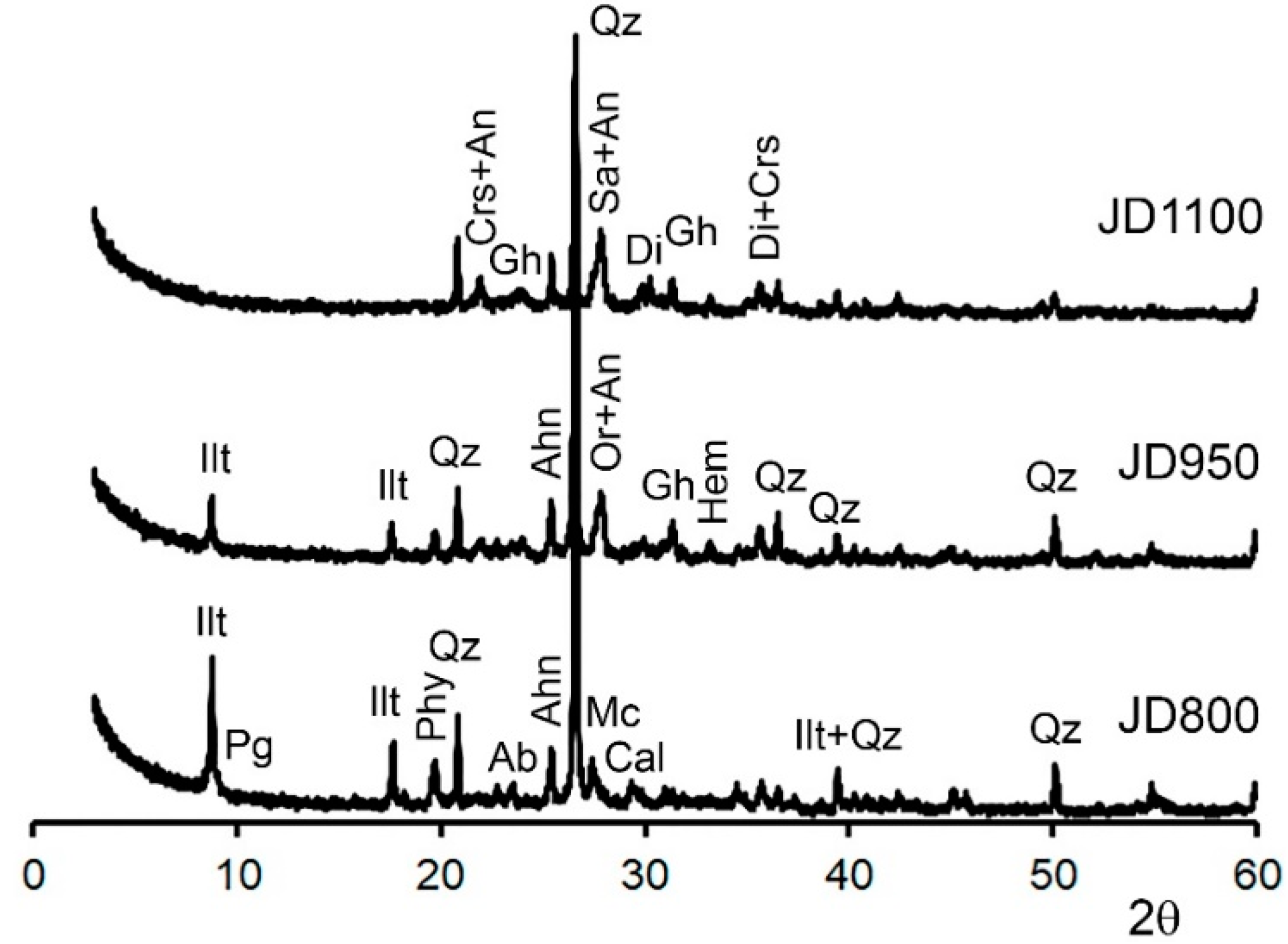

3.2. Mineralogy of Fired Bricks

2KAl2(Si3Al)O10(OH)2 + 6CaCO3 → 3Ca2Al2SiO7 + 3SiO2 + K2O + 2H2O + 6CO2

2KAlSi3O8 + 2CaCO3 → Ca2Al2SiO7 + 5SiO2 + K2O + 2CO2

CaCO3 + 2SiO2 + 2KAlSi3O8 → CaAl2Si2O8 + K2O + 6SiO2 + CO2

CaMg(CO3)2 + 2SiO2 → CaMgSi2O6 + 2CO2

3KAl2(Si3Al)O10(OH)2 + 2SiO2 → Al6Si2O13 + 3KAlSi3O8 + 3H2O

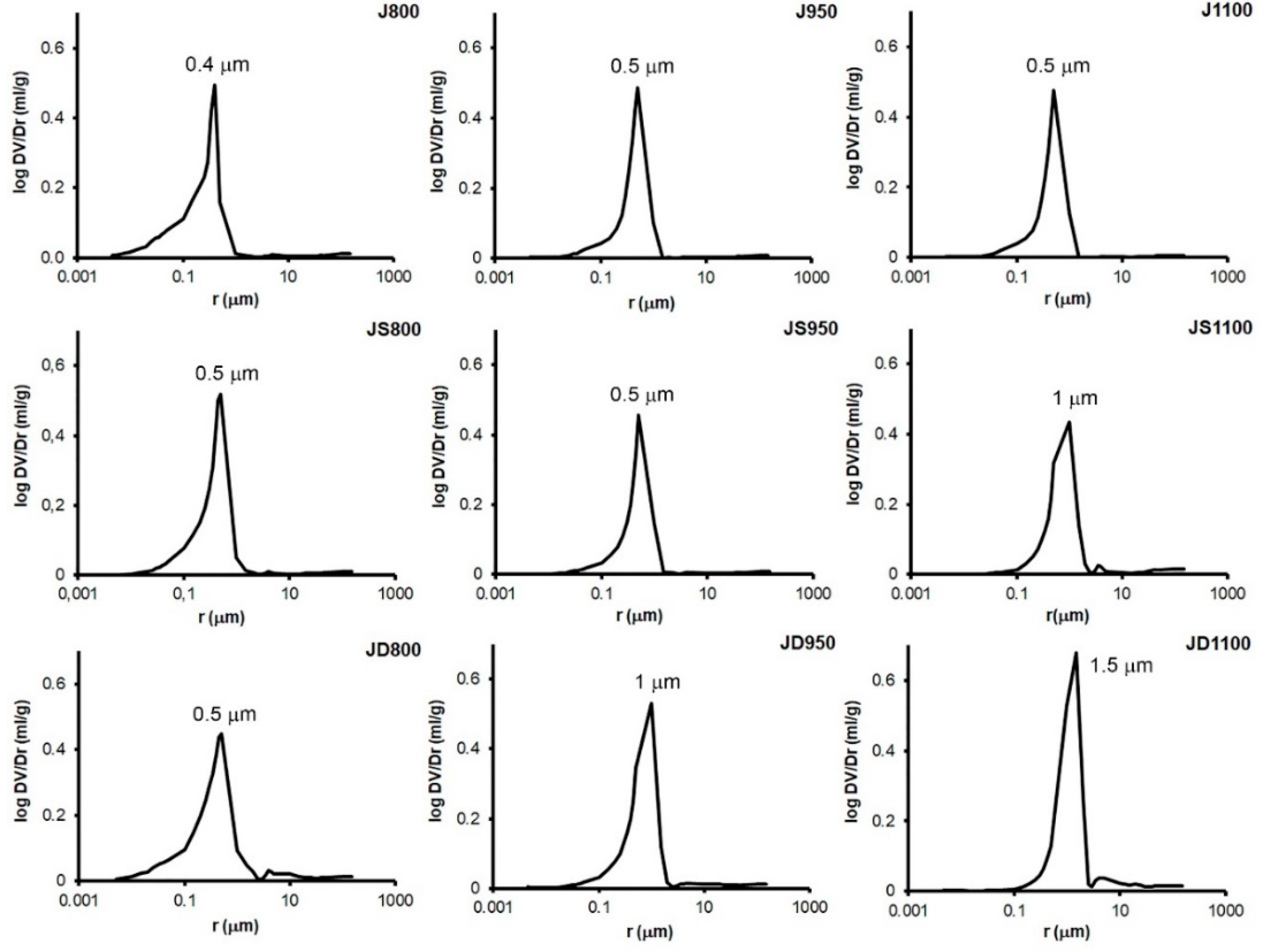

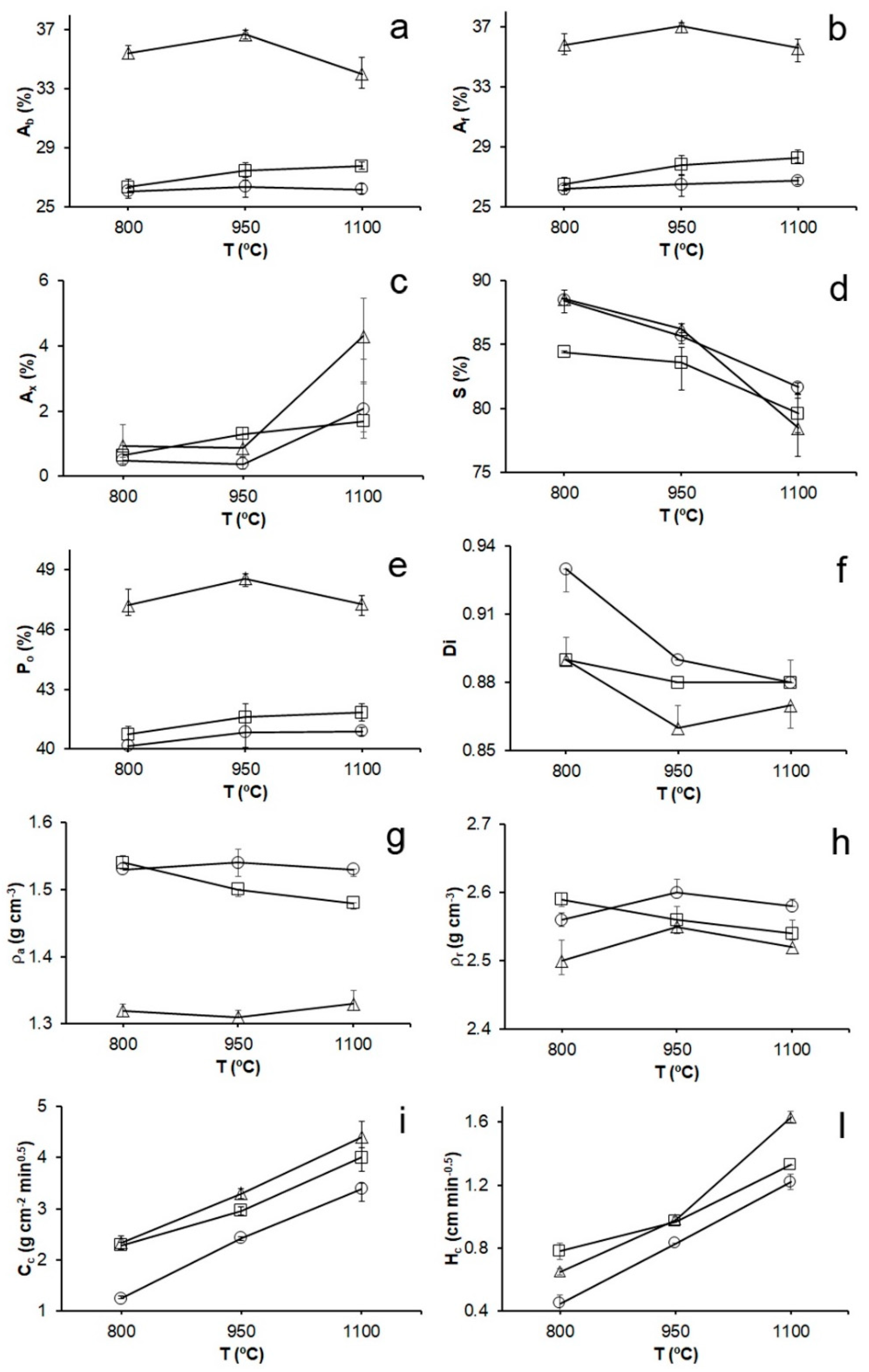

3.3. Porous System

3.4. Ultrasounds

3.5. Colour

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Warren, J. Conservation of Bricks; Butterworth Heinemann: Oxford, UK, 1999. [Google Scholar]

- Hansen, W.; Kung, J.H. Pore structure and frost durability of clay bricks. Mater. Struct. 1988, 21, 443–447. [Google Scholar] [CrossRef]

- Robinson, G.C. The relationship between pore structure and durability of bricks. Ceram. Bull. 1984, 63, 295–300. [Google Scholar]

- Winslow, D.N.; Kilgour, C.L.; Crooks, R.W. Predicting the durability of bricks. J. Test. Eval. 1988, 16, 527–531. [Google Scholar]

- Lu, G.; Lu, G.Q.; Xiao, Z.M. Mechanical properties of porous materials. J. Porous Mat. 1999, 6, 359–368. [Google Scholar] [CrossRef]

- Elert, K.; Cultrone, G.; Rodriguez Navarro, C.; Sebastian Pardo, E. Durability of bricks used in the conservation of historic buildings. Influence of composition and microstructure. J. Cult. Herit. 2003, 4, 91–99. [Google Scholar] [CrossRef]

- Djuric, M.; Marinkovic Neducin, R.; Ranogajec, J.; Radeka, M. Particle size range as a factor influencing compressibility of ceramic powder. Ceram. Int. 1995, 21, 227–230. [Google Scholar] [CrossRef]

- Sveda, M. New look at mathematical relationship among physical properties of brick products. Br. Ceram. Trans. 2000, 99, 181–186. [Google Scholar] [CrossRef]

- Cultrone, G.; Sebastián, E.; Elert, K.; de la Torre, M.J.; Cazalla, O.; Rodriguez Navarro, C. Influence of mineralogy and firing temperature on the porosity of bricks. J. Eur. Ceram. Soc. 2004, 24, 547–564. [Google Scholar] [CrossRef]

- Freyburg, S.; Schwarz, A. Influence of the clay type on the pore structure of structural ceramics. J. Eur. Ceram. Soc. 2007, 27, 1727–1733. [Google Scholar] [CrossRef]

- De Bonis, A.; Cultrone, G.; Grifa, C.; Langella, A.; Leone, A.P.; Mercurio, M.; Morra, V. Different shades of red: The complexity of mineralogical and physic-chemical factors influencing the colour of ceramics. Ceram. Int. 2017, 43, 8065–8074. [Google Scholar] [CrossRef]

- Cerdeño del Castillo, J.; Díaz Rubio, R.; Obis Sánchez, J.; Pérez Lorenzo, A.; Velasco Vélez, J. Manual de Patologías de las Piezas Cerámicas para la Construcción; AITEMIN: Toledo, Spain, 2000. [Google Scholar]

- Coletti, C.; Cultrone, G.; Maritan, L.; Mazzoli, C. How to face the new industrial challenge of compatible, sustainable brick production: Study of various types of commercially available bricks. Appl. Clay Sci. 2016, 124–125, 219–226. [Google Scholar] [CrossRef]

- Manning, D.A.C. Introduction to Industrial Minerals; Chapman & Hall: London, UK, 1995. [Google Scholar]

- Parras, J.; Sánchez Jiménez, C.; Rodas, M.; Luque, F.J. Ceramic applications of Middle Ordovician shales from central Spain. Appl. Clay Sci. 1996, 11, 25–41. [Google Scholar] [CrossRef]

- González, I.; Galán, E.; Miras, A.; Aparicio, P. New uses for brick-making clay materials from the Bailén area (Southern Spain). Clay Miner. 1998, 33, 453–465. [Google Scholar] [CrossRef]

- Dondi, M.; Ercolani, B.; Fabbri, B.; Guarini, G.; Marsigli, M.; Mingazzini, C. Major deposits of brick clays in Italy. Part 2: Technological properties and uses. Tile Brick Int. 1999, 15, 360–370. [Google Scholar]

- Woolley, G.R.; Wainwright, P.J.; Goumans, J.J.J.M. Science and engineering of recycling for environmental protection: An overview of the WASCON 2000 Conference. Waste Manag. 2001, 21, 211–212. [Google Scholar] [CrossRef]

- Goel, G.; Kalamdhad, A.S.; Agrawal, A. Parameter optimisation for producing fired bricks using organic solid wastes. J. Clean. Prod. 2018, 205, 836–844. [Google Scholar] [CrossRef]

- Bianchini, G.; Marrocchino, E.; Tassinari, R.; Vaccaro, C. Recycling of construction and demolition waste materials: A chemical-mineralogical appraisal. Waste Manag. 2005, 25, 149–159. [Google Scholar] [CrossRef] [PubMed]

- Bories, C.; Borredon, M.E.; Vedrenne, E.; Vilarem, G. Development of eco-friendly porous fired clay bricks using pore-forming agents: A review. J. Environ. Manag. 2014, 143, 186–196. [Google Scholar] [CrossRef]

- Singer, F.P.; Singer, S.S. Cerámica Industrial. Vol. I: Principios Generales de la Fabricación Cerámica; URMO, S.A. de Ediciones: Bilbao, Spain, 1979. [Google Scholar]

- Kadir, A.A.; Mohajerani, A. Bricks: An excellent building material for recycling wastes. A review. In Proceedings of the IASTED International Conference Environmental Management and Engineering (EME 2011), Calgary, AB, Canada, 4–6 July 2011; pp. 108–115. [Google Scholar]

- Monteiro, S.N.; Fontes Vieira, C.M. On the production of fired clay bricks from waste materials: A critical update. Constr. Build. Mater. 2014, 68, 599–610. [Google Scholar] [CrossRef]

- Muñoz Velasco, P.; Morales Ortíz, M.P.; Mendívil Giró, M.A.; Muñoz Velasco, L. Fired clay bricks manufactured by adding wastes as sustainable construction material. A review. Constr. Build. Mater. 2014, 63, 97–107. [Google Scholar] [CrossRef]

- Zhang, Z.; Wong, Y.C.; Arulrajah, A.; Horpibulsuk, S. A review of studies on bricks using alternative materials and approaches. Constr. Build. Mater. 2018, 188, 1101–1118. [Google Scholar] [CrossRef]

- Coletti, C. BRICKTECH: Assessment for the Use of Waste in Brick Production. Petrophysical Characterization of New Mix Designs and Optimization of the Firing Conditions. Ph.D. Thesis, University of Padova, Padova, Italy, University of Granada, Granada, Spain, 2016. [Google Scholar]

- Ediz, N.; Bentli, I.; Tatar, I. Improvement in filtration characteristics of diatomite by calcination. Int. J. Miner. Process. 2010, 94, 129–134. [Google Scholar] [CrossRef]

- Hadjar, H.; Hamdi, B.; Jaber, M.; Brendlé, J.; Kessaïssia, Z.; Balard, H.; Donnet, J.B. Elaboration and characterisation of new mesoporous materials from diatomite and charcoal. Microporous Mesoporous Mater. 2008, 107, 219–226. [Google Scholar] [CrossRef]

- Breese, R.O.I. Diatomite. In Industrial Minerals and Rocks, 6th ed.; Carr, D.D., Ed.; Society for Mining and Metallurgy and Exploration Inc.: Littleton, CO, USA, 1994; pp. 397–412. [Google Scholar]

- Zhang, X.; Liu, X.; Meng, G. Sintering kinetics of porous ceramics from natural diatomite. J. Am. Ceram. Soc. 2005, 88, 1826–1830. [Google Scholar] [CrossRef]

- Lin, K.L.; Chang, J.C. Feasibility of recycling waste diatomite and fly ash cosintered as porous ceramics. Environ. Prog. Sustain. Energy 2013, 32, 25–34. [Google Scholar] [CrossRef]

- Galán Arboledas, R.J.; Cotes Palomino, M.T.; Bueno, S.; Martínez García, C. Evaluation of spent diatomite incorporation in clay based materials for lightweight bricks processing. Constr. Build. Mater. 2017, 144, 327–337. [Google Scholar] [CrossRef]

- Rye, O.S. Keeping your temper under control: Materials and manufacture of Papuan pottery. Archeol. Phys. Anthropol. Ocean. 1976, 11, 106–137. [Google Scholar]

- Stimmell, C.; Heimann, R.B.; Hancock, R.G.V. Indian pottery from Mississippi valley: Copying with bad raw materials. In Archaeological Ceramics; Smithsonian Institution Press: Washington, DC, USA, 1982; pp. 219–228. [Google Scholar]

- Cultrone, G.; Sebastián, E.; de la Torre, M.J. Mineralogical and physical behaviour of solid bricks with additives. Constr. Build. Mater. 2005, 19, 39–48. [Google Scholar] [CrossRef]

- Laird, R.T.; Worcerster, M. The inhibiting of lime blowing. Trans. Br. Ceram. Soc. 1956, 55, 545–563. [Google Scholar]

- Govindaraju, K. Compilation of working values and sample description for 383 geostandards. Geostandard. Newsl. 1994, 18, 1–158. [Google Scholar] [CrossRef]

- De Jongh, W.K. X-ray fluorescence analysis applying theoretical matrix corrections. Stainless steel. X-Ray Spectrom. 1973, 2, 151–158. [Google Scholar] [CrossRef]

- Martin, J.D. XPowder, XPowder12, XPowderXTM; A Software Package for Powder X-ray Diffraction Analysis. Available online: http://www.xpowder.com/download/xpowder.pdf (accessed on 18 January 2018).

- Bruton, G. Vapour glycolation. Am. Mineral. 1955, 40, 124–126. [Google Scholar]

- González García, F.; Sánchez Camazano, M. Differentiation of kaolinite from chlorite by treatment with dimetylsulfoxide. Clay Miner. 1968, 7, 447–450. [Google Scholar] [CrossRef]

- Charola, A.E.; Wendler, E. An overview of the water-porous building materials interactions. Restor. Build. Monum. 2015, 21, 55–65. [Google Scholar] [CrossRef]

- UNE-EN 13755. Natural Stone Test Methods. Determination of Water Absorption at Atmospheric Pressure; AENOR: Madrid, Spain, 2008. [Google Scholar]

- Esbert, R.M.; Ordaz, J.; Alonso, F.J.; Montoto, M. Manual de Diagnosis y Tratamiento de Materiales Pétreos y Cerámicos; Col.legi d’Aparelladors i Arquitects Tècnics de Barcelona: Barcelona, Spain, 1997. [Google Scholar]

- Normal 29/88. Misura Dell’indice di Asciugamento (Drying Index); CNR-ICR: Rome, Italy, 1988. [Google Scholar]

- UNE-EN 1925. Natural Stone Test Methods. Determination of Water Absorption Coefficient by Capillarity; AENOR: Madrid, Spain, 1999. [Google Scholar]

- Cultrone, G.; de la Torre, M.J.; Sebastián, E.; Cazalla, O. Evaluation of bricks durability using destructive and non-destructive methods (DT and NDT). Mater. Constr. 2003, 53, 41–59. [Google Scholar] [CrossRef]

- RILEM. Recommended test to measure the deterioration of stone and to assess the differences of treatment methods. Mater. Struct. 1980, 13, 175–253. [Google Scholar]

- ASTM D2845. Standard Test Method for Laboratory Determination of Pulse Velocities and Ultrasonic Elastic Constant of Rock; ASTM: West Conshohocken, PA, USA, 2005. [Google Scholar]

- Guydader, J.; Denis, A. Propagation des ondes dans les roches anisotropies sous contrainte évaluation de la qualité des schistes ardoisers. Bull. Eng. Geol. 1986, 33, 49–55. [Google Scholar] [CrossRef]

- Conservation of Cultural Property. Test Methods. Colour Measurement of Surfaces; I.S. EN 15886:2010; AENOR: Madrid, Spain, 2011.

- López Quirós, A.; Barbier, M.; Martín, J.M.; Puga Bernabéu, A.; Guichet, X. Diagenetic evolution of Tortonian temperate carbonates close to evaporites in the Granada Basin (SE Spain). Sediment. Geol. 2016, 335, 180–196. [Google Scholar] [CrossRef]

- Martin, J.M.; Ortega Huertas, M.; Torres Ruiz, J. Genesis and evolution of strontium deposits of the Granada basin (Southeastern Spain): Evidence of diagenetic replacement of a stromatolite belt. Sediment. Geol. 1984, 39, 28–298. [Google Scholar] [CrossRef]

- Whitney, D.L.; Evans, B.W. Abbreviations for names of rock-forming minerals. Am. Mineral. 2010, 95, 185–187. [Google Scholar] [CrossRef]

- Grapes, R. Pyrometamorphism; Springer: Berlin, Germany, 2010. [Google Scholar]

- Rodriguez Navarro, C.; Cultrone, G.; Sánchez Navas, A.; Sebastián, E. TEM study of mullite growth after muscovite breakdown. Am. Mineral. 2003, 88, 713–724. [Google Scholar] [CrossRef]

- Benavente, D.; García del Cura, M.A.; Fort, R.; Ordóñez, S. Durability estimation of porous building stones from pore structures and strength. Eng. Geol. 2004, 74, 113–127. [Google Scholar] [CrossRef]

- Whiteley, P.; Russman, H.D.; Bishop, J.D. Porosity of building materials. A collection of published results. J. Oil Colour Chem. Assoc. 1977, 60, 142–150. [Google Scholar]

- Coletti, C.; Cultrone, G.; Maritan, L.; Mazzoli, C. Combined multi-analytical approach for study of pore system in bricks: How much porosity is there? Mater. Charact. 2016, 121, 82–92. [Google Scholar] [CrossRef]

- Molina, E.; Cultrone, G.; Sebastián, E.; Alonso, F.J.; Carrizo, L.; Gisbert, J.; Buj, O. The pore system of sedimentary rocks as a key factor in the durability of building materials. Eng. Geol. 2011, 118, 110–121. [Google Scholar] [CrossRef]

- Krakowiak, K.J.; Lourenço, P.B.; Ulm, F.J. Multitechnique investigation of extruded clay brick microstructure. J. Am. Ceram. Soc. 2011, 94, 3012–3022. [Google Scholar] [CrossRef]

- Scherer, G.W. Crystallization in pores. Cem. Concr. Res. 1999, 29, 1347–1358. [Google Scholar] [CrossRef]

- Dohene, E.; Price, C.A. Stone Conservation. An Overview of Current Research; The Getty Conservation Institute: Los Angeles, CA, USA, 2010. [Google Scholar]

- Karagiannis, N.; Karoglou, M.; Bakolas, A.; Krokida, M.; Moropoulou, A. Drying kinetics of building materials capillary moisture. Constr. Build. Mater. 2017, 137, 441–449. [Google Scholar] [CrossRef]

- Scherer, G.W. Theory of drying. J. Am. Ceram. Soc. 1990, 73, 3–14. [Google Scholar] [CrossRef]

- Del Rey Bueno, F. Porosimetría de mercurio. In Técnicas de Diagnóstico Aplicadas a la Conservación de los Materiales de Construcción en los Edificios Históricos; Cuadernos Técnicos vol. 2; Junta de Andalucía: Seville, Spain, 1996; pp. 46–65. [Google Scholar]

- Cultrone, G.; Sebastián, E.; Cazalla, O.; Nechar, M.; Romero, R.; Bagur, M.G. Ultrasound and mechanical tests combined with ANOVA to evaluate brick quality. Ceram. Int. 2001, 27, 401–406. [Google Scholar] [CrossRef]

- Brimblecombe, P.; Grossi, C.M. Aesthetic threshold and blackening of stone buildings. Sci. Total Environ. 2005, 349, 175–189. [Google Scholar] [CrossRef] [PubMed]

- Grossi, C.M.; Brimblecombe, P.; Esbert, R.M.; Alonso, F.J. Colour changes in architectural limestones from pollution and cleaning. Colour Res. Appl. 2007, 32, 320–331. [Google Scholar] [CrossRef]

- Tite, M.S.; Maniatis, Y. Examination of ancient pottery using the scanning electron microscope. Nature 1975, 257, 122–123. [Google Scholar] [CrossRef]

| Sample | SiO2 | Al2O3 | Fe2O3 | MnO | MgO | CaO | Na2O | K2O | TiO2 | P2O5 | LOI |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Raw | 49.27 | 16.92 | 5.69 | 0.07 | 2.50 | 9.65 | 0.99 | 2.98 | 0.67 | 0.14 | 10.39 |

| Diatomite | 66.77 | 5.45 | 2.75 | 0.04 | 1.59 | 3.00 | 2.27 | 1.12 | 0.34 | 0.48 | 15.71 |

| Zr | V | Cr | Co | Ni | Cu | Zn | Ga | Ba | As | Mo | |

| Raw | 201.10 | 168.10 | 97.80 | 21.80 | 44.90 | 24.80 | 85.30 | 18.30 | 423.60 | 24.30 | 4.30 |

| Diatomite | 79.90 | 194.90 | 136.60 | 3.20 | 62.70 | 216.50 | 273.30 | 4.30 | 448.90 | 7.40 | 8.70 |

| Nb | Pb | Rb | Sb | Sr | Th | U | Y | ||||

| Raw | 18.20 | 18.50 | 105.10 | 0.60 | 782.60 | 7.30 | 0.30 | 19.80 | |||

| Diatomite | 5.80 | 22.30 | 32.90 | 1.50 | 75.60 | 7.30 | 6.60 | 14.60 |

| Title | Raw | J800 | J950 | J1100 | JS800 | JS950 | JS1100 | JD800 | JD950 | JD1100 |

|---|---|---|---|---|---|---|---|---|---|---|

| Qz | 36.11 | 35.74 | 35.93 | 24.41 | 40.56 | 32.15 | 25.83 | 35.97 | 32.61 | 23.61 |

| Ilt/Ms | 9.60 | 9.87 | 7.84 | 8.36 | 3.22 | 7.99 | 6.53 | |||

| Chl/kln | 3.81 | |||||||||

| Pg | 6.38 | 7.00 | 5.95 | 5.68 | ||||||

| Cal | 4.65 | 1.44 | 2.36 | |||||||

| Dol | 1.35 | |||||||||

| Gp | 6.08 | |||||||||

| Anh | 8.99 | 12.99 | 11.01 | 13.08 | 12.88 | 10.29 | 9.92 | 10.25 | ||

| Hem | 0.81 | 1.55 | 1.55 | 1.33 | 1.23 | 0.74 | 1.37 | 0.87 | ||

| Mc | 17.90 | 22.97 | 17.37 | 24.87 | ||||||

| Or | 7.39 | 7.79 | 9.32 | |||||||

| Sa | 4.23 | 11.65 | 4.84 | |||||||

| Ab | 14.12 | 13.99 | 11.81 | 11.38 | ||||||

| An | 29.37 | 49.07 | 33.48 | 47.51 | 35.66 | 49.33 | ||||

| Gh | 5.67 | 4.40 | 2.00 | 1.33 | 3.72 | 3.60 | ||||

| Di | 5.32 | 6.20 | 8.56 | 6.10 | ||||||

| Mul | 3.10 | |||||||||

| Crs | 0.72 | 0.88 | 1.40 | |||||||

| Mo | 1.32 | 0.96 | 0.78 | |||||||

| a/c | 0.038 | 0.042 | 0.069 | 0.106 | 0.055 | 0.068 | 0.088 | 0.051 | 0.064 | 0.118 |

| SSA | ρaMIP | ρrMIP | PoMIP | <0.1 | 0.1–1 | 1–10 | >10 | |

|---|---|---|---|---|---|---|---|---|

| J800 | 5.85 | 1.49 | 2.41 | 38.32 | 19.41 | 77.02 | 1.50 | 2.07 |

| J950 | 2.27 | 1.47 | 2.44 | 39.75 | 7.19 | 89.47 | 1.10 | 2.24 |

| J1100 | 2.09 | 1.48 | 2.51 | 40.86 | 6.45 | 90.80 | 0.78 | 1.97 |

| JS800 | 2.98 | 1.45 | 2.47 | 41.42 | 8.93 | 86.96 | 2.03 | 2.08 |

| JS950 | 1.77 | 1.46 | 2.51 | 41.75 | 5.80 | 89.68 | 1.93 | 2.59 |

| JS1100 | 1.12 | 1.39 | 2.45 | 43.36 | 2.13 | 78.66 | 13.57 | 5.64 |

| JD800 | 5.48 | 1.29 | 2.41 | 46.43 | 14.65 | 75.54 | 6.32 | 3.49 |

| JD950 | 2.10 | 1.23 | 2.25 | 45.25 | 5.12 | 81.19 | 9.36 | 4.33 |

| JD1100 | 1.32 | 1.28 | 2.31 | 44.83 | 1.45 | 43.41 | 48.40 | 6.75 |

| VP1 | VP2 | VP3 | ΔM | Δm | ||

|---|---|---|---|---|---|---|

| J800 | 1625 | 2342 | 2339 | 2102 | 30.56 | 0.12 |

| J950 | 1789 | 2338 | 2337 | 2155 | 23.47 | 0.07 |

| J1100 | 2181 | 2438 | 2392 | 2337 | 9.69 | 1.91 |

| JS800 | 1660 | 2212 | 2234 | 2036 | 25.32 | 0.97 |

| JS950 | 1668 | 1943 | 1967 | 1859 | 14.69 | 1.21 |

| JS1100 | 1804 | 2054 | 2002 | 1953 | 11.02 | 2.58 |

| JD800 | 1610 | 1972 | 2051 | 1877 | 19.96 | 3.91 |

| JD950 | 1514 | 2046 | 1835 | 1798 | 21.99 | 10.85 |

| JD1100 | 1796 | 2102 | 2228 | 2042 | 17.03 | 5.83 |

| L* | a* | b* | C* | h(°) | ΔE | |

|---|---|---|---|---|---|---|

| J | 64.10 (0.58) | 1.11 (0.09) | 13.76 (0.61) | 13.80 (0.61) | 85.40 (0.21) | - |

| J800 | 61.87 (0.64) | 15.08 (0.82) | 21.22 (0.82) | 26.03 (1.11) | 54.61 (0.78) | - |

| J950 | 62.06 (0.85) | 16.84 (0.79) | 21.84 (1.07) | 27.57 (1.31) | 52.37 (0.54) | - |

| J1100 | 61.24 (3.17) | 11.01 (1.38) | 19.67 (0.74) | 22.57 (0.88) | 60.82 (3.29) | - |

| JS | 63.63 (2.43) | 1.22 (0.20) | 14.24 (0.45) | 14.30 (0.47) | 85.13 (0.66) | 0.94 |

| JS800 | 66.98 (1.38) | 11.19 (1.48) | 18.50 (0.85) | 21.64 (1.32) | 58.94 (2.87) | 3.33 |

| JS950 | 65.60 (0.74) | 11.04 (1.82) | 19.37 (1.71) | 22.31 (2.33) | 60.46 (2.24) | 5.91 |

| JS1100 | 62.47 (8.92) | 7.48 (1.90) | 18.38 (1.55) | 19.92 (1.52) | 67.85 (5.41) | 5.15 |

| JD | 61.97 (1.02) | 2.00 (0.21) | 16.33 (0.70) | 16.46 (0.72) | 83.04 (0.43) | 3.14 |

| JD800 | 62.51 (1.00) | 15.30 (0.75) | 21.32 (0.66) | 26.24 (0.97) | 54.34 (0.61) | 2.66 |

| JD950 | 63.53 (3.70) | 17.13 (2.96) | 22.47 (2.94) | 28.25 (4.12) | 52.83 (1.34) | 4.20 |

| JD1100 | 57.20 (1.82) | 11.95 (2.44) | 20.93 (0.94) | 24.15 (1.97) | 60.54 (4.09) | 3.69 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elias, M.L.; Cultrone, G. On the Use of Sodium Chloride and Calcined Diatomite Sludge as Additives to Improve the Engineering Properties of Bricks Made with a Clay Earth from Jun (Granada, Spain). Minerals 2019, 9, 64. https://doi.org/10.3390/min9010064

Elias ML, Cultrone G. On the Use of Sodium Chloride and Calcined Diatomite Sludge as Additives to Improve the Engineering Properties of Bricks Made with a Clay Earth from Jun (Granada, Spain). Minerals. 2019; 9(1):64. https://doi.org/10.3390/min9010064

Chicago/Turabian StyleElias, María Laura, and Giuseppe Cultrone. 2019. "On the Use of Sodium Chloride and Calcined Diatomite Sludge as Additives to Improve the Engineering Properties of Bricks Made with a Clay Earth from Jun (Granada, Spain)" Minerals 9, no. 1: 64. https://doi.org/10.3390/min9010064

APA StyleElias, M. L., & Cultrone, G. (2019). On the Use of Sodium Chloride and Calcined Diatomite Sludge as Additives to Improve the Engineering Properties of Bricks Made with a Clay Earth from Jun (Granada, Spain). Minerals, 9(1), 64. https://doi.org/10.3390/min9010064