The Effect of Petrographic Characteristics and Physico-Mechanical Properties of Aggregates on the Quality of Concrete

Abstract

:1. Introduction

2. Geological Setting

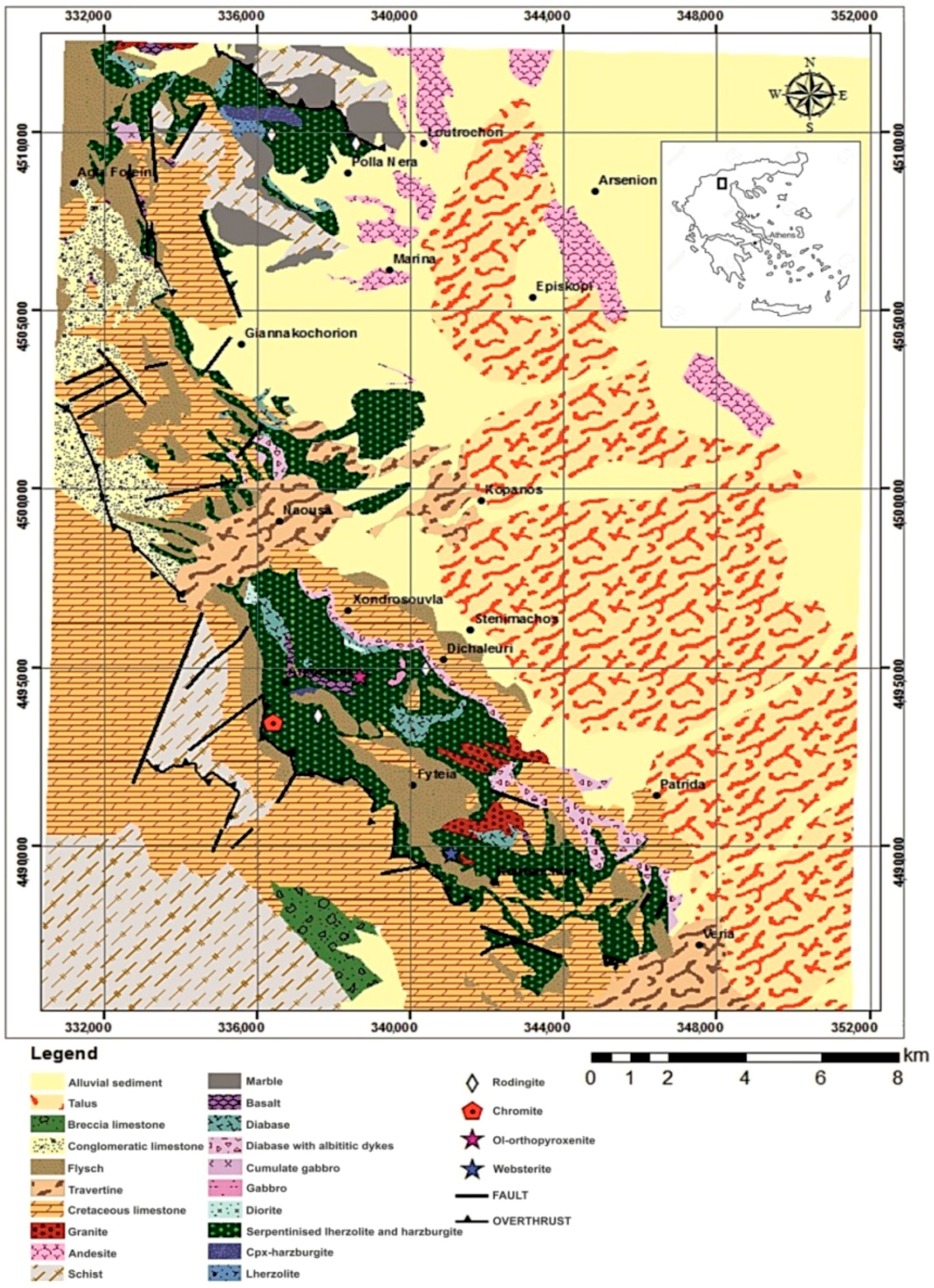

2.1. Veria-Naousa Ophiolitic Complex

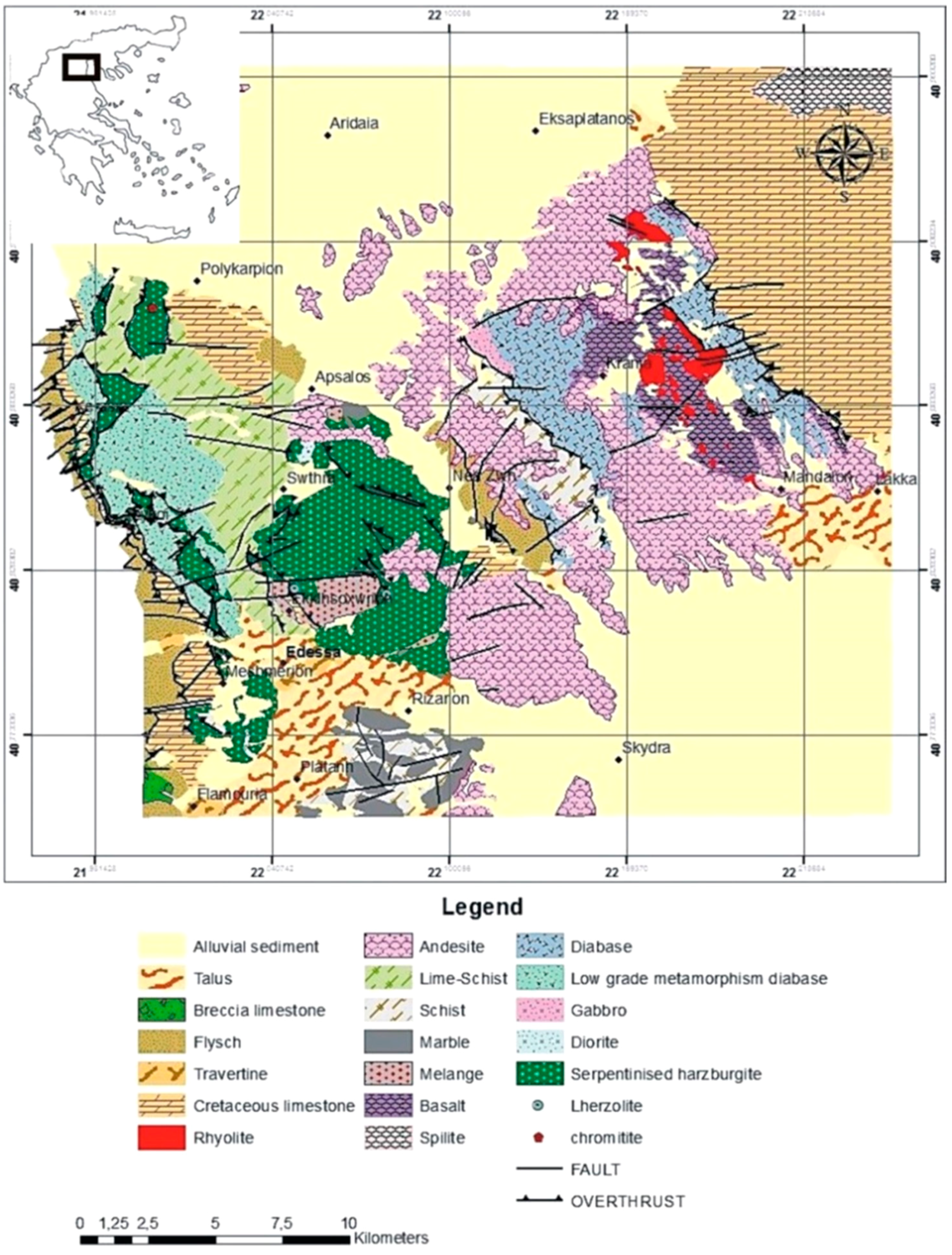

2.2. Edessa Ophiolitic Complex

3. Materials and Methods

3.1. Materials

3.2. Aggregate Tests

3.3. Concrete Tests

4. Results

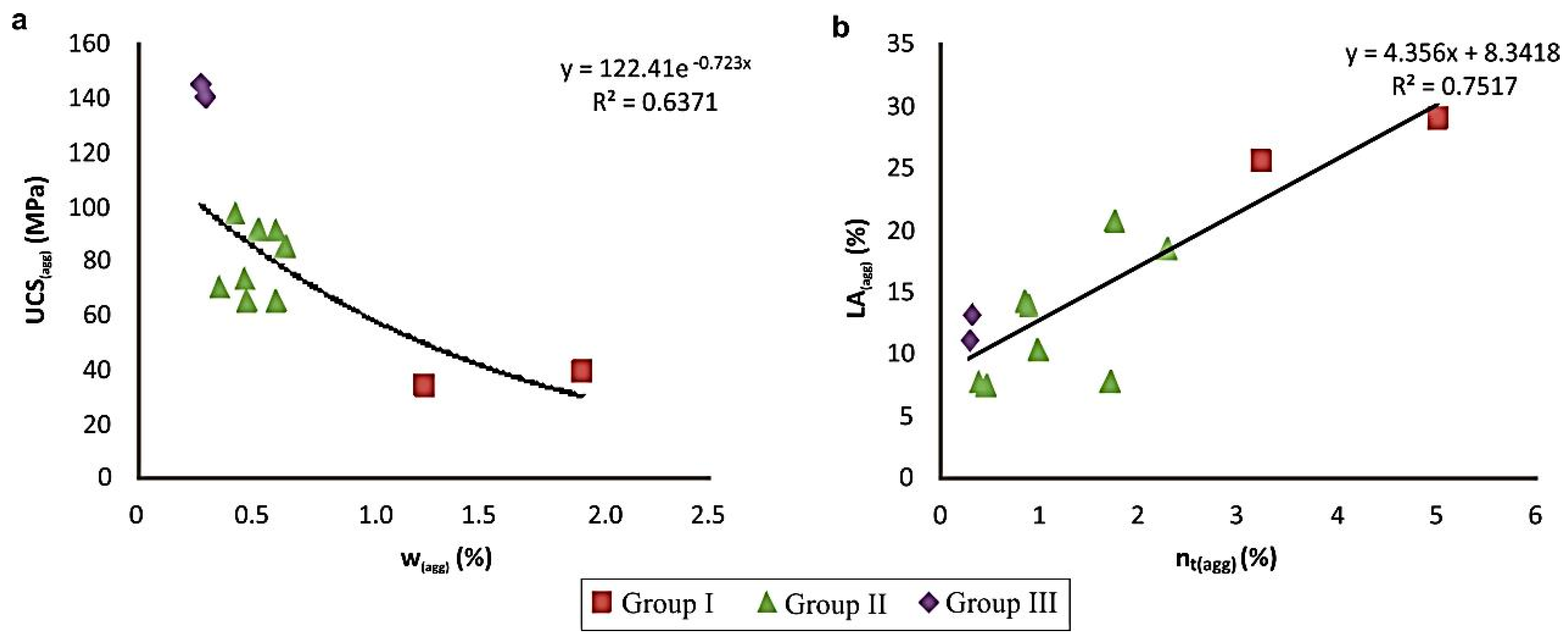

4.1. Physico-Mechanical Properties of Aggregates

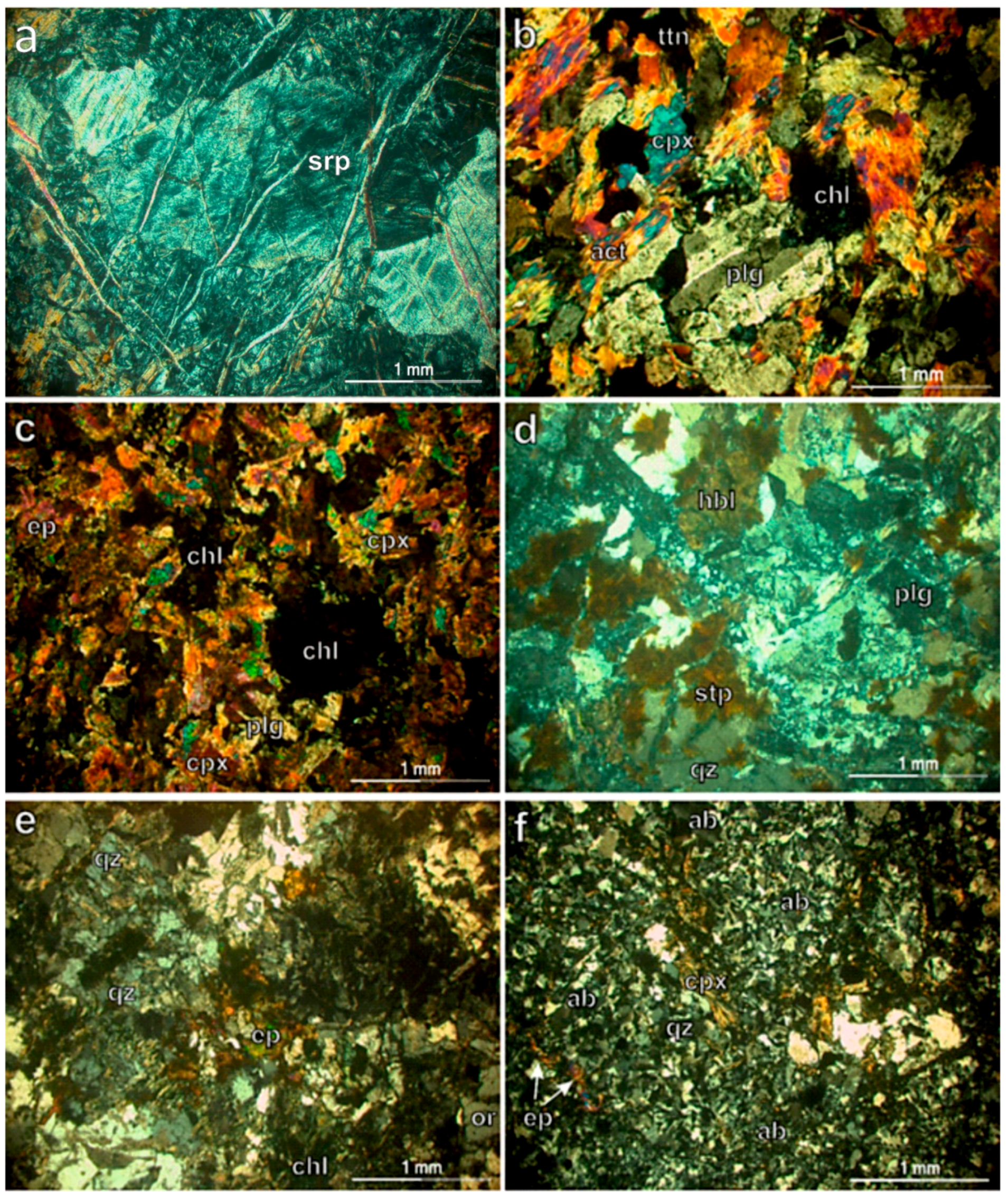

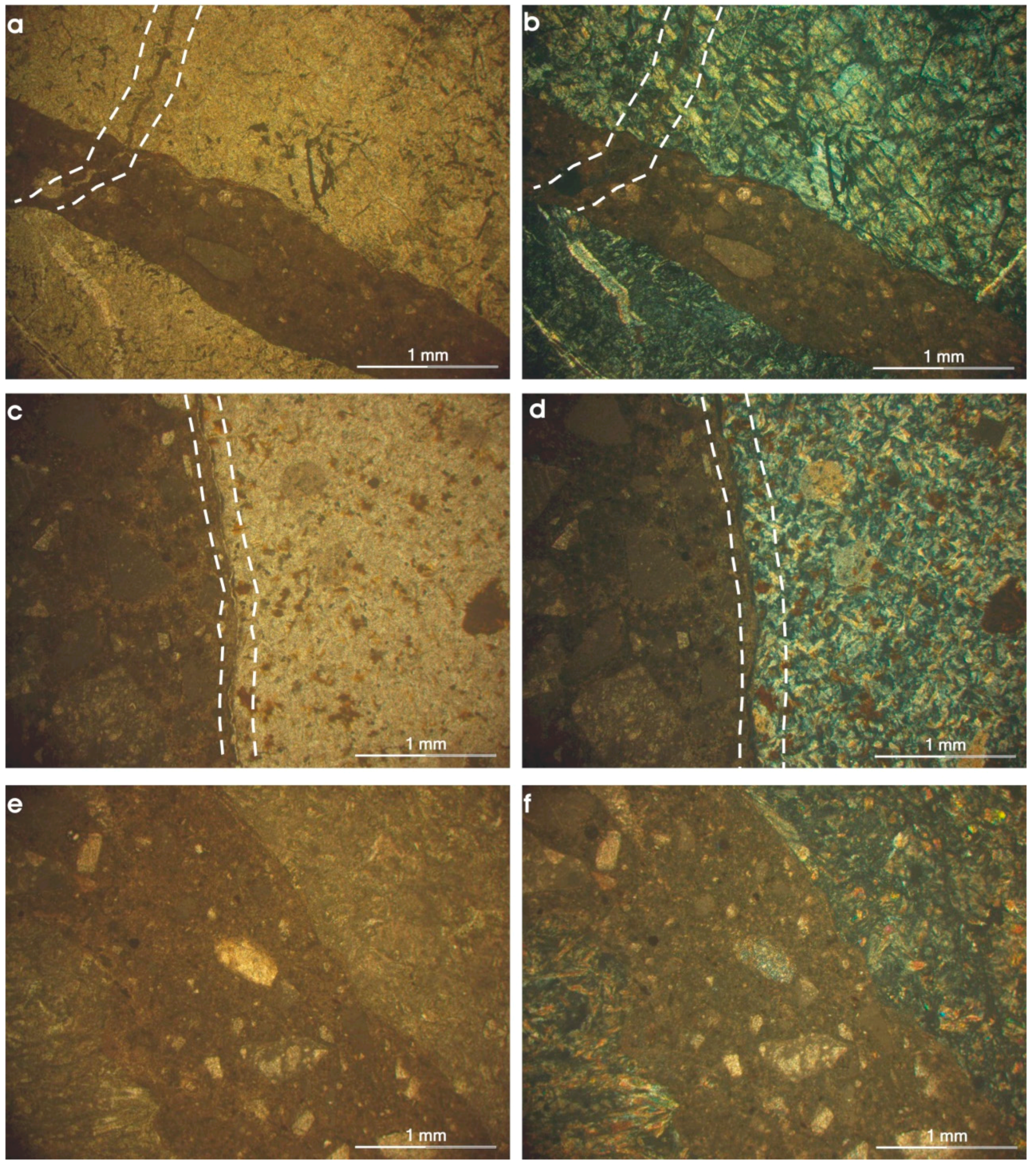

4.2. Petrographic Features of Aggregates

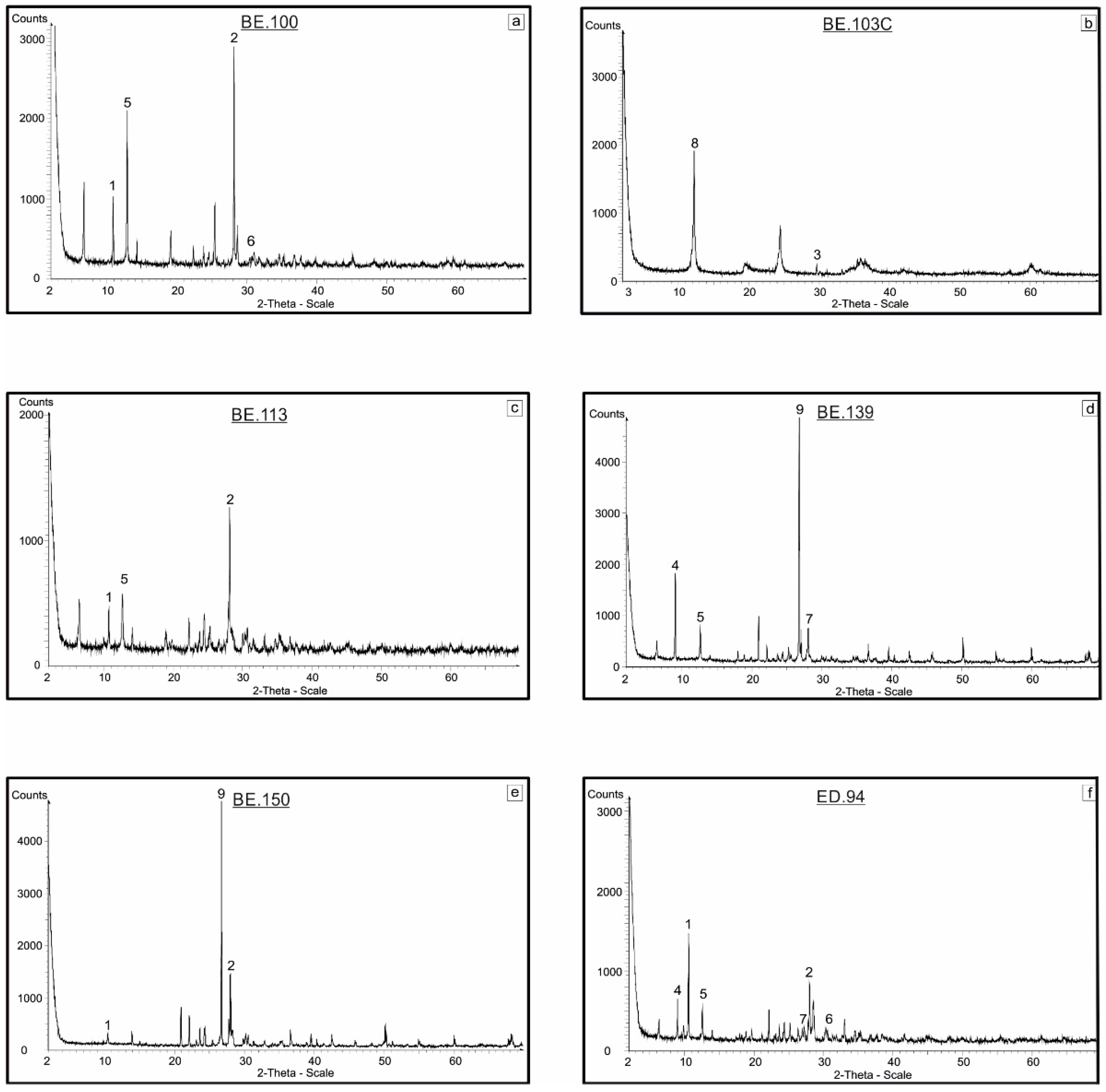

4.3. XRD Analysis of Aggregates

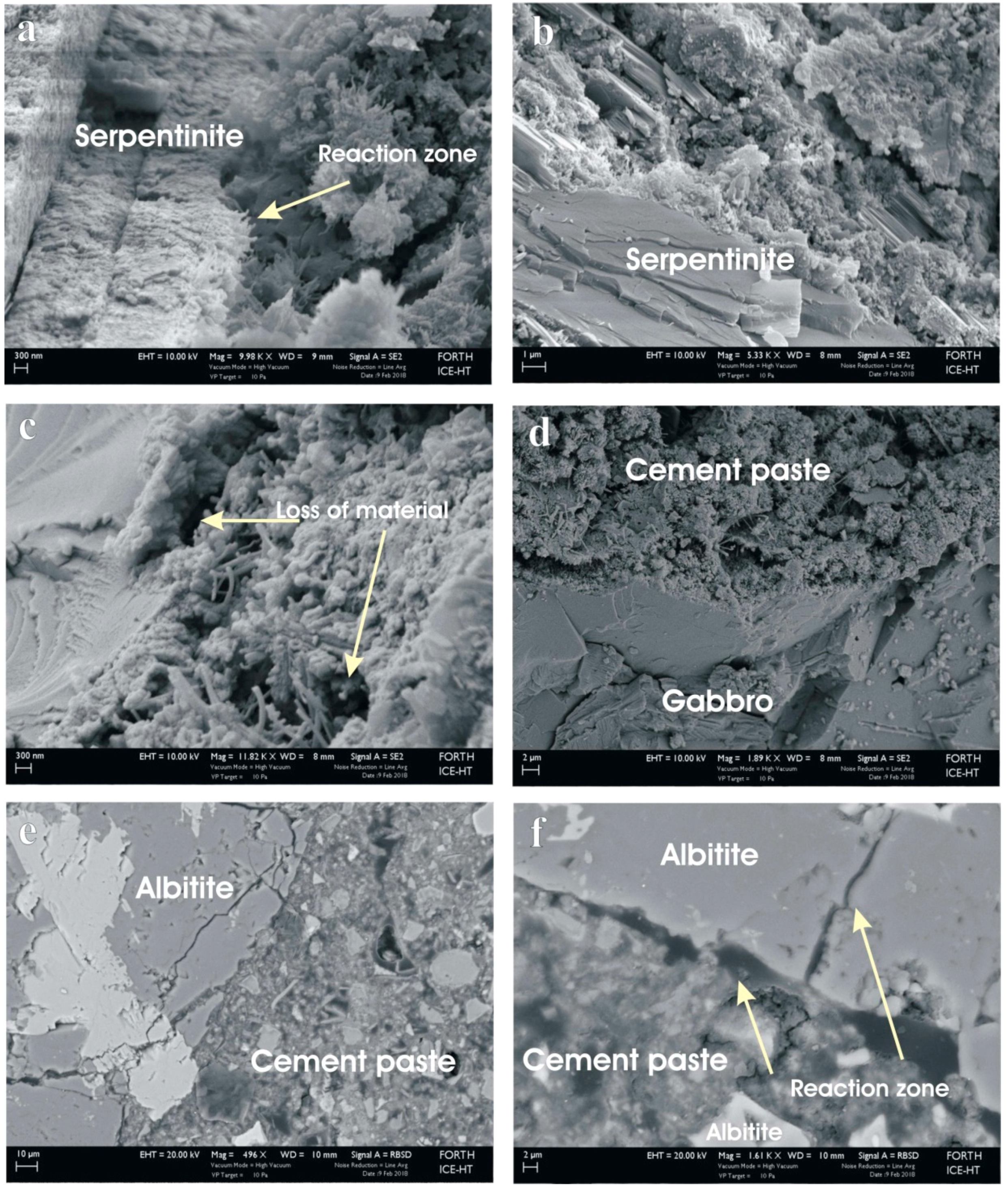

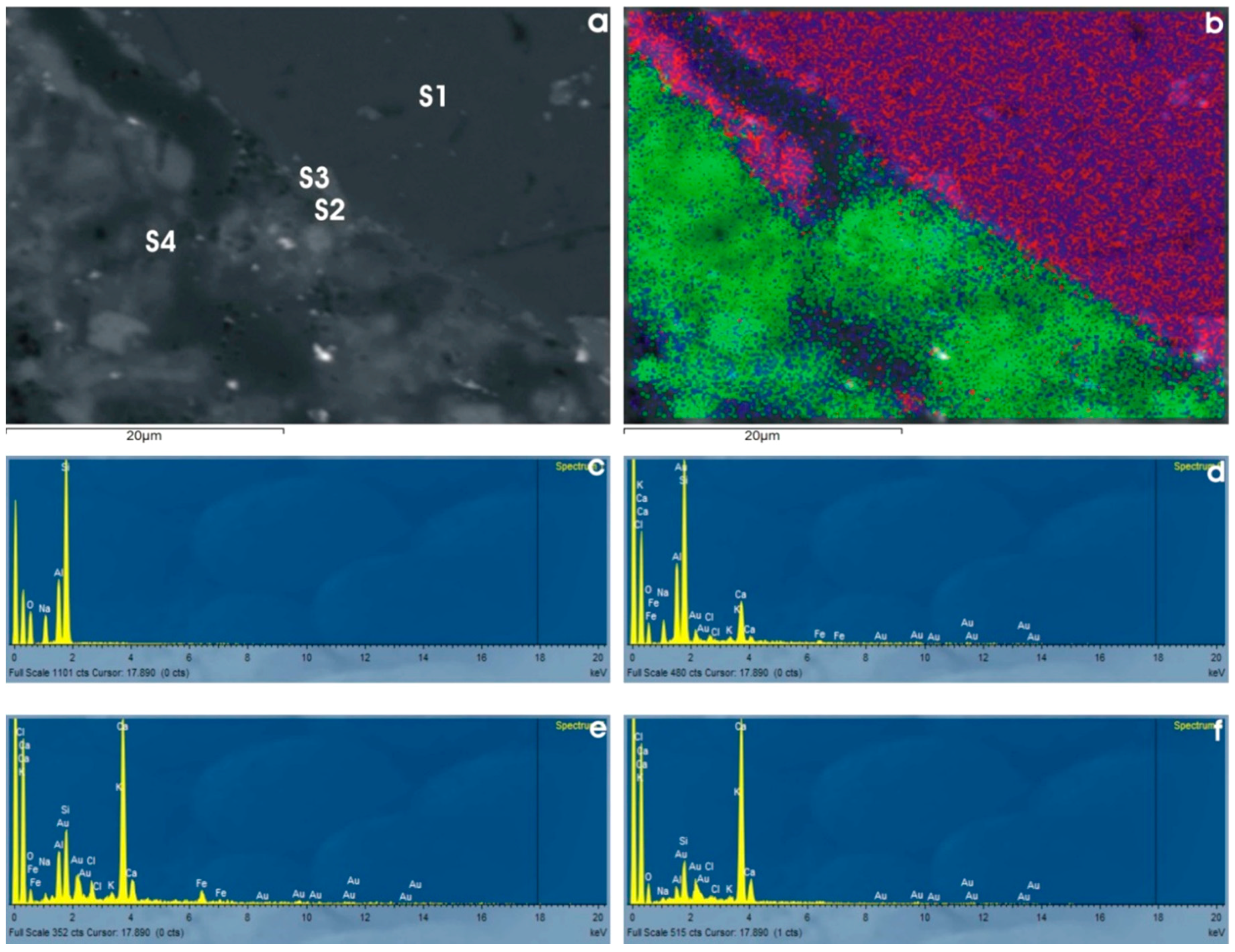

4.4. Surface Texture of Aggregates

4.5. Test Results for Concrete

4.5.1. Compressive Strength of Concrete

4.5.2. Petrographic Features of the Concretes

5. Discussion

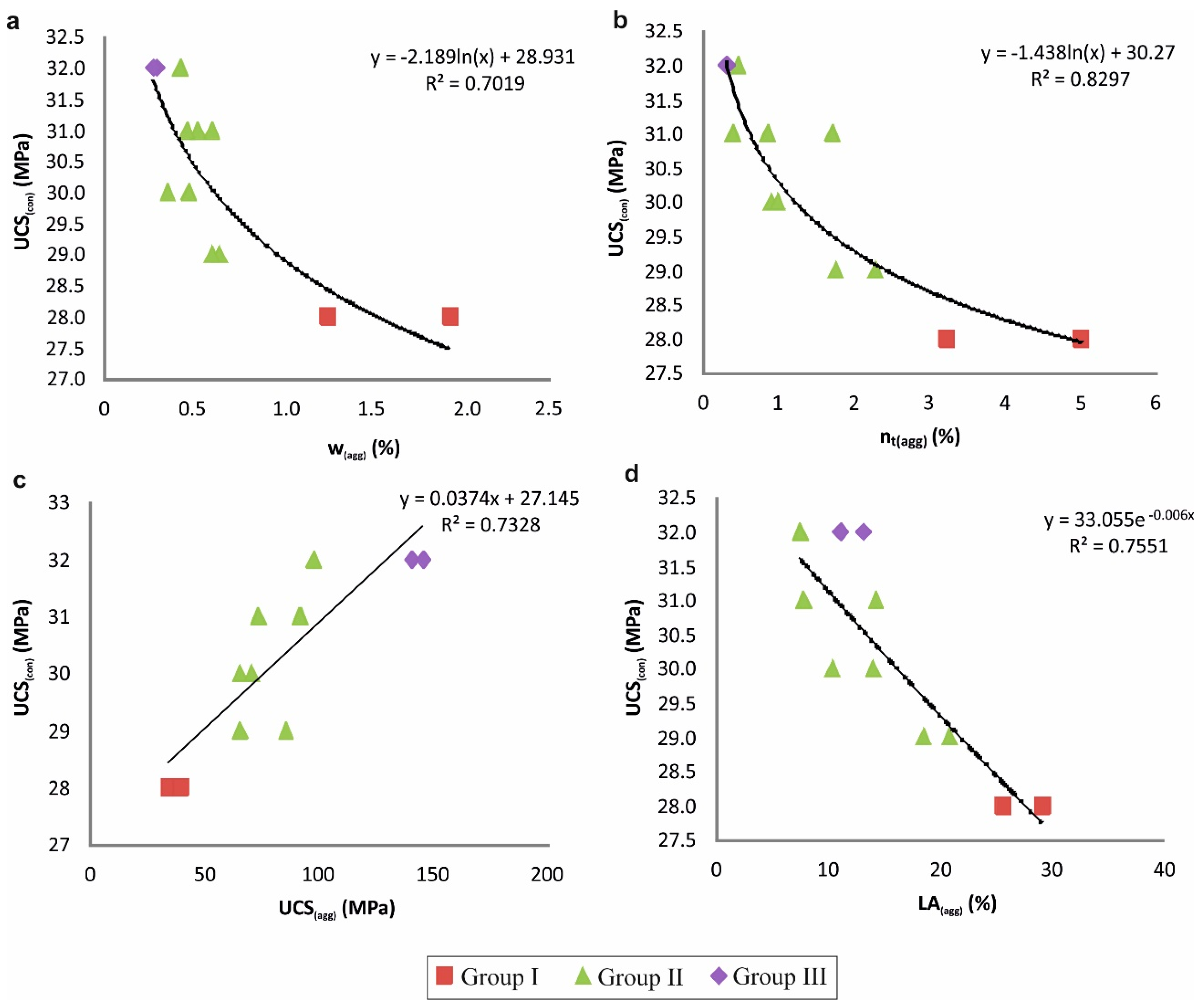

The Impact of the Aggregate Type on the Quality of Concrete

6. Conclusions

- The collected ultramafic rocks (Group I) were not appropriate for concrete aggregates due to the high degrees of alteration and the presence of serpentine, which significantly decreased the quality of the concretes. The collected mafic aggregate rocks as well as the granodiorite (Group II) were generally considered as suitable for the production of concretes. The intermediate aggregate rocks (Group III) presented overall good physicomechanical properties and resulted in the production of the best quality concretes compared to the other tested lithotypes. The limited presence of alkali-silicate reaction did not influence the final products significantly.

- High porosity and moisture content of the aggregates reduced the quality of the aggregate as well as of the concretes due to disturbance of the hydration reactions. This led to the formation of variably porous and weak zones at the interfaces between the particles and the cement paste.

- Strength and resistance to abrasion and attrition of aggregates was a critical factor that largely determined the quality of the concretes positively. Microroughness was a result of differential hardness of juxtaposed minerals on the surface of the particles and largely affected the bonding between the particles and the cement paste for each lithotype. Smooth serpentine had a negative influence; however, small amounts of soft secondary minerals juxtaposed with hard primary phases had a positive effect on the bonding with the cement paste.

- Petrographic analysis of both of the aggregates and concretes provided pertinent information about the structures concrete material and may help engineers to determine the best construction strategy. The root of concrete deterioration can often be attributed to quality issues seen at the microscopic level of the aggregate materials.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Jackson, N. Civil Engineering Materials; Macmillan Press Ltd.: London, UK, 1981. [Google Scholar]

- LaLonde, W.S.; Janes, M.F. Concrete Engineering Handbook; Library of Congress: New York, NY, USA, 1961. [Google Scholar]

- US Concrete Industry Report; Library of Congress: New York, NY, USA, 2001.

- Neville, A.M. Properties of Concrete, ELSB 5th ed.; Pearson Education Publishing Ltd.: London, UK, 2005. [Google Scholar]

- Taylor, G.D. Materials in Construction, 2nd ed.; Longman Group Ltd., Longman House, Burnt Mill: Harlow, UK, 1994. [Google Scholar]

- Rajput, R.K. Engineering Materials, 3rd ed.; S. Chard & Company Ltd.: New Delhi, India, 2006. [Google Scholar]

- Neville, A.M. Properties of Concrete, 4th ed.; Pitman: London, UK, 1995. [Google Scholar]

- Aulia, T.B.; Deutschmann, K. Effect of mechanical properties of aggregate on the ductility of high performance concrete. Lacer 1999, 4, 133–147. [Google Scholar]

- Thomas, M.D.A.; Folliard, K.J. Concrete aggregates and the durability of concrete. Durab. Concr. Cem. Compos. 2007, 247–281. [Google Scholar] [CrossRef]

- Petrounias, P.; Giannakopoulou, P.P.; Rogkala, A.; Stamatis, P.M.; Tsikouras, B.; Papoulis, D.; Lampropoulou, P.; Hatzipanagiotou, K. The influence of alteration of aggregates on the quality of the concrete: A case study from serpentinites and andesites from central Macedonia (North Greece). Geosciences 2018, 8, 115. [Google Scholar] [CrossRef]

- Yilmaz, M.; Turul, A. The effects of different sandstone aggregates on concrete strength. Constr. Build. Mater. 2012, 35, 294–303. [Google Scholar] [CrossRef]

- Petrounias, P.; Rogkala, A.; Kalpogiannaki, M.; Tsikouras, B.; Hatzipanagiotou, K. Comparative study of physico-mechanical properties of ultrabasic rocks (Veria-Naousa ophiolite) and andesites from central Macedonia (Greece). Bull. Geol. Soc. Greece 2016, 50, 1989–1998. [Google Scholar] [CrossRef]

- Giannakopoulou, P.P.; Tsikouras, B.; Hatzipanagiotou, K. The interdependence of mechanical properties of ultramafic rocks from Gerania ophiolitic complex. Bull. Geol. Soc. Greece 2016, 50, 1829–1837. [Google Scholar] [CrossRef]

- Al-Oraimi, S.K.; Taha, R.; Hassan, H.F. The effect of the mineralogy of coarse aggregate on the mechanical properties of high-strength concrete. Constr. Build. Mater. 2006, 20, 499–503. [Google Scholar] [CrossRef]

- Rigopoulos, I.; Tsikouras, B.; Pomonis, P.; Hatzipanagiotou, K. The influence of alteration on the engineering properties of dolerites: The example from the Pindos and Vourinos ophiolites (northern Greece). Int. J. Rock Mech. Min. Sci. 2010, 47, 69–80. [Google Scholar] [CrossRef]

- Yilmaz, N.G.; Goktan, R.M.; Kibici, Y. Relations between some quantitative petrographic characteristics and mechanical strength properties of granitic building stones. Int. J. Rock Mech. Min. Sci. 2011, 48, 506–513. [Google Scholar] [CrossRef]

- Petrounias, P.; Giannakopoulou, P.P.; Rogkala, A.; Lampropoulou, P.; Koutsopoulou, E.; Papoulis, D.; Tsikouras, B.; Hatzipanagiotou, K. The Impact of Secondary Phyllosilicate Minerals on the Engineering Properties of Various Igneous Aggregates from Greece. Minerals 2018, 8, 329. [Google Scholar] [CrossRef]

- Shakoor, A.; Bonelli, R.E. Relationship between petrographic characteristics, engineering index properties and mechanical properties of selected sandstones. Bull. Ass. Eng. Geol. 1991, 28, 55–71. [Google Scholar] [CrossRef]

- Haney, M.G.; Dhakoor, A. The relationship between tensile and compressive strengths for selected sandstones as influenced by index properties and petrographic characteristics. In Proceedings of the 7th International IAEG Congress, Lisbon, Portugal, 5–9 September 1996; Volume IV, pp. 3013–3021. [Google Scholar]

- Turgul, A.; Zarif, I.H. Correlation of mineralogical and textural characteristics with engineering properties of selected granitic rocks from Turkey. Eng. Geol. 1999, 51, 303–317. [Google Scholar]

- Smith, M.R.; Collis, L. Aggregates: Sand, Gravel and Crushed Rock Aggregates for Construction Purposes; Spec. Publ. 17; The Geological Society: London, UK, 2001. [Google Scholar]

- Miskovsky, K.; Tabora, D.M.; Kou, S.Q.; Lindqvist, P.A. Influence of the mineralogical composition and textural properties on the quality of coarse aggregates. J. Mater. Eng. Perform. 2004, 13, 144–150. [Google Scholar] [CrossRef]

- Gonilho Pereira, C.; Castro-Gomes, J.; Pereira de Oliveira, L. Influence of natural coarse aggregate size, mineralogy and water content on the permeability of structural concrete. Constr. Build. Mater. 2009, 23, 602–608. [Google Scholar] [CrossRef]

- Kiliç, A.; Atiş, C.D.; Teymen, A.; Karahan, O.; Özcan, F.; Bilim, C.; Özdemir, M. The influence of aggregate type on the strength and abrasion resistance of high strength concrete. Cement Concr. Comp. 2008, 30, 290–296. [Google Scholar] [CrossRef]

- Piasta, W.; Góra, J.; Turkiewicz, T. Properties and durability of coarse igneous rock aggregates and concretes. Constr. Build. Mater. 2016, 126, 119–129. [Google Scholar] [CrossRef]

- Özturan, T.; Çeçen, C. Effect of coarse aggregate type on mechanical properties of concretes with different strengths. Cem. Concr. 2007, 27, 165–170. [Google Scholar] [CrossRef]

- Rogkala, A.; Petrounias, P.; Tsikouras, B.; Hatzipanagiotou, K. New occurrence of pyroxenites in the veria-naousa ophiolite (North Greece): Implications on their origin and petrogenetic evolution. Geosciences 2017, 7, 92. [Google Scholar] [CrossRef]

- Mercier, J.; Vergely, P.; Bebien, J. Les ophiolites helleniques ‘obductees’ au Jurassique superieursont-elles les vestiges d’ un ocean tethysienou d’ une mermarginale perieuropeenne. C. R. Somm. Soc. Geol. France 1975, 17, 108–112. [Google Scholar]

- Saccani, E.; Photiades, A.; Santato, A.; Zeda, O. New evidence for supra-subduction zone ophiolites in the Vardar zone of northern Greece: Implications for the tectonomagmatic evolution of the Vardar oceanic basin. Ofioliti 2008, 33, 65–85. [Google Scholar]

- Brunn, J.H. Geological Map of Greece, Veroia Sheet, 1:50.000; IGME: Athens, Greece, 1982. [Google Scholar]

- Decourt, J.; Aubouin, J.; Savoyat, E. Le sillon mesohellenique et la zone pelagonienne. Bull. Soc. Geol. Fr. 1977, 1, 32–70. [Google Scholar]

- Michailidis, K.M. Zoned chromites with high MN-contents in the Fe-Ni-Cr-laterite ore deposits from the Edessa area in Northern Greece. Miner. Depos. 1990, 25, 190–197. [Google Scholar] [CrossRef]

- Pe-Piper, G.; Piper, D.J.W. The igneous rocks of Greece. The Anatomy of an Orogen. Beitrge zur Regionalen Geologie der Erde (Series). Stuttgart. Gebrder Borntaeger. 2002. [Google Scholar] [CrossRef]

- Eleftheriadis, G.; Castorina, F.; Soldatos, T.; Masi, U. Geochemical and Sr-Nd isotopic evidence for the genesis of the Late Cainozoic Almopia volcanic rocks (Central Macedonia, Greece). Min. Petrol. 2003, 78, 21–36. [Google Scholar] [CrossRef]

- Mercier, J.L.; Vergely, P. Geological Map of Greece, Edhessa Sheet, 1:50.000; IGME: Athens, Greece, 1984. [Google Scholar]

- Part 1: Composition, Specifications and Conformity Criteria for Common Cements; EN 197-1; European Standard: Warsaw, Poland, 2011.

- AASHTO T255. Standard Method of Test for Total Evaporable Moisture Content of Aggregate by Drying; ASTM International: West Conshohocken, PA, USA, 2000. [Google Scholar]

- ISRM Suggested Methods. Rock Characterization Testing and Monitoring; Brown, E., Ed.; Pergamon Press: Oxford, UK, 1981. [Google Scholar]

- Resistance to Abrasion of Small-Size Coarse Aggregate by Use of the Los Angeles Machine; ASTM C-131; ASTM: Philadelphia, PA, USA, 1989.

- Standard Test Method for Unconfined Compressive Strength of Intact Rock Core Specimens; ASTM D 2938-95; American Society for Testing and Materials: West Conshohocken, PA, USA, 2002.

- Part 3: Procedure and Terminology for Simplified Petrographic Description; EN 932; European Standard: Warsaw, Poland, 1996.

- Methods for Sampling and Testing of Mineral Aggregates, Sands and Fillers, Part 1: Methods for Determination of Particle Size and Shape; BS 812; British Standard Institution: London, UK, 1975.

- Standard for Selecting Proportions for Normal, Heavyweight and Mass Concrete; ACI-211.1-91; American Concrete Institute: Farmington Hills, MI, USA, 2002.

- Part 3: Testing Hardened Concrete. Compressive Strength of Test Specimens; BS EN 12390; British Standard Institution: London, UK, 2009.

- Standard Practice for Petrographic Examination of Hardened Concrete; ASTM C856; American Society for Testing and Materials: West Conshohocken, PA, USA, 2017.

- Rigopoulos, I.; Tsikouras, B.; Pomonis, P.; Hatzipanagiotou, K. The impact of petrographic characteristics on the engineering properties of ultrabasic rocks from northern and central Greece. Q. J. Eng. Geol. Hydrogeol. 2012, 45, 423–433. [Google Scholar] [CrossRef]

- Hartley, A. A review of the geological factors influencing the mechanical properties of road surface aggregates. Q. J. Eng. Geol. 1974, 7, 69–100. [Google Scholar] [CrossRef]

- Barttli, B. The influence of geological factors on the mechanical properties of basic igneous rocks used as road surface aggregates. Eng. Geol. 1992, 33, 31–44. [Google Scholar] [CrossRef]

- Rigopoulos, I.; Tsikouras, B.; Pomonis, P.; Hatzipanagiotou, K. Correlations between petrographic and geometrical properties of ophiolitic aggregates from Greece. Bull. Eng. Geol. Environ. 2014, 73, 1–12. [Google Scholar] [CrossRef]

- Koukis, G.; Sabatakakis, N.; Spyropoulos, A. Resistance variation of low-quality aggregates. Bull. Eng. Geol. Environ. 2007, 66, 457–466. [Google Scholar] [CrossRef]

- Escartin, J.; Hirth, G.; Evans, B. Strength of slightly serpentinized peridotites: Implications for the tectonics of oceanic lithosphere. Geology 2001, 29, 1023–1026. [Google Scholar] [CrossRef]

- Frost, B.R.; Beard, J.S. On silica activity and serpentinization. J. Petrol. 2007, 48, 1351–1368. [Google Scholar] [CrossRef]

- Diamantis, K.; Gartzos, E.; Migiros, G. Study on uniaxial compressive strength, point load strength index, dynamic and physical properties of serpentinites from Central Greece: Test results and empirical relations. Eng. Geol. 2009, 108, 199–207. [Google Scholar] [CrossRef]

- Giannakopoulou, P.P.; Petrounias, P.; Rogkala, A.; Tsikouras, B.; Stamatis, P.M.; Pomonis, P.; Hatzipanagiotou, K. The influence of the mineralogical composition of ultramafic rocks on their engineering performance: A case study from the Veria-Naousa and Gerania ophiolite complexes (Greece). Geosciences 2018, 8, 251. [Google Scholar] [CrossRef]

- Onodera, T.F.; Asoka, K.H.M. Relation between petrographic characteristics, engineering index properties and mechanics properties of selected sandstone. Bull. Ass. Eng. Geol. 1980, 28, 55–71. [Google Scholar]

- Kaplan, M.F. Flexural and compressive strength of concrete as affected by the properties of coarse aggregates. J. Am. Concr. Inst. 1959, 55, 1193–1208. [Google Scholar]

- Sibbick, R.G.; Page, C.L. Susceptibility of various UK aggregates to alkali–aggregate reaction. In Proceedings of the Ninth International Conference on Alkali-Aggregate Reaction in Concrete, London, UK, 27–31 July 1992; pp. 980–987. [Google Scholar]

- Ponce, J.M.; Batic, O.R. Different manifestations of the alkali-silica reaction in concrete according to the reaction kinetics of the reactive aggregate. Cem. Concr. Res. 2006, 1148–1156. [Google Scholar] [CrossRef]

| Aggregate Type | Diabase | Serpentinite | Albitite | Gabbro | Diorite | Granodiorite |

|---|---|---|---|---|---|---|

| Concrete cube | 4 | 2 | 2 | 2 | 1 | 1 |

| Samples Grading | Aggregate | Lithotype | Porosity (%) | Moisture Content (%) | Los Angeles (%) | Compressive Strength (MPa) * (N = 6) |

|---|---|---|---|---|---|---|

| Group I | BE.122B | Serpentinite | 3.21 | 1.25 | 25.51 | 34.00 |

| BE.103C | Serpentinite | 4.99 | 1.94 | 28.97 | 39.00 | |

| Group II | ED.24 | Diabase | 0.84 | 0.52 | 14.15 | 91.33 |

| BE.113 | Diabase | 0.45 | 0.42 | 7.39 | 97.15 | |

| ED.94 | Diorite | 2.27 | 0.64 | 18.40 | 85.00 | |

| ED.66A | Diabase | 0.38 | 0.46 | 7.65 | 73.00 | |

| BE.100 | Gabbro | 0.88 | 0.47 | 13.88 | 65.00 | |

| BE.149 | Diabase | 0.97 | 0.35 | 10.25 | 70.00 | |

| ED.26 | Gabbro | 1.74 | 0.60 | 20.68 | 65.00 | |

| BE.139 | Granodiorite | 1.70 | 0.60 | 7.71 | 91.00 | |

| Group III | BE.108 | Albitite | 0.31 | 0.29 | 13.05 | 140.00 |

| BE.150 | Albitite | 0.29 | 0.27 | 11.00 | 145.00 |

| Samples Grading | Samples | Lithotype | Primary Minerals | Secondary Minerals |

|---|---|---|---|---|

| Group I | BE.103C | Srp. Lherzolite | opx, ol, cpx, sp | srp, mgt, bas |

| BE.122B | Srp. Harzburgite | opx, ol, sp | srp, mgt, bas | |

| Group II | ED.94 | Diorite | plg, hbl, cpx, or, qz, ttn | ser, act, chl, stl |

| BE.100 | Gabbro | cpx, plg, ttn | chl, act, ep | |

| ED.26 | Gabbro | cpx, plg, ttn | chl, ser, ep, phr | |

| ED.24 | Diabase | plg, cpx | act, chl, ep, phr, ser | |

| BE.113 | Diabase | plg, cpx | chl, act, ep | |

| ED.66A | Diabase | plg, cpx | chl, ep, ser, act | |

| BE.139 | Granodiorite | qz, plg, or | chl, ep, ser, stl | |

| BE.149 | Granodiorite | qz, plg, or | chl, ep, ser | |

| Group III | BE.108 | Albitite | plg, cpx, qz | chl, ep, ser |

| BE.150 | Albitite | plg, cpx, qz | chl, ep, ser |

| Aggregate Rock Sample | Lithotype | Compressive Strength (MPa) * | |

|---|---|---|---|

| Group I | BE.122B | Serpentinite | 28 |

| BE.103C | Serpentinite | 28 | |

| Group II | ED.24 | Diabase | 31 |

| BE.113 | Diabase | 32 | |

| ED.94 | Diorite | 29 | |

| ED.66A | Diabase | 31 | |

| BE.100 | Gabbro | 30 | |

| BE.149 | Diabase | 30 | |

| ED.26 | Gabbro | 29 | |

| BE.139 | Granodiorite | 31 | |

| Group III | BE.108 | Albitite | 32 |

| BE.150 | Albitite | 32 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Petrounias, P.; Giannakopoulou, P.P.; Rogkala, A.; Stamatis, P.M.; Lampropoulou, P.; Tsikouras, B.; Hatzipanagiotou, K. The Effect of Petrographic Characteristics and Physico-Mechanical Properties of Aggregates on the Quality of Concrete. Minerals 2018, 8, 577. https://doi.org/10.3390/min8120577

Petrounias P, Giannakopoulou PP, Rogkala A, Stamatis PM, Lampropoulou P, Tsikouras B, Hatzipanagiotou K. The Effect of Petrographic Characteristics and Physico-Mechanical Properties of Aggregates on the Quality of Concrete. Minerals. 2018; 8(12):577. https://doi.org/10.3390/min8120577

Chicago/Turabian StylePetrounias, Petros, Panagiota P. Giannakopoulou, Aikaterini Rogkala, Panagiotis M. Stamatis, Paraskevi Lampropoulou, Basilios Tsikouras, and Konstantin Hatzipanagiotou. 2018. "The Effect of Petrographic Characteristics and Physico-Mechanical Properties of Aggregates on the Quality of Concrete" Minerals 8, no. 12: 577. https://doi.org/10.3390/min8120577

APA StylePetrounias, P., Giannakopoulou, P. P., Rogkala, A., Stamatis, P. M., Lampropoulou, P., Tsikouras, B., & Hatzipanagiotou, K. (2018). The Effect of Petrographic Characteristics and Physico-Mechanical Properties of Aggregates on the Quality of Concrete. Minerals, 8(12), 577. https://doi.org/10.3390/min8120577