Geometallurgy—A Route to More Resilient Mine Operations

Abstract

1. Introduction

- Acquisition of data through sampling and measurement.

- Building spatial models.

- Using these models to optimise value.

- Declining ore grades.

- Geometrically and/or internally more involuted.

- Processing of more challenging ores with refractory and/or textural complexities.

- Deep-seated deposits with potentially high in-situ stress regimes.

- Increasing quantities of mine waste that need to be managed appropriately.

- Higher energy, water, and chemical costs.

- Stricter environmental/permitting and social conditions (the social licence to mine).

- Increasing demand for hard to process specialist/critical metals (e.g., rare earth elements and lithium).

- Commodity market volatility.

- Difficult funding environment.

- Orebody definition and revenue prediction.

- Mining methods that deliver a finer feed to the plant comminution circuit at lower cost.

- Optimised energy-efficient comminution circuits.

- Coarse particle beneficiation to reduce grinding.

- Beneficiation equipment and chemistry.

- Water and energy recovery.

- Leading practice social licence to operate.

2. Overview of Geometallurgy

2.1. Variability and Uncertainty

- Uncertainty associated with in situ variables which is propagated through processes applied to them. For example, the impact of grade uncertainty on mine design, which could be assessed by applying the same design process (e.g., optimal open-pit) to a range of simulated grade realisations.

- Uncertainty transferred to in situ variables by applying a process to them. An example is blasting a block of ground from which ore is selected.

2.2. Metallurgical versus Geometallurgical Approach

2.3. Modern Geometallurgy

2.3.1. Defining Modern Geometallurgy

- Primary variables are rock attributes that are independent of the measurement process employed.

- Response variables are attributes of rock (geology) that measure responses to processes.

2.3.2. Value of Geometallurgy

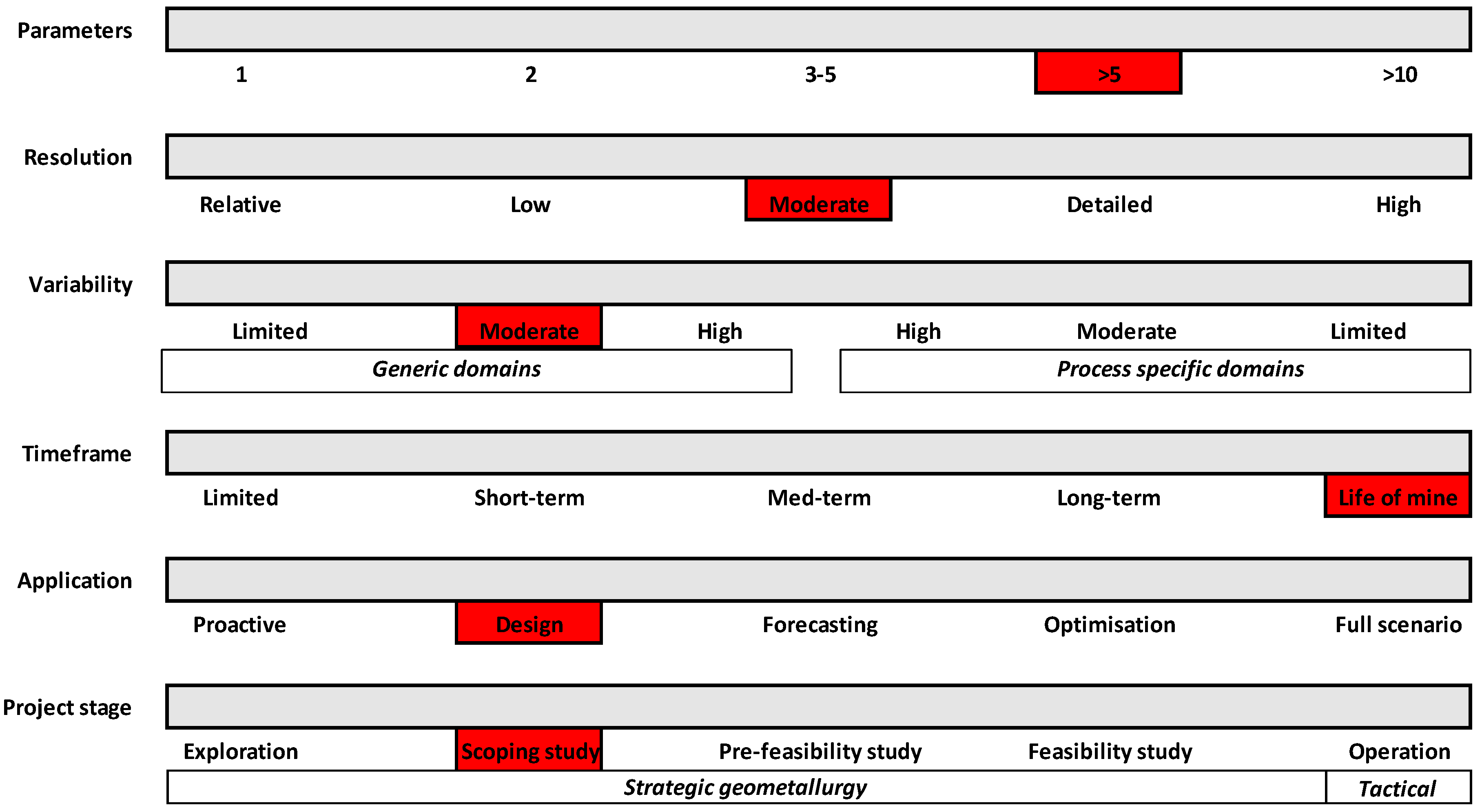

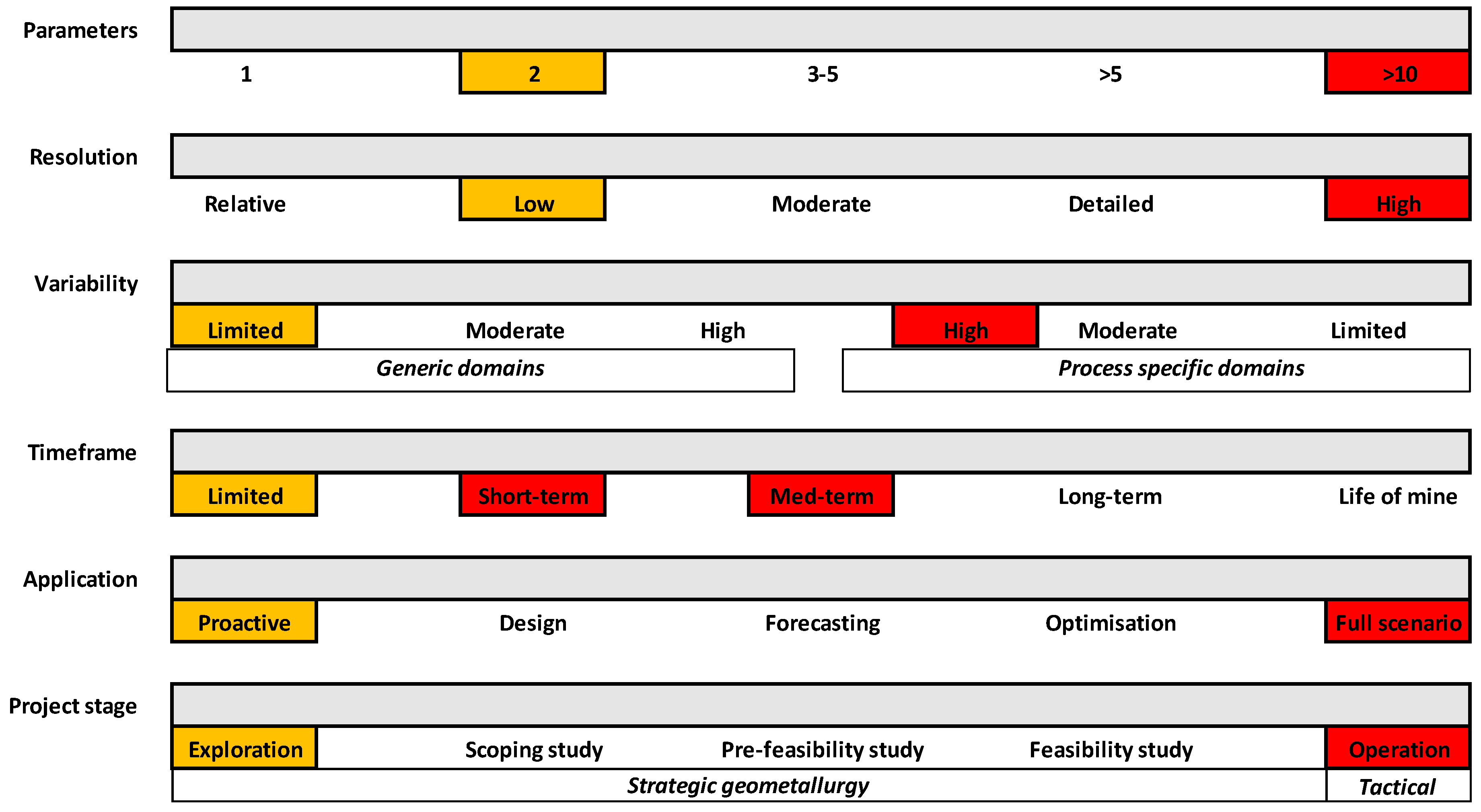

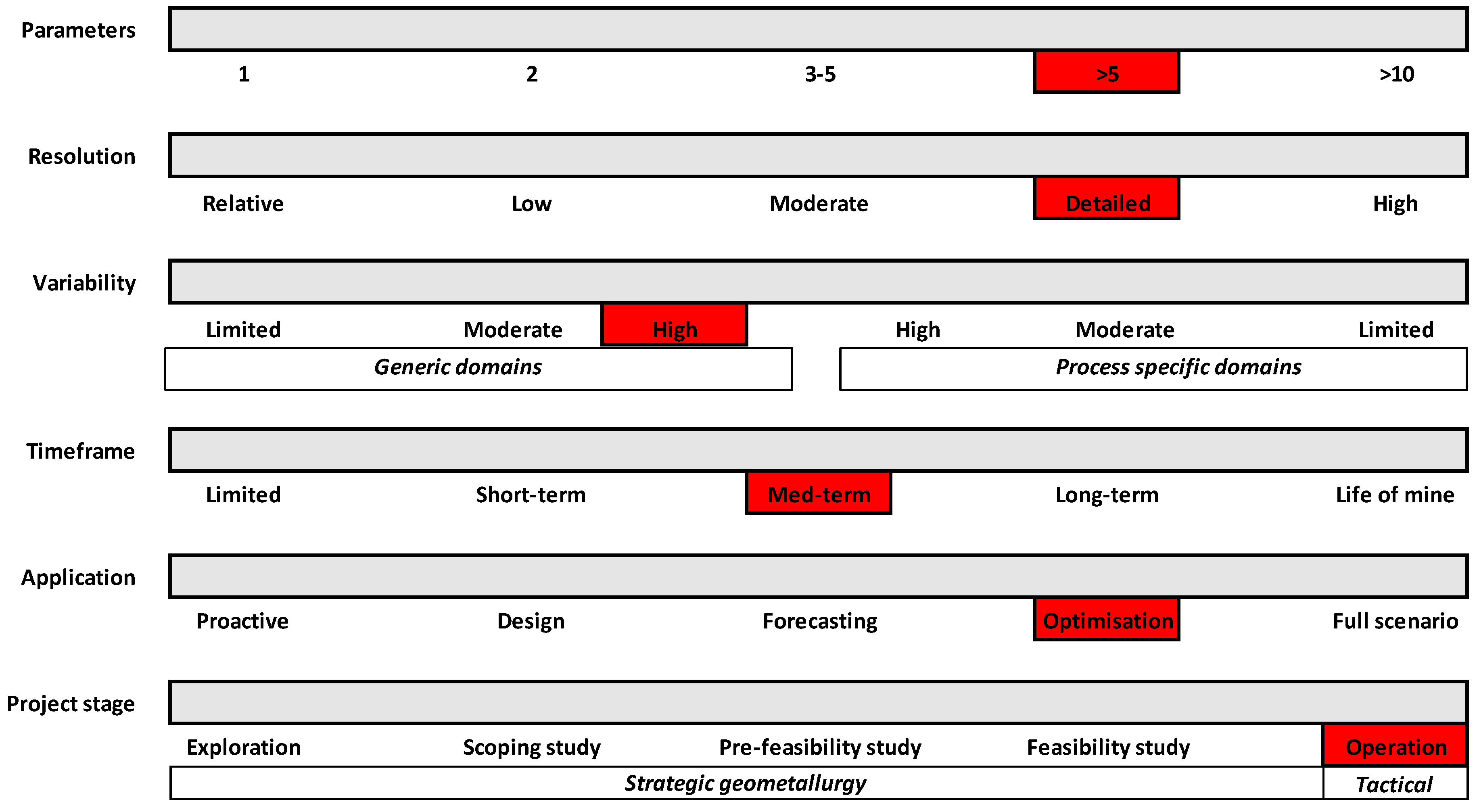

2.3.3. Comparing and Communicating Geometallurgical Programmes

- Parameters: refers to the process parameters being modelled in the programme. These may range from rock mass (RQD and RMR), though to recovery (gravity, leach and flotation), comminution (BWi, SMC and Ai), and/or geoenvironmental parameters (NAF and PAF).

- Resolution: refers to the level of detail in a programme that may range from high to low. In some cases, a detailed knowledge of the parameter (e.g., flotation) and its components (e.g., mineralogy) are needed, whereas in others a relative indication is required. It links to data density, where more data leads to better resolution (e.g., lower uncertainty).

- Variability: A generic domain is a 3D volume based on a geological variable(s) such as lithology or alteration, which may or may not be statistically homogenous for the response(s) in question. A process specific domain is a 3D volume where the response variable under consideration comes from a statistically homogenous population. Within a given domain, there will be a range of variability knowledge from limited to high, where knowledge extends to many or all drill holes within the domains.

- Timeframe: refers to the volume of mineralisation in question as nominal production periods. The shortest time period is limited—essentially a snapshot sampling campaign of a section of the deposit or across the deposit with a broad life of mine view. Other periods are project dependent as short-term (e.g., 6 months), medium-term (e.g., 6–18 months), and long-term (e.g., >18 months or more) production periods.

- Application: relates to how the geometallurgical information is used and ranges from proactive (e.g., developing the programme) through to enough data to provide key parameter forecasts on a given timeframe, and ultimately full scenario-based assessment.

- Project stage: at what stage of the MVC the project sits.

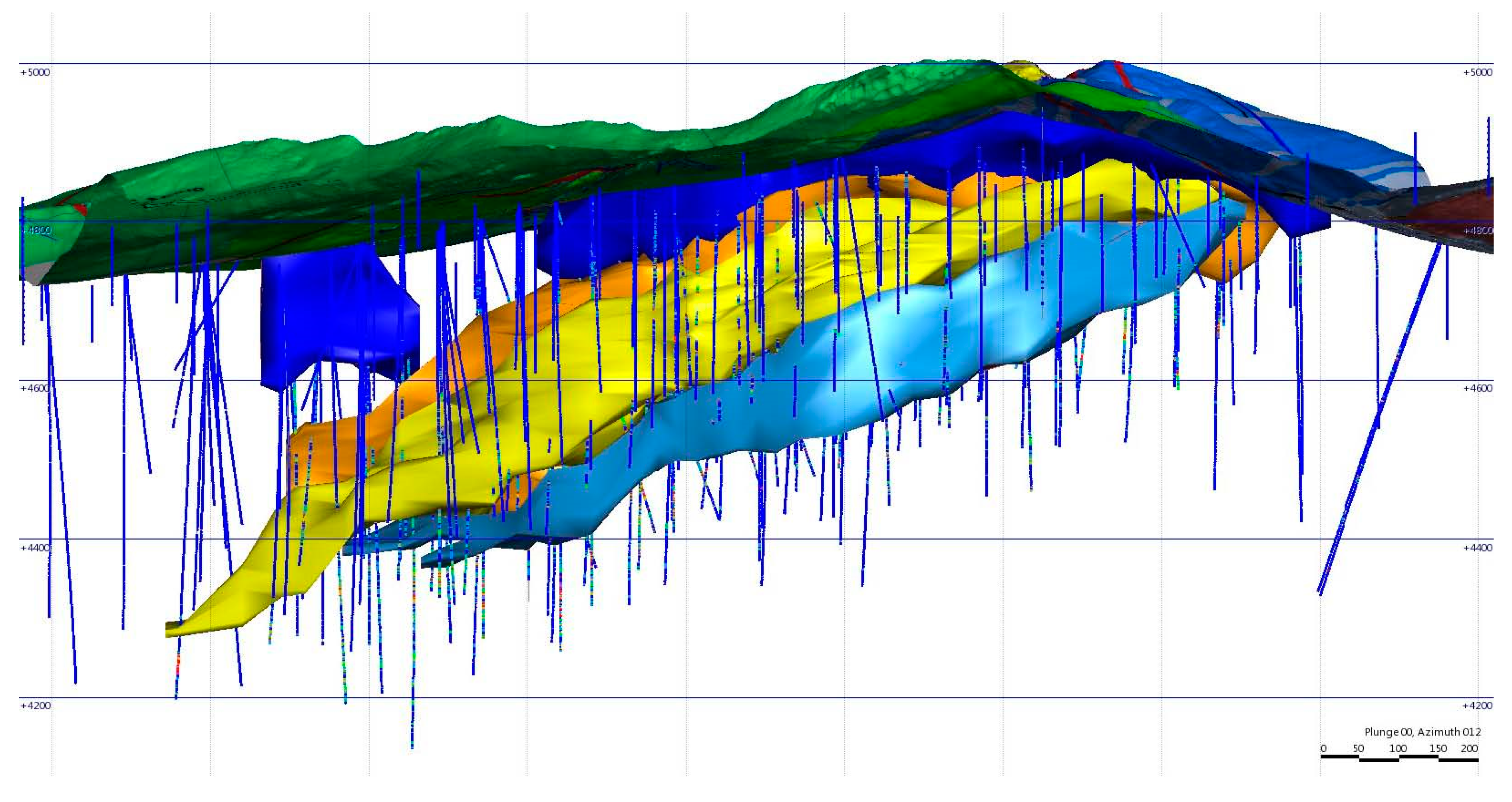

2.3.4. Building Orebody Knowledge

3. Stages and Strategies for Modern Geometallurgy

3.1. Introduction

3.2. Strategic Geometallurgy

3.3. Tactical Geometallurgy

3.4. Geoenvironmental Aspects of Geometallurgy

4. Key Dimensions of Geometallurgy

4.1. Introduction

4.2. Sampling

4.2.1. Introduction

4.2.2. Theory of Sampling and Sampling Errors

- ○

- Distribution of single mineral grains or clusters distributed through the ore domain(s).

- ○

- Continuity of structures or domains such as high-grade carriers within the main host structure or vein-lets within wall rocks.

- ○

- Sample support (sample size—volume-variance).

- ○

- Sample density (number of samples at a given spacing—information effect).

- ○

- Sample collection, preparation, testwork, and assay procedures.

4.2.3. Geometallurgical Sampling

4.2.4. Programme Quality Assurance/Quality Control

4.2.5. Compliance with Reporting Codes

4.3. Ore and Waste Characterisation

4.3.1. Analysis of Textures

4.3.2. Advanced Mineralogical Characterisation

4.3.3. Automated Core Scanning

4.3.4. Down-the-Hole Prediction

4.4. Domains and Models

4.4.1. Domains

4.4.2. Models

- Identify the variables required to understand critical process responses.

- Sample and measure these variables.

- Develop techniques to estimate and simulate these characteristics spatially at the correct scale and incorporate the values into block models.

4.5. Financial Modelling

4.6. Acid and Metalliferous Drainage Prediction

4.7. Waste Management and Recycling

4.8. The Digital Mine

5. Managing Geometallurgical Programmes

5.1. Overview

5.2. Geometallurgical Education

5.3. Geometallurgical Challenges

- Gaining corporate support—projects may require separate financing.

- Geometallurgical teaching—integration across disciplines, including emerging disciplines such as data analytics, artificial intelligence, machine learning, and automation.

- Implementation of studies across a wide range of technical disciplines (e.g., silos) and ensuring silos are broken down to effect data sharing and optimal communication.

- Application across feasibility studies and mine operations.

- Representative sampling programmes and effective ore/waste characterisation.

- Ensuring fit-for-purpose data through proper procedures and QA/QC programmes.

- Integration and interpretation of very large databases.

- Modelling/simulation of numerous different data types.

- Process and mine optimisation tools.

- Developing effective innovations across characterisation, data collection, and modelling, including data analytics, artificial intelligence, and machine learning.

- Ensuring that geometallurgical programmes are fit for purpose and can be reported in accordance with The JORC (2012) or other reporting codes.

5.4. The Future of Geometallurgy

6. Conclusions

- (1)

- Geometallurgy is the integration and utilisation of geological, metallurgical, environmental, and economic information to maximise the value of an orebody, to minimise technical and operational risk, and build a resilient operation. Through a multi-disciplinary approach, it identifies attributes that contribute to the realised value of a resource and enables ore variability to be factored into the flowsheet, infrastructure design, and the production and quality forecasts over the LOM. This includes traditional attributes, such as grade, as well as process factors such as hardness (e.g., crushability and grindability), mineral species and abundance, mineral liberation, metallurgical recovery, concentration of deleterious elements, and acid generating and neutralising potential.

- (2)

- Geometallurgy has reached a maturity beyond a “geology-mineralogy plus metallurgy” activity, though the input and integration of the two is critical. It is recognised as an approach that can both maximise value and predict the risks associated with resource development and mine operations. It is not a “quick fix”, but a long-term commitment to adding value. Geometallurgy complements, but does not replace, existing approaches to design and optimisation of mining and processing operations. Critically, geometallurgical issues vary from one deposit to another, thus there is no fit-all template that can be used.

- (3)

- Key drivers for the geometallurgical approach relate to lower grades and geologically and/or metallurgically more complex orebodies; high grade and metallurgical response variability; increased capital costs and declining profit margins, thus higher financial risk; and the need for well-managed project risk to attract funding.

- (4)

- The process of ore variability testing for metallurgical response and the use of fast, inexpensive metallurgical proxies have been developed in the past decade. Technology continues to advance, and techniques such as hand-held analytical tools, automated core scanning, and down-the-hole measurements allow for faster, less expensive testing.

- (5)

- There is general acceptance within the mining industry that assumed modifying factors defined by the 2012 JORC Code are not sufficient to mitigate the risk of funding projects. The geometallurgical approach is to move away from factored Ore Reserves to data-rich block models providing information for mining, metallurgical, and environmental considerations. Uncertainty models can be derived from this data to support the classification of geometallurgical parameters such as throughput and recovery into reserve categories. The application of geometallurgy generally has the favourable consequence of increasing Mineral Resource to Ore Reserve conversion.

- (6)

- The future sees more challenging and complex deposits being developed, where variability in both orebody and external factors will be material. The data-rich nature of geometallurgy allows orebody variability to be incorporated into an optimised mine plan. The geometallurgical approach has tended to be used on large multi-million tonne type deposits, though is now becoming applied more to smaller deposits and across different commodities.

- (7)

- Geometallurgy encompasses activities that utilise improved understanding of the properties of ore and waste, which impact positively or negatively on the value of the product, concentrate, or metal. Properties not only include those that impact on processing efficiency, but also those of materials which will impact upon other actions such as rock stability, blasting, and waste disposal. Companies that embrace the geometallurgical approach will benefit from increased shareholder value.

- (8)

- Geometallurgy leads to improved team work and communication during project studies and mining. It straddles diverse technical and managerial areas, optimising exploitation by taking an holistic view. Additionally, geometallurgy aims to identify and mitigate technical risk during project development and production. These objectives require strong cross-technical domain communication driven by professionals with the correct technical and leadership skills.

- (9)

- The application of geometallurgy across the MVC aims to improve project resilience and success through a number of ways:

- Identify orebody variability and develop strategies to mitigate the risks (e.g., collect additional data; revise the mine plan; adapt or change the process strategy, or engineer flexibility into the system).

- Identify system constraints and how these impact on performance across the MVC and allow project re-engineering to reduce or eliminate such constraints.

- Assess financial options to support the operation from construction through to sustainable production.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| A*b | Impact indices derived from SMC test |

| Ai | Abrasion index |

| AMA | Automated mineralogical analysis |

| AMD | Acid mine drainage |

| BWi | Bond work index |

| CAPEX | Capital expenditure |

| EQUOtip | EQUOtip hardness tester |

| FS | Feasibility study |

| GEOTEK | Core imaging system |

| GNE | Geological (or in-situ) nugget effect |

| GRG | Gravity recoverable gold |

| HRXCT | High resolution X-ray computed tomography |

| JKCI | JK comminution index |

| JKFI | JK floatability index |

| JKRBT | JK rock breakage test |

| JORC | Joint Ore Reserves Committee, The JORC Code 2012 [60] |

| (LA)-ICPAES/MS | (Laser ablation)-Inductively coupled atomic emission/mass spectrometry |

| LIBS | Laser induced backscatter spectroscopy |

| LOM | Life-of-mine |

| MLA | Mineral liberation analysis |

| MVC | Mine value chain |

| MWD | Measure while drilling |

| NAF | Net acid forming |

| NPV | Net Present Value |

| PAF | Potentially acid forming |

| PFS | Pre-feasibility study |

| PXRF | Portable X-ray florescence |

| RQD | Rock quality designation |

| SEM | Scanning electron microscopy |

| SG | Specific gravity |

| SMC | SAG mill comminution test |

| SMU | Selective mining unit |

| SNE | Sampling nugget effect |

| SPI | SAG power index |

| TIMA | Tescan integrated mineral analysis system |

| TOS | Theory of Sampling (individual TOS errors defined in Table 3) |

| QA/QC | Quality assurance/quality control |

| Q/PXRD | Quantitative/portable X-ray diffraction |

References

- Ehrig, K. Geometallurgy—What do you really need to know from exploration through to production. In We are Metallurgists, Not Magicians; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2018; pp. 33–36. [Google Scholar]

- Ashley, K.J.; Callow, M.I. Ore variability: Excercises in geometallurgy. Eng. Min. J. 2000, 201, 24–28. [Google Scholar]

- Bye, A.R. Case studies demonstrating value from geometallurgy initiatives. In Proceedings of the International Geometallurgy Conference, Brisbane, Australia, 5–7 September 2011; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2011; pp. 3–90. [Google Scholar]

- Vann, J.; Jackson, S.; Bye, A.; Coward, S.; Moayer, S.; Nicholas, G.; Wolff, R. Scenario thinking—A powerful tool for strategic planning and evaluation of mining projects and operations. In Proceedings of the Project Evaluation Conference, Melbourne, Australia, 24–25 May 2012; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2012; pp. 5–14. [Google Scholar]

- Rendu, J.-M. Risk Management in Evaluating Mineral Deposits; Society of Mining, Metallurgy and Exploration: Englewood, CO, USA, 2017; p. 310. [Google Scholar]

- Walters, S. An overview of new integrated geometallurgical research. In Proceedings of the International Congress for Applied Mineralogy, Brisbane, Australia, 8–10 September 2008; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2008; pp. 79–82. [Google Scholar]

- Jackson, J.; McFarlane, A.; Olson Hoal, K. Geometallurgy—Back to the Future: Scoping and Communicating Geomet Programs. In Proceedings of the International Geometallurgy Conference, Burwood, Australia, 5–7 September 2011; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2011; pp. 125–131. [Google Scholar]

- Keeney, L. A geometallurgical methodology suitable for resource definition. SEG Newsl. 2013, 94, 18–19. [Google Scholar]

- Williams, S.R. A historical perspective of the application and success of geometallurgical methodologies. In Proceedings of the International Geometallurgy Conference, Brisbane, Australia, 30 September–2 October 2013; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2013; pp. 37–47. [Google Scholar]

- Lund, C.; Lamberg, P. Geometallurgy—A tool for better resource efficiency. Eur. Geol. 2014, 37, 39–43. [Google Scholar]

- Glass, H.J. Geometallurgy: Driving innovation in the mine value chain. In Proceedings of the International Geometallurgy Conference, Perth, Australia, 15–16 June 2016; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2016; pp. 21–28. [Google Scholar]

- Jackson, S.; Vann, J.E.; Coward, S.; Moayer, S. Scenario-based project evaluation—Full mineral value chain stochastic simulation to evaluate development and operational alternatives. In Proceedings of the International Mining Geology Conference, Adelaide, Australia, 18–20 August 2014; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2014; pp. 1–11. [Google Scholar]

- Coward, S.; Dowd, P.A. Geometallurgical models for the quantification of uncertainty in mining project value chains. In Proceedings of the APCOM Conference, Fairbanks, AK, USA, 23–27 May 2015; Society of Mining Engineers: Englewood, CO, USA, 2015; pp. 360–369. [Google Scholar]

- Shi, F.; Kojovic, T.; Larbi-Bram, S.; Manlapig, E. Development of a rapid particle breakage characterisation device—The JKRBT. Miner. Eng. 2009, 22, 602–612. [Google Scholar] [CrossRef]

- Kojovic, T.; Michaux, S.; Walters, S. Developments of new comminution testing methodologies for geometallurgical mapping of ore hardness and throughput. In Proceedings of the International Mineral Processing Congress, Brisbane, Australia, 6–10 September 2010; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2010; pp. 891–899. [Google Scholar]

- Bradshaw, D.J.; Vos, F. The development of a small scale test for rapid characterisation of flotation response (JKMSI). In Proceedings of the Canadian Mineral Processors Operators Conference, Ottawa, ON, Canada, 22–24 January 2013; Canadian Institute of Mining: Ottawa, ON, Canada, 2013; pp. 43–57. [Google Scholar]

- Vos, C.F.; Stange, W.; Bradshaw, D.J. A new small-scale test to determine flotation performance: Overall performance. Miner. Eng. 2014, 66, 62–67. [Google Scholar] [CrossRef]

- McKay, N.; Vann, J.; Ware, W.; Morley, C.; Hodkiewicz, P. Strategic versus tactical geometallurgy—A systematic process to add and sustain resource value. In Proceedings of the International Geometallurgy Conference, Perth, Australia, 15–16 June 2016; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2016; pp. 29–36. [Google Scholar]

- Baumgartner, R.; Dusci, M.; Gressier, J.; Trueman, A.; Poos, S.; Brittan, M.; Mayata, P. Building a geometallurgical model for early-stage project development—A case study from the Canahuire epithermal Au-Cu-Ag deposit, Peru. In Proceedings of the International Geometallurgy Conference, Brisbane, Australia, 5–7 September 2011; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2011; pp. 53–59. [Google Scholar]

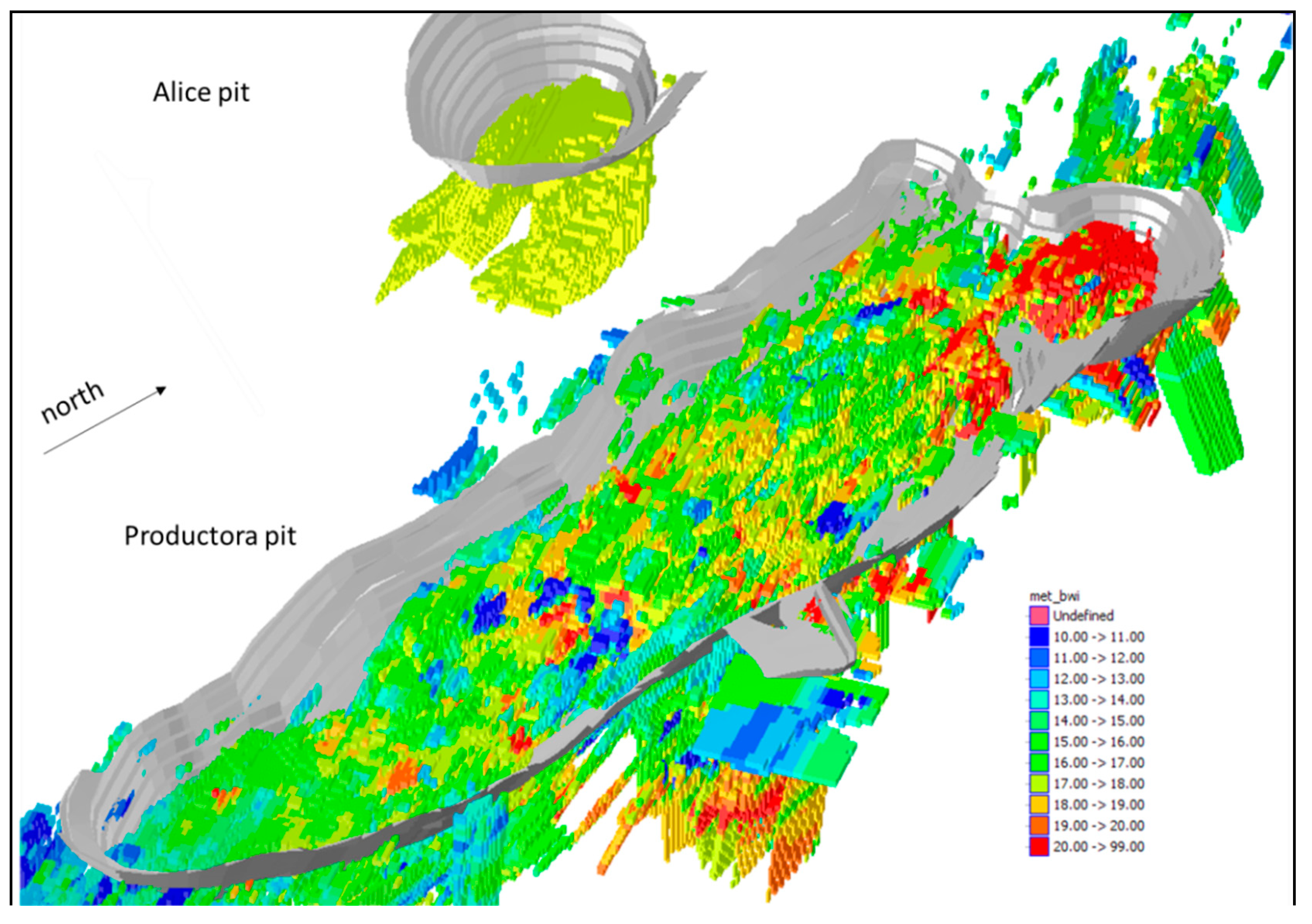

- King, G.S.; Macdonald, J.L. The business case for early-stage implementation of geometallurgy—An example from the Productora Cu-Au-Mo deposit, Chile. In Proceedings of the International Geometallurgy Conference, Perth, Australia, 15–16 June 2016; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2016; pp. 125–133. [Google Scholar]

- Dowd, P.A. Quantifying the impacts of uncertainty. In Handbook of Mathematical Geosciences; Springer Open: Cham, Switzerland, 2018; pp. 349–373. [Google Scholar]

- Dominy, S.C.; O’Connor, L.; Glass, H.J.; Xie, Y. Geometallurgical study of a gravity recoverable gold orebody. Minerals 2018, 8, 186. [Google Scholar] [CrossRef]

- Dominy, S.C.; O’Connor, L.; Glass, H.J.; Purevgerel, S.; Xie, Y. Towards representative metallurgical sampling and recovery testwork programmes. Minerals 2018, 8, 193. [Google Scholar] [CrossRef]

- Kittler, P.; Liebezeit, V.; Ehrig, K.; Macmillan, E.; Lower, C. “It seemed like a good idea at the time…”—Common mistakes in geometallurgy. In Proceedings of the International Geometallurgy Conference, Brisbane, Australia, 5–7 September 2011; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2011; pp. 133–138. [Google Scholar]

- Coward, S.; Vann, J.; Dunham, S.; Stewart, M. The primary-response framework for geometallurgical variables. In Proceedings of the International Mining Geology Conference, Perth, Australia, 17–19 August 2009; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2009; pp. 109–113. [Google Scholar]

- Hunt, J.; Kojovic, T.; Berry, R.J. Estimating comminution indices from ore mineralogy, chemistry and drill core logging. In Proceedings of the International Geometallurgy Conference, Brisbane, Australia, 30 September–2 October 2013; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2013; pp. 173–176. [Google Scholar]

- Keeney, L.; Nguyen, K. The use of EQUOtip as a hardness domaining tool. In Proceedings of the International Mineral Processing Congress, Santiago, Chile, 20–24 October 2014; GECAMIN: Santiago, Chile, 2014; pp. 128–138. [Google Scholar]

- Mwanga, A.; Rosenkranz, J.; Lamberg, P. Testing of ore comminution behaviour in the geometallurgical context—A review. Minerals 2015, 5, 276–297. [Google Scholar] [CrossRef]

- Aasly, K.; Ellefmo, S. Geometallurgy applied to industrial minerals operations. Mineralsproduksjon 2014, 5, A21–A34. [Google Scholar]

- Butler, C.; Dale, R.; Robinson, S.; Turner, A. Geometallurgy—bridging the gap between mine and mill: A case study of the DeGrussa geometallurgy programme. In Proceedings of the International Geometallurgy Conference, Perth, Australia, 15–16 June 2016; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2016; pp. 77–88. [Google Scholar]

- Harbort, G.J.; Lam, K.; Sola, C. The use of geometallurgy to estimate comminution parameters within porphyry copper deposits. In Proceedings of the International Geometallurgy Conference, Brisbane, Australia, 30 September–2 October 2013; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2013; pp. 217–230. [Google Scholar]

- Macfarlane, A.S.; Williams, T.P. Optimising value on a copper mine by adopting a geometallurgical solution. J. South. Afr. Inst. Min. Metall. 2014, 114, 929–936. [Google Scholar]

- Montoya, P.; Keeney, L.; Jahoda, R.; Hunt, J.; Berry, R.; Drews, U.; Chamberlain, V.; Leichliter, S. Geometallurgical modelling techniques applicable to pre-feasibility projects—La Colosa case study. In Proceedings of the International Geometallurgy Conference, Brisbane, Australia, 5–7 September 2011; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2011; pp. 103–111. [Google Scholar]

- Leichliter, S.; Larson, D. Geometallurgy for two recovery process operations at Cripple Creek and Victor gold mine. Min. Eng. 2013, 65, 29–33. [Google Scholar]

- Liebezeit, V.; Ehrig, K.; Robertson, A.; Grant, D.; Smith, M.; Bruyn, H. Embedding geometallurgy into mine planning practices—Practical examples at Olympic Dam. In Proceedings of the International Geometallurgy Conference, Perth, Australia, 15–16 June 2016; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2016; pp. 135–143. [Google Scholar]

- Lechuti-Tlhalerwa, R.B.; Gilika, O.; Field, M. Modelling geometallurgical variability of comminution parameters in Orapa kimberlite ore. In Proceedings of the Geometallurgy Conference, Cape Town, South Africa, 7–8 August 2018; Southern African Institure of Mining and Metallurgy: Johannesburg, South Africa, 2018; pp. 253–263. [Google Scholar]

- Baumgartner, R.; Dusci, M.; Trueman, A.; Poos, S.; Brittan, M. Building a geometallurgical model for the Canahuire epithermal Au-Cu-Ag deposit, Peru—Past, present and future. In Proceedings of the International Geometallurgy Conference, Brisbane, Australia, 30 September–2 October 2013; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2013; pp. 51–57. [Google Scholar]

- Ehrig, K.; Liebezeit, V.; Smith, M.; Macmillan, E.; Lower, C. Geologists and the value chain—How material charaqcterisation by modern mineralogy can optimise design and operation of processing facilities. In Proceedings of the International Mining Geology Conference, Adelaide, South Australia, 18–20 August 2014; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2014; pp. 5–13. [Google Scholar]

- McCarthy, P. Managing technical risk for mine feasibility studies. In Proceedings of the Mining Risk Management Conference, Sydney, Australia, 9–12 September 2003; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2003; pp. 21–27. [Google Scholar]

- Keeney, L. The Development of a Novel Method for Integrating Geometallurgical Mapping and Orebody Mapping. Ph.D. Thesis, University of Queensland, Brisbane, Australia, 2010; p. 324. [Google Scholar]

- Carrasco, C.; Keeney, L.; Walters, S. Development of geometallurgical laboratory tests to characterize metal preconcentration by size. In Proceedings of the International Mineral Processing Congress, Santiago, Chile, 20–24 October 2014; GECAMIN: Santiago, Chile, 2014; pp. 139–159. [Google Scholar]

- Ehrig, K.; Pitard, F.F. Sampling the supergiant Olympic Dam iron-oxide Cu-U-Au-Ag deposit, South Australia. In Proceedings of the World Conference on Sampling and Blending, Perth, Australia, 9–11 May 2017; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2017; pp. 21–27. [Google Scholar]

- Liebezeit, V.; Smith, M.; Ehrig, K.; Kittler, P.; MacMillan, E.; Lower, C. Geometallurgy data management—A significant consideration. In Proceedings of the International Geometallurgy Conference, Brisbane, Australia, 5–7 September 2011; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2011; pp. 237–245. [Google Scholar]

- David, D. Geometallurgical guidelines for miners, geologists and process engineer—Discovery to design. In Mineral Resource and Ore Reserve Estimation Guide to Good Practice; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2014; pp. 443–450. [Google Scholar]

- Goers, M.; Almond, M. Bit to bag—The importance of a total coordinated system in RC drilling. In Proceedings of the Sampling Conference, Perth, Australia, 21–22 August 2012; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2012; pp. 65–77. [Google Scholar]

- Dominy, S.C.; Glass, H.J.; Lam, C.K.; O’Connor, L.; Purevgerel, S.; Minnitt, R.C.A. Integrating the Theory of Sampling into underground grade control strategies. Minerals 2018, 8, 232. [Google Scholar] [CrossRef]

- Mudd, G.M. The Sustainability of Mining in Australia—Key Production Trends and Their Environmental Implications for the Future; Monash University and Mineral Policy Institute: Melbourne, Australia, 2009; p. 277. [Google Scholar]

- Adiansyah, J.S.; Rosano, M.; Vink, S.; Keir, G. A framework for a sustainable approach to mine tailings management: Disposal strategies. J. Clean. Prod. 2015, 108, 1050–1062. [Google Scholar] [CrossRef]

- Noble, T.L.; Parbhakar-Fox, A.; Berry, R.F.; Lottermoser, B.G. Mineral dust emissions at metalliferous mine sites. In Environmental Indicators in Metal Mining; Springer International: Cham, Switzerland, 2017; pp. 281–306. [Google Scholar]

- Parbhakar-Fox, A.; Lottermoser, B.G. A critical review of acid rock drainage prediction methods and practices. Miner. Eng. 2015, 82, 107–124. [Google Scholar] [CrossRef]

- Parbhakar-Fox, A.; Dominy, S.C. Sampling and blending in geoenvironmental campaigns—Current practice and future opportunities. In Proceedings of the World Conference on Sampling and Blending, Perth, Australia, 9–11 May 2017; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2017; pp. 45–54. [Google Scholar]

- Parbhakar-Fox, A.; Glen, J.; Raimondo, B. A Geometallurgical approach to tailings management: An example from the Savage River Fe-Ore mine, Western Tasmania. Minerals 2018, 8, 454. [Google Scholar] [CrossRef]

- Jackson, L.M.; Parbhakar-Fox, A.; Fox, N.; Cooke, D.R.; Harris, A.C. Assessing geoenvironmental risk using intact materials for early life-of-mine planning—A review of established techniques and emerging tools. In From Start to Finish: A Life-of-Mine Perspective; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2018; pp. 1–18. [Google Scholar]

- Gy, P.M. Sampling of Particulate Materials: Theory and Practice; Elsevier: Amsterdam, The Netherlands, 1982; p. 431. [Google Scholar]

- Pitard, F.F. Pierre Gy’s Sampling Theory and Sampling Practice; CRC Press: Boca Raton, FL, USA, 1993; p. 488. [Google Scholar]

- Minnitt, R.C.A. Sampling: The impact on costs and decision making. J. South. Afr. Inst. Min. Metall. 2007, 107, 451–462. [Google Scholar]

- Dominy, S.C. Effects of sample mass on gravity recoverable gold test results in low grade ores. Appl. Earth Sci. 2014, 123, 234–242. [Google Scholar] [CrossRef]

- Dominy, S.C. Predicting the unpredictable—Evaluating high-nugget effect gold deposits. In Mineral Resource and Ore Reserve Estimation; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2014; pp. 659–678. [Google Scholar]

- Ehrig, K.; Liebezeit, V.; Macmillan, E. Metallurgical QAQC–who needs it? The Olympic Dam experience. In Proceedings of the Metallurgical Plant Design and Operating Strategies, Perth, Australia, 11–12 September 2017; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2017; pp. 31–44. [Google Scholar]

- Joint Ore Reserves Committee (JORC). Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves—The JORC Code; Joint Ore Reserves Committee of the Australasian Institute of Mining and Metallurgy, Australian Institute of Geoscientists and Minerals Council of Australia: Melbourne, Australia, 2012; p. 44. [Google Scholar]

- DS3077. Representative Sampling–Horizontal Standard; Danish Standards Foundation: Copenhagen, Denmark, 2013; p. 41. [Google Scholar]

- Perez-Barnuevo, L.; Castroviejo, R.; Pirard, E. New perspectives on quantitative textural analysis. In Proceedings of the International Geometallurgy Conference, Brisbane, Australia, 30 September–2 October 2013; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2013; pp. 191–197. [Google Scholar]

- Lobos, R.; Silva, J.F.; Ortiz, J.M.; Diaz, G.; Egana, A. Analysis and classification of natural rock textures based on new transform-based features. Math. Geosci. 2016, 48, 835–870. [Google Scholar] [CrossRef]

- Zhou, J.; Gu, Y. Geometallurgical characterisation and automated mineralogy of gold ores. In Advances in Gold Ore Processing; Elsevier: Amsterdam, The Netherlands, 2016; pp. 95–111. [Google Scholar]

- Dominy, S.C.; Platten, I.M.; Xie, Y.; Cuffley, B.W.; O’Connor, L. Characterisation of gold ore from the Nick O’Time shoot (Tarnagulla, Australia) using high resolution X-ray computed tomography. In Proceedings of the International Geometallurgy Conference, Perth, Australia, 15–16 June 2016; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2016; pp. 241–254. [Google Scholar]

- Miller, J.D.; Lin, C.L. High resolution X-ray micro CT (HRXMT)—Advances in 3D particle characterisation for mineral processing operations. In Recent Advances in Mineral Processing Plant Design; Society of Mining, Metallurgy and Exploration: Englewood, CO, USA, 2009; pp. 48–59. [Google Scholar]

- Evans, C.L.; Wightman, E.M.; Yuan, X. Quantifying mineral grain size distributions for process modelling using X-ray micro-tomograph. Miner. Eng. 2015, 82, 78–83. [Google Scholar] [CrossRef]

- Harraden, C.L.; Berry, R.; Lett, J. Proposed methodology for utilising automated core logging technology to extract geotechnical index parameters. In Proceedings of the International Geometallurgy Conference, Perth, Australia, 15–16 June 2016; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2016; pp. 114–124. [Google Scholar]

- Walters, S. A review of core scanning sensor technologies to support routine geometallurgical logging and spatial characterisation. In Proceedings of the International Seminar on Geometallurgy, Santiago, Chile, 5–7 December 2012; GECAMIN: Santiago, Chile, 2012; pp. 102–103. [Google Scholar]

- Vantandoost, A.; Fullagar, P. Characterisation of ore crushability using petrophysical properties. In Proceedings of the International Mining Geology Conference, Perth, Australia, 17–19 August 2009; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2009; pp. 119–124. [Google Scholar]

- Jackson, L.M.; Parbhakar-Fox, A.; Fox, N.; Cooke, D.R.; Harris, A.C. Intrinsic neutralisation potential from automated drill core logging for improved geoenvironmental domaining. In Proceedings of the Australian Workshop on Acid and Metalliferous Drainage 2017, Burnie, Australia, 20–23 November 2017; University of Queensland: Brisbane, Australia, 2017; pp. 378–392. [Google Scholar]

- Linton, P.; Browning, D.; Pendock, N.; Harris, P.; Donze, M.; Mxinwa, T.; Mushiana, K. Hyperspectral data applied to geometallurgy. In Proceedings of the Geometallurgy Conference, Cape Town, South Africa, 7–8 August 2018; Southern African Institure of Mining and Metallurgy: Johannesburg, South Africa, 2018; pp. 109–120. [Google Scholar]

- Huntington, J.; Quigley, M.; Yang, K.; Roache, T.; Young, C.; Roberts, I.; Whitbourn, I.L.; Mason, P. A geological overview of HyLogging 18 000 m of core from the Eastern Goldfields of Western Australia. In Proceedings of the International Mining Geology Conference, Darwin, Australia, 21–23 August 2004; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2006; pp. 45–50. [Google Scholar]

- Parbhakar-Fox, A.; Lottermoser, B.G. Predictive waste classification using field-based and environmental geometallurgy indicators, Mount Lyell, Tasmania. In Environmental Indicators in Metal Mining; Springer International: Cham, Switzerland, 2017; pp. 157–177. [Google Scholar]

- Cracknell, M.J. Image texture quantification from Corescan mineral classifications. In Proceedings of the International Association for Mathematical Geosciences Conference, Perth, Australia, 2–9 September 2017; International Association for Mathematical Geosciences: Houston, TX, USA, 2017; p. 130. [Google Scholar]

- Cracknell, M.J.; Parbhakar-Fox, A.; Jackson, L.; Savinova, E. Automated acid rock drainage indexing from drill core imagery. Minerals 2018, 8. Accepted. [Google Scholar]

- Mahmoodi, O.; Smith, R.S.; Tinkham, D.K. Supervised classification of down-hole physical properties measurements using neural network to predict the lithology. J. Appl. Geophys. 2016, 124, 17–26. [Google Scholar] [CrossRef]

- Hegde, C.; Gray, K. Evaluation of coupled machine learning models for drilling optimization. J. Nat. Gas Sci. Eng. 2018, 56, 397–407. [Google Scholar] [CrossRef]

- Kitzig, M.; Kepic, A.; Grant, A. Near real-time classification of iron ore lithology by applying fuzzy inference systems to petrophysical downhole data. Minerals 2018, 8, 276. [Google Scholar] [CrossRef]

- Vezhapparambu, V.S.; Eidsvik, J.; Ellefmo, S.L. Rock classification using multivariate analysis of measurement while drilling data: Towards a better sampling strategy. Minerals 2018, 8, 384. [Google Scholar] [CrossRef]

- Babaei Khorzoughi, M.; Hall, R. Processing of measurement while drilling data for rock mass characterization. Int. J. Min. Sci. Technol. 2016, 26, 989–994. [Google Scholar] [CrossRef]

- Kadkhodaie-Ilkhchi, A.; Monterio, S.T.; Ramos, F.; Hatherly, P. Rock recognition from MWD data: A comparative study of boosting, neural networks and fuzzy logic. IEEE Geosci. Remote Sens. Lett. 2010, 7, 680–684. [Google Scholar] [CrossRef]

- Dowd, P.A.; Xu, C.; Coward, S. Strategic mine planning and design: Some challenges and strategies for addressing them. Min. Technol. 2016, 125, 22–34. [Google Scholar] [CrossRef]

- Dunham, S.; Vann, J. Geometallurgy, geostatistics and project value—Does your block model tell you what you need to know. In Proceedings of the Project Evaluation Conference, Melbourne, Australia, 19–20 June 2007; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2007; pp. 189–196. [Google Scholar]

- Carrasco, P.; Chilès, J.-P.; Seguret, S. Additivity, metallurgical recovery and grade. In Proceedings of the International Geostatistics Congress, Santiago, Chile, 1–5 December 2008; GECAMIN: Santiago, Chile, 2008; pp. 237–246. [Google Scholar]

- Deutsch, C.V. Geostatistical modelling of geometallurgical variables—Problems and solutions. In Proceedings of the International Geometallurgy Conference, Brisbane, Australia, 30 September–2 October 2013; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2013; pp. 7–15. [Google Scholar]

- Deutsch, J.L.; Palmer, K.; Deutsch, C.V.; Szymanski, J.; Etsell, T.H. Spatial modelling of geometallurgical properties: Techniques and a case study. Nat. Resour. Res. 2016, 25, 161–181. [Google Scholar] [CrossRef]

- Muhammad, K.; Glass, H.J. Short-scale variability and uncertainty during mineral resource estimation using a novel fuzzy estimation technique. Geostand. Geoanal. Res. 2011, 35, 369–385. [Google Scholar] [CrossRef]

- Sepulveda, E.; Dowd, P.A.; Xu, C.; Addo, E. Multivariate modelling of geometallurgical variables by point projection. Math. Geol. 2017, 49, 121–143. [Google Scholar]

- Addo, E.; Metcalfe, A.V.; Chanda, E.K.; Sepulveda, E.; Assibey-Bonsu, W.; Adeli, A. Prediction of copper recovery from geometallurgical data using D-vine cupolas. In Proceedings of the Geometallurgy Conference, Cape Town, South Africa, 7–8 August 2018; Southern African Institute of Mining and Metallurgy: Johannesburg, South Africa, 2018; pp. 75–88. [Google Scholar]

- Alruiz, O.M.; Morell, S.; Suazo, C.J.; Naranjo, A. A novel approach to the geometallurgical modelling of the Collahuasi grinding circuit. Miner. Eng. 2009, 22, 1060–1067. [Google Scholar] [CrossRef]

- Powell, M.S. Utilising orebody knowledge to improve comminution circuit design and energy utilisation. In Proceedings of the International Geometallurgy Conference, Brisbane, Australia, 30 September–2 October 2013; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2013; pp. 27–35. [Google Scholar]

- Navarra, A.; Grammatikopoulos, T.; Walters, K.E. Incorporation of geometallurgical modelling into long-term production planning. Miner. Eng. 2018, 120, 118–126. [Google Scholar] [CrossRef]

- Fox, N.; Parbhakar-Fox, A.; Lottermoser, B.G. Critical and deleterious metal deportment in sulfidic waste rocks, Baal Gammon, north Queensland. In Proceedings of the International Geometallurgy Conference, Perth, Australia, 15–16 June 2016; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2016; pp. 173–182. [Google Scholar]

- Dold, B. Acid rock drainage prediction—A critical review. J. Geochem. Explor. 2016, 172, 120–132. [Google Scholar] [CrossRef]

- Parbhakar-Fox, A. Predicting waste properties using the geochemistry-mineralogy-texture-geometallurgy approach. In Environmental Indicators in Metal Mining; Springer International: Cham, Switzerland, 2017; pp. 73–96. [Google Scholar]

- Parbhakar-Fox, A.; Fox, N.; Jackson, L. Geometallurgical evaluations of mine waste—An example from the old tailings dam, Savage River, Tasmania. In Proceedings of the International Geometallurgy Conference, Perth, Australia, 15–16 June 2016; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2016; pp. 193–204. [Google Scholar]

- Babel, B.; Penz, M.; Schach, E.; Boehme, S.; Rudolph, M. Reprocessing of a southern Chilean Zn tailing by flotation—A case study. Minerals 2018, 8, 295. [Google Scholar] [CrossRef]

- Johnson, D.B. The evolution, current status, and future prospects of using biotechnologies in the mineral extraction and metal recovery sectors. Minerals 2018, 8, 343. [Google Scholar] [CrossRef]

- Benndorf, J.; Buxton, M.W.N. Sensor-based real-time resource model reconciliation for improved mine production control—A conceptual framework. Min. Technol. 2016, 125, 54–64. [Google Scholar] [CrossRef]

| Stage | Strategic Geometallurgy | Tactical Geometallurgy | |||

|---|---|---|---|---|---|

| Exploration-Early Evaluation | Resource Definition Drilling | Reserve Definition Drilling | Feasibility | Mining | |

| Study | Scoping (SS) | Pre-feasibility (PFS) | - | Feasibility (FS) | Grade/ore control (Expansion studies) |

| Resources/Reserves | Inferred Mineral Resources | Inferred and Indicated Mineral Resources | Mineral Resources and Ore Reserves | Mineral Resources and Ore Reserves | Mineral Resources and Ore Reserves |

| Key activity | Develop orebody knowledge Drilling and sampling | Develop orebody knowledge Drilling and sampling Data analysis and modelling | Develop orebody knowledge Drilling and sampling Data analysis and modelling | Develop orebody knowledge Drilling and sampling Data analysis and modelling | Develop orebody knowledge Drilling and sampling Data analysis and modelling |

| Inputs | Core logging Develop proxy tests Mineralogy Geochemistry Metallurgical testwork Physical testing | Core logging Proxy tests Mineralogy Geochemistry Metallurgical testwork Physical testing | Core logging Proxy tests Mineralogy Geochemistry Metallurgical testwork Physical testing | Core logging Proxy tests Mineralogy Geochemistry Metallurgical testwork, incl. pilot or trial plant testing Physical testing | Core logging Proxy tests Mineralogy Geochemistry Metallurgical testwork Physical testing |

| Outputs | Establish database Preliminary characteristics of mineralisation Geological model; Geoenvironmental | Expanded database Domains Block model Preliminary mine plan Models Preliminary process design Geoenvironmental | Expanded database across all disciplines | Expanded database Domains Block model Mine plan Models Flow sheet Scenario analysis Economic analysis Geoenvironmental | Expanded database Domains Block model Mine planModels Economic analysis Forecasts Reconciliation Geoenvironmental |

| Potential number of data 1 | 1000 s | 1000–10,000 s | +1000 s | 10,000–100,000 s | 100,000–1,000,000 s |

| Resource uncertainty 2 | High | Moderate-High | Moderate | Low | Low |

| Expected accuracy 3 | ±50% | ±25% | - | ±15% | ±10% |

| Example | Overview | Value | Reference |

|---|---|---|---|

| San Antonio Au, South America | PFS and operational (underground) execution lead to smaller high-grade selective underground mine with smaller more sustainable footprint | Increased NPV by US$15M Reduced CAPEX Revised mine plan Improved resource-reserve conversion | Dominy et al. [22] |

| Ruashi Cu-Co, DRC | Operational (open pit) application lead to model of throughput, acid consumption, and recovery. This drove an improve stockpile and plant feed strategy | Increase NPV by US$127M | Macfarlane and Williams [32] |

| Olympic Dam Cu-Au, Australia | Operational (underground) execution across the short, medium, and long term mine plan | Reduced technical risk across the current operation and future expansions due to variable ore properties | Ehrig [1]; Liebezeit et al. [35] |

| Cripple Creek and Victor Au, USA | Operational execution across the short, medium, and long term mine plan | Optimisation of different ore types to two separate process plants | Leichliter and Larson [34] |

| Productora Cu-Mo-Au, Chile | PFS stage execution to optimise mine and processing (flotation and heap leach) schedules | US$25M increase in NPV 5% reduction in CAPEX | King and Macdonald [20] |

| Degrussa Cu-Au, Australia | Operational execution to quantify key metallurgical variability | Forecasting to allow improved blend strategies and plant performance | Butler at al. [30] |

| Orapa kimberlite (diamond), Botswana | Operational (open cut) application to model kimberlite comminution properties | Feed optimisation to two process plants Improved NPV | Lechuti-Tlhalerwa, Gilika and Field [36] |

| Canahuire Cu-Au-Ag, Peru | Evaluation (PFS) stage execution in complex orebody | Preliminary definition of domains and potential metallurgical recovery variability, ARD potential, and penalty elements | Baumgartner et al. [19,37] |

| La Colosa Au, Colombia | PFS stage execution in complex orebody | Definition of comminution domains | Montoya et al. [33] |

| Stage | Activity | Test work | Outcome | Mass used |

|---|---|---|---|---|

| 1 | Continuous core logging | Logging and photography GEOTEK logger HyLogger EQUOtip | Intact core characteristics | Half HQ core in 2 m lengths (approx. 8.5 kg) |

| 2 | Texture | GEOTEK camera AMA | Core image Polished tablet image | 0.5 kg |

| 3 | Comminution | Crushing Rotary breakage device | A*b JKCI | 2 kg |

| 4 | Analysis | Assay Geochemical analysis | Assay for economic metal(s) Multi-element analysis | Approx. 6 kg (sub-sampled for stages 5–7) |

| 5 | Mineralogy | AMA | AMA on screened fractions | 1–2 kg |

| 6 | Grinding | Batch grind | Batch grind on four size fractions | 1–2 kg |

| 7 | Flotation | JK flotation index | JKFI AMA and assays on selected products | 1–2 kg |

| Stage | Activity | Actions | Outputs |

|---|---|---|---|

| 1 | Drilling | Core logging Core imaging Down-the-hole measurements | Rock types/alteration Geotechnical Geophysical |

| 2 | Testwork | Analysis Mineralogy Physical testwork Recovery testwork | Assays/geochemistry Metal/mineral deportment Comminution/hardness Flotation, leach, gravity |

| 3 | Data management | Database | Validated database |

| 4 | Modelling | Domain analysis Geological modelling Geostatistical modelling | 3D block models

Mine plan/schedule |

| Stage | Activity | Actions | Outputs |

|---|---|---|---|

| 1 | Drilling (Open pit: RC, core, and/or blasthole) (Underground: RC, core, blasthole, or faces) | Measure-while-drilling Core/chip logging | Rock types/alteration Geotechnical Geophysical |

| 2 | Testwork | Analysis Mineralogy Physical testwork Recovery testwork | Assays/geochemistry Metal/mineral deportment Comminution/hardness Flotation, leach, gravity |

| 3 | Modelling | Domain analysis Geological modelling Geostatistical modelling | Update strategic block model Ore control block model Integrated pit or underground mappingBlock allocation |

| 4 | Mining | Mine design/planning Reconciliation | Blast design (stope or bench) Blending strategy Stockpile management Validated model |

| 5 | Processing | Plant feed optimisation Reconciliation | Optimised plant Validated model |

| Location | Site/Field | Laboratory | ||||

|---|---|---|---|---|---|---|

| Stage | Planning | Collection | Transport | Preparation | Testwork | Assaying |

| 1 | 2 | 3 | 4 | 5 | 6 | |

| Activity | Scope Develop Execute | Observe Collect Bag and tag QAQC Integrity/security Chain of custody | Integrity/security Chain of custody | Equipment operation Equipment clean QAQC Integrity/security | Equipment operation Equipment clean QAQC Integrity/security | Equipment operation Equipment clean QAQC Integrity/security |

| Sampling errors | In-situ nugget effect FSE, GSE DE, EE, WE | PE | FSE, GSE DE, EE, WE, PE | FSE, GSE DE, EE, WE, PE | PE AE | |

| Dominant effect on results | Precision Bias | Bias | Precision (if splitting) Bias | Precision (if splitting) Bias | Bias | |

| Material risk assuming average practice | High | Low | Moderate | Moderate | Low | |

| Material risk assuming optimised practice | Moderate | Low | Low | Low | Low | |

| Type | Description | Relationship to Processing | Cost per Sample | Number of Samples | Sample Support | Spatial Coverage |

|---|---|---|---|---|---|---|

| Level 4 | Core composites for metallurgical testwork | Direct | High | Low | Domain or variability composites (>50 kg) | Very limited |

| Level 3 | Discontinuous core intervals for physical testwork | Direct | Moderate | Low-moderate | Relatively short lengths (<1 m) | Limited |

| Level 2 | Continuous core-based measurements | Proxies | Low | High | Measurements taken along entire core length, potentially 100 s m | Very good |

| Level 1 | Continuous core | Direct | Low | High | 1–2 m continuous core composites | Very good |

| Metallurgical factors or assumptions | 1 | The metallurgical process proposed and the appropriateness of that process to the style of mineralisation |

| 2 | Whether the metallurgical process is well-tested technology or novel in nature | |

| 3 | The nature, amount, and representativeness of metallurgical test work undertaken, the nature of the metallurgical domaining applied, and the corresponding metallurgical recovery factors applied | |

| 4 | Any assumptions or allowances made for deleterious elements | |

| 5 | The existence of any bulk sample or pilot scale test work and the degree to which such samples are considered representative of the orebody as a whole | |

| 6 | For minerals that are defined by a specification, has the ore reserve estimation been based on the appropriate mineralogy to meet the specifications? |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dominy, S.C.; O’Connor, L.; Parbhakar-Fox, A.; Glass, H.J.; Purevgerel, S. Geometallurgy—A Route to More Resilient Mine Operations. Minerals 2018, 8, 560. https://doi.org/10.3390/min8120560

Dominy SC, O’Connor L, Parbhakar-Fox A, Glass HJ, Purevgerel S. Geometallurgy—A Route to More Resilient Mine Operations. Minerals. 2018; 8(12):560. https://doi.org/10.3390/min8120560

Chicago/Turabian StyleDominy, Simon C., Louisa O’Connor, Anita Parbhakar-Fox, Hylke J. Glass, and Saranchimeg Purevgerel. 2018. "Geometallurgy—A Route to More Resilient Mine Operations" Minerals 8, no. 12: 560. https://doi.org/10.3390/min8120560

APA StyleDominy, S. C., O’Connor, L., Parbhakar-Fox, A., Glass, H. J., & Purevgerel, S. (2018). Geometallurgy—A Route to More Resilient Mine Operations. Minerals, 8(12), 560. https://doi.org/10.3390/min8120560