Abstract

Gravity beneficiation is a key operation in mineral processing and waste recycling, enabling the production of concentrates with required quality. Among gravity separators, pulsating jigs remain widely applied due to their robustness and adaptability. This study evaluates the KOMAG laboratory jig for upgrading diverse feedstocks: hard coal with variable ash content, gravel aggregates with organic impurities, post-mining waste, and battery scrap. Tests were performed on a two-chamber jig with an air-pulsation system and advanced control. The results confirmed the feasibility of obtaining coal concentrates with 8%–10% ash at 59%–71% yield, complete removal of organic contaminants from aggregates with minimal losses, and recovery of combustible fractions from post-mining waste with favourable separation parameters (d50 = 1.569 g/cm3, imperfection = 0.191). Beneficiation of shredded battery scrap achieved 74%–88% plastic removal and over 99% metallic recovery. Industrial implementations of KOMAG pulsating jigs validated these findings, showing high efficiency in coal, aggregate, and waste processing. This study demonstrates the versatility of pulsating jigging and its relevance in sustainable resource management, confirming that laboratory results can be effectively scaled to industrial practice.

1. Introduction

Most mineral resources consist of a mixture of useful components, waste rock, and oversized particles. In this form, the mineral is not suitable for direct use by potential users. Depending on the properties of each raw material, the technological process and processing operations should be selected to obtain optimal and acceptable quality parameters in the final (commercial) products [1,2].

The aim of beneficiation is to divide the material into groups with precisely defined mineralogical properties, thereby isolating valuable components from waste. This process is the most important operation for ensuring the quality of the products obtained [3].

One of the most frequently used types of enrichment is gravity beneficiation, in which differences in the physical and geometric properties of each particle are used to separate them. The water-pulsating jig is a device widely used for gravitational beneficiation, in which particles are separated in a pulsating water medium, using differences in the sedimentation rate of particles that differ in density [4,5]. This article presents the use of gravitational beneficiation with pulsating jigs for selected materials, based on tests conducted on a laboratory jig at KOMAG. This study demonstrates their potential for recovering high-quality coal from production waste and for aggregate purification. The developed laboratory jig model represents an effective, low-cost technology consistent with circular economy principles.

1.1. Development and Principles of Pulsating Jigs

Pulse jigs are currently among the most commonly used devices for the density separation of many materials (raw materials). The first remarkable description of jigging appeared only in the 16th century in De Re Metallica, the well-known seminal work by Agricola [5]. Over several centuries of existence, pulsating jigs have undergone several transformations: from mechanical induction of sieve movement (Petherick jig), through the use of an eccentric piston drive (Harz jig), to the pistonless design that marks the modern era of jigs (Baum jig). A significant step in the development of jigs was the introduction of under-sieve pulsation resulting from placing the pulsating chambers under the sieve deck (the Tacub Jig, the Batac jig). The development and introduction of electronic control systems, both for single devices and entire jig beneficiation nodes, is extremely important for improving process control and effectiveness [5].

1.2. Applications of Pulsating Jigs in Mineral Processing and Recycling

Pulsating jigs, despite the considerable popularity and advantages of heavy liquid separators (static separators, dense medium cyclones), are still often used in hard coal beneficiation [6,7,8].

Beneficiation of metal ores is another area in which pulsating jigs are widely used. For example, at the Noamundi iron ore mine in India, a BATAC jig is used to reduce alumina in particles sized 10–0.5 mm [9,10]. At the Sishen mine in South Africa, jigs enrich material in the size ranges 25–8 mm, 8–3 mm, and 3–1 mm, with separation densities exceeding 3.6 g/cm3 [11].

Denver Mineral and Harz jigs were also tested in the laboratory to purify low-grade iron ore from silica and alumina. The experimental variables used to determine the effectiveness of the process included particle size, water flow rate, and amplitude, and the results were found to be very close to the theoretical results obtained in density distribution tests [12].

The test results [13] and the implementation of industrial jigs intended for beneficiation of manganese ore [14] are known. The process tested on a pilot scale in Gabon allowed an increase in element concentration and production of a saleable product, although with significant metal losses in the waste.

Jig beneficiation is widely used in the enrichment of tungsten, tin, iron, manganese, coal, and other ores. In China, approximately two thirds of tungsten ore are processed using the jig method. Nowadays, some processing plants with low-magnetic iron ore also use jigs as the main beneficiation equipment [15].

Attempts were made to use a jig beneficiation process to remove dolomite contamination from phosphate ores with a high MgO content. Laboratory tests of fine-particle materials allowed for significant removal of impurities from fine-particle ores (particles < 4 mm) [16].

The jig beneficiation process has been widely used in tests of plastic segregation. Attempts were made to use the jig beneficiation process (TACUB jig machine) to segregate plastic waste [polystyrene (PS), acrylonitrile butadiene styrene (ABS), and polyethylene terephthalate (PET)] used in photocopiers. As a result of the tests, over 98% of the above-mentioned substance was recovered from the separated layers [17].

The separation of small plastic particles such as PE and PV was tested, also using the TACUB jig. The particles’ size was 0.5–3 mm, and their density was approximately 1.1, 1.3 and 1.4 g/cm3. Moderate fluidisation of the particle bed resulted in high separation efficiency [18].

Reverse jig separation tests involving shredded plastics—polypropylene and high-density polyethylene—ref. [19] represent another example of research on plastic density separation.

In subsequent tests regarding the possibility of using the jig beneficiation process, the following six granulated plastics were analysed: polystyrene (PS), polymethyl methacrylate (PMMA), polyethylene terephthalate (PET-S, PET-D), and polyvinyl chloride (PVC-M, PVC-D). The plastic mixtures were beneficiated using a laboratory jig from Denver Mineral.

Beneficiation of plastics with similar densities was ineffective, with separation efficiency below 25%. However, jigging proved effective for two-component mixtures. Differences in density, particle size, and shape significantly influenced the results. For more regularly shaped particles, efficiency improved with larger particle size [20].

The literature also contains information about efforts to explore the feasibility of using the jig process to separate shredded automotive scrap to obtain a product with low ash and chloride content [21].

In turn, in Japan, tests were conducted using the modified TACUB jig called the RETAC jig to separate plastics and metals, including copper (Cu) wires, from residues of a small household appliance recycling plant [22].

The possibility of using the jig process to recover metal from computer printed circuit boards (PCBs) was also tested. PCBs were crushed and divided into three different size fractions: <0.59, 0.59 to 1.68 mm, and >1.68 mm. The enrichment process used for the >1.68 mm class was optimised by testing the impact of pulsation frequency and water flow rate [23].

Pulsating jigs are often used to clean aggregates from organic particles and even those with higher densities (chalk, carbonates). These devices have also found industrial applications for the separation of mine waste and the recovery of useful products from them in the form of energy and mineral fractions [24].

In addition, jigs have been used, or the possibilities of their use have been tested, in areas such as recovery of construction materials or land cleansing [25,26]. Hydraulic jigs can deliver clean Recycled Concrete Aggregate (RCA) as the final product. Classification of RCA can be carried out through hydraulic jigging based on its mortar content, resulting in the production of RCA of various qualities, e.g., low and medium mortar content [27]. Hydraulic jigging can also be used to obtain high-quality RCA with over 99.5% wt. of pure concrete as a direct replacement for natural aggregates [28].

2. Materials and Methods

The present article presents the results of research on the potential application of a jig for the beneficiation of various types of materials. Experiments were carried out to assess the applicability of the jig beneficiation process for different feedstocks. The following materials were analysed:

- Hard coal with variable (high) ash content;

- Natural aggregate contaminated with organic impurities;

- Mining waste from hard coal production, deposited in spoil heaps;

- Battery scrap.

Depending on the characteristics of the analysed materials, particularly their physicochemical properties, it was necessary to carefully adjust the operating parameters of the classification device. The optimisation of these parameters was designed to ensure effective separation and the production of output materials with high utility and quality values. Detailed studies were conducted, and their results are presented in the subsequent sections of the article.

2.1. Test Stand of the Laboratory Jig

At the KOMAG Institute of Mining Technology, tests included preliminary assessment of jig beneficiation, selection of technological and design parameters, and verification of process efficiency using the developed device.

The experimental laboratory jig was designed and built at ITG KOMAG and represents a unique research installation used for simulating industrial beneficiation conditions.

The presented tests were conducted on a laboratory jig experimental stand enabling simulation of real operating conditions of an industrial jig regarding the feed flow rate, pulsation characteristics of the beneficiated material/water mixture, and the collection of the separation products.

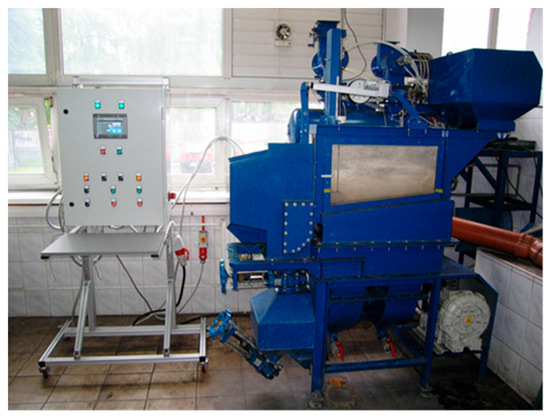

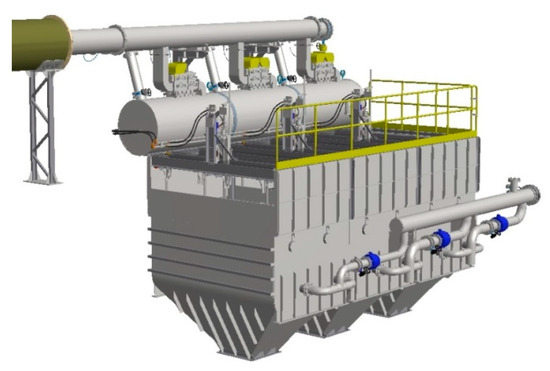

The experimental stand of the laboratory jig (Figure 1) includes the following:

Figure 1.

Test stand of the laboratory jig developed at KOMAG, consisting of a two-chamber jig model with an air-pulsation system, compressor, and control unit. The stand enables simulation of industrial operating conditions, including feed flow, pulsation characteristics, and separation of concentrate and waste products [own study].

- A laboratory jig model;

- An air blower (pulsating);

- A control air compressor.

The laboratory jig is a model composed of a single two-chamber working compartment with dimensions of 0.7 × 0.25 m and a working area of 0.175 m2. At the inlet of the jig, there is a two-part feeding tank with a capacity of 0.06 m3.

The device is equipped with two pairs of inlet and outlet valves that separately supply two pulse chambers located under the sieve deck. Air dampers are installed in front of each pair of valves, which can be used to control the amount of air supplied to the jig. The working trough ends with an overflow threshold, above which the “light” product (concentrate) is separated. The “heavy” product (waste) is discharged through the collection system using a lock made of two knife gate valves.

The model has a partially closed water supply system, which consists of submersible pumps located in the tank (inlet) and rotameters. Process water is supplied to the pulsation chambers (bottom water) and at the feed inlet (top water). Water from the concentrate drain screen is returned to the tank (sump).

The station is equipped with a state-of-the-art control system whose algorithms enable advanced control of water pulsation and product discharge, process control, and recording and processing of acquired data.

The laboratory jig used in the research has a design typical of pulsating jigs employed under industrial conditions. Similarly to industrial-scale equipment, it features water–air (pulsation) chambers located beneath the screen deck. The pulsation valve used (disc-type) to generate a pulsating motion of the separated mixture is one of the two most commonly applied solutions, alongside rotary valves. Disc valves allow flexible adjustment of pulsation characteristics, in contrast to rotary valves.

2.2. Obtaining Low-Ash Coal Concentrate

Extracted hard coal is a collection of various sizes of coal particles, waste rock particles, coal–stone interlayers, and coal shales, and in this form, it is not suitable for direct use [4]. For this reason, it must be directed to beneficiation processes in a number of processing devices, very often in pulsating jigs. The aim of these processes is to destone the material as much as possible and remove as many free pyrite particles as possible.

Description of tests

The aim of the tests was to determine the possibility of obtaining hard coal concentrate with an ash content of 8%–10% from the feed with a particle size of 14–2 mm. The results for density and ash content are presented in Table 1.

Table 1.

Density and ash content of the feed [29].

The material sample was characterised by an average ash content of 20.06% and a significant share of the lowest density fraction (<1.3 g/cm3) of 56.19%.

The tests used a sinusoidal pulsation cycle with a frequency of 60 min−1, and a polyurethane working sieve with slot dimensions of 2 × 15 mm was used as a sieve deck.

The material stratified in the working chamber was selected in the form of three layers, concentrate (top), transition (middle), and waste (bottom), and a small amount of material in the form of the so-called undersize, which was connected to the lower layer for further analyses. The layer heights were determined based on the shares of density fractions, taking into account the impact of particle dispersion in the material (resulting from imperfections in the enrichment process), assuming the ash content in the concentrate product did not exceed 10%.

2.3. Cleaning the Aggregates from Organic Particles

Natural gravel aggregates often contain significant amounts of both organic and inorganic impurities, which must be removed during the production process due to their adverse effect on the aggregate quality. Aggregate cleaning can be conducted in various devices, e.g., aquamators and sword washers. In the case that there are significant amounts of impurities and a small difference in the density of separated particles, high-efficiency aggregate cleaning is ensured by the jig beneficiation process.

The jig process of beneficiating the gravel feeds uses the pulsating classifier to separate contaminants from the aggregate with high separation efficiency for low-density materials, compared to gravel particles, such as plant particles, wood, and coal particles (lignite) [30].

Description of tests

The material for the laboratory separation tests was gravel with a particle size of 16–2 mm contaminated with organic particles. In the raw material (feed), the share of the 16–8 mm particle size was 55%, and the 8–2 mm particle size was 45%.

The feed (16–2 mm) contained 2.67% of impurities with a density <1.8 g/cm3, most of which (89%) were particles with a density <1.5 g/cm3. The share of impurities in the 16–8 mm fraction with a density of <1.5 g/cm3 and 1.5–1.8 g/cm3 was 1.27% and 0.09%, respectively, and in the 8–2 mm fraction, it was much higher and amounted to 3.69% and 0.52%.

Table 2 gives the main water pulsation and other testing parameters.

Table 2.

Testing parameters [31].

To obtain similar conditions for the separation process in the working trough compared to the industrial pulsating classifier, a polyurethane sieve with opening slots of s = 2 mm and an inclination of approximately 6° was used in the tests.

Discharging the light product (impurities) through overflow to the dewatering sieve was carried out continuously along with the flow of process water over the threshold edge, while the heavy product (cleaned gravel) was discharged periodically, depending on the range of fluctuations in the level of the separation layer.

Table 3.

Granulometric composition of the feed [31].

Table 4.

Gravimetric composition of the feed [31].

2.4. Recovery of Useful Raw Materials from Mining Wastes

Mine waste dumps (heaps) created as a result of hard coal production degrade the environment and pose many threats, including fires and the related release of gases polluting the atmosphere, as well as contamination of surface and groundwater [24]. At the same time, these landfills can be a source of useful materials in the form of aggregate and coal fractions. Separating the coal fraction from landfills significantly reduces the abovementioned threats and facilitates recultivation and subsequent land development.

A number of laboratory tests were carried out at the KOMAG Institute to determine the possibility of using the jig beneficiation process for the separation of the abovementioned wastes, as well as the optimisation of the industrial process in terms of maximising the separation efficiency.

Description of tests

A material sample of particle size 35–0 mm used in the test was collected from one of the mine heaps in Upper Silesia. As a result of preliminary technological tests, the controlling parameters of the flow of air and bottom water in the jig were selected according to the particle size of the material to be beneficiated.

The pulsation parameters and process water intensity used during the tests are presented in Table 5.

Table 5.

Pulsating water parameters [32].

After the test, the enriched material was divided into two layers, which were also the separation products. The product with a lower density was a concentrate product (combustible fraction), while the product with a higher density was a waste product (mineral fraction). Additionally, the product that passed through the sieve of the working chamber of the jig was obtained and, after the determination of its quantity, was combined with the material of the lower layer constituting the waste product.

The feed and beneficiation products were separated in heavy liquids with a density of 1.3; 1.4; 1.5; 1.6; 1.7; and 1.8 g/cm3, and the ash content was determined in the fractions obtained. The feed parameters are given in Table 6.

Table 6.

Results of physical and chemical analyses of feed [32].

2.5. Separation of Battery Scrap

A used battery is a potential “ecological bomb”, which is why the law prohibits throwing it into a landfill and requires it to be stored and recycled. The obligations arising from these regulations apply to drivers and sellers, as well as car battery manufacturers.

Battery recycling is related by necessity to lead recycling, as lead constitutes a significant mass share of the battery. One well-known recycling technology is based on the mechanical separation of battery scrap and segregation of products in a heavy liquid into a metal-bearing fraction and a plastic fraction. This technology allows only lead-bearing fractions to be introduced into metallurgical processing, while plastic fractions are further processed to obtain commercial products [33]. Other sources mention solutions using technological systems in which battery scrap is directed to density separation in tanks filled with water [34,35]. The work carried out at the KOMAG Institute aimed to determine the possibility of separating battery scrap in a pulsating water medium.

Description of tests

Tests were carried out to assess the feasibility of using the jig beneficiation process in an aqueous medium for the separation of battery scrap. The feed material consisted of shredded battery scrap in two particle size classes, 30–0.5 mm and 80–0.5 mm, composed of metal and plastic particles. The aim of the study was to increase the concentration of the metallic fraction in one of the separation products. To determine the separation efficiency, density analyses of the tested materials were performed in heavy liquids with a density of 1.5 and 1.8 g/cm3, the results of which are given in Table 7.

Table 7.

Density distribution of the tested feed [36].

The pulsation parameters used during the test are given in Table 8.

Table 8.

Water pulsation parameters [36].

As a result of jig separation, a waste layer (upper) and a concentrate layer (lower) were determined based on a visual assessment of the particle quality. The bottom product was combined with the material of the lower layer, and then the obtained products were subjected to density analysis in heavy liquids with a density of 1.5 and 1.8 g/cm3 to determine the efficiency of the separation of pollutants (plastics) from metallic particles, which comprised a fraction with a density >1.8 g/cm3.

3. Results

3.1. Obtaining Low-Ash Coal Concentrate

The analysis of results (Table 9) showed that the highest yield was in layer I (upper), equal to 53.10%, with an ash content of 7.07%. Layer II (middle), yielding 25.41%, had an ash content of 20.05%. Layer III, located directly on the sieve deck, constituted 20.06% of the total enriched material, and its ash content was 51.53%.

Table 9.

Parameters of jig separation products [29].

A small amount of material, 1.42%, was discharged through the holes in the sieve deck as a result of the beneficiation process, constituting the so-called bottom product. It had the worst parameters among all analysed materials from jig separation products.

Dividing the material into three layers allowed for the analysis of the enriched material for two separation methods (Table 10).

Table 10.

Parameters of the beneficiation products [29].

In the case of Separation I, layer I was assumed as the concentrate, while the remaining layers, including the bottom product, were waste products. In this case, the concentrate with a yield of 53.10% had a low ash content of 7.07%.

In the case of Separation II, layers I and II were considered to be the concentrate, while layer III and the bottom layer constituted the waste product. In this case, the concentrate product, yielding 78.52%, had an ash content of 11.27%.

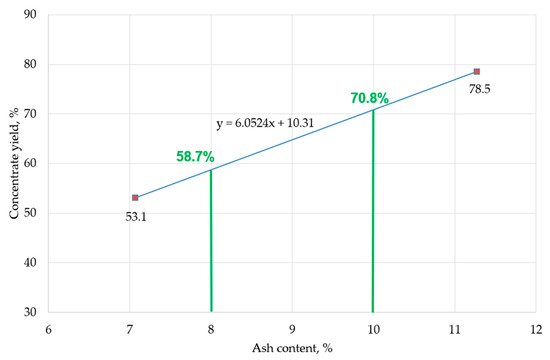

Analysis of the results regarding the yield of “products” and their ash content allows for the prediction, based on a linear relationship, of the possibility of obtaining a concentrate product with an ash content of 8%–10%, with a yield ranging from 58.7% to 70.8%, as shown in Figure 2.

Figure 2.

Relationship between ash content and concentrate yield obtained during jig beneficiation tests of hard coal (14–2 mm). The linear dependence demonstrates the possibility of achieving 8%–10% ash content in concentrate at yields between ~59 and 71% [29].

3.2. Cleaning the Aggregates from Organic Particles

The test results, including the granulometric and density compositions of separation products, are given in Table 11 and Table 12.

Table 11.

Granulometric composition of separation products [31].

Table 12.

Gravimetric composition of the feed and separation products [31].

The applied parameters in the jig material separation process allowed us to obtain the gravel product, in both analysed classes, fully cleaned of particles of a density <1.8 g/cm3. The output of cleaned gravel products with particle sizes of 16–8 mm and 8–2 mm (consisting only of particles with a density >1.8 g/cm3) was 97.93% and 89.35%, respectively, and in the combined material (class 16–2 mm) was equal to 94.07%.

In addition to low-density particles, the overflow products also contained a small share of particles with a density >1.8 g/cm3, considered as aggregate losses. The highest losses were recorded in the 8–2 mm class, with a share of 6.44% of the total material weight. In the 16–8 mm class, the share of particles > 1.8 g/cm3 was only 0.71%. As a result, for the 16–2 mm class, losses amounted to 3.26%. The higher losses in the case of finer particles may result from the larger number of uniformly sinking particles in this class and the greater impact of pulsation movement causing fine aggregate particles to be “thrown” over the overflow threshold of the device.

The test results confirmed a very high efficiency in cleaning the aggregate from organic particles and the possibility of using the jig separation process in industrial conditions.

3.3. Recovery of Useful Raw Materials from Mining Wastes

The results of the analyses are given in Table 13.

Table 13.

Results of the density analysis of the separation products [32].

The feed contained 14.33% of particles of the combustible fraction <1.8 g/cm3, including 7.72% of the fraction <1.5 g/cm3. The ash content of the raw material was 76.29%.

As a result of the jig beneficiation test and separation of the material into two layers, a concentrate product (upper layer) with a yield of 10.04% and a waste product (lower layer) with an output of 89.96% were obtained.

The majority of the concentrate product consisted of fractions with a density of <1.5 g/cm3, the share of which was 68.89%. Interlayer fractions with a density of 1.5–1.8 g/cm3 accounted for 20.60% of the total material weight, and the fraction with the highest analysed density (>1.8 g/cm3) accounted for 10.51%. The ash content in the concentrate product was 20.70%.

The waste product contained a small amount of particles with a density of >1.8 g/cm3, the so-called losses in flammable fractions, equal to 5.94%, including only 0.89% of the particles of the concentrate with a density <1.5 g/cm3. The average ash content in the waste product was 82.49%.

For the results obtained, characteristic parameters of separation accuracy were calculated in the form of probable dispersion and imperfection and are presented in Table 14.

Table 14.

Parameters of the separation accuracy [32].

The calculated parameters, taking into account the nature of the beneficiated material (mining waste) and the wide range of particle sizes, should be considered very favourable.

The results showed the possibility of obtaining two products: a coal concentrate and a material devoid of most flammable substances, which can be successfully treated as an alternative aggregate.

3.4. Separation of Battery Scrap

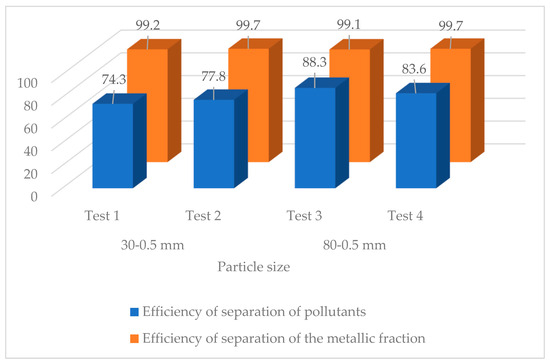

Four beneficiation tests were performed, two for each feed class, in which the unit load of the device with the tested material was varied, and the results of their separation efficiency are given in Table 15 and graphically presented in Figure 3.

Table 15.

Results for separation efficiency [36].

Figure 3.

Effectiveness of battery scrap separation in the laboratory jig for two feed classes (30–0.5 mm and 80–0.5 mm) [36].

Analysis of the test results showed significant separation efficiency of plastic contaminants ranging from 74.3% to 88.3%. Higher effectiveness achieved during separation tests of the 80–0.5 mm class could result from a greater initial share of easily separated low-density contaminants (<1.5 g/cm3). The separation efficiency of the metallic fraction (particles > 1.8 g/cm3) was very high and exceeded 99% in each test. In most cases, separation efficiency was higher for tests conducted with a lower unit load.

The results presented in Table 11 indicate that the use of the density separation process in a pulsating aqueous medium allows for a significant reduction in the waste fraction (plastics) in the concentrate product, with very slight losses of the metallic fraction in the waste.

Taking into account the conditions of laboratory tests of the jig model, mainly the lower value of pulsating air pressure than that used in industry, which limited the height of the concentrate layer containing metallic fractions, it can be predicted that the separation efficiency of battery scrap will increase in industrial devices.

3.5. Implementation of KOMAG-Type Pulsating Jigs

The research work carried out, combined with the long-standing experience of the KOMAG Mining Mechanization Institute in the design and optimisation of raw material beneficiation technologies, enables the development of innovative structural solutions, which ultimately lead to the effective implementation of modern equipment. A key outcome of the development work is the adaptation of the jig design to the requirements of separating and cleaning feed materials with varying grain sizes and mineralogical compositions. The studies contribute, among other things, to improved efficiency in separating hard coal, natural aggregates contaminated with organic inclusions, and waste from post-mining heaps.

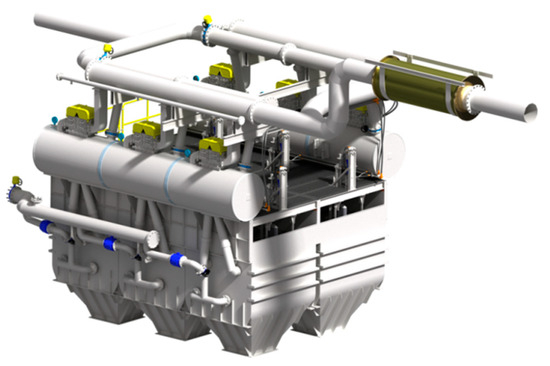

As a result of research on hard coal beneficiation conducted under laboratory and semi-industrial conditions, the effectiveness of pulsating jigs for various density compositions and particle size ranges of coal feed has been verified. Depending on the characteristics of the feed material, the following types of jigs are used: OM-type jigs for coal fines in the 20(30)–0(0.5) mm range (Figure 4 and Figure 5), OS-type jigs for medium coal in the 80(50)–0(0.5) mm fraction, and OZ-type jigs for coarse coal in the 120–20 mm range. High efficiency of operation in terms of feed delivery, pulsating motion generation, and recovery of beneficiation products is ensured by the advanced SSWO KOGA jig control system developed at the KOMAG Institute [37].

Figure 4.

OM-30 pulsating jig installed at the “Sośnica” Coal Mine, designed for beneficiation of coal fines (20–0.5 mm). The jig ensures effective separation of combustible and mineral fractions under industrial operating conditions [own study].

Figure 5.

OM-24 pulsating jig in operation at the “Zofiówka” Coal Mine, applied to medium-sized coal (20–0.5 mm). The device is equipped with the KOMAG SSWO KOGA control system to optimise pulsation parameters and product recovery [own study].

As a result of further material research and modernisation efforts, a jig for the classification of sand and gravel was developed, meeting market quality requirements and offering flexibility in the selection of technological parameters.

The implementation of pulsating jigs in aggregate processing plants (including in Borzęcin (Figure 6) and near Lublin (Figure 7)) demonstrated high efficiency in material cleaning, including effective separation of organic inclusions and mineral fractions with undesirable technological properties. Ongoing modernisation work and further research enabled the development of the jig design to increase reliability, durability, and efficiency in the cleaning process, especially in the case of feed materials containing a significant share of sand fractions and particles sensitive to alkaline environments (e.g., carbonates) [24,38].

Figure 6.

K-100 pulsating jig implemented in a CEMEX Poland aggregate plant (Borzęcin). The device enables high-efficiency cleaning of natural aggregates from organic and carbonate impurities, improving their quality [own study].

Figure 7.

K-80 pulsating jig used in an aggregate processing plant near Lublin. The jig separates undesired fractions and enhances aggregate purity [own study].

Based on the results of research on heap materials and the design of the pulsating jig used in sand and gravel recovery technology, a modernised version of the device was developed for the separation and recovery of valuable fractions from post-mining waste. The K-102-type pulsating jig (Figure 8), resulting from this work, was successfully implemented under industrial conditions at the Przezchlebie storage site. Modern structural and technological solutions, along with an innovative control system developed by KOMAG, enabled efficient processing of feed material in the 35–3 mm grain size range and the production of a coal concentrate with ash content below 12%, while simultaneously reducing the presence of organic substances in the waste product [39]. The control system of the K-102 jig allows for precise adjustment of the device’s operating parameters to meet the quality and quantity requirements of the separation products. This enables the beneficiation of secondary raw materials to be carried out with high efficiency, in accordance with industrial and environmental standards [39].

Figure 8.

K-102 pulsating jig installed at the Przezchlebie site for separation of post-mining waste (35–3 mm). The device enables recovery of low-ash coal concentrate and a mineral fraction suitable as alternative aggregate, equipped with an advanced control system for precise parameter adjustment [own study].

These implementations confirm the possibility of effectively transferring laboratory research results to the mining and raw materials industries, both in terms of the recovery of usable hard coal and the cleaning of natural aggregates and materials from post-mining waste, in accordance with the principles of the circular economy and efficient resource management.

4. Discussion

The laboratory tests confirmed the broad applicability of pulsating jigs for processing mineral raw materials and recovering useful components from waste. The results demonstrated high concentrate yields and favourable separation efficiency for gravity beneficiation in a pulsating water medium.

The KOMAG laboratory jig proved to be a valuable research tool that supports the design and optimisation of industrial equipment and enables the verification of implemented solutions. Pulsating jigs have been applied in Polish coal processing plants for decades, with continuous improvements in design and process parameters. Ongoing research allows further enhancement of their performance, in terms of both structural solutions and beneficiation efficiency [37,40].

One example is the removal of organic pollutants from aggregates. Laboratory tests, relevant due to the negative impact of organic matter on concrete quality, confirmed the possibility of complete separation. Similar tests on carbonate impurities, characterised by higher density, showed a significant reduction in contaminants in the final product, with acceptable aggregate losses [30].

The beneficiation of hard coal confirmed the possibility of obtaining concentrates with specified quality parameters. This has been achieved through technical solutions such as pulsation generation systems, product separation and discharge arrangements, and advanced control algorithms.

From an environmental perspective, an important outcome was the successful separation of battery scrap in a pulsating water medium. The results indicated significant efficiency in separating metallic and plastic fractions, which highlights the potential of this method for waste electrical and electronic equipment recycling.

The scope of industrial use of pulsating jigs has also been extended. In rock mining, they are applied for cleaning aggregates from organic and carbonate impurities. They have also been successfully implemented in the reclamation of mine heaps, enabling recovery of mineral fractions cleaned of combustible material and suitable for use as alternative aggregates [41,42]. The results presented in this study demonstrate the feasibility of obtaining two useful products with favourable parameters: a mineral fraction and an energy fraction. Industrial implementations confirmed the effectiveness of this method under operational conditions, providing an alternative to heavy liquid technologies.

The results presented and the literature review confirm the potential of pulsating jigs and justify further research aimed at expanding their fields of application and improving operational effectiveness, particularly in terms of control and reliability. The findings also contributed to the preparation of technical documentation and successful industrial implementations, demonstrating the practical relevance of this technology. Moreover, activities related to waste processing and recovery of valuable fractions are consistent with sustainable development principles and the circular economy, reducing landfilling and saving non-renewable mineral resources. Moreover, activities related to waste processing and recovery of valuable fractions are consistent with sustainable development principles and the circular economy, reducing landfilling and saving non-renewable mineral resources. The results obtained correspond well with findings reported in earlier studies and are consistent with outcomes of industrial-scale trials, which confirms their reliability.

5. Conclusions

The investigations conducted demonstrated that pulsating jig beneficiation is an effective and versatile method for the recovery and upgrading of diverse mineral and waste materials. Laboratory results confirmed that the process allows for the production of high-quality concentrates with controlled yield and purity, while maintaining favourable separation accuracy. The findings are consistent across a wide range of feed types, from mineral raw materials to industrial waste, thereby proving the robustness of the method.

The main conclusions can be summarised as follows:

- Hard coal (14–2 mm): A low-ash concentrate was obtained at 53.10% yield with 7.07% ash (layer I). When combining Layers I and II, the concentrate reached 78.52% yield with 11.27% ash. A linear relationship indicated the feasibility of achieving concentrates with 8%–10% ash at ~58.7%–70.8% yield.

- Gravel aggregate (16–2 mm) with organic impurities: Complete removal of particles with density <1.8 g/cm3 was achieved in the cleaned gravel product. Outputs of cleaned material were 97.93% for the 16–8 mm class and 89.35% for the 8–2 mm class; for the combined 16–2 mm class, the yield was 94.07%. Aggregate losses with a density >1.8 g/cm3 amounted to only 3.26% of the feed.

- Post-mining waste (35–0 mm): Beneficiation produced a concentrate with 10.04% yield and 20.70% ash and a waste fraction with 89.96% yield and 82.49% ash. The process was characterised by favourable separation parameters: d50 = 1.569 g/cm3, probable dispersion = 0.109 g/cm3, and imperfection = 0.191.

- Battery scrap (30–0.5 mm and 80–0.5 mm): The removal efficiency of plastics ranged from 74.3% to 88.3%, while metallic fraction recovery exceeded 99% in all cases. Higher separation efficiencies were generally obtained at lower unit loads.

- Cross-cutting observation: The jigging process proved adaptable to feeds with diverse density distributions, and operating load was a critical factor, with reduced load enhancing separation efficiency in battery scrap tests.

The study demonstrated that pulsating jigging enables efficient beneficiation of diverse raw materials and waste streams. The laboratory results, despite certain limitations, indicate that comparable efficiency can be expected at industrial scale.

Author Contributions

Conceptualisation, D.K.; methodology, M.L. and P.M.; validation, D.P.; formal analysis, K.K.; investigation, D.K.; resources, R.B.; data curation, R.B. and P.F.; writing—original draft preparation, D.K. and P.M.; writing—review and editing, M.L.; visualisation, P.F.; supervision, D.P.; project administration, K.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Ward, C.R. Coal Geology. In Encyclopedia of Physical Science and Technology, 3rd ed.; Academic Express: Cambridge, MA, USA, 2003; pp. 45–77. [Google Scholar] [CrossRef]

- Matusiak, P.; Kowol, D.; Suponik, T.; Franke, D.M.; Nuckowski, P.M.; Tora, B.; Pomykała, R. Selective Crushing of Run-of-Mine as an Important Part of the Hard Coal Beneficiation Process. Energies 2021, 14, 3167. [Google Scholar] [CrossRef]

- Blaschke, W. Przeróbka Węgla Kamiennego—Wzbogacanie Grawitacyjne; Wydawnictwo Instytutu Gospodarki Surowcami Mineralnymi i Energią PAN: Kraków, Poland, 2009. [Google Scholar]

- Ambros, W.M. Gravity Concentration in Urban Mining Applications—A Review. Recycling 2023, 8, 85. [Google Scholar] [CrossRef]

- Ambrós, W.M. Jigging: A Review of Fundamentals and Future Directions. Minerals 2020, 10, 998. [Google Scholar] [CrossRef]

- Venugopal, R.; Patel, J.P.; Bhar, C. Coal washing scenario in India and future prospects. Int. J. Coal Sci. Technol. 2016, 3, 191–197. [Google Scholar] [CrossRef]

- Baic, I.; Blaschke, W.; Gaj, B. Przeróbka węgla kamiennego w Polsce –stan obecny i trendy przyszłościowe. Zesz. Nauk. Inst. Gospod. Surowcami Miner. I Energią Pol. Akad. Nauk. 2019, 108, 83–98. [Google Scholar] [CrossRef]

- Matusiak, P.; Kowol, D. Use of state-of-the-art jigs of KOMAG type for a beneficiation of coking coal. Min. Mach. 2020, 1, 46–55. [Google Scholar] [CrossRef]

- Sundar Ramam, D.B. Jigging in Iron Ore Beneficiation: Process Parameter Optimization to Improve Consistency In Product Quality (Abstract). International Mineral Processing Congress. 2012. Available online: https://onemine.org/documents/jigging-in-iron-ore-beneficiation-process-parameter-optimization-to-improve-consistency-in-product-quality (accessed on 30 March 2025).

- Shukla, V.; Kumar, C.R.; Chakraborty, D.P.; Kumar, A. Optimization of Jigging Process Parameters to Beneficiate Iron Ore Fines—A Case Study of Tatasteel. Inzynieria Miner. Pol. Miner. Eng. Soc. 2019, 2, 165–170. [Google Scholar] [CrossRef]

- Myburgh, H.A.; Nortje, A. Operation and performance of the Sishen jig plant. J. South. Afr. Inst. Min. Metall. 2014, 114, 569–574. [Google Scholar]

- Das, B.; Prakash, S.; Das, S.; Reddy, P. Effective Beneficiation of Low Grade Iron Ore Through Jigging Operation. J. Miner. Mater. Charact. Eng. 2008, 7, 27–37. [Google Scholar] [CrossRef]

- Sivrikaya, O.; Arol, A.İ. Investigation of Beneficiation of a Manganese Ore By Jig. In Proceedings of the XVII. Balkan Mineral Processing Congress, Antalya, Turkey, 1–3 November 2017. [Google Scholar]

- Rousseau, M.; Blancher, S.B.; Contessotto, R.; Wallmach, T. Beneficiation of Low Grade Manganese Ore By Jigging in a Specially Designed Ore Dressing Unit. In Proceedings of the XXVIII International Mineral Processing Congress Proceedings, Quebec City, QC, Canada, 11–15 September 2016. [Google Scholar]

- The Complete Guide of Jig for Mineral Processing. Available online: https://www.miningpedia.cn/gravity-separation/complete-guide-of-jig.html (accessed on 25 July 2025).

- Carlson, J.; Eisele, T.; Kawatra, S.K. Investigation of jigging as a method for removing dolomite from high-MgO phosphate ores. Min. Metall. Explor. 2012, 29, 56–60. [Google Scholar] [CrossRef]

- Tsunekawa, M.; Naoi, B.; Ogawa, S.; Hori, K.; Hiroyoshi, N.; Ito, M.; Hirajima, T. Jig separation of plastics from scrapped copy machines. Int. J. Miner. Process. 2005, 76, 67–74. [Google Scholar] [CrossRef]

- Hori, K.; Tsunekawa, M.; Hiroyoshi, N.; Ito, M. Optimum water pulsation of jig separation for crushed plastic particles. Int. J. Miner. Process. 2009, 92, 103–108. [Google Scholar] [CrossRef]

- Ito, M.; Tsunekawa, M.; Ishida, E.; Kawai, K.; Takahashi, T.; Abe, N.; Hiroyoshi, N. Reverse jig separation of shredded floating plastics—Separation of polypropylene and high density polyethylene. Int. J. Miner. Process. 2010, 97, 96–99. [Google Scholar] [CrossRef]

- Pita, F.; Castilho, A. Influence of shape and size of the particles on jigging separation of plastics mixture. Waste Manag. 2016, 48, 89–94. [Google Scholar] [CrossRef]

- Kuwayama, Y.; Ito, M.; Hiroyoshi, N.; Tsunekawa, M. Jig separation of crushed automobile shredded residue and its evaluation by float and sink analysis. J. Mater. Cycles Waste Manag. 2011, 13, 240–246. [Google Scholar] [CrossRef]

- Phengsaart, T.; Ito, M.; Hamaya, N.; Tabelin, C.; Hiroyoshi, N. Improvement of jig efficiency by shape separation, and a novel method to estimate the separation efficiency of metal wires in crushed electronic wastes using bending behavior and “entanglement factor”. Miner. Eng. 2018, 129, 54–62. [Google Scholar] [CrossRef]

- Sarvar, M.M. Salarirad, M.A. Shabani. Characterization and mechanical separation of metals from computer Printed Circuit Boards (PCBs) based on mineral processing methods. Waste Manag. 2015, 45, 246–257. [Google Scholar] [CrossRef]

- Kowol, D.; Matusiak, P. Use of a jig beneficiation process for obtaining mineral raw materials. IOP Conf. Ser. Mater. Sci. Eng. 2019, 545, 012006. [Google Scholar] [CrossRef]

- Jungmann, A. Building rubble treatment using the alljig in Europe and USA. Aufbereistung-Tech. 1997, 38, 543–549. [Google Scholar]

- Kellerwessel, H. Jigs and their particular Application for Recycling—Possibilities, Limits, Types. Aufbereit.-Tech. 1993, 34, 521–530. [Google Scholar]

- Khoury, E.; Abrós, W.; Cazacliu, B.; Sampaio, C.H.; Remond, S. Heterogeneity of recycled concrete aggregates, an intrinsic variability. Constr. Build. Mater. 2018, 175, 705–713. [Google Scholar] [CrossRef]

- Gschwenter, V.L.; Tubino, R.M.; Ambrós, W.M.; Miltzarek, G.L.; Sampaio, C.H.; Moncunill, J.O.; Cazacliu, B.G.; Dal Molin, D.C. Production of high-quality coarse recycled aggregates through a two-stage jigging process. Minerals 2022, 12, 532. [Google Scholar] [CrossRef]

- Kowol, D. Laboratory tests on the possibility of obtaining hard coal concentrate with an ash content of 8–10% using the jigging enrichment process. Gliwice, Poland. 2022; unpublished. [Google Scholar]

- Kowol, D.; Matusiak, P. Tests of effectiveness of removal of carbonate grains from aggregate in jigs. Min. Sci. Miner. Aggreg. 2015, 1, 83–92. [Google Scholar]

- Łągódka, M. Laboratory tests of the effectiveness of separation of “light” grains (organic pollutants) from gravel-sand feed based on the gravity enrichment process. Gliwice, Poland. 2011; unpublished. [Google Scholar]

- Łągódka, M.D. Laboratory comparative tests of the effectiveness of enriching coal waste in classes 30-3(2) mm and 30-0 mm. Gliwice, Poland. 2016; unpublished. [Google Scholar]

- Kamińska, E.; Merkisz, J. Automotive recycling lead acid batteries—Environmental aspect. Manag. Syst. Prod. Eng. 2011, 1, 29–33. [Google Scholar]

- Available online: https://jmhpower.com/how-it-works-the-step-by-step-of-lead-acid-battery-recycling/ (accessed on 30 July 2025).

- Available online: https://www.ecobatt.net/how-to-recycle-a-lead-acid-battery/ (accessed on 30 July 2025).

- Lenartowicz, M. Laboratory tests for the separation of contaminated metallic fraction obtained from the processing of battery scrap. Gliwice, Poland. 2005, unpublished. Gliwice, Poland. unpublished.

- Jendrysik, S.; Kowol, D.; Matusiak, P.; Dymarek, A.; Kędzia, K.; Polnik, B.; Szczygieł, M.; Trawiński, T.; Starak, M. Fuzzy Controller in the Products Collecting System of the Jig for Minerals Beneficiation. Electronics 2023, 12, 772. [Google Scholar] [CrossRef]

- Kowol, D.; Matusiak, P. Zastosowania klasyfikatora pulsacyjnego KOMAG do oczyszczania trudnowzbogacalnych surowców mineralnych (Possibilities of use of KOMAG pulsatory jig for purification of hard-to-enrich minerals). Min. Sci. Miner. Aggreg. 2014, 21, 99–108. [Google Scholar]

- Matusiak, P.; Kowol, D. Zastosowanie inteligentnych rozwiązań w procesach produkcji kruszyw mineralnych (Use of intelligent solutions in production of mineral aggregates). Krus. Miner. t 2018, 2, 133–142. [Google Scholar]

- Malec, M. Innovative Mining Techniques and Technologies—Review of Selected KOMTECH-IMTech 2019 Conference Proceedings—Part 1. Min. Mach. 2020, 1, 9–17. [Google Scholar] [CrossRef]

- Lutyński, A. KOMAG activities in the domestic and international research areas. Min. Mach. 2021, 4, 47–60. [Google Scholar] [CrossRef]

- Matusiak, P.; Kowol, D. Możliwości poprawy jakości kruszywa poprzez zastosowanie klasyfikatora pulsacyjnego typu KOMAG. Min. Sci. 2013, 136, 109–118. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).