Abstract

Lithium has emerged as a critical element in contemporary society. It has been classified as an indispensable feedstock in the manufacture of lithium-ion batteries for electric mobility, portable electronics, and stationary energy storage systems, which are essential for the integration of intermittent renewable energy sources. This metal also has other industrial applications and is projected to support future developments in semiconductor and aerospace technology. However, the exponential growth in global Li demand driven by energy transition and technological innovation requires a resilient and sustainable supply chain where both technological and environmental challenges should be addressed. This review discusses and analyzes some of current challenges associated with the Li supply chain given a particular emphasis on its separation methods. First, statistics of the Li market and its applications are provided, including the main sources from which to recover Li and the environmental impact associated with conventional Li extraction techniques from mineral ores and salar brines. Different separation methods (e.g., solvent extraction, adsorption, ion exchange, membrane technology) to recover Li from different sources are reviewed. Recent advances and developments in these separation strategies are described, including a brief analysis of their main limitations and capabilities. The importance and potential of recycling strategies for end-of-life batteries and industrial residues are also highlighted. A perspective on the gaps to be resolved with the aim of consolidating the Li supply chain to support the energy transition agenda is provided in this review.

1. Introduction

The global energy transition has increased the demand of raw materials and, particularly, clean energy technologies require metals such as copper, nickel and lithium (Li). Particularly, Li is the 25th most abundant metal on Earth and has important characteristics that make it a relevant feedstock for the clean energy transition [1,2]. Its concentration has been estimated at 0.005%–1.6% and its natural sources are brines of salt lakes, inorganic compounds in rocks, clays, geothermal brines and zeolites [2,3]. It is the first element from the alkali group of the periodic table with an atomic weight of 6.94 amu, and it is the lightest solid element at room temperature (0.534 g/m3), immediately after H and He [1]. Li is a soft metal due to its loosely bound valence electrons, which allow easy deformation without significant resistance. It tends to form hydroxides and exhibits chemical and physical properties that are characteristic of those of alkaline earth metals [1]. The most relevant properties of Li include its high thermal conductivity, calorific capacity, and liquid state over a wide temperature range resulting in very low density and viscosity [1,3]. Li ions are smaller than those of other alkali metal ions, generating a high charge density and reactivity especially with water, making it an excellent reducing agent [1,3]. Li ions can enhance the electrical and thermal properties of different materials, and consequently, can be applied in the energy sector [4]. Li metal exhibits the lowest electrical potential of any element (i.e., −3.04 V) [5]. It is a valuable material for the rechargeable batteries industry and is currently considered a critical element that has been called “new white gold” because of its high technological and economic relevance, but with limited availability from primary sources and critical demand for energy transition and electromobility [6].

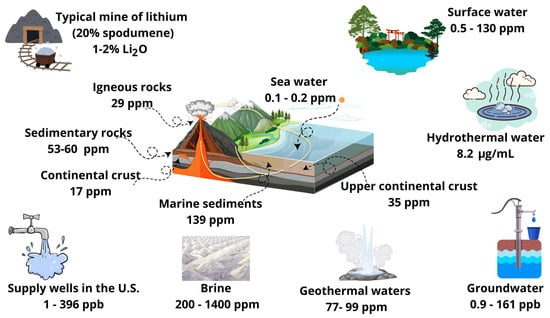

Li can react with water, oxygen, and nitrogen contained in air under natural conditions; consequently, it does not exist in its pure state [1]. In nature, Li can be found as a mixture of stable Li7 and Li6 isotopes with abundances of 92.5 and 7.5%, respectively [7]. A variety of 124 lithium-based minerals have been identified including lithiophosphate, lithiophilite, amblygonite, lepidolite, petalite, triphylite, elbaite, and spodumene [8]. Table 1 summarizes the most common Li-containing minerals. This metal can be extracted from lepidolite and spodumene, which are the Li primary ore sources. However, it is convenient to indicate that an economical typical ore grade for Li has a concentration higher than 1% (by mass). The crustal abundance of Li is estimated to be 17–35 mg/kg [1]. It can also be found at different concentrations in other natural systems such as seawater, brine, marine sediments, and groundwater, see Figure 1. However, Li is usually diluted in nature; therefore, it must be enriched via chemical and physical routes [Balaram, Oliviera]. Various studies have indicated that economically viable Li concentrations range from <100 mg/kg in granites to 9000 mg/kg in pegmatites [9].

Table 1.

Main minerals that contain lithium.

Figure 1.

Lithium concentrations reported for several geological and nature systems. This figure was prepared using data reported in [1].

Li production has increased significantly and statistics from the World Economic Forum indicate that it surpassed 100,000 tonnes for the first time in 2021, quadrupling from 2010, and its global demand is expected to reach 1.5 million tonnes of lithium carbonate equivalent by 2025 and over 3 million tonnes by 2030 [14]. Li demand is expected to increase at least 40 times by 2040 [15], and Li-ion batteries, particularly those used in electric vehicle manufacturing, will constitute over 85% of the market by 2025 [16]. Considering the panorama on current and short-term lithium needs as well as the basic requirements for its extraction from various sources, it is important to mention that Li resources worldwide are estimated to range 40–98 million tons [6,17], where approximately 70% relies on the salar deposits from South America in the so-called “Lithium Triangle” involving areas of Chile, Bolivia and Argentina [15]. It has been documented that the main global Li production accounts for mineral tailing and brine operations in China, Chile, Argentina, Brazil and Australia. Australian Li production is based on ore mining extraction, while Chilean and Argentinian production is based on brine evaporation processes. China instead has a production contribution based on the extraction of Li or mining and brines. Other countries such as Zimbabwe, United States, Portugal and Canada also contribute to Li production operations but to a minor extent [2], while the exploration and recovery of Li from brine are being developed in the United States, China and Bolivia. Other mineral-based Li projects are progressing in several countries from America (United States, Peru, Canada, Brazil), Europe (Spain, Portugal, Germany, Finland, Austria), Asia (China, Thailand, Kazakhstan, Serbia), and Africa (Zimbabwe, Ethiopia, Democratic Republic of Congo, Ghana, Nigeria, Mali, Namibia) [2].

The increases in both Li demand and price have resulted in the implementation of national strategies to address the current supply chain challenges. For instance, the U.S. Department of Energy has established an internal agenda to increase the U.S. Li reserves by funding $1.6 billion for projects aimed at supporting new commercial-scale domestic facilities for Li extraction and processing, battery recycling, manufacturing of battery components, and developing new technologies [2]. The current critical goal of technology companies in Asia, Europe, and North America is to ensure a reliable Li supply chain. Consequently, several corporations have formed strategic partnerships to consolidate and diversify Li sources to support the battery production and electromobility industries.

Given the significant growth demand for Li-ion batteries for electrical vehicles expected in the following decades, there is concern about the resilience capacity of the supply chain. There are still challenges in terms of developing new technologies to improve Li recovery and separation, minimize environmental impact, and reduce associated risks to human health and ecosystems derived from Li extraction and technological implementation, as well as other minor but relevant technical and economic issues linked to its industrial application and recycling of Li-containing products. Therefore, the objective of this review is to discuss and analyze key aspects of some of these challenges. A special emphasis is given to technologies applied for Li separation and recovery. This review provides a perspective on the gaps to be resolved with the aim of consolidating the Li supply chain to support the energy transition agenda.

2. Li Market and Its Main Applications

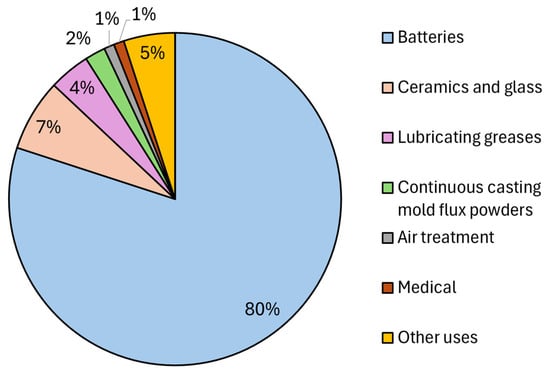

The inherent properties of Li and the discovery of a wide variety of technological uses have driven the exploitation of this metal since the last century [18]. The National Minerals Information Center of the U.S. government has estimated the distribution of global Li end-use market, see Figure 2 [2]. Although 80% of the current Li production is used in the battery industry, this metal has a wide spectrum of applications in the aerospace, nuclear, pharmaceutical, chemical, steel and agricultural sectors [19], see Table 2. A summary of selected Li-based compounds and their utilization is provided below.

Figure 2.

Estimated distribution of lithium applications in different sectors. This figure was prepared using data reported in [2].

The consumption of Li-ion batteries has grown significantly for electric vehicles, mobile phones, tablets, computers, and as a component of power supply systems integrated with photovoltaic and wind energy to provide storage capacity [20,21]. In the Li-ion batteries, Li ion plays a key role as it moves in the organic electrolyte from cathode to anode during charging, and from the anode to cathode during discharging. The Li-ion battery consumption trend is mainly due to technological advancements and the increasing need for sustainable energy production and storage solutions [22,23]. Li-ion batteries currently represent the main source of rechargeable energy in various applications due to their high energy density (250 Wh/kg), cycling performance, and absence of memory effects [24]. Li anode battery has a theoretical capacity of 3860 mAh/g, which significantly outperforms its graphite counterpart (372 mAh/g) [24]. After 1990, Li-ion batteries have received significant attention not only because of their high ionic conductivity and energy density but also because of their high chemical stability [23]. Advanced cathode materials containing Li have also been explored as electrodes, demonstrating their potential in next-generation battery technologies [24]. It is convenient to highlight that the current technological applications have also driven the rapid deployment of Li-ion battery recycling plants. Available statistics from November 2022 indicated that more than 90 companies located in Europe, United States and Canada planned to recycle Li batteries [25]. In addition, there are initiatives of strategic cooperation between recyclers and automobile industries to supply battery materials [2].

Table 2.

Applications of several lithium compounds.

Table 2.

Applications of several lithium compounds.

| Lithium Compound | Chemical Structure | Applications | Reference |

|---|---|---|---|

| Lithium ferrite | LiFe5O8 | Electronics and medicine, the ferrofluid industry, gas sensors, contrast agents in magnetic resonance imaging, drug delivery, and rechargeable Li-ion batteries, high density data storage, catalysts, information storage systems, magnetic bulk cores, microwave absorbers, and medical diagnostics and therapy. | [26] |

| Lithium bromide | LiBr | Greases, lubricants, synthetic rubbers. | [13] |

| Lithium carbonate | Li2CO3 | Pharmaceuticals, control of thermal expansion in ceramics. | [13,27] |

| Lithium chloride | LiCl | Moisture absorber in air conditioning systems and batteries, and in the production of lightweight alloys. | [27] |

| Lithium hydroxide | LiOH | Alkaline storage batteries, manufacture of lithium soaps, and additive in industrial batteries. | [27] |

| Lithium cobaltate | LiCoO2 | Storage batteries | [24] |

| Lithium ferrophosphate | LiFePO4 | Storage batteries | [24] |

| Lithium titanate | LiTiO3 | Source of tritium in the nuclear fusion reactors. | [10] |

| Lithium zirconate | Li2ZrO3 | Source of tritium in the nuclear fusion reactors. | [10] |

| Lithium hydride | LiH | Storage of hydrogen fuel. | [28] |

Li has been widely used in the production of glass and ceramics [29,30], and lithium carbonate is the main feedstock to produce porcelain glazes. This industry was the primary Li consumer before the expansion of the battery sector [31]. Various ceramic and glass materials containing Li can be utilized in dental applications and energy storage technologies [24,32]. Li incorporation into glass ceramics enhances their mechanical properties, biocompatibility, and functionality, generating versatile materials for both restorative dentistry and battery production. For instance, glass-ceramics based on zirconia-reinforced lithium silicate and disilicate can be applied in dental restorations [32]. However, the long-term stability and potential cytotoxicity of novel Li-based materials require further investigation [33].

High-performance parts and structures can be manufactured from alloys containing Li and other metals such as manganese, copper, cadmium, and aluminum [34,35]. Particularly, aluminum-lithium (Al-Li) alloys are an interesting feedstock for the structural production of aircraft and high-speed trains because of their superior corrosion resistance, mechanical properties, and weight-reduction capabilities [34,35,36]. These alloys have also been considered essential for modern aerospace and aeronautic applications to enhance the mechanical performance and fuel efficiency of aircraft [35,37]. Despite these benefits, challenges remain particularly regarding the production cost of Al-Li alloys and their performance characterization under extreme conditions. Hydrogen storage is another potential application of Li-based compounds [28]. LiH has a promising potential for H2 adsorption because of its volumetric capacity (4.95 kg/100 L) and gravimetric density [28]. However, the drawbacks associated with high desorption temperatures (600–700 K) and material stability must be addressed to achieve large-scale industrial applications [28,38]. Other Li-based products include chemicals utilized to enhance cement properties [39], additives for the aluminum industry [37], and catalysts for polymer production [40,41].

Nuclear reactions can be carried out using high-purity Li7 and Li6 isotopes [42]. In this application, Li7 functions as a molten salt coolant for high-temperature reactors because of its heat transfer and thermodynamic properties, providing a low-shock section for neutrons [10,42]. This isotope is also a pH controller for refrigerant materials that can be applied in pressurized water nuclear reactors [10,43], while Li6 acts as a radiation shield to control nuclear reactors without emitting gamma rays [10]. Other compounds, such as Li2O, LiAlO2, LiTiO3, Li2ZrO3, and Li4SiO4, have been tested in fusion reactors [10,42,43].

Lithium hydroxide is the main Li-based compound used in catalysis, lubrication and high-voltage lithium-ion batteries [44,45]. Lithium stearate has been widely utilized as a lubricant grease thickener and high-temperature lubricant in the machinery industry [46,47]. Li-based lubricating greases are applied in automotive, railway, and aerospace sectors. Compounds containing Li can also be used in brass and autogenous welding and as additives to enhance the performance and lifetime of alkaline storage batteries [48,49].

Drying, dehumidifier and air-conditioning industries utilize concentrated brine containing lithium chloride and bromine because of its humidity absorption properties over a wide temperature range [50,51].

Li is an essential feedstock in medicine sector for producing drugs to treat bipolar disorder [52]. Lithium carbonate salt is an effective mood stabilizer, as well as an antidepressant. Sufficient scientific evidence has been published to support that Li can help regulate bone metabolism and reduce fracture risk [53], while lithium carbonate, chloride salts and their mixtures can also act as anticancer agents [54]. Li can also be utilized to manufacture protective glass shields for attenuating the gamma photons released during the radiation generated in cardiology, radiotherapy, tomography, and nuclear medical treatments [55]. For instance, thermoluminescent monitoring aids can be obtained using lithium fluoride [56] aluminum-doped lithium triborate [57], and lithium tetraborate [58].

3. Li Extraction, Environmental Impact and Toxicology

Li supply chain generates environmental pollution that may represent a threat to ecosystems and society if proper regulations and sustainable processes are not incorporated for its industrial exploitation. Therefore, it is important to discuss briefly the environmental impact generated by the main sources for Li extraction and the toxicological profile of this element.

3.1. Li Extraction and Its Environmental Impact

Li extraction is usually performed via two primary methods: ore mining from hard rocks that contributes approximately 60%, and brine (i.e., salt lake) extraction accounting for ~40% [17,59]. Hard rock mining usually ends in Li(OH), while brine extraction and processing usually end in lithium carbonate (Li2CO3).

Ore extraction involves mining hard rock sources (e.g., lepidolite, petalite, and spodumene) to concentrate Li. This recovery route is energy intensive (from 5 to 15 GJ/ton of Li2CO3) and requires both mining and processing to achieve economically viable product yields. The brine extraction is performed in saline waters with high concentrations of dissolved Li salts (e.g., lithium chloride) [60,61] and in geothermal water [62], thus avoiding ore mining. The final product is achieved by concentration via natural evaporation processes and purification process. It has been estimated that this route consumes 400–2000 L of freshwater per kg of Li2CO3 and is also energy intensive. This approach is common in arid regions (e.g., Li triangle in South America) and involves pumping brine into a series of shallow open-air evaporation and precipitation ponds to increase Li concentration over time leading to a concentrated brine [61,63]. This process begins by pumping hypersaline water into evaporation pools (through the action of sun and wind), which are characterized by being shallow and covering large surface areas, varying from several square kilometers to hectares [22,64]. The final product can contain other elements (e.g., boron, calcium, potassium, and manganese), depending on the hydrogeological source [61]. Concentrated brine is sent to a purification process involving boron solvent extraction, precipitation, ionic column exchange and carbonation. In the process, several chemicals are consumed to remove impurities. Calcium hydroxide and sodium carbonate are the most important reactants used along the process. Note that the production process requires intensive use of water, which has generated concern due to the significant hydrological alteration.

Overall, Li extraction routes have different trade-offs in terms of cost, energy consumption, environmental impact, and resource sustainability. Different studies have indicated that Li brine extraction is often more cost-effective and energy-efficient than ore mining. However, both Li extraction routes inevitably generate solid waste, pollutants and intensive water consumption that can harm ecosystems, degrade both soil and water quality, and pose risks to human health [65].

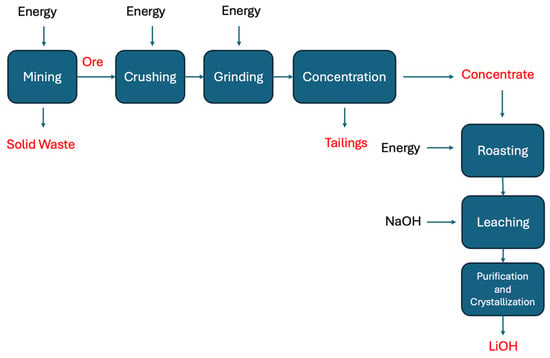

The ore extraction enables year-round Li production regardless of climate conditions, but generates tailings, dust, land disturbance and environmental impact [12,59]. It affects air quality via dust production due to rock crushing and grinding, which causes wind-based particle dispersion [66]. The leaching of mining ore, a step required for Li extraction from hard rock, can also generate soil and water pollution [67]. Also, mining activities and concentration by flotation require large amounts of water that can strain the local water resources and impact aquatic ecosystems. The management of tailings and residual materials generated during ore processing is challenging and paramount to mitigate the environmental pollution [12,62,68,69,70]. For illustration, Figure 3 shows a standard flowsheet for a Li hard-rock extraction process where the main products (including residues) and energy inputs are indicated.

Figure 3.

Lithium extraction flowsheet process diagram of a standard hard-rock ore.

Few studies have provided quantitative data on the presence of Li in water reservoirs or soil affected by mining [71]. Li extraction from brines depends on local water resources and climate conditions, which can lead to depletion and local biodiversity disruption in arid environments, as well as affecting agriculture, soil and water availability, in addition to polluting local communities [12,15,61,72]. Yang et al. [73] analyzed the impact of Li mining from lepidolite on the pollution of the Jinjiang River in southeastern China. These authors found Li concentrations of up to 103.9 µg/L that suggested substantial Li discharge into the river via inadequately treated wastewater from the industrial zone [73].

Some studies have suggested that Li reserves in salt lakes are more abundant and can be processed with a lower environmental impact and reduced cost by 30%–50% compared to ore mining [59]. Brine extraction is often viewed as a more viable approach for consolidating Li supply [1,74]. Kelly et al. [75] reported the results of a Life Cycle Assessment (LCA) to produce battery-grade LiOH·H2O and Li2CO3 from spodumene ores in Australia and brine from the salar in Atacama, Chile. This LCA covered Li salt production and the corresponding end-products (i.e., full batteries and battery cathode materials). The calculations indicated that the freshwater consumption per kg of salt and life cycle green-house gases emissions to produce LiOH·H2O (6.9–7.3 kg CO2eq/kg) and Li2CO3 (2.7–3.1 kg CO2eq/kg) from brine-based resources were lower than those obtained for the ore-based counterpart (16–20 kg CO2eq/kg) [68]. Nikfar et al. [76] performed LCA with TRACI method to compare Li recovery from brine for producing Li2CO3 via membrane electrolysis, nanofiltration, adsorption, and solvent extraction. Calculated CO2 emissions per kg of Li2CO3 were: nanofiltration (17.7 kg CO2eq/kg) < adsorption (47.9 CO2eq/kg) < solvent extraction (52.7 kg CO2eq/kg) < membrane electrolysis (80.57 kg CO2eq/kg). These results indicate that nanofiltration is a promising alternative for mitigating the environmental impact caused by Li extraction. However, these and other environmental studies have concluded that it is paramount to develop more sustainable processes for Li recovery and processing [76]. It is convenient to note that mineral waste obtained from Li extraction activities can capture and allow the storing of CO2 from the atmosphere (via carbonation reactions related to calcium concentration), but the residues need to go to disposal alternatives that generate lower environmental impact. For instance, calcium carbonate is a solid waste resulting from the industrial procedures of Li extraction in brines and needs to be carried out to the disposal ponds.

Another important environmental challenge is the natural mobility of Li. This metal can be released into the environment via natural processes that have been identified as geogenic sources [77]. Li release from natural deposits (e.g., rocks, minerals, geothermal water, and salt flats) occurs because of the natural processes and cycles that occur on Earth [78]. One of them is weathering, in which rocks and minerals found on the Earth’s surface decompose and transform into smaller and less-structured materials over time [67]. These materials can easily be transported to new locations by natural agents (e.g., water and wind) [79]. The weathering and disintegration of rocks primarily occur due to erosion caused by the sand and gravel movement by wind or water currents [80]. Toupal et al. [67] reported high Li concentrations (>20 µg/L) in water samples near the Cínovec reservoir from Europe in comparison with the average concentration found in surface waters worldwide. They concluded that the potential cause of this result was the erosion of mica deposits due to the high Li content in the rocks and their proximity to the surface [67]. Another relevant geogenic source of Li pollution corresponds to volcanic eruptions where both volcanic rocks and ash that are dispersed can contaminate soil and water [80,81,82,83]. Note that it has been estimated that the natural concentration of Li in surface waters is <0.04 mg/L, and 0.05–1.0 mg/L in mineral water [84], depending on the climate and lithology. However, environmental Li concentrations can increase due to the exacerbated mobilization caused by anthropogenic activities that promote water system pollution, making it necessary to identify, quantify and evaluate the risks to aquatic ecosystems and public health [78,85].

Additional anthropogenic pollution sources occur at various stages of Li life cycle, including metal processing after its extraction, the manufacturing of Li-based materials, their use and final disposal [86]. The scientific community has highlighted the importance of Li pollution generated from the application, use, and disposal of Li-containing products [87]. The management and final disposal of residues containing Li are often not conducted responsibly, possibly because of inadequate (if any) regulations or a lack of awareness of proper protocols [87]. This issue is more relevant when the general population has easy access to a wide spectrum of Li-based commercial products, such as batteries, medications, and ceramics [88]. These items are commonly disposed of in regular trash, which ends up in municipal landfills causing the potential metal leaching into the soil [89,90], or they are disposed of in the drain (for example, medications) when they expire, thus generating water pollution [91,92].

3.2. Li Toxicological Profile

Li toxicology is important because its use and valuable applications generate direct and indirect environmental pollution with potential negative effects on human health and ecosystems [84,85,93]. This metal has been categorized as the fifth unregulated pollutant in 2021 by the U.S. Environmental Protection Agency [94]. The U.S. Environmental Protection Agency (EPA) has established a Health Reference Level (HRL) of 10 μg/L for Li in drinking water [95], while the World Health Organization (WHO) has not published a permissible limit for Li concentrations. However, there is a lack of information on the safety limits of Li in drinking water based on the daily human intake. A recent study used the Health Based Screening Level (HBSL) of 10 μg/L and the threshold of 60 μg/L to compare the groundwater Li concentrations from several public and domestic water supplies in the USA. This study was based on the EPA provisional reference dose of 0.002 mg/kg per day, considering that drinking water was the unique source of Li intake [82]. The authors observed that a significant proportion of public and domestic supplies exceeded these thresholds.

Recent studies have addressed the toxicological effects of short- and long-term Li exposure on different organisms [94,96]. Li meets the criteria for hormonal disrupters, affecting thyroid, hepatic, and nervous functions [27]. A meta-analysis showed that Li exerts toxicological effects on the kidneys (hyposthenuria), thyroid (hypothyroidism), and parathyroid (hyperparathyroidism) glands; however, Li-linked teratogenesis remains unclear [97]. The molecular mechanisms of toxicity in organs and glands are not completely understood yet. They seem to be related to a progressive dose-dependent disfunction associated with an alteration of the cellular redox homeostasis, DNA damage, dysregulation of cell cycles and apoptosis [98]. Further studies are necessary to elucidate the underlying mechanisms of the pathogenic effects of short- and long-term Li exposure, as well as those conditions leading to Li-toxicity predisposition [98]. Toxicokinetic experiments have demonstrated that soluble Li is instantly absorbed by the gastrointestinal tract, by the lungs via inhalation, and it can cross the placenta and reach breast milk [27]. Some studies have also suggested that toxic effects of Li consumption can occur at very close levels of therapeutic doses (1.2–2.4 mg/Kg b.w. per day) [99].

Table 3 summarizes the lethal concentration 50% (LC50) reviewed and reported for some aquatic organisms. It has been shown that Li exposure in rainbow trout (Oncorhynchus mykiss) reaches higher levels in the brain and plasma after 96 h of exposure to a nominal concentration of 1 mg/L. This result was accompanied by increased levels of arachidonic acid, altered ion composition, and dysfunction of ion transporters, lipoproteins, and prostaglandin synthesis [100]. Li-induced toxicity in Mytilus galloprovincialis after 28 days, using a concentration range of 100–750 μg/L, has been related to a redox system imbalance (oxidative stress), dysfunction of biotransforming enzymes, reduced glutathione depletion, neurotoxicity and decreased acetylcholinesterase activity [94]. It has been suggested that these toxicological effects may be potentialized by other factors. Consequently, further studies are required for determining the toxicokinetic and toxicodynamic parameters of Li exposure in other living organisms for elucidating the toxicological mechanisms of action, and to develop appropriate therapies to counteract or antagonize these effects.

Table 3.

Lethal concentration (LC50) of lithium reported for different aquatic species.

4. Methods for Li Separation

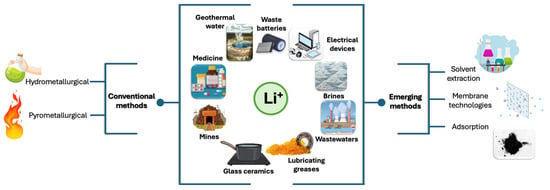

The battery industry and other relevant technological applications demand salts with more than 99% purity and residual amounts of impurities. Consequently, purification technologies are required to satisfy these industrial requirements. Figure 4 shows the different methods for Li separation from various sources such as brine, wastewater, ore, waste and residual products. Li purification can be performed using several technologies including chemical precipitation [106,107], ion exchange [108], adsorption [109], membrane technology [110], and solvent extraction [111].

Figure 4.

Conventional and novel emerging methods to separate lithium.

Chemical precipitation is widely used to separate Li from the fluids generated during mining activities, waste recycling processes, and wastewater treatment [112,113]. In this process, a specific agent is added to the fluid containing ions other than Li to generate an insoluble compound [114]. This separation technique is characterized by its efficacy, minimal requirement for expensive or sophisticated equipment, and low energy consumption [115]. However, the pretreatment of Li sources can be required in some cases before applying this method [116]. This pretreatment may include other processes (e.g., leaching or evaporation) to ensure that the metal is dissolved and/or concentrated in the solution, allowing precipitation to occur [117,118]. Leaching is applied when Li is present in solid matrices such as batteries or ores [119]. Chemical precipitation can be alkaline or acidic, depending on the reagent used, and it can also be performed with the assistance of bacterial or fungal cultures [120,121].

Membrane technology has been established as an effective and versatile separation method for the selective recovery of ions in various industrial and environmental scenarios [122]. Membranes act as barriers that allow for the controlled transport of certain ions and restrict the passage of other ions, facilitating their separation [123]. This approach is useful for desalination, wastewater treatment, mining, and recovery of valuable metals [122]. Membrane-based processes have been suggested as sustainable and competitive alternatives to conventional methods, such as chemical precipitation or solvent extraction, because of their high efficacy and adaptability to different operating conditions [124,125,126]. They have been diversified into a wide range of configurations designed to efficiently separate and recover specific compounds [127,128]. The most prominent operations include osmosis (reverse or direct), nanofiltration, dialysis (diffusion or cross-ion), electrodialysis, ion-imprinted membrane, supported liquid membrane, and membrane distillation [129,130]. The main advantage of membranes is their high selectivity, which allows separation or blockage of the passage of a specific ion [131]. This is particularly useful for solutions that contain several ions with similar chemical characteristics. For example, Li+ and Mg2+ are difficult to separate efficiently using conventional methods such as solvent extraction [132] and, consequently, membrane-based processes can be an effective alternative.

Adsorption is a separation method to recover various components present in fluids [121]. It is useful for Li extraction industry because of its selectivity, efficiency, and moderate-to-low environmental impact compared to other purification methods, making it a cost-effective alternative [76,133,134,135]. This technique allows the exploitation of sources with low Li concentrations, thereby expanding its feasibility for diverse applications [121]. Adsorption relies on the use of organic and inorganic materials (usually porous) that can selectively retain Li ions from fluids (e.g., wastewater or brine) [136]. After the saturation of the adsorbent surface with the target metal, desorption can be performed to regenerate the material and recuperate the adsorbate [137]. Adsorbents for Li separation include Li-ion sieves [138,139], polymers [140], metal–organic frameworks (MOFs) [141], functionalized nanotubes [142], porous carbon-based materials [143], composites [144], and ion-exchange resins [145,146].

Solvent extraction can be of importance for recovering Li from various sources, including brines, clay minerals, and even spent Li-ion batteries. Solvent extraction separates Li from fluids using a combination of solvents [132]. This technique is based on the selective separation of Li ions from the aqueous phase (brine or leachates) with an organic phase, usually composed of an extractant and a diluent. The organic phase selectively separates Li from the rest of the ions in the brine, particularly Mg and Ca. After mixing, the organic phase settles over the brine from where it is separated from this matrix mechanically. The loaded Li in the organic phase requires at least one stripping or discharging step where Li ion exchanged for protons provided by an acid, usually HCl giving the chlorine nature of the brine. In some systems, an additional solvent is added that serves as a co-extractant [147]. The extractant aids in the formation of complexes that are insoluble in the aqueous phase but highly soluble in the organic phase [148]. The co-extracting agent increases the extraction efficacy by collaborating with the extracted complex compound due to its solvation with it via the extracted metal, while the diluent stabilizes the organic phase and improves mass transfer [149,150]. The main advantages of this separation route are its productivity, easily scalable and reduced energy consumption [151].

Electrochemical methods are emerging alternatives for Li separation that are characterized by high efficiency, low energy consumption, and selectivity in extracting Li from various sources including brines, spent Li-ion batteries, and wastewater [152]. These methods rely on the principles of electrolysis, where electric currents drive chemical reactions to separate Li ions from other substances. Electrochemical processes (e.g., aqueous electrolysis, electrochemical ion exchange, electrochemical ion pumping or capacitive deionization) can achieve the effective separation of Li from other ions, even in complex mixtures [130,152,153]. It is important to note that in some cases, electrochemical technologies are used in conjunction with other methods described here to optimize the recovery process, which can further improve the overall separation efficacy and economic benefits [153]. In this review, only the electrodialysis in membranes method will be addressed. The discussion of other electrochemical methods is out of the scope of this manuscript but interested readers are referred to other reviews covering this topic [152,153].

The selection of the appropriate separation method depends on several factors, such as economic metrics, environmental impact, and recovery efficacy. However, the concentration of Li in the raw source is fundamental to determine the most suitable separation technology [154]. For instance, chemical precipitation is only viable for Li concentrations above 1300 mg Li/L [154]. Novel organic solvents offer advantages for Li extraction from dilute sources, such as sea bittern (e.g., ≤10 mg/L), particularly for selective separation [154]. Other methods, such as evaporation or conventional solvent extraction, exhibit low separation efficacy with seawater-based sources (0.17–2 mg/L), whereas electrochemical, membrane, and adsorption methods effectively overcome the challenges associated with low Li concentrations and enable processing Li-containing materials in a wide range of concentrations [143,155]. A combination of technologies (e.g., electrosorption, electrodialysis, reaction-coupled separation) can address the challenges associated with a wide range of initial Li concentrations depending on the raw material conditions [156]. For example, hybrid reverse osmosis combined with electrodialysis has been studied for Li recovery from industrial wastewater containing 7800 mg/L of LiCl [122], while electrodialysis achieved a recovery of 85% from initial concentration of 500 mg/L of LiCl solution [157].

An overview of recent advances and developments for chemical precipitation, adsorption, membranes and solvent extraction technologies is provided in the following subsections.

4.1. Chemical Precipitation

Chemical precipitation offers several operational advantages, including simplicity, scalability, and relatively low processing costs. However, the process effectiveness depends on various factors such as pH, temperature, concentration of competing ions, and the nature of the precipitating agent used. Several studies have focused on optimizing precipitation conditions to improve Li separation efficiency. A selection of key manuscripts that explore different aspects of chemical precipitation techniques for Li recovery are reviewed in this section highlighting the advancements, challenges, and practical applications of this approach.

Table 4 provides a survey of studies on Li recovery using chemical precipitation. Biswal et al. [158] compared acid leaching using inorganic acids (i.e., nitric and sulfuric acids) with bioleaching based on fungi Aspergillus niger MM1 and SG1 to treat a complex mixture of dust extracted from spent Li-based batteries. They determined that Li concentration obtained with the fungus (22.7–24.2 mg/L) was even higher than that obtained with nitric acid (20.7 mg/L), which resulted in greater availability of Li for precipitation with Na2CO3, ultimately recovering Li up to 73.6% in the carbonate form. Shi et al. [159] also recovered Li from spent battery powder using Na2CO3, which was obtained from nickel-manganese-cobalt (NMC) lithium-ion batteries. The metal was leached using hydrogen peroxide and sulfuric acid, and Li was precipitated at 95 °C for 1.5 h, recovering up to 99.85%. CO2 is another precipitating agent that can be used to obtain lithium carbonate. Velázquez et al. [160] and Tawonezvi et al. [161] used this gas to precipitate Li from the leachate of spent battery powder and successfully recovered 80.4 and 91% Li, respectively. Note that this metal can also be precipitated using Na3PO4 or H3PO4. Mahandra and Ghahreman [119] reported the leaching of Li from spent battery powder with H2O2 and acetic acid solution achieving a high Li selectivity of 94.1% with only 6% of impurity elements (i.e., Al, Fe); then, Li recovery with Na3PO4 in a double precipitation process, first at 60 °C and then at 90 °C, reached 99.5% as Li2CO3, in a process with reduced acid consumption. Chen et al. [162] applied H3PO4 to precipitate lithium phosphate from a leachate of battery powder. The separation process reported in this study involved a single precipitation step at 25 °C, achieving a metal recovery of up to 92.7%.

Table 4.

Recent studies on lithium recovery by chemical precipitation.

The temperature is an operating parameter that significantly influences Li separation via chemical precipitation, as higher temperatures result in higher recovery yields. Han et al. [167] demonstrated that the separation yield using CO2 ranged from 41.6 to 45.5% at 50 °C, which significantly outperformed the 22.6–25.6% yield obtained at 25 °C. Battaglia et al. [170] also observed the temperature effect by comparing Li recovery yields via the carbonate form from a dilute LiCl solution at 50 and 80 °C. They determined that the separation yield was 55% at 50 °C, which increased to 77% at 80 °C. The increase in temperature enhances the solubility of compounds, facilitating their interaction, and thus favoring their precipitation [168]. However, it should be noted that this effect also depends on other important factors such as stirring speed, precipitating agent and its concentration [167,168]. The temperature effect is particularly noticeable for certain chemicals, such as sodium carbonate, which require relatively high temperatures because of their low solubility to achieve competitive results, in contrast to CO2, which can be used effectively at low temperatures [171].

The agitation speed also plays an important role in Li separation performance, particularly affecting the size of precipitated particles. As the agitation speed increased, the particle size tended to decrease, likely due to more frequent particle collisions. Gu et al. [173] studied this effect on Li precipitation using sodium carbonate and leachate from spent batteries. The results indicated that increasing the agitation speed from 200 to 800 rpm reduced the particle size from 169 to 116 μm. pH also significantly affects Li precipitation. If the pH is not optimal, Li solubility in the solution may be too high, preventing the formation of the desired precipitate or favoring the formation of unwanted compounds from the precipitating agents. Carbonic acid can be formed under acidic conditions or phosphate compounds may undergo hydrolysis [177].

The composition of Li source is fundamental to achieving a successful separation. Salt lake brine, seawater or Li-batteries are mixed systems that commonly contain a variety of coexisting ions like Na, K, Ca, Mg, Co, Ni, and Mn that affect the separation process [178,179]. Li (radius ≈ 0.076 nm) has similar ionic properties to Mg (radius ≈ 0.072 nm) and, since their ionic size is nearly identical [180], their separation is difficult. The presence of co-ions can significantly affect the solubility and precipitation kinetics of Li salts and can lead to the formation of unwanted by-products or precipitates, thereby reducing the purity and yield of Li products [179,181]. Gu et al. [173] observed that Ni and Co ions were incorporated into the crystal lattice of Li2CO3, affecting the growth and morphology of lithium carbonate. Ca ions can precipitate as calcium carbonate, which competes with Li for precipitation and decreases the efficiency of Li recovery [182]. Magnesium ions may cause the formation of magnesium hydroxide, which can co-precipitate with Li compounds, complicating the separation process [182]. In terms of the application of strategies to control the presence of these competing ions is important to improve the process performance, Quintero et al. [182] removed Ca impurities from industrial Li-rich brines using oxalic acid as precipitating agent, reducing Ca from 300 to 30 mg/L. A high purity Li2CO3 with controlled concentrations of Mg (i.e., 0.05% as Mg(OH)2) was obtained via a co-precipitation step of Mg salts (initial 1.14%) using NaOH.

The complexity of impurity management and the requirement for cost-effective reagents implies additional challenges to improve the separation efficiency and Li quality [175,181]. To overcome these drawbacks, advanced chemical precipitation methods have been proposed [175]. Chang et al. [175] obtained high-purity salts (i.e., Li2CO3, Co2O3, Ni(OH)2, and MnO2) successfully recovered from Li-ion batterie cathodes, achieving purities > 99% (by mass) for Co and Li salts where the impurities such as Al, Cu, and Fe were effectively removed. The process consisted of the leaching of material using sulfuric acid and hydrogen peroxide. The precipitation step was conducted using reagents such as NaOH, Na2CO3, KMnO4, and NaClO.

The particle size of the powder samples plays a crucial role in the precipitation process. The diverse types of Li-ores and spent Li-ion batteries with complex compositions generate additional challenges for effective leaching and separation [183]. Smaller particles have a larger surface area, which enhances the rate of precipitation by increasing the interaction between the solute and the precipitating agent [176]. Excessively fine particles can also cause agglomeration, leading to poor separation and filtration issues, which reduce the overall process efficiency [184]. It has been shown that controlling the particle size distribution within an optimal range can improve the kinetics of Li precipitation and facilitate easier handling and separation [176]. This stage is paramount since Li precursors for battery manufacturing (mostly as Li2CO3 salt) must achieve stringent quality conditions, explicitly, a purity ≥ 99.5% and a particle size distribution defined by d10 ≥ 1 μm, 3 μm ≤ d50 ≤ 8 μm, and 9 μm ≤ d90 ≤ 15 μm [185].

Intensified chemical precipitation processes have been tested for Li separation [166]. Ultrasound has also been explored to optimize the reagent and improve the precipitation efficiency. The application of ultrasound during precipitation step is also a promising approach to reduce particle size and achieve the desired distribution [185]. Biswal et al. [158] analyzed the impact of ultrasonic waves and proved an increase in Li recovery yield, even with low initial metal concentrations, while also enabling the production of high-purity compounds in a shorter time (35 min). This technique eliminates the need for prior pre-concentration steps such as evaporation before precipitation. They recovered approximately 45% of Li in the carbonate form with an initial concentration of 5 g/L using traditional agitation, whereas the recovery rate increased to over 60% by applying ultrasonic-based precipitation [158].

Chemical precipitation has also been applied to recover Li from other sources, such as brine and wastewater. Zhao et al. [166] and Alsabbagh et al. [168] employed wastewater and Dead Sea brine for Li recovery, respectively, using sodium phosphate. Zhao et al. [166] implemented a preliminary step to remove other metals via precipitation, ultimately achieving 84.26% Li recovery at 60 °C, while Alsabbagh et al. [168] recovered Li with >40% yield at 40 °C. Wang et al. [164] utilized brine from Taijinaier Salt Lake in China for Li recovery using MgAlCO3-layered double hydroxide materials to obtain lithium carbonate, achieving 91.94% yield where a prior step was incorporated to remove impurity ions. Several studies on Li separation via chemical precipitation have focused on spent Li-ion batteries because they represent one of the primary Li sources that can be commercially implemented on an industrial scale [186].

Although well-established chemical precipitation processes for obtaining Li compounds from minerals are used at the industrial level, further studies are required to optimize their operating conditions, improve Li recovery efficiencies, reduce costs, and develop more environmentally friendly separation routes [118]. Some drawbacks of current technologies can be illustrated using examples of the production of lithium phosphate from lepidolite [169] and lithium hydroxide from bauxite clay [171]. Li extraction from lepidolite requires energy-intensive processing because it involves concentration followed by roasting at temperatures of up to 1000 °C, and afterwards leaching with acids that have poor selectivity, making it difficult to purify the resulting liquors. An alternative approach is alkaline leaching with NaOH; however, the recovery efficiency remains low due to the high sodium content, which interferes with carbonate precipitation. Mulwanda et al. [169] opted for NaOH leaching, testing various concentrations, agitation speeds, and temperatures to obtain a reduced aluminum solution, which allowed them to precipitate Li in the form of phosphate. This phosphate can then be further treated to produce lithium ferrophosphate or lithium carbonate. Guan et al. [171] proposed NaOH to address the challenges caused by the high aluminum content in ores and to achieve competitive Li extraction. After precipitation, calcination was performed, followed by leaching, to selectively isolate the target metal.

4.2. Membrane-Based Technologies

A variety of membrane technologies have been used to separate Li, which can be classified in pressure-driven membrane process, electrically driven membrane process, and thermally driven membrane process [129].

Pressure-driven membrane technology used in Li recovery is categorized into three types based on membrane pore size and transmembrane pressure difference: ultrafiltration (UF), nanofiltration (NF), and reverse osmosis (RO) [187]. UF membranes, with pore sizes between 1 nm and 0.05 μm, can separate macromolecules and colloids with a molecular mass higher than 500 kD [188]. NF membranes have characteristics that lie between those of UF and RO membranes, typically possessing pore sizes around 1 nm [187,188].

Reverse osmosis is a highly effective technique for increasing the salt concentration of a solution because membranes allow water to pass through, while retaining salts with high efficacy [187,189]. However, this requires external pressure for operation, being energy intensive and prone to fouling, which can reduce separation efficacy, and increase operational costs and maintenance demands. Direct osmosis is an alternative to reverse osmosis for treating effluents with complex compositions such as geothermal brine [124]. This membrane-based process does not rely on external pressure; instead, it uses an extraction solution to generate the necessary osmotic gradient that drives water flow through the semipermeable membrane [190]. Nanofiltration operates based on both Donnan exclusion and steric hindrance, being capable of rejecting multivalent ions but permitting monovalent ions to pass [187,191]. Dialysis is a separation method that does not rely on an osmotic pressure gradient but on a concentration gradient [192]. Ceramic membranes can be used in this process because they offer high selectivity; however, their use requires precautions because of their fragility. Polymeric membranes are more flexible and resistant but offer lower selectivity.

Electrically powered membrane processes use electricity as the main driving force and rely on ion-exchange membranes that are integrated into a polymer matrix with a fixed charge. These membranes are highly selective, allowing only ions with an opposite charge to pass through, while preventing ions with the same charge from penetrating [188]. Ion-exchange membranes are widely applied in operations such as electrodeionization, diffusion dialysis, membrane electrolysis, and electrodialysis [188].

Temperature-driven membrane technologies separate substances based on temperature differences, causing substances to diffuse or migrate via the membrane at different rates [188]. Examples of these technologies include membrane crystallization, membrane distillation, and systems that combine membranes with multi-effect distillation. These processes are also effective for recovering Li [188].

A hybrid technology that combines solvent extraction and membranes is the supported liquid membrane (SLM) that uses a membrane that absorbs an organic phase to separate two aqueous phases, transferring a substance from the feed phase to the stripping phase [191]. For hydrophilic metal ion separation, the organic phase contains an extracting molecule that selectively binds to the target metal, forming lipophilic metal–organic complexes. SLM is an attractive alternative for Li separation due to its low energy consumption, reduced solvent use, high selectivity, and integrated extraction and stripping in one stage [191].

An ion-imprinted membrane (IIM) can be applied in Li separation. It is typically created by grafting an ion-imprinted polymer (IIP) on the membrane surface that reacts with template molecules (e.g., Li), then the template is removed, creating binding sites with molecular recognition properties. IIPs exhibit high affinity for the template molecules. The use of powdery Li ion-sieves in column operations leads to significant pressure drops and adsorbent loss, limiting their industrial application. Li ion-sieve membranes have been developed to combine the benefits of ion-sieves (high surface area and selectivity) with those of membranes (immobilized adsorbents and low energy consumption) with synergistic benefits [187,191]. The hybrid membrane distillation crystallization (MDC) has been used to recover Li from high-concentration brines. It offers faster crystallization rates and better-controlled nucleation kinetics. In MDC, water vapor passes through a hydrophobic membrane under a thermal gradient and condenses on the permeate side, allowing Li to be concentrated and recovered in the crystallizer [191]. Electrodialysis (ED) is a widely used electro-membrane separation process where cation and anion exchange membranes are arranged alternately and an electrical field drives cations and anions towards their respective electrodes [191]. To address the separation of ions with same charge (e.g., Li and Mg), selective ED with monovalent ion-exchange membranes have been developed, enabling the separation of monovalent ions from divalent ones.

Table 5 shows recent studies on Li separation using membrane-based processes. He et al. [193] achieved a remarkable selectivity coefficient of 430 when recovering Li from a solution containing MgCl2 via the application of (PPS/PAH)2.5—poly(styrene sulfonate) and—poly(allylamine hydrochloride) membranes, which were positively charged to reject Mg2+ ions in a nanofiltration process via the Donnan exclusion mechanism. Mg2+ and Li+ ions have similar hydrated radii and can pass through membranes, making size-based separation difficult. These authors showed that the efficacy of tested separation process depends on factors such as brine concentration and pH. It was found that a high total brine concentration and low pH of 2.7 favored Li separation. He et al. [194] used nanofiltration via a membrane with a PES substrate and an intermediate layer formed by NH2—multi-walled carbon nanotubes modified with polydopamine to separate Li from the leachate of spent Li ternary batteries, which contained high concentrations of Ni2+, Co2+, and Mn2+. This process achieved Li recovery of 79.2% due to an improvement in the Donnan effect provided by the advanced membrane structure [195].

Table 5.

Recent studies on lithium recovery by membrane technologies.

The integration of different membrane-based processes is an effective approach to optimize Li recovery. Pramanik et al. [123] combined nanofiltration with membrane distillation, taking advantage of the fact that the latter method increases the salt concentration to saturate the solution using sustainable energy. These authors evaluated two filtration membranes (NF90 and NF270) to recover Li from a simulated brine containing Li and Mg. They observed that Li rejection was higher in the presence of Mg, reaching rejection values of 77 and 56% with NF90 and NF270 membranes, respectively, after 24 h at pH 5. Li-enriched solution was concentrated to 80% after distillation using a hydrophobic polytetrafluoroethylene membrane. The objective of this two-step process was to maximize Mg removal (with nanofiltration) because its presence can form deposits on the distillation membrane, which decreases its performance and accelerates membrane deterioration during prolonged use in brines. The authors recognized that these membranes still present limitations, particularly steric hindrance and Donnan exclusion. They emphasized the need to optimize these aspects to significantly increase the Li recovery efficiency, promoting a simpler process that facilitates the separation of these valuable metals. Qiu et al. [122] used three different membrane-based processes to concentrate Li from industrial wastewater. They used cation exchange resins (CH-93) to separate Ca2+ and Mg2+, so that they would not interfere with subsequent methods. Once these cations were removed, reverse osmosis was applied to obtain a preconcentrated solution containing Li, which was then used in electrodialysis (with CIMS/ACS/CMTE membranes) to further enrich the solution with LiCl. They obtained 28.5 g/L of Li with reverse osmosis alone, and up to 87.09 g/L after completing the electrodialysis process [122].

Regarding reverse and direct osmosis, previous studies have demonstrated the performance of direct osmosis to separate Li [194,198]. Pham et al. [200] used NaCl and MgCl2 solutions and a simulated brine containing Mg2+, K+, B3+, and Na+ to assess Li recovery. The authors designed the direct osmosis systems to concentrate Li from the simulated brine and LiCl solution where membranes composed of thin films and cellulose triacetate were applied for this purpose. The results showed that when using MgCl2 as extraction solution and LiCl as feed solution, Li concentration increased up to five times when using the thin film composite membrane since this salt presents a higher osmotic pressure. Li concentration was four times higher for the same membrane when simulated brine was used for both the feed and extraction solutions. Note that MgCl2 solution does not generate a significant reverse solute, whereas NaCl can be easily separated and reused, which contributes to reducing the process costs. Mustika et al. [202] applied direct osmosis to concentrate Li from a synthetic geothermal brine composed of various salts (NaCl, KCl, MgCl2, CaCl2, LiCl) using an asymmetric cellulose triacetate membrane and NaCl extraction solution at different concentrations to evaluate its impact on process performance. The results showed that the highest NaCl concentration (i.e., 5 M) significantly increased the water flux, reaching to 38.16 L/m2·h, due to the increased ionic activity of NaCl solution. This concentration, combined with a flow rate of 4 L/h at 42 °C, generated Li rejection of ~80%.

Ounissi et al. [199] combined the advantages of using different types of membrane in dialysis to develop a flexible system with high Li selectivity. The membrane was produced using Li ionic conductive glass-ceramics and a matrix composed of PECH-DABCO+PES-NH2. This membrane was evaluated using diffusion dialysis (DD) and cross-ion dialysis (CID). DD is the simplest process because it is based on the passage or retention of ions according to their size, resulting in a slow process; but, it is more efficient than the conventional evaporation used to treat brines. Li concentrated up to 22.1% from a lithium chloride solution after 27 days using DD. In contrast, Li enrichment reached 33% in 24 h using CID with HCl as the receiving solution. Acidic media favor ionic transfer by improving ion mobility and maximizing diffusion.

These studies indicated that the use of membrane-based processes for Li recovery and enrichment is an effective approach. Some improvements are still required, especially in membrane fouling, material degradation, cleaning and maintenance of membranes after prolonged periods of use, as this implies an increase in operating costs in addition to the generation of solid waste, affecting the sustainability of this separation process [205]. This is because Li-sources are corrosive containing complex chemicals and may contain high metal concentrations, which complicate membrane treatment [187,188]. Metal ions can deposit on membrane surfaces or react chemically, causing damage or reduced material performance. Corrosive environments accelerate membrane degradation, and the presence of organic solvents and chemicals leads to contamination [188]. High temperatures and osmotic pressures also threaten membrane integrity. To address these challenges, corrosion-resistant materials like ceramic, specialized synthetic polymer membranes, and membrane surface modifications are crucial for maintaining membrane performance and extending service life [187,188].

4.3. Adsorption

Adsorption is an effective method to separate Li due to its efficiency and low energy consumption where a variety of adsorbents such as activated carbon, zeolites, metal–organic frameworks (MOFs), or ion-exchange resins, have been tested. Adsorption offers several advantages, including the ability to recover Li from low-concentration sources, ease of implementation, and the potential for regeneration of the adsorbent, making it a sustainable option for large-scale applications. The performance of adsorption is influenced by factors such as adsorbent properties, ionic strength, temperature, and the presence of competing ions. A selection of studies that focus on the development and optimization of adsorption-based methods for Li recovery is reported in Table 6.

Ion sieves represent one of the best options from an environmental perspective for Li recovery, as they do not require large amounts of water, have low energy consumption, and are regenerable, leading to a reduction in solid waste generation. The most studied adsorbents are Li sieves based on titanium and manganese oxides, because of their high adsorption capacities and reduced toxicity [206]. These materials allow effective Li recovery from aqueous solutions with high purity and efficacy without requiring additional purification steps [138]. Wang et al. [207] synthesized manganese-based sieves to adsorb Li+ ions from leachates of spent battery powders, achieving an adsorption capacity of 31.62 mg/g with Li separation efficiency of 99.9%, even in the presence of other ions such as Co2+ and Ni2+. Wang et al. [139] recovered 36.34 mg/g of Li using titanium-based sieves from a brine containing Mg2+, Ca2+, K+, and Na+. This study proved that pH is a critical factor in this separation process. Li adsorption using this material was higher at pH 8.8 due to the reduction in surface charge, thereby improving the electrostatic interactions between the cations and the adsorbent surface. The authors emphasized the importance of maintaining pH < 8.8 to prevent the formation of magnesium precipitates. The adsorption properties of Li sieves can be improved via surface doping. Molybdenum-doped titanium sieves have an adsorption capacity of 78 mg/g [206]. It was concluded that molybdenum can improve the dispersion of active sites for Li adsorption. One of the main drawbacks of manganese-based sieves for industrial scale applications is pollution caused by metal leaching. Metallic cation doping is also an alternative method for improving the structural stability of materials and reducing Mn dissolution. Gao et al. [208] developed a manganese oxide sieve doped with iron that also exhibited magnetic properties. This material was tested to separate Li and achieved an adsorption capacity of 34.8 mg/g. It retained 70% of its original adsorption capacity with a Mn loss of only 0.51% after five adsorption cycles, whereas the undoped sieve exhibited a significantly higher Mn loss of 2.48% [208].

Table 6.

Recent studies on lithium recovery using adsorbents and ion exchange membranes.

Table 6.

Recent studies on lithium recovery using adsorbents and ion exchange membranes.

| Lithium Recovery Source | Lithium Source Pretreatment | Adsorbent | Adsorbent Preparation Conditions | Adsorption Conditions | Adsorption Capacity, mg/g | Reference |

|---|---|---|---|---|---|---|

| Spent Li-ion battery powders | Leaching by NH3·H2O–NH4HCO3 solutions with H2O2 | Manganese type lithium ion-sieve powder | --- | Initial concentration of Li+ 2.5 g/L, 2 g/L of Ni2+ and Co2+, 150 g/L of NH4+ at 30 °C for 6 h | 31.62 | [207] |

| Enriched salt lake brine from Qaidam basin in China | --- | Titanium type lithium ion sieve (HxTiO3) powder | 0.5 g of H2TiO3 and 7.5 g of tetrabutylamine, 2.5 mol/L of LiOH at 170 °C for 24 h. Pickled with 0.5 M HCl at 30 °C for 24 h | 0.1 g of HxTiO3, 20 mL of brine, at 25 °C for 24 h, initial pH 8.8 | 36.34 | [139] |

| Concentrated brine from the Qaidam area of China | Adjust to pH 8.8 with Ca(OH)2. Precipitate removal | Iron-doped lithium ion sieve powder | Precursor: LiOH, TiO2/Fe2O3 molar ratio of 0.15 at 600 °C for 3 h. 2 g of precursor, 0.5 M HCl at 25 °C for 24 h | 0.1 g of iron-doped lithium ion sieves, brine (1.6 g/L) at 25 °C for 55 h | 34.8 | [209] |

| Lithium solution | --- | Lithium ion imprinted polymers (LIP) Non-lithium ion imprinted polymers (NLIPs) | 1 dose of liquor: 0.3 g of DB14C4, 0.0689 g of LiNO3 and 0.17 mL of α-MAA in 60 mL of methanol and DMF at 25 °C for 30 min. 1 dose of liquor and 0.5 g of MWCNTs (for 5 min), 3.96 g of EGDMA and 125 mg of AIBN | 15 mg of LIP, 300 mg/L of Li+, pH 6, 25 °C for 2 | 9.45 0.52 | [210] |

| Synthetic brine (LiCl and NaCl) | --- | Commercial ion-exchange resins Lewatit TP 207 TP 208 K2629 | Matrix of crosslinked polyestirene TP 207 and TP 208 are macroporous cation exchange weakly acidic resins. K2629 is microporous, strongly acidic resin | 50 mL of synthetic brine (100 mg/L), 25 °C, 20 min | 4.30 4.34 3.24 | [211] |

| LiOH solution (1.8 g/L) | --- | Molybdenum-titanium oxide lithium ion sieve (Mo/Ti-LIS) powder | TiO2, LiOH∙H2O, MoO2 at 600 °C for 3 h. Pickled with 0.5 M HCl at 25 °C for 24 h | 0.1 g of Mo/Ti-LIS, 100 rpm, 25 °C, 50 h | 78 | [206] |

| LiOH solution | --- | Fe3O4-doped magnetic lithium ion-sieve powder | Mixture: 0.1 g of magnetic Fe3O4 nanospheres, 3.9 g of MnCl2 in 50 mL of water, 30 min of ultrasonication. Mixture containing 2.5 g of LiOH and 2.5 mL of H2O2 in 50 mL of water under stirring for 2 h. Final mixture at 170 °C for 10 h | 0.4 g of adsorbent in 500 mL of LiOH (50 mg/L), pH 10.1, 24 h | 29.33 | [212] |

| Lithium solution | --- | Pristine titanate nanotubes (pTNTs) Urea-Titanate nanotubes (UTNTs) Melamine-Titanate nanotubes (MTNTs) Polyacrylonitrile-Titanate nanotubes (PANTNTs) | pTNT: 2 g of anatase titanium (IV) oxide powder, 60 mL of 10 M NaOH at 130 °C for 26 h. UTNTs, MTNTs and PANTNTs: 1 g of urea, melamine or polyacrylonitrile in 20 mL of ethanol at 40 °C for 20 min and then 1 g of pTNTs at 80 °C for 2 h | 0.15 g of powder adsorbent, 250 mL of Li solution (30 mg/L) at 25 °C, pH 8 | 34.4 35.31 40.26 31.81 | [142] |

| Lithium solution | --- | Magnetic carbon-based lithium ion-imprinted material (Li+-IIP-Fe3O4@C) | Magnetic carbon nanospheres salinization by γ-methacryloxypropyltrimethoxysilane and functionalized with methacrylic acid. Grafting with 2-hydroxymethyl-12-crown-4 and LiClO4 | 5 mg of adsorbent, 10 mL of lithium solution (300 mg/L), 25 °C | 22.94 | [140] |

| Lithium solution | --- | Fe-doped manganese oxide lithium ion-sieves (LiMn2-xFexO4) | Calcination of LiOH, MnO2 and Fe2O3 at 450 °C for 6 h. Calcined obtained with 1 M HCl for 6 h | 0.150 L of LiCl (200 mg/L), 0.15 g of adsorbent, 2 h, pH 12 | 34.8 | [208] |

| West Taijinar salt lake brine | Adjust to pH 8.8 with NH3 1 M | Shaped titanium-based lithium ion sieve (HTO-P) | Titanium-based lithium ion sieve powder was pressed into a sheet and crushed (0.64 mm) | 0.15 g of HTO-P, 30 mL of brine, pH 8.8, 30 °C, 24 h | 19.22 | [213] |

| Seawater reverse osmosis brine (43 mg-Li/L, 17 mg-Sr/L) | --- | Li-ion-imprinted polymer (IIP) | Solution 1: 20 mL of acetonitrile, 74.5 mg of dicyclohexane-18-crown-6, 21.3 mg of LiCl at 25 °C and sonicated. 0.8 g of EGDMA (Crosslinker), 0.13 g of tertbutyl acrylate (monomer), 0.3 g of potassium persulphate with solution 1 at 25 °C | 10 mg of IIP, 30 mL of seawater brine, 45 °C, pH 10, 24 h | 300 | [214] |

| LiOH solution | --- | Porous Li1.33Mn1.67O4 (H-LMO) disc | LMO: Li2CO3/MnCO3 molar ratio of 1.33/1.67, 500 °C, 4 h. LMO disc: Mixture of LMO and 25% (by mass) petroleum pitch at 150 °C for 30 min. Pressing with a disc-shaped mold (20 mm) at 150 °C for 30 min. Extraction of Li+ with 0.3 M HCl for 6 days | 1.5 g of adsorbent, 0.5 L of Li+ solution (200 mg/L), 72 h at 25 °C. | 24 | [215] |

| LiCl solution | --- | Ionic Liquid-Cellulose nanocrystals-Date pits (IL-CNC@DP) | IL-CNC: C7H8INO and DMSO at 65 °C; cellulose nanocrystals at 65 ° for 1 h. IL-CNC@DP: IL-CNC and 5 g of date pit | 0.05 g of adsorbent, 50 mL of LiCl (100 mg/L) 25 °C, pH 6 | 105 | [144] |

| LiOH solution | --- | Ti-LIS Ti-LIS-Zr E-12/Ti-LIS-Zr | For lithium ion sieve (LIS) pellets: Li2CO3, TiO2 and Zr(NO3)4 at 650 °C for 4 h. 0.25 M HCl for 24 h | 0.5 g of adsorbent, 50 mL of LiOH (1.8 g/L), 24 h | 56.3 93.2 47.5 | [216] |

| LiNO3 solution | --- | MIL-100(Fe) MOF (Metal–organic framework) | Iron powder, H3BTC, HF, HNO3 in 10 mL of water at 150 °C for 12 h in teflon-lined autoclave | 20 mg of adsorbent, 2 of mL LiNO3 (12 g/L), 15 °C, 8 h | 83.9 | [141] |

| Lithium solution Qarhan salt lake brine | --- | Hydrogen manganese oxide-sepiolite (HMO-SEP) | MO-SEP: MnSO4·H2O and Na2S2O8 by hydrothermal method LMO-SEP: 2.0462 g of MO-SEP and 25 mL of LiNO3 (0.5 M) for 1 h HMO-SEP: LMO-SEP and 0.2 M HCl for 48 h | 25 °C, 8 h, 300 mg, 2.5 m/L of Li, pH 12 50 mg of adsorbent, 20 mL of brine, pH 12, 25 °C, 24 h | 52.41 47.25 | [217] |

| LiCl solution | --- | Commercial Dowex G26 resin as powder | --- | 1.5 L of Li, 1 g of adsorbent, 0.16 mL/min, 3 h, pH 9 | 12 | [145] |

| Lithium solution | --- | Tungsten-doped Ti-based Li-ion sieve (HTO-W) | LiOH·H2O, TiO2 and WO3 in 20 mL water at 160 °C for 24 h. Calcination at 600 °C for 2 h. 0.2 M HCl at 30 °C for 24 h | LiCl solution (425 mg/L), 30 °C, 3 h | 43.01 | [218] |

| Li2CO3 solution | Simulated lithium solution (2.5 g/L): Li2CO3 and H2SO4 | Porous carbon beads-Fe3O4 Porous carbon beads-FeCl3 | Beads: Coal tar pitch and THF/DMF in isopropyl alcohol. Beads carbonization at 800 °C, 2 h. Beads activation at 850 °C, 2 h. Spherical droplets with coal tar pitch in isopropyl alcohol and water. Magnetization impregnated with FeCl3 | 30 mg of adsorbent, 10 mL of lithium solution, 5 h | 73.8 79.8 | [143] |

| Simulated seawater | --- | HTO/MXene@PVC hybrid film | Precursor: MXene, Li2TiO3, LIS, 13 mL of NMP sonication for 15 min. HTO/MXene@PVC precursor: precursor and 3 g of PVC at 80 °C. HTO/MXene@PVC LIS: 0.1 M HCl for 24 h | 200 mg/L of Li+, for 24 h at 30 °C, pH 9 | 25.4 | [219] |

| Synthetic Li-ion battery waste leachate (2.45 g/L) | --- | Commercial chelating resin with aminomethylphosphonic acid functional group Lewatit® MDS TP 260 | --- | Simulated moving bed with 6 jacketed glass columns arranged in 1-1-1-3, 15 mm diameter, switch time 25 min, 1.64 L/h | 100% | [146] |

Nomenclature—AIBN: 2,20-azobisisobutyronitrile; H3BTC: Benzene-1,3,5-tricarboxylic acid; DB14C4: Dibenzo14-crown-4; DMF: N,N-dimethyl formamide; DMSO: Dimethyl sulphoxide; EGDMA: Ethyleneglycol dimethacrylate; HTO: Titanium-based LIS; LIS: Lithium-ion sieve; LMO-SEP: Lithium manganese oxide-Sepiolite; α-MAA: α-Methacrylic; MO-SEP: Manganese oxide-Sepiolite; MWCNTs: multi-wall carbon nanotubes; PVC: Poly(vinyl chloride); THF: Tetrahydrofuran.

Adsorbents based on ion-imprinted polymers have gained popularity as promising materials with specific binding sites for ion separation. Huang and Wang [210] achieved an adsorption capacity of 1363 μmol/g with imprinted polymers, compared to 75 μmol/g obtained with non-imprinted polymers. This result demonstrated a significant improvement in Li adsorption due to the introduction of DB14C4, which favored the formation of unique coordination cavities between the chelating agent and Li ions. Alshuiael and Al-Ghouti [214] also synthesized ion-imprinted polymers to adsorb Li from reverse osmosis seawater brine, recovering up to 2500 µg of Li per gram of adsorbent. A high adsorption capacity was achieved because of the increase in temperature at pH 10, which significantly influenced the adsorption rate. The increase in pH promotes the ionization of the carboxyl groups of the polymers, enhancing their interactions with the target ions. However, this operating parameter also reduced the solution viscosity, which in turn improved the diffusion of adsorbate ions [214].

MOF-based adsorbents are promising for the separation of various ions because of their excellent adsorption capacities. Huangfu et al. [141] used MIL-100(Fe) to separate Li from LiNO3 solution obtaining an adsorption capacity of 83.9 mg/g in 2 h, and the adsorbent structure was stable over four adsorption cycles. Kamran and Park [142] evaluated titanium nanotubes (TNTs) to separate Li. These nanotubes are considered exceptional porous materials because of their tubular structure that is stabilized by hydrothermal treatment and can be chemically modified. The authors functionalized TNTs with urea, melamine, and polyacrylonitrile. The batch studies were performed at room temperature, basic conditions using Li concentration of 30 mg/L with both functionalized and unfunctionalized TNTs to separate Li in the absence of other ions. They determined that the melamine-functionalized adsorbent exhibited the highest Li adsorption capacity (i.e., 40 mg/g) in comparison to the non-functionalized adsorbent (31 mg/g). For recovery of the adsorbed Li ions, 0.3 M HCl was evaluated as eluting agent, achieving 3 cycles with the same initial adsorption capacity [142]. Various porous carbon-based materials have been applied for Li recovery. Liu et al. [143] reported Li adsorption from solutions with low pH using magnetized porous carbon beads. This study showed that the mesopore volume of the tested adsorbent favored Li separation, with an adsorption capacity of 80 mg/g, which prevailed after five adsorption cycles [143]. Other Li adsorbents include biomass waste and composites. Wahib et al. [144] studied date pits impregnated with nanocrystals of cellulose and an ionic liquid (IL-CNC@DP) to separate Li achieving 90% efficiency with an adsorption capacity of 99 mg/g at pH 6. Chen et al. [219] reported an adsorbent based on a titanium hybrid membrane incorporating MXene, which is a 2D advanced material known for its excellent properties in terms of surface area, conductivity, and strength. The adsorption capacity of this novel material was lower than 26 mg/g, but it exhibited excellent reusability, maintaining over 90% of its adsorption properties after several adsorption–desorption cycles [219].

Ion-exchange resins are versatile materials for the selective recovery of valuable metals in various industrial contexts, see Table 6. Arroyo et al. [211] Cunha et al. [145] and Wesselborg et al. [147] used different resins to demonstrate their effectiveness for separating Li from various sources. The results indicated that resin TP207 is an interesting alternative for processing brines [211]. Dowex G26 resin was effective to handle leachates from lepidolite and spodumene ores achieving a maximum loading capacity of 1.8 meq of Li/g and a recovery of 71%, with an elution of up to 82% [145]. Wesselborg et al. [146] analyzed a continuous resin-based process for Li separation from battery cathode leachates and achieved high purity in the refined product. This method outperformed the solvent extraction and precipitation methods.

Recent advances in material design and process optimization have enabled the handling of competing ions during Li separation [117,220]. As stated, the importance of adsorption, compared to other Li separation techniques, relies on its versatility and flexibility [221]. This allows the use of a wide range of adsorbents to separate Li from fluids, involving physical interactions, electrostatic forces, ion exchange, and chemisorption [190,216,222,223,224]. Different studies have documented that physisorption is relevant for Li separation from sources such as brine or polluted water [225]. Shoghi et al. [226] used H4Ti5O12 spinel nanotubes for Li recovery and determined that the adsorption mechanism followed physisorption where Dubinin-Radushkevitch isotherm fitted experimental data. This result was confirmed by the calculation of the adsorption energy, which was ~5 kJ/mol indicating the presence of van der Waals forces for the interaction between Li ions and the adsorbent surface [226]. Liu et al. [143] showed that Li adsorption process from a brine using magnesium oxide-based adsorbent implied physisorption. These authors proved that adsorbent regeneration can be performed using an HCl solution [143]. Note that the materials functionalized with active groups can form specific chemical bonds with Li ions even in systems with high concentrations of other competitive ions [223]. Marthi et al. [227] analyzed Li adsorption mechanism using H2TiO3 and the results indicated the relevant role of electrostatic forces in the separation process, while Zhou et al. [216] studied sieves doped with Zr and epoxy granular compounds, demonstrating that Li adsorption process involved predominantly chemisorption. Another study reported that Li adsorption on Mn- and Al-based composites could be governed by a combination of chemisorption and physisorption [228].

Aluminum-based materials can be used as ion sieves for Li extraction because their laminar structure allows them to selectively exchange ions even in the presence of other cations such as Mg, Ca, or Na. For example, the recovery of lithium from brines can be performed using lithium-aluminum double hydroxide (LADH-Cl) with high magnesium chloride content. The results demonstrated that the lithium adsorption efficiency depends mainly on the crystalline defects of LADH-Cl matrix [229].