Phase and Composition Study of 18th Century Qallaline Tiles, Tunis

Abstract

1. Introduction

2. Materials and Methods

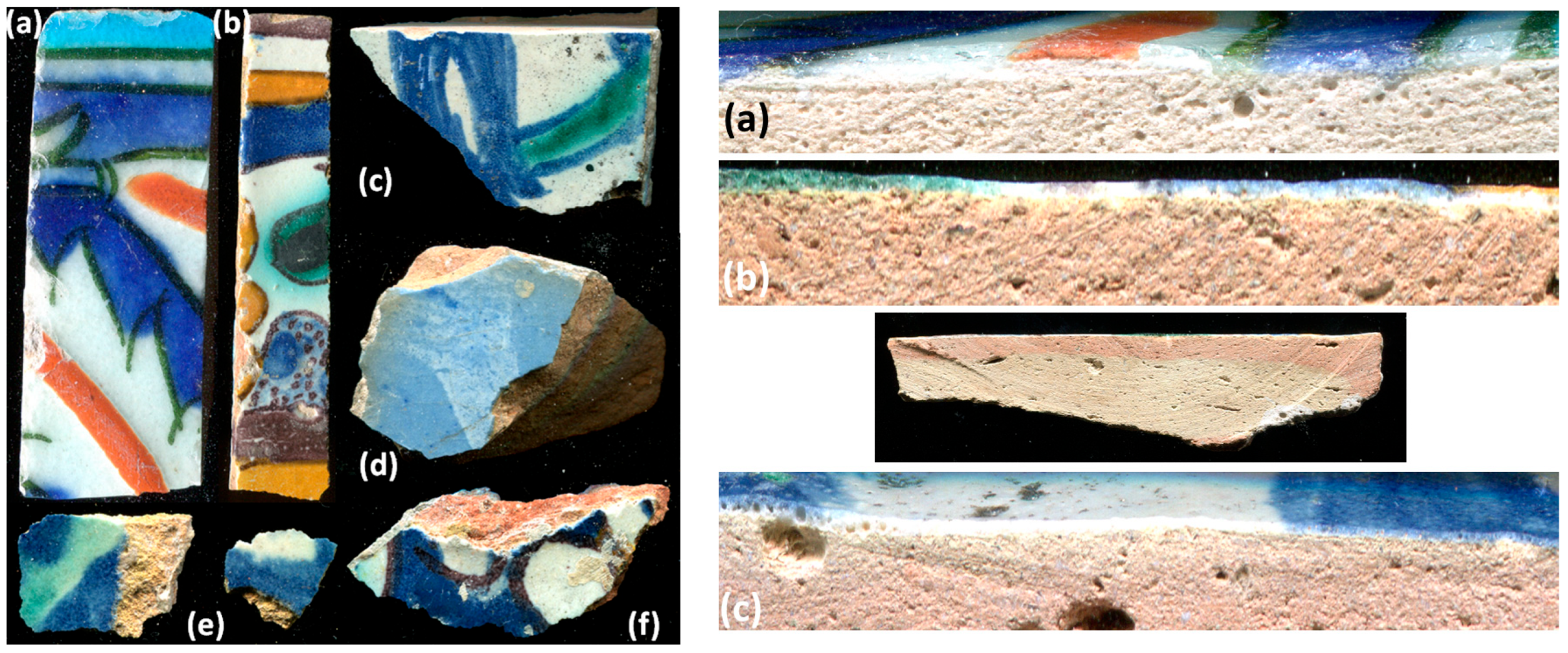

2.1. Artifacts

2.2. Methods

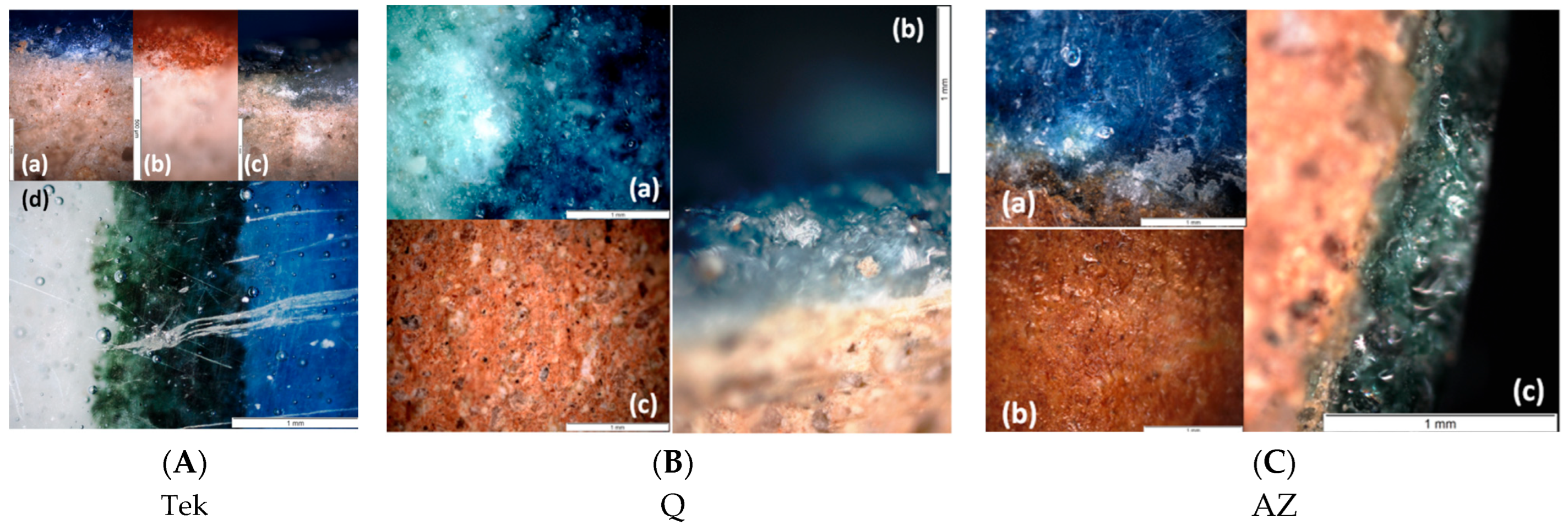

2.2.1. Optical Microscopy

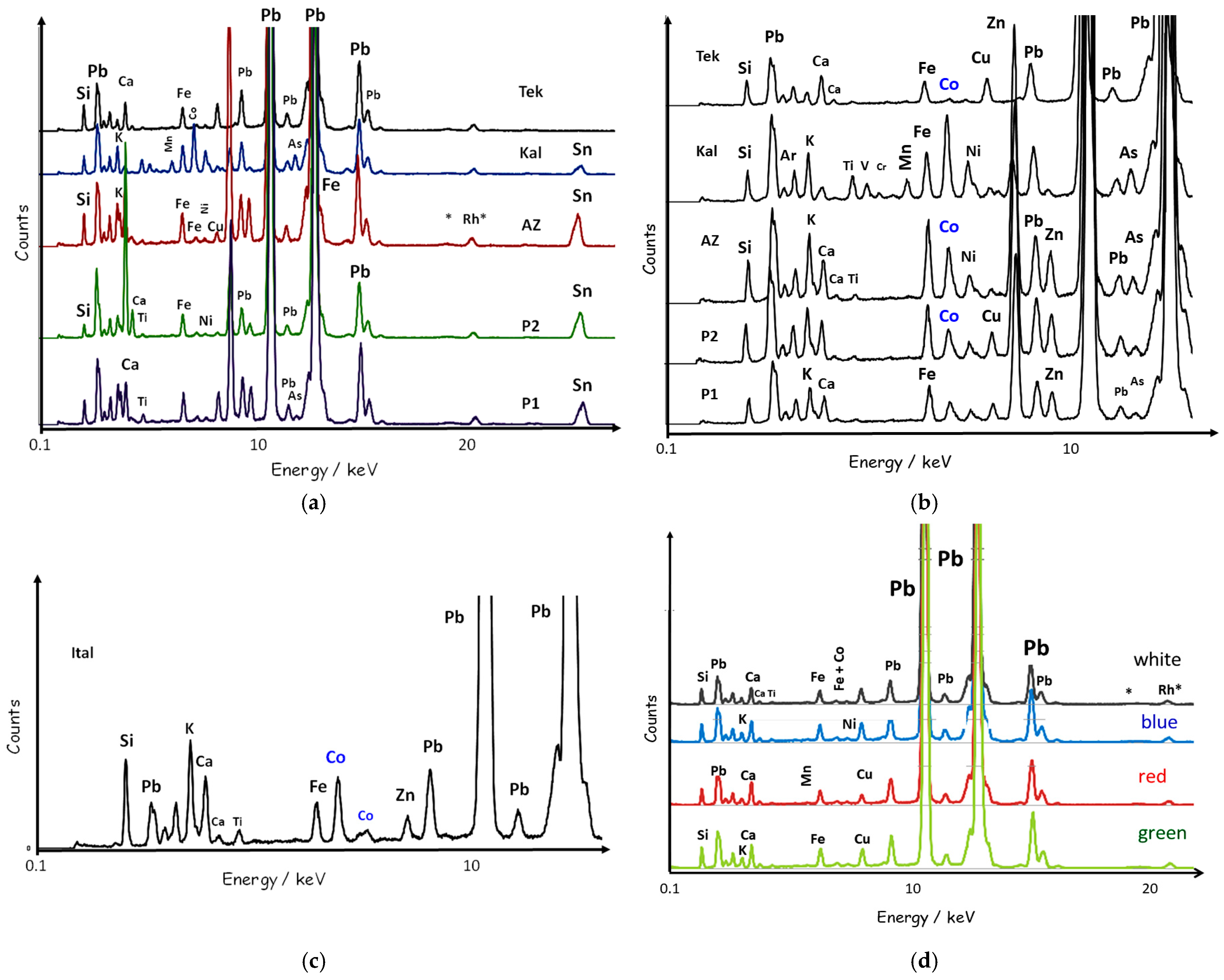

2.2.2. Portable X-Ray Fluorescence Spectroscopy (pXRF)

2.2.3. Raman Microspectroscopy

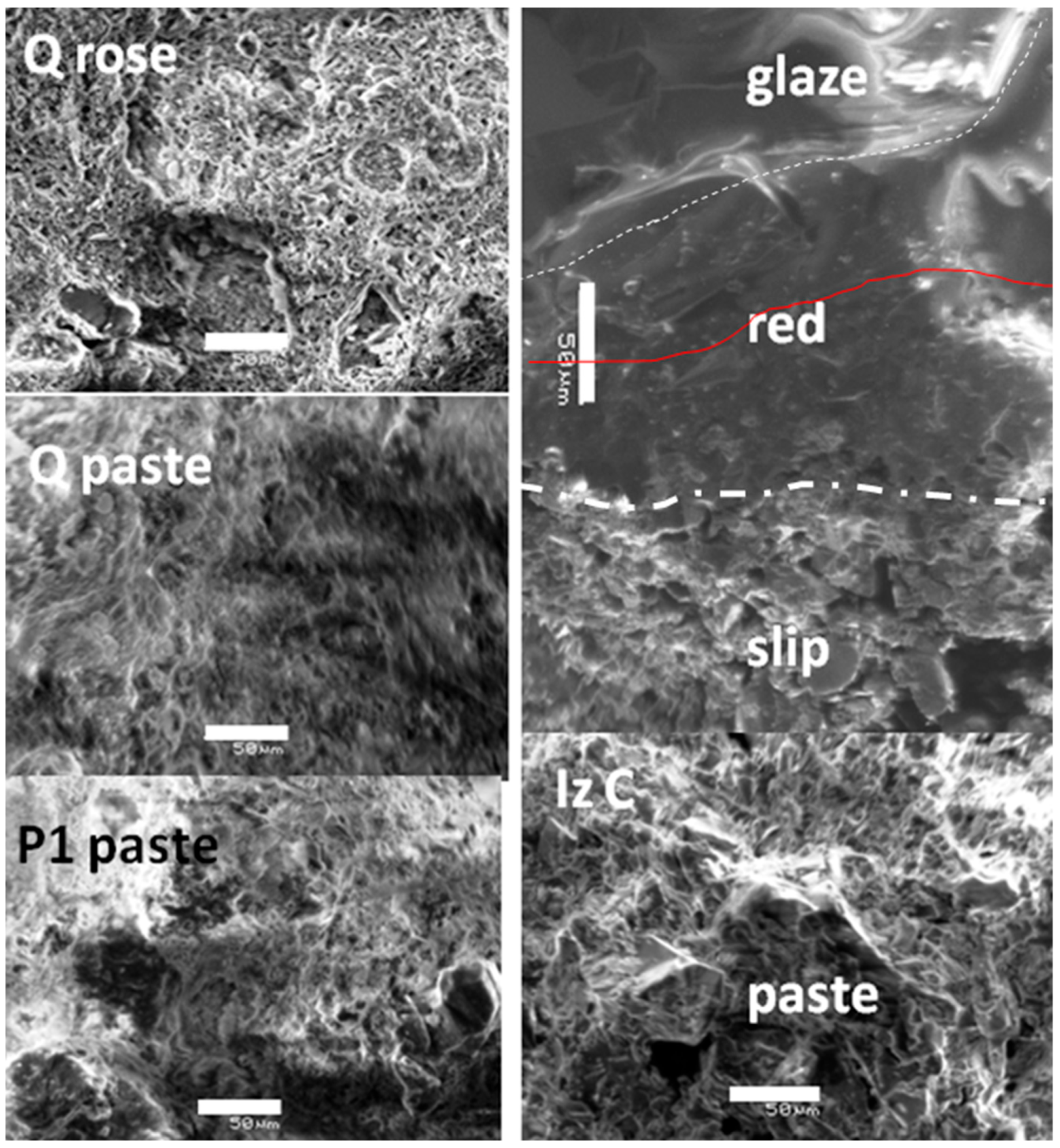

2.2.4. Scanning Electron Microscopy–Electron-Dispersive Spectroscopy

3. Results

3.1. Microstructure and Composition Comparison

3.1.1. Paste

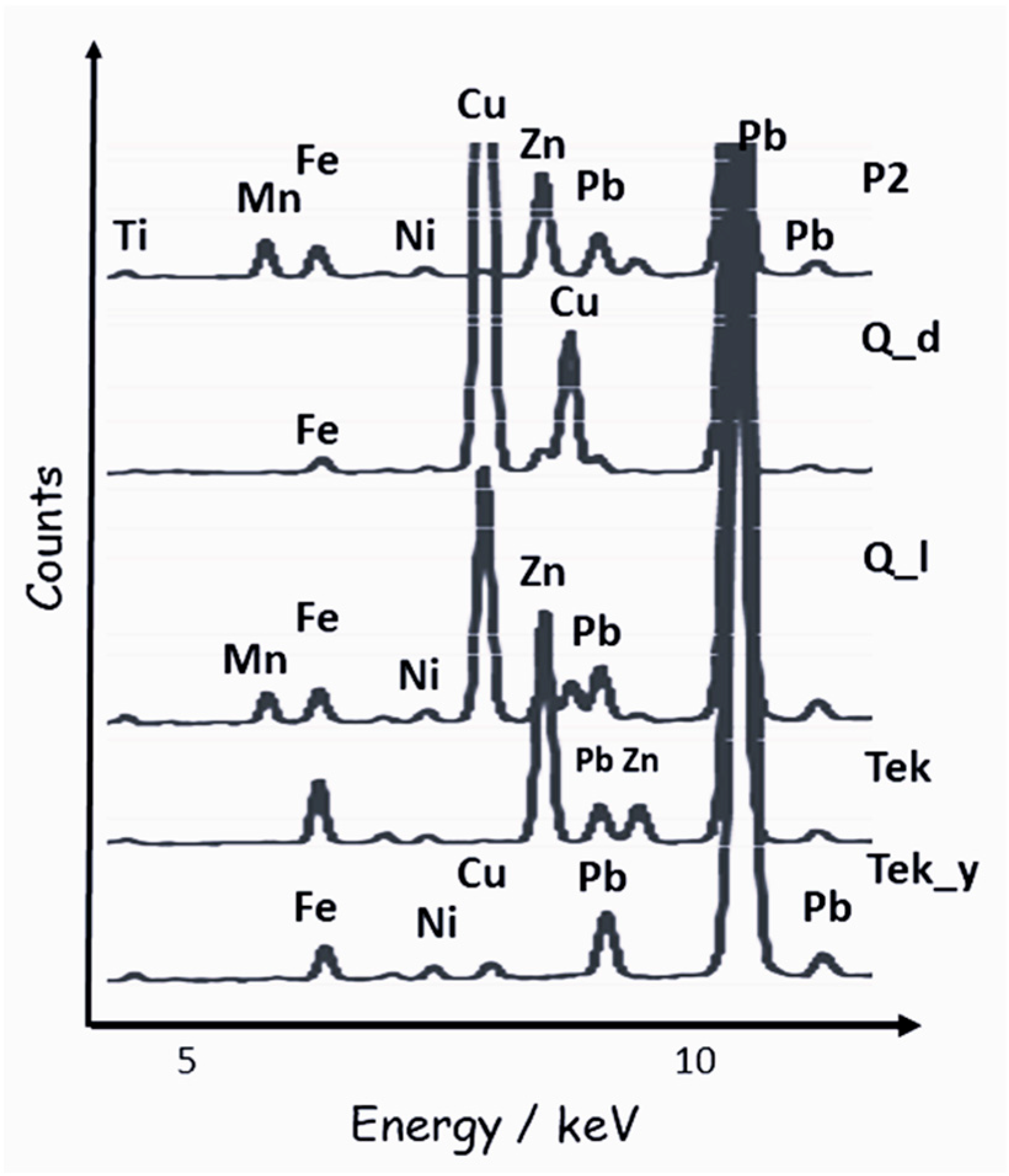

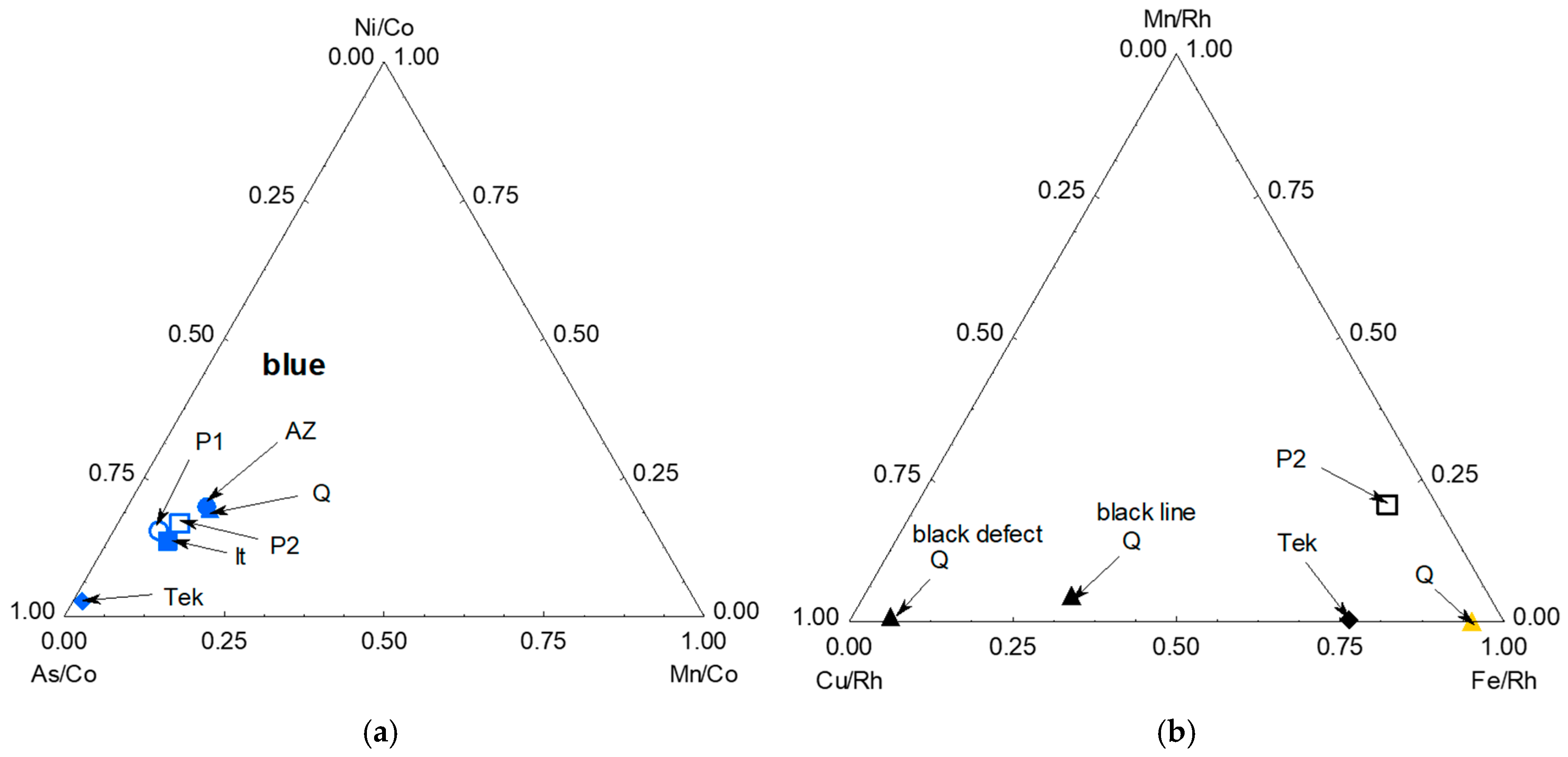

3.1.2. Glazed Decoration

3.1.3. Blue Zones

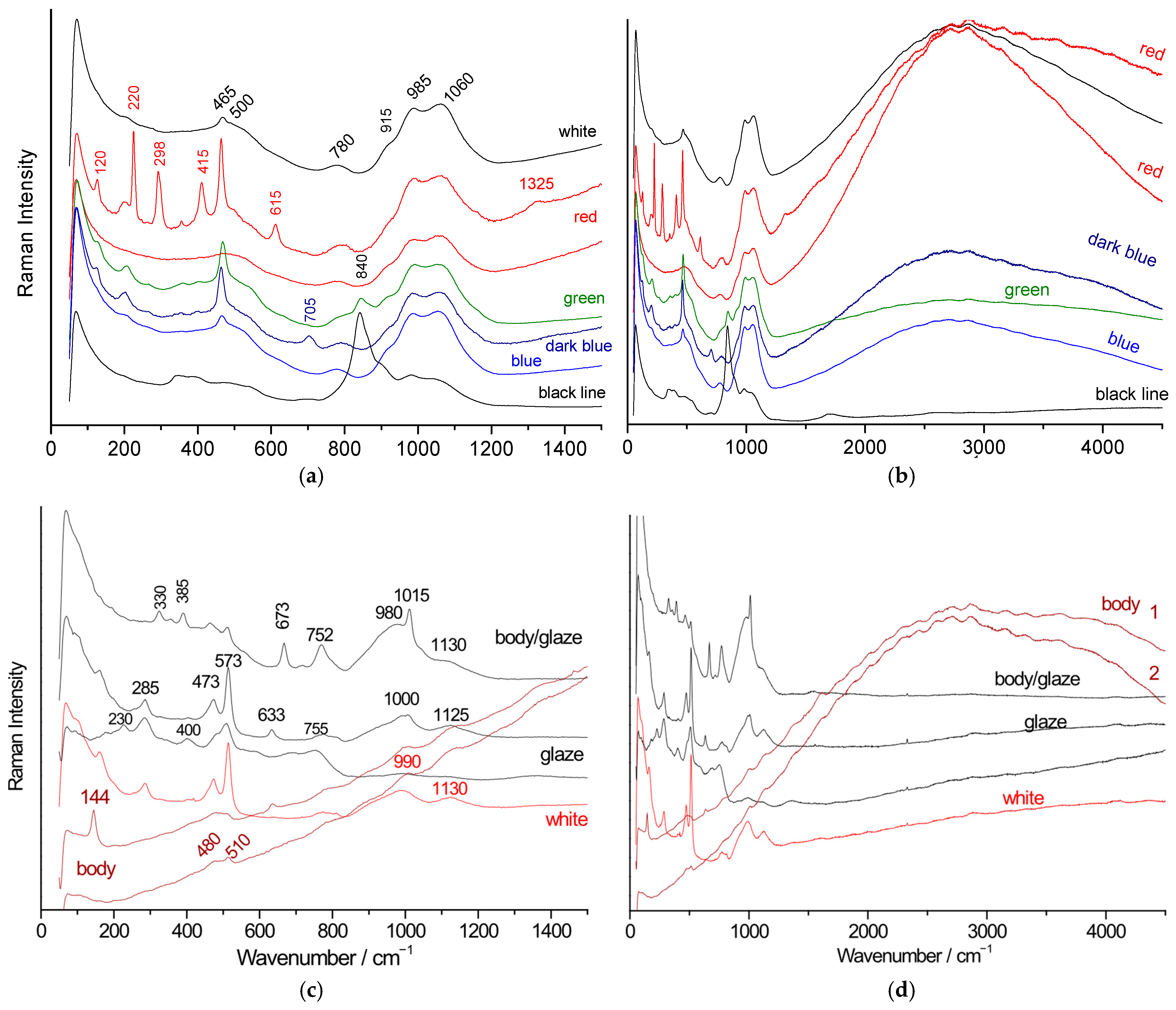

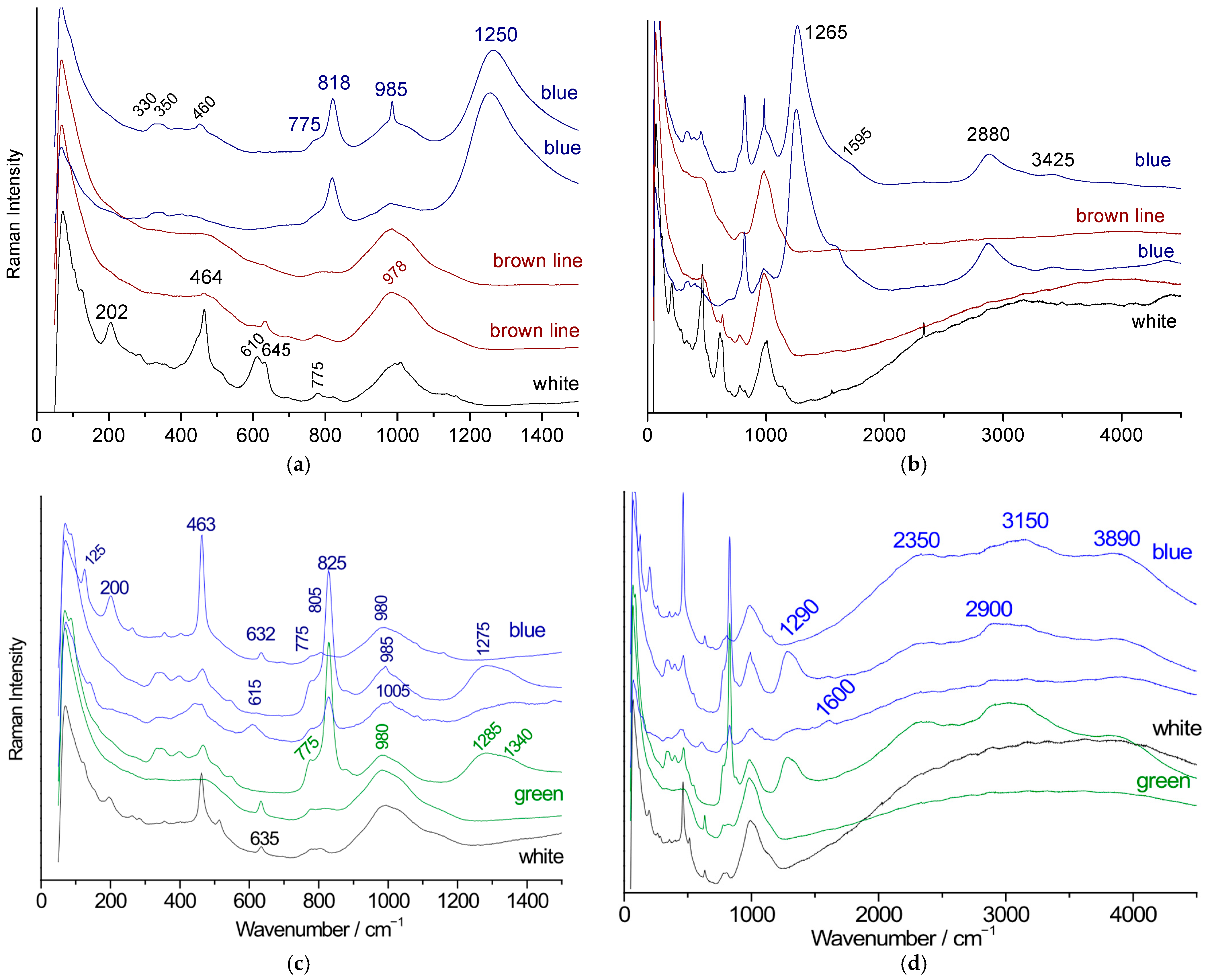

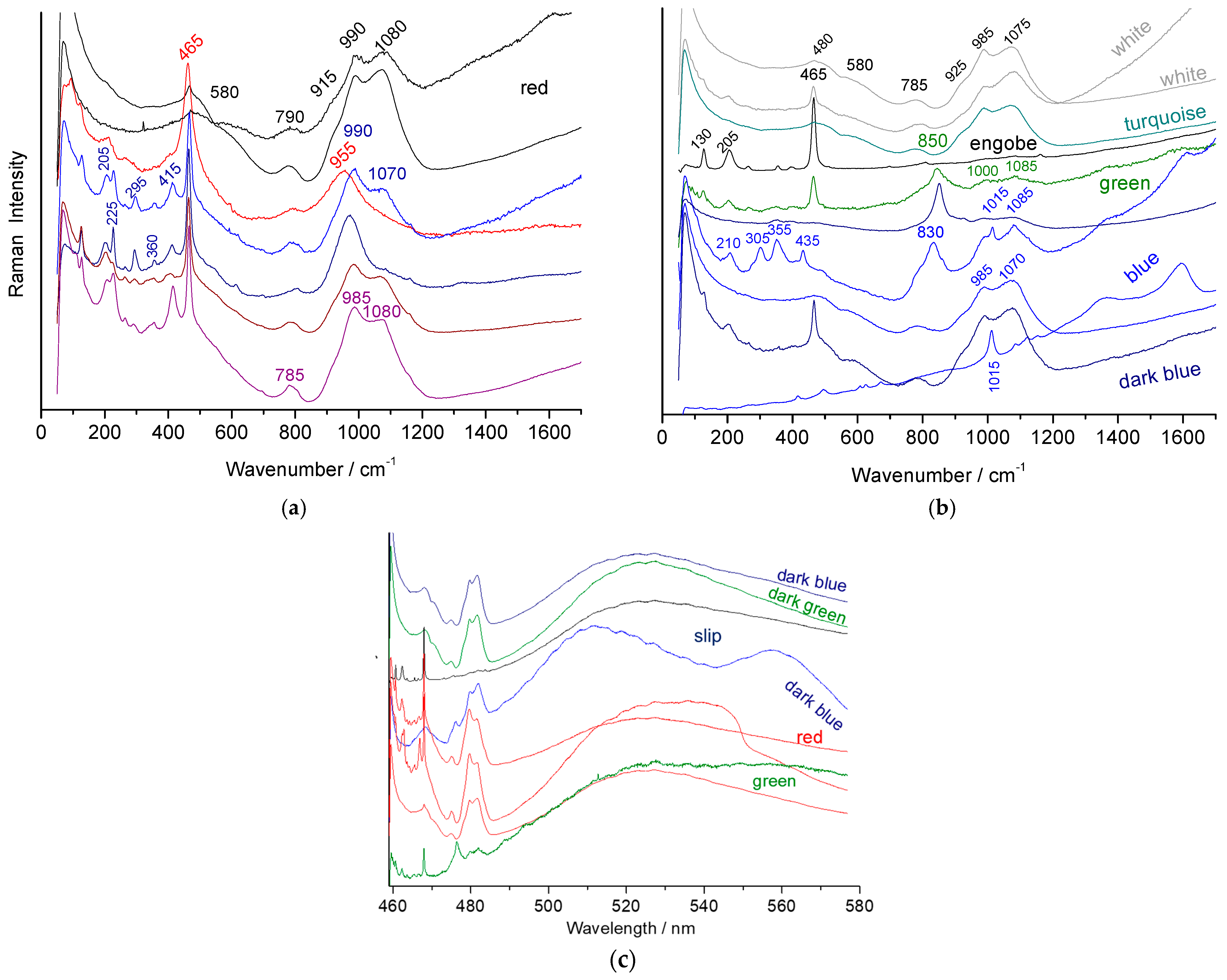

3.2. Raman Signatures of Glazes

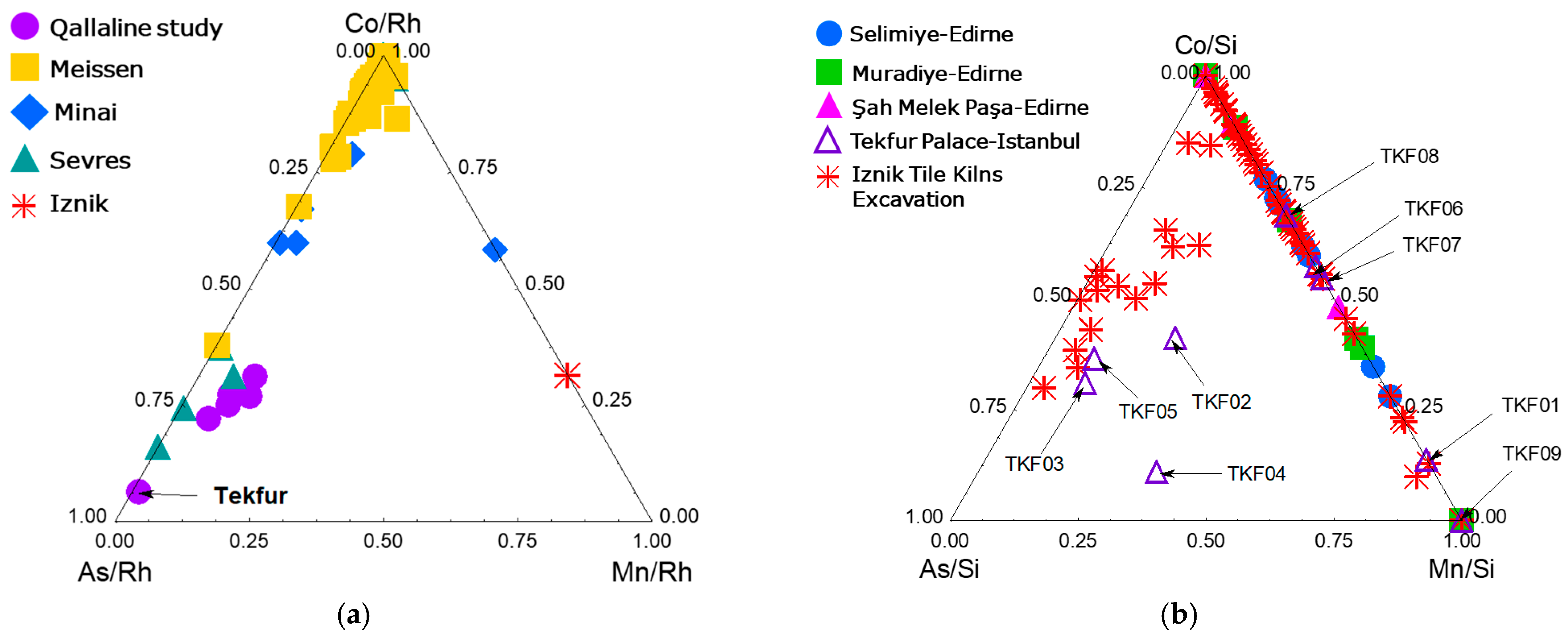

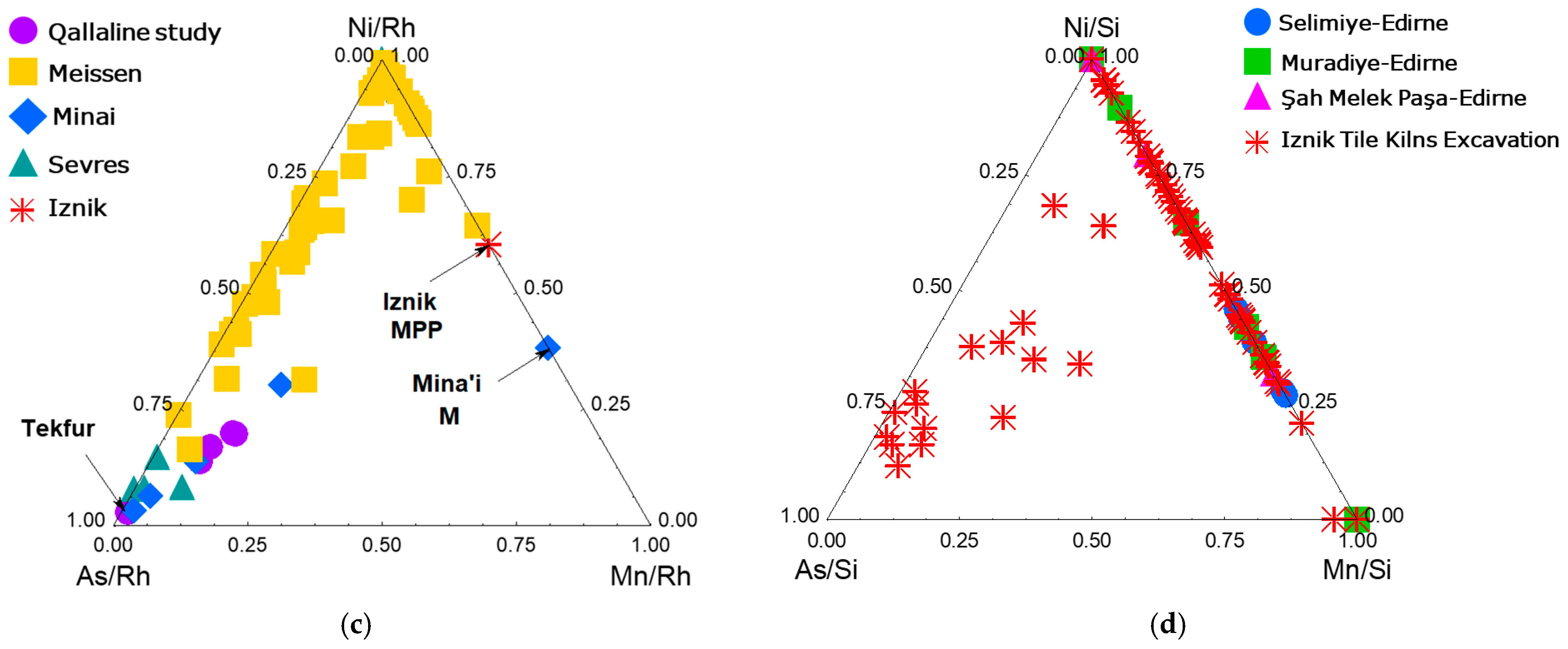

4. Discussion on Raw Material Provenance

- (1)

- The presence of tin in the body of some tiles attributed to the Qallaline kilns;

- (2)

- The presence of lead in the bodies of both Qallaline and Tekfur tiles;

- (3)

- The presence of tin in some Tekfur glazes.

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zubizarreta Villanueva, O. The Moriscos in Tunisia. (ch. 14). In The Expulsion of the Moriscos from Spain—A Mediterranean Diaspora; Garcia-Arenal, M., Wiegers, G., Eds.; Lopez-Morillas, C.; Beagles, M., Translators; The Medieval and Early Modern Iberian World; Brill: Leiden, The Netherlands, 2014; Volume 56, pp. 357–388. [Google Scholar] [CrossRef]

- Binous, J.; Baklouti, N.; Tanfous, A.B.; Bouteraa, K.; Rammah, M.; Zouari, A. Ifriqiya: Thirteen Centuries of Art and Architecture in Tunisia; Museum With No Frontiers, MWNF (Museum Ohne Grenzen): Vienna, Austria, 2013. [Google Scholar]

- Kura, N. Tunisian Tiles: Ottoman Inspiration from the 16th to the 19th Centuries. Ph.D. Thesis, Bilkent Universitesi, Ankara, Turkey, 1995. [Google Scholar]

- Louhichi, A. De Raqqada à Qallaline; Neapolis Céram: Nabeul, Tunisia, 2000. [Google Scholar]

- Ben Amara, A.; Schvoerer, M.; Haddad, M.; Akerraz, A. Recherche d’indices sur les techniques de fabrication de Zelliges du XIVe siècle (Chellah, Maroc). Rev. Archéom. 2003, 27, 103–113. Available online: https://www.persee.fr/doc/arsci_0399-1237_2003_num_27_1_1046 (accessed on 10 July 2025). [CrossRef]

- El Amraoui, M.; Azzou, A.; Haddad, M.; Bejjit, L.; Ait Lyazidi, S.; El Amraoui, Y. Zelliges from Dar-El Beïda Palace in Meknes (Morocco): Optical Absorption and Raman Spectrometry. Spectrosc. Lett. 2007, 40, 777–783. [Google Scholar] [CrossRef]

- Ibtissem, H.; Khaldi, M. L’art du Zellige Dans L’architecture Musulmane. «Cas des Mosquées Zianides de Tlemcen». El Hiwar El Thakafi (Cult. Dialogue J.) 2018, 7, 17–26. Available online: https://asjp.cerist.dz/en/article/57558 (accessed on 13 August 2025).

- Zucchiatti, A.; Azzou, A.; El Amraoui, M.; Haddad, M.; Bejjit, L.; Ait Lyazidi, S. PIXE analysis of Moroccan architectural glazed ceramics of 14th–18th centuries. Int. J. PIXE 2009, 19, 175–187. [Google Scholar] [CrossRef]

- El Halim, M.; Daoudi, L.; El Alaoui El Fels, A.; Rebbouh, L.; El Ouahabi, M.; Fagel, N. Non-destructive portable X-ray Fluorescence (pXRF) method for the characterization of Islamic architectural ceramic: Example of Saadian tombs and El Badi palace ceramics (Marrakech, Morocco). J. Archaeol. Sci. Rep. 2020, 32, 102422. [Google Scholar] [CrossRef]

- Pereira, M.; de Lacerda-Aroso, T.; Gomes, M.J.M.; Mata, A.; Alves, L.C.; Colomban, P. Ancient Portuguese ceramic wall tiles (“Azulejos”): Characterization of the glaze and ceramic pigments. J. Nano Res. 2009, 8, 79–88. [Google Scholar] [CrossRef]

- Coentro, S.; Muralha, V.; Lima, A.; Pais, A.; Silva, A.; Mimoso, J. The colors and techniques of 17th century Portuguese Azulejos: A multi-analytical study. Microsc. Microanal. 2011, 17, 1782–1783. [Google Scholar] [CrossRef]

- Ferreira, L.V.; Casimiro, T.M.; Colomban, P. Portuguese tin-glazed earthenware from the 17th century. Part 1: Pigments and glazes characterization. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2013, 104, 437–444. [Google Scholar] [CrossRef] [PubMed]

- Pereira, S.R.; Conte, G.; Esteves, L.; Pais, A.N.; Mimoso, J.M. Evolution of azulejo glaze technology in Portugal from the 16th to the onset of the 19th century. J. Eur. Ceram. Soc. 2023, 43, 3804–3815. [Google Scholar] [CrossRef]

- Ferreira, L.V.; Machado, I.F.; Pereira, M.F.C.; Mangucci, C. Archaeometry of tiles (azulejos) produced in the region of Lisbon–16th to 18th centuries. A comparison of Lisbon and Seville pastes for the cuerda seca and arista tiles. J. Archaeol. Sci. Rep. 2023, 49, 104041. [Google Scholar] [CrossRef]

- Coentro, S.; Alves, L.C.; Conesa, J.C.; Ferreira, T.; Mirão, J.; da Silva, R.C.; Trindade, R.; Muralha, V.S.F. White on blue: A study on underglaze-decorated ceramic tiles from 15th-16th-century Valencian and Sevillian productions. J. Archaeol. Sci. Rep. 2020, 30, 102254. [Google Scholar] [CrossRef]

- Simsek, G.; Unsalan, O.; Bayraktar, K.; Colomban, P. On-site pXRF analysis of glaze composition and colouring agents of “Iznik” tiles at Edirne Mosque (15th and 16th-centuries). Ceram. Int. 2019, 45, 595–605. [Google Scholar] [CrossRef]

- Allen, W.J. Tekfur Saray in Istanbul: An Architectural Study; The Johns Hopkins University: Baltimore, MD, USA, 1981. [Google Scholar]

- Simsek, G.; Demirsar Arli, B.; Kaya, S.; Colomban, P. On-site pXRF analysis of body, glaze and colouring agents of the tiles at excavation site of Iznik kilns. J. Eur. Ceram. Soc. 2019, 39, 2199–2209. [Google Scholar] [CrossRef]

- Necipoglu, G. From International Timurid to Ottoman: A Change of Taste in Sixteenth-Century Ceramic Tiles. Muqarnas 1990, 7, 136–170. [Google Scholar] [CrossRef]

- Sarıgüzel, M.; Yılmaz, Ş.; Günay, E. An Investigation of Nanoparticles in Contemporary Lustres on Modern Iznik Tiles. J. Austral. Ceram. Soc. 2015, 51, 34–39. [Google Scholar]

- Henderson, J.; Raby, J. The technology of fifteenth century Turkish tiles: An interim statement on the origins of the Iznik industry. World Archaeol. 1989, 21, 115–132. [Google Scholar] [CrossRef]

- Demirsar Arlı, B. Evaluation of Iznik Tiles Examples from Iznik Tile Excavation. J. Hist. Cult. Art Res. 2018, 7, 578–594. [Google Scholar] [CrossRef]

- İmer, C.; Günay, E.; Öveçoğlu, M.L. An investigation of thin lustre layers developed by ion-exchange mechanism on the surface of Iznik tiles. Ceram. Int. 2015, 41, 11489–11497. [Google Scholar] [CrossRef]

- Gokce, E. Iznik Ceramics: History and Present-Day. Athens J. Humanit. Arts 2018, 5, 225–242. [Google Scholar] [CrossRef]

- Colomban, P.; Sagon, G.; Louhichi, A.; Binous, H.; Ayed, N. Identification par microscopie Raman des tessons et pigments de glaçures de céramiques de l’Ifriqiya (Dougga, XI-XVIIIe siècles). Rev. Archéom. 2001, 25, 101–112. [Google Scholar] [CrossRef]

- Colomban, P.; Milande, V.; Le Bihan, L. On-site Raman analysis of Iznik pottery glazes and pigments. J. Raman Spectrosc. 2004, 35, 527–535. [Google Scholar] [CrossRef]

- Colomban, P.; de Laveaucoupet, R.; Milande, V. On Site Raman Analysis of Kütahya fritwares. J. Raman Spectrosc. 2005, 36, 857–863. [Google Scholar] [CrossRef]

- Ben Mami, B. Les Madrasa-s de la Médina de Tunis de l’époque hafside à l’époque Husaynite; XIIIe-XIXe siècles, مدارس مدينة تونس من العهد الحفصي الى العهد الحسيني; INP: Tunis, Tunisia, 2006; 396p. [Google Scholar]

- Alvarez-Dopico, C.-I. L’empreinte Mauresque et la Tradition Hispano-Arabe Dans la Céramique Architecturale Tunisoise des XVIe et XVIIe Siècles: L’exemple du Bardo, Mémoire de DEA: Hist. Art; Université Paris Sorbonne-Paris IV: Paris, France, 2002. [Google Scholar]

- Melliti-Chemi, W. La Céramique de Revêtement Mural Dans la Médina de Tunis, Qallaline et Céramique Importée: XVIe–XIXe Siècles. Ph.D. Thesis, Faculté des Sciences Humaines et Sociales, Université de Tunis, Tunis, Tunisia, 2009. [Google Scholar]

- Saadaoui, A. Naissance et essor de la faïence typiquement Tunisoise de Qallaline, les ateliers d’Abdewâhid al-Maghribî et de l’Usta Mascûd al-Sabac (Première moitié du XVIIIe). In Les Couleurs de la Ville, Faïences et Architecture à Tunis; Saadaoui, A., Ed.; Centre de Publication Universitaire, Laboratoire d’Archéologie et d’Architecture maghrébines: Tunis, Tunisia, 2021. [Google Scholar]

- Louhichi, A. Céramique Islamique de Tunisie, Ecole de Kairouan—Ecole de Tunis; Agence de Mise en Valeur du Patrimoine et de Promotion Culturelle: Tunis, Tunisia, 2010; p. 199. [Google Scholar]

- Ben Youssef, M.S. Mechrca el-Melki, Chronique Tunisienne 1705–1771; Serres, V.; Lasram, M., Translators; Impr. Rapide: Tunis, Tunisia, 1900; p. 15. [Google Scholar]

- Van Lemmen, H. 5000 Years of Tiles; Smithsonian Books: Washington, DC, USA, 2013. [Google Scholar]

- Geckinli, A.E.; Goektas, A.A.; Süer, A.; Yenisehirlioglu, F. Characterization studies of late Ottoman ceramics recovered from Istanbul Tekfur Palace excavation. Key Eng. Mater. 2002, 206–213, 909–912. [Google Scholar] [CrossRef]

- Yenişehirlioğlu, F. From Excavation to Exhibition: Tekfur Palace (Palace of Porphyrogenitus) Museum. J. Turk. Inst. Archaeol. Cult. Herit. 2023, 3, 103–134. [Google Scholar] [CrossRef]

- Dumlupınar, Z. The 17th Century Tile Revetments in Topkapi Palace Harem Section. J. Acad. Stud. 2015, 17, 1–12. [Google Scholar]

- Gündeş, S.; Oktuğ, M.; Özden, D. Tales of Tiles in Ottoman Empire. Colour Des. Creat. 2008, 9, 1–7. [Google Scholar]

- Demirsar Arli, B.; Şimsek Franci, G.; Kaya, Ş.; Arli, H. On-Site, Non-Destructive Studies at Iznik Tile Kilns Excavation, AIECM3, XIII Congreso Internacional Sobre Cerámica Medieval y Moderna en el Mediterráneo (AIECM3); García Porras, A., Busto Zapico, M., Martín Ramos, L., Peregrina Sánchez, M.J., Eds.; Ediciones de la Ergastula, S.L.: Madrid, Spain, 2024; pp. 727–732. [Google Scholar]

- Yenisehirlioglu, F. A Digital Database for Tiles at the Topkapi Palace Museum Storage Rooms. In 14th International Congress of Turkish Art; Republic of Turkey Ministry of Culture and Tourism: Ankara, Turkey, 2011; p. 12. [Google Scholar]

- Simsek, G.; Geckinli, A.E. An assessment study of tiles from Topkapı Palace Museum with energy-dispersive X-ray and Raman spectrometers. J. Raman Spectrosc. 2012, 43, 917–927. [Google Scholar] [CrossRef]

- Altun, A. (Ed.) The Story of Ottoman Tiles and Ceramics; Istanbul Stock Exchange: Istanbul, Turkey, 1997–1999. [Google Scholar]

- Geçkinli, A.E. Characterization of Ceramic Finds from Tekfur Palace. In Proceedings of the 22nd International Excavation, Research, and Archaeometry Symposium, İzmir, Turkey, 22–26 May 2000. [Google Scholar]

- Geçkinli, A.E. Conference on Technical Characteristics of Ottoman Tiles, Historical Environment, and Building Conservasionists Association. Available online: https://www.arkeolojikhaber.com/haber-prof-dr-a-emel-geckinli-osmanli-cinilerinin-teknik-ozelliklerini-anlatacak-24666/ (accessed on 13 August 2025).

- Colomban, P.; Simsek Franci, G.; Gironda, M.; d’Abrigeon, P.; Schumacher, A.-C. pXRF Data Evaluation Methodology for On-Site Analysis of Precious Artifacts: Cobalt Used in the Blue Decoration of Qing Dynasty Overglazed Porcelain Enameled at Customs District (Guangzhou), Jingdezhen and Zaobanchu (Beijing) Workshops. Heritage 2022, 5, 1752–1778. [Google Scholar] [CrossRef]

- Colomban, P.; Franci, G.S.; Gallet, X. Non-Invasive Mobile Raman and pXRF Analysis of Armorial Porcelain with the Coat of Arms of Louis XV and others Enamelled in Canton: Analytical Criteria for Authentication. Heritage 2024, 7, 4881–4913. [Google Scholar] [CrossRef]

- Bruker. Available online: https://xrfcheck.bruker.com/InfoDepth (accessed on 9 April 2025).

- Tite, M.; Watson, O.; Pradell, T.; Matin, M.; Molina, G.; Domoney, K.; Bouquillon, A. Revisiting the beginnings of tin-opacified Islamic glazes. J. Archaeol. Sci. 2015, 57, 80–91. [Google Scholar] [CrossRef]

- Colomban, P.; Kırmızı, B.; Simsek Franci, G. Cobalt and associated impurities in blue (and green) glass, glaze and enamel: Relationships between raw materials, processing, composition, phases and international trade. Minerals 2021, 11, 633. [Google Scholar] [CrossRef]

- Bouchard, M.; Gambardella, A. Raman microscopy study of synthetic cobalt blue spinels used in the field of art. J. Raman Spectrosc. 2010, 41, 1477–1485. [Google Scholar] [CrossRef]

- Beglaryan, H.; Isahakyan, A.; Terzyan, A.; Stepanyan, V.; Elovikov, D.; Gusarov, V.; Melikyan, S.; Zulumyan, N. Precipitation synthesis of Zn2-xCoxSiO4 blue ceramic pigments: Color performance and application. Ceram. Int. 2024, 50, 21386–21395. [Google Scholar] [CrossRef]

- Colomban, P.; Simsek Franci, G. Timurid, Ottoman, Safavid and Qajar ceramics: Raman and composition classification of the different types of glaze and pigments. Minerals 2023, 13, 977. [Google Scholar] [CrossRef]

- Colomban, P.; Tournié, A.; Bellot-Gurlet, L. Raman Identification of glassy silicates used in ceramic, glass and jewellry: A tentative differentiation guide. J. Raman Spectrosc. 2006, 37, 841–852. [Google Scholar] [CrossRef]

- Froment, F.; Tournié, A.; Colomban, P. Raman identification of natural red to yellow pigments: Ochre and iron-containing ores. J. Raman Spectrosc. 2008, 39, 560–568. [Google Scholar] [CrossRef]

- Bersani, D.; Lottici, P.P. Raman spectroscopy of minerals and mineral pigments in archaeometry. J. Raman Spectrosc. 2016, 47, 499–530. [Google Scholar] [CrossRef]

- Sempio, A.; Galtieri, A.F. Mineralogy of the Grès de Thiviers (northern Aquitaine, France). Per. Miner. 2002, 71, 65–84. [Google Scholar]

- Marco de Lucas, M.C.; Moncada, F.; Rosen, J. Micro-Raman study of red decorations in French faiences of the 18th and 19th centuries. J. Raman Spectrosc. 2006, 37, 1154–1159. [Google Scholar] [CrossRef]

- Stangarone, C.; Tribaudino, M.; Prencipe, M.; Lottici, P.P. Raman modes in Pbca enstatite (Mg2Si2O6): An assignment by quantum mechanical calculation to interpret experimental results. J. Raman Spectrosc. 2016, 47, 1247–1258. [Google Scholar] [CrossRef]

- Ohsaka, T.; Izumi, F.; Fujiki, Y. Raman spectrum of anatase, TiO2. J. Raman Spectrosc. 1978, 7, 321–324. [Google Scholar] [CrossRef]

- Colomban, P.; Treppoz, F. Identification and Differentiation of Ancient and Modern European Porcelains by Raman Macro- and Microspectroscopy. J. Raman Spectrosc. 2001, 32, 93–102. [Google Scholar] [CrossRef]

- Colomban, P.; Milande, V. On-site Raman analysis of the earliest known Meissen porcelain and stoneware. J. Raman Spectrosc. 2006, 37, 606–613. [Google Scholar] [CrossRef]

- Jayapandi, S.; Premkumar, S.; Lakshmi, D. Reinforced photocatalytic reduction of SnO2 nanoparticle by La incorporation for efficient photodegradation under visible light irradiation. J. Mater. Sci. Mater. Electron. 2019, 30, 8479–8492. [Google Scholar] [CrossRef]

- Burlot, J.; Vangu, D.; Bellot-Gurlet, L.; Colomban, P. Raman identification of pigments and opacifiers: Interest and limitation of multivariate analysis by comparison with solid state spectroscopical approach. II. Arsenic-based opacifiers and relation with cobalt ores. J. Raman Spectrosc. 2024, 55, 184–199. [Google Scholar] [CrossRef]

- Manoun, B.; Azdouz, M.; Azrour, M.; Essehli, R.; Benmokhtar, S.; El Ammari, L.; Ezzahi, A.; Ider, A.; Lazor, P. Synthesis, Rietveld refinements and Raman spectroscopic studies of tricationic lacunar apatites Na1-xKxPb4(AsO4)3 (0 < x < 1). J. Mol. Struct. 2011, 986, 1–9. [Google Scholar] [CrossRef]

- Van Pevenage, J.; Lauwers, D.; Herremans, D.; Verhaeven, E.; Vekemans, B.; De Clercq, W.; Vincze, L.; Moens, L.; Vandenabeele, P. A Combined Spectroscopic Study on Chinese Porcelain Containing Ruan-Cai Colours. Anal. Methods 2014, 6, 387–394. [Google Scholar] [CrossRef]

- Colomban, P.; Ngo, A.-T.; Fournery, N. Non-Invasive Raman Analysis of 18th Century Chinese Export/Armorial Overglazed Porcelain: Identification of the Different Enameling Techniques. Heritage 2022, 5, 233–259. [Google Scholar] [CrossRef]

- Hassan, H.K.; Torell, L.M.; Börjesson, L.; Doweidar, H. Structural changes of B2O3 through the liquid-glass transition range: A Raman-scattering study. Phys. Rev. B 1992, 45, 12797. [Google Scholar] [CrossRef] [PubMed]

- Ciceo-Lucatel, R.; Ardelean, R. FT-IR and Raman study of silver lead borate-based glasses. J. Non-Crystall. Solids 2007, 353, 2020–2024. [Google Scholar] [CrossRef]

- Satyanarayana, T.; Kityk, I.V.; Piasecki, M.; Bragiel, P.; Brik, M.G.; Gandhi, Y.; Veeraiah, N. Structural investigations on PbO–Sb2O3–B2O3: CoO glass ceramics by means of spectroscopic and dielectric studies. J. Phys. Condens. Matter 2009, 21, 245104. [Google Scholar] [CrossRef] [PubMed]

- Moshkina, E.; Gudim, I.; Temerov, V.; Krylov, A. Temperature-dependent absorption lines observation in Raman spectra of SmFe3(BO3)4 ferroborate. J. Raman Spectrosc. 2018, 49, 1732–1735. [Google Scholar] [CrossRef]

- Kamura, S.; Tani, T.; Matsuo, H.; Onaka, Y.; Fujisawa, T.; Unno, M. New probe for porcelain glazes y luminescence at Near-Infrared excitation. ACS Omega 2021, 6, 7829–7833. [Google Scholar] [CrossRef]

- Laakso, K.; Kangas, L.; Häkkänen, H.; Kaski, S.; Leveinen, J. Enhanced quantification of wollastonite and calcite in limestone using fluorescence correction based on continuous wavelet transformation for Raman. Appl. Spectrosc. Rev. 2021, 56, 67–84. [Google Scholar] [CrossRef]

- Böhme, N.; Hauke, K.; Neuroth, M.; Geisler, T. In situ Raman imaging of high-temperature solid-state reactions in the CaSO4–SiO2 system. Int. J. Coal Sci. Technol. 2019, 6, 247–259. [Google Scholar] [CrossRef]

- Sun, J.; Wu, Z.; Cheng, H.; Zhang, Z.; Frost, R.L. A Raman spectroscopic comparison of calcite and dolomite. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2014, 117, 158–162. [Google Scholar] [CrossRef] [PubMed]

- De Wild, J.; Robert, E.V.C.; Adib, B.E.; Abou-Ras, D.; Dale, P.J. Secondary phase formation during monoclinic Cu2SnS3 growth for solar cell application. Sol. Energy Mater. Sol. Cell 2016, 157, 259–265. [Google Scholar] [CrossRef]

- Simsek Franci, G.; Demirsar Arli, V.B.; Kaya, S. Color Trials—Establishment of Characterization Methodology of Underglaze Decorated Iznik Tiles with Non-Destructive and Portable Spectroscopic Techniques (Raman Spectroscopy and Portable XRF); 2nd Development Report of 123M874; The Scientific and Technological Research Council of Türkiye (TÜBİTAK): Ankara, Türkiye, 2025. [Google Scholar]

- Colomban, P.; Simsek Franci, G.; Gerken, M.; Gironda, M.; Mesqui, V. Non-Invasive On-Site XRF and Raman Classification and Dating of Ancient Ceramics: Application to 18th and 19th Century Meissen Porcelain (Saxony) and Comparison with Chinese Porcelain. Ceramics 2023, 6, 2178–2212. [Google Scholar] [CrossRef]

- Colomban, P.; Franci, G.S.; Gerken, M.; Gironda, M.; Mesqui, V. Chemical and Vibrational Criteria for Identifying Early Sèvres Factory Porcelain Productions. Ceramics 2024, 7, 1905–1927. [Google Scholar] [CrossRef]

- Colomban, P.; Simsek Franci, G.; Gerken, M.; Gironda, M.; Mesqui, M. Non-invasive Raman and XRF study of mīnā’ī decoration, the first sophisticated painted enamels. Materials 2025, 18, 575. [Google Scholar] [CrossRef]

- Molera, J.; Climent-Font, A.; Garcia, G.; Pradell, T.; Vallcorba, O.; Zucchiatti, A. A study of historical processing of cobalt arsenides in XV–XVI century Europe. J. Archaeol. Sci. Rep. 2021, 36, 102797. [Google Scholar]

| Provenance | Production Place (Expected) | Period (Colors) [Remarks] | Tile View | Label | Refs |

|---|---|---|---|---|---|

| Art market, Tunis, Tunisia Expected from the dribad of BirLahjar madrasa | Qallaline, Tunisia | 18th century? (circa 1735–1756) (blue, green, eggplant, brown-orange, and milky white) |  | Q | [28,29,30,31,32,33] |

| Sidi Ali Azzuz mausoleum (zâwiya), Zaghouan, Tunisia | Qallaline, Tunis, Tunisia | Second half of 18th century [signature from Usta mascûdal-Sabac] |  | AZ | [30,31,32] |

| Sidi Ali Azzuz mausoleum (zâwiya), Tunis, Tunisia | Qallaline, Tunis, Tunisia | Second half of 18th century (circa 1756) (blue, green, brown, and milky white) |  | P1 | [30,31,32] |

| Sidi Ali Azzuz mausoleum (zâwiya), Zaghouan, Tunisia | Qallaline, Tunis, Tunisia or Türkiye? | First half of 18th century (circa 1710) (blue, green, brown, and milky white) |  | P2 P3 | [30,31,32,33] |

| Mosquée des Teinturiers (Jamc J’did, Dyers’ mosque), Tunis, Tunisia | Tekfur Palace, Türkiye | First half of 18th century (circa 1727) (blue, turquoise, coral red, black line covered with optically clear colorless glaze) |  | Tek | [30,34,35,36,37,38,39] |

| Art market Tunis, Tunisia | Italy, Naples mark | 19th or 20th century (?) (blue, white) |  | It | |

| Art market France | Iznik Türkiye | 16th century |  | Iz1C | [16,17,18,40,41] |

| Art market France | Iznik Türkiye | Middle 16th century |  | Iz2Tr | [16,17,18,40,41] |

| Sample | Si/Al | Na | K | Ca | Ca/Na + K | Pb | Fe | Ti |

|---|---|---|---|---|---|---|---|---|

| Q white | 2.76 | 5.93 | 1.04 | 13.57 | 1.95 | - | 3.88 | 0.30 |

| Q rose | 2.48 | 1.17 | 0.62 | 14.47 | 8.08 | - | 3.31 | 0.32 |

| AZ | 4.36 | 1.19 | 1.25 | 14.62 | 5.99 | - | 2.3 | 0.79 |

| 2.83 | 0.81 | 1.21 | 12.39 | 6.13 | 0.88 | 1.41 | 0.17 | |

| 4.25 | 1.69 | 2.17 | 9.25 | 2.40 | 1.54 | 1.69 | 0.14 | |

| P1 | 2.20 | 1.06 | 0.63 | 19.14 | 11.32 | - | 3.53 | 0.31 |

| P2 | 14.21 | 1.74 | 1.54 | 6.12 | 1.87 | - | 0.61 | 0.04 |

| It | 2.33 | 1.03 | 2.07 | 6.99 | 3.74 | - | 2.72 | 0.33 |

| Iz1C grain | 16.18 15.91 17.19 | 2.48 2.99 2.4 | 0.46 0.65 0.32 | 0.66 1.42 0.67 | 0.22 0.39 0.25 | - 0.13 0.06 | 0.31 0.73 0.78 | 0.1 0.1 0.03 |

| Iz2Tr | 24.31 9.78 | 1.95 1.47 | 0.28 0.62 | 1.3 3.89 | 0.58 1.86 | 0.02 - | 0.16 0.04 | 0.06 - |

| Tek | 19.48 | 2.61 | 0.52 | 1.48 | 0.47 | 0.12 | 0.55 | 0.04 |

| Sample | Si/Al | Na + K + Ca | Pb | Sn | Fe | Ti | Cu | Co | Zn | Ce//Sc | As | Mn//Cr |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Qallaline | ||||||||||||

| glaze (white) | 8.75 | 4.55 | 3.92 | 0.28 | 0.02 | - | - | - | - | - | - | - |

| blue | 10.39 | 5.54 | 6.86 | ? | 0.22 | 0.29 | - | 0.30 | - | 0.16//- | - | 0.07//- |

| brown-yellow | 7.41 | 4.28 | 5.28 | ? | 0.20 | - | - | - | 0.12 | -//0.09 | - | - |

| eggplant | 4.50 | 4.29 | 3.02 | 0.12 | 0.08 | - | 0.07 | - | - | - | - | 0.21//- |

| green-black | 7.58 | 6.68 | 4.65 | 1.32 | 0.44 | 0.05 | 1.78 | - | - | - | - | -//0.03 |

| green | 7.67 | 6.79 | 5.42 | 1.11 | 0.42 | 0.09 | 2.1 | - | - | - | - | -//0.03 |

| green 2 | 10.12 | 6.63 | 7.11 | 3.36 | 0.42 | - | 4.86 | - | - | - | - | - |

| black | 1.93 | 5.92 | 4.1 | 0.73 | 0.40 | - | 2.97 | - | - | - | - | - |

| Sidi Azoug Azzuz AZ | ||||||||||||

| glaze (white) | 5.18 | 4.19 | 1.83 | 0.56 | 0.04 | - | - | - | 0.05 | - | - | - |

| glaze (white) 2 | 5.72 | 5.9 | 2.95 | 1.01 | 0.09 | - | - | - | - | - | - | - |

| blue | 5.44 | 4.67 | 2.57 | - | 0.14 | - | - | 0.03 | 0.12 | - | 0.06 | - |

| green | 8.25 | 9.63 | 5.17 | 0.73 | 0.46 | 0.06 | 0.61 | 1.65 | - | - | - | |

| Sidi Azoug Azzuz P1 | ||||||||||||

| glaze (white) | 3.63 | 8.21 | 2.75 | 0.61 | 0.03 | - | - | - | - | - | 0.03 | - |

| dark blue | 3.52 | 5.24 | 4.65 | ? | 0.17 | - | - | - | - | - | - | - |

| blue | 8.13 | 6.48 | 5.87 | ? | 0.18 | - | - | 0.09 | - | - | - | - |

| Sidi Azoug Azzuz P2 | ||||||||||||

| glaze (white) | 5.77 | 5.48 | 5.75 | 0.39 | 0.09 | - | - | - | - | - | 0.01 | - |

| blue | 9.19 | 6.65 | 6.41 | ? | 0.56 | 1.14 | - | 0.44 | - | 0.54//- | 0.28 | - |

| black line | 13.13 | 7.69 | 8.66 | ? | 0.53 | 0.28 | - | 0.21 | 0.2 | - | - | 0.7//- |

| Italian tile It | ||||||||||||

| blue | 8.0 | 8.47 | 0.45 | - | 0.93 | 0.17 | - | - | - | - | - | - |

| white | ||||||||||||

| Iznik Iz1C | ||||||||||||

| blue 1 | 9.58 | 3.24 | 4.0 | - | 0.09 | - | 0.11 | 0.01 | - | - | - | - |

| blue 2 | 8.52 | 8.34 | 5.66 | 0.5 | 0.15 | - | 0.09 | 0.06 | - | - | - | - |

| blue 3 | 23.97 | 5.84 | 5.02 | 0.43 | 0.19 | - | 0.18 | 0.06 | - | - | - | - |

| blue 4 | 14.89 | 8.19 | 4.26 | 0.36 | 0.16 | - | 0.09 | 0.01 | - | - | - | -//0.11 |

| blue 5 | 38.23 | 4.67 | 4.41 | 0.44 | 0.10 | - | 0.13 | 0.06 | - | - | - | - |

| red 1 | 14.32 | 6.82 | 2.69 | 0.16 | 1.08 | - | - | - | - | - | - | - |

| red 2 1500 | 19.80 | 7.18 | 3.42 | - | 0.49 | - | - | - | - | - | - | - |

| Iznik Iz2Tr | ||||||||||||

| blue | 12.20 | 8.55 | 4 | 0.42 | 1.24 | - | 0.23 | 0.01 | - | - | - | -//0.32 |

| red | 25.57 | 3.86 | 0.1 | ? | 1.61 | - | - | - | - | - | - | - |

| Dyers’ mosque (Tek) | ||||||||||||

| glaze (white) | 14.71 | 9.68 | 1.95 | - | 0.06 | - | - | - | - | - | - | - |

| glaze (white) 2 | 7.21 | 14.86 | - | - | 0.07 | - | 0.01 | - | - | - | - | - |

| light blue | 17 | 4.63 | 4.86 | - | 0.14 | - | 0.22 | - | - | - | - | - |

| blue | 3.42 | 2.25 | 1.8 | - | 0.03 | - | 0.06 | 0.01 | - | - | - | - |

| red | 51.21 | 6.76 | 0.93 | - | 2.94 | - | - | - | - | - | - | - |

| turquoise 2 | 16.53 | 16.22 | 4.5 | - | 0.10 | - | 0.11 | - | - | - | - | - |

| turquoise 1 | 2.38 | 3.46 | 1.28 | - | 0.03 | - | 0.12 | - | - | - | - | - |

| turquoise 3 | 5.74 | 12.88 | 2.76 | - | 0.06 | - | 0.03 | - | - | - | - | - |

| turquoise 4 | 7.75 | 5.09 | 2.4 | - | 0.08 | - | 0.16 | - | - | - | - | - |

| black | 3.46 | 11.88 | 1.39 | - | 1.35 | 0.15 | 1.86 | - | - | - | - | - |

| black 2 | 4.59 | 12.21 | 4.26 | - | 0.24 | 0.03 | 0.3 | - | - | - | - | - |

| black 3 | 17.32 | 15.53 | - | - | 0.26 | - | 0.12 | - | - | - | - | - |

| Kiln. (Previous Assignment) | Location | Sample (Origin) | Paste | Glaze | Blue | Black | Remarks |

|---|---|---|---|---|---|---|---|

| Qallaline | Tunis | Q | Two layers (red Si-rich layer + white Pb-doped layer) | Pb-based Ce traces Low Ca | Low As | Cu-based | Association of Group 1 and Group 2′ Qallaline |

| Qallaline, | Zaghouan | AZ | Pb traces | Pb-based | Low As | ||

| Qallaline | Tunis | P1 | Pb added | Pb-based | Group 2 Qallaline Group 2′ Qallaline | ||

| Qallaline or Türkiye | Zaghouan | P3 | Pb traces | Pb-based | |||

| Qallaline or Türkiye | Zaghouan | P2 | Pb traces | Pb-based Ce traces | |||

| Tekfur | Tunis | Tek | Pb-based | Mixed Pb-alkalis | High As | Fe-based | |

| Italy | Tunis | It | No Pb | No Sn Low Ca | |||

| Iznik | Türkiye | Mixed Pb-alkalis | CrO4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Colomban, P.; Simsek-Franci, G.; Gallet, X.; Ngo, A.-T.; Melliti-Chemi, W.; Ayed, N. Phase and Composition Study of 18th Century Qallaline Tiles, Tunis. Minerals 2025, 15, 865. https://doi.org/10.3390/min15080865

Colomban P, Simsek-Franci G, Gallet X, Ngo A-T, Melliti-Chemi W, Ayed N. Phase and Composition Study of 18th Century Qallaline Tiles, Tunis. Minerals. 2025; 15(8):865. https://doi.org/10.3390/min15080865

Chicago/Turabian StyleColomban, Philippe, Gulsu Simsek-Franci, Xavier Gallet, Anh-Tu Ngo, Wided Melliti-Chemi, and Naceur Ayed. 2025. "Phase and Composition Study of 18th Century Qallaline Tiles, Tunis" Minerals 15, no. 8: 865. https://doi.org/10.3390/min15080865

APA StyleColomban, P., Simsek-Franci, G., Gallet, X., Ngo, A.-T., Melliti-Chemi, W., & Ayed, N. (2025). Phase and Composition Study of 18th Century Qallaline Tiles, Tunis. Minerals, 15(8), 865. https://doi.org/10.3390/min15080865