Preparation and Performance Study of Alkali-Activated Conductive Mortar via Response Surface Methodology

Abstract

1. Introduction

2. Materials and Methods

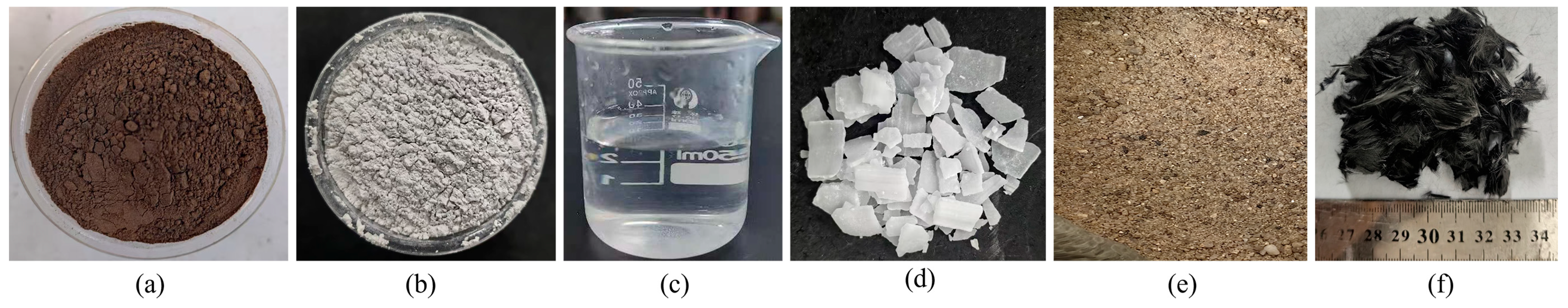

2.1. Materials

2.2. Experimental Design

2.2.1. Experimental Ratio

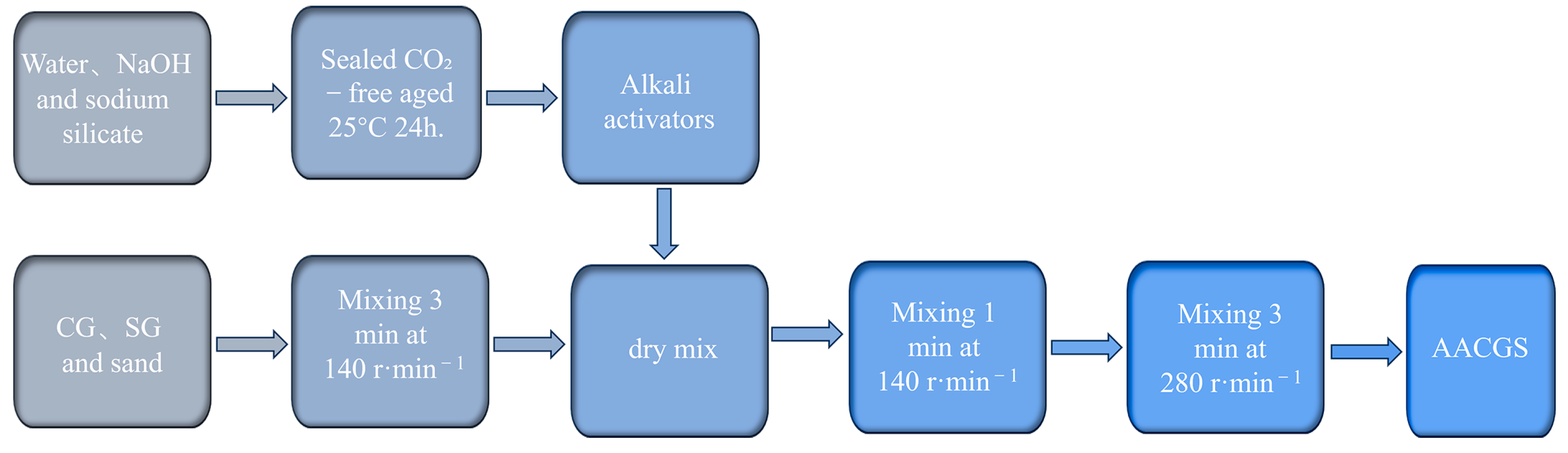

2.2.2. Preparation of Conductive Mortar

2.3. Testing Methods

2.3.1. Flexural Strength Test and Compressive Strength Test

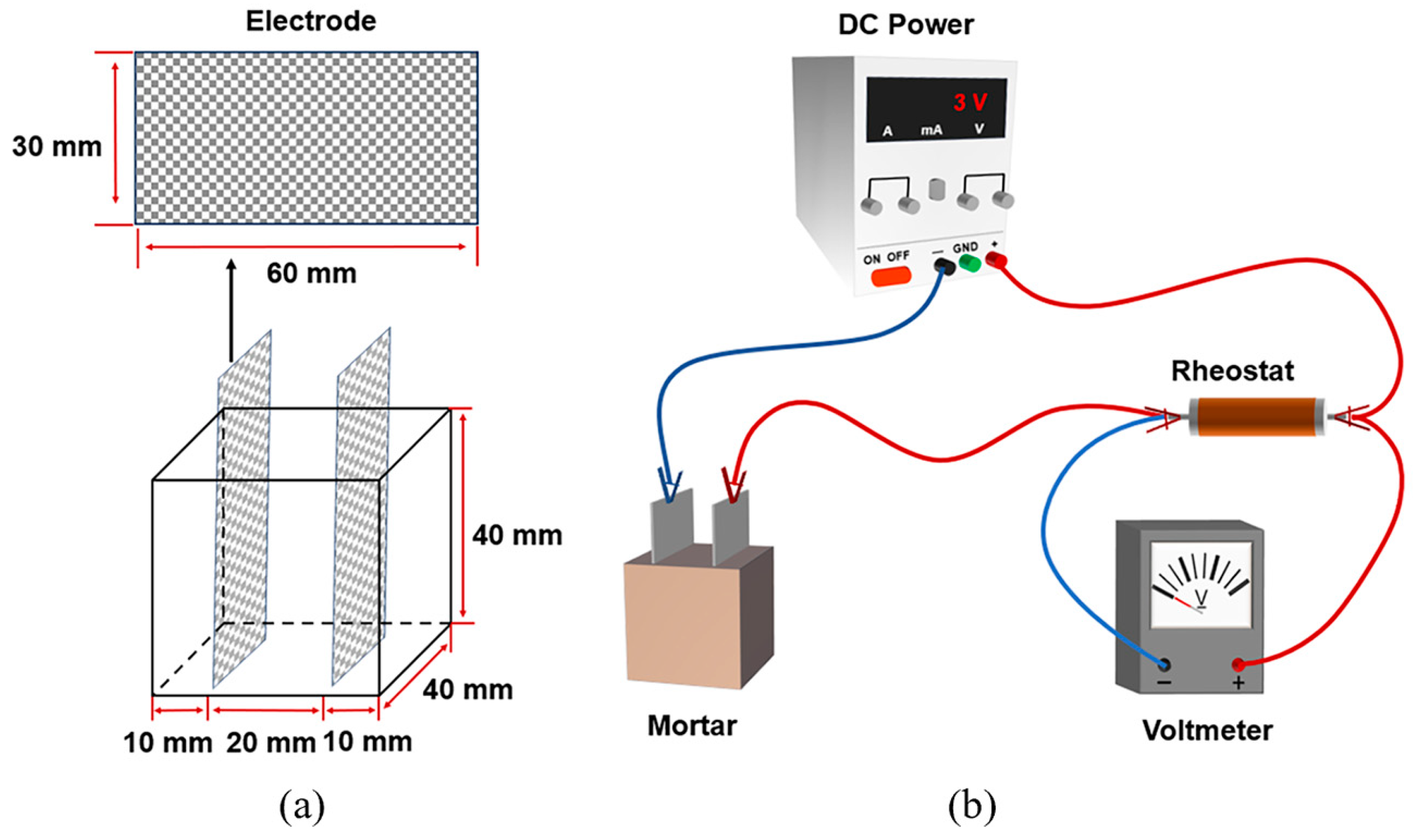

2.3.2. Conductivity Test

2.3.3. XRD and SEM-EDS Test

3. Results and Discussion

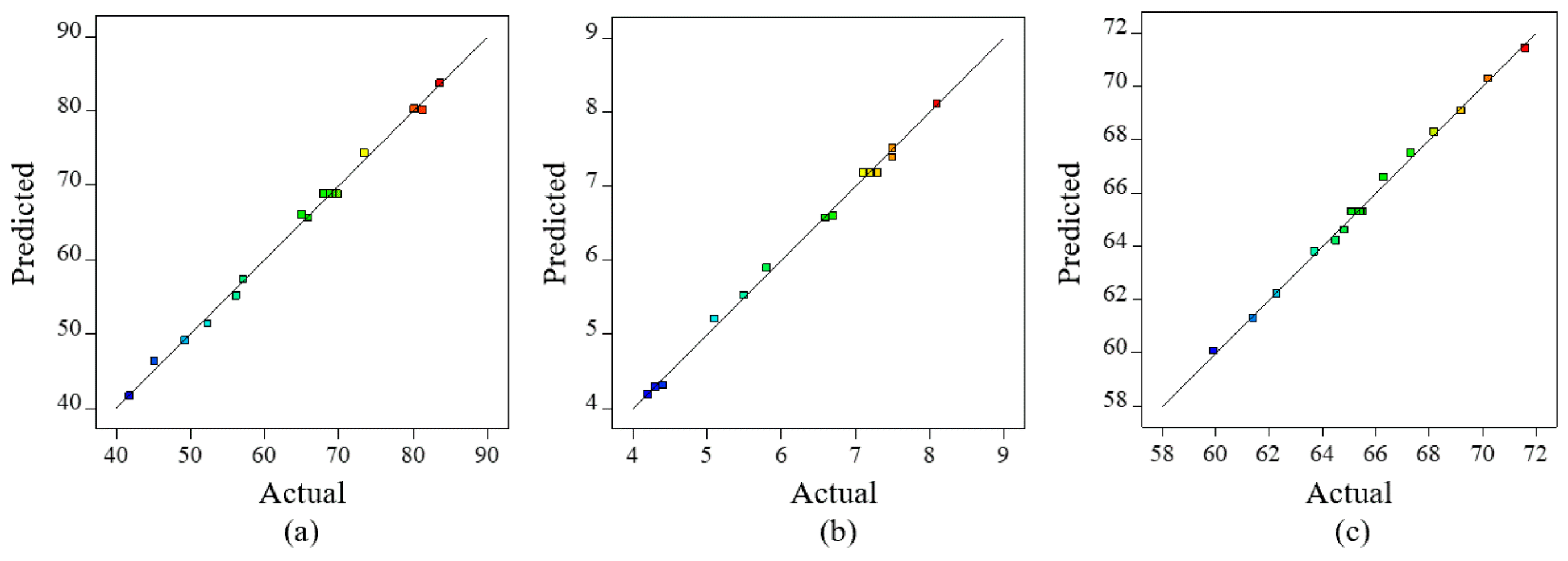

3.1. Model Validity Analysis

3.2. Response Surface Analysis

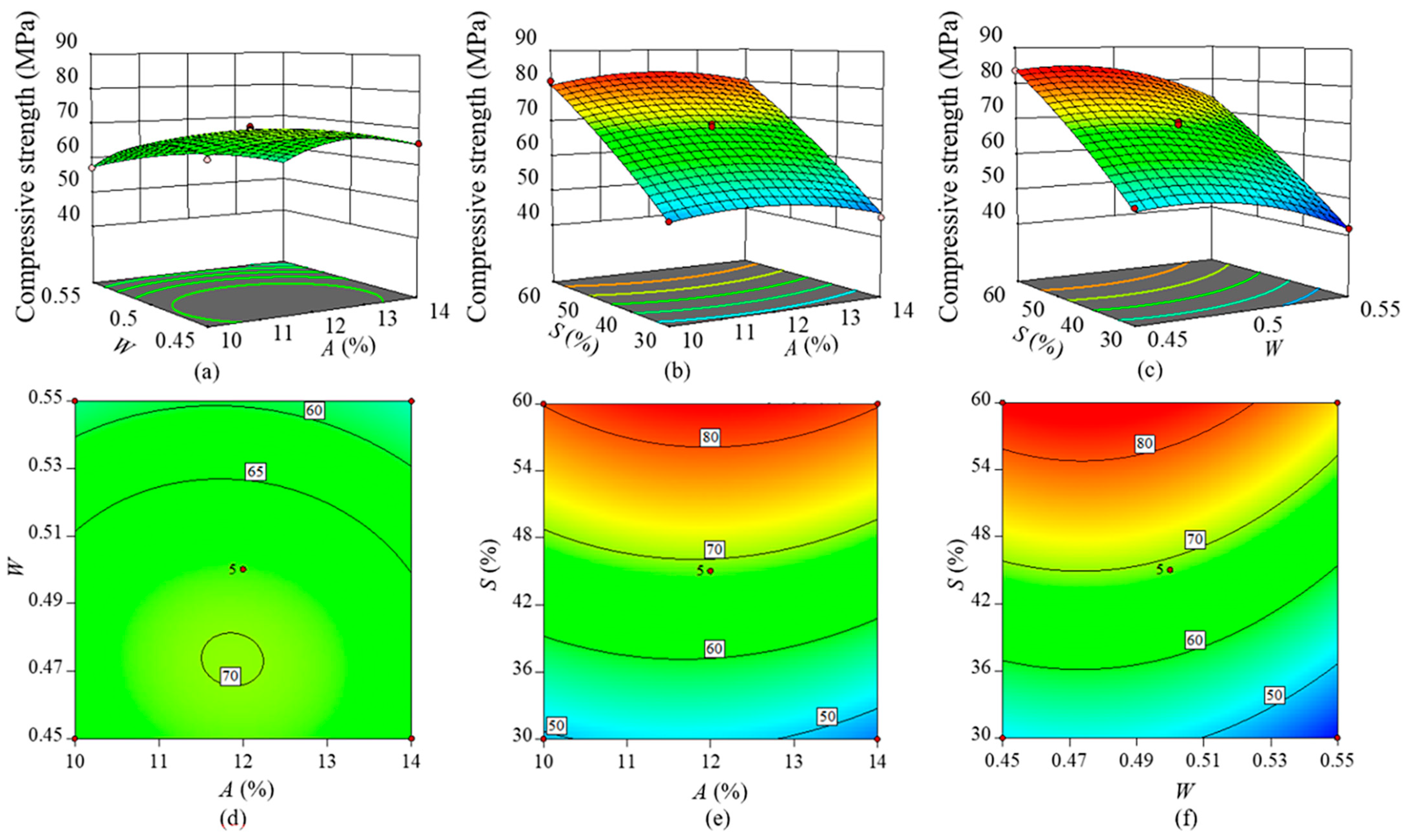

3.2.1. Compressive Strength

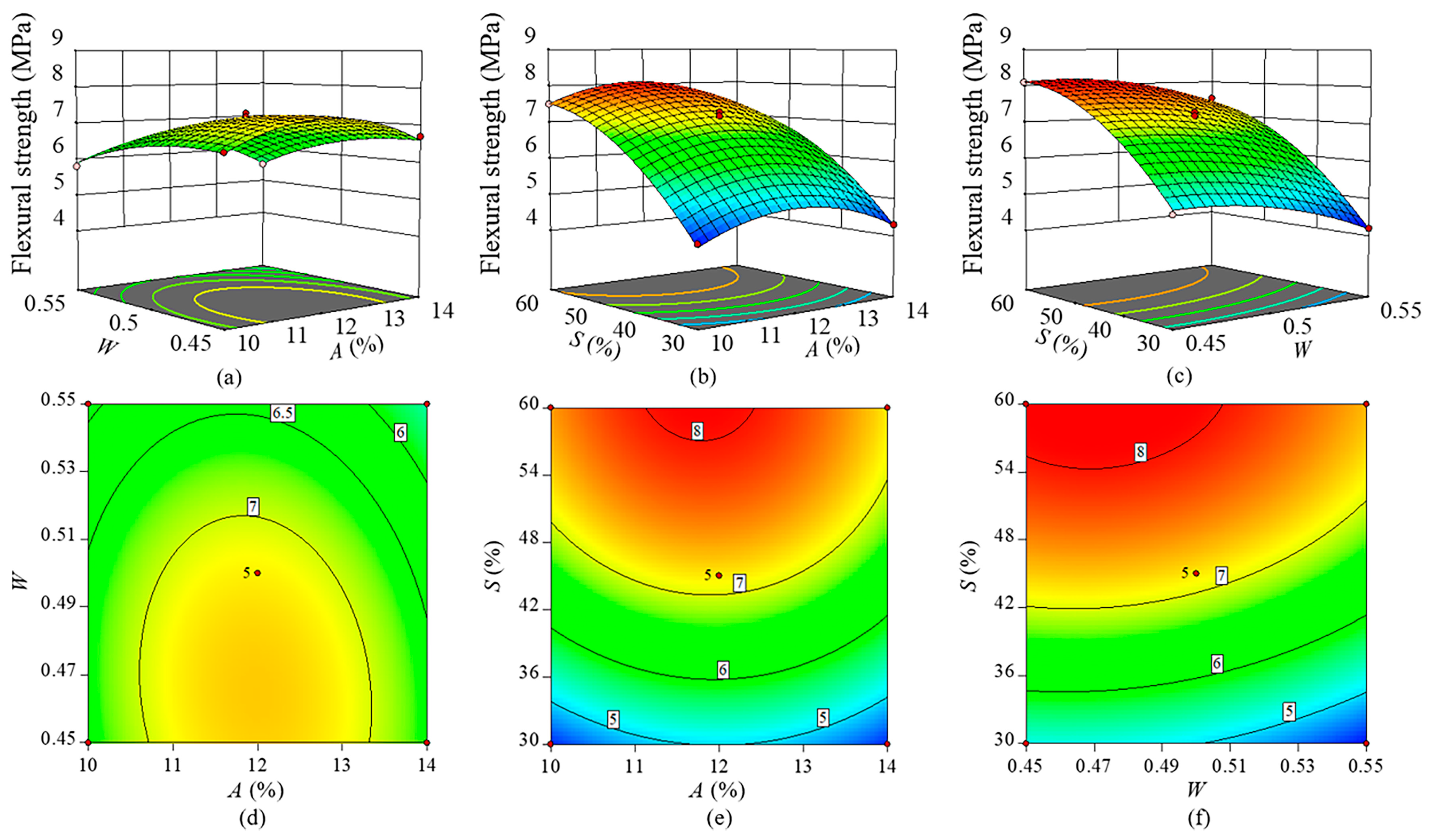

3.2.2. Flexural Strength

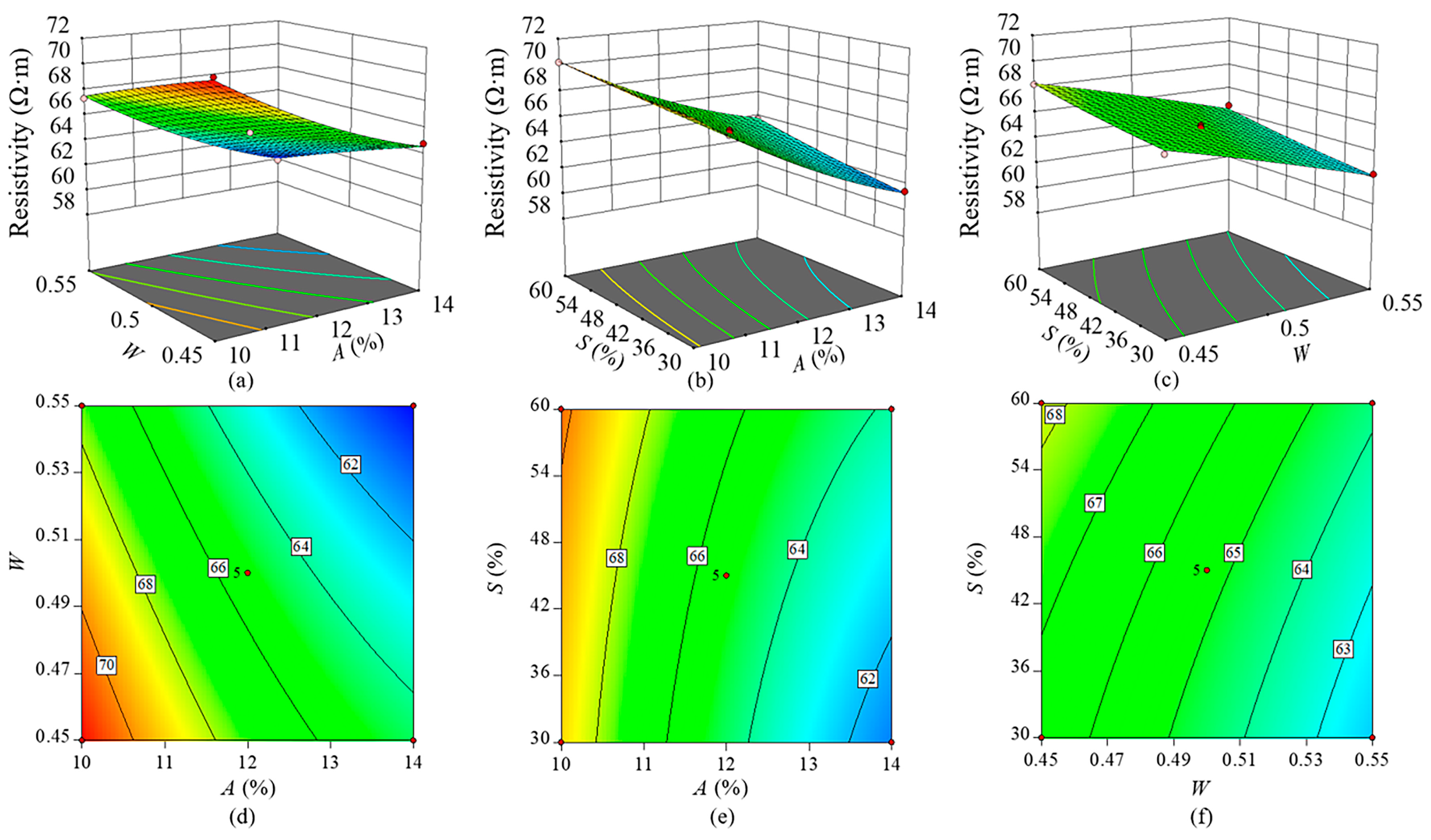

3.2.3. Resistivity

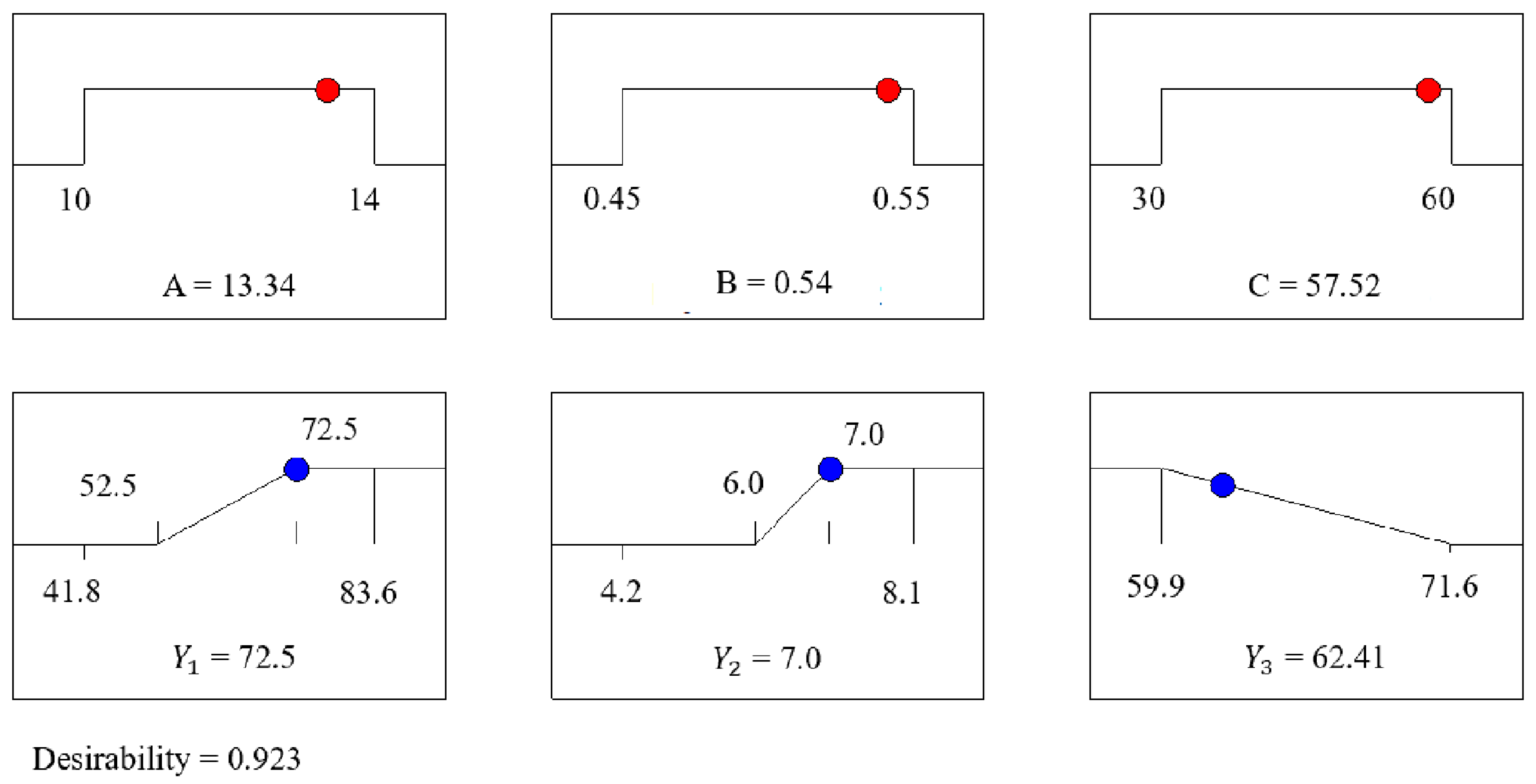

3.3. Response Surface Optimization Results and Validation

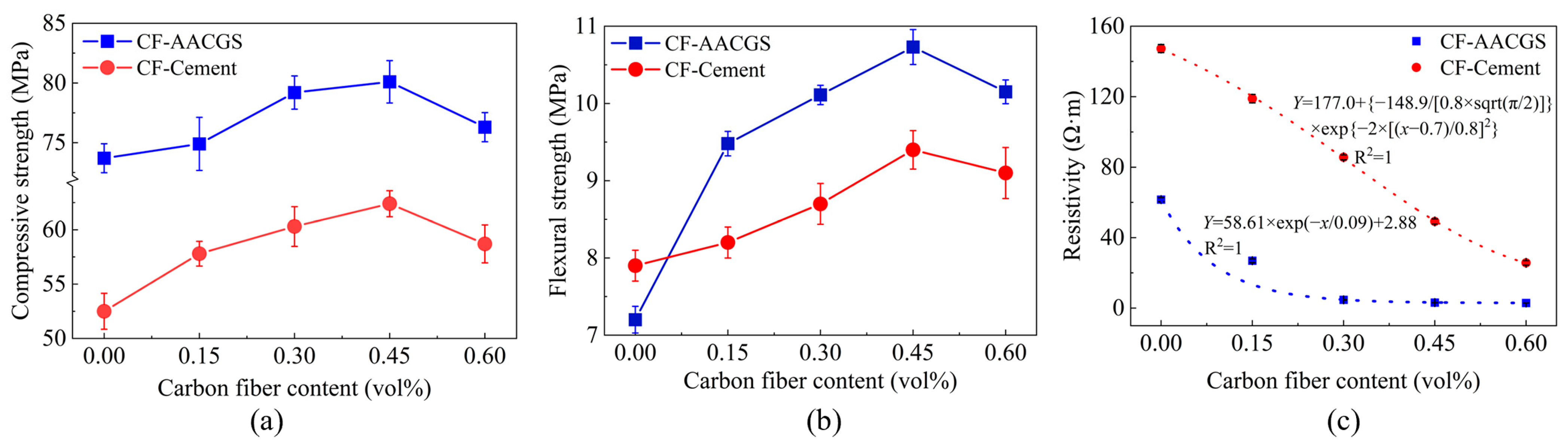

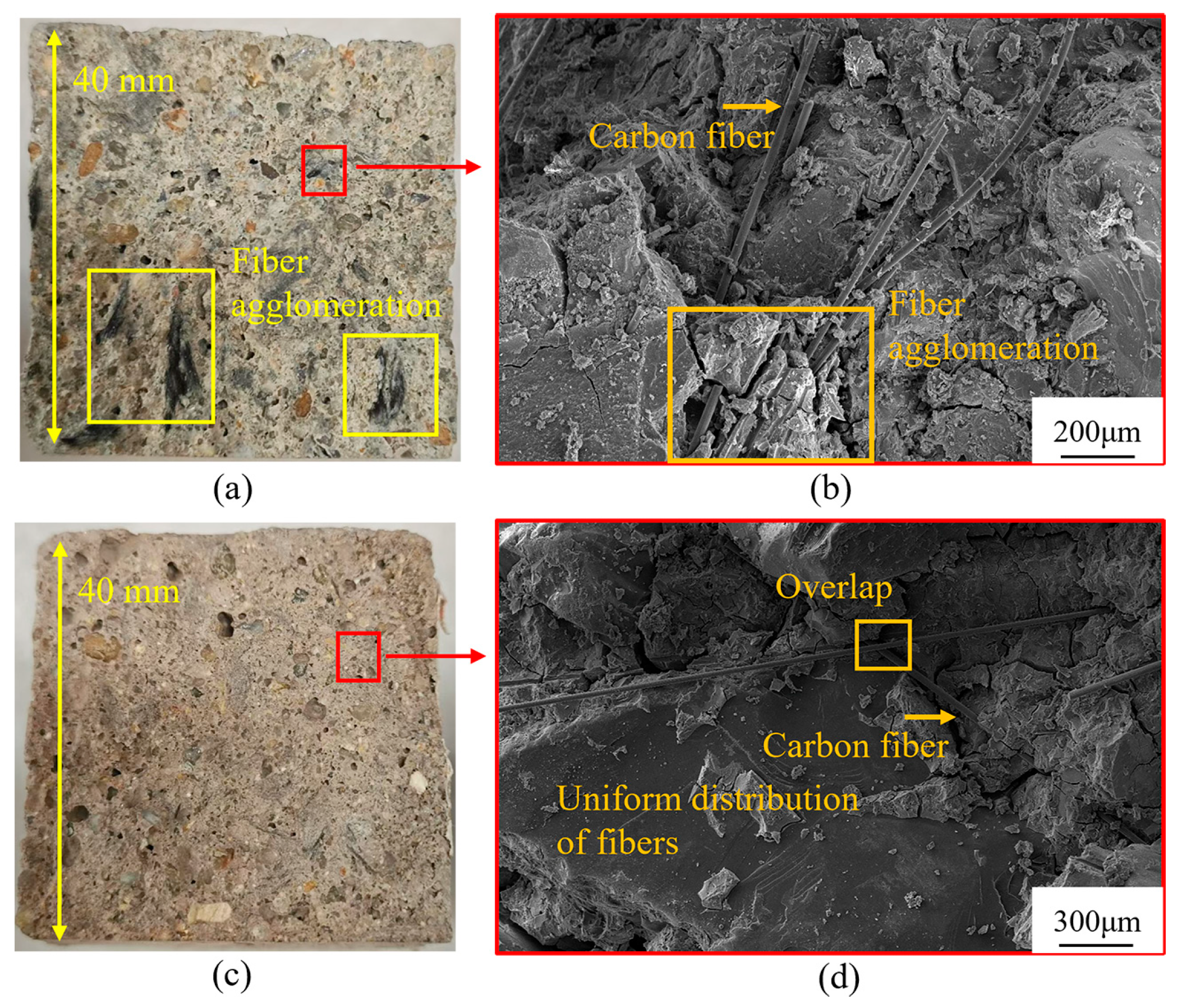

3.4. Performance Analysis of CF-AACGS

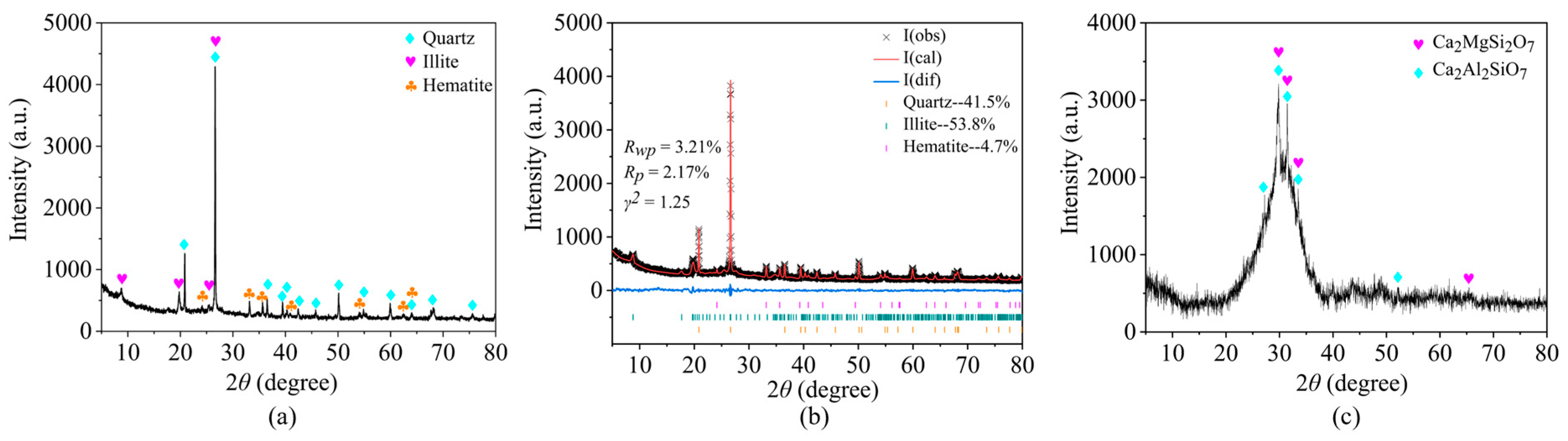

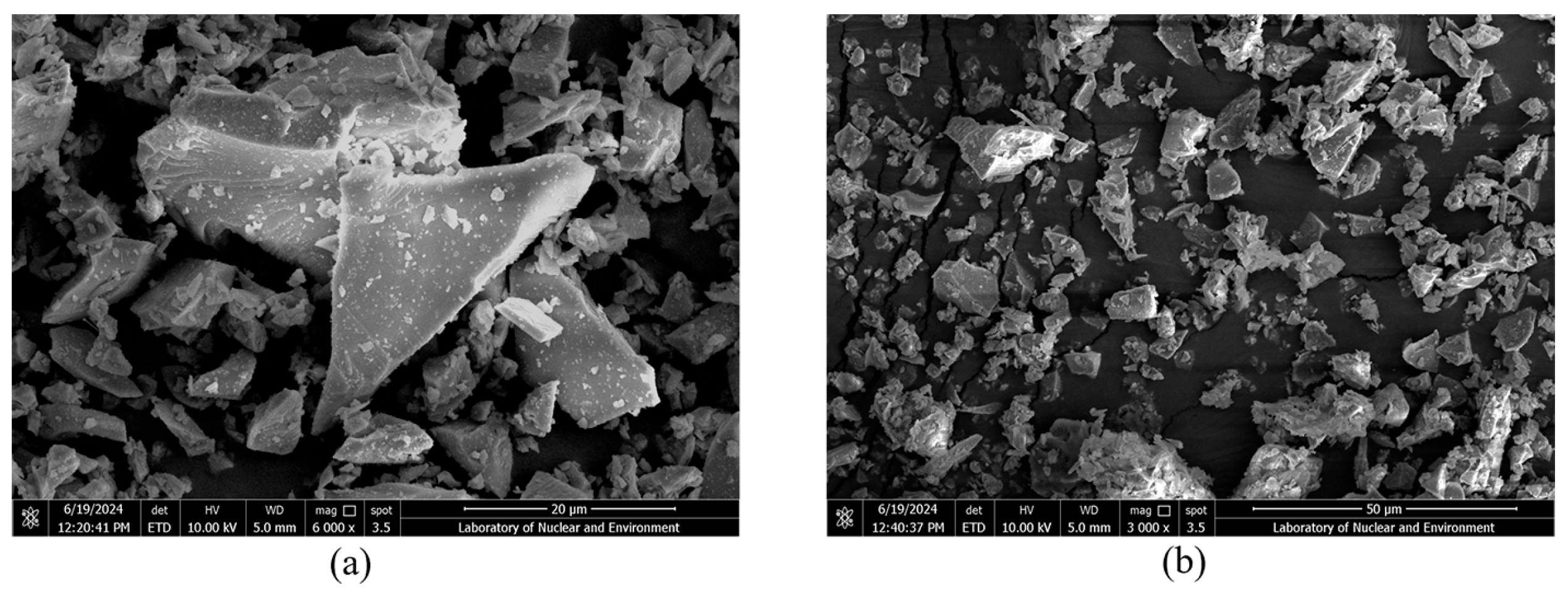

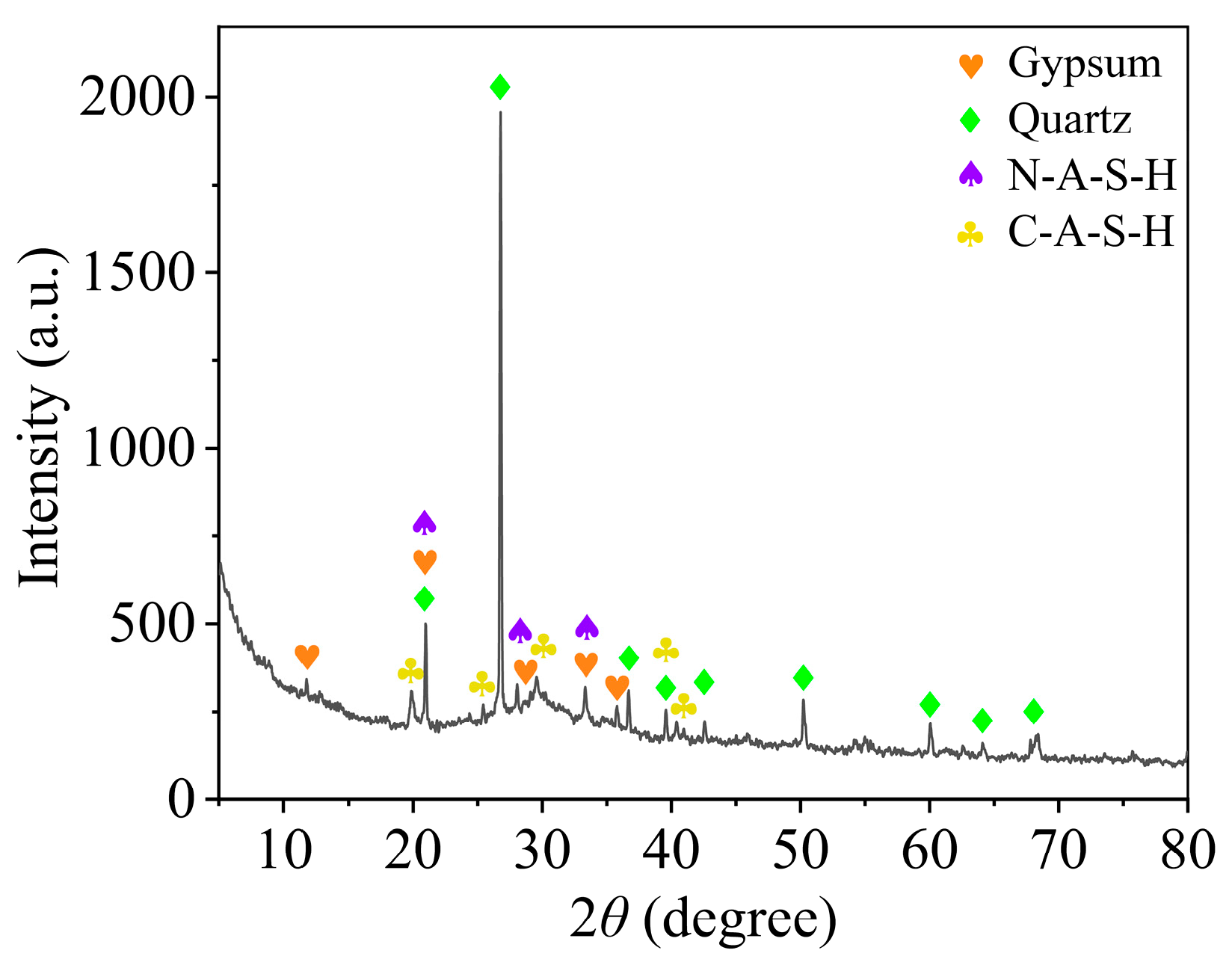

3.5. XRD and SEM-EDS Analysis

4. Conclusions

- Using response surface methodology to develop statistical models correlating the alkali equivalent, water-to-binder ratio, and slag content with the compressive strength, flexural strength, and resistivity of alkali-activated materials. Statistical tests such as variance analysis and coefficient of variation indicated that the model possesses high reliability.

- Based on RSM multi-objective optimization, the optimal performance of alkali-activated materials was achieved when the alkali equivalent, water-to-cement ratio, and slag content were 13.34%, 0.54, and 57.52%, respectively. Under these conditions, the alkali-activated materials achieve compressive strength, flexural strength, and resistivity of 72.5 MPa, 7.0 MPa, and 62.41 Ω·m at 28 days.

- When the same amount of carbon fiber is added, the 28-day compressive and flexural strengths of alkali-activated conductive mortar are significantly higher than those of cement conductive mortar. This improvement is attributed to the reaction of coal gangue and slag with the alkali activator, which produces a denser N, C-(A)-S-H gel structure, thereby enhancing the interface transition zone between carbon fiber and alkali-activated materials.

- By optimizing fiber dispersion, the alkali-activated materials increase the density of conductive contact points. Therefore, when the carbon fiber content reaches 0.3 vol%, alkali-activated conductive mortar can meet the performance requirements for de-icing and snow removal. Furthermore, at the same carbon fiber content, its resistivity is typically an order of magnitude lower than that of cement conductive mortar.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, P.; Dong, B.; Wang, Y.; Hong, S.; Fang, G.; Zhang, Y. Electrical conductive mortar based on expanded graphite for auxiliary anode. Case Stud. Constr. Mater. 2024, 20, e03268. [Google Scholar] [CrossRef]

- Downey, A.; D’Alessandro, A.; Baquera, M.; García-Macías, E.; Rolfes, D.; Ubertini, F.; Laflamme, S.; Castro-Triguero, R. Damage detection, localization and quantification in conductive smart concrete structures using a resistor mesh model. Eng. Struct. 2017, 148, 924–935. [Google Scholar] [CrossRef]

- Gürer, C.; Fidan, U.; Korkmaz, B.E. Investigation of using conductive asphalt concrete with carbon fiber additives in intelligent anti-icing systems. Int. J. Pavement Eng. 2023, 24, 2077941. [Google Scholar] [CrossRef]

- Wanasinghe, D.; Aslani, F.; Ma, G. Effect of water to cement ratio, fly ash, and slag on the electromagnetic shielding effectiveness of mortar. Constr. Build. Mater. 2020, 256, 119409. [Google Scholar] [CrossRef]

- Hemalatha, T.; Sangoju, B.; Muthuramalingam, G. A study on copper slag as fine aggregate in improving the electrical conductivity of cement mortar. Sādhanā 2022, 47, 141. [Google Scholar] [CrossRef]

- Li, L.G.; Chen, S.-Y.; Ma, J.; Ng, P.-L. Synergistic effects of single-walled carbon nanotube and carbon fiber on performance of conductive mortar. J. Build. Eng. 2024, 92, 109784. [Google Scholar] [CrossRef]

- Donnini, J.; Bellezze, T.; Corinaldesi, V. Mechanical, electrical and self-sensing properties of cementitious mortars containing short carbon fibers. J. Build. Eng. 2018, 20, 8–14. [Google Scholar] [CrossRef]

- Wang, S.; Wang, X.; He, J.; Xin, M. Mechanical behavior and microstructure of graphene oxide electrodeposited carbon fiber reinforced cement-based materials. Crystals 2022, 12, 964. [Google Scholar] [CrossRef]

- Li, H.; Liebscher, M.; Yang, J.; Zhang, Y.; Mechtcherine, V. Influence of electrophoretic deposition of micro- or nanosized silica particles on the microstructure of carbon fibers and their bond behavior with cementitious matrices. Mater. Struct. 2024, 57, 107. [Google Scholar] [CrossRef]

- Li, H.; Schamel, E.; Liebscher, M.; Zhang, Y.; Fan, Q.; Schlachter, H.; Köberle, T.; Mechtcherine, V.; Wehnert, G.; Söthje, D. Recycled carbon fibers in cement-based composites: Influence of epoxide matrix depolymerization degree on interfacial interactions. J. Clean. Prod. 2023, 411, 137235. [Google Scholar] [CrossRef]

- Hussain, S.; Matthews, J.; Amritphale, S.; Edwards, R.; Matthews, E.; Paul, N.; Kraft, J. Influence of Steel and Poly Vinyl Alcohol Fibers on the Development of High-Strength Geopolymer Concrete. Minerals 2024, 14, 1007. [Google Scholar] [CrossRef]

- Jindal, B.B. Investigations on the properties of geopolymer mortar and concrete with mineral admixtures: A review. Constr. Build. Mater. 2019, 227, 116644. [Google Scholar] [CrossRef]

- Dathe, F.; Overmann, S.; Koenig, A.; Dehn, F. The Role of Water Content and Binder to Aggregate Ratio on the Performance of Metakaolin-Based Geopolymer Mortars. Minerals 2024, 14, 823. [Google Scholar] [CrossRef]

- Shi, C.; Xie, P. Interface between cement paste and quartz sand in alkali-activated slag mortars. Cem. Concr. Res. 1998, 28, 887–896. [Google Scholar] [CrossRef]

- Luo, T.; Wang, Q.; Fang, Z. Effect of graphite on the self-sensing properties of cement and alkali-activated fly ash/slag based composite cementitious materials. J. Build. Eng. 2023, 77, 107493. [Google Scholar] [CrossRef]

- Wang, L.; Aslani, F. Electrical resistivity and piezoresistivity of cement mortar containing ground granulated blast furnace slag. Constr. Build. Mater. 2020, 263, 120243. [Google Scholar] [CrossRef]

- Zhong, M.; Meng, J.; Ning, B.; Na, F.; Cui, T.; Shi, X.; Cui, T. Preparation and alkali excitation mechanism of coal gangue-iron ore tailings non-sintering ceramsite. Constr. Build. Mater. 2024, 426, 136209. [Google Scholar] [CrossRef]

- Wang, M.; Xu, J.; Zhang, X.; Tan, L.; Mei, Y. Mechanical Performance Optimization and Microstructural Mechanism Study of Alkali-Activated Steel Slag–Slag Cementitious Materials. Buildings 2024, 14, 1204. [Google Scholar] [CrossRef]

- Lou, Y.; Huang, M.; Kang, S.; Hu, M.; Wu, W.; Chen, S. Study on basic performance and drying shrinkage of binary solid waste geopolymer prepared with recycled powders and slag. Case Stud. Constr. Mater. 2024, 20, e03195. [Google Scholar] [CrossRef]

- Li, Z.; Du, P.; Zhou, Y.; Wang, J.; Cheng, X. Synchronous Hot-pressed Metakaolin-fly ash Based Geopolymer: Compressive strength and hydration products. J. Build. Eng. 2024, 97, 110997. [Google Scholar] [CrossRef]

- Yan, G.-M.; Yan, X.; Yan, H.-X.; Wang, H. Optimization and performance study of graphene oxide reinforced geopolymer. J. Build. Eng. 2025, 104, 112269. [Google Scholar] [CrossRef]

- Hanjitsuwan, S.; Hunpratub, S.; Thongbai, P.; Maensiri, S.; Sata, V.; Chindaprasirt, P. Effects of NaOH concentrations on physical and electrical properties of high calcium fly ash geopolymer paste. Cem. Concr. Compos. 2014, 45, 9–14. [Google Scholar] [CrossRef]

- Xie, J.; Wang, J.; Zhang, B.; Fang, C.; Li, L. Physicochemical properties of alkali activated GGBS and fly ash geopolymeric recycled concrete. Constr. Build. Mater. 2019, 204, 384–398. [Google Scholar] [CrossRef]

- Sun, Z.; Li, Y.; Su, L.; Niu, D.; Luo, D.; He, W.; Xie, S. Investigation of electrical resistivity for fiber-reinforced coral aggregate concrete. Constr. Build. Mater. 2024, 414, 135011. [Google Scholar] [CrossRef]

- Wang, X.; Liu, F.; Pan, Z.; Chen, W.; Muhammad, F.; Zhang, B.; Li, L. Geopolymerization of coal gangue via alkali-activation: Dependence of mechanical properties on alkali activators. Buildings 2024, 14, 787. [Google Scholar] [CrossRef]

- Ma, H.; Zhu, H.; Chen, H.; Ni, Y.; Wang, T.; Yang, S. Effects and mechanisms of slag reinforced coal gangue geopolymers. IOP Conf. Ser. Mater. Sci. Eng. 2019, 474, 012040. [Google Scholar] [CrossRef]

- Sun, Q.; Wei, X.; Cai, R.; Li, D. Study on the Properties of Alkali-Excited Concrete Modified by Nano-SiO2 Based on Response Surface Methodology. Materials 2025, 18, 2292. [Google Scholar] [CrossRef]

- Song, B.; Huang, J.; Yang, M.; Zheng, M.; Yang, L.; Wang, F. Study on high supplementary cementitious materials content cement: Design and analysis based on response surface method. Constr. Build. Mater. 2025, 467, 140398. [Google Scholar] [CrossRef]

- Aghajanzadeh, I.; Ramezanianpour, A.M.; Amani, A.; Habibi, A. Mixture optimization of alkali activated slag concrete containing recycled concrete aggregates and silica fume using response surface method. Constr. Build. Mater. 2024, 425, 135928. [Google Scholar] [CrossRef]

- Jiang, M.; Qian, Y.; Sun, Q. Preparation of controlled low-strength materials from alkali-excited red mud-slag-iron tailings sand and a study of the reaction mechanism. Environ. Sci. Pollut. Res. 2023, 30, 22232–22248. [Google Scholar] [CrossRef] [PubMed]

- Wu, D.; Wang, J.; Miao, T.; Chen, K.; Zhang, Z. Performance optimization of FA-GGBS geopolymer based on response surface methodology. Polymers 2023, 15, 1881. [Google Scholar] [CrossRef]

- Song, H.; Nam, K. Development of a potassium-based soil washing solution using response surface methodology for efficient removal of cesium contamination in soil. Chemosphere 2023, 332, 138854. [Google Scholar] [CrossRef]

- Altawil, H.; Olgun, M. Optimization of mechanical properties of geopolymer mortar based on Class C fly ash and silica fume: A Taguchi method approach. Case Stud. Constr. Mater. 2025, 22, e04332. [Google Scholar] [CrossRef]

- Rattanasak, U.; Chindaprasirt, P. Influence of NaOH solution on the synthesis of fly ash geopolymer. Miner. Eng. 2009, 22, 1073–1078. [Google Scholar] [CrossRef]

- Ramalingam, M.; Mohan, P.; Kathirvel, P.; Murali, G. Flexural performance and microstructural studies of trough-shaped geopolymer ferrocement panels. Materials 2022, 15, 5477. [Google Scholar] [CrossRef]

- Bala, A.; Gupta, S.; Matsagar, D.C.P.V. Performance Evaluation of Recron Fibre and Glass Wool Fibre Reinforced Self-Compacting Mortar at Elevated Temperature: A comparative study. Results Eng. 2025, 27, 105778. [Google Scholar] [CrossRef]

- He, H.; Wang, Y.; Wang, J. Compactness and hardened properties of machine-made sand mortar with aggregate micro fines. Constr. Build. Mater. 2020, 250, 118828. [Google Scholar] [CrossRef]

- Jin, L.; Wang, Z.; Wu, T.; Liu, P.; Zhou, P.; Zhu, D.; Wang, X. Mesoscale-based mechanical parameters determination and compressive properties of fully recycled coarse aggregate concrete. J. Build. Eng. 2024, 90, 109366. [Google Scholar] [CrossRef]

- Cai, J.; Pan, J.; Li, X.; Tan, J.; Li, J. Electrical resistivity of fly ash and metakaolin based geopolymers. Constr. Build. Mater. 2020, 234, 117868. [Google Scholar] [CrossRef]

- GB/T 17671-2021; Test Method of Cement Mortar Strength (ISO Method). State Administration for Market Regulation, Standardization Administration of the People’s Republic of China: Beijing, China, 2021.

- Salim, M.U.; Moro, C. Towards sustainable construction: Performance evaluation of slag-cenosphere geopolymers under different NaOH concentrations. J. Build. Eng. 2024, 91, 109605. [Google Scholar] [CrossRef]

- Ameri, F.; Zareei, S.A.; Behforouz, B. Zero-cement vs. cementitious mortars: An experimental comparative study on engineering and environmental properties. J. Build. Eng. 2020, 32, 101620. [Google Scholar] [CrossRef]

- Liu, S.; Ge, Y.; Wu, M.; Xiao, H.; Kong, Y. Properties and road engineering application of carbon fiber modified-electrically conductive concrete. Struct. Concr. 2021, 22, 410–421. [Google Scholar] [CrossRef]

- Han, B.; Zhang, L.; Zhang, C.; Wang, Y.; Yu, X.; Ou, J. Reinforcement effect and mechanism of carbon fibers to mechanical and electrically conductive properties of cement-based materials. Constr. Build. Mater. 2016, 125, 479–489. [Google Scholar] [CrossRef]

- Li, H.; Wu, Y.; Zhou, A.; Zhao, C.; Deng, L.; Lu, F. Experimental study on self-healing performance of tunnel lining concrete based on response surface methodology. Constr. Build. Mater. 2024, 425, 136105. [Google Scholar] [CrossRef]

- Su, C.; Zhang, J.; Ding, Y. Research on reactivity evaluation and micro-mechanism of various solid waste powders for alkali-activated cementitious materials. Constr. Build. Mater. 2024, 411, 134374. [Google Scholar] [CrossRef]

- Xu, C.; Jing, H.; Liu, F.; Zhang, Z. The multi-objective optimization and mix parameter evaluation of one-part alkali-activated grouting material. J. Clean. Prod. 2024, 448, 141638. [Google Scholar] [CrossRef]

- Zha, W.; Lv, W.; Li, J.; Xu, T.; Yang, K.; Hua, X.; Chen, D. Optimized the performance of conductive mortar with hybrid fiber and steel-slag via RSM and MOPSO. Constr. Build. Mater. 2025, 459, 139776. [Google Scholar] [CrossRef]

- Nakkeeran, G.; Krishnaraj, L.; Bahrami, A.; Almujibah, H.; Panchal, H.; Zahra, M.M.A. Machine learning application to predict the mechanical properties of glass fiber mortar. Adv. Eng. Softw. 2023, 180, 103454. [Google Scholar] [CrossRef]

- Shah, S.A.R.; Kahla, N.B.; Atig, M.; Anwar, M.K.; Azab, M.; Mahmood, A. Optimization of fresh and mechanical properties of sustainable concrete composite containing ARGF and fly ash: An application of response surface methodology. Constr. Build. Mater. 2023, 362, 129722. [Google Scholar] [CrossRef]

- Wang, T.; Fan, X.; Gao, C. Development of high-strength geopolymer mortar based on fly ash-slag: Correlational analysis of microstructural and mechanical properties and environmental assessment. Constr. Build. Mater. 2024, 441, 137515. [Google Scholar] [CrossRef]

- Zhou, Z.; Xie, N.; Cheng, X.; Feng, L.; Hou, P.; Huang, S.; Zhou, Z. Electrical properties of low dosage carbon nanofiber/cement composite: Percolation behavior and polarization effect. Cem. Concr. Compos. 2020, 109, 103539. [Google Scholar] [CrossRef]

- Liu, J.; Xie, H.; Wang, C. Optimization of compressive strength and sound absorption of foamed gypsum-cement composites based on response surface methodology. Case Stud. Constr. Mater. 2025, 22, e04566. [Google Scholar] [CrossRef]

- Zhou, Y.; Yu, P.; Yang, H.; Xia, X.; He, S.; Huang, X. Utilization of municipal solid waste incinerator fly ash under high temperature sintering and alkali excitation for use in cementitious material. J. Build. Eng. 2024, 94, 110005. [Google Scholar] [CrossRef]

- Feng, X.; Yao, J.; Wu, P.; Zhang, S.; Sunahara, G.; Ni, W. Effect of water quenched silicomanganese slag as fine aggregate on mechanical properties and microstructure characteristics of solid waste-based mortar and concrete. J. Build. Eng. 2024, 88, 109115. [Google Scholar] [CrossRef]

- Wang, A.; Liu, P.; Mo, L.; Liu, K.; Ma, R.; Guan, Y.; Sun, D. Mechanism of thermal activation on granular coal gangue and its impact on the performance of cement mortars. J. Build. Eng. 2022, 45, 103616. [Google Scholar] [CrossRef]

- Li, A.; Wang, Y.; Zhang, S.; Niu, D.; Guo, B. Study on the mechanical and electrical conductivity properties of waste short carbon fibers concrete and the establishment of conductivity models. J. Build. Eng. 2024, 95, 110296. [Google Scholar] [CrossRef]

- Cui, Q.; Feng, Z.-g.; Shen, R.; Li, X.; Wang, Z.; Yao, D.; Li, X. Piezoresistive response of self-sensing asphalt concrete containing carbon fiber. Constr. Build. Mater. 2024, 426, 136121. [Google Scholar] [CrossRef]

- Chung, D. Electrically conductive cement-based materials. Adv. Cem. Res. 2004, 16, 167–176. [Google Scholar] [CrossRef]

- Aydın, S.; Baradan, B. The effect of fiber properties on high performance alkali-activated slag/silica fume mortars. Compos. Part B Eng. 2013, 45, 63–69. [Google Scholar] [CrossRef]

- Hu, S.; Wang, H.; Zhang, G.; Ding, Q. Bonding and abrasion resistance of geopolymeric repair material made with steel slag. Cem. Concr. Compos. 2008, 30, 239–244. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, X.; Lu, H.; Xiao, R.; Hu, W.; Jiang, X.; Zhou, H.; Huang, B. Laboratory investigation on electrical and mechanical properties of asphalt mixtures for potential snow-melting and deicing pavements. Constr. Build. Mater. 2024, 413, 134901. [Google Scholar] [CrossRef]

- Çelikten, S.; Sarıdemir, M.; Deneme, İ.Ö. Mechanical and microstructural properties of alkali-activated slag and slag+ fly ash mortars exposed to high temperature. Constr. Build. Mater. 2019, 217, 50–61. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, J.; Fu, Y.; Long, W.; Dong, B. Synthesis of one-part geopolymers from alkaline-activated molybdenum tailings: Mechanical properties and microstructural evolution. J. Clean. Prod. 2024, 443, 141129. [Google Scholar] [CrossRef]

- Qing, L.; Shaokang, S.; Zhen, J.; Junxiang, W.; Xianjun, L. Effect of CaO on hydration properties of one-part alkali-activated material prepared from tailings through alkaline hydrothermal activation. Constr. Build. Mater. 2021, 308, 124931. [Google Scholar] [CrossRef]

- Zhang, D.; Shahin, M.A.; Yang, Y.; Liu, H.; Cheng, L. Effect of microbially induced calcite precipitation treatment on the bonding properties of steel fiber in ultra-high performance concrete. J. Build. Eng. 2022, 50, 104132. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, L.; Li, A.; Li, W.; Guo, B. Effect of modified recycled carbon fibers on the conductivity of cement-based materials. Constr. Build. Mater. 2024, 415, 135033. [Google Scholar] [CrossRef]

- Sambucci, M.; Al-Noaimat, Y.A.; Nouri, S.M.; Chougan, M.; Ghaffar, S.H.; Valente, M. Influence of Nanoceramic-Plated Waste Carbon Fibers on Alkali-Activated Mortar Performance. Ceramics 2024, 7, 821–839. [Google Scholar] [CrossRef]

| Materials | SiO2 | Al2O3 | CaO | MgO | SO3 | K2O | Fe2O3 | Na2O | P2O5 | Others |

|---|---|---|---|---|---|---|---|---|---|---|

| CG | 56.26 | 18.34 | 0.52 | 5.58 | -- | 6.74 | 5.74 | 4.42 | 0.89 | 1.51 |

| SG | 33.06 | 15.04 | 39.29 | 9.96 | 1.90 | -- | -- | -- | -- | 0.75 |

| Nominal Sieve Opening (mm) | Percentage Retained on Sieve (%) | Cumulative Percentage Retained (%) | Percentage Passing (%) |

|---|---|---|---|

| 4.75 | 0.0 | 0.0 | 100.0 |

| 2.36 | 9.8 | 9.8 | 90.2 |

| 1.18 | 20.4 | 30.2 | 69.8 |

| 0.60 | 20.3 | 50.5 | 49.5 |

| 0.30 | 29.0 | 79.5 | 20.5 |

| 0.15 | 12.5 | 92.0 | 8.0 |

| <0.15 | 8.0 | 100.0 | 0.0 |

| Fineness Modulus | Apparent Density (kg/m3) | Packing Density (kg/m3) | Water Absorption (%) | Maximum Particle Size (mm) |

|---|---|---|---|---|

| 2.62 | 2602 | 1475 | 1.5 | 4.75 |

| Length (mm) | Fiber Diameter (μm) | Density (g·cm−3) | Tensile Strength (GPa) | Tensile Modulus of Elasticity (GPa) |

|---|---|---|---|---|

| 6.00 | 7.00 | 1.76 | 4.12 | 245.00 |

| Ignition Loss (%) | Specific Surface (m2·kg−1) | Setting Time (min) | Compressive Strength (MPa) | Flexural Strength (MPa) | |||

|---|---|---|---|---|---|---|---|

| Initial | Final | 3d | 28d | 3d | 28d | ||

| 3.89 | 364 | 202 | 259 | 27.4 | 48.2 | 6.4 | 7.5 |

| Factor | Variant | Unit | Level | ||

|---|---|---|---|---|---|

| −1 | 0 | 1 | |||

| Water-to-binder ratio | W | -- | 0.45 | 0.50 | 0.55 |

| Alkali equivalent | A | % | 10.0 | 12.0 | 14.0 |

| Slag content | S | % | 30.0 | 45.0 | 60.0 |

| Specimen No. | Factor | Mix Proportions of Mortar (kg·m−3) | Consistence (mm) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Water-to-Binder Ratio | Alkali Equivalent (%) | Slag Content (%) | CG | SG | Water | NaOH | Sodium Silicate | Sand | ||

| W50A12S45 | 0.50 | 12.0 | 45.0 | 322.3 | 263.7 | 139.0 | 43.4 | 272.5 | 1758.0 | 262 |

| W55A10S45 | 0.55 | 10.0 | 45.0 | 322.3 | 263.7 | 193.8 | 36.3 | 227.4 | 1758.0 | 278 |

| W45A12S60 | 0.45 | 12.0 | 60.0 | 234.4 | 315.8 | 109.7 | 43.4 | 272.5 | 1758.0 | 241 |

| W50A12S45 | 0.50 | 12.0 | 45.0 | 322.3 | 263.7 | 139.0 | 43.4 | 272.5 | 1758.0 | 262 |

| W50A12S45 | 0.50 | 12.0 | 45.0 | 322.3 | 263.7 | 139.0 | 43.4 | 272.5 | 1758.0 | 262 |

| W55A12S30 | 0.55 | 12.0 | 30.0 | 410.2 | 175.8 | 168.3 | 43.4 | 272.5 | 1758.0 | 279 |

| W50A12S45 | 0.50 | 12.0 | 45.0 | 322.3 | 263.7 | 139.0 | 43.4 | 272.5 | 1758.0 | 262 |

| W50A10S60 | 0.50 | 10.0 | 60.0 | 234.4 | 315.8 | 164.5 | 36.3 | 227.4 | 1758.0 | 287 |

| W45A12S30 | 0.45 | 12.0 | 30.0 | 410.2 | 175.8 | 109.7 | 43.4 | 272.5 | 1758.0 | 235 |

| W55A14S45 | 0.55 | 14.0 | 45.0 | 322.3 | 263.7 | 142.5 | 50.4 | 318.2 | 1758.0 | 237 |

| W55A12S60 | 0.55 | 12.0 | 60.0 | 234.4 | 315.8 | 168.3 | 43.4 | 272.5 | 1758.0 | 284 |

| W45A10S45 | 0.45 | 10.0 | 45.0 | 322.3 | 263.7 | 135.2 | 36.3 | 227.4 | 1758.0 | 254 |

| W50A14S30 | 0.50 | 14.0 | 30.0 | 410.2 | 175.8 | 113.2 | 50.4 | 318.2 | 1758.0 | 209 |

| W50A10S30 | 0.50 | 10.0 | 30.0 | 410.2 | 175.8 | 164.5 | 36.3 | 227.4 | 1758.0 | 271 |

| W50A14S60 | 0.50 | 14.0 | 60.0 | 234.4 | 315.8 | 113.2 | 50.4 | 318.2 | 1758.0 | 215 |

| W50A12S45 | 0.50 | 12.0 | 45.0 | 322.3 | 263.7 | 139.0 | 43.4 | 272.5 | 1758.0 | 262 |

| W45A14S45 | 0.45 | 14.0 | 45.0 | 322.3 | 263.7 | 83.9 | 50.4 | 318.2 | 1758.0 | 195 |

| Specimen No. | Water-to-Binder Ratio | Alkali Equivalent (%) | Slag Content (%) | Compressive Strength (MPa) | Flexural Strength (MPa) | Resistivity (Ω·m) | |||

|---|---|---|---|---|---|---|---|---|---|

| Average Value | Standard Deviation | Average Value | Standard Deviation | Average Value | Standard Deviation | ||||

| W50A12S45 | 0.50 | 12.0 | 45.0 | 67.9 | 1.49 | 7.1 | 0.34 | 65.1 | 1.11 |

| W55A10S45 | 0.55 | 10.0 | 45.0 | 57.1 | 1.14 | 5.8 | 0.30 | 67.3 | 1.57 |

| W45A12S60 | 0.45 | 12.0 | 60.0 | 83.6 | 1.83 | 8.1 | 0.39 | 68.2 | 1.65 |

| W50A12S45 | 0.50 | 12.0 | 45.0 | 68.6 | 1.74 | 7.2 | 0.36 | 65.3 | 1.66 |

| W50A12S45 | 0.50 | 12.0 | 45.0 | 68.7 | 1.65 | 7.1 | 0.28 | 65.2 | 1.32 |

| W55A12S30 | 0.55 | 12.0 | 30.0 | 41.8 | 1.87 | 4.2 | 0.34 | 62.3 | 1.39 |

| W50A12S45 | 0.50 | 12.0 | 45.0 | 69.8 | 1.49 | 7.2 | 0.26 | 65.5 | 2.10 |

| W50A10S60 | 0.50 | 10.0 | 60.0 | 81.3 | 1.76 | 7.5 | 0.44 | 70.2 | 1.82 |

| W45A12S30 | 0.45 | 12.0 | 30.0 | 52.3 | 1.95 | 5.1 | 0.23 | 66.3 | 1.11 |

| W55A14S45 | 0.55 | 14.0 | 45.0 | 56.2 | 1.84 | 5.5 | 0.26 | 59.9 | 1.57 |

| W55A12S60 | 0.55 | 12.0 | 60.0 | 73.4 | 1.59 | 7.5 | 0.29 | 64.5 | 2.34 |

| W45A10S45 | 0.45 | 10.0 | 45.0 | 65.0 | 1.69 | 6.6 | 0.21 | 71.6 | 2.00 |

| W50A14S30 | 0.50 | 14.0 | 30.0 | 45.2 | 1.06 | 4.3 | 0.23 | 61.4 | 2.23 |

| W50A10S30 | 0.50 | 10.0 | 30.0 | 49.3 | 1.21 | 4.4 | 0.35 | 69.2 | 1.49 |

| W50A14S60 | 0.50 | 14.0 | 60.0 | 80.1 | 1.56 | 7.1 | 0.31 | 63.7 | 1.39 |

| W50A12S45 | 0.50 | 12.0 | 45.0 | 69.1 | 1.25 | 7.3 | 0.27 | 65.4 | 2.63 |

| W45A14S45 | 0.45 | 14.0 | 45.0 | 65.9 | 1.42 | 6.7 | 0.26 | 64.8 | 1.87 |

| Source | Compressive Strength (Y1, MPa) | Flexural Strength (Y2, MPa) | Resistivity (Y3, Ω·m) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| F-Value | p-Value | Sig. | F-Value | p-Value | Sig. | F-Value | p-Value | Sig. | |

| Model | 220.00 | <0.0001 | Y | 215.02 | <0.0001 | Y | 246.87 | <0.0001 | Y |

| W | 2.48 | 0.1359 | Y | 4.74 | 0.0660 | Y | 1536.69 | <0.0001 | Y |

| A | 148.20 | <0.0001 | Y | 118.44 | <0.0001 | Y | 540.35 | <0.0001 | Y |

| S | 1702.22 | <0.0001 | Y | 1439.06 | <0.0001 | Y | 103.60 | 0.2814 | Y |

| WA | 0.65 | 0.4451 | Y | 3.09 | 0.1220 | Y | 1.36 | 0.0393 | Y |

| WS | 1.70 | 0.2336 | Y | 1.74 | 0.2286 | Y | 6.39 | 0.5779 | Y |

| AS | 0.02 | 0.8965 | Y | 1.74 | 0.2286 | Y | 0.34 | 0.0008 | Y |

| W2 | 36.73 | 0.0005 | Y | 166.49 | <0.0001 | Y | 31.23 | 0.4509 | Y |

| A2 | 68.46 | <0.0001 | Y | 32.32 | 0.0007 | Y | 0.64 | 0.3516 | Y |

| S2 | 8.28 | 0.0237 | Y | 133.40 | <0.0001 | Y | 0.10 | 0.2814 | Y |

| Lack of fit | 4.59 | 0.0874 | N | 2.98 | 0.1597 | N | 4.83 | 0.0811 | N |

| Model | R2 | Adj. R2 | Pred. R2 | C.V. Value (%) | Adep Precision |

|---|---|---|---|---|---|

| Y1 | 0.9965 | 0.9919 | 0.9551 | 1.73 | 49.26 |

| Y2 | 0.9964 | 0.9918 | 0.9584 | 1.78 | 45.01 |

| Y3 | 0.9969 | 0.9928 | 0.9596 | 0.39 | 57.57 |

| Response | Predicted Result | Experimental Results | Deviation (%) |

|---|---|---|---|

| Compressive strength (Y1, MPa) | 72.5 | 73.7 | 1.7 |

| Flexural strength (Y2, MPa) | 7.0 | 7.2 | 2.9 |

| Resistivity (Y3, Ω·m) | 62.4 | 61.6 | 1.3 |

| Specimen No. | CF | Cement | CG | SG | NaOH | Sodium Silicate | Water | Sand |

|---|---|---|---|---|---|---|---|---|

| CA0 | 0 | -- | 249.1 | 336.9 | 56.6 | 252.0 | 174.0 | 1758.0 |

| CA15 | 2.6 | -- | 249.1 | 336.9 | 56.6 | 252.0 | 174.0 | 1758.0 |

| CA30 | 5.2 | -- | 249.1 | 336.9 | 56.6 | 252.0 | 174.0 | 1758.0 |

| CA45 | 7.8 | -- | 249.1 | 336.9 | 56.6 | 252.0 | 174.0 | 1758.0 |

| CA60 | 10.5 | -- | 249.1 | 336.9 | 56.6 | 252.0 | 174.0 | 1758.0 |

| CC0 | 0 | 586.0 | -- | -- | -- | -- | 316.4 | 1758.0 |

| CC15 | 2.6 | 586.0 | -- | -- | -- | -- | 316.4 | 1758.0 |

| CC30 | 5.2 | 586.0 | -- | -- | -- | -- | 316.4 | 1758.0 |

| CC45 | 7.8 | 586.0 | -- | -- | -- | -- | 316.4 | 1758.0 |

| CC60 | 10.5 | 586.0 | -- | -- | -- | -- | 316.4 | 1758.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lv, W.; Zha, W.; Xu, T.; Sun, M. Preparation and Performance Study of Alkali-Activated Conductive Mortar via Response Surface Methodology. Minerals 2025, 15, 787. https://doi.org/10.3390/min15080787

Lv W, Zha W, Xu T, Sun M. Preparation and Performance Study of Alkali-Activated Conductive Mortar via Response Surface Methodology. Minerals. 2025; 15(8):787. https://doi.org/10.3390/min15080787

Chicago/Turabian StyleLv, Wenfang, Wenhua Zha, Tao Xu, and Minqian Sun. 2025. "Preparation and Performance Study of Alkali-Activated Conductive Mortar via Response Surface Methodology" Minerals 15, no. 8: 787. https://doi.org/10.3390/min15080787

APA StyleLv, W., Zha, W., Xu, T., & Sun, M. (2025). Preparation and Performance Study of Alkali-Activated Conductive Mortar via Response Surface Methodology. Minerals, 15(8), 787. https://doi.org/10.3390/min15080787