Influence of Mineralogical and Petrographic Properties on the Mechanical Behavior of Granitic and Mafic Rocks

Abstract

1. Introduction

2. Geological Conditions of Study Area

2.1. Shuangjiangkou Granite

2.2. Chengde Anorthosite

2.3. Chengde Mangerite

3. Materials and Methods

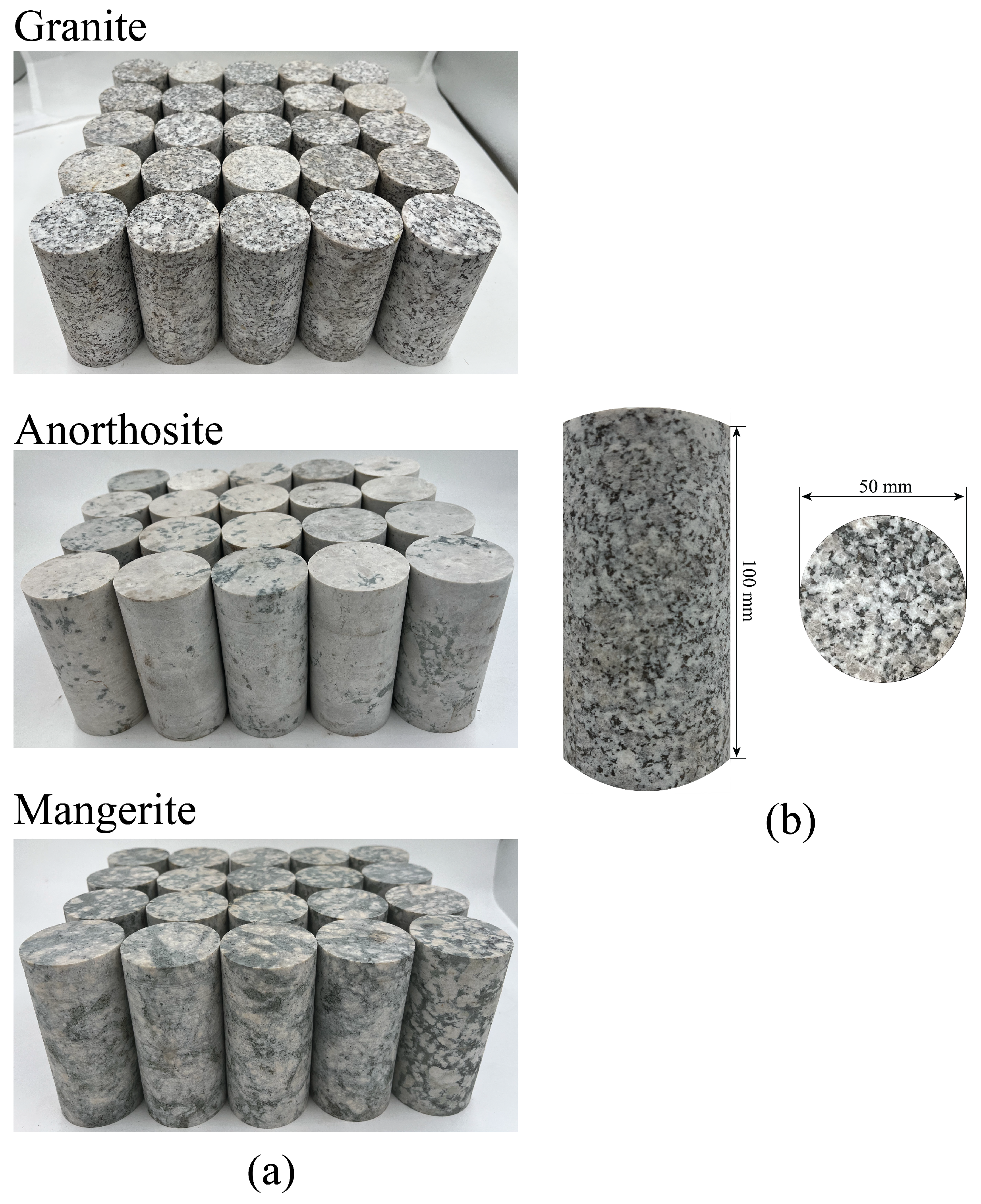

3.1. Specimen Preparation

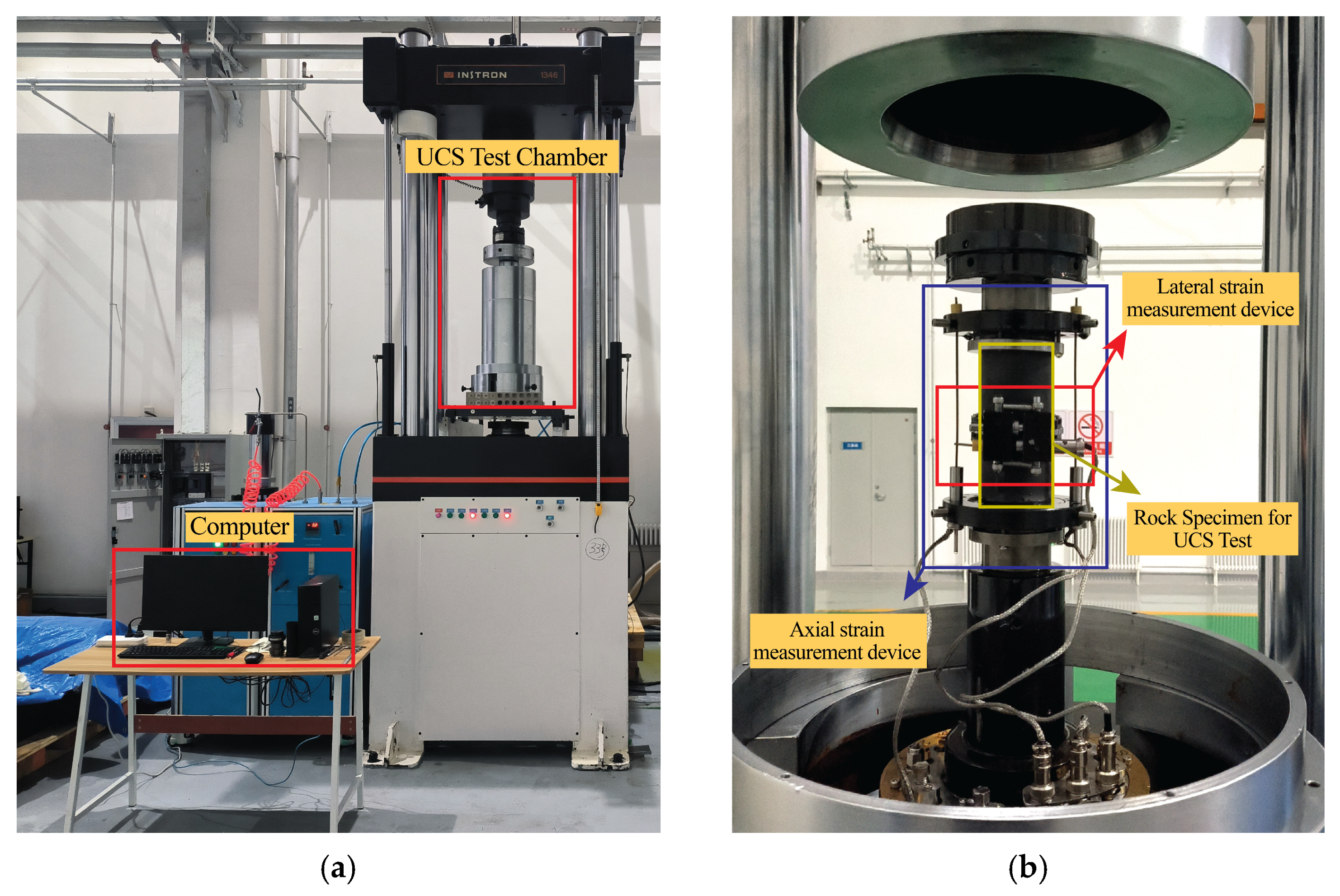

3.2. Engineering Properties

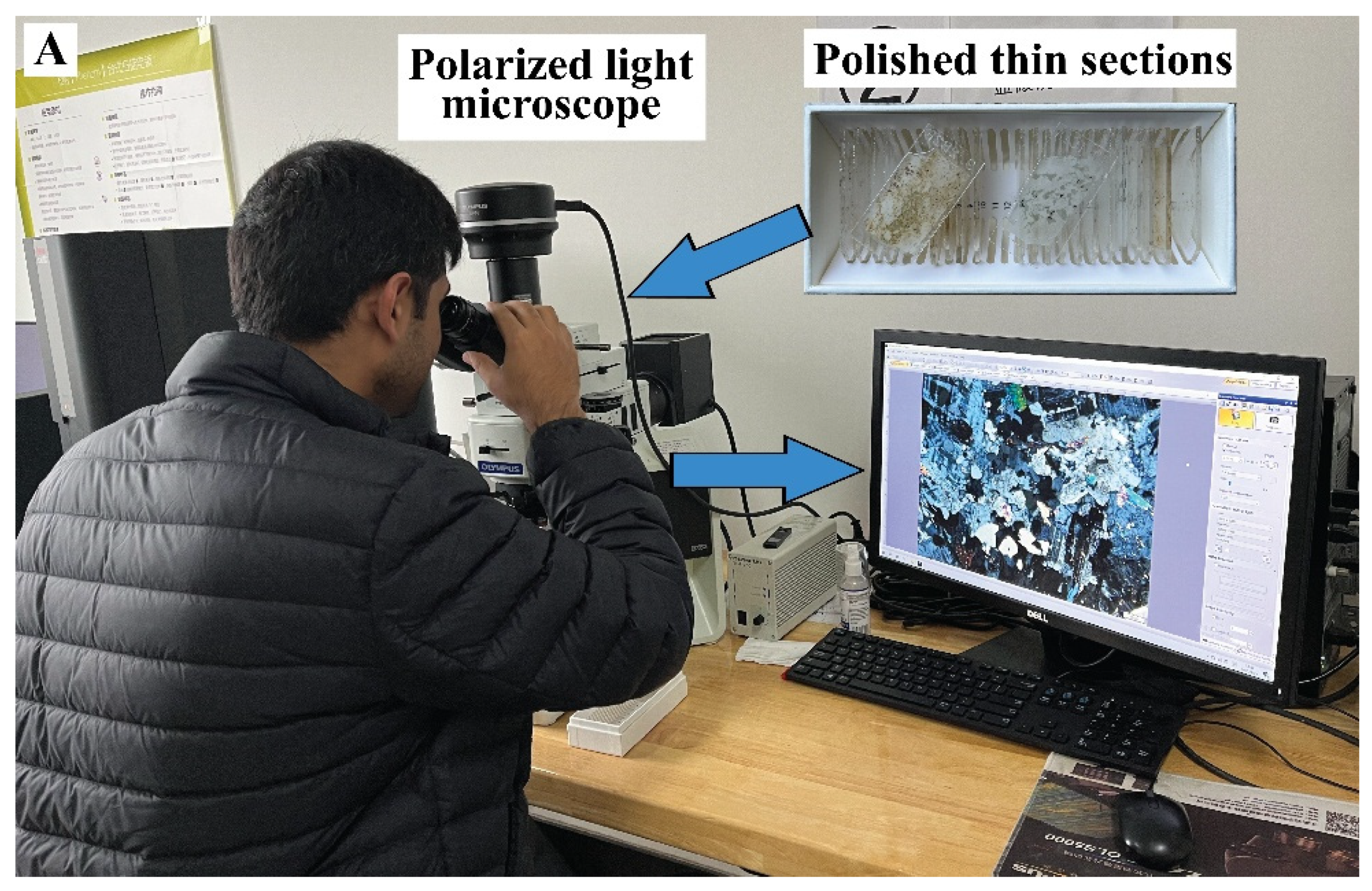

3.3. Petrographic Characterization

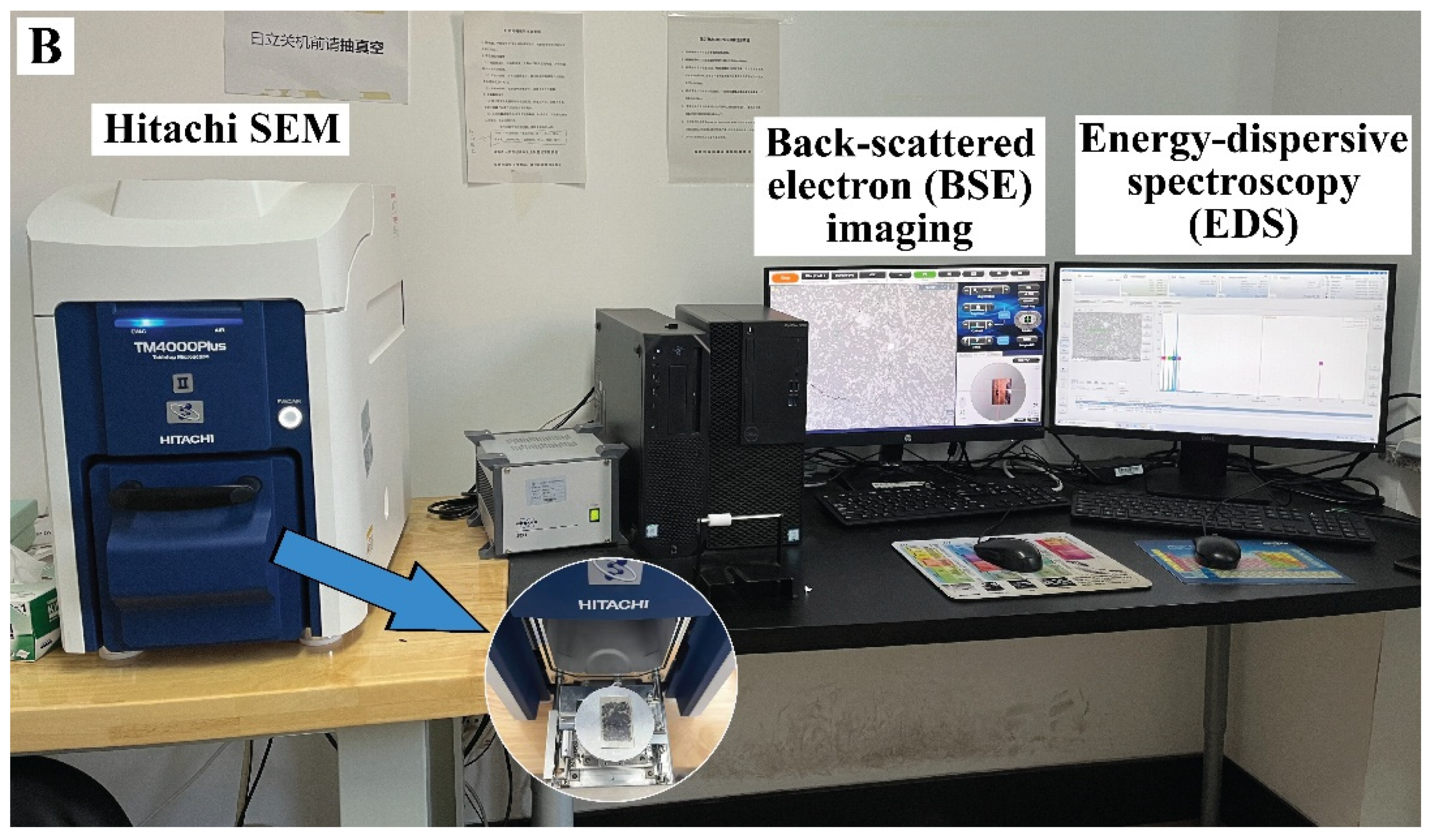

3.4. SEM-EDS Mineralogical Analysis

4. Results

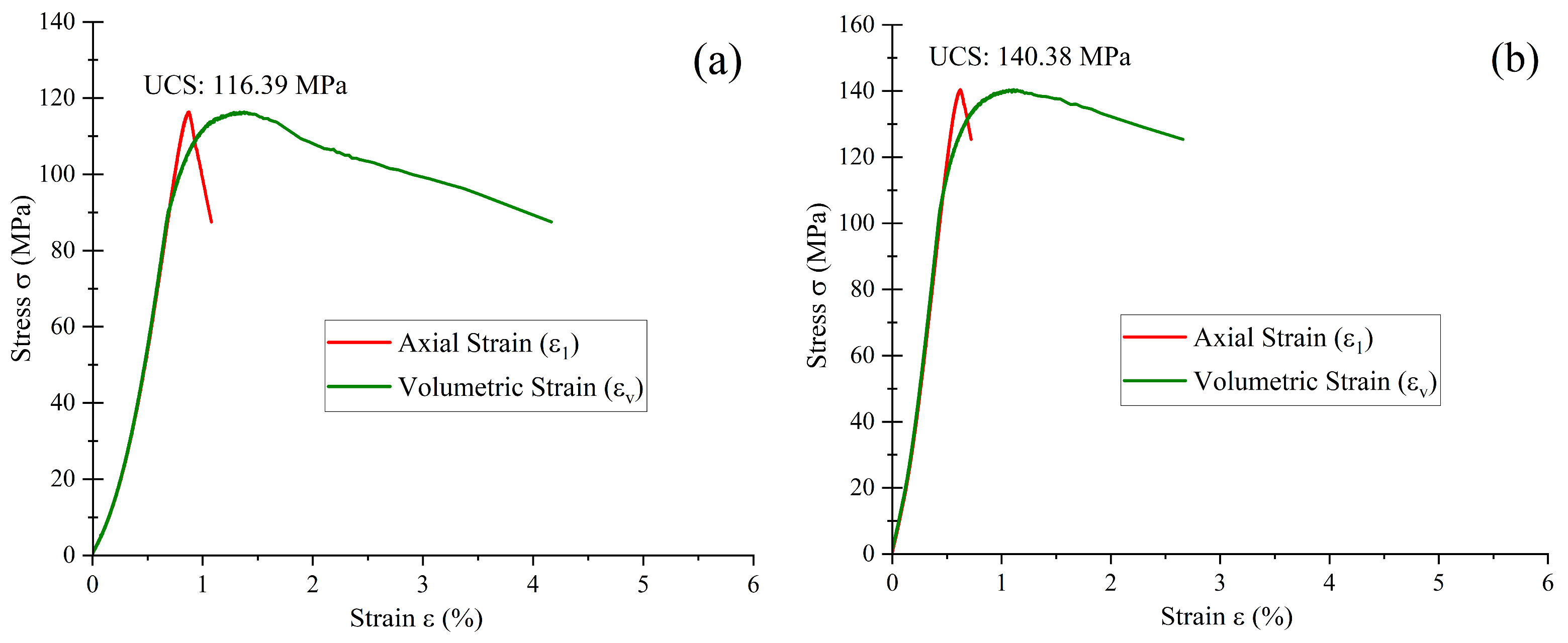

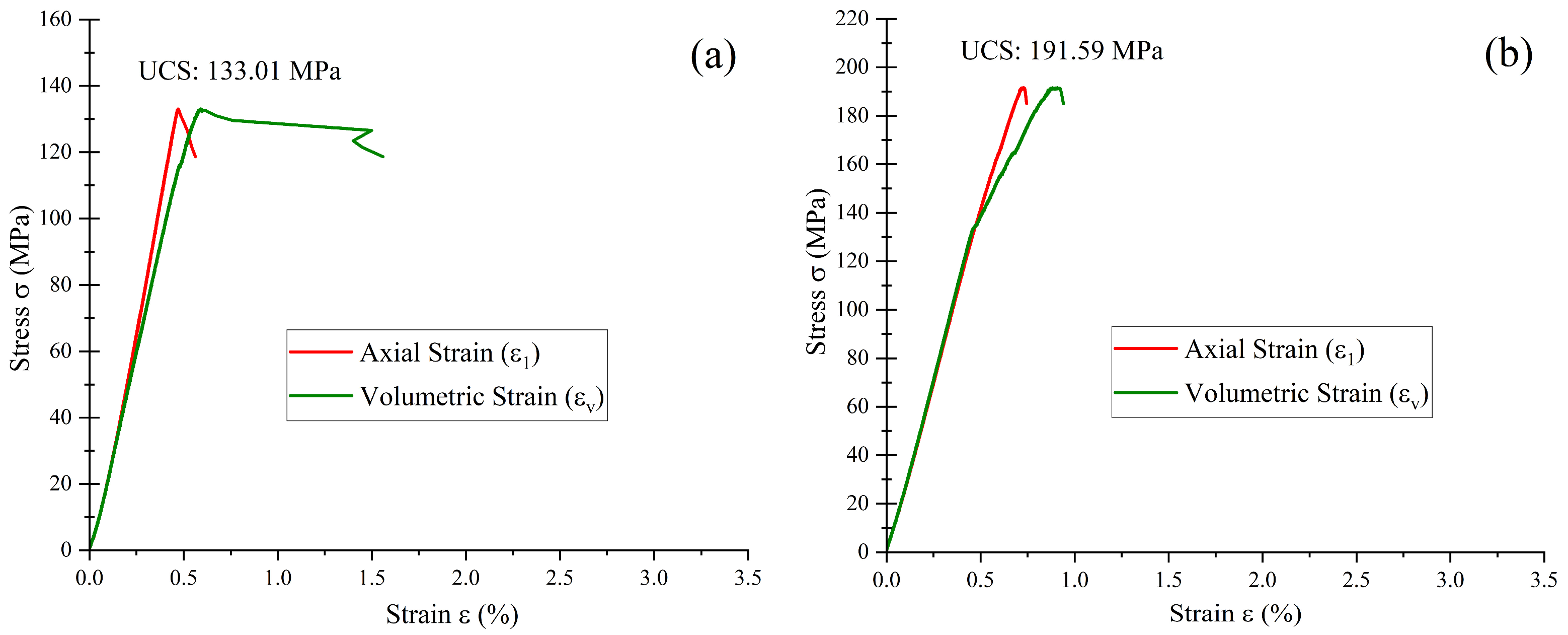

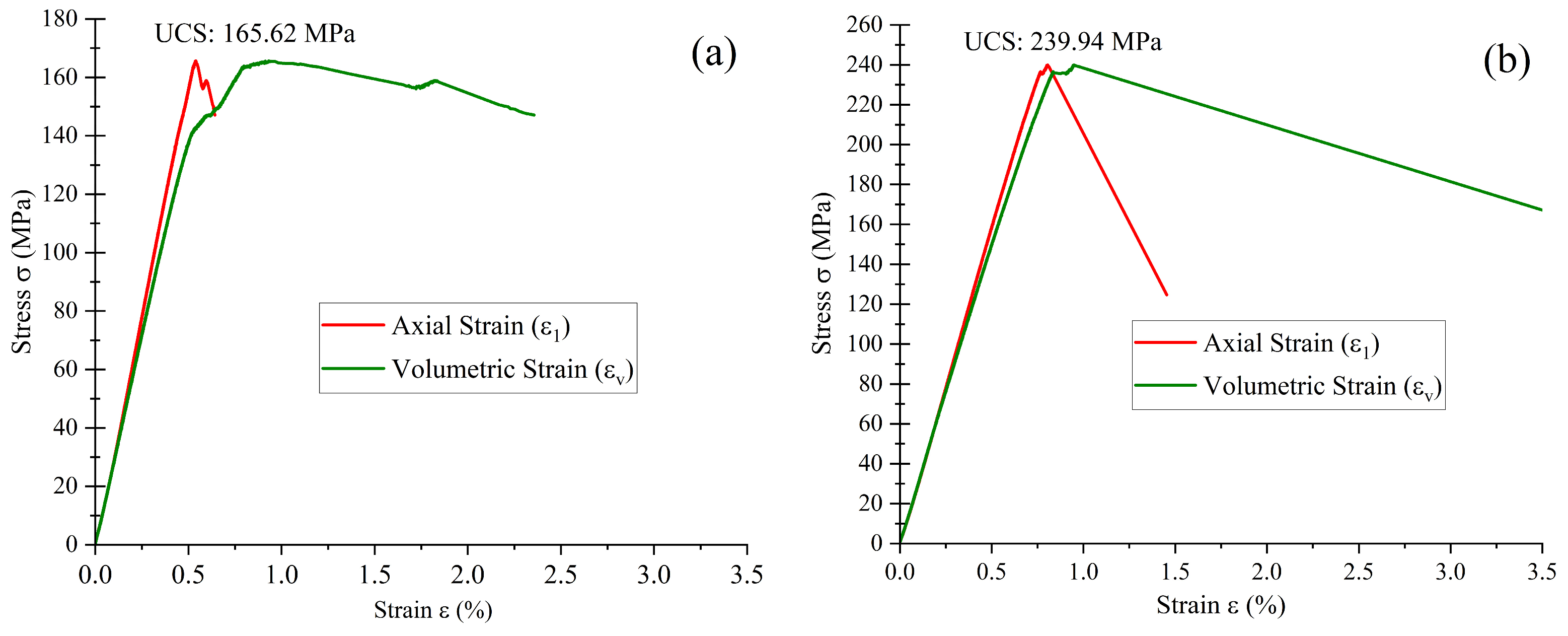

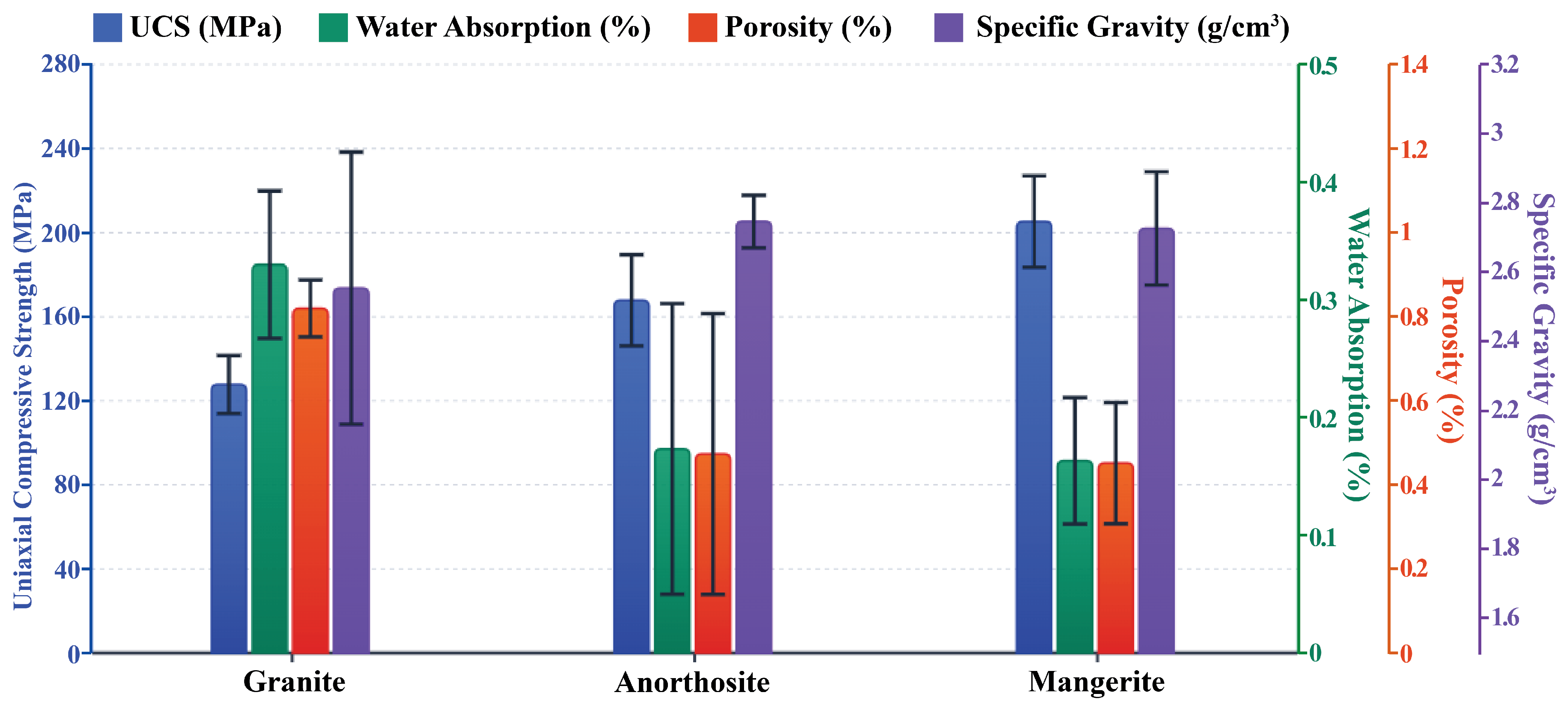

4.1. Mechanical Behavior of Rocks

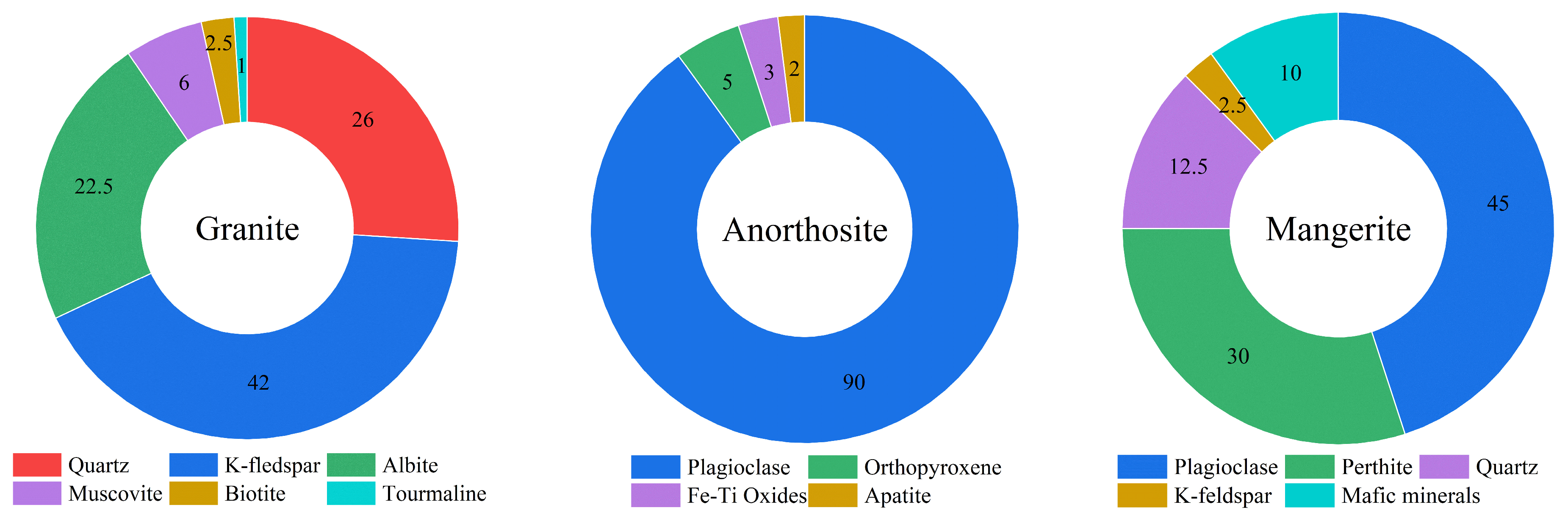

4.2. Petrographic and Mineralogical Characteristics

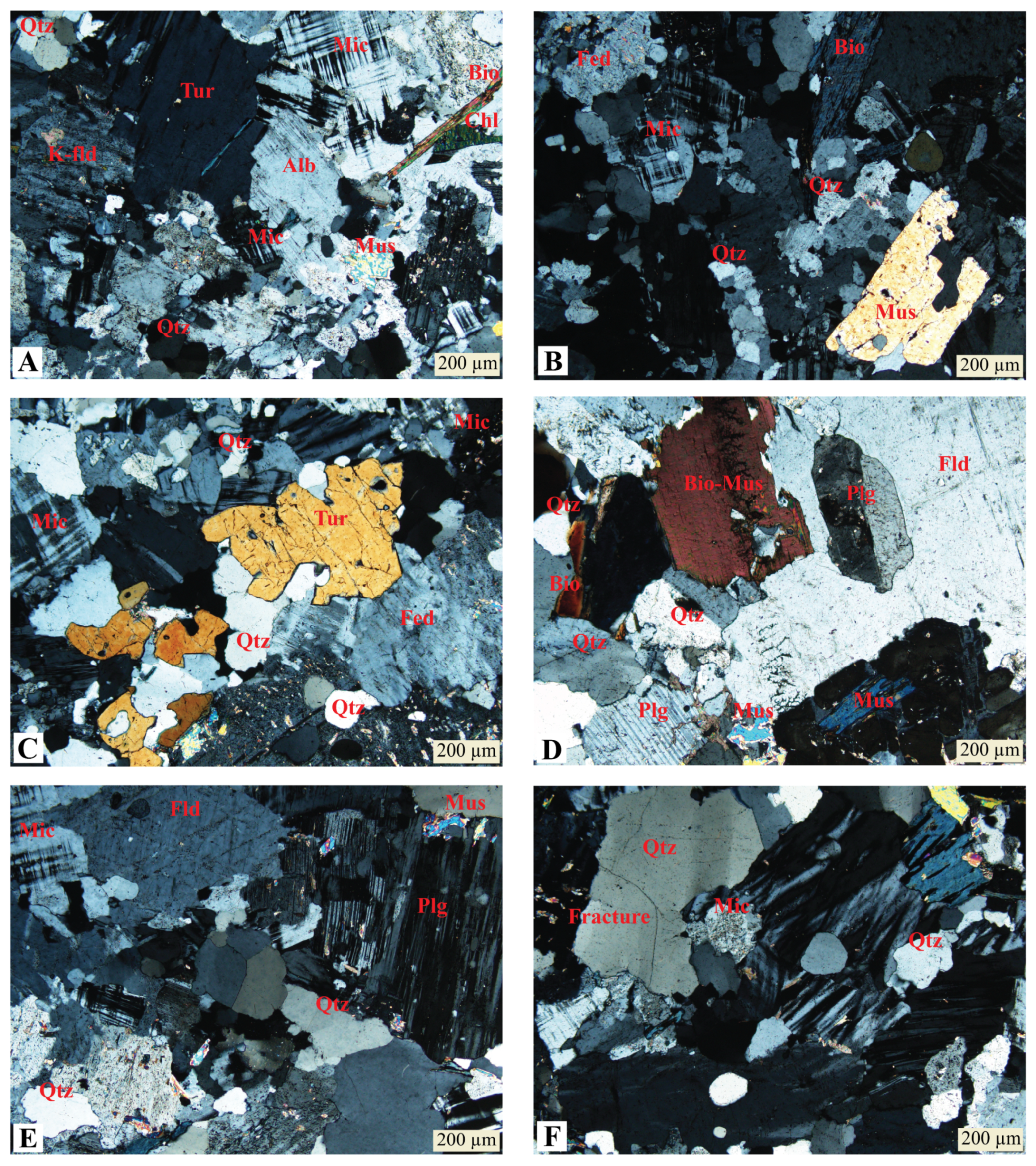

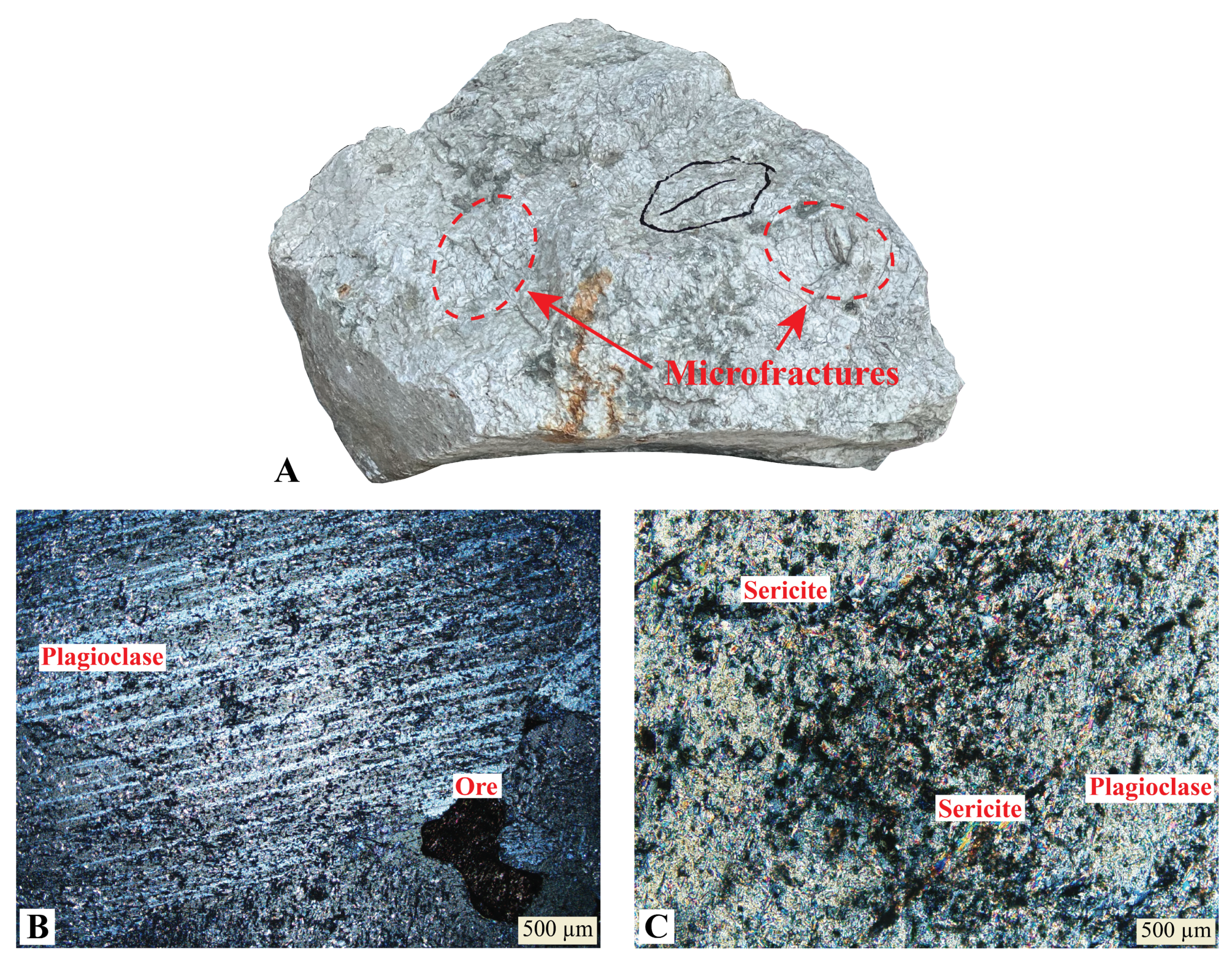

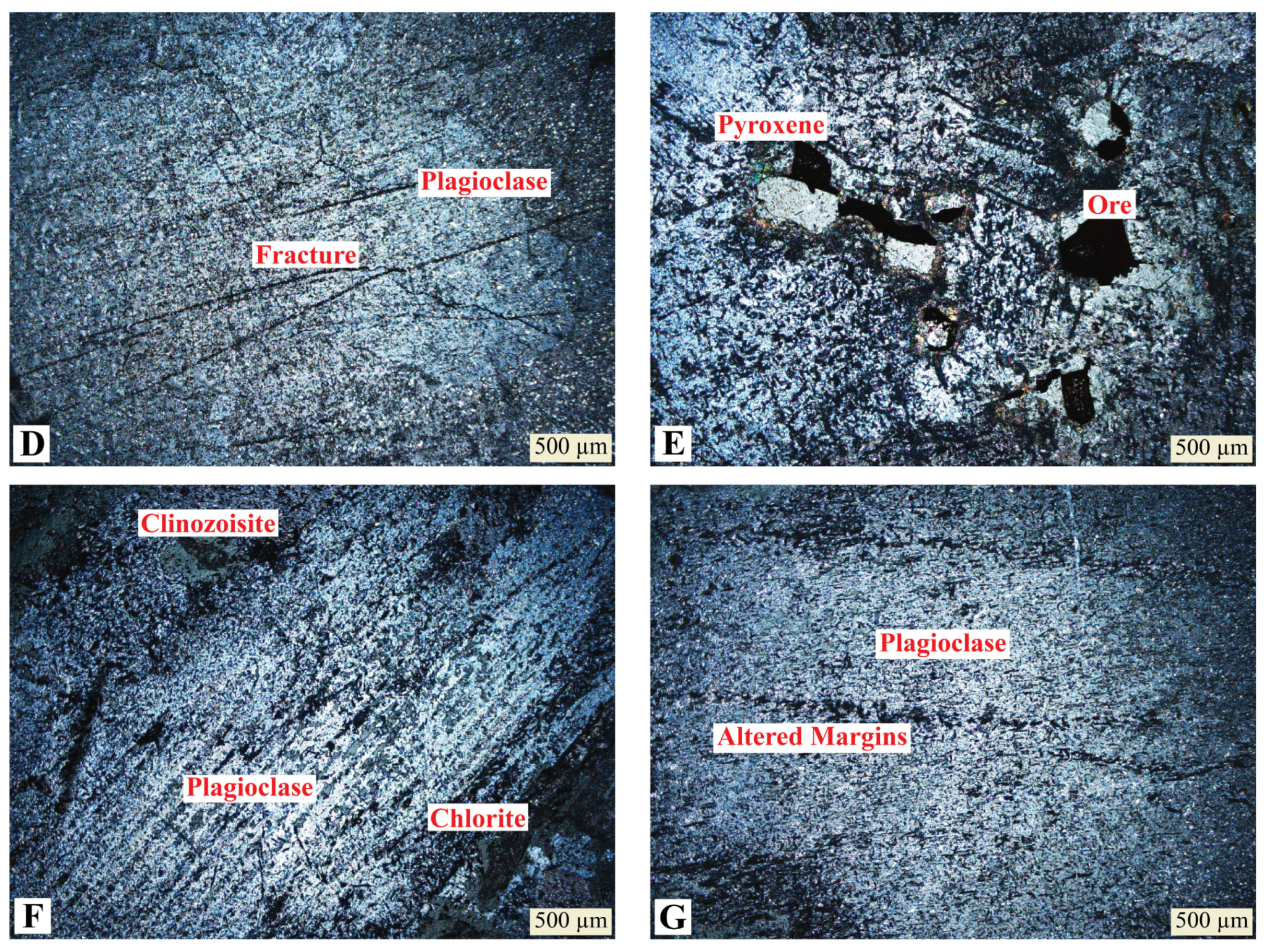

4.2.1. Microstructural Features (Optical Microscopy)

- (a)

- Granite

- (b)

- Anorthosite

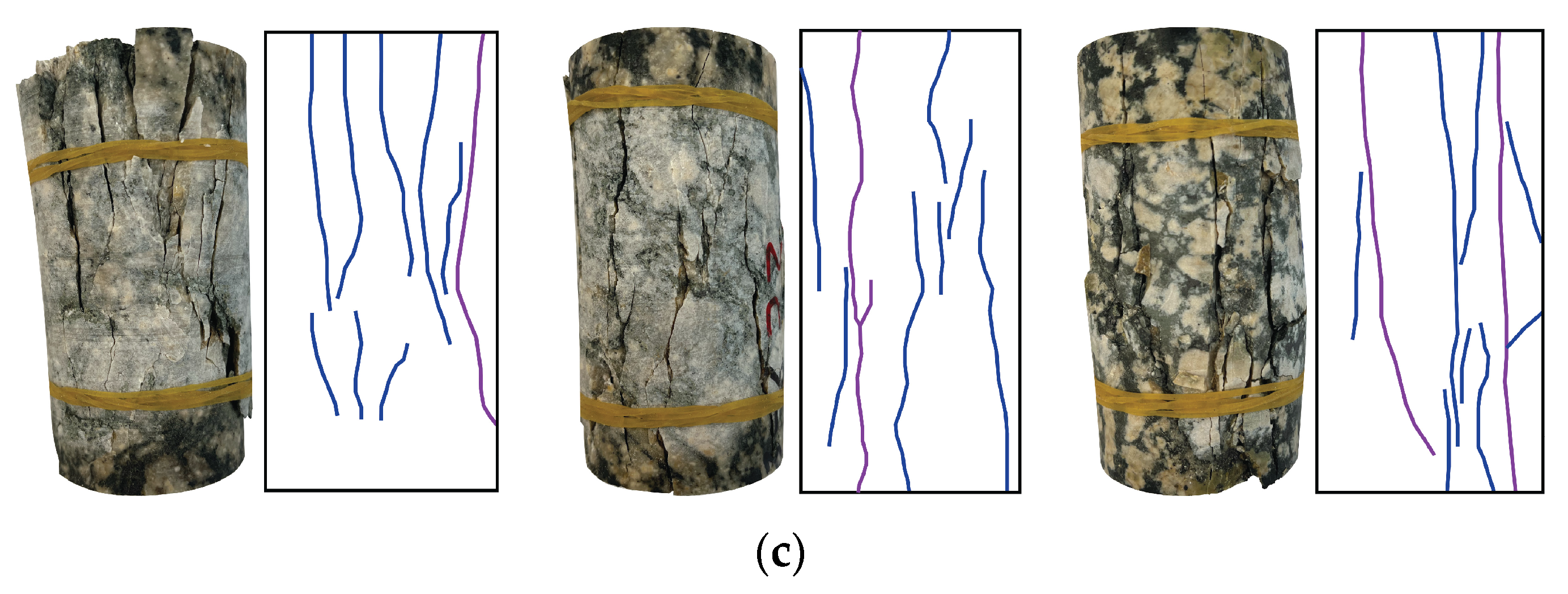

- (c)

- Mangerite

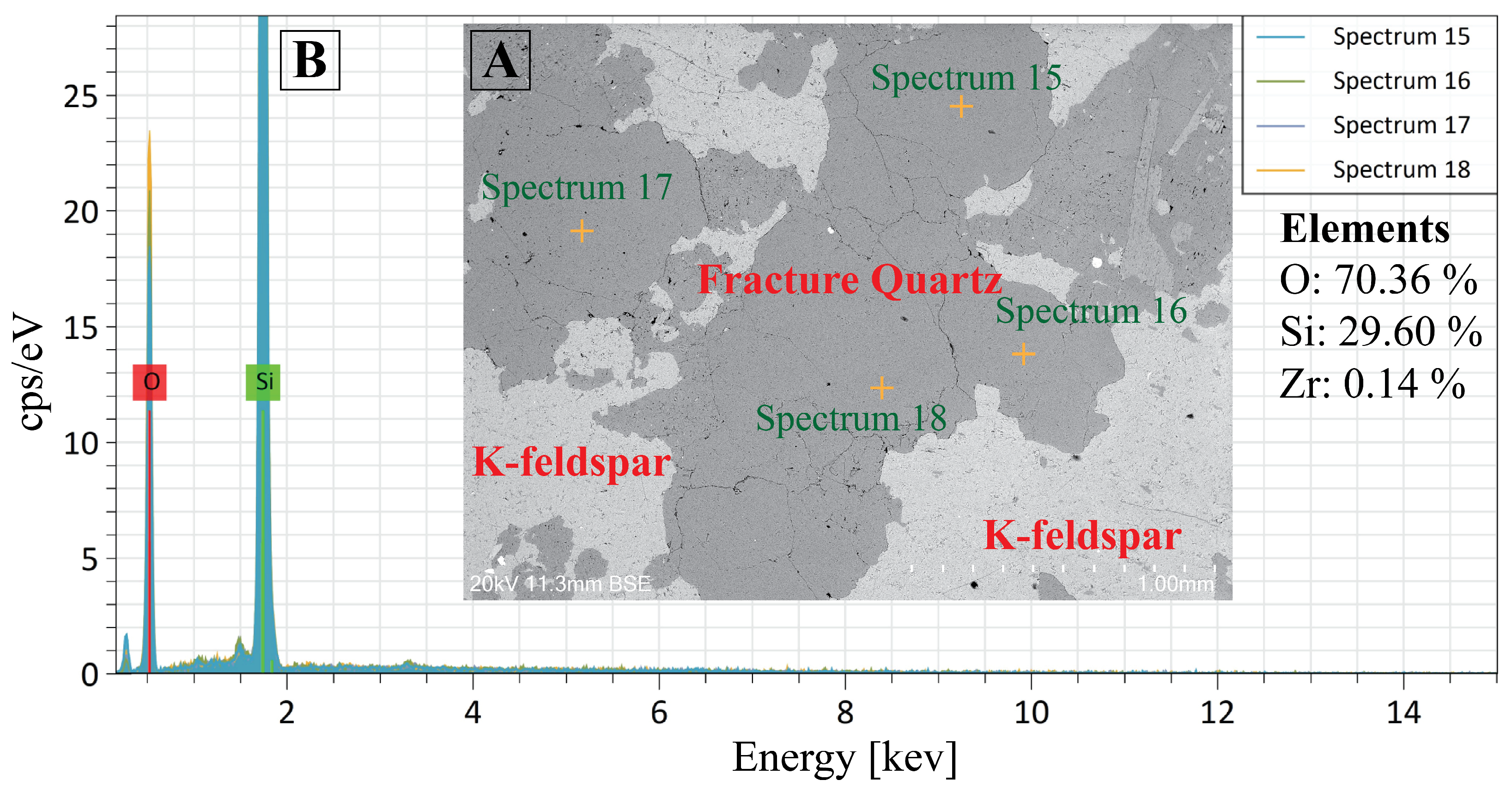

4.2.2. Mineralogical Composition and Texture (SEM, EDS)

- (a)

- Granite

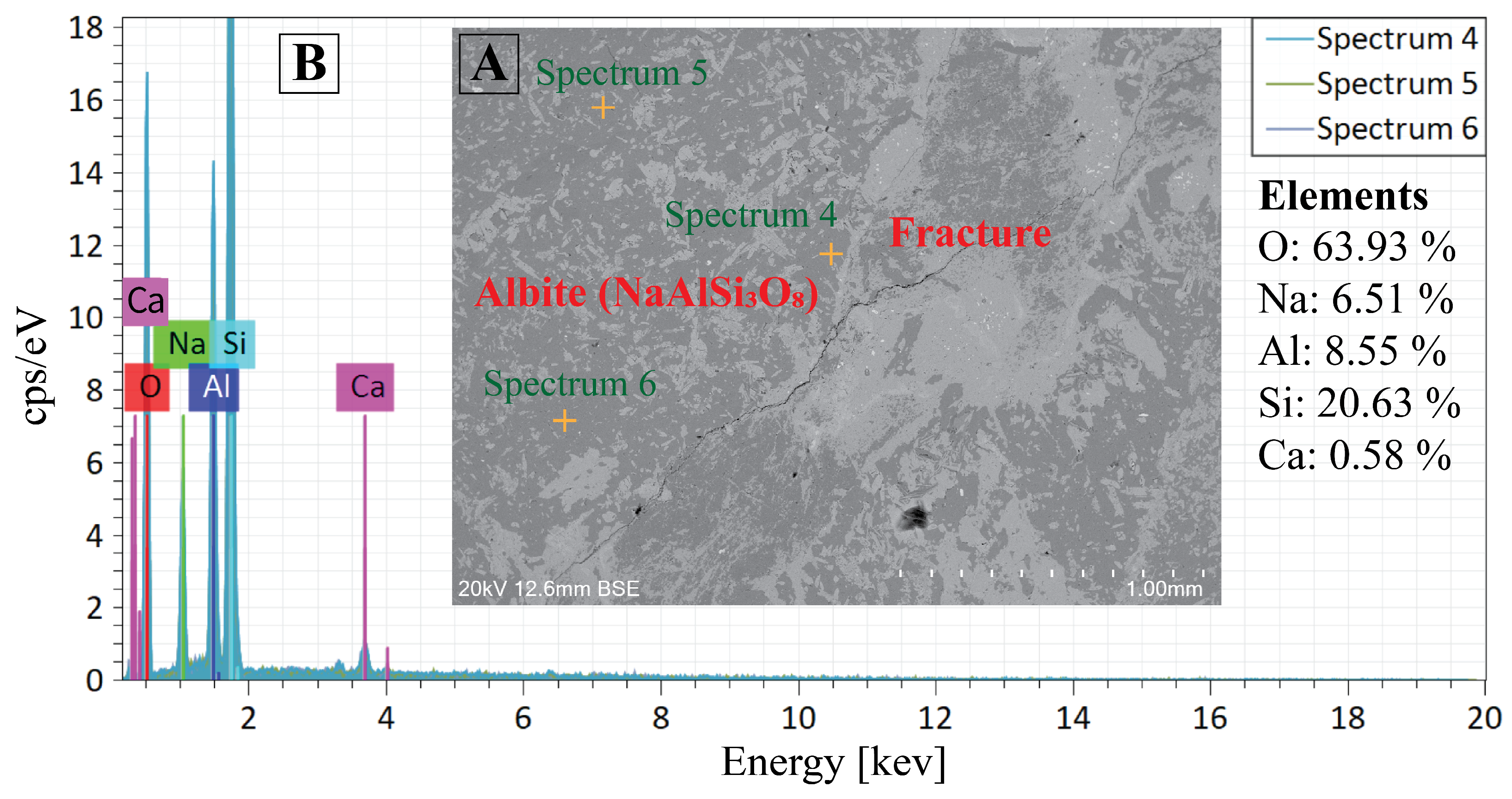

- (b)

- Anorthosite

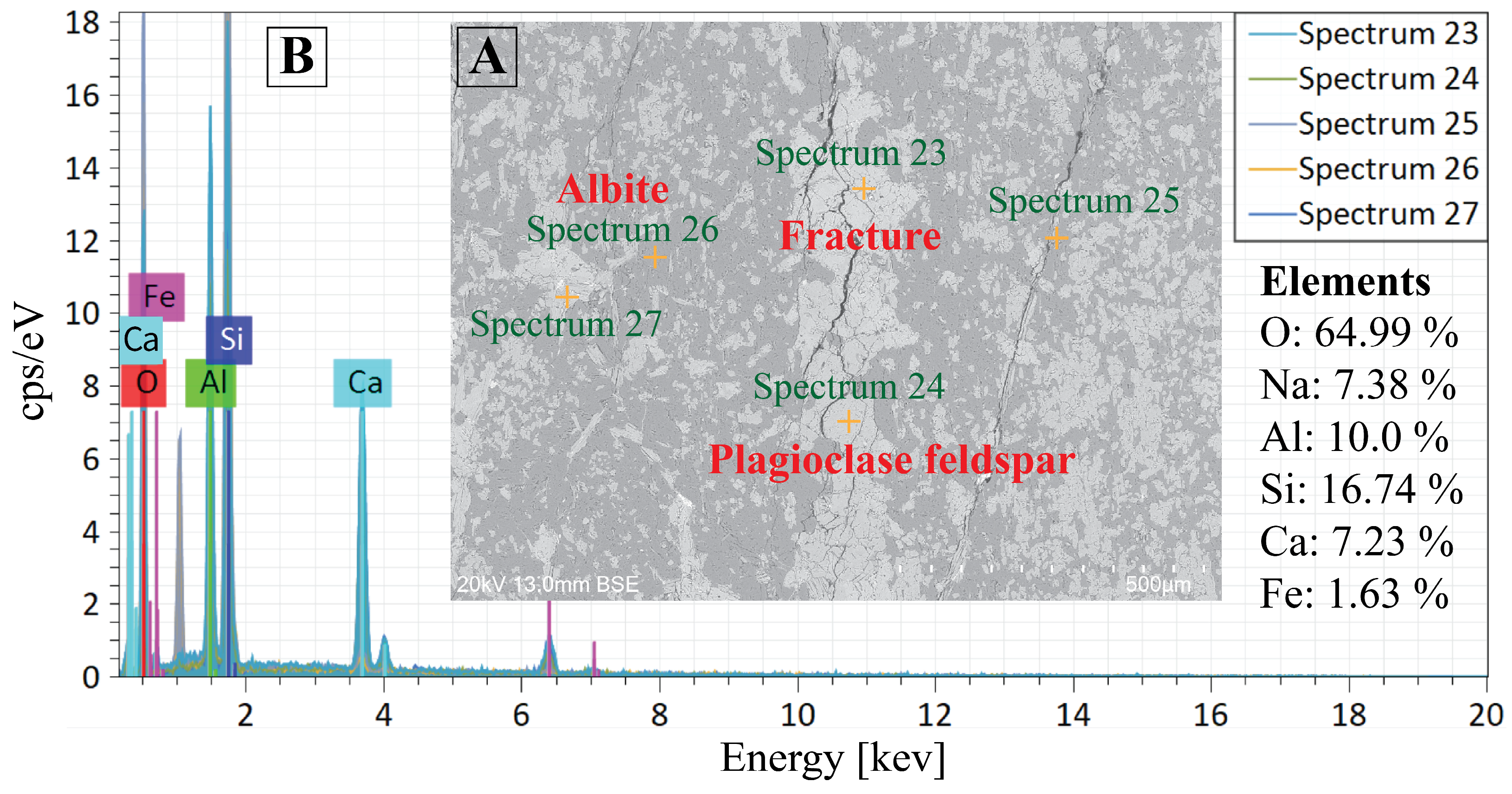

- (c)

- Mangerite

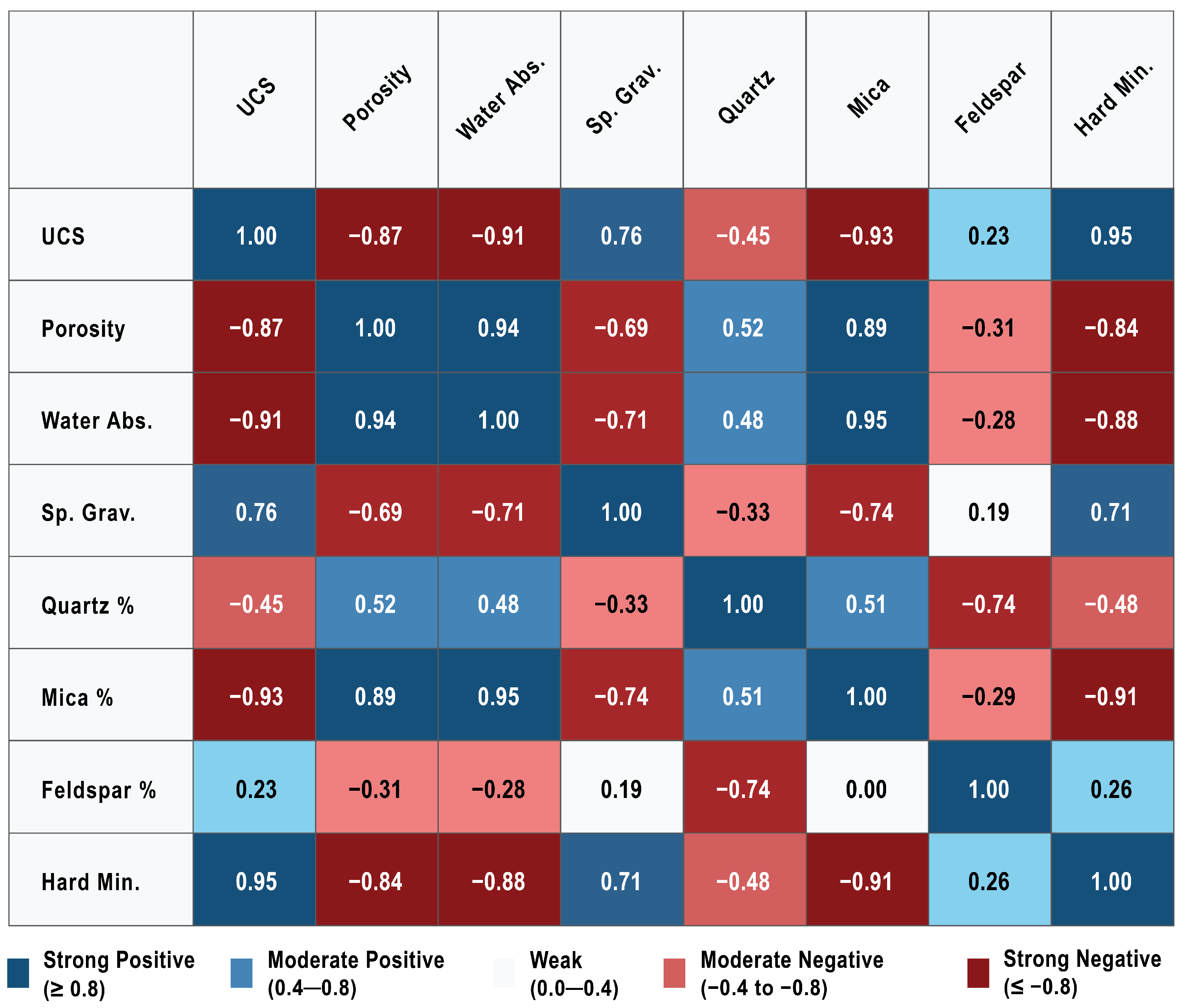

5. Discussion

5.1. Petrography Control on Physico-Mechanical Properties

5.2. Failure Mode Analysis of Specimens

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, B.; Wang, X.; Zhao, H.; Xu, D.; Wang, G.; Su, T.; An, X. A Multi-Scale Observation and Crack Statistics Based Method for Analyzing Failure Mechanism of Pre-Flawed Rock under True Triaxial Stress. PLoS ONE 2025, 20, 1–19. [Google Scholar] [CrossRef] [PubMed]

- Luo, P.; Fang, X.; Li, D.; Yu, Y.; Li, H.; Cui, P.; Ma, J. Evaluation of Excavation Method on Point Load Strength of Rocks with Poor Geological Conditions in a Deep Metal Mine. Geomech. Geophys. Geo-Energy Geo-Resour. 2023, 9, 90. [Google Scholar] [CrossRef]

- Ersoy, H.; Acar, S. Influences of Petrographic and Textural Properties on the Strength of Very Strong Granitic Rocks. Environ. Earth Sci. 2016, 75, 1–15. [Google Scholar] [CrossRef]

- Wang, Z.; Yao, J.; Tian, N.; Zheng, J.; Gao, P. Mechanical Behavior and Damage Evolution for Granite Subjected to Cyclic Loading. Adv. Mater. Sci. Eng. 2018, 2018, 4312494. [Google Scholar] [CrossRef]

- Zhang, M.; Liang, L.; Liu, X. Impact Analysis of Different Rock Shear Failure Criteria to Wellbore Collapse Pressure. Chin. J. Rock Mech. Eng. 2017, 36, 372–378. [Google Scholar]

- Zhang, M.; Fan, X.; Zhang, Q.; Yang, B.; Zhao, P.; Yao, B.; He, L. Influence of Multi-Planes of Weakness on Unstable Zones near Wellbore Wall in a Fractured Formation. J. Nat. Gas. Sci. Eng. 2021, 93, 104026. [Google Scholar] [CrossRef]

- Zhang, M.; Wen, J.; Xu, Z.; Xu, Z.; Feng, J.; Zhao, X. Study of Borehole Stability of Volcanic Rock Formation with the Influence of Multiple Factors. J. Pet. Explor. Prod. Technol. 2024, 14, 3367–3382. [Google Scholar] [CrossRef]

- Gao, R.; Kuang, T.; Meng, X.; Huo, B. Effects of Ground Fracturing with Horizontal Fracture Plane on Rock Breakage Characteristics and Mine Pressure Control. Rock Mech. Rock Eng. 2021, 54, 3229–3243. [Google Scholar] [CrossRef]

- Gao, R.; Bai, D.; Yu, B.; Tai, Y.; Meng, X.; Zhang, W. Ground Fracturing of Multi-Strata for Strong Ground Pressure Control in Extra-Thick Coal Seams with Hard Roofs: Numerical Simulation and Case Study. Eng. Fract. Mech. 2024, 303, 110129. [Google Scholar] [CrossRef]

- Keikha, T.; Keykha, H.A. Correlation between Mineralogical Characteristics and Engineering Properties of Granitic Rocks. Electron. J. Geotech. Eng. 2013, 18, 4055–4065. [Google Scholar]

- Lasheen, E.S.R.; Rashwan, M.A.; Azer, M.K. Effect of Mineralogical Variations on Physico-Mechanical and Thermal Properties of Granitic Rocks. Sci. Rep. 2023, 13, 10320. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.; Li, D.; Liu, J.; Zhang, D.; Zhang, Y.; Cui, K. The Modification of Mohr-Coulomb Criteria Based on Shape Function and Determination Method of Undetermined Parameters. Mech. Mater. 2023, 185, 104772. [Google Scholar] [CrossRef]

- Irfan, T.Y. Mineralogy, Fabric Properties and Classification of Weathered Granites in Hong Kong. Q. J. Eng. Geol. Hydrogeol. 1996, 29, 5–35. [Google Scholar] [CrossRef]

- Cowie, S.; Walton, G. The Effect of Mineralogical Parameters on the Mechanical Properties of Granitic Rocks. Eng. Geol. 2018, 240, 204–225. [Google Scholar] [CrossRef]

- Rashwan, M.A.; Lasheen, E.S.R.; Azer, M.K. Thermal and Physico-Mechanical Evaluation of Some Magmatic Rocks at Homrit Waggat Area, Eastern Desert, Egypt: Petrography and Geochemistry. Bull. Eng. Geol. Environ. 2023, 82, 199. [Google Scholar] [CrossRef]

- Zada, K.; Arif, M.; Sajid, M. Controls and Implications of Geo-Technical Variation in Quartzose Rocks from Peshawar Basin, North-Western Pakistan. Geomaterials 2015, 5, 85–98. [Google Scholar] [CrossRef][Green Version]

- Eroğlu, G.; Calik, A. Relationship of Petrographic and Mineralogical Characteristics with Mechanical Strength Properties of Granitic Rocks: A Case Study from the Biga Peninsula, NW Turkey. Turk. J. Earth Sci. 2023, 32, 126–143. [Google Scholar] [CrossRef]

- Basu, A.; Celestino, T.B.; Bortolucci, A.A.; Keikha, T.; Keykha, H.A. Evaluation of Rock Mechanical Behaviors under Uniaxial Compression with Reference to Assessed Weathering Grades. Rock Mech. Rock Eng. 2009, 42, 73–93. [Google Scholar] [CrossRef]

- Eberhardt, E.; Stimpson, B.; Stead, D.; Tuǧrul, A.; Miskovsky, K.; Duarte, M.T.; Kou, S.Q.; Lindqvist, P.-A. Influence of the Mineralogical Composition and Textural Properties on the Quality of Coarse Aggregates. Eng. Geol. 2004, 32, 81–99. [Google Scholar]

- Tuǧrul, A. The Effect of Weathering on Pore Geometry and Compressive Strength of Selected Rock Types from Turkey. Eng. Geol. 2004, 75, 215–227. [Google Scholar] [CrossRef]

- Fan, C.; Liu, J.; Meng, F. Microcracking Process Characterization and Failure Time Prediction of Three Typical Rocks upon Uniaxial Compression Based on Acoustic Emission Activity. Rock Mech. Rock Eng. 2024, 57, 9145–9164. [Google Scholar] [CrossRef]

- Yılmaz, N.G.; Goktan, R.M.; Kibici, Y. Relations between Some Quantitative Petrographic Characteristics and Mechanical Strength Properties of Granitic Building Stones. Int. J. Rock Mech. Min. Sci. 2011, 48, 506–513. [Google Scholar] [CrossRef]

- Zhang, M.; Fan, X.; Zhang, Q.; Yang, B.; Zhao, P.; Yao, B.; Ran, J. Parametric Sensitivity Study of Wellbore Stability in Transversely Isotropic Medium Based on Polyaxial Strength Criteria. J. Pet. Sci. Eng. 2021, 197, 108078. [Google Scholar] [CrossRef]

- Fan, Z.; Song, X.; Wang, D.; Ayasrah, M.; Li, S. Poroelastic Solutions of a Semipermeable Borehole under Nonhydrostatic In Situ Stresses within Transversely Isotropic Media. Int. J. Geomech. 2025, 25, 4024342. [Google Scholar] [CrossRef]

- Åkesson, U.; Lindqvist, J.; Göransson, M.; Stigh, J. Relationship between Texture and Mechanical Properties of Granites, Central Sweden, by Use of Image-Analysing Techniques. Bull. Eng. Geol. Environ. 2001, 60, 277–284. [Google Scholar] [CrossRef]

- Heidari, M.; Momeni, A.A.; Rafiei, B.; Khodabakhsh, S.; Torabi-Kaveh, M. Relationship between Petrographic Characteristics and the Engineering Properties of Jurassic Sandstones, Hamedan, Iran. Rock Mech. Rock Eng. 2013, 46, 1091–1101. [Google Scholar] [CrossRef]

- Coggan, J.S.; Stead, D.; Howe, J.H.; Faulks, C.I. Mineralogical Controls on the Engineering Behavior of Hydrothermally Altered Granites under Uniaxial Compression. Eng. Geol. 2013, 160, 89–102. [Google Scholar] [CrossRef]

- Siegesmund, S.; Dürrast, H. Physical and Mechanical Properties of Rocks. In Stone in Architecture: Properties, Durability; Springer: Berlin/Heidelberg, Germany, 2010; pp. 97–225. [Google Scholar]

- Bandini, A.; Berry, P. Influence of Marble’s Texture on Its Mechanical Behavior. Rock Mech. Rock Eng. 2013, 46, 785–799. [Google Scholar] [CrossRef]

- ASTM E1621-13; Standard Guide for Elemental Analysis by Wavelength Dispersive X-Ray Fluorescence Spectrometry. ASTM: Washington, DC, USA, 2013.

- Ghazvinian, E.; Perras, M.; Diederichs, M.; Labrie, D. The Effect of Anisotropy on Crack Damage Thresholds in Brittle Rocks. In Proceedings of the ARMA US Rock Mechanics/Geomechanics Symposium, San Francisco, CA, USA, 23–26 June 2013; p. ARMA-2013. [Google Scholar]

- Cui, L.; Sheng, Q.; Zheng, J.; Luo, S.; Miao, C. Strain-Softening Model for Granite and Sandstone Based on Experimental and Discrete Element Methods. Sci. Rep. 2024, 14, 24308. [Google Scholar] [CrossRef] [PubMed]

- Cao, Y.; Xu, J.; Chen, L.; Wu, P.; Shaikh, F. Experimental Study on Granite Acoustic Emission and Micro-Fracture Behavior with Combined Compression and Shear Loading: Phenomenon and Mechanism. Sci. Rep. 2020, 10, 22051. [Google Scholar] [CrossRef] [PubMed]

- Diederichs, M.S. Mechanistic Interpretation and Practical Application of Damage and Spalling Prediction Criteria for Deep Tunnelling. Can. Geotech. J. 2007, 44, 1082–1116. [Google Scholar] [CrossRef]

- Li, H.; Li, L.; Zhang, Z.; Santosh, M.; Liu, M.; Cui, Y.; Yang, X.; Chen, J.; Yao, T. Alteration of the Damiao Anorthosite Complex in the Northern North China Craton: Implications for High-Grade Iron Mineralization. Ore Geol. Rev. 2014, 57, 574–588. [Google Scholar] [CrossRef]

- Teng, X.; Santosh, M. A Long-Lived Magma Chamber in the Paleoproterozoic North China Craton: Evidence from the Damiao Gabbro-Anorthosite Suite. Precambrian Res. 2015, 256, 79–101. [Google Scholar] [CrossRef]

- He, H.-L.; Song, X.-Y.; Zhai, M.-G.; Yu, S.-Y.; Du, Z.-S. Lower Crustal Contribution to the Magma Formation of the Damiao Massif-Type Anorthosite, North China Craton: Evidence from Zircon Hf-O Isotopes. Precambrian Res. 2019, 332, 105396. [Google Scholar] [CrossRef]

- Wang, M.; Veksler, I.; Zhang, Z.; Hou, T.; Keiding, J.K. The Origin of Nelsonite Constrained by Melting Experiment and Melt Inclusions in Apatite: The Damiao Anorthosite Complex, North China Craton. Gondwana Res. 2017, 42, 163–176. [Google Scholar] [CrossRef]

- Chen, W.T.; Zhou, M.F.; Zhao, T.P. Differentiation of Nelsonitic Magmas in the Formation of the ~1.74 Ga Damiao Fe-Ti-P Ore Deposit, North China. Contrib. Mineral. Petrol. 2013, 165, 1341–1362. [Google Scholar] [CrossRef]

- He, H.L.; Yu, S.Y.; Song, X.Y.; Du, Z.S.; Dai, Z.H.; Zhou, T.; Xie, W. Origin of Nelsonite and Fe-Ti Oxides Ore of the Damiao Anorthosite Complex, NE China: Evidence from Trace Element Geochemistry of Apatite, Plagioclase, Magnetite and Ilmenite. Ore Geol. Rev. 2016, 79, 367–381. [Google Scholar] [CrossRef]

- Liang, Z.; Xue, R.; Xu, N.; Li, W. Characterizing Rockbursts and Analysis on Frequency-Spectrum Evolutionary Law of Rockburst Precursor Based on Microseismic Monitoring. Tunn. Undergr. Space Technol. 2020, 105, 103564. [Google Scholar] [CrossRef]

- Xiao, P.; Mao, H.; Qian, B.; Li, B.; Yang, X.; Xu, N. Stability Analysis of Surrounding Rock Mass in Underground Powerhouse Considering Damage Effect of Microfractures. J. Rock Mech. Geotech. Eng. 2022, 14, 1115–1130. [Google Scholar] [CrossRef]

- Luo, Y.; Gong, H.; Xu, K.; Pei, C.; Wei, X.; Li, X. Progressive Failure Characteristics and Energy Accumulation of Granite with a Pre-Fabricated Fracture during Conventional Triaxial Loading. Theor. Appl. Fract. Mech. 2022, 118, 103219. [Google Scholar] [CrossRef]

- Guo, G.; Xu, D.; Feng, G.; Wu, X.; Zhou, Y. Strength and Energy Evolution Law of Deep-Buried Granite Under Triaxial Conditions. Front. Environ. Sci. 2022, 165, 931757. [Google Scholar] [CrossRef]

- Liu, X.-Y.; Xu, D.-P.; Jiang, Q.; Ma, X.-D. Excavation Response and Reinforcement Practice of Large Underground Caverns within High-Stress Hard Rock Masses: The Case of Shuangjiangkou Hydropower Station, China. Tunn. Undergr. Space Technol. 2024, 147, 105698. [Google Scholar] [CrossRef]

- Xu, D.; Huang, X.; Jiang, Q.; Li, S.; Zheng, H.; Qiu, S.; Xu, H.; Li, Y.; Li, Z.; Ma, X. Estimation of the Three-Dimensional in Situ Stress Field around a Large Deep Underground Cavern Group near a Valley. J. Rock Mech. Geotech. Eng. 2021, 13, 529–544. [Google Scholar] [CrossRef]

- Li, L.X.; Zi, J.W.; Li, H.M.; Meng, J. Characterizing a New Type of Nelsonite Recognized in the Damiao Anorthosite Complex, North China Craton, with Implications for the Genesis of Giant Magmatic Fe-Ti Oxide Deposits. Am. Mineral. 2024, 109, 184–197. [Google Scholar] [CrossRef]

- Zhao, T.P.; Chen, W.; Zhou, M.F. Geochemical and Nd-Hf Isotopic Constraints on the Origin of the ~ 1.74-Ga Damiao Anorthosite Complex, North China Craton. Lithos 2009, 113, 673–690. [Google Scholar] [CrossRef]

- Zhang, S.-H.; Liu, S.-W.; Zhao, Y.; Yang, J.-H.; Song, B.; Liu, X.-M. The 1.75–1.68 Ga Anorthosite-Mangerite-Alkali Granitoid-Rapakivi Granite Suite from the Northern North China Craton: Magmatism Related to a Paleoproterozoic Orogen. Precambrian Res. 2007, 155, 287–312. [Google Scholar] [CrossRef]

- Li, L.X.; Li, H.M.; Li, Y.Z.; Yao, T.; Yang, X.Q.; Chen, J. Origin of Rhythmic Anorthositic-Pyroxenitic Layering in the Damiao Anorthosite Complex, China: Implications for Late-Stage Fractional Crystallization and Genesis of Fe-Ti Oxide Ores. J. Asian Earth Sci. 2015, 113, 1035–1055. [Google Scholar] [CrossRef]

- Zhao, G.; Sun, M.; Wilde, S.A.; Sanzhong, L.; Zhang, S.H.; Liu, S.W.; Zhao, Y.; Yang, J.H.; Song, B.; Liu, X.M. Late Archean to Paleoproterozoic Evolution of the North China Craton: Key Issues Revisited. Precambrian Res. 2005, 136, 177–202. [Google Scholar] [CrossRef]

- Ye, D.H. The Geological Setting and Ore Genesis of Heishan Vanadic-Titano Magnetite and Apatite Deposits in Chengde, Hebei. A Monograph of the No.4 Team of Hebei Geological Survey. 1989, pp. 1–355. Available online: https://www.ngac.cn/dzzlfw_sjgl/d2d/dse/category/detail.do?method=cdetail&_id=223_11892&tableCode=ty_qgg_edmk_t_ajxx&categoryCode=dzzlk (accessed on 14 July 2025). (In Chinese).

- Bieniawski, Z.T.; Bernede, M.J. Suggested Methods for Determining the Uniaxial Compressive Strength and Deformability of Rock Materials: Part 1. Suggested Method for Determining Deformability of Rock Materials in Uniaxial Compression. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1979, 16, 138–140. [Google Scholar] [CrossRef]

- Feng, X.-T.; Zhang, X.; Kong, R.; Wang, G. A Novel Mogi Type True Triaxial Testing Apparatus and Its Use to Obtain Complete Stress–Strain Curves of Hard Rocks. Rock Mech. Rock Eng. 2016, 49, 1649–1662. [Google Scholar] [CrossRef]

- ASTM D6473-15; Standard Test Method for Specific Gravity and Absorption of Rock For Erosion Control 1. ASTM: Washington, DC, USA, 2015. [CrossRef]

- Du, K.; Sun, Y.; Zhou, J.; Khandelwal, M.; Gong, F. Mineral Composition and Grain Size Effects on the Fracture and Acoustic Emission (AE) Characteristics of Rocks under Compressive and Tensile Stress. Rock Mech. Rock Eng. 2022, 55, 6445–6474. [Google Scholar] [CrossRef]

- Griffiths, L.; Heap, M.J.; Baud, P.; Schmittbuhl, J. Quantification of Microcrack Characteristics and Implications for Stiffness and Strength of Granite. Int. J. Rock Mech. Min. Sci. 2017, 100, 138–150. [Google Scholar] [CrossRef]

- Wyering, L.D.; Villeneuve, M.C.; Wallis, I.C.; Siratovich, P.A.; Kennedy, B.M.; Gravley, D.M.; Cant, J.L. Mechanical and Physical Properties of Hydrothermally Altered Rocks, Taupo Volcanic Zone, New Zealand. J. Volcanol. Geotherm. Res. 2014, 288, 76–93. [Google Scholar] [CrossRef]

- Rigopoulos, I.; Tsikouras, B.; Pomonis, P.; Hatzipanagiotou, K. The Impact of Petrographic Characteristics on the Engineering Properties of Ultrabasic Rocks from Northern and Central Greece. Q. J. Eng. Geol. Hydrogeol. 2012, 45, 423–433. [Google Scholar] [CrossRef]

- Hemmati, A.; Ghafoori, M.; Moomivand, H.; Lashkaripour, G.R. The Effect of Mineralogy and Textural Characteristics on the Strength of Crystalline Igneous Rocks Using Image-Based Textural Quantification. Eng. Geol. 2020, 266, 105467. [Google Scholar] [CrossRef]

- Eberhardt, E.; Stimpson, B.; Stead, D. Effects of Grain Size on the Initiation and Propagation Thresholds of Stress-Induced Brittle Fractures. Rock Mech. Rock Eng. 1999, 32, 81–99. [Google Scholar] [CrossRef]

- Lasheen, E.S.R.; Sami, M.; Hegazy, A.A.; Arman, H.; Sanislav, I.V.; Ahmed, M.S.; Rashwan, M.A. Petrological Characteristics and Physico-Mechanical Properties of Dokhan Volcanics for Decorative Stones and Building Material Applications. Buildings 2024, 14, 3418. [Google Scholar] [CrossRef]

- Yadav, R.K.; Tiwari, R.P.; Dube, A.K. A Study of Variation in Physical and Engineering Characteristics of Hybrid Granitic Rocks. J. Archit. Civ. Eng. 2021, 6, 44–49. [Google Scholar]

- Tuğrul, A.; Zarif, I.H. Correlation of Mineralogical and Textural Characteristics with Engineering Properties of Selected Granitic Rocks from Turkey. Eng. Geol. 1999, 51, 303–317. [Google Scholar] [CrossRef]

- Ahmed, I.; Basharat, M.; Sousa, L.; Mughal, M.S. Evaluation of Building and Dimension Stone Using Physico-Mechanical and Petrographic Properties: A Case Study from the Kohistan and Ladakh Batholith, Northern Pakistan. Environ. Earth Sci. 2021, 80, 1–17. [Google Scholar] [CrossRef]

- Smith, J.V.; Brown, W.L. Crystal Structures, Physical, Chemical, and Microtextural Properties. In Feldspar Minerals; Springer: Berlin/Heidelberg, Germany, 1988. [Google Scholar]

- Li, L.-X.; Li, H.-M.; Zi, J.-W.; Rasmussen, B.; Sheppard, S.; Wilde, S.A.; Meng, J. Role of Fluids in Fe–Ti–P Mineralization of the Proterozoic Damiao Anorthosite Complex, China: Insights from Baddeleyite–Zircon Relationships in Ore and Altered Anorthosite. Ore Geol. Rev. 2019, 115, 103186. [Google Scholar] [CrossRef]

- Přikryl, R. Some Microstructural Aspects of Strength Variation in Rocks. Int. J. Rock Mech. Min. Sci. 2001, 38, 671–682. [Google Scholar] [CrossRef]

- Fredrich, J.T.; Evans, B.; Wong, T. Effect of Grain Size on Brittle and Semibrittle Strength: Implications for Micromechanical Modelling of Failure in Compression. J. Geophys. Res. Solid Earth 1990, 95, 10907–10920. [Google Scholar] [CrossRef]

- Arıkan, F.; Ulusay, R.; Aydın, N. Characterization of Weathered Acidic Volcanic Rocks and a Weathering Classification Based on a Rating System. Bull. Eng. Geol. Environ. 2007, 66, 415–430. [Google Scholar] [CrossRef]

- Palchik, V.; Hatzor, Y.H. The Influence of Porosity on Tensile and Compressive Strength of Porous Chalks. Rock Mech. Rock Eng. 2004, 37, 331–341. [Google Scholar] [CrossRef]

- Ulusay, R.; Türeli, K.; Ider, M.H. Prediction of Engineering Properties of a Selected Litharenite Sandstone from Its Petrographic Characteristics Using Correlation and Multivariate Statistical Techniques. Eng. Geol. 1994, 38, 135–157. [Google Scholar] [CrossRef]

- Olsson, W.A. Grain Size Dependence of Yield Stress in Marble. J. Geophys. Res. 1974, 79, 4859–4862. [Google Scholar] [CrossRef]

- Yilmaz, I. Influence of Water Content on the Strength and Deformability of Gypsum. Int. J. Rock Mech. Min. Sci. 2010, 47, 342–347. [Google Scholar] [CrossRef]

- Kahraman, S. Evaluation of Simple Methods for Assessing the Uniaxial Compressive Strength of Rock. Int. J. Rock Mech. Min. Sci. 2001, 38, 981–994. [Google Scholar] [CrossRef]

- Gupta, A.S.; Rao, K.S. Weathering Effects on the Strength and Deformational Behaviour of Crystalline Rocks under Uniaxial Compression State. Eng. Geol. 2000, 56, 257–274. [Google Scholar] [CrossRef]

- Bell, F.G. The Physical and Mechanical Properties of the Fell Sandstones, Northumberland, England. Eng. Geol. 1978, 12, 1–29. [Google Scholar] [CrossRef]

- Xu, Y.H.; Cai, M.; Zhang, X.W.; Feng, X.-T. Influence of End Effect on Rock Strength in True Triaxial Compression Test. Can. Geotech. J. 2017, 54, 862–880. [Google Scholar] [CrossRef]

- Feng, X.T.; Zhang, X.; Yang, C.; Kong, R.; Liu, X.; Peng, S. Evaluation and Reduction of the End Friction Effect in True Triaxial Tests on Hard Rocks. Int. J. Rock Mech. Min. Sci. 2017, 97, 144–148. [Google Scholar] [CrossRef]

| Rocks | Sample ID | UCS (MPa) | UCS Mean | UCS SD | Absolute Axial Strain (%) | Volumetric Strain (%) | Water Absorption (%) | Porosity (%) | Specific Gravity |

|---|---|---|---|---|---|---|---|---|---|

| Shuangjiangkou Granite | SJK Gr A | 145.68 | 127.53 | 15.07 | 0.46 | 0.23 | 0.25 | 0.75 | 3.03 |

| SJK Gr B | 127.03 | 0.11 | 0.11 | 0.32 | 0.79 | 2.67 | |||

| SJK Gr C | 116.39 | 0.88 | 1.38 | 0.38 | 0.88 | 2.40 | |||

| SJK Gr D | 140.38 | 0.62 | 1.11 | 0.28 | 0.76 | 2.79 | |||

| SJK Gr E | 109.17 | 0.55 | 0.97 | 0.42 | 0.92 | 1.88 | |||

| Chengde Anorthosite | CD An A | 133.01 | 167.81 | 23.45 | 0.47 | 0.59 | 0.44 | 1.20 | 2.67 |

| CD An C | 190.97 | 0.66 | 0.77 | 0.11 | 0.31 | 2.76 | |||

| CD An D | 175.82 | 0.67 | 1.15 | 0.12 | 0.33 | 2.75 | |||

| CD An E | 146.83 | 0.66 | 1.19 | 0.18 | 0.47 | 2.68 | |||

| CD An F | 191.59 | 0.73 | 0.91 | 0.07 | 0.20 | 2.90 | |||

| CD An G | 168.65 | 0.53 | 1.06 | 0.12 | 0.33 | 2.72 | |||

| Chengde Mangerite | CD Mgr A | 212.01 | 205.12 | 23.87 | 0.65 | 0.78 | 0.12 | 0.35 | 2.77 |

| CD Mgr C | 165.62 | 0.54 | 0.93 | 0.25 | 0.69 | 2.43 | |||

| CD Mgr E | 202.59 | 0.46 | 0.67 | 0.22 | 0.60 | 2.70 | |||

| CD Mgr I | 207.71 | 0.61 | 1.53 | 0.14 | 0.36 | 2.75 | |||

| CD Mgr K | 203.84 | 0.72 | 1.08 | 0.15 | 0.42 | 2.72 | |||

| CD Mgr N | 239.94 | 0.81 | 0.95 | 0.10 | 0.29 | 2.99 |

| Mineral | Granite | Anorthosite | Mangerite |

|---|---|---|---|

| Quartz (%) | 25–27 | - | 10–15 |

| K-feldspar (%) | 40–45 | - | 1–4 |

| Plagioclase (%) | - | 88–92 | 40–50 |

| Albite (%) | 20–25 | - | - |

| Perthite (%) | - | - | 25–35 |

| Orthopyroxene (%) | - | 3–7 | - |

| Muscovite (%) | 5–7 | - | - |

| Biotite (%) | 2–3 | - | |

| Mafic minerals (%) | - | - | 8–12 |

| Tourmaline (%) | 1 | - | - |

| Apatite (%) | - | 1–3 | - |

| Fe-Ti oxides (%) | - | 1–5 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Waqar, M.F.; Guo, S.; Qi, S.; Karim, M.A.M.; Zada, K.; Ahmed, I.; Shang, Y. Influence of Mineralogical and Petrographic Properties on the Mechanical Behavior of Granitic and Mafic Rocks. Minerals 2025, 15, 747. https://doi.org/10.3390/min15070747

Waqar MF, Guo S, Qi S, Karim MAM, Zada K, Ahmed I, Shang Y. Influence of Mineralogical and Petrographic Properties on the Mechanical Behavior of Granitic and Mafic Rocks. Minerals. 2025; 15(7):747. https://doi.org/10.3390/min15070747

Chicago/Turabian StyleWaqar, Muhammad Faisal, Songfeng Guo, Shengwen Qi, Malik Aoun Murtaza Karim, Khan Zada, Izhar Ahmed, and Yanjun Shang. 2025. "Influence of Mineralogical and Petrographic Properties on the Mechanical Behavior of Granitic and Mafic Rocks" Minerals 15, no. 7: 747. https://doi.org/10.3390/min15070747

APA StyleWaqar, M. F., Guo, S., Qi, S., Karim, M. A. M., Zada, K., Ahmed, I., & Shang, Y. (2025). Influence of Mineralogical and Petrographic Properties on the Mechanical Behavior of Granitic and Mafic Rocks. Minerals, 15(7), 747. https://doi.org/10.3390/min15070747