Effects of Expansive Clay Content on the Hydromechanical Behavior of Liners Under Freeze-Thaw Conditions

Abstract

1. Introduction

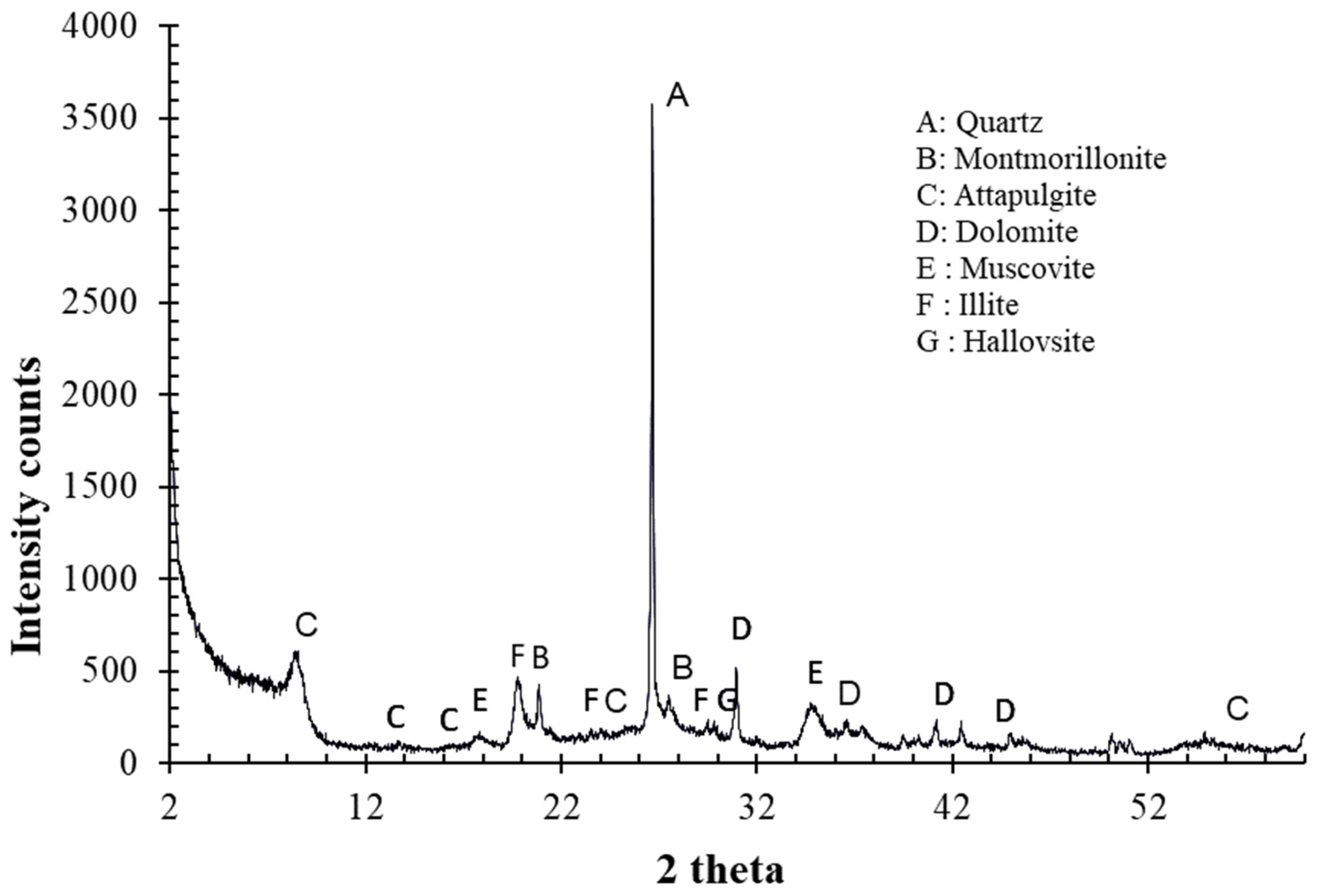

2. Materials and Characterizations

3. Experimental Program

3.1. Preparing the Samples

3.2. Swelling and Compressibility Testing

3.3. Hydraulic Conductivity Testing

4. Results and Discussion

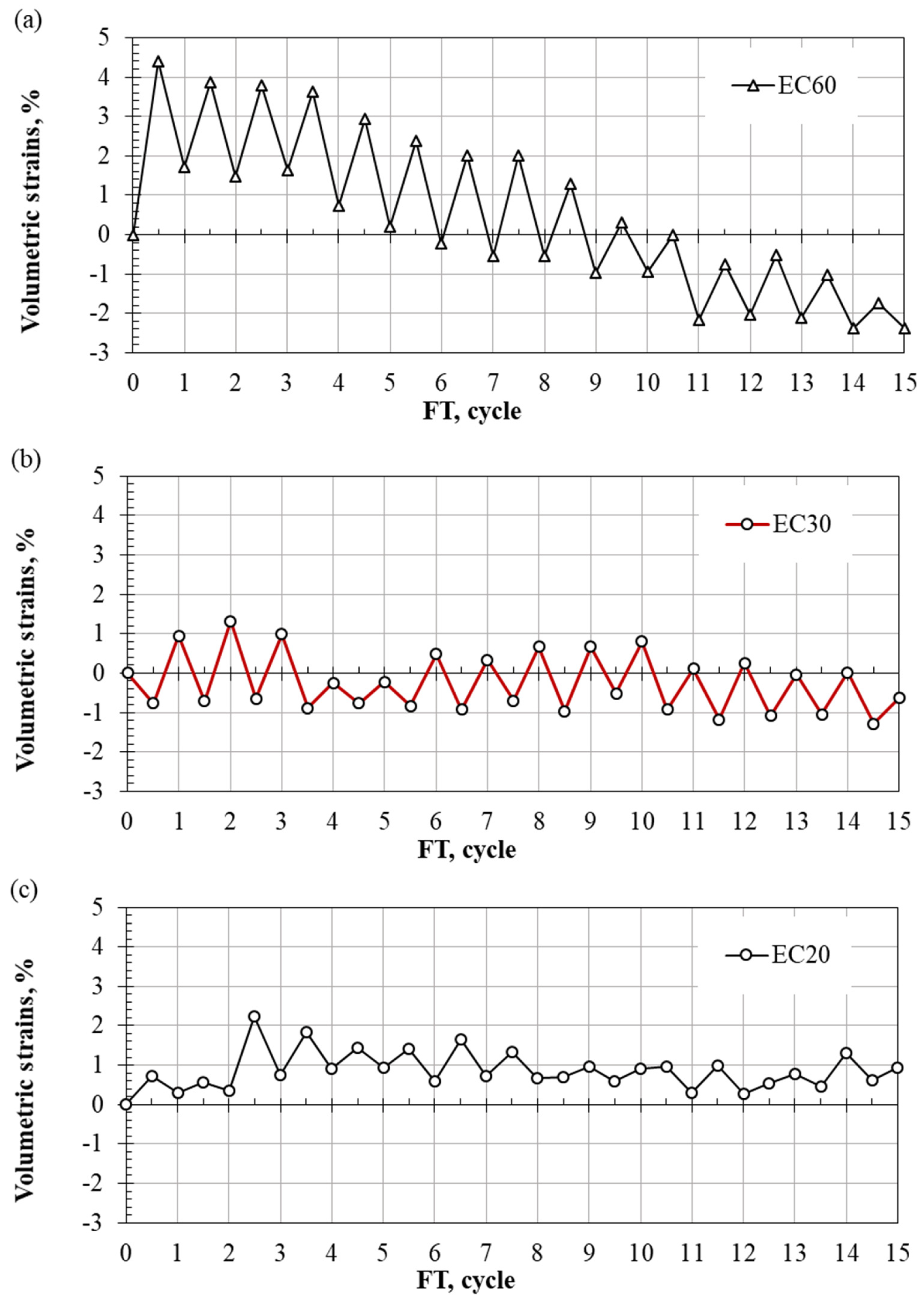

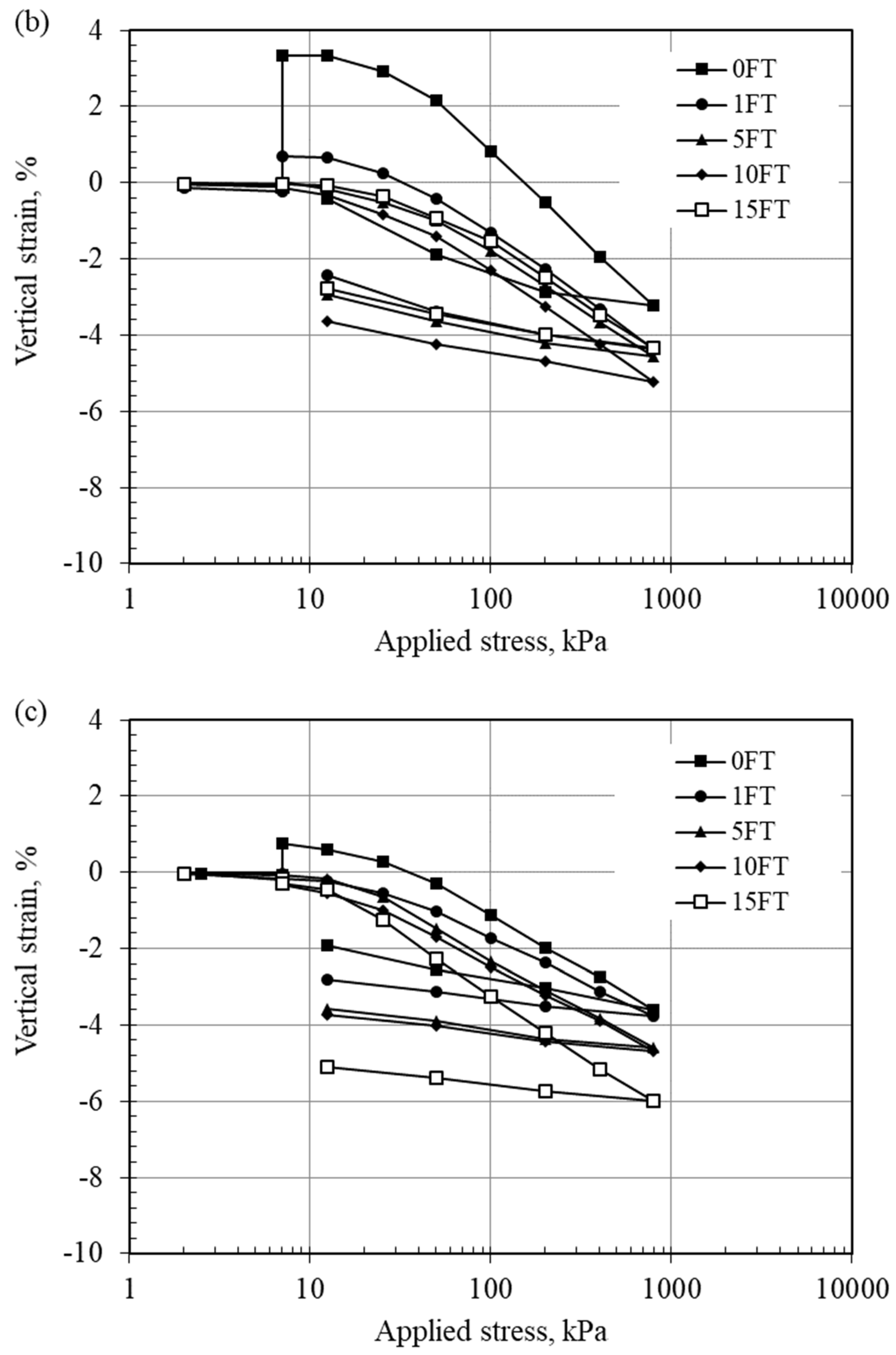

4.1. Volumetric Strains During FT Cycles

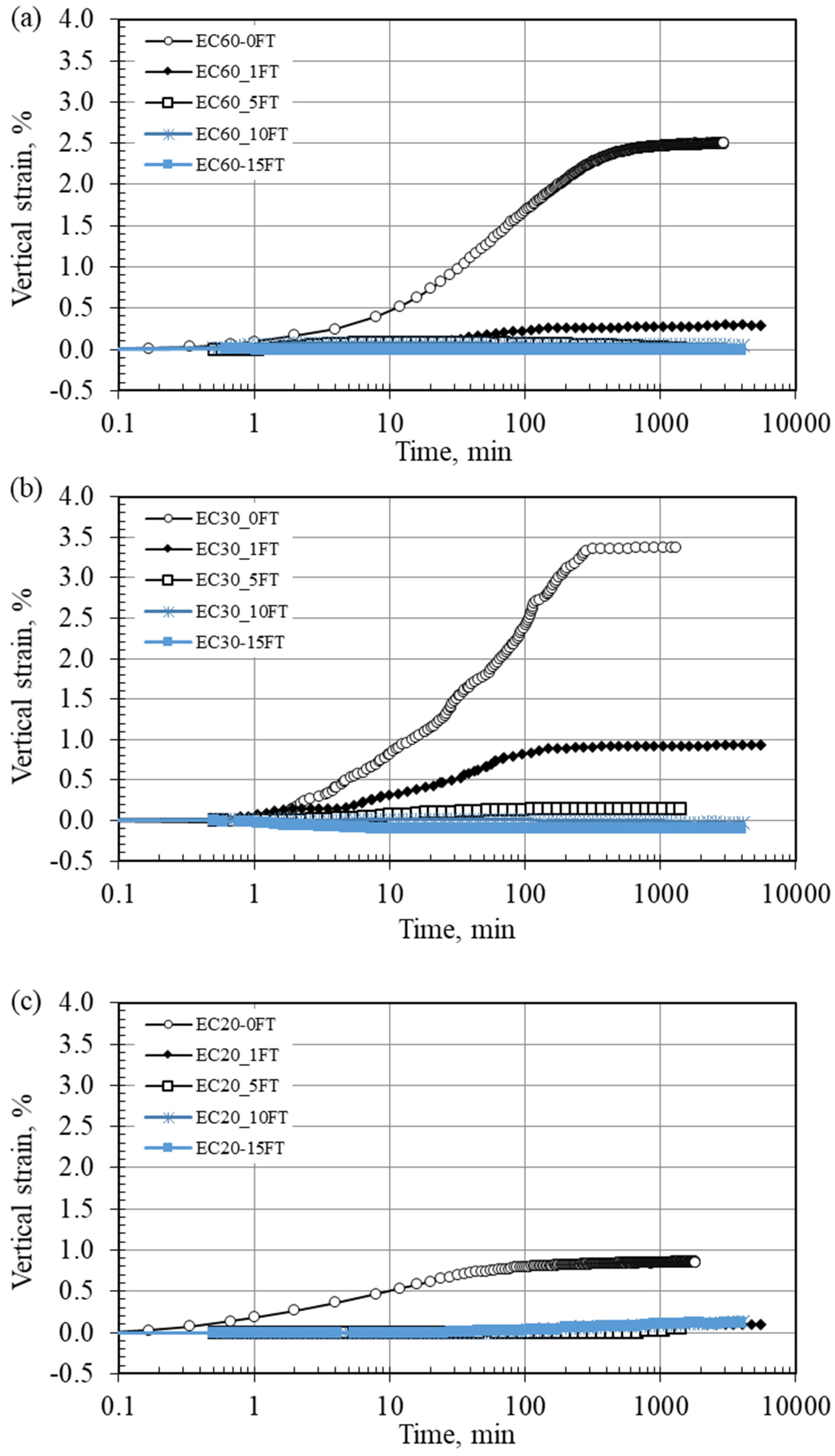

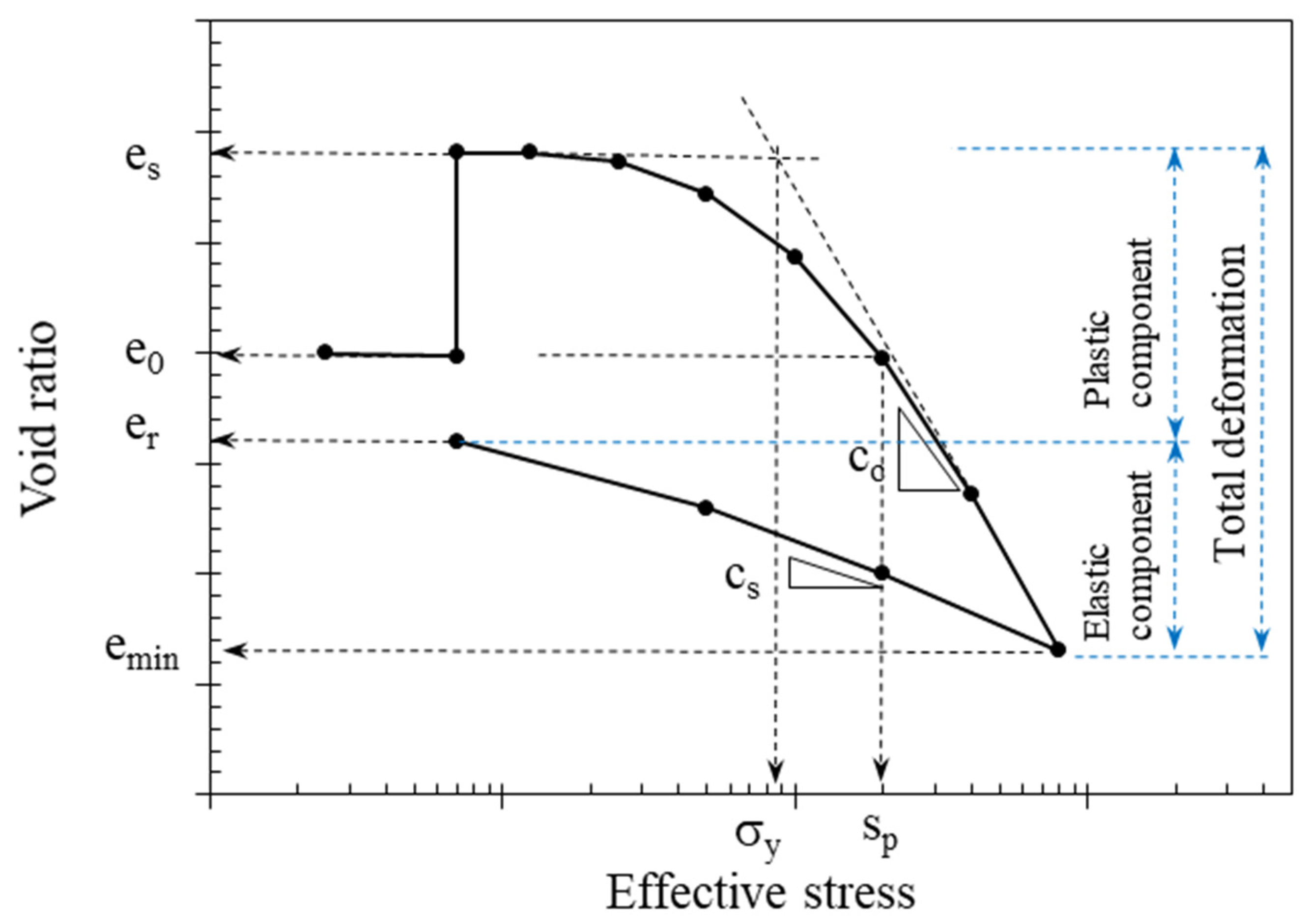

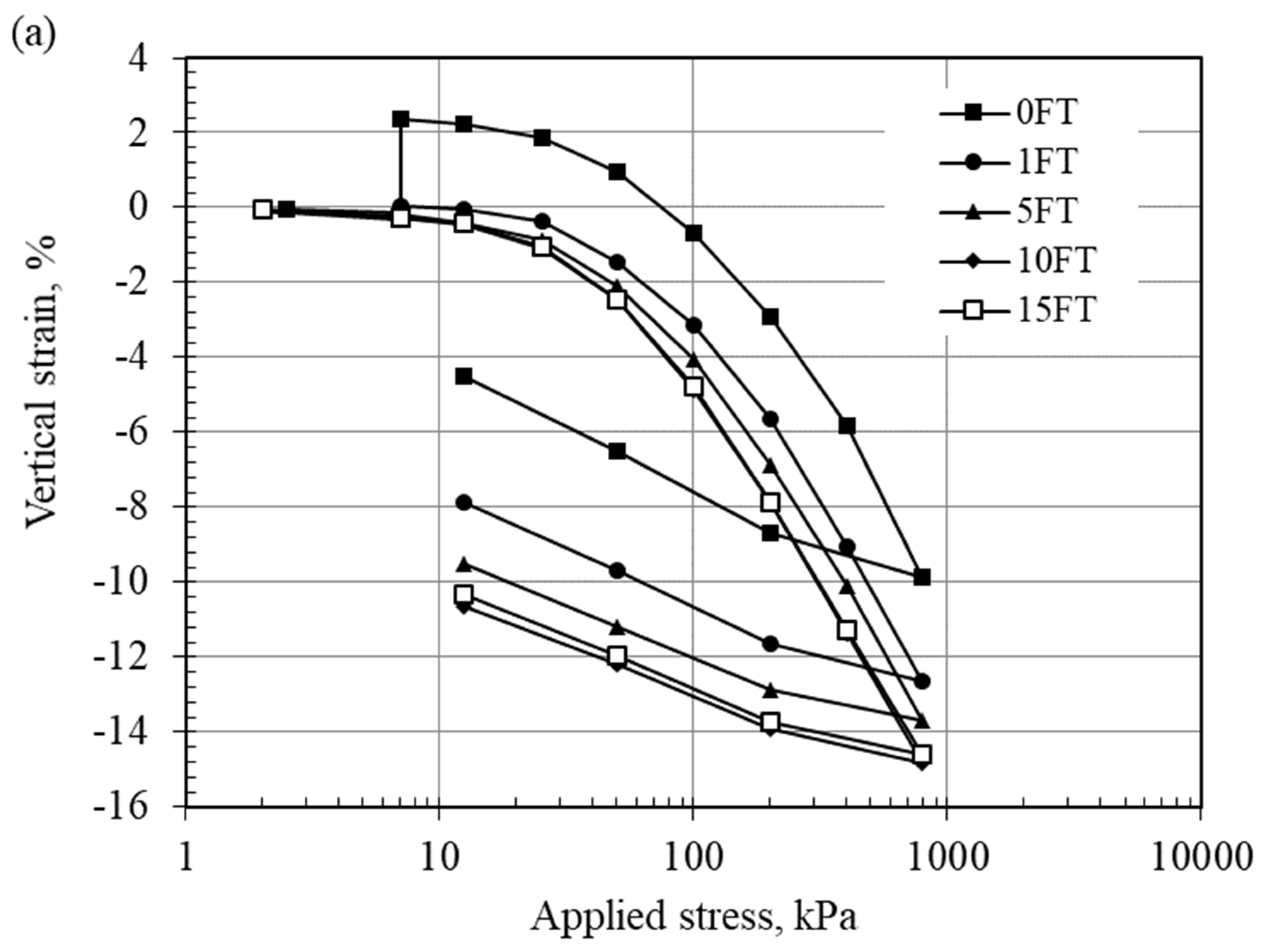

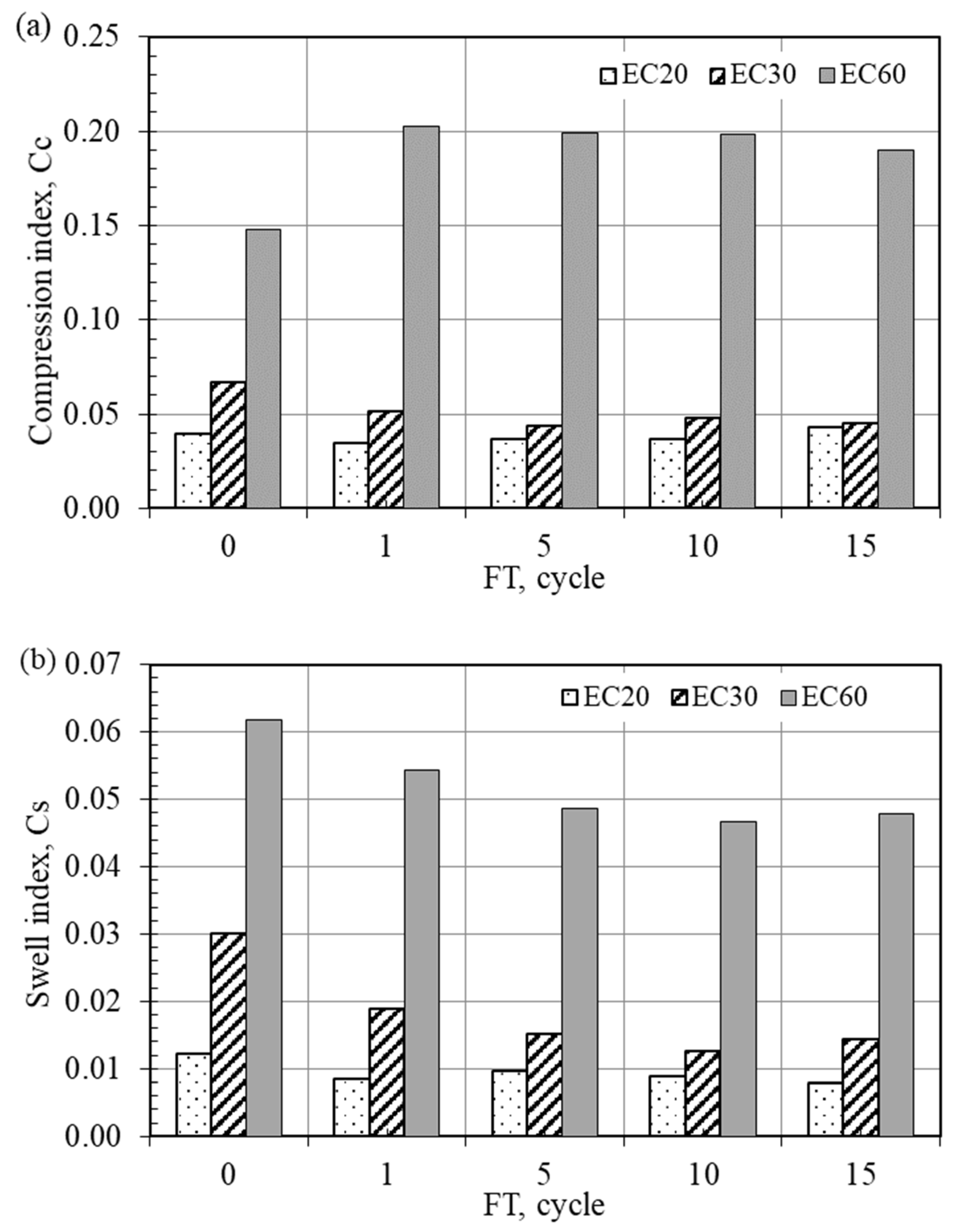

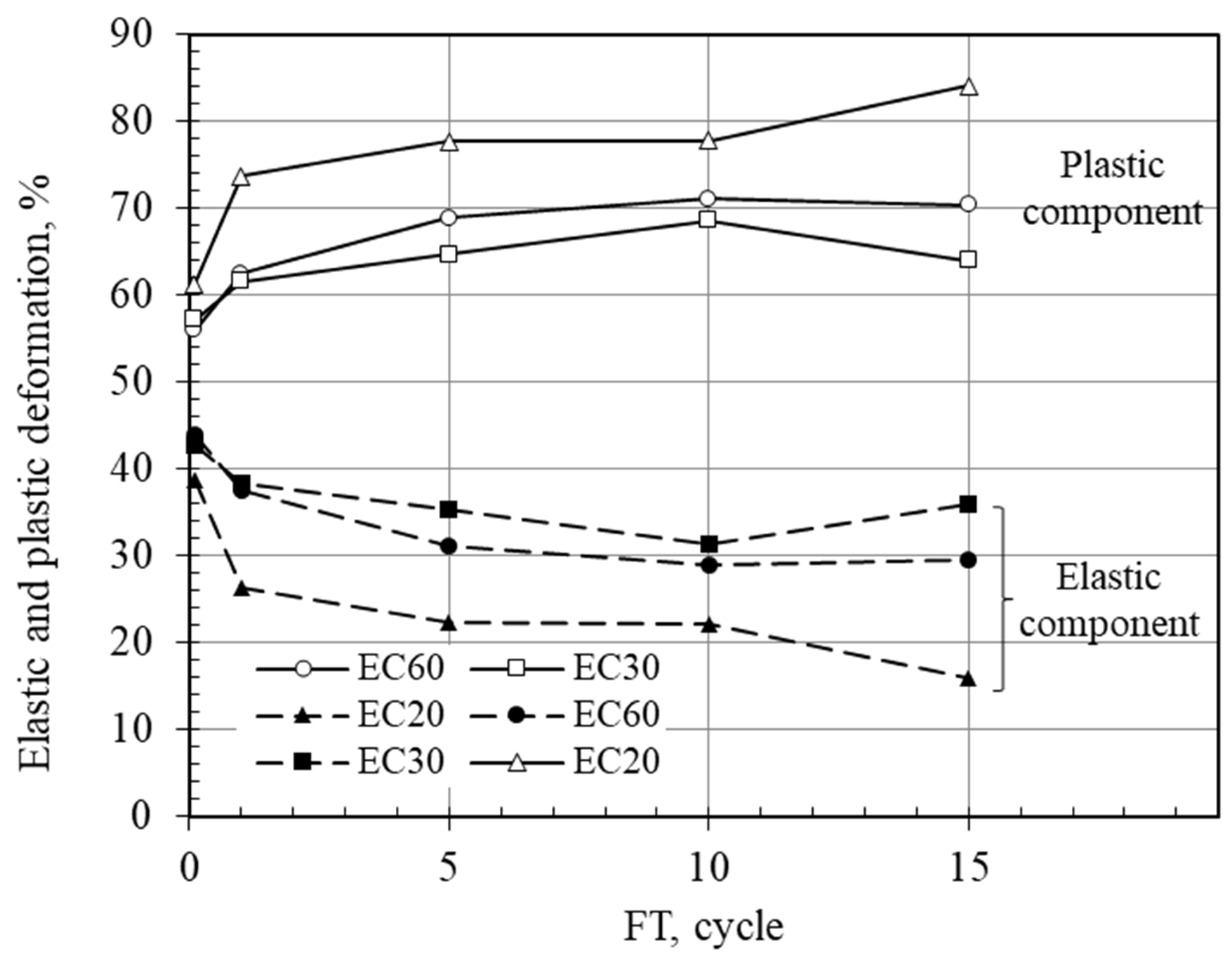

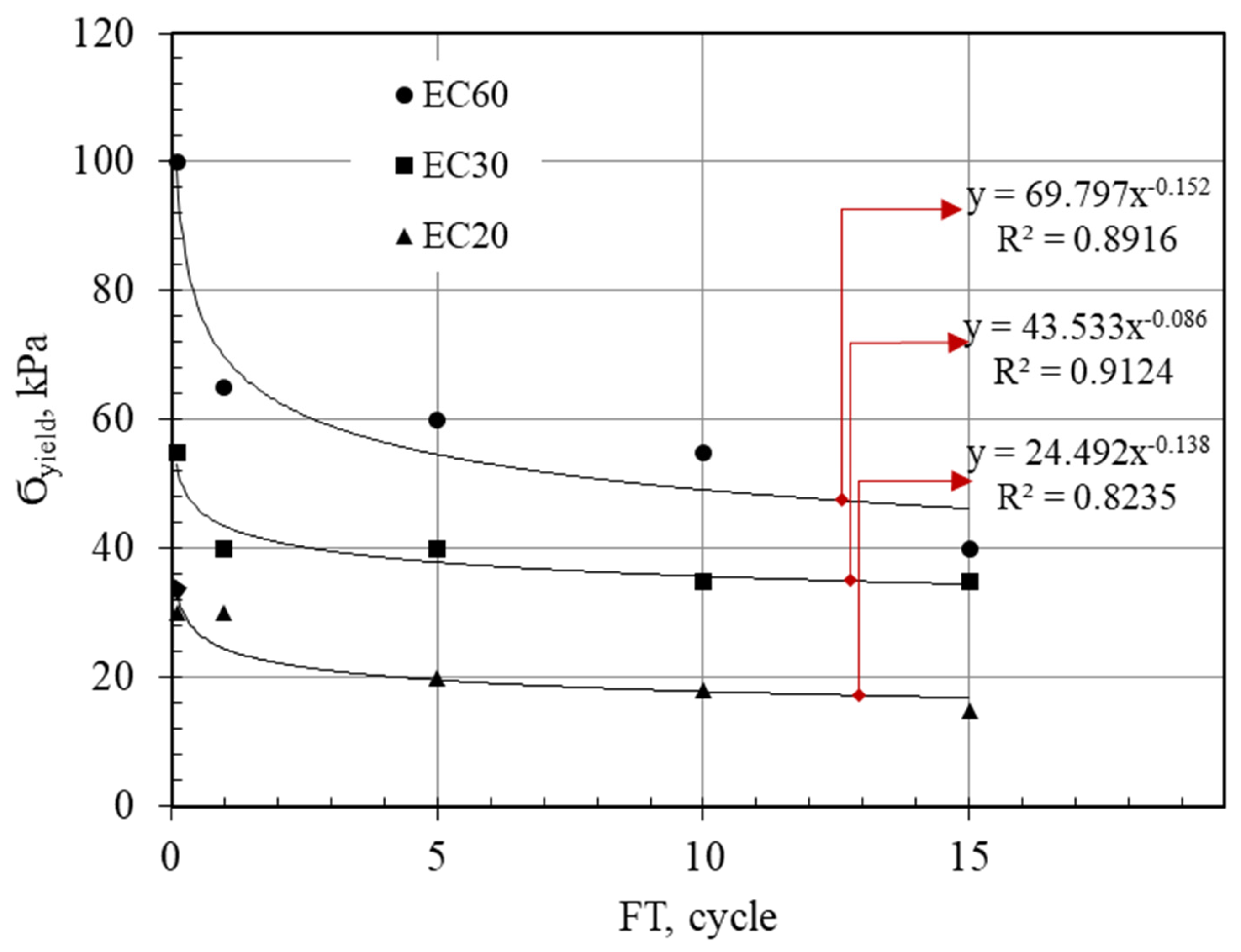

4.2. Effect of FT Cycles on the Swelling and Compressibility of Tested Liners

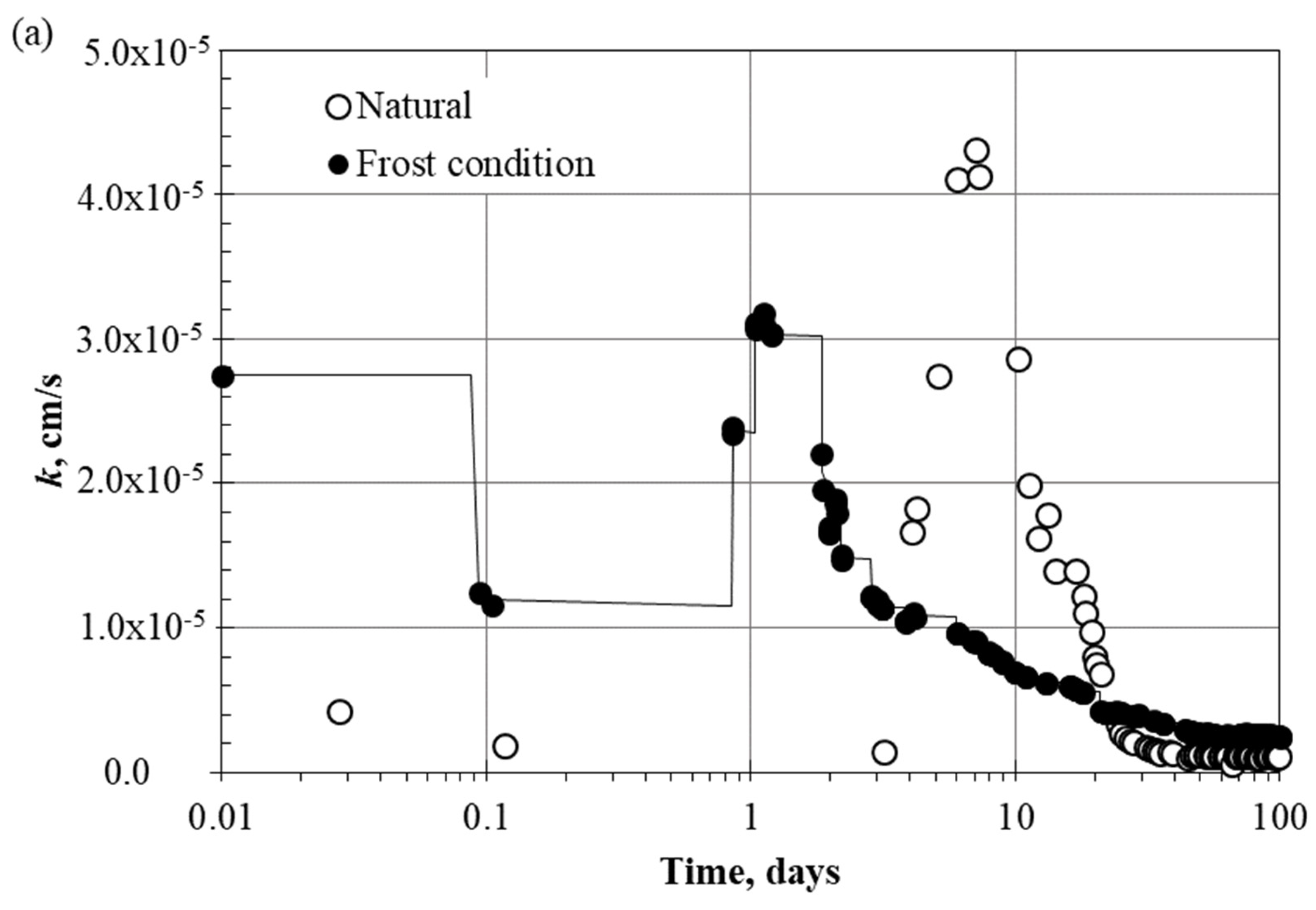

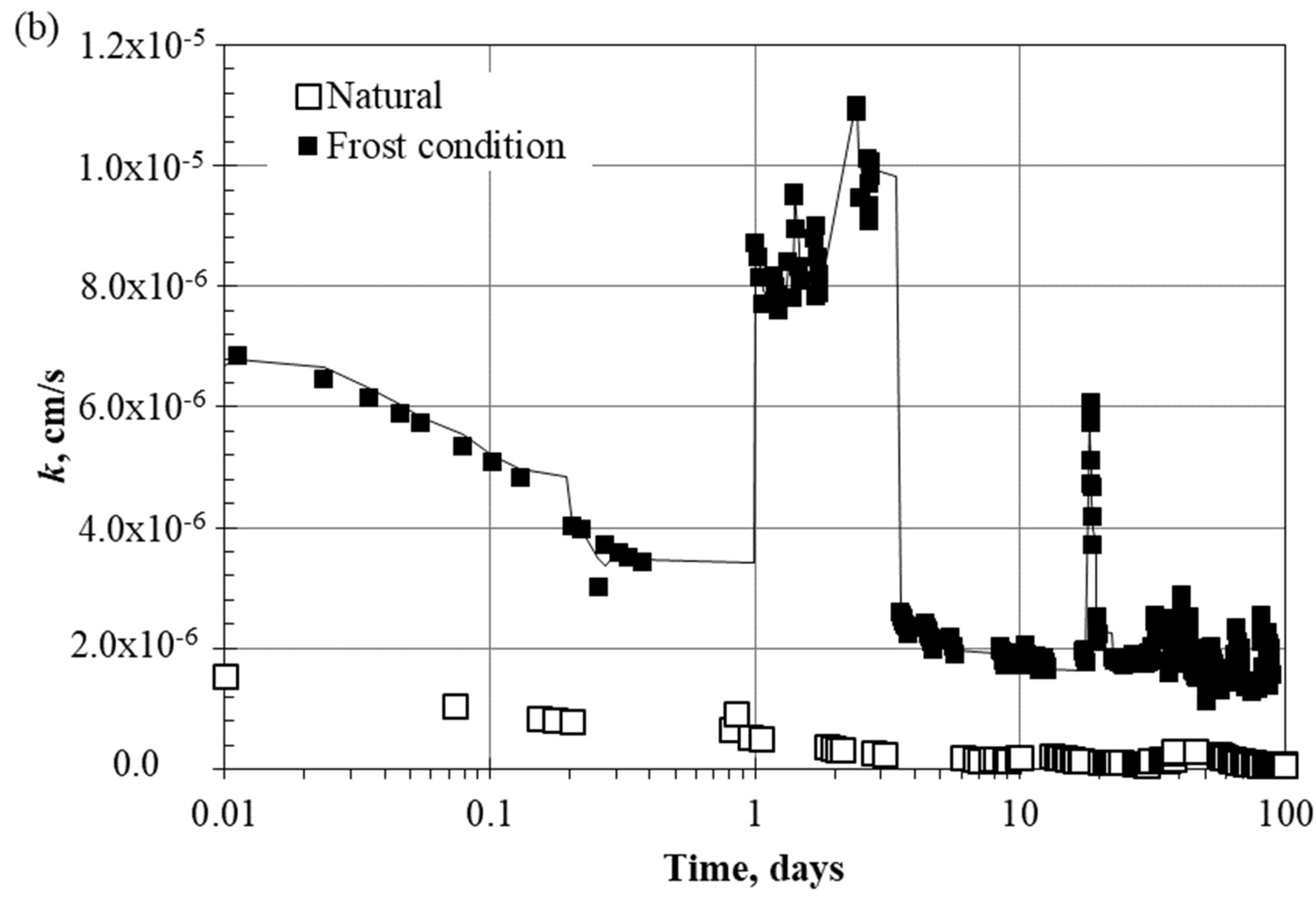

4.3. Effect of FT Cycles on the Long-Term Performance of Hydraulic Conductivity for Liners

5. Summary and Conclusions

- The volumetric strains developed during subsequent FT cycles are significant and proportional to the kind and amount of expanding minerals (i.e., montmorillonite), and they reached a value of 4.5% for liners with a greater expansive soil content.

- After the initial FT cycle, vertical strains under wetting conditions were decreased by almost 90%; this indicates that soil structure has been extremely altered even for a single FT cycle.

- The increased clay content was shown to increase compressibility and induce undesirable vertical movement. The compressibility index appears to change within significant ranges, accompanied by a distinct shift in vertical strain.

- FT actions also alter the elastoplastic response of these liners; the plastic deformation component has been increased versus the reduction of the elastic component with the increase in FT cycles during consolidation.

- The compression index Cc for clay contents showed an increase of 3 to 4 folds for 60% clay content at FT circumstances, and that can cause excessive settlement. The swell index can also change, although it normally remains constant after the first few cycles. The yield stress was reduced by about 60% along with elevating FT cycles.

- The hydraulic conductivity during an extended period of 100 days shows dramatic changes and deterioration due to FT actions, structural changes associated with FT actions, and developed cracks as key factors in increasing hydraulic conductivity several folds.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tiongson, J.M. and Adajar, M.A.Q. Hydraulic conductivity characteristics of a fine grained soil potential for landfill liner application. Int. J. GEOMATE 2021, 20, 56–61. [Google Scholar] [CrossRef]

- Tan, S.A.; Liang, K.M.; Yong, K.Y.; Lee, S.L. Drainage efficiency of sand layer in layered clay-sand reclamation. J. Geotech. Eng. 1992, 118, 209–228. [Google Scholar] [CrossRef]

- Al-Mahbashi, A.M.; Dafalla, M.; Shaker, A.; Al-Shamrani, M.A. Sustainable and Stable Clay Sand Liners over Time. Sustainability 2021, 13, 7840. [Google Scholar] [CrossRef]

- Zou, Y.Z.; Boley, C. Compressibility of fine-grained soils subjected to closed-system freezing and thaw consolidation. Min. Sci. Technol. (China) 2009, 19, 631–635. [Google Scholar] [CrossRef]

- Fan, W.; Yang, P.; Yang, Z. Impact of freeze-thaw on the physical properties and compressibility of saturated clay. Cold Reg. Sci. Technol. 2019, 168, 102873. [Google Scholar] [CrossRef]

- Al-Mahbashi, A.M.; Dafalla, M.; Al-Shamrani, M. Long-Term Performance of Liners Subjected to Freeze-Thaw Cycles. Water 2022, 14, 3218. [Google Scholar] [CrossRef]

- Othman, M.A.; Benson, C.H. Effect of freeze-thaw on the hydraulic conductivity and morphology of compacted clay. Can. Geotech. J. 1993, 30, 236–246. [Google Scholar] [CrossRef]

- Yilmaz, F.; Fidan, D. Influence of freeze-thaw on strength of clayey soil stabilized with lime and perlite. Geomech. Eng. 2018, 14, 301–306. [Google Scholar]

- Baldovino, J.D.J.A.; dos Santos Izzo, R.L.; Rose, J.L. Effects of freeze-thaw cycles and porosity/cement index on durability, strength and capillary rise of a stabilized silty soil under optimal compaction conditions. Geotech. Geol. Eng. 2021, 39, 481–498. [Google Scholar] [CrossRef]

- Pei, Q.Y.; Zou, W.L.; Han, Z.; Wang, X.Q.; Xia, X.L. Compression behaviors of a freeze–thaw impacted clay under saturated and unsaturated conditions. Acta Geotech. 2024, 19, 4485–4502. [Google Scholar] [CrossRef]

- Ren, X.; Liu, E.; Yu, Q.; Zhang, Z. Influence of freeze–thaw cycles on the compressibility of the clay of core-wall soil materials. Bull. Eng. Geol. Environ. 2024, 83, 84. [Google Scholar] [CrossRef]

- Chapuis, R.P. Sand–bentonite liners: Predicting permeability from laboratory tests. Can. Geotech. J. 1990, 27, 47–57. [Google Scholar] [CrossRef]

- Kenney, T.C.; Van Veen, W.A.; Swallow, M.A.; Sungaila, M.A. Hydraulic conductivity of compacted bentonite-sand mixture. Can. Geotech. J. 1992, 29, 364–374. [Google Scholar] [CrossRef]

- Othman, M.A. Effect of Freeze-Thaw on the Structure and Hydraulic Conductivity of Compacted Clays; The University of Wisconsin Madison: Madison, WI, USA, 1992; p. 20. [Google Scholar]

- Fouli, Y.; Cade-Menun, B.J.; Cutforth, H.W. Freeze–thaw cycles and soil water content effects on infiltration rate of three Saskatchewan soils. Can. J. Soil. Sci. 2013, 93, 485–496. [Google Scholar] [CrossRef]

- Sterpi, D. Effect of freeze-thaw cycles on the hydraulic conductivity of a compacted clayey silt and influence of the compaction energy. Soils Found. 2015, 55, 1326–1332. [Google Scholar] [CrossRef]

- ASTM D2487-17; Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System). ASTM International: West Conshohocken, PA, USA, 2017.

- Rafi, A. Engineering Properties and Mineralogical Composition of Expansive Clays in Al-Qatif Area. Ph.D. Thesis, KFUPM, Dhahran, Saudi Arabia, 1988. [Google Scholar]

- ASTM D4546-14; Standard Test Methods for One-Dimensional Swell or Collapse of Cohesive Soils. ASTM International: West Conshohocken, PA, USA, 2014.

- Abduljauwad, S.N.; Al-Sulaimani, G.J. Determination of Swell Potential of Al-qatif Clay. Geotech. Test. J. ASTM 1993, 16, 469–484. [Google Scholar] [CrossRef]

- Elkady, T.Y.; Abbas, M.F.; Shamrani, M.A. Behavior of compacted expansive soil under multi-directional stress and deformation boundary conditions. Bull. Eng. Geol. Environ. 2016, 75, 1741–1759. [Google Scholar] [CrossRef]

- Al-Mahbashi, A.M.; Elkady, T.Y.; Alrefeai, T.O. Soil water characteristic curve and improvement in lime treated expansive soil. Geomech. Eng. 2015, 8, 687–706. [Google Scholar] [CrossRef]

- Chittoori, B.C.S.; Moghal, A.A.B.; Pedarla, A.; Al-Mahbashi, A.M. Effect of unit weight on porosity and consolidation characteristics of expansive clays. J. Test. 2017, 45, 94–104. [Google Scholar] [CrossRef]

- Shalabi, F.I.; Mazher, J.; Khan, K.; Alsuliman, M.; Almustafa, I.; Mahmoud, W.; Alomran, N. Cement-stabilized waste sand as sustainable construction materials for foundations and highway roads. Materials 2019, 12, 600. [Google Scholar] [CrossRef]

- Aljlil, S.A. Fabrication of bentonite–silica sand/suspended waste palm leaf composite membrane for water purification. Membranes 2020, 10, 290. [Google Scholar] [CrossRef] [PubMed]

- ASTM D698-2000; Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Standard Effort (12400 ft-lbf/ft3 (600 kNm/m3)). ASTM International: West Conshohocken, PA, USA, 2000; Volume 4.08.

- Al-Mahbashi, A.M.; Dafalla, M. Impact of placement and field conditions on hydraulic conductivity and lifetime of liners. J. King Saud. Univ. Sci. 2021, 33, 101410. [Google Scholar] [CrossRef]

- ASTM D560-2003; Standard Test Methods for Freezing and Thawing Compacted Soil-Cement Mixtures (Withdrawn 2012). ASTM International: West Conshohocken, PA, USA, 2003.

- Aldaood, A.; Bouasker, M.; Al-Mukhtar, M. Effect of water during freeze-thaw cycles on the performance and durability of lime-treated gypseous soil. Cold Reg. Sci. Technol. 2016, 123, 155–163. [Google Scholar] [CrossRef]

- ASTM D2435-11; Standard Test Methods for One-Dimensional Consolidation Properties of Soils Using Incremental Loading. ASTM International: West Conshohocken, PA, USA, 2011.

- ASTM D7928-17; Standard Test Method for Particle-Size Distribution (Gradation) of Fine-Grained Soils Using the Sedimentation (Hydrometer) Analysis. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D5856-02; Standard Test Method for Measurement of Hydraulic Conductivity of Porous Material Using a Rigid-Wall, Compaction-Mold Permeameter. ASTM International: West Conshohocken, PA, USA, 2002.

- Li, D.; Selig, E.T. Cumulative Plastic Deformation for Fine-Grained Subgrade Soils. J. Geotech. Eng. 1996, 122, 1006–1013. [Google Scholar] [CrossRef]

- Norrish, K.; Rausell-Colom, J.A. Effect of freezing on the swelling of clay minerals. Clay Miner. Bull. 1962, 5, 9–16. [Google Scholar] [CrossRef]

- Lei, H.; Song, Y.; Qi, Z.; Liu, J.; Liu, X. Accumulative plastic strain behaviors and microscopic structural characters of artificially freeze-thaw soft clay under dynamic cyclic loading. Cold Reg. Sci. Technol. 2019, 168, 102895. [Google Scholar] [CrossRef]

- Alonso, E.E.; Vaunat, J.; Gens, A. Modelling the Mechanical Behaviour of Expansive Clays. Eng. Geol. 1999, 54, 173–183. [Google Scholar] [CrossRef]

- Alonso, E.E.; Romero, E.; Hoffmann, C.; García-Escudero, E. Expansive Bentonite–Sand Mixtures in Cyclic Controlled-Suction Drying and Wetting. Eng. Geol. 2005, 81, 213–226. [Google Scholar] [CrossRef]

- Stoltz, G.; Cuisinier, O.; Masrouri, F. Weathering of a lime-treated clayey soil by drying and wetting cycles. Eng. Geol. 2014, 181, 281–289. [Google Scholar] [CrossRef]

- Podgorney, R.; Bennett, J. Evaluating the Long-Term Performance of Geosynthetic Clay Liners Exposed to Freeze-Thaw. J. Geotech. Geoenvironmental Eng. 2006, 132, 265–268. [Google Scholar] [CrossRef]

| Test | Value |

|---|---|

| Expnasive soil | |

| Specific Gravity, Gs | 2.70 |

| Liquid Limit, LL (%) | 160% |

| Plastic Limit, PL (%) | 60% |

| Shrinkage Limit, wsh (%) | 12% |

| % passing Sieve No. 200 | 65–95% |

| Unified soil classification | CH |

| Swelling potential [19] | 16–25% |

| Swelling pressure [19] | 450–800 kN/m2 |

| pH value | 7.6 |

| Sand | |

| Cation exchange capacity, meq/100 gm | 55.80 |

| Specific Gravity, Gs | 2.86 |

| Unified soil classification | SP |

| Uniformity coefficient, Cu | 1.745 |

| Curvature coefficient, Cc | 0.945 |

| Particles size range | 0.1 mm–0.6 mm |

| Element | Expansive Soil | Sand |

|---|---|---|

| K+ (%) | 1.8 | - |

| K2O (%) | 2.2 | >0.1 |

| Al (%) | 3.3 | - |

| Al2O3 (%) | 6.3 | 0.25 |

| Si (%) | 8.1 | - |

| SiO2(%) | 17.3 | 99.43 |

| Ca2+ (%) | 0.7 | - |

| CaO (%) | 0.9 | 0.16 |

| Fines or Clay Content in a Liner | Optimum Moisture Content, % | Maximum Dry Density, gm/cm3 |

|---|---|---|

| 20% | 13.6 | 1.86 |

| 30% | 13.7 | 1.84 |

| 60% | 25.0 | 1.60 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Mahbashi, A.M.; Dafalla, M. Effects of Expansive Clay Content on the Hydromechanical Behavior of Liners Under Freeze-Thaw Conditions. Minerals 2025, 15, 291. https://doi.org/10.3390/min15030291

Al-Mahbashi AM, Dafalla M. Effects of Expansive Clay Content on the Hydromechanical Behavior of Liners Under Freeze-Thaw Conditions. Minerals. 2025; 15(3):291. https://doi.org/10.3390/min15030291

Chicago/Turabian StyleAl-Mahbashi, Ahmed M., and Muawia Dafalla. 2025. "Effects of Expansive Clay Content on the Hydromechanical Behavior of Liners Under Freeze-Thaw Conditions" Minerals 15, no. 3: 291. https://doi.org/10.3390/min15030291

APA StyleAl-Mahbashi, A. M., & Dafalla, M. (2025). Effects of Expansive Clay Content on the Hydromechanical Behavior of Liners Under Freeze-Thaw Conditions. Minerals, 15(3), 291. https://doi.org/10.3390/min15030291