Machine Learning-Based Mineral Quantification from Lower Cambrian Shale in the Sichuan Basin: Implications for Reservoir Quality

Abstract

1. Introduction

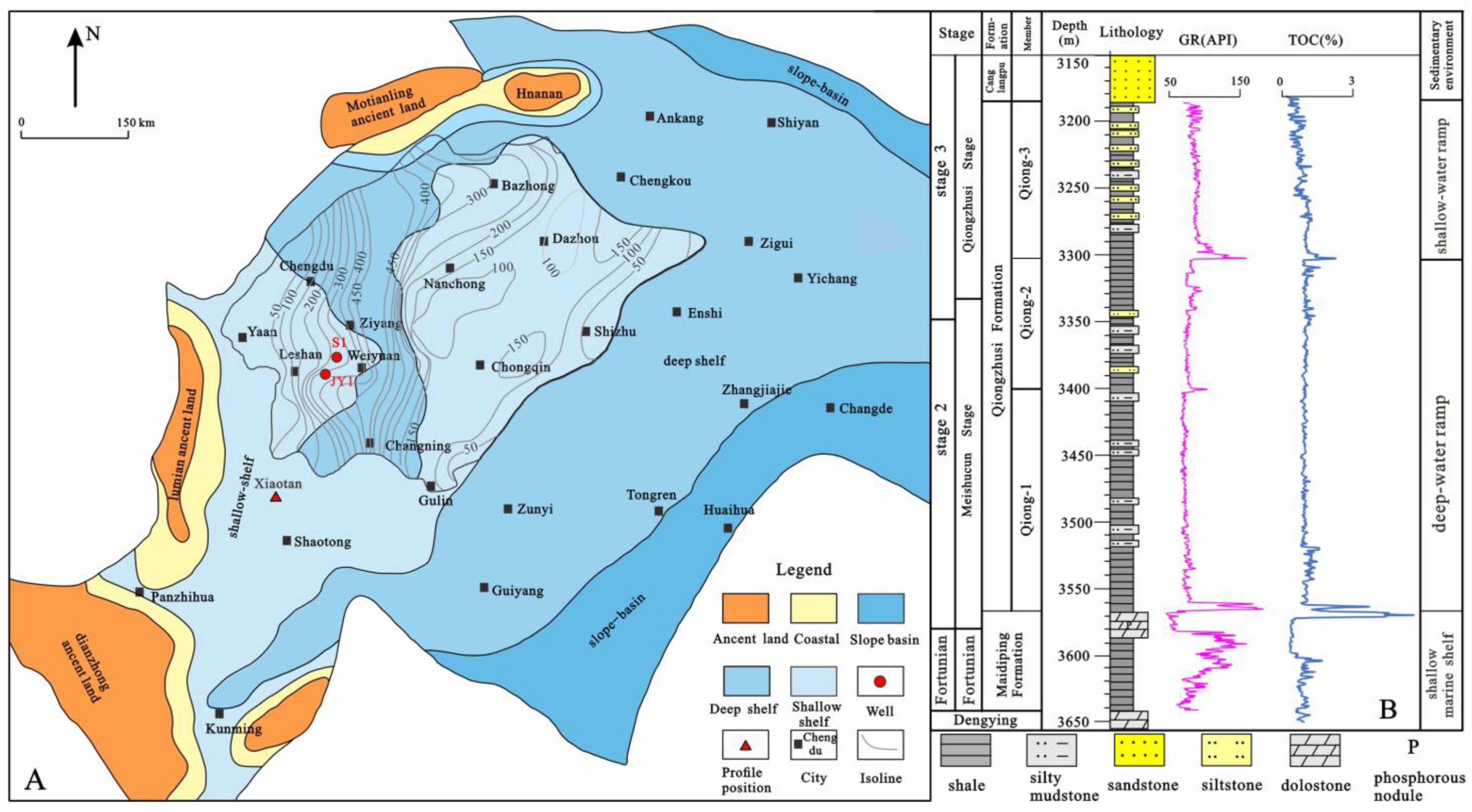

2. Geological Background

3. Materials and Methods

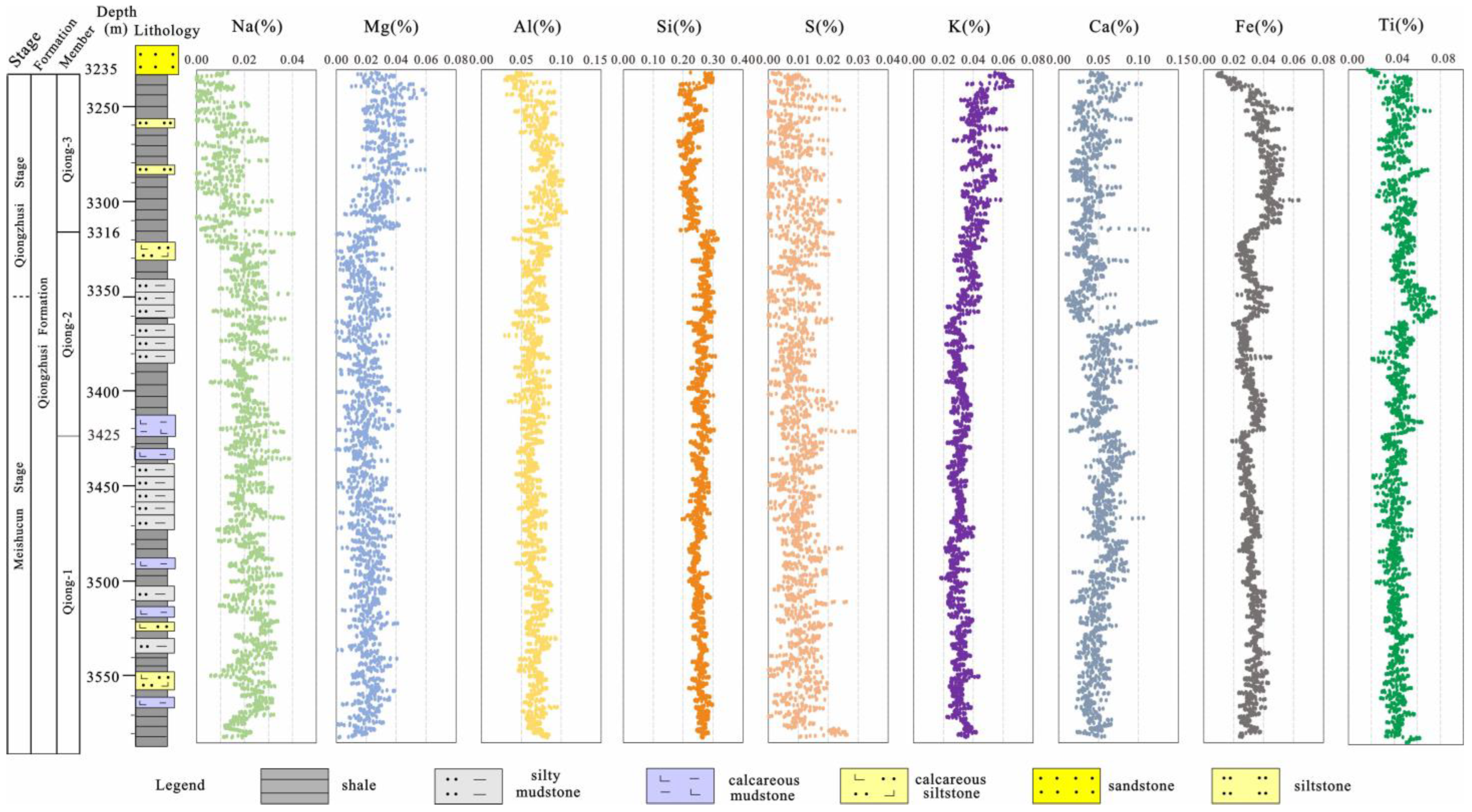

3.1. Geochemical Testing

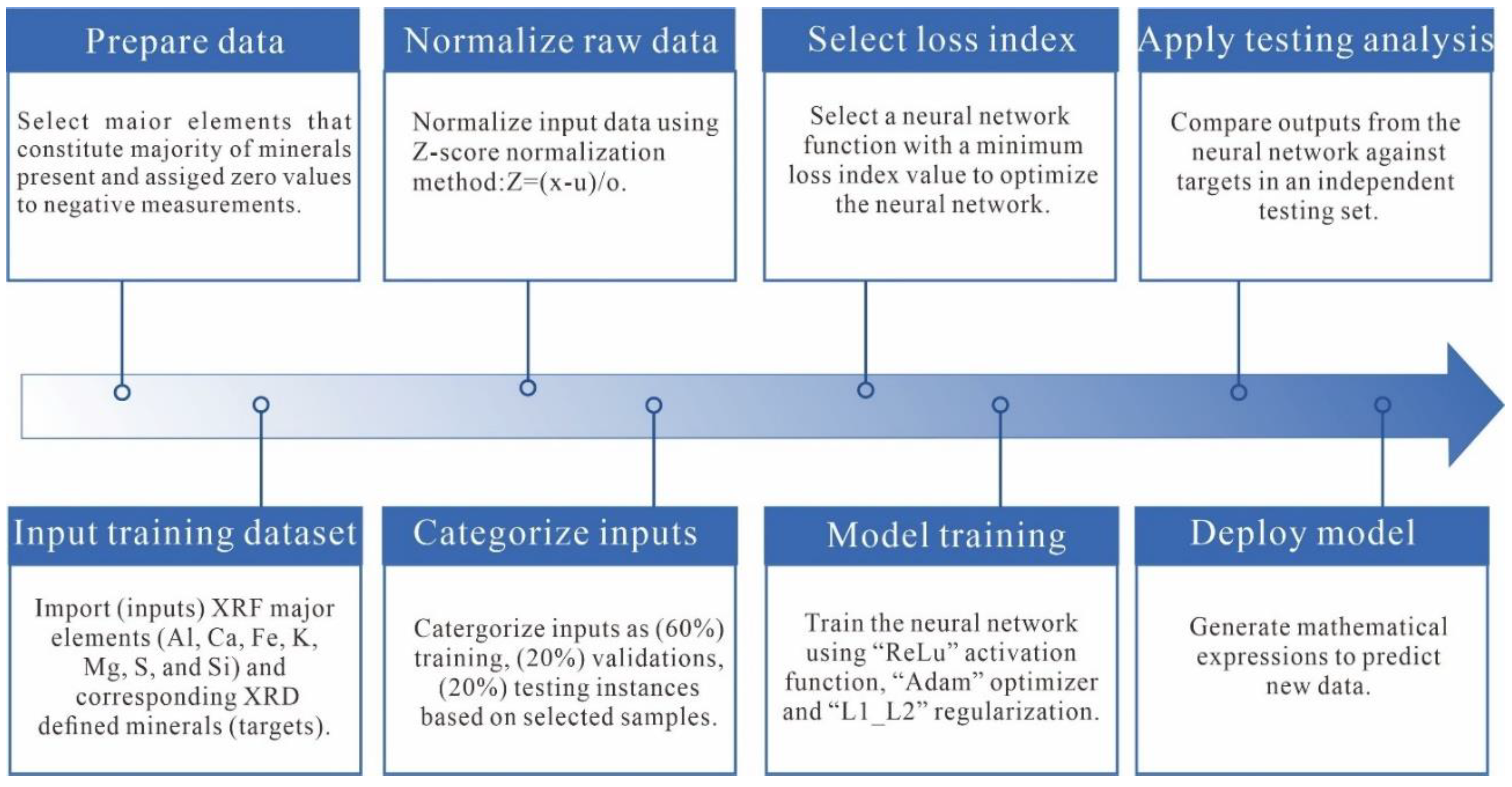

3.2. Methodology for Mineralogical Quantification

3.2.1. Data Preparation

3.2.2. Input Training Dataset

3.2.3. Normalizing Raw Data

3.2.4. Categorizing Inputs

3.3. Model Tuning and Performance Evaluation

3.3.1. Loss Index Selection

3.3.2. Performance Evaluation

4. Results

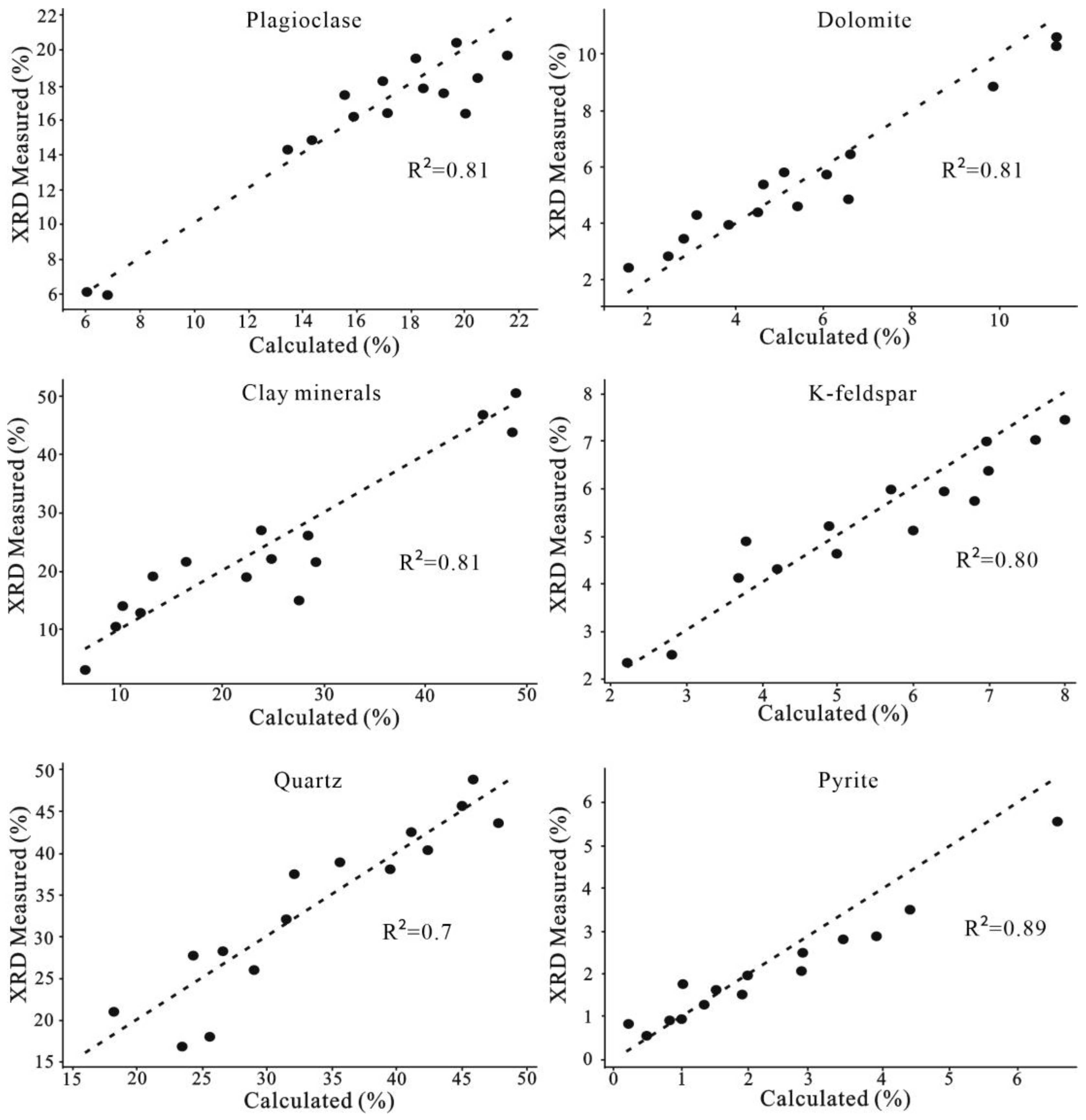

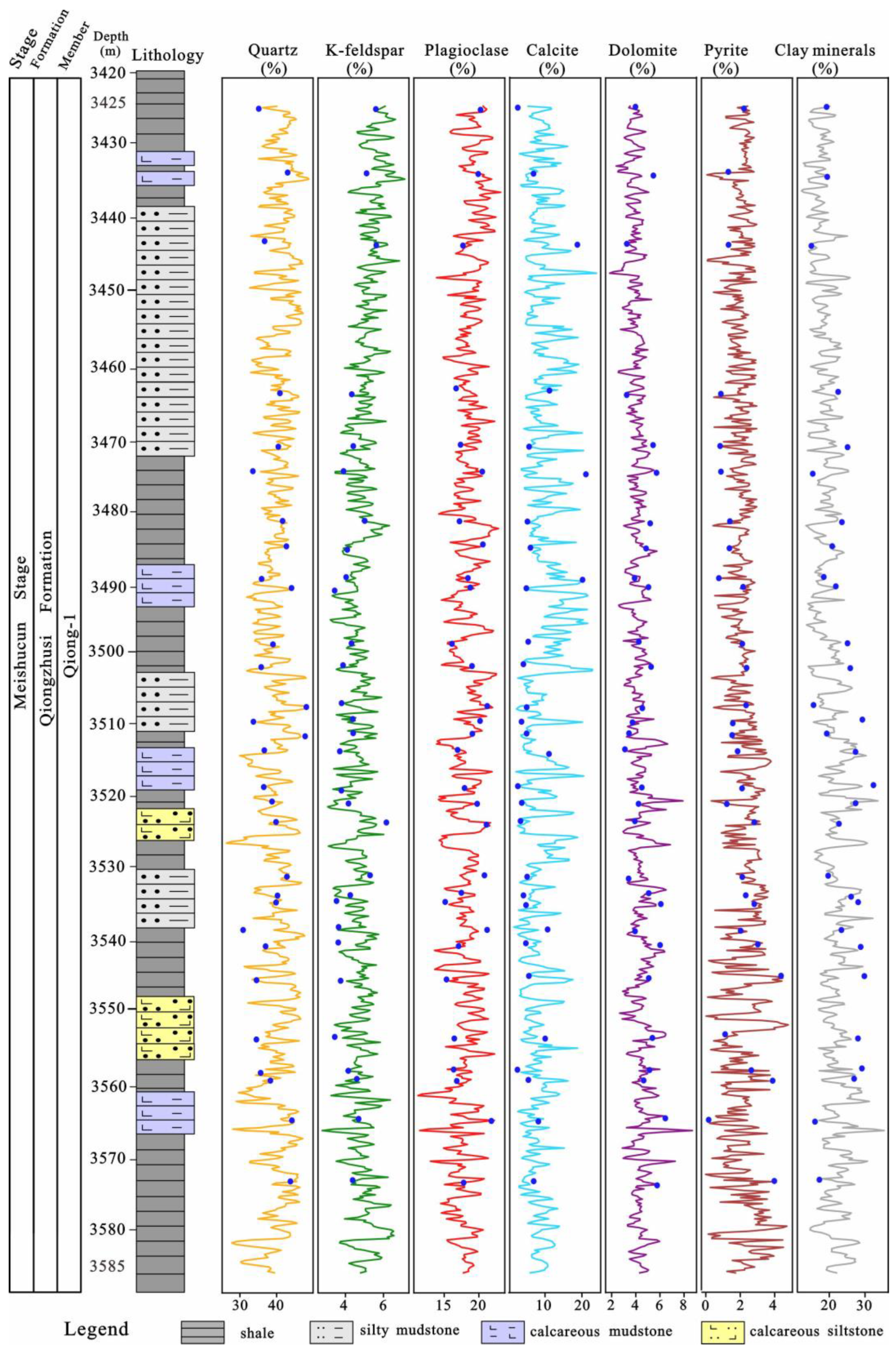

4.1. Mineralogical Quantification

4.2. Geological Validation

5. Discussion

5.1. Technical Advantages

5.2. Current Limitations

6. Conclusions

- (1)

- Advancement in Mineralogical Analysis: This study marks a significant step forward in understanding the mineralogical composition of the Qiongzhusi Formation within the Sichuan Basin, utilizing neural network analysis to develop a machine learning-driven model for shale mineralogy.

- (2)

- Semi-Quantitative Methodology: The developed methodology offers a semi-quantitative approach to resolving complex mineral systems in the Qiongzhusi shales, providing continuous relative abundance profiles that add substantial interpretive value over discrete XRD measurements.

- (3)

- Framework for Data Integration: An initial framework has been established for integrating publicly available datasets with regional Lower Cambrian stratigraphic records, facilitating more comprehensive analyses and interpretations.

- (4)

- Operational Applications: The proposed semi-quantitative mineralogical approach enables operators to create predictive models during drilling operations by performing XRF analyses on core samples or drill cuttings, offering real-time mineralogical insights.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ryan, J.G.; Shervais, J.W.; Li, Y.; Reagan, M.K.; Li, H.Y.; Heaton, D.; Godard, M.; Kirchenbaur, M.; Whattam, S.A.; Pearce, J.A.; et al. The IODP Expedition 352 Scientific Team. Application of a handheld X-ray fluorescence spectrometer for real-time, high-density quantitative analysis of drilled igneous rocks and sediments during IODP Expedition 352. Chem. Geol. 2017, 451, 55–66. [Google Scholar] [CrossRef]

- Peng, J.; Larson, T.E. A Novel Integrated Approach for chemofacies characterization of organic-Rich mudrocks. AAPG Bull. 2022, 106, 437–460. [Google Scholar] [CrossRef]

- Pszonka, J.; Götze, J. Quantitative estimate of interstitial clays in sandstones using Nomarski differential interference contrast (DIC) microscopy and image analysis. J. Pet. Sci. Eng. 2018, 161, 582–589. [Google Scholar] [CrossRef]

- Gebregiorgis, D.; Giosan, L.; Hathorne, E.C.; Anand, P.; Nilsson-Kerr, K.; Plass, A.; Lückge, A.; Clemens, S.C.; Frank, M. What Can We Learn From X-Ray Fluorescence Core Scanning Data? A Paleomonsoon Case Study. Geochem. Geophys. Geosyst. 2020, 21, e2019GC008414. [Google Scholar] [CrossRef]

- Cao, H.Y.; Wang, H.; Zhao, R. The Application of the Handheld Energy-Dispersive X-Ray Fluorescence (ED-XRF) in the Cyclostratigraphy Research—A Case Study from the Xiagon Formation of the Lower Cretaceous in the Qingxi Sag, Jiuquan Basin. Earth Sci. 2017, 42, 2299–2311. [Google Scholar] [CrossRef]

- Pszonka, J.; Godlewski, P.; Fheed, A.; Dwornik, M.; Schulz, B.; Wendorff, M. Identificationand quantification of intergranular volume using SEM automated mineralogy. Mar. Pet. Geol. 2024, 162, 106708. [Google Scholar] [CrossRef]

- Jiang, C.; Zhang, D.; Chen, S. Lithology Identification from Well-Log Curves via Neural Networks with Additional Geologic Constraint. Geophysics 2021, 86, IMS85–IM100. [Google Scholar] [CrossRef]

- Zhang, J.; He, Y.; Zhang, Y.; Li, W.; Zhang, J. Well-Logging-Based Lithology Classification Using Machine Learning Methods for High-Quality Reservoir Identification: A Case Study of Baikouquan Formation in Mahu Area of Junggar Basin, NW China. Energies 2022, 15, 3675. [Google Scholar] [CrossRef]

- Rohit; Manda, S.R.; Raj, A.; Dheeraj, A.; Rawat, G.S.; Choudhury, T. Identification of Lithology from Well Log Data Using Machine Learning. EAI Endorsed Trans. Internet Things 2024, 10, 104605. [Google Scholar] [CrossRef]

- van der Meer, F.D.; van der Werff, H.M.A.; van Ruitenbeek, F.J.A.; Hecker, C.A.; Bakker, W.H.; Noomen, M.F.; van der Meijde, M.; Carranza, E.J.M.; de Smeth, J.B.; Woldai, T. Multi- and Hyperspectral Geologic Remote Sensing: A Review. Int. J. Appl. Earth Obs. Geoinf. 2012, 14, 112–128. [Google Scholar] [CrossRef]

- Harvey, A.; Fotopoulos, G. Geological Mapping Using Machine Learning Algorithms. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2016, 41, 423–430. [Google Scholar] [CrossRef]

- Honarmand, M.; Shahriari, H.; Zadeh, M.H.; Ghorbani, A. Enhancing Zn-bearing gossans from GeoEye-1 and Landsat 8 OLI data for non-sulphide Zn deposit exploration. Egypt. J. Remote Sens. Space Sci. 2024, 27, 93–107. [Google Scholar] [CrossRef]

- Sabins, F.F. Remote Sensing for Mineral Exploration. Ore Geol. Rev. 1999, 14, 157–183. [Google Scholar] [CrossRef]

- Ali, A.; Chiang, Y.W.; Santos, R.M. X-Ray Diffraction Techniques for Mineral Characterization: A Review for Engineers of the Fundamentals, Applications, and Research Directions. Minerals 2022, 12, 312. [Google Scholar] [CrossRef]

- Burkett, D.A.; Graham, I.T.; Ward, C.R. The Application of Portable X-Ray Diffraction to Quantitative Mineralogical Analysis of Hydrothermal Systems. Can. Mineral. 2015, 53, 429–454. [Google Scholar] [CrossRef]

- Alnahwi, A.; Loucks, R.G. Mineralogical Composition and Total Organic Carbon Quantification Using X-Ray Fluorescence Data from the Upper Cretaceous Eagle Ford Group in Southern Texas. AAPG Bull. 2019, 103, 2891–2907. [Google Scholar] [CrossRef]

- Chan, S.A.; Hassan, A.M.; Usman, M.; Humphrey, J.D.; Alzayer, Y.; Duque, F. Total Organic Carbon (TOC) Quantification Using Artificial Neural Networks: Improved Prediction by Leveraging XRF Data. J. Pet. Sci. Eng. 2022, 208 Pt E, 109302. [Google Scholar] [CrossRef]

- Li, Z.X. Tectonic history of the major East Asian lithospheric blocks since the Mid-Proterozoic—A synthesis. In Mantle Dynamics and Plate Interactions in East Asia; Flower, M.F.J., Chung, S.L., Lo, C.H., Eds.; American Geophysical Union: Washington, DC, USA, 1998; pp. 221–243. [Google Scholar] [CrossRef]

- Li, W.; Zhang, J.; Li, H.; Wang, X.; Zou, Q.; Jiang, H.; Fu, X.; Wang, P.; Xu, Z.; Ma, L. Distribution characteristics of intracratonic rift and its exploration significance in western Hubei and eastern Chongqing area. Nat. Gas Geosci. 2020, 31, 675–685. [Google Scholar] [CrossRef]

- Liu, S.; Sun, W.; Luo, Z.; Song, J.; Zhong, Y.; Tian, Y.; Peng, H. Xingkai taphrogenesis and petroleum exploration in the Lower Assemblage of Sichuan Basin. J. Chengdu Univ. Technol. (Sci. Technol. Ed.) 2013, 40, 511–520. [Google Scholar] [CrossRef]

- Liu, S.; Wang, Y.; Sun, W.; Zhong, Y.; Hong, H.; Deng, B.; Xia, M.; Song, J.; Ying, C.; Wu, J. Control of Intracratonic Sags on the Hydrocarbon Accumulations in the Marine Strata Across the Sichuan Basin, China. J. Chengdu Univ. Technol. (Sci. Technol. Ed.) 2016, 43, 1–23. [Google Scholar] [CrossRef]

- Li, D.; Ling, H.; Shields-Zhou, G.; Chen, X.; Cremonese, L.; Och, L.; Thirlwall, M.; Manning, C. Carbon and strontium isotope evolution of seawater across the Ediacaran–Cambrian transition: Evidence from the Xiaotan section, NE Yunnan, South China. Precambrian Res. 2013, 225, 128–147. [Google Scholar] [CrossRef]

- Zou, C.; Dong, D.; Wang, Y.; Li, X.; Huang, J.; Wang, S.; Guan, Q.; Zhang, C.; Wang, H.; Liu, H.; et al. Shale gas in China: Characteristics, challenges and prospects (I). Pet. Explor. Dev. 2015, 42, 753–767. [Google Scholar] [CrossRef]

- Zhao, J.; Jin, Z.; Lin, C.; Liu, G.; Liu, K.; Liu, Z.; Zhang, Y. Sedimentary Environment of the Lower Cambrian Qiongzhusi Formation Shale in the Upper Yangtze Region. Oil Gas Geol. 2019, 40, 701–715. [Google Scholar] [CrossRef]

- Wu, D.; Deng, H.; Xiong, L.; Cao, K.; Dong, X.; Zhao, Y.; Wei, L.; Wang, T.; Ma, R. Sequence filling and evolutionary model of the Lower Cambrian Maidiping Formation and Qiongzhusi Formation in the Sichuan Basin and its surrounding areas. Pet. Explor. Dev. 2023, 42, 753–767. [Google Scholar] [CrossRef]

- Xiong, L.; Deng, H.; Wu, D.; Wei, L.; Wang, T.; Zhou, H.; Cao, K.; Jie, X.; Ma, R.; Zhong, Y. Characteristics and influencing factors of fine-grained sedimentation in the Qiongzhusi Formation of the Lower Cambrian in the Sichuan Basin and its surrounding areas. Pet. Exp. Geol. 2023, 45, 857–871. [Google Scholar] [CrossRef]

- Yuan, Y.; Li, Y.; Fan, T.; Du, W.; Chen, G.; Zhang, T.; Kuang, M.; Liu, W. High-precision sequence stratigraphic characteristics and filling evolution model of fine-grained sedimentary rocks of the Lower Cambrian in the southwestern Sichuan region. Geosci. Front. 2023, 14, 162–180. [Google Scholar] [CrossRef]

- Luo, J.; Zhu, H.; Liang, X.; Liang, X.; Zhang, J.; Zhang, T.; Min, H.; Zhang, X.; Zou, C.; Li, J. Lithofacies paleogeography and distribution of high-quality shale of the Cambrian Qiongzhusi Formation in the Dianqianbei Depression. Acta Sedimentol. Sin. 2023, 41, 1257–1270. [Google Scholar] [CrossRef]

- He, X.; Liang, F.; Li, H.; Zheng, M.; Zhao, Q.; Liu, Y.; Liu, W. Breakthrough and enrichment mode of marine shale gas in the Lower Cambrian Qiongzhusi Formation in high-yield wells in Sichuan Basin. China Pet. Explor. 2024, 29, 142–155. [Google Scholar] [CrossRef]

- Rowe, H.; Hughes, N.; Robinson, K. The quantification and application of handheld energy-dispersive x-ray fluorescence (ED-XRF) in mudrock chemostratigraphy and geochemistry. Chem. Geol. 2012, 324-325, 122–131. [Google Scholar] [CrossRef]

- Adams, C.; Brand, C.; Dentith, M.; Fiorentini, M.; Caruso, S.; Mehta, M. The use of pXRF for light element geochemical analysis: A review of hardware design limitations and an empirical investigation of air, vacuum, helium flush and detector window technologies. Geochem. Explor. Environ. Anal. 2020, 20, 366–380. [Google Scholar] [CrossRef]

- Refaeilzadeh, P.; Tang, L.; Liu, H. Cross-Validation. Encycl. Database Syst. 2009, 1, 532–538. [Google Scholar] [CrossRef]

- Nawi, N.M.; Atomi, W.H.; Rehman, M.Z. The effect of data pre-processing on optimized training of artificial neural networks. Procedia Technol. 2013, 11, 32–39. [Google Scholar] [CrossRef]

- Meyer, F.O.; Price, R.C.; Al-Ghamdi, I.A.; Al-Goba, I.M.; Al-Raimi, S.M.; Cole, J.C. Sequential stratigraphy of outcropping strata equivalent to Arab-D reservoir, Wadi Nisah, Saudi Arabia. GeoArabia 1996, 1, 435–456. [Google Scholar] [CrossRef]

- Nguyen, G.H.; Bouzerdoum, A.; Phung, S.L. Learning pattern classification tasks with imbalanced data sets. Pattern Recognit. 2009, 10, 1322–1328. [Google Scholar]

- Zhao, H.; Gallo, O.; Frosio, I.; Kautz, J. Loss functions for image restoration with neural networks. IEEE Trans. Comput. Imaging 2016, 3, 47–57. [Google Scholar] [CrossRef]

- Prokudin, S.; Gehler, P.; Nowozin, S. Deep directional statistics: Pose estimation with uncertainty quantification. In Proceedings of the European Conference on Computer Vision (ECCV), Munich, Germany, 8–14 September 2018; pp. 534–551. [Google Scholar] [CrossRef]

- Xie, J.; Liu, S.; Chen, J.; Jia, J. Huber loss based distributed robust learning algorithm for random vector functional-link network. Artif. Intell. Rev. 2023, 56, 8197–8218. [Google Scholar] [CrossRef]

- Schmidt-Hieber, J. Nonparametric regression using deep neural networks with ReLU activation function. Ann. Stat. 2020, 48, 1875–1897. [Google Scholar] [CrossRef]

- Ying, X. An overview of overfitting and its solutions. J. Phys. Conf. Ser. 2019, 1168, 022022. [Google Scholar] [CrossRef]

- Szandała, T. Review and comparison of commonly used activation functions for deep neural networks. In Bio-Inspired Neurocomputing; Springer: Berlin/Heidelberg, Germany, 2021; pp. 203–224. [Google Scholar] [CrossRef]

- Rimmer, S.M. Geochemical paleoredox indicators in Devonian–Mississippian black shales, central Appalachian Basin (USA). Chem. Geol. 2004, 206, 373–391. [Google Scholar] [CrossRef]

- Pearce, C.R.; Cohen, A.S.; Coe, A.L.; Burton, K.W. Molybdenum isotope evidence for global ocean anoxia coupled with perturbations to the carbon cycle during the Early Jurassic. Geology 2008, 36, 231–234. [Google Scholar] [CrossRef]

- Mark, S.Z.; Abbott, M.B.; Rodbell, D.T.; Moy, C.M. XRF analysis of Laguna Pallcacocha sediments yields new insights into Holocene El Niño development. Earth Planet. Sci. Lett. 2022, 593, 117657. [Google Scholar] [CrossRef]

- Ross, P.S.; Bourke, A.; Fresia, B. Improving lithological discrimination in exploration drill-cores using portable X-ray fluorescence measurements: (1) testing three Olympus Innov-X analysers on unprepared cores. Geochem. Explor. Environ. Anal. 2014, 14, 171–185. [Google Scholar] [CrossRef]

- Löwemark, L.; Chen, H.F.; Yang, T.N.; Kylander, M.; Yu, E.; Hsu, Y.; Lee, T.; Song, S.; Jarvis, S. Normalizing XRF-scanner data: A cautionary note on the interpretation of high-resolution records from organic-rich lakes. J. Asian Earth Sci. 2011, 40, 1250–1256. [Google Scholar] [CrossRef]

| Input: XRF Elemental Data, % | Targets: XRD Mineralogical Data, % | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Depth (m) | Fe | Al | Ca | Mg | S | Si | K | Quartz | K-Feldspar | Plagioclase | Calcite | Dolomite | Pyrite | Clay Minerals | |

| Qiong-3 | 3314.79 | 4.1 | 8.9 | 1.8 | 3.8 | 1.7 | 22.6 | 4.3 | 28 | 2 | 5.4 | 2.3 | 11.3 | 2.4 | 48.6 |

| 3315.82 | 4.1 | 8.1 | 2.4 | 4.1 | 1.3 | 22.6 | 3.9 | 28.9 | 2.2 | 6.1 | 4.4 | 11.3 | 1.6 | 45.5 | |

| 3317.65 | 3.7 | 6.2 | 9.4 | 2.2 | 1.3 | 20.4 | 4 | 29.6 | 2.5 | 6.4 | 2.1 | 7.5 | 3.3 | 48.6 | |

| 3317.99 | 3.6 | 5.7 | 11 | 2.1 | 1.6 | 19.2 | 3.8 | 31 | 2.4 | 6.8 | 2.1 | 7.4 | 4.3 | 46 | |

| 3319.15 | 3.2 | 6.9 | 1.5 | 1.8 | 1.8 | 29.7 | 3.5 | 40.9 | 3.9 | 12.9 | 2.0 | 7.2 | 1.8 | 31.3 | |

| 3320.29 | 3.7 | 8.1 | 2.5 | 0.0 | 2.0 | 29.4 | 3.8 | 42.9 | 5.1 | 12.8 | 2.7 | 6.7 | 1.5 | 28.3 | |

| 3322.19 | 2.8 | 6.0 | 2.7 | 2.4 | 0.6 | 28.9 | 2.9 | 43.0 | 4.1 | 14 | 2.5 | 6.0 | 1.2 | 29.2 | |

| 3325.27 | 2.5 | 7.0 | 4.4 | 2.6 | 1.4 | 25.5 | 4.0 | 46.9 | 3.8 | 12.6 | 4.4 | 8.8 | 1.5 | 22 | |

| 3328.81 | 2.4 | 8.3 | 2.6 | 1.3 | 1.4 | 28.2 | 3.6 | 45.1 | 4.2 | 14.8 | 3 | 6.6 | 1.0 | 25.3 | |

| 3330.42 | 2.6 | 7.4 | 3.3 | 2.1 | 0.9 | 27.1 | 3.4 | 43.6 | 3.9 | 14.7 | 2.9 | 4.6 | 1.9 | 28.4 | |

| 3332.20 | 3.0 | 7.0 | 2.4 | 1.4 | 0.6 | 29.6 | 3.5 | 46.5 | 4.2 | 13.8 | 1.9 | 5.6 | 0.9 | 27.1 | |

| 3333.10 | 3.1 | 7.5 | 4.0 | 0.8 | 0.8 | 27.8 | 3.3 | 50.0 | 4.3 | 16.7 | 3.0 | 5.4 | 1.9 | 18.7 | |

| 3339.21 | 2.7 | 6.6 | 5.2 | 0.8 | 0.6 | 28.0 | 3.2 | 37.9 | 6.6 | 19.0 | 3.0 | 5.8 | 1.0 | 26.7 | |

| 3342.32 | 2.9 | 5.3 | 5.3 | 2.1 | 1.2 | 27.0 | 3.3 | 43.9 | 7.2 | 18.3 | 3.2 | 3.8 | 2.3 | 21.3 | |

| 3345.57 | 3.4 | 6.9 | 3.4 | 1.9 | 1.1 | 27.1 | 3.8 | 45.4 | 7.1 | 15.9 | 6.6 | 4.4 | 0.8 | 19.8 | |

| 3347.38 | 3.6 | 6.9 | 3.6 | 0.5 | 1.7 | 28.7 | 3.5 | 40.4 | 5.7 | 18.7 | 2.7 | 6.4 | 0.9 | 25.2 | |

| 3348.61 | 4 | 5.9 | 4.4 | 2.2 | 1.6 | 26.1 | 3.9 | 32 | 4.6 | 19.9 | 13.8 | 3.4 | 1.5 | 24.8 | |

| 3350.15 | 3.1 | 5.8 | 4.4 | 1.7 | 0.1 | 28.1 | 3.5 | 38.6 | 4.7 | 21.6 | 5.1 | 4.2 | 3.4 | 22.4 | |

| 3351.90 | 3.4 | 7.3 | 2.8 | 2.6 | 1.6 | 26.4 | 3.1 | 32.3 | 6.6 | 17 | 10.7 | 3.9 | 1.5 | 28 | |

| 3353.87 | 3.7 | 6.2 | 3.6 | 0.8 | 0 | 29.2 | 3.6 | 42.5 | 5.6 | 19 | 1.7 | 4.8 | 0.2 | 26.2 | |

| 3355.10 | 3.4 | 7.8 | 1.1 | 2.8 | 0.7 | 27.3 | 3.1 | 52.1 | 5.5 | 18.1 | 2.9 | 3 | 0.3 | 18.1 | |

| 3356.12 | 3.4 | 6.3 | 2.5 | 2.3 | 0.4 | 28.2 | 2.9 | 47.2 | 6.4 | 16.5 | 1.3 | 4.2 | 0.4 | 24 | |

| 3356.78 | 3.8 | 7.4 | 2.7 | 1.7 | 1.4 | 27.4 | 3.2 | 47.7 | 6.5 | 18.8 | 1.6 | 3.3 | 0.3 | 21.8 | |

| 3358.32 | 4 | 7.4 | 1.8 | 2.3 | 1.4 | 27.3 | 2.8 | 50.5 | 5.5 | 15.7 | 2.5 | 2.7 | 0.4 | 22.7 | |

| 3360.87 | 4.1 | 4.9 | 2.4 | 2.7 | 1.3 | 28.8 | 3.6 | 46.8 | 5.5 | 17.3 | 2 | 3.1 | 0.5 | 24.8 | |

| 3361.70 | 3.6 | 5.9 | 2.7 | 1.9 | 0.5 | 28.9 | 3.5 | 46.9 | 5.7 | 18.2 | 2.1 | 2.6 | 3.5 | 21 | |

| 3363.12 | 3.4 | 4.8 | 2.6 | 3.5 | 0 | 28.2 | 3.5 | 46.1 | 5.5 | 17.2 | 2.5 | 3.7 | 0.6 | 24.4 | |

| 3367.82 | 2 | 4.1 | 10.1 | 2.2 | 0.9 | 23.8 | 3.1 | 43.7 | 7 | 24.7 | 9.9 | 2 | 0.7 | 12 | |

| 3370.55 | 2.6 | 5.7 | 8.7 | 1.5 | 0.9 | 23.9 | 2.6 | 47.2 | 6.8 | 23.9 | 2.6 | 1.9 | 0.6 | 17 | |

| 3371.35 | 2.8 | 5.4 | 6.6 | 0.9 | 1.3 | 27.5 | 2.6 | 45.7 | 8 | 19.5 | 4.3 | 1.5 | 0.3 | 20.7 | |

| 3379.78 | 2.8 | 6.3 | 4.5 | 1.6 | 1.1 | 27.7 | 2.6 | 48.6 | 4.5 | 20.7 | 6.5 | 5.6 | 0.5 | 13.6 | |

| 3381.21 | 3.1 | 6 | 4.4 | 1.8 | 0.9 | 27.5 | 2.8 | 44.5 | 5.4 | 17.6 | 3.8 | 4.6 | 5.3 | 18.8 | |

| 3382.58 | 2.5 | 5.9 | 5.6 | 2.2 | 0.6 | 26.4 | 2.5 | 41 | 5.9 | 20.1 | 3.3 | 5.2 | 2.3 | 22.2 | |

| 3393.46 | 2.6 | 6.4 | 6.8 | 1.5 | 0.9 | 25.4 | 3 | 46.7 | 5.9 | 20.9 | 4.3 | 3.1 | 1.1 | 18 | |

| 3394.25 | 3.3 | 5 | 5.1 | 2.2 | 0.6 | 27.4 | 3 | 47.6 | 6.8 | 21.7 | 5.2 | 3.6 | 0.9 | 14.2 | |

| 3395.70 | 3.1 | 6.7 | 3.6 | 2.2 | 1.2 | 27 | 2.9 | 45 | 5.9 | 17.8 | 3.6 | 3.9 | 1.2 | 22.6 | |

| 3398.22 | 2.7 | 6 | 7.5 | 2.9 | 0.1 | 23 | 2.7 | 41.1 | 6.5 | 18.8 | 8.5 | 3.4 | 1.1 | 20.6 | |

| 3399.23 | 3.3 | 7.1 | 5.5 | 1.7 | 0.1 | 25 | 3 | 40.2 | 5.6 | 21.4 | 5.8 | 2.8 | 1 | 23.2 | |

| 3400.99 | 3 | 7.5 | 6.2 | 3.1 | 0.8 | 21.7 | 3 | 42.3 | 6.1 | 21.5 | 7.3 | 3.3 | 1.9 | 17.6 | |

| 3401.88 | 3.1 | 5.8 | 5.3 | 2.9 | 0.9 | 25.1 | 3.3 | 44.4 | 7.2 | 20.5 | 7.9 | 2.7 | 1.1 | 16.2 | |

| 3402.35 | 3.3 | 5.4 | 5.1 | 3.4 | 1.4 | 24.7 | 2.9 | 46.7 | 5.4 | 19.7 | 5.7 | 2.9 | 1.8 | 17.8 | |

| 3404.52 | 3.4 | 5.3 | 4.7 | 2.6 | 0 | 26.7 | 3.6 | 43.4 | 4.3 | 17.8 | 6.2 | 2.7 | 2.7 | 22.9 | |

| 3412.46 | 4 | 6.6 | 6 | 0.9 | 2 | 25.6 | 2.5 | 40.3 | 3.7 | 16.2 | 9.5 | 3.8 | 1.3 | 25.2 | |

| 3413.32 | 3.4 | 6 | 3.2 | 4.1 | 0.5 | 25.3 | 3.1 | 35.4 | 6.8 | 17 | 22.4 | 4 | 1 | 13.4 | |

| 3416.22 | 4 | 7.3 | 1.7 | 1.8 | 1.2 | 28.2 | 3.3 | 48.9 | 6.3 | 20.1 | 4.9 | 2.9 | 1.5 | 15.4 | |

| 3419.31 | 3.4 | 6 | 4.2 | 2.6 | 0.6 | 26.4 | 3.1 | 43.5 | 4.6 | 21.7 | 4 | 3.3 | 1.8 | 21.1 | |

| 3424.33 | 3.2 | 7.5 | 1.6 | 1.8 | 2.8 | 28.8 | 3.1 | 41.1 | 5.9 | 19.9 | 3.7 | 3 | 2.7 | 23.7 | |

| Qiong-2 | 3425.52 | 2.5 | 5.9 | 7.4 | 1.5 | 0.5 | 25.3 | 2.8 | 33.9 | 5.6 | 20.2 | 1.8 | 3.7 | 2.2 | 32.6 |

| 3434.48 | 3.2 | 5.2 | 5.3 | 1.5 | 1.4 | 27.8 | 3 | 42 | 5.1 | 19.9 | 6.5 | 5.8 | 1.3 | 19.4 | |

| 3444.11 | 2.9 | 5.5 | 6.2 | 0.9 | 0.8 | 27.8 | 3.2 | 36.2 | 5.7 | 17.4 | 21.3 | 3.2 | 1.3 | 14.9 | |

| 3464.42 | 3 | 4.9 | 7.2 | 2.9 | 0.3 | 24.1 | 3.2 | 40.8 | 4.3 | 16.6 | 11.4 | 3.5 | 1 | 22.4 | |

| 3471.71 | 3.3 | 5.3 | 4.6 | 3.3 | 0.8 | 25.7 | 3.1 | 40.6 | 4.6 | 17.3 | 5.3 | 5.8 | 0.9 | 25.5 | |

| 3475.16 | 3.4 | 7.4 | 6.2 | 1.2 | 0.6 | 24.5 | 3.4 | 32.4 | 4 | 20.5 | 21.1 | 5.6 | 1 | 15.4 | |

| 3481.99 | 2.9 | 7.2 | 6.6 | 1.2 | 1.1 | 24.8 | 2.7 | 41.4 | 4.9 | 17.2 | 5.1 | 5.4 | 1.4 | 24.6 | |

| 3485.45 | 3 | 7.9 | 7 | 0.7 | 2.2 | 24.2 | 3 | 42.4 | 4.1 | 20.6 | 5.8 | 4.8 | 1.5 | 20.8 | |

| 3489.76 | 3.3 | 6.7 | 6.2 | 1.2 | 1 | 25.5 | 3.3 | 35.1 | 4.1 | 18.5 | 19.1 | 3.9 | 0.8 | 18.5 | |

| 3490.97 | 3 | 7.5 | 6.5 | 1.7 | 1.7 | 23.6 | 2.7 | 44.2 | 3.5 | 18.5 | 4.6 | 5.1 | 2.2 | 21.9 | |

| 3498.73 | 3.6 | 6.6 | 2.1 | 2.5 | 1.9 | 27.9 | 2.4 | 38.9 | 4.2 | 16 | 5.4 | 4.2 | 2.1 | 29.2 | |

| 3502.09 | 3 | 6.4 | 6.8 | 2.7 | 0.8 | 23.1 | 3 | 35.7 | 3.8 | 18.9 | 3.5 | 5.2 | 2.4 | 30.5 | |

| 3507.27 | 3.1 | 6.5 | 4.6 | 2.8 | 0.4 | 25.3 | 2.6 | 48.2 | 3.9 | 21.1 | 4.6 | 4.5 | 2.2 | 15.5 | |

| 3509.25 | 3.7 | 6.3 | 4.6 | 3.2 | 1.2 | 24.4 | 2.9 | 34 | 4.4 | 20.1 | 2.9 | 3.8 | 1.6 | 33.2 | |

| 3511.32 | 3.9 | 7.1 | 2.9 | 0.9 | 1.1 | 28.8 | 3.5 | 48.1 | 4.4 | 19 | 4.6 | 3.4 | 1.5 | 19 | |

| 3513.51 | 3.8 | 8.1 | 2.6 | 1.7 | 1 | 26.9 | 3.7 | 36.3 | 3.4 | 17.1 | 11.1 | 3.1 | 1.9 | 27.1 | |

| 3518.49 | 3.3 | 8.7 | 5.5 | 0.8 | 1.1 | 24.6 | 3.1 | 35.5 | 3.8 | 17.6 | 2.2 | 4.5 | 2.1 | 34.3 | |

| 3520.65 | 3.4 | 8.1 | 5.2 | 1.7 | 0.6 | 24.1 | 3.4 | 39.3 | 4.3 | 19.9 | 3.3 | 4.3 | 1.2 | 27.7 | |

| 3523.32 | 3.5 | 6.6 | 5.9 | 1.2 | 0.5 | 25.7 | 3.3 | 39.8 | 6.2 | 21.2 | 2.9 | 4 | 2.8 | 23.1 | |

| 3530.65 | 3.5 | 5.7 | 4.1 | 2.1 | 0.9 | 27.5 | 2.8 | 43.6 | 5.3 | 21.3 | 4.7 | 3.4 | 2.1 | 19.6 | |

| 3533.12 | 3.3 | 9.4 | 3.2 | 2.5 | 1.6 | 23.5 | 3.6 | 40.3 | 4.3 | 17.5 | 3.7 | 5 | 2.4 | 26.8 | |

| 3534.32 | 3.3 | 7.1 | 4.8 | 1.9 | 1.4 | 25.3 | 3.3 | 39.9 | 3.6 | 15.1 | 4.4 | 6.2 | 2.8 | 28 | |

| 3537.99 | 3.5 | 8.3 | 3.7 | 1.7 | 1.3 | 25.6 | 3.5 | 30.2 | 3.7 | 21.6 | 15.3 | 4 | 1.9 | 23.3 | |

| 3539.99 | 3.7 | 5.9 | 4.8 | 2 | 1.1 | 26.5 | 3.1 | 37 | 3.7 | 17.3 | 4 | 6 | 2.9 | 29.1 | |

| 3544.62 | 3.2 | 6.4 | 4.6 | 2.7 | 1.4 | 25.5 | 3 | 34.5 | 3.5 | 15.2 | 5.3 | 4.8 | 4.4 | 32.3 | |

| 3552.82 | 3.8 | 6 | 5.3 | 1.8 | 0.1 | 26 | 4 | 34 | 3.4 | 16.5 | 10.1 | 5.5 | 1.2 | 29.3 | |

| 3557.28 | 3.1 | 6.2 | 5.4 | 2.8 | 0.7 | 24.8 | 3 | 35.3 | 4.2 | 16.6 | 1.9 | 4.5 | 2.8 | 34.7 | |

| 3558.65 | 3.4 | 7 | 5.7 | 2.6 | 1.2 | 23.4 | 2.7 | 38.3 | 4.6 | 16.7 | 4.4 | 4.6 | 4 | 27.4 | |

| 3564.12 | 3.4 | 6.2 | 3.5 | 3.1 | 0.9 | 26 | 2.4 | 44 | 4.6 | 21.7 | 7.1 | 6.5 | 0.2 | 15.9 | |

| 3572.49 | 3.2 | 8.1 | 4.3 | 1.9 | 0.5 | 25.1 | 3.5 | 43.6 | 4.4 | 17.7 | 7.3 | 5.7 | 4 | 17.3 | |

| Mean | - | 3.3 | 6.6 | 4.6 | 2 | 1 | 26.1 | 3.2 | 41.2 | 4.9 | 17.7 | 5.7 | 4.6 | 1.7 | 24.2 |

| Standard deviation | - | 0.4 | 1.1 | 2 | 0.8 | 0.6 | 2.2 | 0.4 | 5.6 | 1.3 | 3.7 | 4.6 | 1.8 | 1.1 | 7.6 |

| Regression Analysis Statistics | Calcite | Plagioclase | Dolomite | Clay Minerals | K-Feldspar | Quartz | Pyrite |

|---|---|---|---|---|---|---|---|

| Intial training loss | 3.97 | 17.40 | 9.56 | 21.78 | 4.33 | 39.77 | 1.26 |

| Final training loss | 0.55 | 1.66 | 1.94 | 2.26 | 0.44 | 2.89 | 0.12 |

| Intial validation loss | 3.58 | 17.33 | 9.42 | 20.70 | 4.64 | 38.78 | 0.94 |

| Final validation loss | 0.40 | 1.06 | 3.07 | 1.93 | 0.31 | 2.33 | 0.12 |

| Coefficient of determination (test set) | 0.95 | 0.81 | 0.81 | 0.81 | 0.80 | 0.70 | 0.89 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ye, X.; Liu, Y.; Huang, T.; Chen, T.; Liu, C.; Liu, S.; Jin, S. Machine Learning-Based Mineral Quantification from Lower Cambrian Shale in the Sichuan Basin: Implications for Reservoir Quality. Minerals 2025, 15, 286. https://doi.org/10.3390/min15030286

Ye X, Liu Y, Huang T, Chen T, Liu C, Liu S, Jin S. Machine Learning-Based Mineral Quantification from Lower Cambrian Shale in the Sichuan Basin: Implications for Reservoir Quality. Minerals. 2025; 15(3):286. https://doi.org/10.3390/min15030286

Chicago/Turabian StyleYe, Xin, Yan Liu, Tianyu Huang, Ting Chen, Chenglin Liu, Sibing Liu, and Siding Jin. 2025. "Machine Learning-Based Mineral Quantification from Lower Cambrian Shale in the Sichuan Basin: Implications for Reservoir Quality" Minerals 15, no. 3: 286. https://doi.org/10.3390/min15030286

APA StyleYe, X., Liu, Y., Huang, T., Chen, T., Liu, C., Liu, S., & Jin, S. (2025). Machine Learning-Based Mineral Quantification from Lower Cambrian Shale in the Sichuan Basin: Implications for Reservoir Quality. Minerals, 15(3), 286. https://doi.org/10.3390/min15030286