1. Introduction

Microwave is a kind of electromagnetic wave, which can be used in communication, heating and many other aspects, and microwave-assisted rock breaking is a new technology developed in recent years in the rock engineering industry. In foreign countries, research on microwave-assisted rock breaking started relatively early and was applied to the mining industry earlier too. S.W. Kingman, Vorster W, and Rowson N A elucidated the influence of mineralogy on microwave-assisted grinding. A detailed mineralogical analysis of various commercially exploited ores was carried out, and the textural relationships between the individual mineral phases were established. Microwave heating profiles were determined for each constituent mineral [

1]. Ferri Hassani et al. investigated the effect of microwave radiation on temperature profiles and strength reduction in hard rocks (norite, granite and basalt) for a range of exposure times and microwave power levels [

2]. Michael Toifl carried out a three-dimensional numerical analysis of various constant microwave power or constant energy on granite samples, obtained dielectric and thermal properties from experiments, carried out the finite-difference time-domain simulation and evaluated the temperature and stress field [

3]. Khashayar Teimoori simulated the rock–microwave interaction by the finite element method and tested several numerical models; these models and experiments considered different microwave parameters and solved for the electric and magnetic fields [

4]. Feng Xiating et al. invented a high-power microwave mechanical integrated continuous mining device, which can realize the simultaneous microwave and mechanical cutting of hard rock [

5]. With the continuous progress of science and technology, the application of microwave-assisted breaking has made new progress, such as in oil exploitation [

6], concrete recycling [

7,

8] and assisted hard rock breaking [

9,

10,

11]. Preliminary studies show that microwave-assisted rock breaking can increase the amount of rock breaking by the disc cutter and reduce the cutting force required by TBM, so as to further improve the rock crushing efficiency of TBM [

12]. The fundamental scientific problem of microwave-assisted rock breaking is the influence of microwave irradiation on the mechanical properties of rock, such as strength and deformation properties. The factors that impact the effect of microwave irradiation include not only internal factors, such as the mineral composition and microstructure, but also external factors, such as the microwave intensity, time span and interval related to the irradiation mode. And among these factors, the influence of the minerals from rock is fundamental.

Rock is composed of different kinds of minerals. The microwave absorption ability of minerals directly influences the effect of microwave-assisted rock breaking. However, studies on the effect of microwave irradiation on minerals are reported rarely. Most studies are based on the numerical simulation method, and these relevant research results reflect the law of stress distribution and failure under the interaction of minerals. According to the sensitivity and thermal expansion characteristics of rock-forming minerals to microwaves, Lu Gaoming analyzed the mechanism of the different thermal effects of different types of rocks [

13] and studied the interaction effect between microwaves and major rock-forming minerals [

14]. Haitham M. Ahmed studied the failure mechanism of rock by two microwave heating methods and the effect of absorbing minerals [

15]. The thermophysical characteristics of granites, sandstones and basalts such as hartlieb, toifl and Kuchar have been discussed [

16]. Dai Jun, Pan Yanbin, et al. studied the failure process of rock minerals pyrite and calcite by using Particle Flow Code (later referred to as PFC) [

17]. Previous studies have shown that minerals have a significant impact on the temperature, stress and crack formation in rock during microwave irradiation, and the reaction of minerals to microwave irradiation is one of the key reasons. In this paper, K-feldspar, calcite and pyroxene, common rock-forming minerals, were studied by microwave irradiation.

Generally, under the same irradiation conditions, strong-absorbing minerals will absorb more microwaves and generate a lot of heat energy, which makes the internal thermal stress stronger and the damage to the mineral more significant. In this paper, through a series of physical experiments, the changes in the properties of common minerals under microwave irradiation were studied. Through the point load experiment, etc., the changes in the strength, microstructure and quality of minerals under microwave irradiation were studied.

2. Experiment and Process

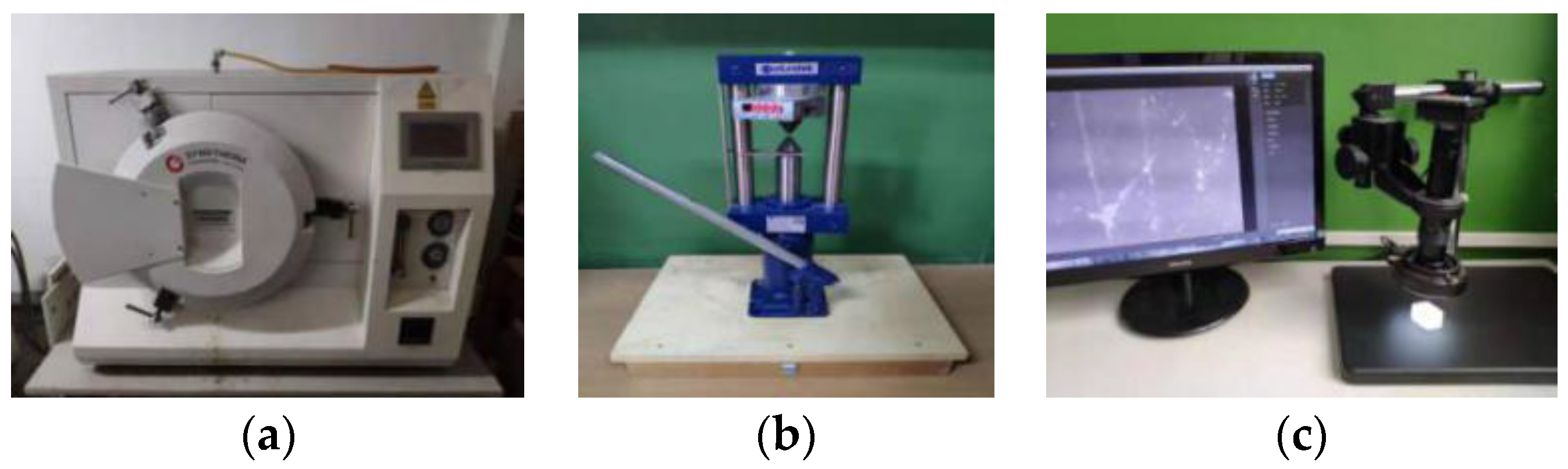

In this paper, the microwave irradiation and related testing of minerals were mainly carried out by physical experiments, and the equipment included a microwave oven, point load instrument and microscope.

2.1. Mineral Selection

Rocks are made up of minerals, which are abundant in nature. In this paper, three kinds of minerals, namely K-feldspar, calcite and pyroxene, which are relatively common in rock, were selected as samples. Among them, pyroxene has a strong wave-absorbing ability and exists widely in hard rocks; K-feldspar is a kind of rock composition in the earth; calcite is a kind of weak-absorbing mineral. Calcite is a regular transparent block in nature, with a small amount of the light refraction joint surface visible inside. Pyroxene is a random black block covered with reddish-brown impurities, with cracks distributed irregularly on the surface. K-feldspar is flesh red, with few impurities, and white regular fine cracks are visible on the surface. The shape and appearance of each mineral are shown in

Figure 1.

2.2. Main Test Equipment

Microwave heating experiments were performed to irradiate the mineral samples by a hamilab-v1500 high temperature test furnace. The equipment is produced by Changsha Longtai microwave thermal Co., Ltd. (Changsha, China), as shown in

Figure 2a, and the microwave frequency of the equipment is 2.45 GHz, which is a constant temperature microwave furnace with variable power and maximum power up to 1.5 kW. It can realize constant power, constant temperature and constant temperature rise to control the process of microwave heating. In this paper, the minerals were heated by a constant heating rate, and the highest heating temperature was 900 °C. The strength was tested by an a0125 oil pressure point load tester, produced by the French controllab company, as shown in

Figure 2b, and the rated bearing capacity of the instrument sensor is 100 kN. In order to observe and obtain the microstructure of the minerals, the surface of the minerals before and after being irradiated was observed at 800 times magnification using an industrial high-definition microscope, and the industrial high-definition microscope used was a CREAFORM SCAN 50 Metra SCAN 750 made in Quebec, Canada, as shown in

Figure 2c.

2.3. Test Process and Data Processing

According to the needs of the research content, this paper mainly carried out the following sample preparation and testing procedures.

Sample preparation: Due to the existence of the large number of natural cracks and cleavages in natural minerals, it is very difficult to use large-scale samples, and small samples with side lengths of 2.5~3 cm were selected for testing. The samples were processed and manufactured by a manual rock cutting machine, and the finished mineral samples are shown in

Figure 3.

- 2

Quality test: record the quality and changes in the mineral sample by using an electronic scale with an accuracy of 0.001 g before and after microwave irradiation.

- 3

Microstructural observation: observe the mineral surface and fracture surface at 800 times magnification with an industrial high-definition microscope and record the microstructural images before and after microwave irradiation.

- 4

Microwave irradiation experiment: place the prepared mineral sample in the cavity of the microwave oven with the heating path set, take out the sample after heating to the predetermined temperature and test the quality and observe the microstructure after natural cooling. The heating path is set to make the minerals reach 400, 600 and 800 °C at a constant heating speed of 1 °C/s.

- 5

Strength test: carry out the point load test on the mineral specimen by using an a0125 point load tester and record the peak load of the specimen.

In this paper, the experiment flow is as follows: sample preparation—mass test—microstructure observation—microwave irradiation—mass test—microstructure observation.

Due to the irregular shape of the samples, the uniaxial compressive strength was converted by the mid-point load strength conversion formula in the standard for engineering rock mass test methods. For irregular test blocks, the equivalent core diameter of its size was calculated according to Equation (1):

where D is the spacing between loading points (mm), W is the width or average width of the minimum section between two loading points (mm) and D

e is the equivalent core diameter (mm). The load strength of the test block point was calculated according to Equation (2):

where I

s is the uncorrected point load strength of rock (MPa); P is the failure load (N). When the equivalent core diameter was not 50 mm, the test data are few. The point load strength index of rock was calculated according to the following formula:

where I

s(50) is the point load strength index (MPa) of rock with an equivalent core diameter of 50 mm; m is the correction index, which can be taken as 0.40–0.45, which was taken as 0.45 according to experience with similar rocks in this paper.

For comparing expediently, in this paper, the point load strength of the test block was converted into the uniaxial compressive strength of the mineral according to the method recommended by the test methods committee of the International Society of Rock Mechanics, as shown in Equation (4):

In order to eliminate the error, the three maximum values and three minimum values were removed from the test data processing, and the average data of six samples were taken as the uniaxial compressive strength of the scheme.

3. Results and Analysis

In this section, analyses of the strength, surface, fracture surface characteristics and mass loss of the minerals preliminarily under different microwave irradiation schemes are reported.

3.1. Effect of Microwave Irradiation on Mineral Strength

In order to compare conveniently, the temperature of the mineral sample without microwave irradiation was set at 20 °C as the normal temperature. So, the four temperature schemes in this paper were 20, 400, 600 and 800 °C.

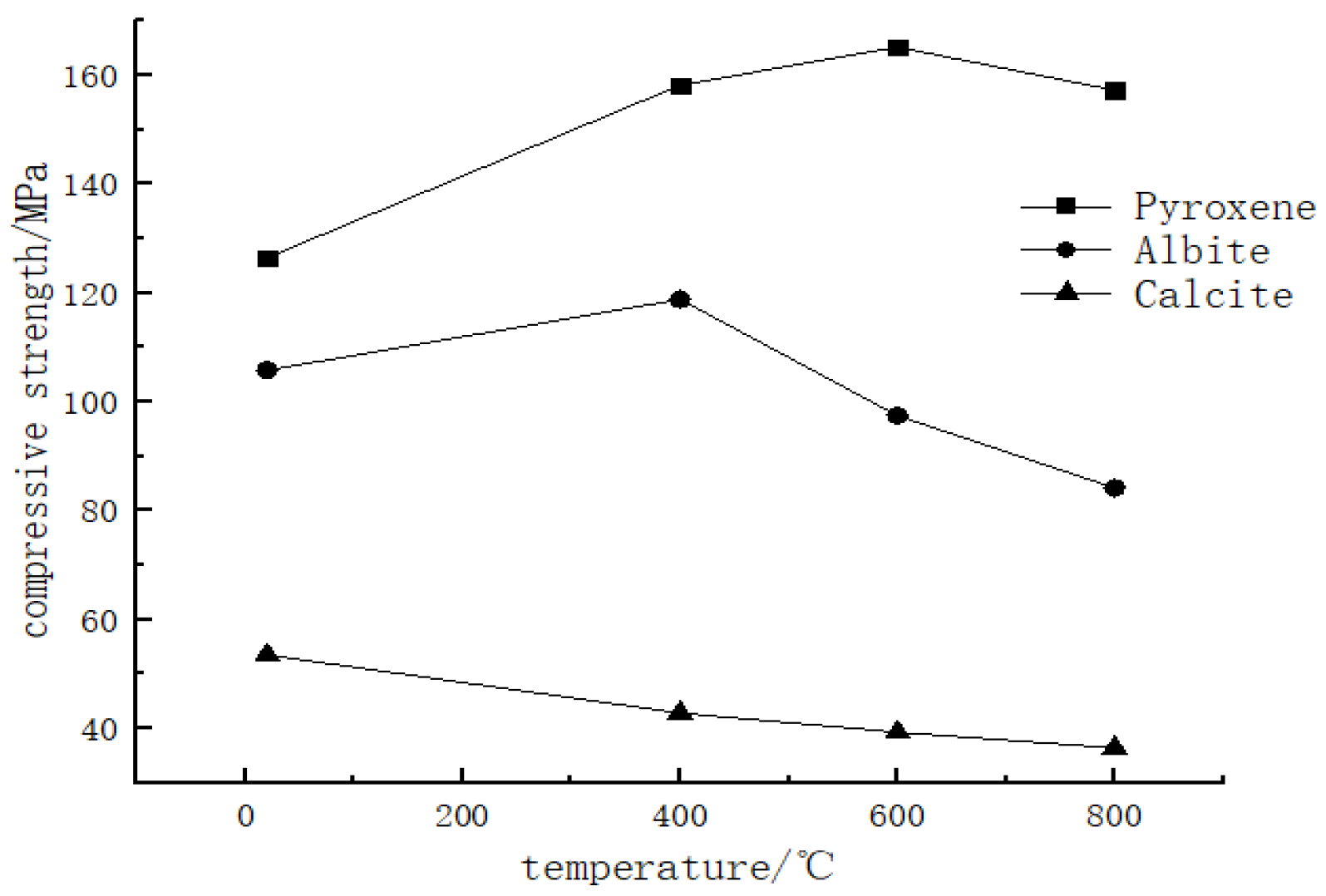

According to the test results, the uniaxial compressive strength of pyroxene is 126.48, 158.14, 165.12 and 157.22 MPa after microwave irradiation at 20, 400, 600 and 800 °C, respectively, and the strength of K-feldspar is 105.77, 118.81, 97.47 and 84.15 MPa, respectively, under the four schemes; the strength of calcite is 53.50, 42.85, 39.30 and 36.41 MPa, respectively, under the four schemes. The strength change curve of each mineral after different microwave irradiation schemes is shown in

Figure 4.

For pyroxene, its strength increases with microwave irradiation before microwave heating to 600 °C, and its uniaxial compressive strength decreases when heated to more than 600 °C. Its compressive strength is similar to that at 400 °C when microwave-heated to 800 °C, but its strength after microwave irradiation is greater than that without irradiation.

The strength of K-feldspar is similar to that of pyroxene, which increases first and then decreases with the increase in irradiation temperature; the difference is that the strength of the two minerals decreases at different temperatures. The strength of pyroxene decreases at 600 °C and K-feldspar at 400 °C, and the strength of K-feldspar at 800 °C is lower than that without irradiation. The variation in calcite strength is different from those of K-feldspar and pyroxene after irradiation, and the strength keeps decreasing.

The calcite compressive strength is reduced by 20% from 20 °C to 400 °C, and the reduction in the uniaxial compressive strength from 400 °C to 600 °C and from 600 °C to 800 °C is 8% and 7%, respectively. The uniaxial compressive strength of calcite is only one-half~one-third of those of K-feldspar and pyroxene, and the strength gap increases with the increase in temperature. Therefore, the strength of the rock is significantly reduced by microwave irradiation when there is more calcite in the rock. It can also be seen that the compressive strength of pyroxene is greater than that of K-feldspar at each stage in

Figure 4, while the compressive strength of K-feldspar is greater than that of calcite at each stage.

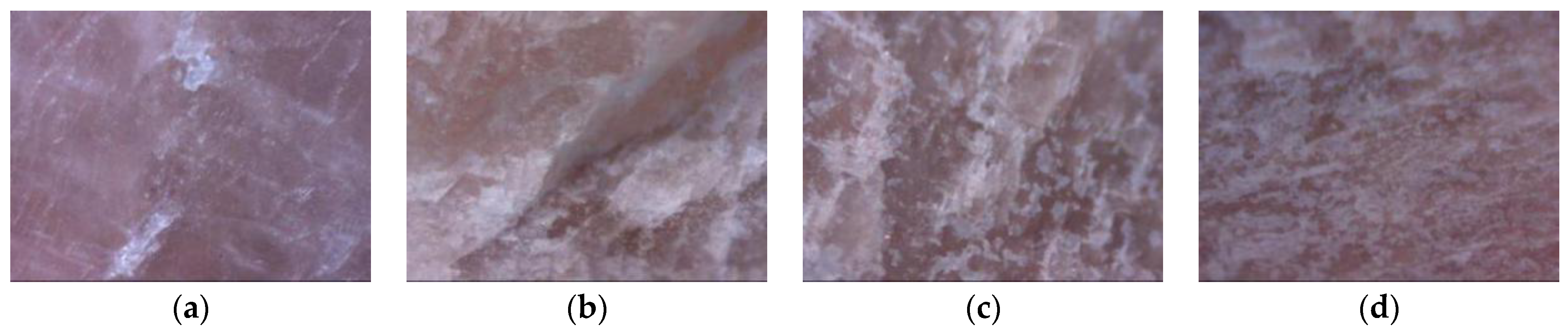

3.2. Characteristics of Mineral Surface and Fracture Surface

Pyroxene, K-feldspar and calcite were observed microscopically by using an 800× HD industrial electron microscope, and the same points on the minerals were marked under different microwave irradiation schemes.

Figure 5 shows the surface photos after different schemes. It can be seen that the overall gloss of the minerals with a white attachment layer on the mineral surface is poor under normal temperature. The color of the attachment layer on the mineral surface becomes scorched yellow, and the gloss of the black part of pyroxene increases after microwave irradiation at 400, 600 and 800 °C. It can be further found that the pyroxene component melts to a certain extent under microwave irradiation, and the fine Matte concave and convex parts on the surface become smooth after melting. The mineral becomes more dense with the filling of some micropores on the melting surface.

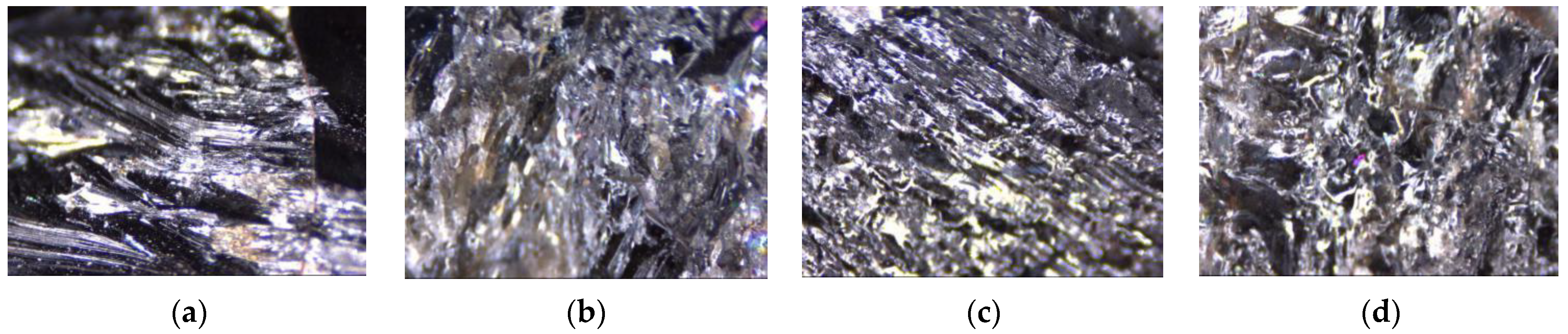

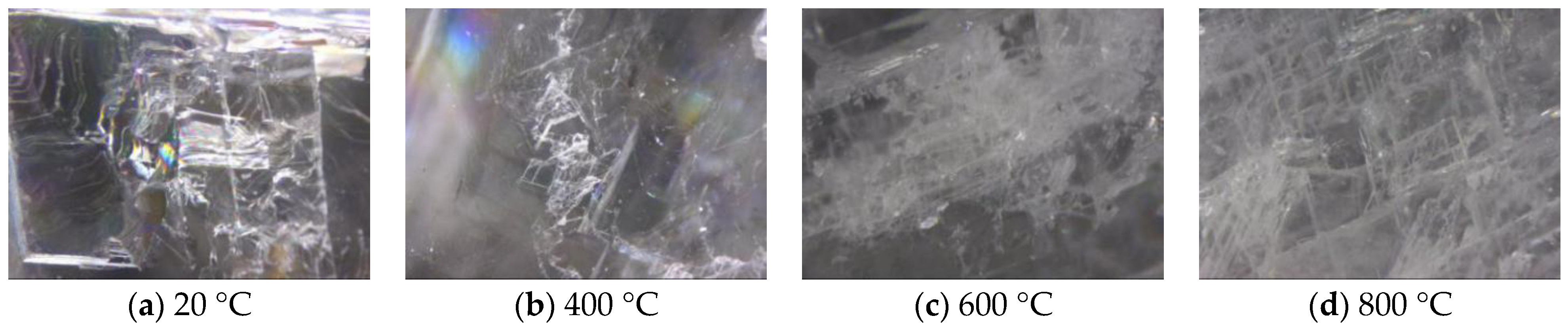

Figure 6 shows typical photos of pyroxene fracture under each scheme. There are parallel sliding striations and step fractures on the pyroxene fracture surface at 20 °C. The pull-down filamentous cracks basically disappear at 400 °C, and the light refractive index at the flat part of the step fracture cleavage plane is enhanced and more smooth. The step fracture plane basically disappears at 600 °C, most of the complete fracture surfaces are water ripple fracture and the light linear refractive index at the flat part is higher. The water ripple formed on the fracture surface becomes thinner at 800 °C, and the part has a directional flow water ripple arrangement.

K-feldspar is a flesh-red mineral with white cleavage cracks on its surface. K-feldspar presents a glassy luster at normal temperature. The surface gloss decreases and a gray-black spot-like substance is produced that wraps the entire mineral when the temperature of microwave irradiation increases, as shown in

Figure 7.

The surface of the K-feldspar cracks along the cleavage surface as the temperature rises during the heating process, and some samples crack as a whole. The inside of K-feldspar is damaged along the structural plane during the rapid rise in temperature, as shown in

Figure 8.

According to the photos at 200 times magnification of the K-feldspar fracture through the point load experiment under different microwave irradiation schemes shown in

Figure 9, the section of K-feldspar is relatively smooth under normal temperature, and local step-like fracture appears, but the whole is smooth, which mainly belongs to the whole fracture of the grain boundary; the flatness of the fracture surface at 400 °C is lower than that under normal temperature, and the fracture surface is uneven, while the step-like section is divided. There are more intergranular fracture patterns; more point intergranular fracture can be seen on the fracture surface at 600 °C, and more fine intergranular fracture can be seen at 800 °C. More and more fine cracks appear in the inner crystals of the minerals, and the integrity of K-feldspar decreases with the increase in irradiation temperature. The whole fracture along the grain boundary gradually develops into a small crack along the loading point.

The apparent change in calcite is great after microwave irradiation. The integrity of calcite is good at room temperature; there are a lot of cracks along the grain boundary on the surface and inside under the microwave irradiation of 400 °C; the crack further increases and the transparency further decreases at 600 °C; a lot of broken crystals fall from the surface of calcite, and the whole crack phenomenon appears; the number of calcite cracks continues to increase and crisscross at 800 °C, which can be easily broken by hand. The cleavage fracture is magnified 200 times, as shown in

Figure 10. The fracture surface of calcite has a wavy pattern and large step-like fracture at 20 °C; the wavy pattern basically disappears and the local fracture cracks are mainly step-like fracture with clear cracks at 400 °C. And the crystal structure of calcite is visible, and the cleavage plane formed under microwave irradiation is completely destroyed in other places with glass luster and relatively flat sections. Due to the dense distribution of intergranular fracture at 600 °C, the fracture surface under 200 times magnification shows a cotton-like pattern, and crystal slag can be seen everywhere after fragmentation with serious falling off; the fracture surface is step-like, and root-like cracks crisscross at 800 °C, and the mechanical properties are basically lost after irradiation, which can be easily broken by the point load instrument.

The cracks gradually increase inside calcite when the irradiation temperature increases, resulting in a large number of intergranular fractures. Because the calcite structure is complete at normal temperature, it is not damaged along the crystal structure surface in the process of the point load experiment and produces a wavy fracture pattern under high tensile stress. The fracture of the calcite crystal structure surface is mainly tensile when the temperature rises, which consists of a step-like fracture along the microcracks of the calcite crystal structure surface. The number of microcracks increases when the temperature is higher, and the pattern of step-like cracks decreases, and the size of dropped calcite crystal particles is smaller.

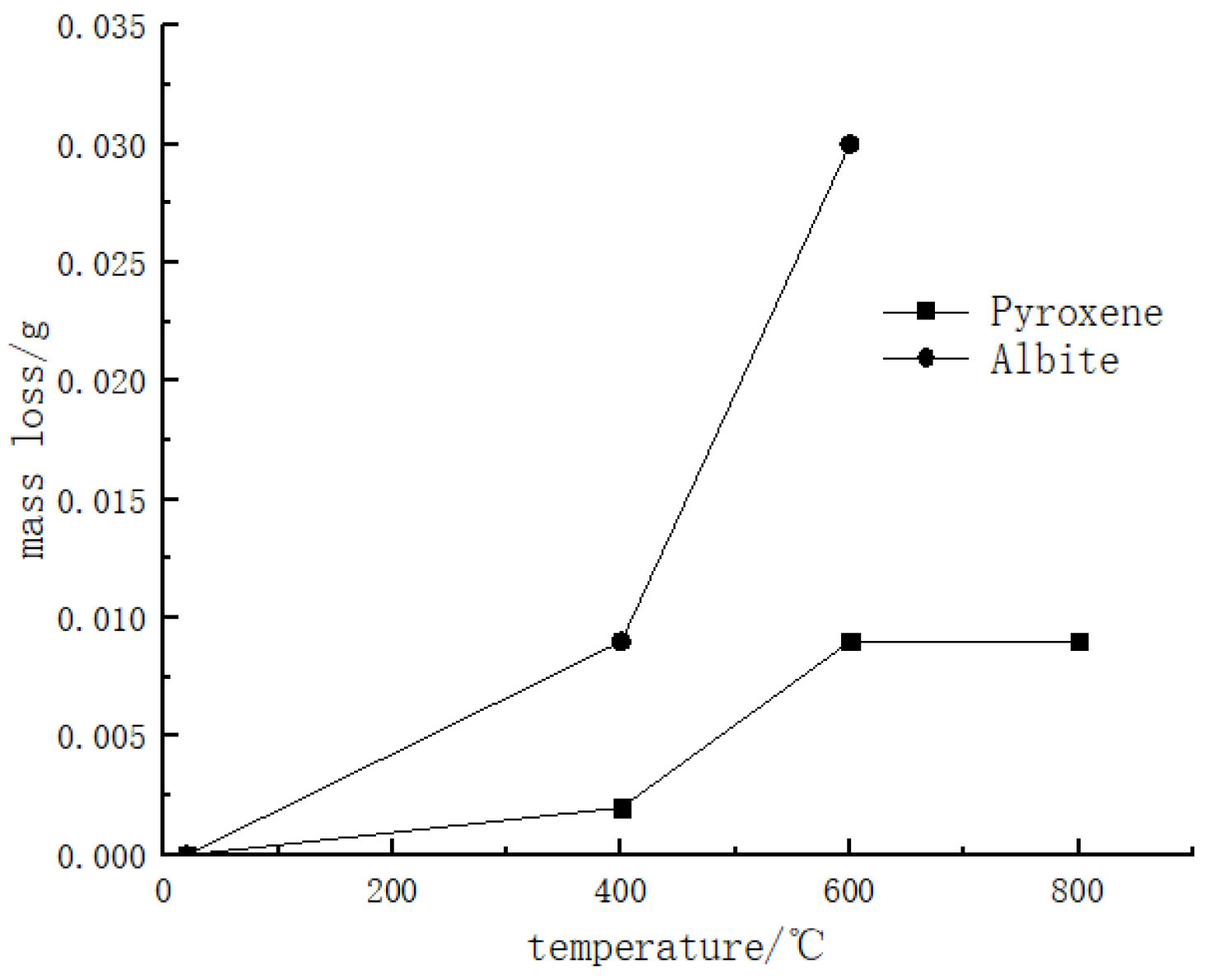

3.3. Loss of Mineral Quality

Microwave irradiation has a certain impact on the mass of the mineral block. The mass loss of different schemes compared with the scheme of normal temperature is shown in

Figure 11. Due to the small-sized ore crystal disintegration around the block under microwave irradiation, the mass loss of the ore crystal cannot be accurately measured. Only the mass loss results of pyroxene and K-feldspar are shown in

Figure 11.

In conclusion, the mass loss of K-feldspar increases obviously with the increase in microwave irradiation temperature; the main reasons are the falling off of mineral powder on the surface of K-feldspar and the oxidation reaction of the internal partition under high temperature. In comparison, the mass loss of pyroxene is less, reflecting that the increase in the microwave irradiation temperature has no significant effect on the mass loss of the mineral pyroxene.

4. Discussion

Under the condition of microwave irradiation, the strength, microstructure and mass of the three minerals change significantly with the increase in microwave irradiation temperature, and the change rule is obviously different.

The compressive strengths of pyroxene and K-feldspar increase first and then decrease with the increase in microwave irradiation temperature. The transition irradiation temperatures of pyroxene and K-feldspar are around 600 °C and 400 °C. In the initial stage, the increase in pyroxene’s strength is mainly due to the softening and melting of minerals during the microwave heating, and the original cracks in the internal part of the minerals gradually close and disappear with the softening process, which makes the internal structure of the minerals uniform. The strength increases inversely after cooling to normal temperature. When the irradiation temperature is higher than 600 °C, the damage caused by microwave irradiation is greater than the strength increase caused by melt cooling, and the strength is reduced. The results show that the strength of K-feldspar increases under microwave irradiation, mainly due to the closure of micropores and original cracks in K-feldspar minerals when the temperature increases and is less than 400 °C, while the strength of K-feldspar minerals is higher than that caused by the closure of original cracks when the temperature is more than 400 °C. The compressive strength of calcite decreases gradually with the increase in temperature. When calcite is heated and expanded, the number of internal cracks increases with the increase in temperature, which directly leads to the decrease in its strength.

The fracture surface of pyroxene is mainly composed of step-like and sliding-like cracks at normal temperature under microscope observation. The fracture surface is mainly destroyed with the original internal cracks during the experiment. The sliding-like cracks disappear and the step-like cracks become smaller at 400 °C, while water ripple-like cracks gradually appear. The water ripple-like cracks mainly appear at 600 °C and 800 °C. The arrangement of craze cracks at 600 °C is more directional than that at 800 °C. The fracture of K-feldspar is flesh red, and the main form is integral fracture at normal temperature. There are some cracks inside K-feldspar at 400 °C, and the fracture appears to have a step-like distribution. The distribution of fine cracks is finer and denser at 600 °C and 800 °C, and the damage gradually develops into small crack fracture. And the internal cracks of calcite become finer and visible with the rise in temperature. The internal cracks of calcite break along the structural plane and the transparency decreases with the rise in irradiation temperature under the microscope, and the cracks appear to have a white flocculent distribution and become denser.

5. Conclusions

In this paper, taking pyroxene, K-feldspar and calcite as research objects, a series of microwave irradiation, intensity and microstructure observation experiments were carried out. The changes in the strength and microstructure of each mineral were analyzed. The main conclusions are as follows:

In the process of microwave heating, pyroxene and K-feldspar show the trend of strength decreasing at 600 °C and 400 °C, respectively. The compressive strength of pyroxene at 400~600 °C is higher than that at normal temperature, and the compressive strength of K-feldspar at 600 and 800 °C is lower than that at normal temperature. The compressive strength of calcite decreases gradually with the increase in temperature.

The melting of minerals and the closure of original natural cracks mainly lead to the increase in the compressive strength of pyroxene after microwave heating. After heating, the micropores and original cracks in K-feldspar are closed, and the crack does not develop at 400 °C, resulting in a short-term increase in strength. Later, the compressive strength is reduced below the compressive strength of nonirradiated K-feldspar with the development of internal cracks. After heating, a large number of cracks are produced along the structural surface of calcite, which mainly leads to the reduction in strength.

With the increase in irradiation temperature, pyroxene fracture gradually transitions from wire-like drawing and step-like fracture to water ripple-like fracture; K-feldspar fracture gradually transitions from complete fracture surface at normal temperature to fracture surface generated by intergranular fine cracks, and calcite fracture gradually transitions from water ripple-like fracture surface at normal temperature to a crisscross flocculent surface.

The mineral mass exhibits a significant loss with the increase in microwave irradiation temperature.

Author Contributions

Conceptualization, Z.Z. and F.C.; methodology, Z.Z.; software, G.Z.; validation, G.Z. and Q.Z.; formal analysis, Q.Z.; investigation, G.Z.; resources, Q.Z.; data curation, Q.Z.; writing—original draft preparation, G.Z.; writing—review and editing, Q.Z.; visualization, Z.Z.; supervision, F.C.; project administration, Z.Z.; funding acquisition, Z.Z. All authors have read and agreed to the published version of the manuscript.

Funding

The scientific research program was funded by the National Natural Science Foundation (11872301) and the Natural Science Basic Research Program of Shaanxi (2022JC-LHJJ-083).

Data Availability Statement

Data cannot be obtained due to privacy.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kingman, S.W.; Vorster, W.; Rowson, N.A. The influence of mineralogy on microwave assisted grinding. Miner. Eng. 2000, 13, 313–327. [Google Scholar] [CrossRef]

- Hassani, F.; Nekoovaght, P.; Gharib, N. The influence of microwave irradiation on rocks for microwave-assisted underground excavation. J. Rock Mech. Geotech. Eng. 2015, 8, 1–15. [Google Scholar] [CrossRef]

- Toifl, M.; Hartlieb, P.; Meisels, R. Numerical study of the influence of irradiation parameters on the microwave-induced stresses in granite for industrial applications. Miner. Eng. 2016, 103–104, 78–92. [Google Scholar]

- Teimoori, K.; Cooper, R. Multiphysics study of microwave irradiation effects on rock breakage system. Int. J. Rock Mech. Min. Sci. 2021, 140, 104586. [Google Scholar] [CrossRef]

- Feng, X.-T.; Lin, F.; Zhang, J.; Yang, C.; Ao, Y.; Tong, T. Development of high-power microwave mechanical integrated continuous mining device. J. Rock Mech. Geotech. Eng. 2023, 7, 1674–7755. [Google Scholar] [CrossRef]

- Gharibshahi, J.R. Nanoparticles assisted microwave radiation: Fluid-rock interactions in oil reservoirs. Pet. Sci. 2021, 18, 1797–1812. [Google Scholar]

- Chen, X.; Dai, J.; Meng, Z. Microblog-assisted mechanical selection of recycled concrete aggregate. J. Xi’an Univ. Sci. Technol. 2013, 33, 604–608. (In Chinese) [Google Scholar]

- Xiao, Y.; Shao, Z.; Wei, W.; Jiang, Y.; Chai, S.; Zong, Z.; Chen, X. Study on mechanism of strength weakening of concrete subjected to microwaves in microwave-assisted concrete recycling. Int. J. Heat Mass Transf. 2023, 213, 124353. [Google Scholar] [CrossRef]

- Meisels, R.; Toifl, M.; Hartlieb, P.; Kuchar, F.; Antretter, T. Microwave propagation and absorption and its thermo-mechanical consequences in hetergeneous rock. Int. J. Min. Process. 2015, 135, 40–51. [Google Scholar] [CrossRef]

- Deyab, S.M.; Rafezi, H.; Hassani, F.; Kermani, M.; Sasmito, A.P. Experimental investigation on the effects of microwave irradiation on kimberlite and granite rocks. J. Rock Mech. Geotech. Eng. 2020, 13, 267–274. [Google Scholar] [CrossRef]

- Lu, G.; Feng, X.; Li, Y.; Zhang, X. Influence of microwave treatment on mechanical behaviour of compact basalts under different confining pressures. J. Rock Mech. Geotech. Eng. 2020, 12, 213–222. [Google Scholar] [CrossRef]

- Lu, G.; Zhou, J.; Zhang, L.; Gao, W. Experimental investigation on the influence of microwave exposure on the cutting performance of TBM disc cutter cutting of hard rocks—ScienceDirect. Results Eng. 2024, 12, 100285. [Google Scholar] [CrossRef]

- Lu, G.; Zhou, J.; Li, Y.; Zhang, X.; Gao, W. The influence of minerals on effect of microwave-induced fracturing of rocks. J. Appl. Geophys. 2020, 180, 104123. [Google Scholar] [CrossRef]

- Lu, G.M.; Li, Y.H.; Hassani, F.; Zhang, X. The influence of microwave irradiation on thermal properties of main rock-forming minerals. Appl. Therm. Eng. 2017, 112, 1523–1532. [Google Scholar] [CrossRef]

- Ahmed, H.M.; Ahmadihosseini, A.; Hassani, F.; Hefni, M.A.; Ahmed, H.M.; Saleem, H.A.; Moustafa, E.B.; Sasmito, A.P. Numerical and experimental analyses of rock failure mechanisms due to microwave treatment. J. Rock Mech. Geotech. Eng. 2023, 15, 2483–2495. [Google Scholar] [CrossRef]

- Hartlieb, P.; Toifl, M.; Kuchar, F.; Meisels, R.; Antretter, T. Thermo-physical properties of selected hard rocks and their relation to microwave-assisted comminution. Miner. Eng. 2016, 91, 34–41. [Google Scholar] [CrossRef]

- Dai, J.; Pan, Y. Numerical simulation of rock damage under microwave irradiation. Coal Technol. 2016, 35, 5–7. (In Chinese) [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).