1. Introduction

The presence of badgers, porcupines, and foxes in proximity to the Po River embankments causes alterations of the external and internal geometry of the earthen structure with different impacts on their hydraulic performance and structural integrity, thus increasing the risk of landslide disasters. As a consequence, animal burrowing can be a cause of a flood defense breaching, and the consequences can be disastrous, as was seen with the levee failure along the Secchia River in Italy [

1]. Recent studies reflect the increased attention among levee management boards and maintenance agencies, such as the AIPo (Italian acronym for the Interregional Agency for the Po River embankments). In 2022, Nocilla et al. [

2] proposed a possible sustainable solution to address the need, from a management perspective, for an effective and quick repair to prevent adverse consequences to earthen structures after damage caused by animal burrowing, which would otherwise be vulnerable and no longer homogeneous in terms of permeability, mechanical and volume stability, and internal and external erosion resistance [

3]. The sustainable solution mentioned is shown in

Figure 1 and represents a compromise between the two most common interventions suggested by the International Levee Handbook [

4]: excavation of the area around the hole with subsequent backfill, and/or injection of a low-pressure flowable grout, such as cement and bentonite mixes or polyurethane foam. The first solution, although economically advantageous and sustainable, involves the weakening of the embankment due to the different compaction of the new material compared to the in situ compacted one, and the uncertainty of complete filling due to the length and complexity of the animal burrow network. As for the second intervention of injections at the low pressure of grouts, which are more likely to go upward to fill all voids, it can cause shrinkage of the grouting mixture and create an additional seepage path and piping between the grout and the existing soil. Therefore, the different characteristics of permeability, strength, and stiffness of the two materials (existing soil and injected mixture) are a concern for the levee body continuity and sustainability requirements.

It is well known that the treatment improves mechanical characteristics in soils that can be characterised by several particle size distributions e.g., [

5,

6,

7,

8,

9,

10,

11,

12,

13,

14,

15,

16]. Changes in the microstructural can be clearly seen in the chemo-mechanical response [

17]. Treatments can provide the reduction of the maximum dry density attainable from a fill, and the optimum moisture content typically shifts towards the wet side. Lime treatment, which is a technique commonly used in earthworks and is considered a sustainable solution (e.g., [

4]), tends to produce a relatively flat curve when results of dry density are plotted against moisture content, so that higher void ratios can result together with similar mechanical behaviour, with attention to permeability matters, e.g., [

18,

19]. Cement treatment can also be considered, e.g., [

6,

20,

21] for its ease of mixing and its ability to improve the mechanical characteristics of soils. Only organic or very clayey soils do not seem suitable for cement treatments. Nocilla et al. (2022) [

2] showed similar compressibility features between two soils (points A and C in

Figure 1a): the first is without treatment and compacted at a low water content, and the second has been treated with lime and has a higher water content (slurry).

The continuity between the two materials—compacted in situ soil and injected treated soil—in order to prevent interface problems, piping phenomena, and the weakening of the embankments or the uncertainty of the complete filling, can be achieved by this proposed intervention [

2], paying attention to the fact that the treated soil (e.g., with lime), even if not compacted, might show similar characteristics to the more compacted (i.e., higher energy of compaction) soil in situ forming the pre-existing earthen structure.

Flowable injection of treated soils (either with lime or cement) must guarantee an adequate compromise between viscosity, which must be low enough to allow the mixture to flow into the hole with site machines (

Figure 2), and account for any shrinkage that might occur over time according to the hole boundary conditions, which can be consistent if high water contents are added to the mixtures. At the same time, the intervention must improve the mechanical features of the low-viscosity injected mixture, whether it has been previously treated with lime or cement, so that continuity with the compacted natural soil surrounding the hole is maintained.

The scope of the present research is to highlight the best compromise among several recipes of treated soils mixed with lime or cement, different percentages of water, and other additives. An interdisciplinary experimental programme was then carried out on four natural soils collected from the embankments of the Po River or its tributaries, and two artificial ones derived by one grading and two mixing operations. Each soil was classified according to its particle size distribution and Atterberg limits. The mineralogy of each soil was also determined. Mixtures were created, and for many of them, the viscosity was determined using the Marsh Cone test. Each mixture was then poured into cylinders made of Plexiglas and the volume reduction was determined over a period of 21 days using several methods of measurement. The erosion susceptibility was then determined through crumb tests. Improvement of strength after treatment was also determined for one of the soils used. As a first estimation, a graphical representation (abacus) of the best compromise between viscosity and shrinkage characteristics will then be proposed to give applicative indications on the best recipe for the mixture.

2. Materials and Methods

Mixtures were created as a combination of soil, lime, or cement and, for some of them, other additives such as super-plasticizing admixtures and expansive admix for controlled shrinkage. Different types of soils were used to prepare the flowable mixtures. In detail, the four soils used were collected from sites on embankments of the middle course of the Po River and its tributaries. In

Figure 3, the sites of collection—Tassone, Chiavica Rossi, Caorso and Isolone—are localised. In the following section, the soils and additives used will be presented.

Each soil was dried and passed through an 850 μm sieve. From the soil Tassone, two particle size distributions were artificially created to investigate the influence of particle size distribution (finer or coarser) on the behaviour of the mixture. These two artificial gradings (Tassone Artificial Coarse and Tassone Artificial Fine) were obtained by separating the soil Tassone into its constituent particle size ranges and creating the artificial gradings by mixing soil from different sieve intervals in the proportion required for a specific coarser or finer grading; the resulting two particle size distributions were then checked through a further particle size analysis. Particle size distributions of the collected and artificial soils are shown in

Figure 4.

Gradings of

Figure 4 belong to the typical grading range for the Po River embankments damaged by animal burrowing [

2]. In

Table 1, particle size ranges are listed according to the British System BS 5930 classification system.

Atterberg limits were determined on the 425 μm passing soil using standard procedures (British System BS 1377-2 for liquid and plastic limits) and the results are shown in

Table 2.

The tested soils can be classified according to the plasticity chart BS 1377-2 and the BS 5930 descriptive terms, as follows: Caorso and Isolone are classified as low plasticity silt (ML); Chiavica Rossi and Tassone are classified as low plasticity clays (CL), while Tassone Artificial Fine can be considered as a clay of intermediate plasticity (CI).

X-ray powder diffraction (XRD) mineralogy analyses [

22] were carried out on the 850 μm passing collected dried soils at the Chemistry for Technologies Laboratory of the University of Brescia, Brescia, Italy, using the PANalytical XPert Pro MPD Diffractometer. Results are shown in

Figure 5. The phase composition of the principal elements, spectrum, and peaks highlighted the presence of more than 35% alpha-quartz, followed by calcite. Then, each of the four soils features modest quantities (or none) of albite, alunogen, kaolinite, dolomite, magnetite, ortoclasio, lizardite, titanite, butlerite, and amorphous. Results showed the absence of zeolites, minerals that can interfere with pozzolanic reactions, which are necessary for soil improvement.

In order to define the soil-lime proportion for soil improvement, the mixtures were created using the results of Initial Consumption of Lime tests (ASTM D6276-19 [

23]) presented in Nocilla et al. (2022) [

2] on the same original soils (e.g., Tassone and Chiavica Rossi). Authors [

2] highlighted that, for these soils, lime consumption is quite fast; after one hour, pH values are greater than the reference percentage for stabilizing the soils (i.e., pH = 12.4), regardless of the lime percentage, and an asymptotic value can be reached for all mixes featuring 5% of lime by dry weight, with no further improvement for greater percentages. Then, 5% of hydrated lime ((calcium hydroxide Ca(OH)

2), Kalkwasser, supplied by GroTech company was added for the lime-treated mixtures of the present study. Bell (1993) [

21] highlighted the amount of cement to add to cement/soil mixtures, suggesting that cement contents may range from 3% to 16% by dry weight of soil, depending on the type of soil and the improvement required. According to the literature [

21,

24], if soils are classified as CL or ML (low-plasticity clay or silt), the typical range of cement required is between 8% and 13%, with 10% considered optimal for moisture–density tests. For the purpose of this research, 10% by dry weight of soil was chosen as the percentage to add to cement/soil mixtures.

For the intervention, mixtures must be injected into the hole with site machines, and the proposed mixtures must show adequate viscosity with the lowest possible amount of water in order to keep the potential shrinkage within compatible values. Therefore, for some of the tested mixtures, a super-plasticizing sulphonated naphthalene admixture was added in order to investigate its influence on the resulting viscosity and shrinkage once the soil, cement, or lime percentage and amount of water are set. Mapefluid N200 (manufactured by Mapei, Milan, Italy) is the commercial fluid product that was used. The suggested quantities vary between 1% and 1.5% of the dry weight of soil.

Injections of the soil-treated mixtures must guarantee hydraulic and mechanical continuity with the existing embankment and a reduction of shrinkage phenomena that may occur frequently with cement–bentonite grout mixtures. The sustainable product Expancrete by Mapei was used. Expancrete is an expansive white powder admixture for controlled-shrinkage concrete. Hence, percentages between 5% and 8% by dry weight of the tested soils were considered. It is expected that there will be expansive potential within the first two days in a wet environment.

Each mixture of soil, along with the treatment powder (lime or cement) and additives, was carefully mixed, adding distilled water in a controlled amount. In detail, three amounts of water were used according to the water content at the liquid limit (wL) of the soil being considered. Hence, mixtures were featured at 1.5 wL, 2 wL, and/or 2.5 wL.

For the purposes of this research, 45 flowable mixtures were created by mixing the four natural collected soils—or the two artificial ones derived by Tassone—plus water and lime (5%) or cement (10%) and, eventually, the super-plasticising (1% or 1.5%) and/or expansive additives (5%, 8%). Mixtures were obtained by treating the dry raw material with the amount of chosen water (1.5 wL, 2 wL, and/or 2.5 wL) and a dry powder of hydrated lime or cement in the set proportion. Furthermore, additives such as super-plasticising admixtures and/or expansive admixtures for controlled shrinkage were added as requested by each recipe.

3. Methods

The experimental programme was carried out on 45 mixtures. The experimental programme included viscosity analyses by means of the Marsh cone test and volume measurements (i.e., shrinkage test) over a period of about 21 days. Five different methods, including 3D scanning (carried out at the commercial laboratory Opto 3 (Rezzato (BS), Italy), were used to measure volumes. Strength after seven days of curing was qualitatively measured using a pocket penetrometer, while erosion susceptibility was measured through immersion tests (crumb test) after various days of curing. The aim of the crumb test method is to give a qualitative assessment of the disaggregating shape of a dry soil specimen immersed in water as a function of time (10 s, 10 min, 1 h, 24 h, 8 days), and after a disturbance (8 days plus wave). To achieve this, all soil specimens, which had been left to dry for varying numbers of days (i.e., days before immersion), were placed in a large container of water and monitored using a digital camera.

Table 3 presents the mixtures and provides details on the tests carried out on each, including the Marsh cone test, shrinkage test, measurement of strength 7 days after its realisation using a pocket penetrometer, number of days the specimen was left to dry before immersion during the crumb test, and measurement of strength after the crumb test (for intact samples only).

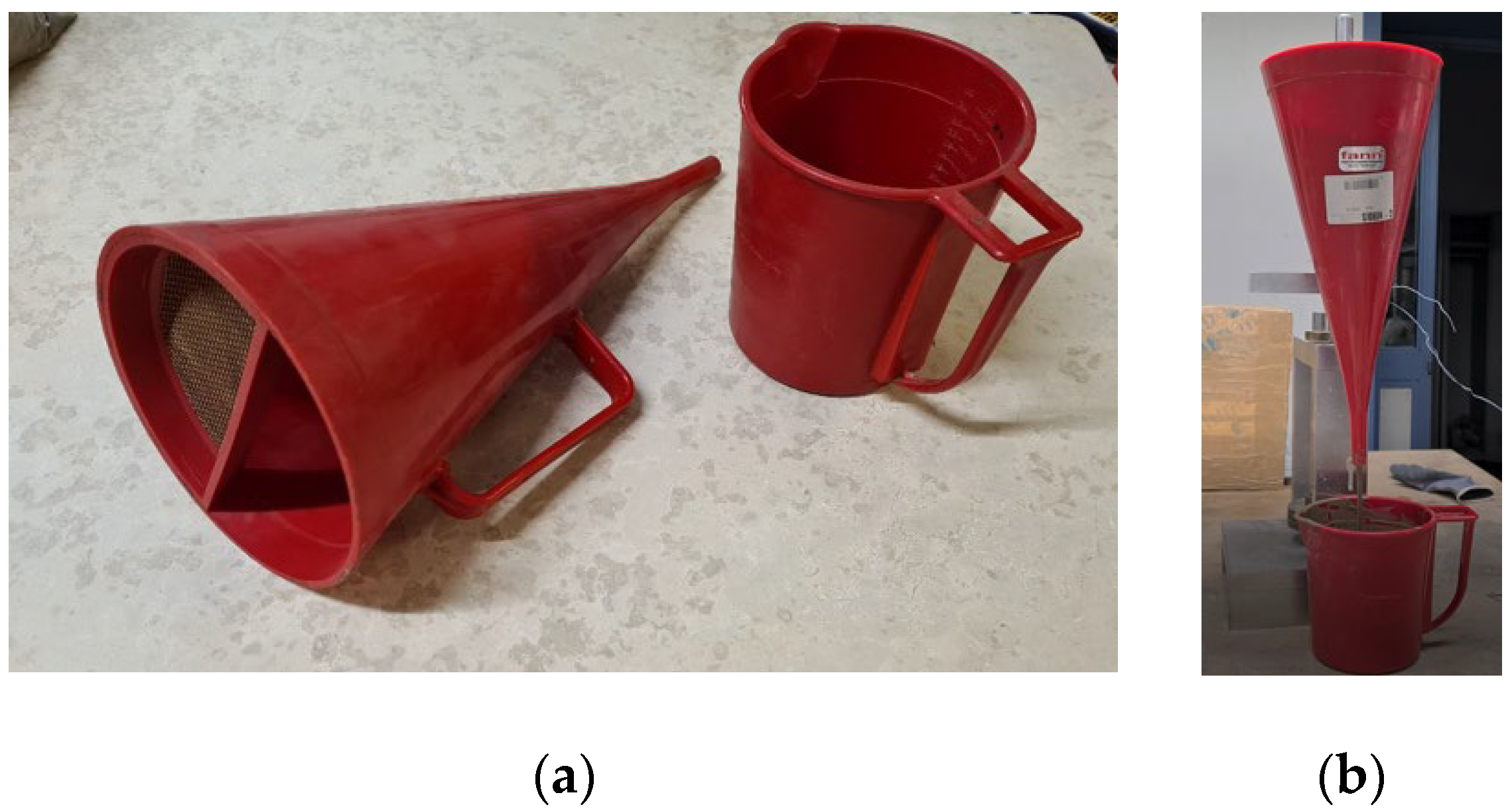

Hence, once the required amount of dry soil, lime, or cement, water, and additives was mixed, the flowability of the mixture was estimated using the Marsh cone test. In

Figure 6, the Marsh cone test tools (

Figure 6a) and procedure (

Figure 6b) are shown. The procedure consists of passing a volume of the fresh mixture through the 4.75 mm test nozzle and recording the time that it takes to pass 1000 mL. For standard site machines, times between 35″ and 55″ are recommended, although times up to 120″ or 240″ can still be considered still as optimal or acceptable, respectively.

In

Figure 7, the non-standard procedure of the shrinkage test carried out on each mixture is shown. The mixture was poured into the Plexiglas cylinder up to a height of approximately 6 cm. A filter paper was then gently placed on top. A porous stone and a sheet of filter paper were at the bottom of the cylinder to allow for drainage (see

Figure 7a). Measurements of the cylinder’s cross-sectional diameters (

Figure 7b) and the initial height were taken. As shown in

Figure 7c, after approximately 48 h, the cylinder was pulled out, and the material stuck at the surface was weighed and taken into account in the volume and weight calculations. Tests ran for approximately 21 days (

Figure 7d). The tests were conducted at the geotechnical laboratory of the University of Brescia, where the temperature is maintained at around 20 degrees. After the mixture slurries were prepared, they were immediately poured into the cylinder. Small temperature and humidity fluctuations can have an influence on the shrinkage rate; however, a final water content check after 21 days ensured that a dry condition was achieved for all specimens. Five methods were used to estimate the volume [

22].

Method 1 only measured heights. Method 4 measured both diameters and heights. Both methods were carried out using a digital caliper (see

Figure 8a,b).

Method 2 and Method 3 are based on a combination of takeovers—photographs (

Figure 9) taken in two orthogonal directions after 48 h, 72 h, 7 days, and 21 days—and caliper measurements (at the beginning and the end) on the released sample. Photographs were then used to estimate measurements using AutoCAD (version 23.1, Autodesk Inc., San Francisco, CA, USA).

The two methods differ in their assumption of the shape of the cross-sectional area of the cylinder; Method 2 assumes a rectangular trapezoid, while Method 3 assumes a scalene trapezoid 3. These shapes are highlighted in

Figure 10a,b.

Method 5, as seen in

Figure 11, was carried out at the OPTO3 private company. It is based on a 3D measurement of the volume that was conducted using triangulation measurements taken with an optical scanner. Measurements were carried out when the sample was pulled out after 48 h, 72 h, 7 days, and 21 days. Volumetric strains were determined taking into account the uncertainty of each method [

22] which is influenced by the uncertainty of the measurement instruments. All methods were correlated to the most accurate (Method 5). Method 5 was considered the most accurate, even though the uncertainty of the optical scanner (±0.03 mm) is larger than that of the caliper’s (±0.02) because the optical scanner method considers all the irregularities of the solid, whereas the other methods assume the volume to be a cylinder or a truncated cone. Details of this analysis are reported in a technical report from the University of Brescia [

22].

In

Figure 12, the qualitative tests carried out with the pocket penetrometer on Caorso soil samples were shown. The tests were carried out on the seventh day of the shrinkage test on four samples (

Table 3) featuring, approximately, the same amount of water except for the third sample, which was a cement and bentonite sample (no soil) with a very high amount of water (as standardized in situ, w = 340%). The three soil samples were improved with lime, cement, or nothing. Super-plasticising sulphonated naphthalene admixture was added. Of course, it was added to all of the soil mixtures to maintain similar conditions.

After the shrinkage tests, as reported in

Table 3, indicating the days before immersion, all 45 samples were dipped in water according to the crumb test. In

Figure 13, three examples were shown at five different times during which the water was stationary (10 s, 10 min, 1 h, 24 h, 8 days). The last row of pictures in

Figure 13 refers to a time after the application of a wave. The three examples in the

Figure 13 (samples 8, 42, and 43) refer to the three different final states of the sample after the crumb test: destroyed, broken into pieces, and intact, respectively.

4. Results

Volumetric strains (ΔV/V

0) and times of the Marsh cone test are reported in

Table 4.

It is clear that viscosity—which must be low in order for the mixture to flow into the hole with site machines—and the volumetric strains that might occur are inversely proportional variables; indeed, low viscosity corresponds to high water content, resulting in reduced times for the marsh cone test and high volumetric strains. Therefore, a compromise is necessary and will be discussed later.

However, it is important to highlight that the cement/bentonite sample (44), although its appreciable to Marsh cone time (33″), it shows a volumetric strain that is much larger than the other samples (i.e., 0.647).

The results of the pocket penetrometer tests are reported in

Table 5.

It seems that lime treatment is more effective in terms of improving mechanical features when compared to the cement–soil mixture. In any case, both cement and lime treatments (i.e., samples 36 and 38, respectively) improve resistance when compared to the untreated mixture sample (i.e., 45). As expected, for sample 39 the qualitative resistance measured in the cement–bentonite sample noticeably increased.

For the crumb test, 23 samples were destroyed, 9 samples were broken into pieces, and 13 samples remained intact. No trend is clearly detectable. It would seem that samples made of coarser soils and lime mostly remained intact. The procedure needs to be standardized (days after the shrinkage test) before a more reliable comparison can be made.

5. Discussion

For the optimal operating mixture, searching for the best compromise between the two required features (low viscosity and low volumetric strain), data from all mixtures were analyzed. For standard site machines, as already mentioned, times at the Marsh cone test up to 120″ can be considered ideal. However, there is still the possibility of injecting, with some commercial site machines, mixtures with a Marsh cone test time of less than 240″ that can still be considered acceptable; longer times are not acceptable because they are characterized by an unacceptable viscosity.

To make a satisfactory judgment, boundary conditions were first set. In

Table 6 and

Table 7, these boundary conditions were set for the volumetric strain and the time at the marsh cone test, respectively.

Therefore, to assess the quality of any mixture of

Table 4, the flowchart of

Figure 13 can be proposed. According to the results of the marsh cone test and the volumetric strain values, three main behaviours for each mixture can be assessed: good, middling, and bad. “Good behaviour” is characterized by a suitable compromise between viscosity, which must be adequate to allow the mixture to be injected into the hole with on-site machines, and the lowest compatible volumetric strain. “Middling behaviour” describes mixtures that, even if they have good viscosity, still exhibit a relatively high volumetric strain. “Bad behaviour” refers to mixtures that, even if the volumetric strain is kept at a minimum, have a viscosity that makes the mixture unsuitable for injection using on-site machines.

Following the flowchart in

Figure 14, after adding the data for each mixture (featured by its final volumetric strain, its initial water content and its behaviour after the crumb test) the abacus in

Figure 15 can be drawn accordingly. Any point on the abacus corresponds to a mixture, represented by its coordinates (i.e., initial water content and volumetric strain). Interestingly, it is possible to observe that all behaviours of the mixtures judged as “GOOD” lie mainly in the green area. While no clear trend was detected, the crumb test results suggested the persistence of intact samples in the green area. Nevertheless, to assess the quality of the mixture using crumb test results, it is crucial to standardize the tests and ensure that the number of tests is statistically significant in each area.

6. Conclusions

In summary, the research found that although cement treatment reduces volumetric strain, it also increases the viscosity of the mixture compared to lime treatment, making lime treatment a preferred option. The flowable injection of these treated soils (with either lime or cement) must strike a balance between viscosity, which must be low enough to allow the mixture to flow into the hole with site machines, and accounting for any potential shrinkage over time according to the hole boundary conditions, which can be consistent if high water contents are added to the mixtures. The paper aimed to find the best compromise between viscosity and shrinkage characteristics through a graphical representation (abacus). Based on the abacus built with the results, a judgment on the best mixtures made with the four soils belonging to the typical grading range for the Po River embankments damaged by animal burrowing and treated with lime or cement is proposed. The behaviour of the mixtures was divided into three categories corresponding to three different areas in the abacus. “Good behaviour” is characterized by the best compromise between viscosity and the lowest compatible volumetric strain. “Middling behaviour” describes mixtures that, even if with good viscosity, still exhibit a relatively high volumetric strain. “Bad behaviour” refers to mixtures that, even with low volumetric strain, have a viscosity that makes the mixture unsuitable for injection. Analysing mixtures that fall in the green area, it was possible to identify some common characteristics: the “good behaviour” is featured by a water content of 2 WL (i.e., two times the water content at the liquid limit for that particular soil), an amount of the expansive additive of 5%, and super-plasticizer added at a rate of 1%. Therefore, this recipe is considered to be the best compromise that was researched.