1. Introduction

The discrete element method (DEM) has progressed as an analytical tool for various bulk materials in diverse industries, such as mining, pharmaceutical, and food. In the mining industry, DEM has been widely used to model all types of machines [

1], such as SAG mills [

2], vibrating screens [

3], cone crushers [

4], gyratory crushers [

5], and jaw crushers [

6], in order to provide information about the design, optimization, and operation of these types of equipment. The ore, from run-of-mine, has an irregular shape and a broad particle size distribution prior to the comminution process. Because of this, it is almost impossible to model the exact shape and size of each particle. Furthermore, the calibration of contact parameters of these irregular-shaped particles cannot be accurately measured through experimental methods [

7]. Therefore, a better calibration of parameters is required to improve the prediction of these numerical models [

8].

In total, two general approaches are used in the calibration: direct measurement (DMA) and bulk calibration (BCA) [

9]. Density calibration will be used as an example to differentiate both approaches. With direct measurement, the material density of a sample of particles would be measured individually, and a representative value (mean) would be used in the model without considering the modeled particle shape that will affect the porosity of the simulated particles. Instead, in bulk calibration, a sample is chosen, and the bulk density of the entire sample is measured. With these data and with a defined particle shape and size distribution, the material density is adjusted in the DEM model to achieve the same bulk density.

In DEM models, the parameters usually calibrated are particle shape, particle size distribution, coefficient of restitution, contact stiffness, particle density, friction coefficients (between particles and particle-boundary), and rolling resistance, among others [

10], as is presented in

Table 1. For different calibration parameters, researchers have established several methods to optimize this process, such as the design of experiment, neural network method based on Latin hypercube sampling, and artificial neural network method [

7]. Rackl and Hanley [

11] presented a methodical calibration approach based on Latin hypercube sampling and Kriging implemented in LIGGGHTS and GNU Octave. Particle density, friction coefficients, and Young modulus were calibrated in function of repose and bulk density tests. Zhou et al. [

12] established a radial basis function neural network to calibrate particle density, sliding frictions, coefficients of restitution, and Poisson’s ratio regarding the angle of repose and bulk density using the EDEM commercial software. Westbrink et al. [

13] proposed a novel approach for DEM calibration with a parameter optimization based on multi-objective reinforcement learning. Richter et al. [

14] showed a new modular algorithm called generalized surrogate modeling-based calibration. Using surrogate models and the Draw Down Test, the friction coefficients of a DEM model with spherical particles are calibrated. Boikov et al. [

15] presented a universal calibration approach by conducting full-scale symmetrical experiments in a DEM simulation in Rocky DEM. The friction coefficient and restitution coefficients were calibrated using computer vision and an iterative calculation.

Degrassi et al. [

16] performed a parameter calibration using Rocky DEM and a proprietary algorithm to optimize. The DEM model of the same test was compared with experimental data of angles of repose. The simulations were conducted using spherical particles, and the Hysteretic Linear Spring contact model. Nasato et al. [

17] used artificial neural networks to calibrate static and rolling friction in function of the dynamic angle of repose and void fraction. Richter and Will [

18] described a new method called metamodel-based Global Calibration. The metamodel was trained with data from several hundred simulation runs and can predict simulation responses based on a given parameter set with very high accuracy. In addition, commercial codes such as EDEM and Rocky DEM perform their calibration procedure with preconfigured simulations and post-processing scripts.

The selection of particle shape is between two main options: spherical and non-spherical particles. Spheres are used from the beginning of the formulation of DEM, and the main advantage is the simplicity and low computational cost [

19]. In this approach, rolling resistance is used to numerically provide non-sphericity to the particles [

20]. Moreover, despite the significant simplification in their geometric representation, spherical particles can achieve results close to the experimental ones [

20,

21]. An alternative to spheres is to use multi-spherical particles, which are clustered-spherical-particle that represent more complex shapes. Although the multi-sphere method represents advancement compared to the use of simple spherical bodies for approximating complex three-dimensional shapes, it is a method based on estimations that may introduce new errors itself at least on the single grain level [

22]. Nevertheless, researchers state that it is necessary to simulate with non-spherical particles and can represent various particle types in granular matters [

23,

24,

25,

26]. In mining applications, bucket–-soil interaction [

24], grinding mills [

27], bucket filling for a mining rope shovel [

26], hopper [

28], cyclone [

29], cone crusher [

4], and gyratory crusher [

5] were modeled with polyhedral particles. Mathematically, spherical particles are characterized only by their size (one parameter), and polyhedral particles can be represented by their size and four geometrical parameters. Polyhedral particles, therefore, add more parameters to the calibration.

There are several alternatives available to calibrate the coefficient of friction between particles (sliding and rolling) [

30]. The most common and straightforward is measurement of the angle of repose. The disadvantage of this test is that it relates a single parameter (angle of repose) with at least two variables (friction coefficients). This means that there will then be more than one solution to the mathematical problem. Roessler et al. [

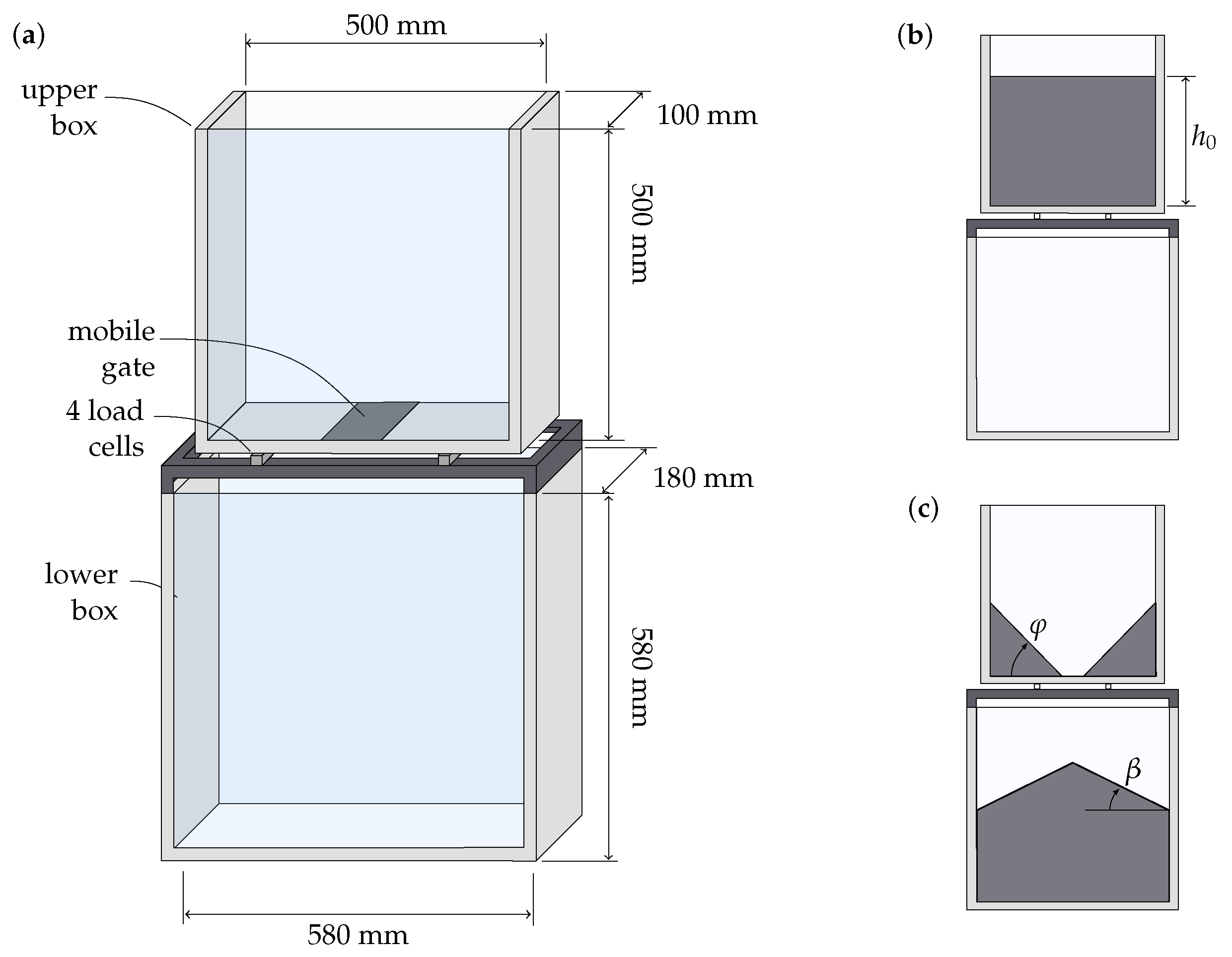

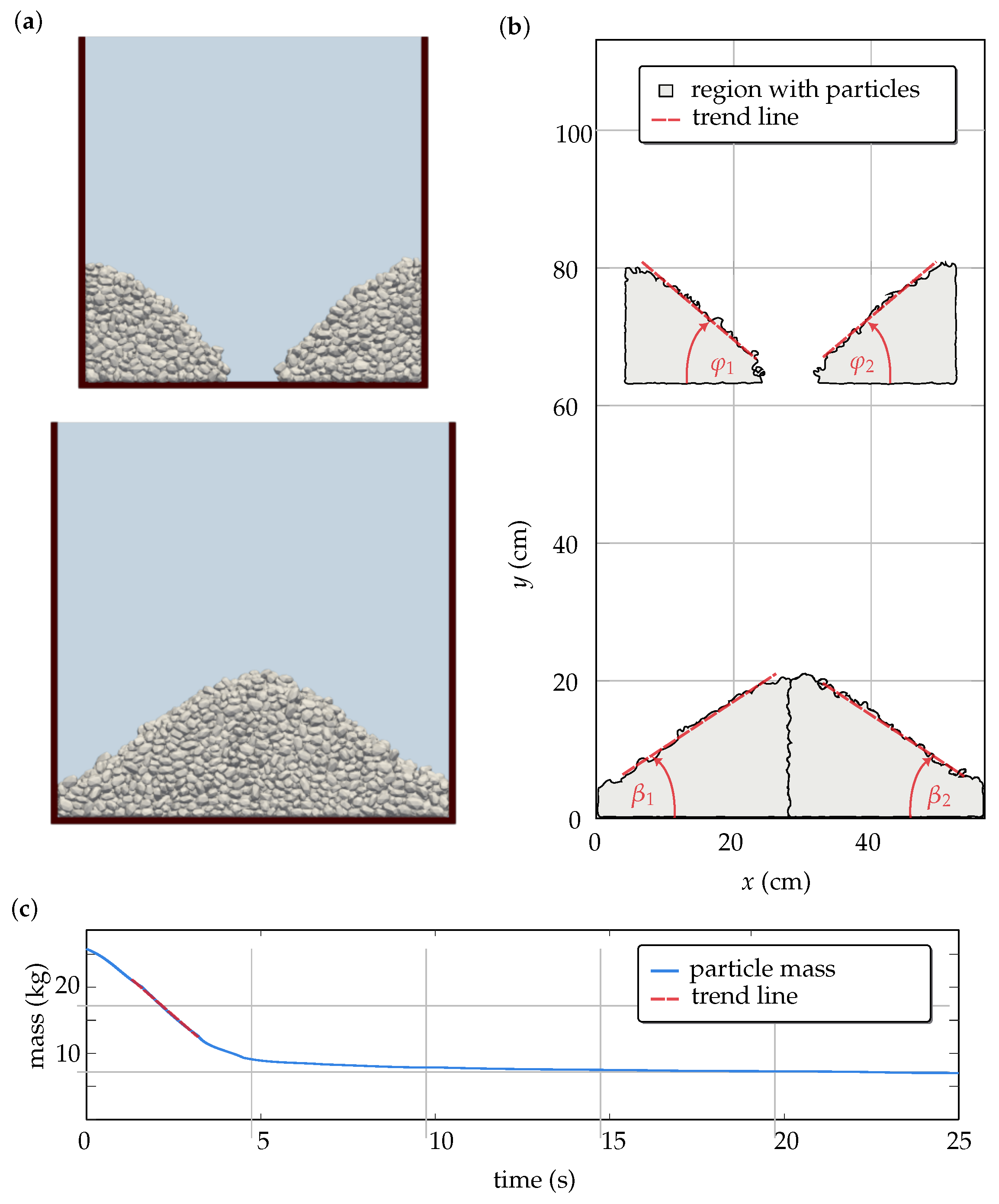

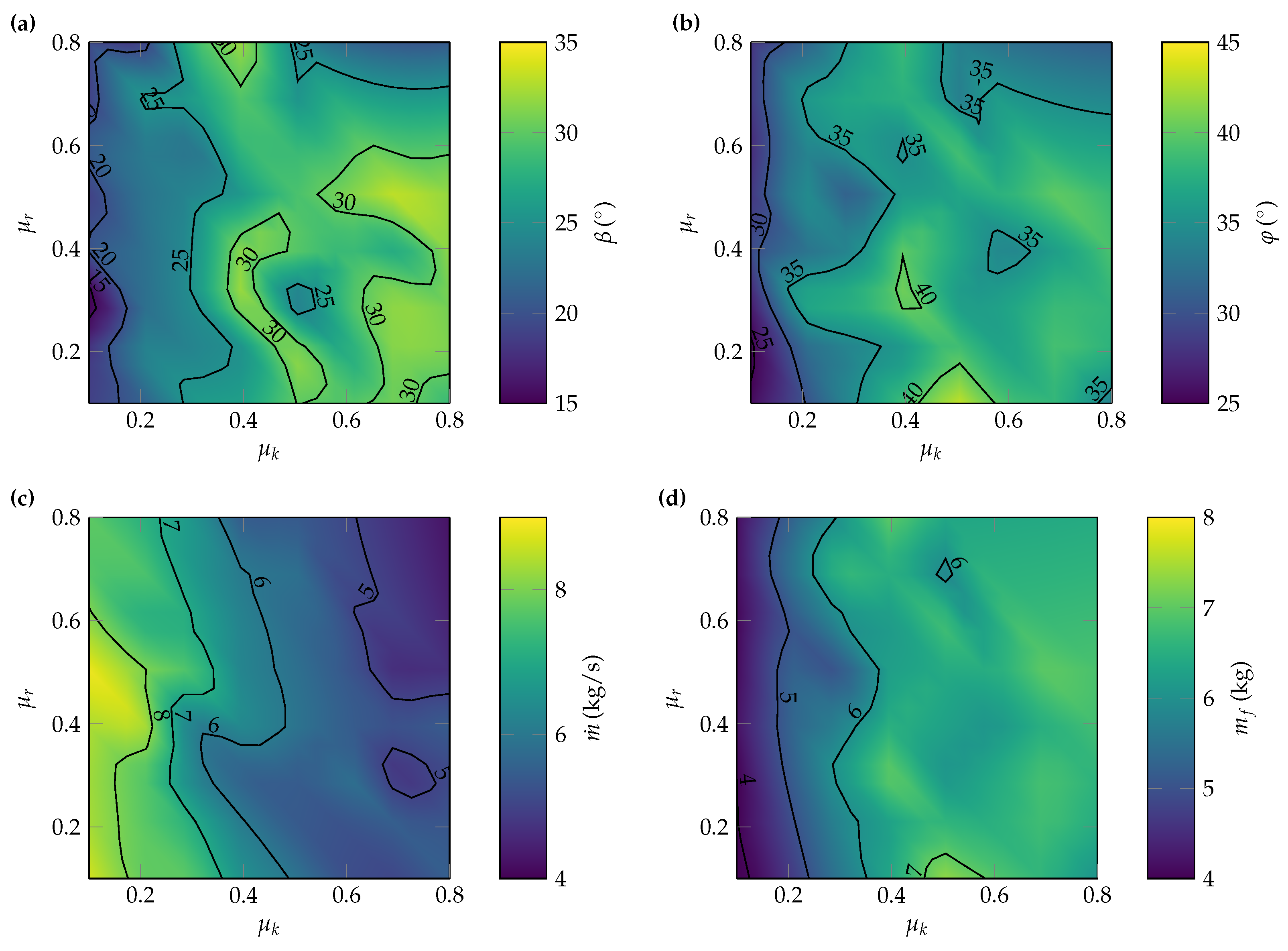

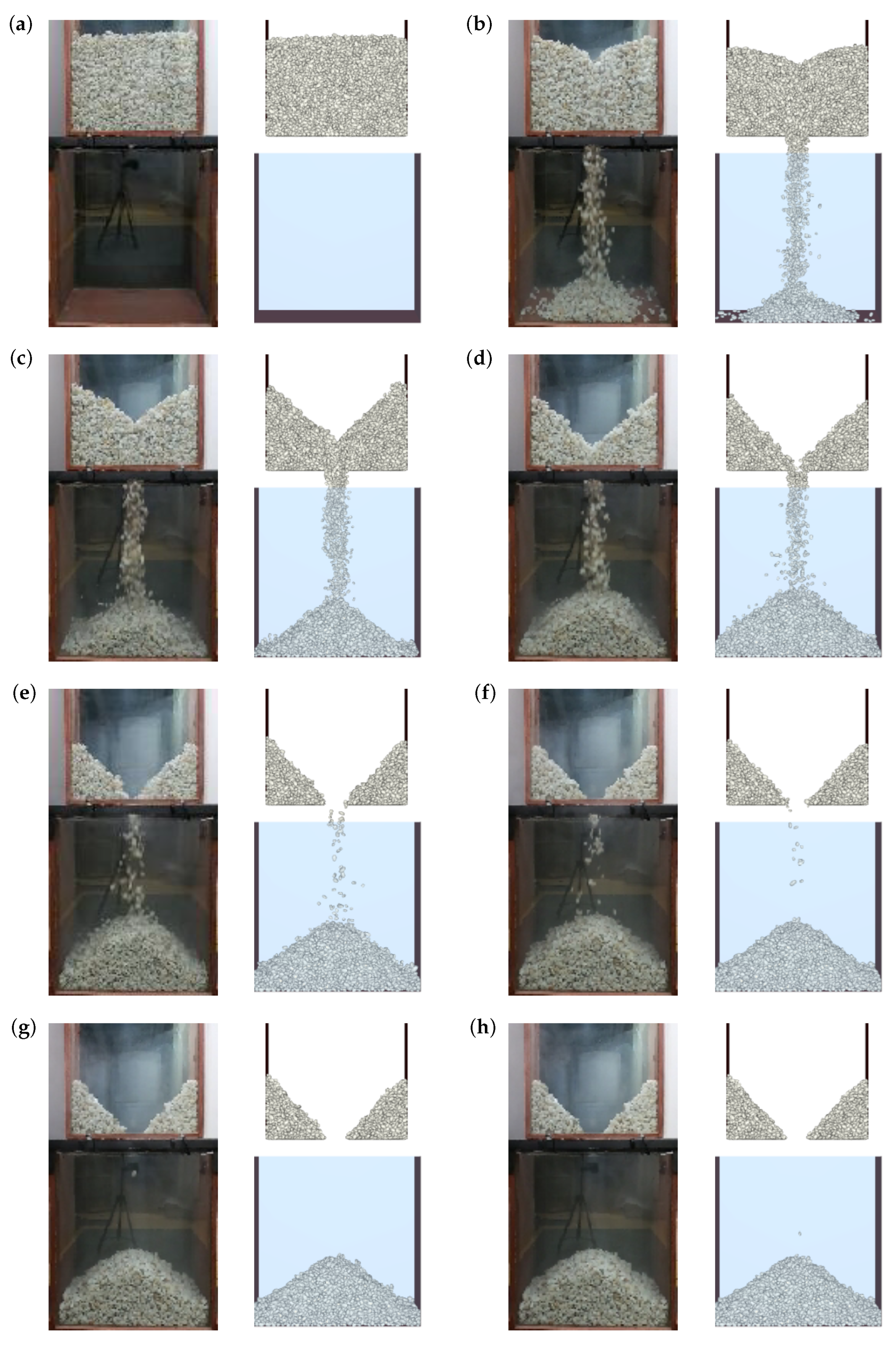

31] proposed an experimental test called Draw Down Test (DDT), which through a single experiment, allows four experimental results to be obtained: angle of repose, shear angle, mass flow rate, and final mass, which are directly contrasted with results of the DEM model. Adjusting the coefficients of friction between particles makes it possible to find a set of parameters that predicts the experimental results and avoids calibration ambiguity.

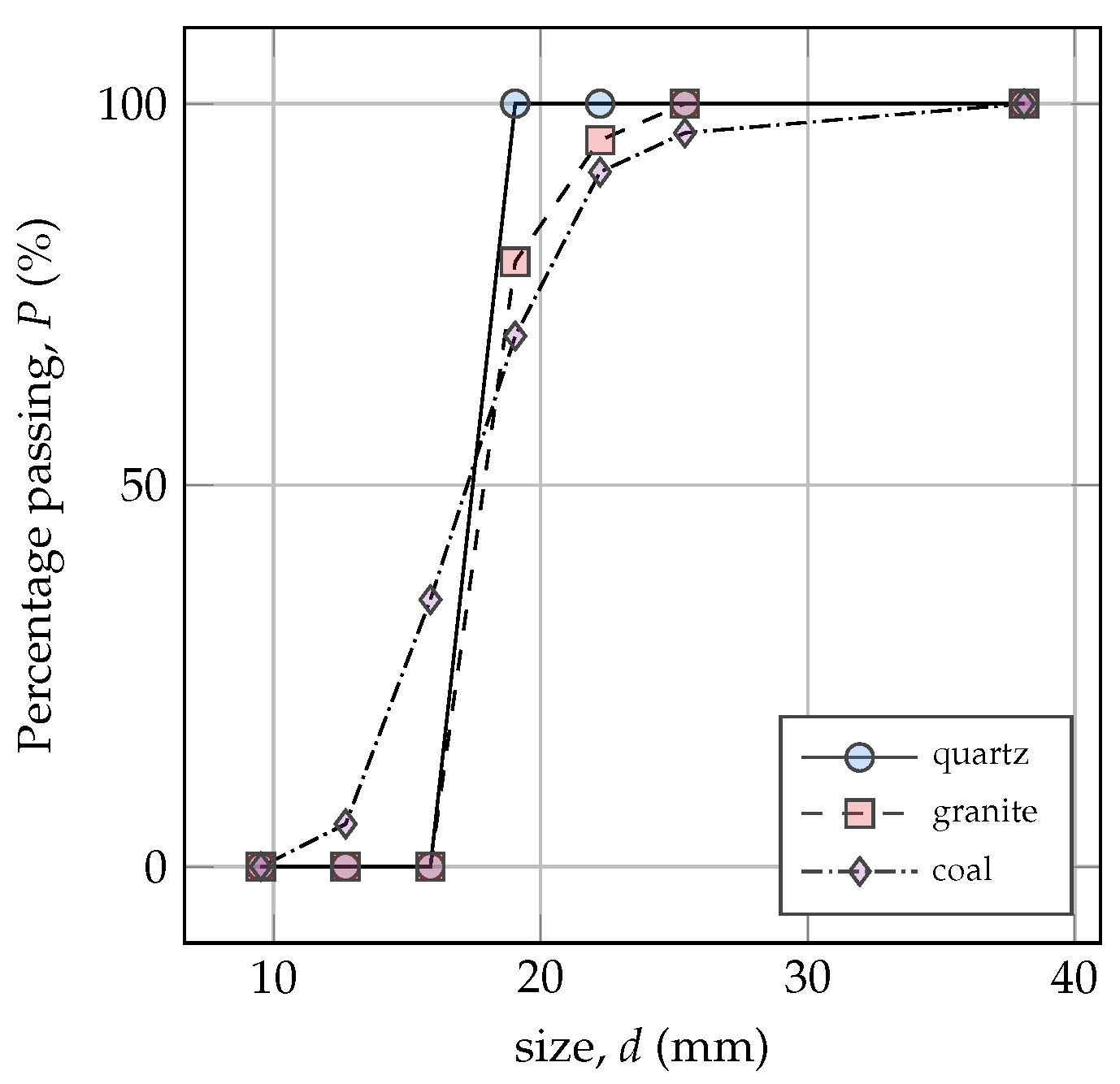

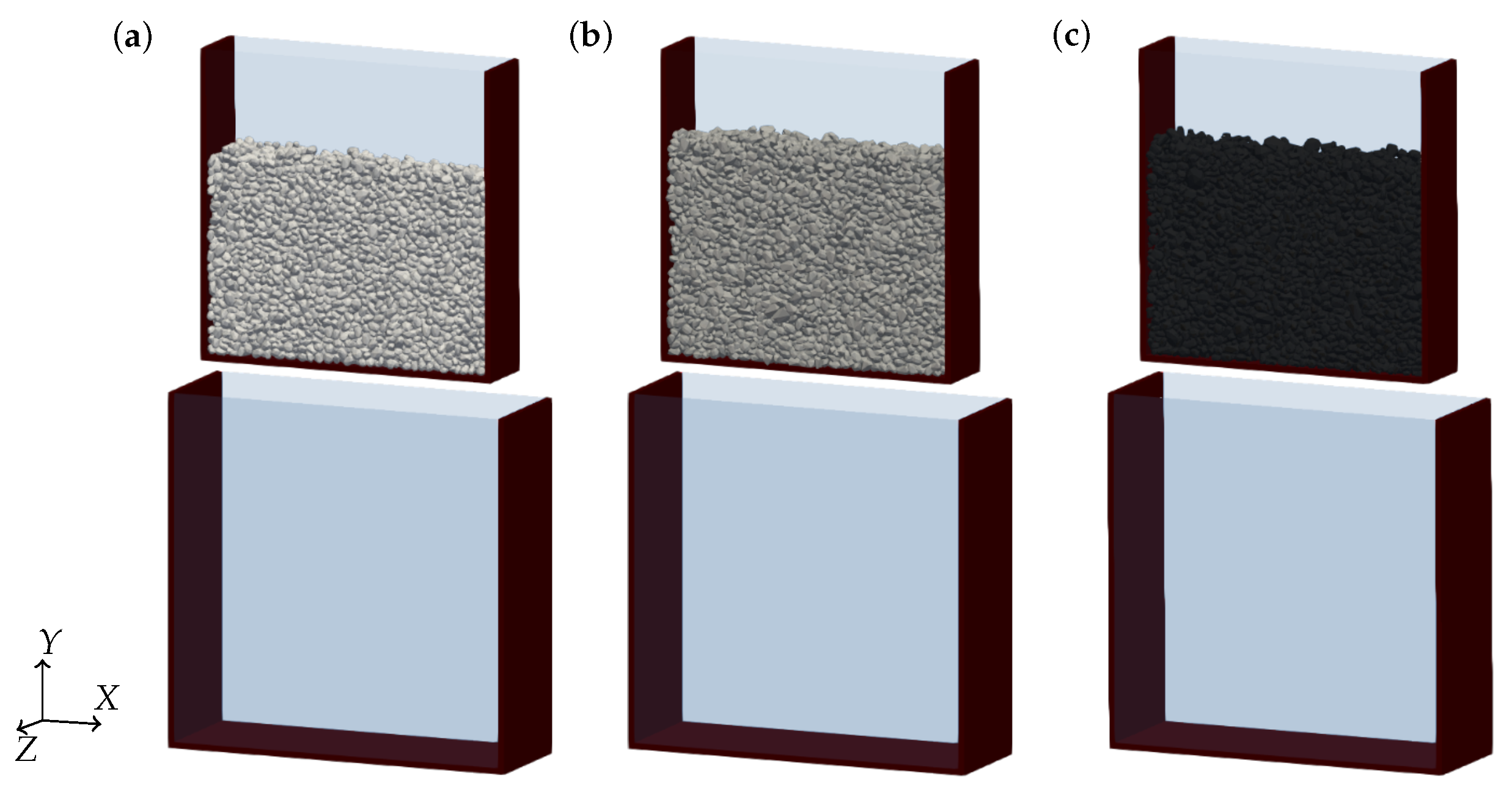

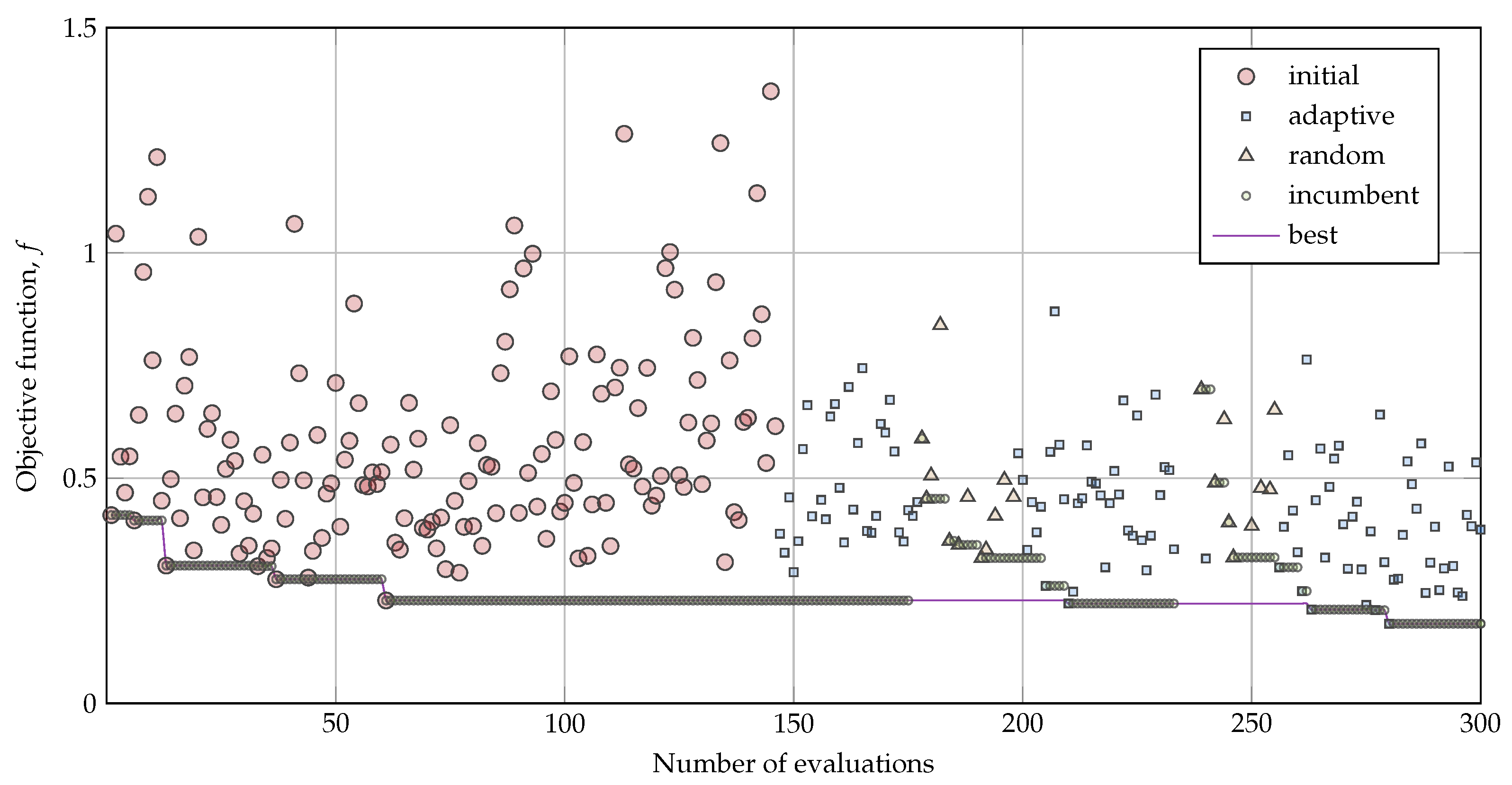

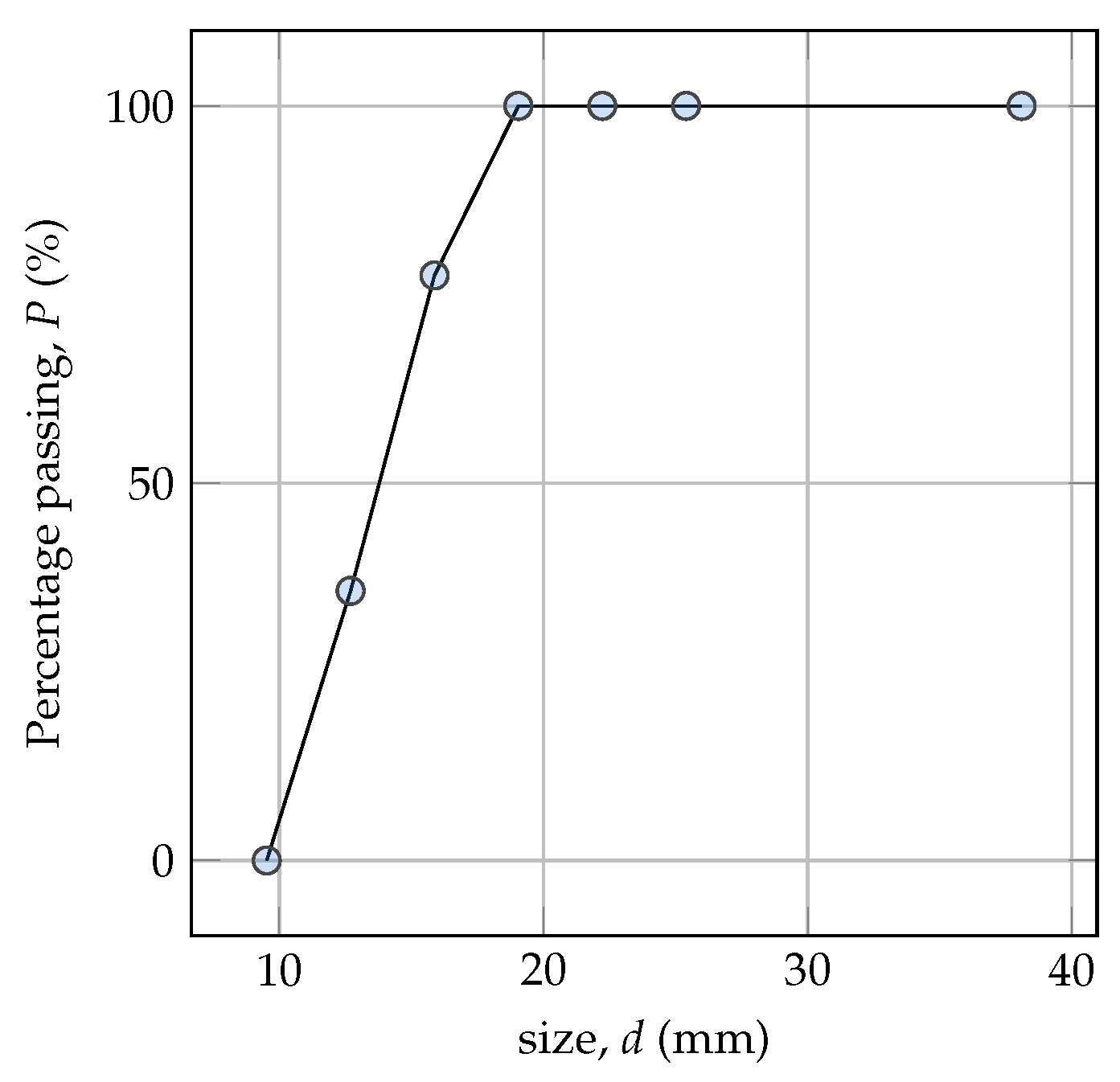

In this work, the contact parameters of three materials are calibrated for use in DEM models with non-cohesive spherical and polyhedral particles using a combination of BCA and DMA, with the aim of comparing the influence of shape on the calibration of the coefficient of friction. The DEM simulations are performed using Rocky DEM software to calibrate the friction coefficients as a function of the angle of repose, shear angle, mass flow rate, and final mass for each material with experimental data of Draw Down Tests. Experimental tests are performed to measure the particle shape directly, coefficients of restitution, and friction coefficient between particles and boundaries. The search for the combination of parameters is an optimization problem where the objective function is computationally expensive. Consequently, the number of iterations must be kept under control. In order to deal with the task, a surrogate model with radial basis functions is utilized. The influence of particle shape is studied, comparing the calibrated parameters: static coefficient of friction, dynamic coefficient of friction, and rolling friction, with spherical and polyhedral particles.

4. Conclusions

A better fit in friction coefficients, regarding the results of a Draw Down Test, can be obtained using more complex particle shapes, as tested with quartz, granite, and coal ore modeled with 4-polyhedral particles, 2-polyhedral particles, and spherical particles. The difference in WMSE in the calibration between spherical and polyhedral particles is considerable, and the calibrated coefficients of friction change between different particle shapes. As a result, all ore samples selected are completely characterized for use in a DEM model.

The combination of bulk calibration and direct measurement of material parameters in sample models presents a viable alternative to perform, and allows for improvements in the prediction of DEM models. Optimization using a surrogate function is helpful for optimization problems where the objective function is expensive, such as in the simulations presented.

Regardless of the best fit of polyhedral particles, computation time must be considered when choosing the particle shape. For instance, in the DEM simulations analyzed, calculations with spheres occurred 24-times faster than polyhedra. Considering particle shape, calibration, and computation time, recommendations include:

Spherical particles present the best alternative in scenarios where modeling the particle shape is not required, and it is necessary to reduce simulation times while ensuring calibration is still performed thoroughly.

Polyhedral particles are suggested when the particle shape is essential, and precision is required in calculations. Furthermore, some DEM breakage models only work with polyhedral particles, as in the case of breakage models of the software Rocky DEM. A particle replacement model with polyhedral particles can conserve mass and volume, whereas, this is not possible with spherical particles.

Overall, a method is proposed to study less expensive optimization methods for polyhedral particles. The simulations performed with polyhedral particles incurred high computational cost, so the use of polyhedral particles might be excluded in several applications due to the expenses associated with calibration. However, its good behavior demonstrated by the model makes it pertinent to examine less expensive calibration procedures. A viable approach is through a previous calibration of spherical particles that delivers initial values of the parameters. In addition, as each application case presents a different distribution of size and shape, it is a complex process to unify a calibration method for all possible applications.