A Methodology Combining IDEF0 and Weighted Risk Factor Analysis for the Strategic Planning of Mine Reclamation

Abstract

1. Introduction

- (a)

- Geoenvironmental problems related to soil disturbance, landscape fragmentation, alterations of landforms, instability of slopes, degradation of ecosystems, biodiversity loss, water toxicity, loss of fertile soils, and, in general, any other impacts or consequences to the natural environment due to intensive extracting operations;

- (b)

- Socioeconomic problems related to the impacts on the communities because of the transformation of a mine from a heavily industrialized plant to a sustainable and new land use system. The most common consequences of these problems are unemployment, income losses, social conflicts, disputes among stakeholders, permitting delays, social disruptions, and any other impacts affecting the local economy and production, the quality of life, and the livelihood of the affected populations.

2. Strategic Planning: Overview and Research Questions

- -

- Understanding the public policies and legislative/regulatory constraints;

- -

- Identification of the reclamation project business processes and their functionality;

- -

- -

- Analysis of the alterations in morphology;

- -

- Investigation of soil and water quality;

- -

- Understanding of the geoenvironmental and geotechnical problems;

- -

- Selection of methods for improvement of soil and waste dumps;

- -

- Identification of methods for recycling excavated soil wastes and ore residuals;

- -

- Assessment of socioeconomic impacts;

- -

- Delineation of the new/improved land use system;

- -

- Elaboration of engineering solutions and site specifications;

- -

- Selection of the optimal reclamation methods that support the development of the new land use system proposed for the project concerned;

- -

- Effective stakeholder engagement;

- -

- Obtaining reclamation permits and site development licenses;

- -

- Consideration of the specific project’s bankability and funding requirements.

- (a)

- How can the strategic planning of an extended and long-term reclamation project be analyzed and structured with content-specific functional elements?

- (b)

- What are the fundamental strategic processes by which a reclamation project can be structured as an integrated and multidisciplinary business model consisting of specific technical and administrative activities?

- (c)

- Which tool(s)/method(s) are suitable for the analysis, design, and implementation of the reclamation project processes?

- (d)

- Which risk analysis method is recommended for the effective, qualitative, and quantitative assessment of reclamation planning risks?

- (e)

- How can the experts’ knowledge and insight support the response to the previous questions?

3. Materials and Methods

3.1. Suggested Methodology

- (a)

- The reclamation projects consist of tasks with technical and business content specific to the geoenvironmental and socioeconomic problems. Thus, the project’s strategic planning can be performed using a business process modelling technique. In this paper, the IDEF0 technique was adopted as the most suitable tool [59];

- (b)

- The assessment of reclamation risks (identification, probability, impact analysis, response development; see also: [55,60]) is crucial for the successful organization, development, and execution of reclamation projects. The earlier and proactive assessment of risks, the time needed and cost overruns is required later on in the execution of reclamation activities. Weighted Risk Factor (WRF) analysis was adopted as a tool for combining theoretical and practical purposes of risk management in project environments [61]. The relative weight of each risk factor was evaluated using the Analytical Hierarchy Process (AHP) method;

- (c)

- The strategic planning and the risk assessment of any project is a group effort. For this reason, the contribution of experts is indispensable and particularly valuable. For example, a team of experts can provide valuable support in developing the IDEF0 model design and validating the AHP application, evaluating reclamation risk likelihoods and impacts, and the response planning.

3.2. Validation of Applied Techniques

3.2.1. The IDEF0 Process Modelling Technique

3.2.2. The Weighted Risk Factor Analysis

- Step 1: identification of risks and risk dependencies with the IDEF0 model activities;

- Step 2: definitions:

- (a)

- is the number of risk sources; ;

- (b)

- m is the number of risks; (: the set of natural numbers).

- Step 3: identification of the weighted risk factors Wi, where and , with an effect on the project objectives, using the AHP method;

- Step 4: composition of the likelihood and impact severity, or risk exposure, matrix;

- Step 5: identification of the priority weight, , of each risk factor with an effect on the project, where

- Step 6: computation of the Composite Likelihood Factor of risk j, , (Equation (2)), as a weighted average (using the formula of the expected value):where are the likelihoods corresponding to risk sources;

- 7.

- Step 7: computation of the Composite Impact Factor of the risk , , as a weighted average (using the formula of the expected value) (Equation (3)):where ,, are the impacts corresponding to risk sources;

- 8.

- Step 8: computation of the risk exposure, (Equation (4)):

- 9.

- Step 9: performing the risk response planning analysis, presenting the main actions required for every single risk, based on the values for every identified risk, .

3.2.3. The Analytical Hierarchy Process

3.2.4. Experts’ Judgement

- -

- Contribution to the conceptual design and validation of the IDEF0 strategic model;

- -

- Definition of the priority weights of the risk sources;

- -

- Definition of risks correlation/dependency with the strategic processes;

- -

- Identification of planning risk sources;

- -

- -

- Risk data collection: quantification of risk likelihoods and impacts of and ;

- -

- Composition of the response planning register.

- -

- Mining Operations Manager (Ex1);

- -

- Lignite Mine Site Manager (Ex2);

- -

- Project Management Expert in projects in the energy sector (Ex3);

- -

- Socioeconomic Senior Expert (Ex4);

- -

- Public Official with expertise in sustainability and permits (Ex5).

4. Case Study

4.1. Reclamation of a Closing Lignite Mine

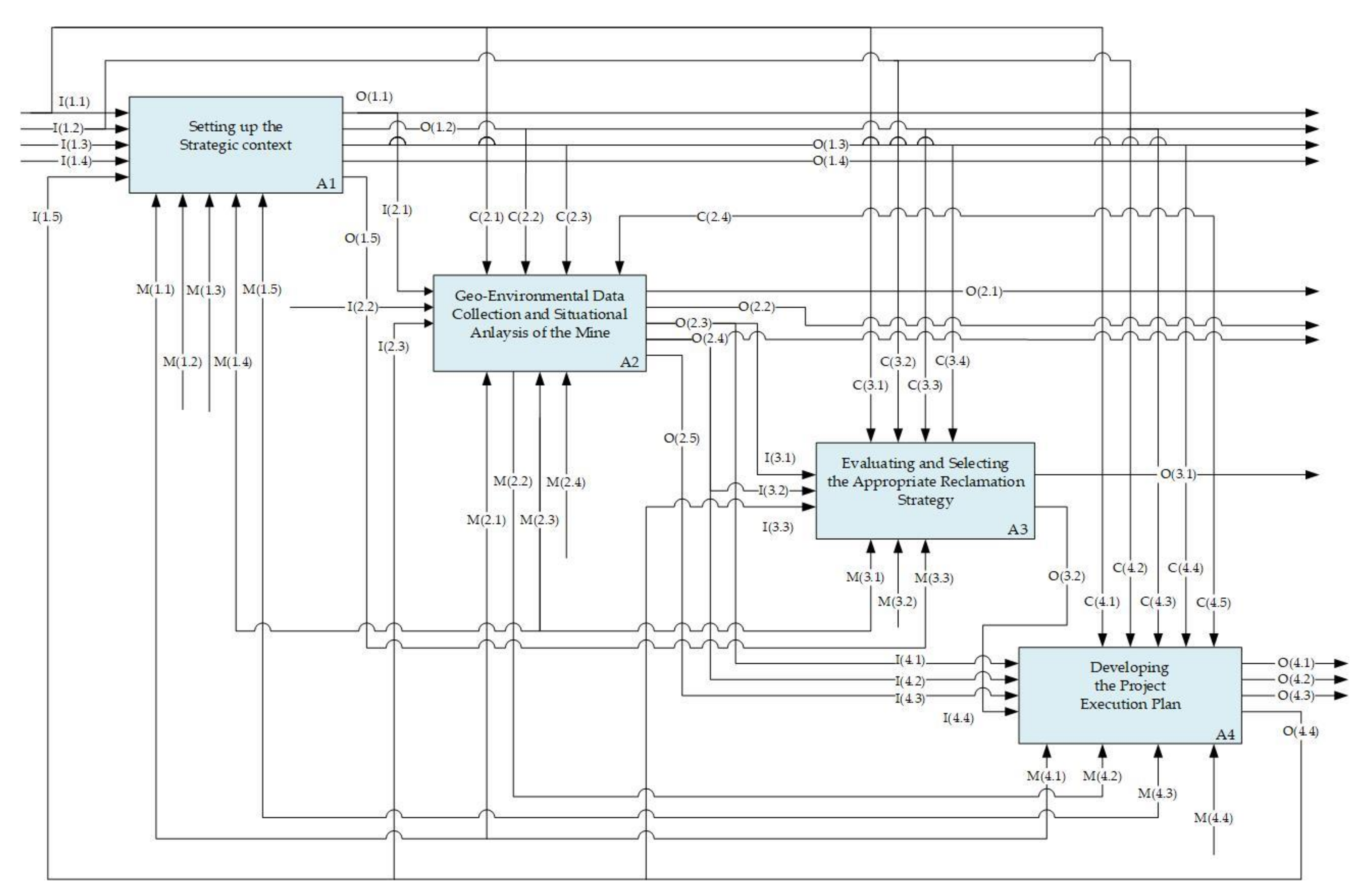

4.2. The IDEF0 Reclamation Process Model

- (a)

- “A-0-Strategic Planning of a Post-Mining Reclamation Project” (top-event): is the concept diagram identifying the strategic target of the reclamation planning;

- (b)

- “A1-Setting-Up the Strategic Context”: refers to the activities a mining company performs to understand the sustainability policies, define alternative reclamation strategies, analyze the overall socioeconomic impacts, evaluate the expectations of stakeholders and prepare the baseline techno-economic assessments by which a reclamation project can be proven a financially and socio-environmentally feasible business entity; the analysis of strengths, weaknesses, opportunities, and threats (SWOT) for the mine transition to sustainability is also foreseen in this sub-process;

- (c)

- “A2-Geo-Environmental Data Collection and Situational Analysis of the Mine”: refers to the detailed geoenvironmental analysis of the mine, engineering and technical design studies for the erection/construction of the infrastructures required for the sustainable reclamation, taking into consideration the 3R (and/or other) circular economy policies (reuse, recycle and reduce materials and energy consumption; see also: [22]. The same sub-process includes the elaboration of an integrated environmental and social impacts assessment justifying the impacts and mitigation measures/policies, which each alternative reclamation solution deals with;

- (d)

- “A3-Evaluating and Selecting the Appropriate Reclamation Strategy” refers to a participatory decision-making process, where the most advantageous reclamation strategy is selected through an accredited and scientifically substantial group decision method supported by mining and environmental experts, stakeholders, society key informants, and representatives of the competent authorities;

- (e)

- “A4-Developing the Project Execution Plan”: refers to the establishment of a project management system by which the post-mining sustainability framework can be executed according to the financial, quality, safety, and performance principles, aligned with the social and corporate responsibility policies of the mining company and the regulatory, environmental and social compliance constraints/requirements set by the authorities and stakeholders.

4.3. Identification of Risks

4.4. Qualitative Risk Analysis

4.4.1. Risk Factors and Priority Weights

- (a)

- Technical performance risk factor : refers to the relative weight of the scope of pure technical activities, the environmental and socioeconomic content of the project, and the regulatory and legislative framework of the project;

- (b)

- Schedule risk factor : refers to the relative weight of the reclamation time complexity and planning, the critical path sensitivity, various misalignments in project activities’ escalation, and the definition of milestones;

- (c)

- Cost risk factor : refers to the relative weight of estimations for the capital expenditures and operating expenses (CAPEX/OPEX), including services of management, field logistics, funding, insurance, engineering, procurement of equipment and materials, erection and construction, permits, and environmental and social management activities;

- (d)

- Quality risk factor : refers to the relative weight of the potential quality effects due to changes in the scope, workload, managerial misalignments, cost, technical factors, and other failures that may occur during the project.

4.4.2. Likelihood and Impact Severity Matrix (LIM)

4.4.3. Composite Likelihood and Impact Factors ( and )

4.4.4. Risk Exposure and Response Planning

5. Discussion

5.1. Methodology Review

5.2. The Risk Analysis Results

5.3. Techno-Economic Viewpoint

6. Conclusions and Further Research

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Pavloudakis, F.; Roumpos, C.; Karlopoulos, E.; Koukouzas, N. Planning and Implementing Surface Mines Reclamation Works under the New EU Strategy for the Transition ofLignite Intensive Regions to a Post-mining Era. In Proceedings of the 12th International Conference of Mining Closure, Leipzig, Germany, 3 September 2018; pp. 139–146. [Google Scholar]

- Buchholz, P.; Brandenburg, T. Demand, Supply, and Price Trends for Mineral Raw Materials Relevant to the Renewable Energy Transition Wind Energy, Solar Photovoltaic Energy, and Energy Storage. Chem. Ing. Tech. 2018, 90, 141–153. [Google Scholar] [CrossRef]

- Fortner, A.; Smith, D.; Rohrer, C. GIS as a Prioritization and Planning Tool in Abandoned Mine Reclamation. In Proceedings of the Incorporating Geospatial Technologies into SMCRA Business Processes, Atlanta, GA, USA, 25–27 March 2008. [Google Scholar]

- Kretschmann, J.; Efremenkov, A.B.; Khoreshok, A.A. From Mining to Post-Mining: The Sustainable Development Strategy of the German Hard Coal Mining Industry. IOP Conf. Ser. Earth Environ. Sci. 2017, 50, 012024. [Google Scholar] [CrossRef]

- Kivinen, S. Sustainable Post-Mining Land Use: Are Closed Metal Mines Abandoned or Re-Used Space? Sustainability 2017, 9, 1705. [Google Scholar] [CrossRef]

- Zhao, Y.; Zang, L.; Li, Z.; Qin, J. Discussion on the Model of Mining Circular Economy. Energy Procedia 2012, 16, 438–443. [Google Scholar] [CrossRef]

- Knabe, W. Methods and Results of Trip-Mine Reclamation in Germany. Ohio J. Sci. 1964, 64, 74–105. [Google Scholar]

- Stewart, D.G. Handbook of Western Reclamation of Techniques, 2nd ed.; University of Wyoming and US Office of Surface Mining Reclamation and Enforcement: Denver, CO, USA, 2006. [Google Scholar]

- Kraemer, C. Cultivation of Overburden Dumps from the Lignite Mines of Lower Lusatia; Breslau University: Breslau, Poland, 1935. [Google Scholar]

- Kopp, E. The Influence of Organic Carbonaceous Admixtures on the Cultural Value of the Pleistocene and Miocene Cover rock Masses of the Lower Lusatia Open-Cast Mines; University of Berlin: Berlin, Germany, 1960. [Google Scholar]

- Hochhaeuser, H. Forstliche Rekultivierungen. Braunkohle Waerme Energie Duesseldorf 1960, 12, 329–334. [Google Scholar]

- Wemper, O. Recultivation in the Cologne lignite mining area. Braunkohle Westdeutsche Wirtschaftsmonographien 1962, 2, 57–62. [Google Scholar]

- Bradshaw, A. Restoration of mined lands—Using natural processes. Ecol. Eng. 1997, 8, 255–269. [Google Scholar] [CrossRef]

- Schulz, F.; Wiegleb, G. Development options of natural habitats in a post-mining landscape. In Land Degradation & Development; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2000; Volume 11. [Google Scholar]

- Sinha, S.R.K. Overview on Reclamation and Rehabilitation of Mines; Indian Bureau of Mines: Rajastan, India, 2015. [Google Scholar]

- Chuman, T. Restoration Practices Used on Post Mining Sites and Industrial Deposits in the Czech Republic with an Example of Natural Restoration of Granodiorite Quarries and Spoil Heaps. J. Landsc. Ecol. 2015, 8, 29–46. [Google Scholar] [CrossRef]

- McCullogh, C.D. Key Mine Closure Lessons to be Learned; Australian Centre for Geomechanics: Perth, Australia, 2016; pp. 319–332. ISBN 978-0-99248810-4-9. [Google Scholar]

- Rovolis, A.; Kalimeris, P. Roadmap for the Transition of the Western Macedonia Region to a Post-Lignite Era; WWF Economic and Technical Assessment; Panteion University of Athens: Athina, Greece, 2016. [Google Scholar]

- LUMINANT. An Overview of Lignite Mine Reforestation at Luminant’s Martin Lake Mines in Eastern Texas; Luminant Co: Dallas, TX, USA, 2015. [Google Scholar]

- Sloss, L. Coal Mine Site Reclamation; IEA Clean Coal Centre: Paris, France, 2013. [Google Scholar] [CrossRef]

- Yonk, R.M.; Smith, J.T.; Wardle, A.R. Exploring the Policy Implications of the Surface Mining Control and Reclamation Act. Resources 2019, 8, 25. [Google Scholar] [CrossRef]

- Pavloudakis, F.; Roumpos, C.; Karlopoulos, E.; Koukouzas, N. Sustainable Rehabilitation of Surface Coal Mining Areas: The Case of Greek Lignite Mines. Energies 2020, 13, 3995. [Google Scholar] [CrossRef]

- Stacey, J.; Naude, A.; Hermanus, M.; Frankel, P. The socio-economic aspects of mine closure and sustainable development: Literature overview and lessons for the socio-economic aspects of closure-Report 1. J. S. Afr. Inst. Min. Metall. 2010, 110, 379–394. [Google Scholar]

- Spanidis, P.-M.; Roumpos, C.; Pavloudakis, F. A Multi-Criteria Methodology for Low-Risk Evaluation of Mine Closure Restoration in Continuous Surface Lignite Mining Projects. In Proceedings of the 14th International Symposium of Continuous Surface Mining, Thessaloniki, Greece, 23 September 2018. [Google Scholar]

- Roumpos, C.; Spanidis, P.-M.; Pavloudakis, F. Environmental Reclamation Planning of Continuous Surface Lignite Mines in Closure Phase: A Risk-Based Investigation. In Proceedings of the 14th International Symposium of Continuous Surface Mining, Greece, Thessaloniki, 23 September 2018; pp. 551–562. [Google Scholar]

- Spanidis, P.-M.; Roumpos, C.; Pavloudakis, F. A Multi-Criteria Approach for the Evaluation of Low Risk Restoration Projects in Continuous Surface Lignite Mines. Energies 2020, 13, 2179. [Google Scholar] [CrossRef]

- Imboden, C.; Moczek, N. Risks and Opportunities in the Biodiversity Management and Related Stakeholder Involvement of the RWE Hambach Lignite Mine; International Union for Conservation of Nature and Natural Resources: Gland, Switzerland, 2015. [Google Scholar]

- Zhenqi, H.; Peijun, W.; Jing, L. Ecological Restoration of Abandoned Mine Land in China. J. Resour. Ecol. 2012, 3, 289–296. [Google Scholar] [CrossRef]

- Tropek, R.; Konvicka, M. Can quarries supplement rare xeric habitats in a piedmont region? Spiders of the Blansky les Mts, Czech Republic. Land Degrad. Dev. 2008, 19, 104–114. [Google Scholar] [CrossRef]

- Loch, R.; Vacher, C. Assessing and managing erosion risk for constructed landforms on mine sites. In Proceedings of the Goldfields Environmental Management group Workshop on Environmental Management, Kalgoorlie–Boulder, Australia, 24 December 2006; pp. 121–127. [Google Scholar]

- McCullough, C.D.; Lund, M.A. Bioremediation of Acidic and Metalliferous Drainage (AMD) through organic carbon amendment by municipal sewage and green waste. J. Environ. Manag. 2011, 92, 2419–2426. [Google Scholar] [CrossRef]

- Moodley, I.; Sheridan, C.M.; Kappelmeyer, U.; Akcil, A. Environmentally sustainable acid mine drainage remediation: Research developments with a focus on waste/by-products. Miner. Eng. 2018, 126, 207–220. [Google Scholar] [CrossRef]

- Gammons, C.H.; Duaime, T.E. Long Term Changes in the Limnology and Geochemistry of the Berkeley Pit Lake, Butte, Montana. Mine Water Environ. 2006, 25, 76–85. [Google Scholar] [CrossRef]

- Spanidis, P.-M.; Pavloudakis, F.; Roumpos, C. A Methodology for Natural Hazards Risk Management in Continuous Surface Lignite Mines. In Proceedings of the 2nd International Conference on Natural Hazards & Infrastructure (ICONHIC2019), Chania, Greece, 23–26 June 2019. [Google Scholar]

- Pavloudakis, F.; Spanidis, P.-M.; Roumpos, C. Investigation of Natural and Technological Hazards and associated Risks in Continuous Surface Lignite Mines. In Proceedings of the 2nd International Conference on Natural Hazards & Infrastructure (ICONHIC2019), Chania, Greece, 23–26 June 2019. [Google Scholar]

- Spanidis, P.-M.; Roumpos, C.; Pavloudakis, F. A Fuzzy-AHP Methodology for Planning the Risk Management of Natural Hazards in Surface Mining Projects. Sustainability 2021, 13, 2369. [Google Scholar] [CrossRef]

- Bradshaw, A.D. The Reconstruction of Ecosystems: Presidential Address to the British Ecological Society, December 1982. J. Appl. Ecol. 1983, 20, 1. [Google Scholar] [CrossRef]

- Tischew, S.; Kirmer, A.; Lorenz, A. Alternative Restoration Strategies In Former Lignite Mining Areas Of Eastern Germany. In Biodiversity: Structure and Function; EOLSS Publishers Co. Ltd.: Oxford, UK, 2009. [Google Scholar]

- Kasztelewicz, Z. Approaches to Post-Mining Land Reclamation in Polish Open-Cast Lignite Mining. Civ. Environ. Eng. Rep. 2014, 12, 55–67. [Google Scholar] [CrossRef]

- Candeias, C.; Ávila, P.; Coelho, P.; Teixeira, J.P. Mining Activities: Health Impacts. In Encyclopedia of Environmental Health; Elsevier: Amsterdam, The Netherlands, 2019; pp. 415–435. ISBN 978-0-444-63952-3. [Google Scholar]

- Pavloudakis, F.; Roumpos, C.; Galetakis, M. Critical environmental and social parameters affecting the development of new surface mines. In Proceedings of the 2nd International Conference on: “Advances in Mineral Resources Management and Environmental Geotechnology, Hania, Greece, 25–27 September 2006. [Google Scholar]

- Pavloudakis, F.; Roumpos, C.; Galetakis, M. Public acceptance of surface mining projects and the determination of the marginal environmental cost. Int. J. Min. Reclam. Environ. 2012, 26, 292–308. [Google Scholar] [CrossRef]

- Richards, I.G.; Palmer, J.P.; Barratt, P.A. The Reclamation of Former Coal Mines and Steelworks; Elsevier: New York, NY, USA; Amsterdam, The Netherlands, 1993; ISBN 9781281793416. [Google Scholar]

- Marais, L.; Atkinson, D. Towards a Post-Mining Economy in a Small Town: Challenges, Obstacles and Trends; Desert Knowledge Australia: Alice Springs, Australia, 2006. [Google Scholar]

- Haney, M.; Shkaratan, M. Mine Closure and its Impact on the Community: Five Years After Mine Closure in Romania, Russia and Ukraine; Policy Research Working Paper; World Bank: Washington, DC, USA, 2003. [Google Scholar]

- Neil, C.; Tykkylainen, M.; Bradbury, J. Coping with Closure: An International Comparison of Mine Town Experiences, 1st ed.; Routledge: London, UK, 1992; ISBN 978-0-415-06651-8. [Google Scholar]

- Siwik, R.; Clemens, M. Mine closure-Past, present and perpetuity. In Proceedings of the International Mine Closure Congress, Vancouver, Canada, 1 June 2015; pp. 1–10. [Google Scholar]

- McCullough, C.; Fourie, A.B. Key Mine Closure Lessons still to be Learned. In Proceedings of the 11th International Conference on Mine Closure, Perth, Australia, 15–17 March 2016; pp. 325–338. [Google Scholar]

- Swason, S. What type of lake do we want? Stakeholder engagement in planning for beneficial end uses of pit lakes. In Proceedings of the Sixth International Conference on Mine Closure, Perth, Australia, 18–21 September 2011. [Google Scholar]

- Steiner, G.A. Strategic Planning: What Every Manager must Know; Simon and Schuster: New York, NY, USA, 1979; ISBN 978-0-02-931110-3. [Google Scholar]

- Nickols, F. Strategy, Strategic Management, Strategic Planning and Strategic Thinking. Manag. J. 2016, 1, 4–7. [Google Scholar]

- Nickols, F. Strategic Decision Making-Commitment to Strategic Action; Presented at the Distance Consulting LLC: Columbus, OH, USA, 2005. [Google Scholar]

- Garvin, D.A. The Processes of Organization and Management, Sloan Management Review. MIT Sloan Manag. Rev. 1998, 39, 33–50. [Google Scholar]

- Davenport, T.H. The Coming Commoditization of Processes. Harv. Bus. Rev. 2005, 86, 100–108. [Google Scholar]

- Project Management Institute. A Guide to the Project Management Body of Knowledge: PMBOK® Guide, 5th ed.; PMI Global Standard; PMI: Newtown Square, PA, USA, 2013; ISBN 978-1-935589-67-9. [Google Scholar]

- Harmon, P. The Scope and Evolution of Business Process Management. In Handbook on Business Process Management 1; Brocke, J., Rosemann, M., Eds.; Springer: Berlin/Heidelberg, Germany, 2010; pp. 37–81. ISBN 978-3-642-00415-5. [Google Scholar]

- Pavloudakis, F.; Galetakis, M.; Roumpos, C. A spatial decision support system for the optimal environmental reclamation of open-pit coal mines in Greece. Int. J. Min. Reclam. Environ. 2009, 23, 291–303. [Google Scholar] [CrossRef]

- Prach, K.; Hobbs, R.J. Spontaneous Succession versus Technical Reclamation in the Restoration of Disturbed Sites. Restor. Ecol. 2008, 16, 363–366. [Google Scholar] [CrossRef]

- Spanidis, P.-M.; Pavloudakis, F.; Roumpos, C. Introducing the IDEF0 Methodology in the Strategic Planning of Projects for Reclamation and Repurposing of Surface Mines. Mater. Proc. 2021, 5, 26. [Google Scholar]

- Dey, P.K. Project risk management using multiple criteria decision-making technique and decision tree analysis: A case study of Indian oil refinery. Prod. Plan. Control 2012, 23, 903–921. [Google Scholar] [CrossRef]

- Nicholas, J.M.; Steyn, H. Project Management for Business, Engineering, and Technology: Principles and Practice, 3rd ed.; Elsevier Butterworth-Heinemann: Amsterdam, The Netherlands; Heidelberg, Germany, 2008; ISBN 978-0-7506-8399-9. [Google Scholar]

- Davenport, T.H.; Prusak, L. Process Innovation: Reengineering Work through Information Technology; Harvard Business School Press: Boston, MA, USA, 1998. [Google Scholar]

- Tserng, H.-P.; Cho, I.-C.; Chen, C.-H.; Liu, Y.-F. Developing a Risk Management Process for Infrastructure Projects Using IDEF0. Sustainability 2021, 13, 6958. [Google Scholar] [CrossRef]

- Goldratt, E.M. What is This Thing Called Theory of Constraints and how Should it be Implemented? North River Press: Great Barrington, MA, USA, 1990; ISBN 978-0-88427-085-0. [Google Scholar]

- Hammer, M.; Champy, J. Reengineering the Corporation: A Manifesto for Business Revolution; Brealey: London, UK, 1994; ISBN 978-1-86373-505-6. [Google Scholar]

- Lambert, J.H.; Jennings, R.K.; Nilesh, N.J. Integration of Risk Identification with Business Process Models, Systems Engineering, 3rd ed.; Wiley Periodicals, Inc.: Hoboken, NJ, USA, 2006; Volume 9. [Google Scholar]

- Ahmed, A.; Kayis, B.; Amornsawadwatana, S. A review of techniques for risk management in projects. Benchmarking Int. J. 2007, 14, 22–36. [Google Scholar] [CrossRef]

- Lundgren, J.H.; Bjork, B.-C. A model integrating the facilities management process with the building end user’s business process (ProFacil). Nord. J. Surv. Real Estate Res. 2004, 1, 190–204. [Google Scholar]

- Erasmus, J.; Vanderfeesten, I.; Traganos, K.; Grefen, P. Using business process models for the specification of manufacturing operations. Comput. Ind. 2020, 123, 103297. [Google Scholar] [CrossRef]

- Kassem, M.; Dawood, N.; Mitchell, D.A. A structured Methodology for Enterprise Modeling: A Case Study for Modeling the Operation of a British Organization. J. Inf. Technol. Constr. 2011, 16, 381–410. [Google Scholar]

- ISO/TR 9007; Information Processing Systems-oncepts and Terminology for the Conceptual Schema and the Information Base. The International Organization for Standardization: London, UK, 1987.

- Lang, A.; Ellefmo, S.; Aasly, K. Geometallurgical Flowsheet as a Tool for Designing and Communicating Geometallurgical Programs. Minerals 2018, 8, 372. [Google Scholar] [CrossRef]

- Akinsola, A.; Dawood, N.; Hobbs, B. Construction planning process improvement using information technology tools. In Proceedings of the CIT, Taking the Construction Industry into the 21st Century, Reykjavik, Iceland, 28–30 June 2000; pp. 40–51. [Google Scholar]

- Jeong, K.-Y.; Wu, L.; Hong, J.-D. IDEF method-based simulation model design and development framework. J. Ind. Eng. 2009, 2, 337–359. [Google Scholar] [CrossRef][Green Version]

- Toba, A.-L.; Seck, M. Modeling Social, Economic, Technical & Environmental Components in an Energy System. Procedia Comput. Sci. 2016, 95, 400–407. [Google Scholar] [CrossRef]

- Presley, A.; Liles, D.H. The Use of IDEF0 for the Design and Specification of Methodologies; Small Business Administration, and the State of Texas Advanced Technology Program; National Center for Manufacturing Sciences: Farmington Hills, MI, USA, 1998. [Google Scholar]

- Waissi, G.R.; Demir, M.; Humble, J.E.; Lev, B. Automation of strategy using IDEF0—A proof of concept. Oper. Res. Perspect. 2015, 2, 106–113. [Google Scholar] [CrossRef]

- Kusiak, A.; Larson, N. System Reliability and Risk Assessment: A Quantitative Extension of IDEF Methodologies; Technical Report SS-94-04; Association for the Advancement of Artificial Intelligence (AAAI): Palo Alto, CA, USA, 1994. [Google Scholar]

- Raftery, J. Risk Analysis in Project Management; Spon: London, UK; Glasgow, Scotland; New York, NY, USA, 1994; ISBN 978-0-419-18420-1. [Google Scholar]

- ISO 31000:2018; Risk Management-Guidelines. The International Organization for Standardization: Geneva, Switzerland, 2018.

- ISO/TR 31004 ISO/TR 31004; Risk Management-Guidance for the Implementation of ISO 31000. The International Organization for Standardization: Geneva, Switzerland, 2013.

- IEC 31010:2019; Risk Management-Risk Assessment Techniques. International Electrotechnical Commission IEC: Geneva, Switzerland.

- Suddle, S.; Ale, B. The third spatial dimension risk approach for individual risk and group risk in multiple use of space. J. Hazard. Mater. 2005, 123, 35–53. [Google Scholar] [CrossRef]

- Suddle, S. The weighted risk analysis. Saf. Sci. 2009, 47, 668–679. [Google Scholar] [CrossRef]

- Taylor, M.D. How to Effectively Manage Project Risks; Systems Management Services: Chula Vista, CA, USA, 2009. [Google Scholar]

- Mahase, M.J. A survey of applications of multi-criteria decision analysis methods in mine planning and related case studies. J. S. Afr. Inst. Min. Metall. 2016, 116, 1051–1056. [Google Scholar] [CrossRef][Green Version]

- Saaty, T.L. The Analytic Hierarchy Process; Applications and Studies: Berlin/Heidelberg, Germany, 1980. [Google Scholar]

- Saaty, T.L. Decision making with the analytic hierarchy process. Int. J. Serv. Sci. 2008, 1, 83–98. [Google Scholar] [CrossRef]

- Dey, P. K Project Risk Management: A Combined Analytic Hierarchy Process and Decision Tree Approach. Cost Eng. 2002, 44, 13–26. [Google Scholar]

- Szwed, P.S. Expert Judgment in Project Management: Narrowing the Theory-Practice Gap; Project Management Institute, Inc.: Newtown Square, PA, USA, 2016; ISBN 978-1-62825-146-3. [Google Scholar]

- Velasquez, M.; Hester, P.T. An analysis of multi-criteria decision making methods. Int. J. Oper. Res. 2013, 10, 56–66. [Google Scholar]

- Orwig, R.; Dean, D.L. A Method for Building a Referent Business Activity Model for Evaluating Information Systems: Results from a Case Study. Commun. Assoc. Inf. Syst. 2007, 20, 53. [Google Scholar] [CrossRef]

- Saaty, T.L.; Vargas, L.G. Prediction, Projection and Forecasting; Springer: Dordrecht, The Netherlands, 1991; ISBN 978-94-015-7954-4. [Google Scholar]

- Triantaphyllou, E. Multi-Criteria Decision Making Methods: A Comparative Study; Applied Optimization; Springer US: Boston, MA, USA, 2000; Volume 44, ISBN 978-1-4419-4838-0. [Google Scholar]

- Hillson, D. Managing Risk in Projects; Fundamentals of Project Management; Gower: Farnham, UK, 2009; ISBN 978-0-566-08867-4. [Google Scholar]

- Hillson, D.; Grimaldi, S.; Rafele, C. Managing Project Risks Using a Cross Risk Breakdown Matrix. Risk Manag. 2006, 8, 61–76. [Google Scholar] [CrossRef]

- Teli, S.N.; Magali, V.S.; Bushi, U.M. Role of Cost of Quality in the Automotive Industry; Datta Meghe College of Engineering: Navi Mumbai, India, 2010. [Google Scholar]

| a. Description of IDEF0 Process Model Activities (Adapted from [59]). | ||||||

|---|---|---|---|---|---|---|

| Sub-Process-ID: “A1—Setting-up the Strategic Context” | ||||||

| A(1.1) | Analysis of sustainability policies | A(1.6) | Analysis of strengths and weaknesses | |||

| A(1.2) | Consideration of environmental impacts | A(1.7) | Scope pre-screening | |||

| A(1.3) | Consideration of socioeconomic impacts | A(1.8) | Preliminary time planning | |||

| A(1.4) | Investigation of reclamation/repurposing technologies | A(1.9) | Budgetary estimation of alternative reclamation scenarios | |||

| A(1.5) | First round of stakeholder engagement | A(1.10) | Outlining the concept of reclamation strategies | |||

| Sub-Process-ID: “A2—Geo-Environmental Data Collection and Situational Analysis of the Mine” | ||||||

| A(2.1) | Preparation of site layouts for the landscape and landforms | A(2.7) | Sampling of contaminated/polluted receptors (soil–water–air) | |||

| A(2.2) | Analysis of mine’s waste management records/procedures | A(2.8) | Impact analysis and mitigation measures | |||

| A(2.3) | Analysis of satellite imagery and remote sensing data | A(2.9) | Review of previous mine development plans and risk assessments | |||

| A(2.4) | Analysis of biotic, non-biotic, and ecological factors | A(2.10) | Considering the legislative constraints and development programs | |||

| A(2.5) | Analysis of socioeconomic factors, land use, and infrastructures | A(2.11) | Evaluating the mining material and space suitability for 3R initiatives | |||

| A(2.6) | Geological, geotechnical, and geophysical investigation | A(2.12) | Second round of stakeholder engagement | |||

| Sub-Process-ID: A3—“Evaluating and Selecting the Appropriate Reclamation Strategy” | ||||||

| A(3.1) | Identification of the alternative strategies | A(3.6) | Finalizing the cost analysis (for each strategy) | |||

| A(3.2) | Submission of the reclamation/repurposing plan to stakeholders | A(3.7) | Finalizing the feasibility assessment | |||

| A(3.3) | Public consultation | A(3.8) | Selection of strategy (by using a multicriteria decision-making method) | |||

| A(3.4) | Consideration of stakeholders’/authorities’ feedback | A(3.9) | Approval of the selected strategy | |||

| A(3.5) | Filling the gaps and reformulating the strategies | |||||

| Sub-Process-ID: A4—“Developing the Project Execution Plan” | ||||||

| A(4.1) | Developing the project and construction management systems | A(4.4) | Work and cost breakdown analysis | |||

| A(4.2) | Preparation of tendering | A(4.5) | Set up of the quality, risk, and HSSE management systems | |||

| A(4.3) | Organization and planning of the project | A(4.6) | Set up of the environmental monitoring and management | |||

| A(4.7) | Request for proposal (RfP) and bidder evaluation | |||||

| b. ICOM Entities of the IDEF0 Process Model (Adapted from [59]) | ||||||

| Description of Entities | Processes | |||||

| A1 | A2 | A3 | A4 | |||

| Mine decommissioning plan | I(1.1) | C(2.1) | C(3.1) | C(4.1) | ||

| Policies/regulations for the sustainable development and circular economy | I(1.2) | C(3.2) | C(4.2) | |||

| Mine company corporate and social responsibility | I(1.3) | |||||

| Mine operation and field inspection archives | I(1.4) | |||||

| Lessons learned | I(1.5) | I(2.3) | I(3.3) | O(4.4) | ||

| Prefeasibility assessment | O(1.1) | I(2.1) | ||||

| Reclamation planning and timeline | O(1.2) | C(2.2) | C(3.3) | C(4.3) | ||

| Preliminary cost estimation (CAPEX and OPEX) | O(1.3) | C(2.3) | C(3.4) | |||

| Risk and natural hazard assessment | O(1.4) | C(4.4) | ||||

| Stakeholders’ feedback (authorities, municipalities, NGOs, etc.) | O(1.5) | M(3.3) | ||||

| Standards for quality, HSSE, and risk management | M(1.1) | M(2.1) | M(4.1) | |||

| Policies/instruments of International Finance Corporations (IFC) | M(1.2) | |||||

| Business and financial analysis tools (SWOT, BCA, NPV/IRR, etc.) | M(1.3) | |||||

| Legislation for occupational health and safety | C(2.4) | C(4.5) | ||||

| Satellite imagery and remote sensing data | I(2.2) | |||||

| Situational analysis of the mine | O(2.1) | |||||

| Environmental and social impact assessment (ESIA) | O(2.2) | I(3.1) | ||||

| Mine landscape and landform upgrading plan | O(2.3) | I(4.1) | ||||

| Feasibility study (final) | O(2.4) | I(3.2) | I(4.2) | |||

| Engineering studies (specifications, technical reports, area layouts, etc.) | O(2.5) | I(4.3) | ||||

| Design codes, standards, and best practices of the mining industry | M(2.2) | M(4.2) | ||||

| Public consultation Minutes of Meeting (MOMs)/protocols | O(3.1) | |||||

| Reclamation/repurposing strategy (selected) | O(3.2) | I(4.4) | ||||

| Expert teams (managers, engineers, ecologists, financial analysts, etc.) | M(1.4) | M(2.3) | M(3.1) | |||

| Decision-making software tools (for AHP, TOPSIS, or other methods) | M(3.2) | |||||

| Project development and execution plan | O(4.1) | |||||

| Tender packages | O(4.2) | |||||

| Detailed cost analysis | O(4.3) | |||||

| Project and risk management tools (MS-Project, @Risk, etc.) | M(1.5) | M(4.3) | ||||

| Environmental and social impact assessment mitigation measures/plans | M(4.4) | |||||

| Risk-ID | Risk Identification | A1 (2) | A2 (2) | A3 (2) | A4 (2) |

|---|---|---|---|---|---|

| R-01 | Poor conceptual analysis of the strategic planning process model (IDEF0) | M | M | M | M |

| R-02 | Lack of scientific knowledge and experience of the project team | H | H | H | H |

| R-03 | Delays of the strategic activities’ execution | L | H | M | M |

| R-04 | Weak points of sustainability legislation/policy | H | L | M | L |

| R-05 | Lack of sustainability management knowledge | H | L | L | L |

| R-06 | Unclear definition of the reclamation strategies | H | M | M | L |

| R-07 | Defects of the mining company corporate policy | H | L | L | L |

| R-08 | Deviations from restoration cost estimate (CAPEX, OPEX) | H | M | M | H |

| R-09 | Inefficient stakeholder engagement/management | L | L | H | L |

| R-10 | Poor field data collection (at the mine sites) | L | M | L | L |

| R-11 | Poor situational analysis of the mine | L | H | L | L |

| R-12 | Insufficient management of mine’s infrastructure/equipment | L | H | M | L |

| R-13 | Inefficient environmental/social impact analysis | L | H | M | M |

| R-14 | Reclamation/restoration activities’ deficiencies/failures | L | H | L | H |

| R-15 | Reclamation/restoration activities’ scope extension | L | H | H | M |

| R-16 | Selection of socioenvironmentally inappropriate land uses (post-mining era) | L | L | H | H |

| R-17 | Failure to meet the requirements of society | M | H | M | M |

| R-18 | Failure to meet the legal and regulatory requirements | M | L | H | L |

| R-19 | Insufficient funding or failure to execute the funding schedule | L | L | L | H |

| R-20 | Poor analysis of natural and technological hazards | L | M | M | H |

| 1 | Equal importance |

| 3 | Moderate importance |

| 5 | Strong or essential importance |

| 7 | Very strong importance |

| 9 | Extreme importance |

| 2, 4, 6, 8 | Values for inverse comparison |

| Risk Factors | RFi | T | S | C | Q |

|---|---|---|---|---|---|

| Technical Performance | T | 1 | 1/4 | 1/4 | 3 |

| Schedule | S | 4 | 1 | 1/2 | 3 |

| Cost | C | 4 | 2 | 1 | 5 |

| Quality | Q | 1/3 | 1/3 | 1/5 | 1 |

| Risk Factors | RFi | T | S | C | Q | Σ(RFi) | Priority Vector—(Wi) |

|---|---|---|---|---|---|---|---|

| Technical Performance | T | 0.11 | 0.07 | 0.13 | 0.25 | 0.56 | WT = 0.139 |

| Schedule | S | 0.43 | 0.28 | 0.26 | 0.25 | 1.21 | Ws = 0.304 |

| Cost | C | 0.43 | 0.56 | 0.51 | 0.42 | 1.92 | WC = 0.479 |

| Quality | Q | 0.04 | 0.09 | 0.10 | 0.08 | 0.31 | WQ = 0.079 |

| Consistency Control: λmax = 4.211; CI = 0.70; CI/RI = 0.078 < 0.10 | |||||||

| Likelihood Level | Likelihood Range | Point Values * |

|---|---|---|

| Remote | P < 0.2 | 0.10 |

| Unlikely | 0.2 ≤ P < 0.4 | 0.30 |

| Likely | 0.4 ≤ P < 0.6 | 0.50 |

| Very Likely | 0.6 ≤ P < 0.8 | 0.70 |

| Near Certainty | 0.8 < P | 0.90 |

| a. Risk Factor Impact Analysis: Technical Performance and Schedule | |||

|---|---|---|---|

| Impact Level | Point Values (1) | Technical Performance Impact Factor | Schedule Impact Factor |

| Very Low (VL) | 0.05 | Insignificant change | Insignificant |

| Low (LO) | 0.10 | Controllable change | <5% of the TS (2) |

| Medium (ME) | 0.20 | Significant change | 5–10% of the TS |

| High (HI) | 0.40 | Non-Acceptable change | 10–20% of the TS |

| Very High (VH) | 0.80 | Project cancelling | >20% of the TS |

| b. Risk Factor Impact Analysis: Cost and Quality. | |||

| Impact Level | Point Values (1) | Cost Impact Factor | Quality Impact Factor |

| Very Low (VL) | 0.05 | Insignificant | Insignificant |

| Low (LO) | 0.10 | <5% of the budget | Controllable defects |

| Medium (ME) | 0.20 | 5–10% of the budget | Owner’s approval required |

| High (HI) | 0.40 | 10–20% of the budget | Non-acceptable defects |

| Very High (VH) | 0.80 | 20% of the budget < | Project cancelling |

| Likelihood (L) | Impact (I) | ||||

|---|---|---|---|---|---|

| VL | LO | ME | HI | VH | |

| Near Certainty | 0.05 | 0.09 | 0.18 | 0.36 | 0.72 |

| Very Likely | 0.04 | 0.07 | 0.14 | 0.28 | 0.56 |

| Likely | 0.03 | 0.05 | 0.10 | 0.20 | 0.40 |

| Unlikely | 0.02 | 0.03 | 0.06 | 0.12 | 0.24 |

| Remote | 0.01 | 0.01 | 0.02 | 0.04 | 0.08 |

| : Technical Performance | : Schedule | ||||||||||||||

| Risk-ID | Ex1 | Ex2 | Ex3 | Ex4 | Ex5 | Ex1 | Ex2 | Ex3 | Ex4 | Ex5 | |||||

| R-001 | 0.70 | 0.70 | 0.30 | 0.70 | 0.70 | 0.62 | 0.70 | 0.30 | 0.30 | 0.30 | 0.30 | 0.10 | 0.26 | 0.30 | |

| R-002 | 0.30 | 0.50 | 0.30 | 0.50 | 0.50 | 0.42 | 0.50 | 0.10 | 0.10 | 0.30 | 0.10 | 0.10 | 0.14 | 0.10 | |

| R-003 | 0.70 | 0.90 | 0.90 | 0.90 | 0.70 | 0.82 | 0.90 | 0.30 | 0.50 | 0.30 | 0.50 | 0.30 | 0.38 | 0.30 | |

| R-004 | 0.10 | 0.10 | 0.30 | 0.10 | 0.10 | 0.14 | 0.10 | 0.30 | 0.30 | 0.10 | 0.10 | 0.10 | 0.18 | 0.10 | |

| R-005 | 0.30 | 0.30 | 0.10 | 0.10 | 0.10 | 0.18 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | |

| R-006 | 0.70 | 0.50 | 0.50 | 0.30 | 0.30 | 0.46 | 0.50 | 0.30 | 0.10 | 0.30 | 0.50 | 0.30 | 0.30 | 0.40 | |

| R-007 | 0.10 | 0.10 | 0.10 | 0.70 | 0.10 | 0.22 | 0.30 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | |

| R-008 | 0.50 | 0.30 | 0.50 | 0.50 | 0.50 | 0.46 | 0.50 | 0.30 | 0.50 | 0.50 | 0.70 | 0.70 | 0.54 | 0.50 | |

| R-009 | 0.30 | 0.50 | 0.50 | 0.90 | 0.70 | 0.58 | 0.50 | 0.10 | 0.10 | 0.30 | 0.30 | 0.10 | 0.18 | 0.10 | |

| R-010 | 0.90 | 0.30 | 0.50 | 0.50 | 0.50 | 0.54 | 0.50 | 0.10 | 0.50 | 0.50 | 0.50 | 0.70 | 0.46 | 0.50 | |

| R-011 | 0.70 | 0.70 | 0.70 | 0.50 | 0.70 | 0.66 | 0.70 | 0.30 | 0.50 | 0.50 | 0.30 | 0.30 | 0.38 | 0.30 | |

| R-012 | 0.30 | 0.30 | 0.50 | 0.50 | 0.10 | 0.34 | 0.30 | 0.10 | 0.30 | 0.30 | 0.30 | 0.10 | 0.10 | 0.10 | |

| R-013 | 0.50 | 0.30 | 0.10 | 0.10 | 0.10 | 0.22 | 0.30 | 0.10 | 0.30 | 010 | 0.50 | 0.10 | 0.22 | 0.30 | |

| R-014 | 0.90 | 0.90 | 0.70 | 0.90 | 0.70 | 0.82 | 0.90 | 0.70 | 0.90 | 0.50 | 0.70 | 050 | 0.66 | 0.70 | |

| R-015 | 0.50 | 0.30 | 030 | 0.30 | 0.50 | 0.38 | 0.30 | 0.30 | 0.50 | 0.30 | 0.10 | 0.10 | 0.26 | 0.30 | |

| R-016 | 0.70 | 0.70 | 0.50 | 0.70 | 0.70 | 0.66 | 0.70 | 0.10 | 0.50 | 0.50 | 0.70 | 0.90 | 0.54 | 0.50 | |

| R-017 | 0.50 | 0.10 | 0.30 | 0.70 | 0.10 | 0.34 | 0.30 | 0.30 | 0.30 | 0.50 | 0.30 | 0.30 | 0.34 | 0.30 | |

| R-018 | 0.30 | 0.10 | 0.30 | 0.10 | 0.50 | 0.26 | 0.30 | 0.10 | 0.30 | 0.50 | 0.10 | 0.10 | 0.22 | 0.30 | |

| R-019 | 0.70 | 0.90 | 0.90 | 0.90 | 0.30 | 0.74 | 0.70 | 0.30 | 0.30 | 0.50 | 0.30 | 0.50 | 0.38 | 0.30 | |

| R-020 | 0.30 | 0.10 | 0.10 | 0.10 | 0.10 | 0.14 | 0.10 | 0.10 | 0.30 | 0.10 | 0.10 | 0.10 | 0.14 | 0.10 | |

| : Cost | : Quality | ||||||||||||||

| Risk-ID | Ex1 | Ex2 | Ex3 | Ex4 | Ex5 | Ex1 | Ex2 | Ex3 | Ex4 | Ex5 | |||||

| R-001 | 0.50 | 0.50 | 0.50 | 0.50 | 0.30 | 0.46 | 0.50 | 0.10 | 0.30 | 0.10 | 0.10 | 0.10 | 0.14 | 0.10 | 0.44 |

| R-002 | 0.10 | 0.30 | 0.30 | 0.30 | 0.10 | 0.22 | 0.30 | 0.10 | 0.10 | 0.10 | 0.30 | 0.10 | 0.14 | 0.10 | 0.25 |

| R-003 | 0.50 | 0.50 | 0.70 | 0.70 | 0.70 | 0.62 | 0.70 | 0.50 | 0.50 | 0.30 | 0.70 | 0.10 | 0.42 | 0.50 | 0.59 |

| R-004 | 0.30 | 0.10 | 0.30 | 0.30 | 0.30 | 0.26 | 0.30 | 0.10 | 0.10 | 0.10 | 0.10 | 0.30 | 0.14 | 0.10 | 0.20 |

| R-005 | 0.30 | 0.10 | 0.30 | 0.10 | 0.50 | 0.26 | 0.30 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.20 |

| R-006 | 0.50 | 0.30 | 0.50 | 0.50 | 0.50 | 0.46 | 0.50 | 0.30 | 0.10 | 0.30 | 0.10 | 0.30 | 0.22 | 0.30 | 0.45 |

| R-007 | 0.30 | 0.50 | 0.50 | 0.30 | 0.30 | 0.38 | 0.30 | 0.30 | 0.30 | 0.30 | 0.50 | 0.30 | 0.34 | 0.30 | 0.24 |

| R-008 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.30 | 0.10 | 0.10 | 0.10 | 0.22 | 0.30 | 0.48 |

| R-009 | 0.10 | 0.50 | 0.50 | 0.50 | 0.30 | 0.38 | 0.30 | 0.30 | 0.30 | 0.10 | 0.50 | 0.30 | 0.30 | 0.30 | 0.27 |

| R-010 | 0.30 | 0.70 | 0.50 | 0.70 | 0.30 | 0.50 | 0.50 | 0.50 | 0.30 | 0.50 | 0.30 | 0.50 | 0.42 | 0.50 | 0.50 |

| R-011 | 0.30 | 0.30 | 0.50 | 0.50 | 0.50 | 0.42 | 0.50 | 0.50 | 0.50 | 0.50 | 0.30 | 0.50 | 0.46 | 0.50 | 0.47 |

| R-012 | 0.10 | 0.10 | 0.30 | 0.10 | 0.30 | 0.18 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.13 |

| R-013 | 0.10 | 0.30 | 0.30 | 0.30 | 0.30 | 0.26 | 0.30 | 0.30 | 0.30 | 0.30 | 0.10 | 0.30 | 0.26 | 0.30 | 0.30 |

| R-014 | 0.50 | 0.70 | 0.50 | 0.50 | 0.30 | 0.50 | 0.50 | 0.50 | 0.50 | 0.70 | 0.70 | 0.50 | 0.58 | 0.50 | 0.62 |

| R-015 | 0.50 | 0.50 | 0.30 | 0.30 | 0.70 | 0.46 | 0.50 | 0.10 | 0.10 | 0.30 | 0.10 | 0.10 | 0.14 | 0.10 | 0.38 |

| R-016 | 0.30 | 0.10 | 0.50 | 0.10 | 0.30 | 0.26 | 0.30 | 0.30 | 0.30 | 0.30 | 0.30 | 0.50 | 0.34 | 0.30 | 0.42 |

| R-017 | 0.30 | 0.10 | 0.10 | 0.30 | 0.10 | 0.18 | 0.10 | 0.10 | 0.30 | 0.10 | 0.10 | 0.10 | 0.14 | 0.10 | 0.19 |

| R-018 | 0.10 | 0.10 | 0.10 | 0.30 | 0.30 | 0.18 | 0.10 | 0.10 | 0.30 | 0.10 | 0.10 | 0.10 | 0.14 | 0.10 | 0.19 |

| R-019 | 0.10 | 0.50 | 0.30 | 0.50 | 0.50 | 0.38 | 0.30 | 0.30 | 0.30 | 0.10 | 0.10 | 0.10 | 0.18 | 0.10 | 0.34 |

| R-020 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.20 | 0.30 | 0.12 |

| : Technical Performance | : Schedule | ||||||||||||||

| Risk-ID | Ex1 | Ex2 | Ex3 | Ex4 | Ex5 | Ex1 | Ex2 | Ex3 | Ex4 | Ex5 | |||||

| R-001 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.40 | 0.20 | 0.40 | 0.40 | 0.20 | 0.32 | 0.40 | |

| R-002 | 0.20 | 0.10 | 0.10 | 0.10 | 0.10 | 0.12 | 0.10 | 0.20 | 0.20 | 0.40 | 0.20 | 0.10 | 0.22 | 0.20 | |

| R-003 | 0.20 | 0.20 | 0.40 | 0.40 | 0.80 | 0.40 | 0.40 | 0.80 | 0.80 | 0.80 | 0.40 | 0.80 | 0.72 | 0.80 | |

| R-004 | 0.05 | 0.10 | 0.10 | 0.05 | 0.10 | 0.08 | 0.10 | 0.20 | 0.20 | 0.20 | 0.20 | 0.20 | 0.20 | 0.20 | |

| R-005 | 0.10 | 0.10 | 0.20 | 0.10 | 0.10 | 0.12 | 0.10 | 0.20 | 0.20 | 0.10 | 0.05 | 0.20 | 0.15 | 0.20 | |

| R-006 | 0.40 | 0.20 | 0.40 | 0.20 | 0.80 | 0.40 | 0.40 | 0.20 | 0.40 | 0.40 | 0.80 | 0.40 | 0.44 | 0.40 | |

| R-007 | 0.40 | 0.20 | 0.10 | 0.20 | 0.20 | 0.22 | 0.20 | 0.05 | 0.10 | 0.10 | 0.05 | 0.05 | 0.07 | 0.10 | |

| R-008 | 0.40 | 0.20 | 0.10 | 0.20 | 0.20 | 0.22 | 0.20 | 0.40 | 0.40 | 0.40 | 0.40 | 0.20 | 0.36 | 0.40 | |

| R-009 | 0.20 | 0.10 | 0.10 | 0.05 | 0.20 | 0.13 | 0.10 | 0.20 | 0.20 | 0.05 | 0.10 | 0.05 | 0.12 | 0.10 | |

| R-010 | 0.40 | 0.20 | 0.20 | 0.10 | 0.10 | 0.20 | 0.20 | 0.20 | 0.40 | 0.40 | 0.20 | 0.10 | 0.26 | 0.20 | |

| R-011 | 0.10 | 0.20 | 0.20 | 0.20 | 0.40 | 0.22 | 0.20 | 0.20 | 0.40 | 0.20 | 0.40 | 0.20 | 0.28 | 0.20 | |

| R-012 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.05 | 0.05 | 0.10 | 0.20 | 0.10 | 0.10 | |

| R-013 | 0.20 | 0.10 | 0.10 | 0.10 | 0.10 | 0.12 | 0.10 | 0.10 | 0.05 | 0.10 | 0.05 | 0.10 | 0.08 | 0.10 | |

| R-014 | 0.40 | 0.20 | 0.40 | 0.40 | 0.20 | 0.32 | 0.40 | 0.40 | 0.80 | 0.40 | 0.80 | 0.80 | 0.64 | 0.80 | |

| R-015 | 0.20 | 0.20 | 0.10 | 0.20 | 0.10 | 0.16 | 0.20 | 0.40 | 0.40 | 0.20 | 0.80 | 0.20 | 0.40 | 0.40 | |

| R-016 | 0.20 | 0.20 | 0.10 | 0.10 | 0.20 | 0.16 | 0.20 | 0.10 | 0.20 | 0.10 | 0.05 | 0.10 | 0.11 | 0.10 | |

| R-017 | 0.20 | 0.20 | 0.20 | 0.10 | 0.20 | 0.18 | 0.20 | 0.10 | 0.05 | 0.05 | 0.20 | 0.40 | 0.16 | 0.20 | |

| R-018 | 0.20 | 0.20 | 0.20 | 0.20 | 0.10 | 0.18 | 0.20 | 0.10 | 0.10 | 0.20 | 0.20 | 0.20 | 0.16 | 0.20 | |

| R-019 | 0.40 | 0.20 | 0.80 | 0.80 | 0.20 | 0.48 | 0.40 | 0.05 | 0.20 | 0.10 | 0.20 | 0.40 | 0.19 | 0.20 | |

| R-020 | 0.20 | 0.10 | 0.20 | 0.10 | 0.20 | 0.16 | 0.20 | 0.10 | 0.10 | 0.10 | 0.20 | 0.05 | 0.11 | 0.10 | |

| : Cost | : Quality | ||||||||||||||

| Risk-ID | Ex1 | Ex2 | Ex3 | Ex4 | Ex5 | Ex1 | Ex2 | Ex3 | Ex4 | Ex5 | CIFj | ||||

| R-001 | 0.40 | 0.40 | 0.40 | 0.40 | 0.20 | 0.36 | 0.40 | 0.10 | 0.05 | 0.05 | 0.05 | 0.10 | 0.07 | 0.10 | 0.33 |

| R-002 | 0.10 | 0.20 | 0.10 | 0.10 | 0.10 | 0.12 | 0.10 | 0.10 | 0.05 | 0.10 | 0.10 | 0.10 | 0.09 | 0.10 | 0.13 |

| R-003 | 0.40 | 0.40 | 0.40 | 0.40 | 0.40 | 0.40 | 0.40 | 0.20 | 0.05 | 0.10 | 0.05 | 0.05 | 0.09 | 0.10 | 0.50 |

| R-004 | 0.10 | 0.20 | 0.20 | 0.20 | 0.20 | 0.18 | 0.20 | 0.10 | 0.10 | 0.05 | 0.10 | 0.10 | 0.09 | 0.10 | 0.18 |

| R-005 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.10 | 0.10 | 0.10 | 0.08 | 0.10 | 0.11 |

| R-006 | 0.40 | 0.40 | 0.40 | 0.80 | 0.40 | 0.48 | 0.40 | 0.20 | 0.20 | 0.40 | 0.20 | 0.20 | 0.24 | 0.20 | 0.38 |

| R-007 | 0.20 | 0.10 | 0.10 | 0.20 | 0.20 | 0.16 | 0.20 | 0.40 | 0.20 | 0.20 | 0.10 | 0.10 | 0.20 | 0.20 | 0.17 |

| R-008 | 0.40 | 0.40 | 0.20 | 0.40 | 0.40 | 0.36 | 0.40 | 0.20 | 0.20 | 0.20 | 0.10 | 0.20 | 0.18 | 0.20 | 0.36 |

| R-009 | 0.40 | 0.40 | 0.40 | 0.40 | 0.40 | 0.40 | 0.40 | 0.10 | 0.10 | 0.10 | 0.20 | 0.05 | 0.11 | 0.10 | 0.24 |

| R-010 | 0.40 | 0.10 | 0.20 | 0.10 | 0.10 | 0.18 | 0.20 | 0.20 | 0.20 | 0.20 | 0.10 | 0.40 | 0.22 | 0.20 | 0.20 |

| R-011 | 0.40 | 0.40 | 0.20 | 0.40 | 0.40 | 0.36 | 0.40 | 0.20 | 0.40 | 0.40 | 0.40 | 0.20 | 0.32 | 0.40 | 0.31 |

| R-012 | 0.10 | 0.10 | 0.05 | 0.10 | 0.10 | 0.09 | 0.10 | 0.10 | 0.10 | 0.05 | 0.20 | 0.10 | 0.11 | 0.10 | 0.10 |

| R-013 | 0.10 | 0.10 | 0.10 | 0.05 | 0.10 | 0.09 | 0.10 | 0.10 | 0.10 | 0.10 | 0.20 | 0.10 | 0.12 | 0.10 | 0.10 |

| R-014 | 0.40 | 0.40 | 0.40 | 0.40 | 0.40 | 0.40 | 0.40 | 0.20 | 0.20 | 0.20 | 0.20 | 0.20 | 0.20 | 0.20 | 0.51 |

| R-015 | 0.40 | 0.80 | 0.80 | 0.40 | 0.40 | 0.56 | 0.40 | 0.10 | 0.10 | 0.20 | 0.10 | 0.10 | 0.12 | 0.10 | 0.35 |

| R-016 | 0.40 | 0.80 | 0.40 | 0.80 | 0.40 | 0.56 | 0.40 | 0.10 | 0.20 | 0.20 | 0.20 | 0.10 | 0.16 | 0.20 | 0.27 |

| R-017 | 0.20 | 0.40 | 0.20 | 0.10 | 0.40 | 0.26 | 0.20 | 0.20 | 0.40 | 0.40 | 0.20 | 0.20 | 0.28 | 0.20 | 0.20 |

| R-018 | 0.10 | 0.40 | 0.40 | 0.40 | 0.40 | 0.34 | 0.40 | 0.20 | 0.40 | 0.20 | 0.20 | 0.20 | 0.24 | 0.20 | 0.30 |

| R-019 | 0.80 | 0.80 | 0.80 | 0.80 | 0.80 | 0.80 | 0.80 | 0.40 | 0.40 | 0.80 | 0.80 | 0.80 | 0.64 | 0.80 | 0.56 |

| R-020 | 0.10 | 0.05 | 0.10 | 0.10 | 0.10 | 0.09 | 0.10 | 0.20 | 0.20 | 0.20 | 0.10 | 0.20 | 0.20 | 0.20 | 0.12 |

| Risk-ID | Risk Exposure | Classification * | ||

|---|---|---|---|---|

| R-001 | 0.44 | 0.33 | 0.15 | Moderate |

| R-002 | 0.25 | 0.13 | 0.03 | Low |

| R-003 | 0.59 | 0.50 | 0.29 | High |

| R-004 | 0.20 | 0.18 | 0.03 | Low |

| R-005 | 0.20 | 0.11 | 0.02 | Low |

| R-006 | 0.45 | 0.38 | 0.17 | Moderate |

| R-007 | 0.24 | 0.17 | 0.04 | Low |

| R-008 | 0.48 | 0.36 | 0.17 | Moderate |

| R-009 | 0.27 | 0.24 | 0.07 | Moderate |

| R-010 | 0.50 | 0.20 | 0.10 | Moderate |

| R-011 | 0.47 | 0.31 | 0.15 | Moderate |

| R-012 | 0.13 | 0.10 | 0.01 | Low |

| R-013 | 0.30 | 0.10 | 0.03 | Low |

| R-014 | 0.62 | 0.51 | 0.31 | High |

| R-015 | 0.38 | 0.35 | 0.13 | Moderate |

| R-016 | 0.42 | 0.27 | 0.11 | Moderate |

| R-017 | 0.19 | 0.20 | 0.04 | Low |

| R-018 | 0.19 | 0.30 | 0.06 | Moderate |

| R-019 | 0.34 | 0.56 | 0.19 | High |

| R-020 | 0.12 | 0.12 | 0.01 | Low |

| Risk-ID | Actions of Response Planning | |

|---|---|---|

| R-001 | Moderate | In a deep analysis of the strategic concept; cooperation with systems engineering and business process modelling experts. |

| R-002 | Low | Organization of knowledge/technology transfer (KTT) training courses; literature review(s); investigation in technical libraries/databases; external consultation and lessons learned. |

| R-003 | High | Project risk analysis; preventive actions and recovery management plan; mitigation measures and realignment of mechanisms of reclamation activities for organizational purposes. |

| R-004 | Low | Support of experienced and specialized legal experts; review of the legislation requirements and provisions; lessons learned from frameworks established for similar projects in the past; |

| R-005 | Low | Partnership with experts specialized in projects of sustainability financing and recycling economics. |

| R-006 | Moderate | Performance of strategic concept with a definition of feasible options (alternative strategies) for the mine’s transition to sustainability; experts’ judgement and validation is required. |

| R-007 | Low | Reformulation of company’s policies to align with sustainability and circular economy goals. |

| R-008 | Moderate | Systematic cost estimates based on empirical evidence, cost databases, and detailed cost analysis of services and materials; elaboration of an effective contingency plan. |

| R-009 | Moderate | Performance of an effective stakeholder engagement plan based on the international standards of recognized organizations and funding corporations (e.g., EBRD, World Bank). |

| R-010 | Moderate | Detailed analysis of the scope of work for the field data collection, laboratory investigations and reporting; recovery plan in cases of data collection omissions or gaps due to low validity of data. |

| R-011 | Moderate | Performance of a detailed plan for the data collection, engineering specifications/solutions and geoenvironmental factor evaluation; recovery plan in case of low-performance analyses. |

| R-012 | Low | Organizational resetting and re-engineering of mining operation functionality, insofar as required |

| R-013 | Low | Cooperation with environmental/social consultants with extensive experience in similar projects. |

| R-014 | High | Intensive supervision of site works; fieldwork risk management and controlling plan (for the low-quality, technically inadequate, or inappropriate field activities). |

| R-015 | Moderate | Reclamation scope definition based on mine’s situational analysis, methods suggested in the literature and empirical evidence; systematic scope reviews prior to the decision making is required. |

| R-016 | Moderate | Land use changing model validation by a multidisciplinary team of experts and society representatives; consideration of regional/national development plans is suggested. |

| R-017 | Low | Close collaborations with stakeholders and society representatives: key informants, focus groups, vulnerable communities, regional agencies, municipalities, Non-Governmental Organizations. |

| R-018 | Moderate | The legal aspects of the strategic plan need to be validated by a legal expert; due diligence framework to examine/analyze the regulatory provisions for the mine’s transition to a circular economy. |

| R-019 | High | Elaboration of a bankability study; funding flow monitoring; risk management plan; a plan for the management of potential project funding/financing problems is also required. |

| R-020 | Low | Support from risk and hazardousness analysis/research experts; mine’s physical environment; microclimate data and records of hazardous events for early planning. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Spanidis, P.-M.; Roumpos, C.; Pavloudakis, F. A Methodology Combining IDEF0 and Weighted Risk Factor Analysis for the Strategic Planning of Mine Reclamation. Minerals 2022, 12, 713. https://doi.org/10.3390/min12060713

Spanidis P-M, Roumpos C, Pavloudakis F. A Methodology Combining IDEF0 and Weighted Risk Factor Analysis for the Strategic Planning of Mine Reclamation. Minerals. 2022; 12(6):713. https://doi.org/10.3390/min12060713

Chicago/Turabian StyleSpanidis, Philip-Mark, Christos Roumpos, and Francis Pavloudakis. 2022. "A Methodology Combining IDEF0 and Weighted Risk Factor Analysis for the Strategic Planning of Mine Reclamation" Minerals 12, no. 6: 713. https://doi.org/10.3390/min12060713

APA StyleSpanidis, P.-M., Roumpos, C., & Pavloudakis, F. (2022). A Methodology Combining IDEF0 and Weighted Risk Factor Analysis for the Strategic Planning of Mine Reclamation. Minerals, 12(6), 713. https://doi.org/10.3390/min12060713