A Method to Detect Abnormal Gas Dispersion Conditions in Flotation Machines

Abstract

:1. Introduction

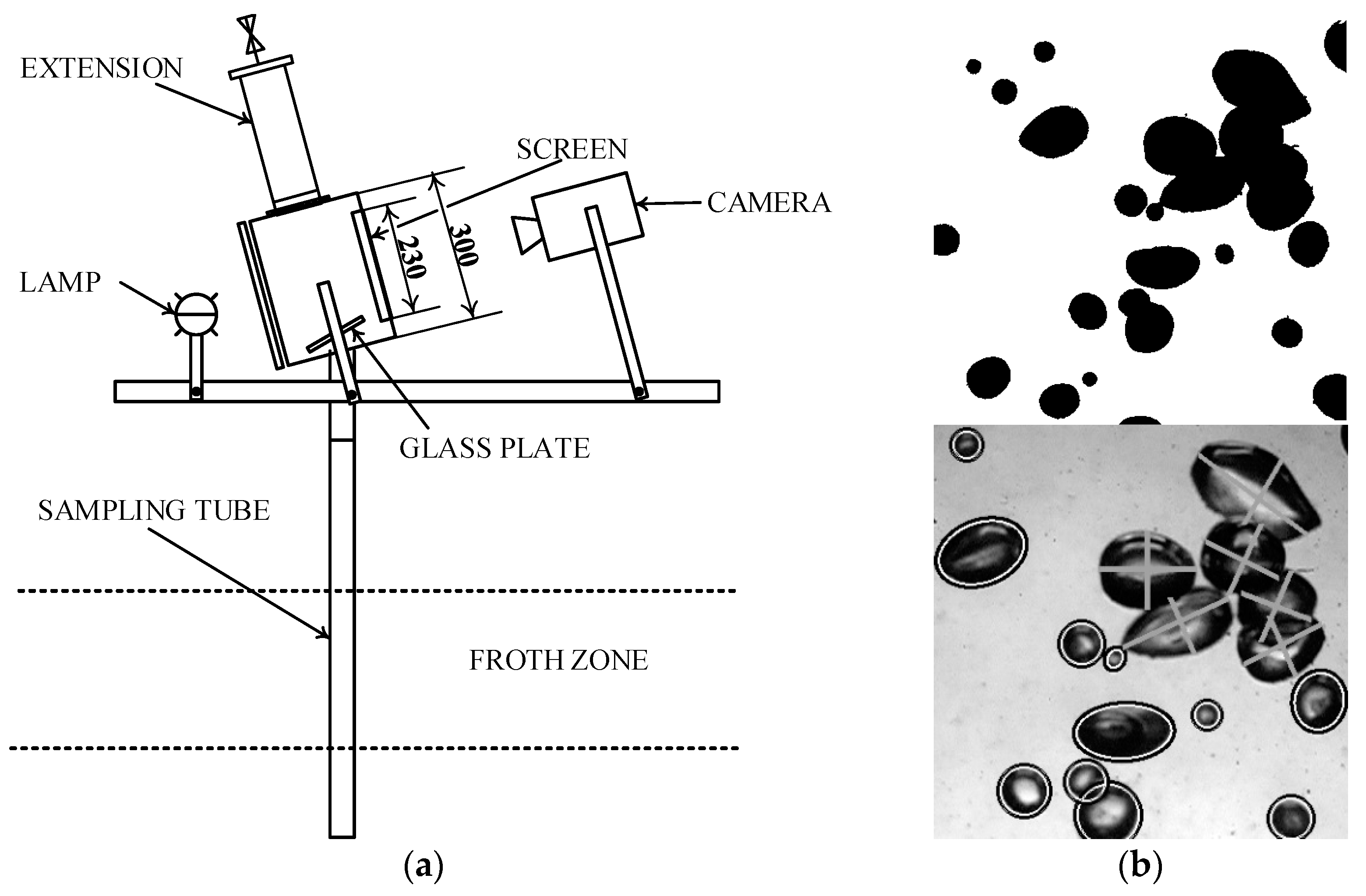

2. Materials and Methods

3. Results and Discussions

4. Conclusions

- The presence of cap-shaped bubbles caused peaks in the instantaneous shadow percentage, increasing its variability. This variability was significantly lower under spherical and spherical–ellipsoidal regimes.

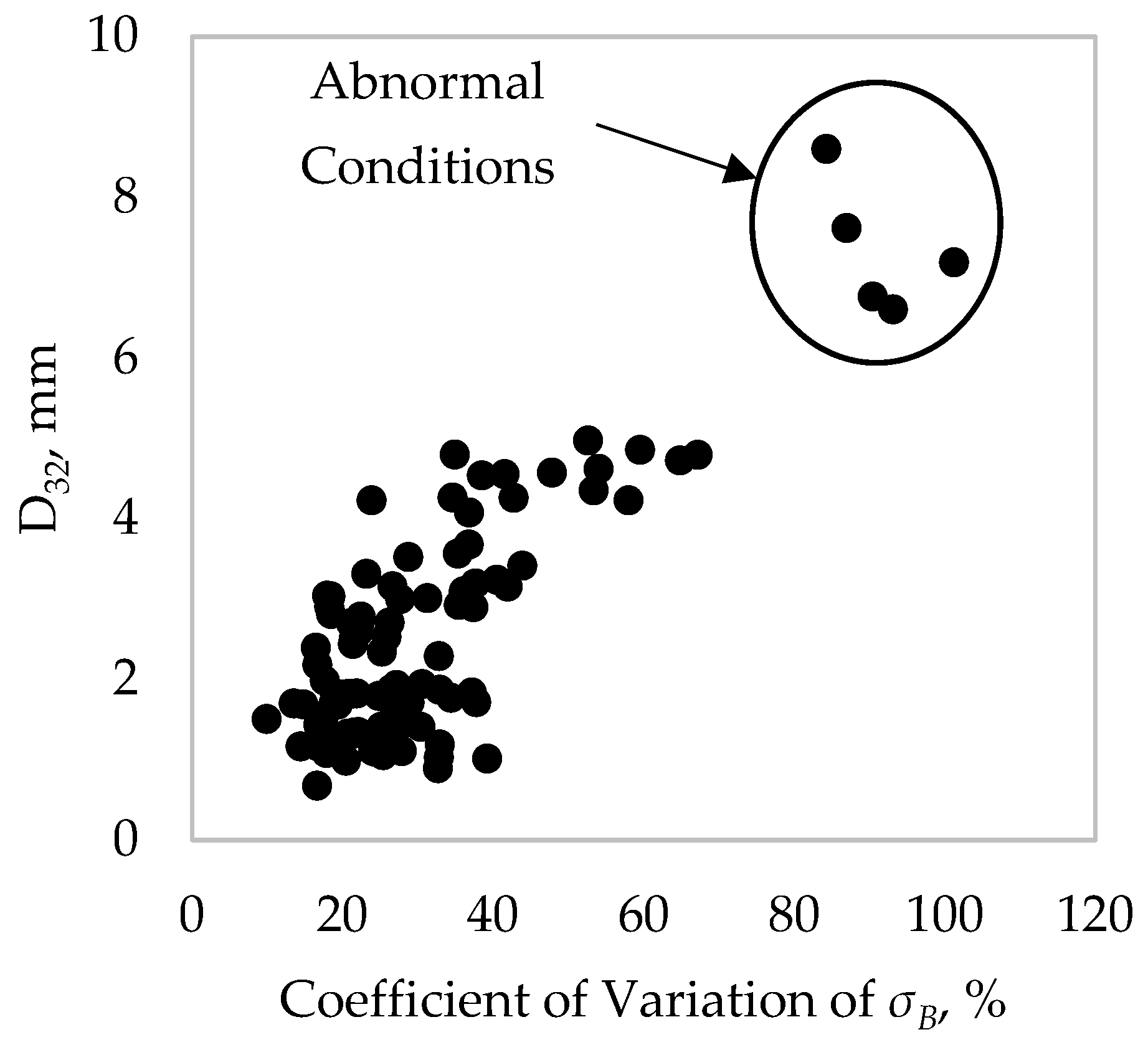

- The relative variability of the shadow percentage justified part of the variability of the Sauter mean diameter. Under spherical and spherical–ellipsoidal regimes, a noisy increasing trend between the cvσB and the D32 was observed.

- An abrupt increase in the coefficient of variation of the shadow percentage was observed in abnormal gas dispersion operations.

- A threshold of cvσB ≈ 80% was determined as suitable to detect a significant presence of cap-shaped bubbles in flotation machines. From this threshold, D32 > 6 mm were observed.

Author Contributions

Funding

Conflicts of Interest

References

- Gorain, B.K.; Franzidis, J.P.; Manlapig, E.V. Studies on impeller type, impeller speed and air flow rate in an industrial scale flotation cell. Part 4: Effect of bubble surface area flux on flotation performance. Miner. Eng. 1997, 10, 367–379. [Google Scholar] [CrossRef]

- Massinaei, M.; Kolahdoozan, M.; Noaparast, M.; Oliazadeh, M.; Yianatos, J.; Shamsadini, R.; Yarahmadi, M. Hydrodynamic and kinetic characterization of industrial columns in rougher circuit. Miner. Eng. 2009, 22, 357–365. [Google Scholar] [CrossRef]

- Hernandez-Aguilar, J.R.; Rao, S.R.; Finch, J.A. Testing the k–Sb relationship at the microscale. Miner. Eng. 2005, 18, 591–598. [Google Scholar] [CrossRef]

- Grau, R.A.; Laskowski, J.S. Role of frothers in bubble generation and coalescence in a mechanical flotation cell. Can. J. Chem. Eng. 2006, 84, 170–182. [Google Scholar] [CrossRef]

- Guven, O.; Batjargal, K.; Ozdemir, O.; Karakashev, S.I.; Grozev, N.A.; Boylu, F.; Çelik, M.S. Experimental procedure for the determination of the critical coalescence concentration (CCC) of simple frothers. Minerals 2020, 10, 617. [Google Scholar] [CrossRef]

- Cho, Y.-S.; Laskowski, J. Effect of flotation frothers on bubble size and foam stability. Int. J. Miner. Process. 2002, 64, 69–80. [Google Scholar] [CrossRef] [Green Version]

- Castro, S.; Miranda, C.; Toledo, P.; Laskowski, J.S. Effect of frothers on bubble coalescence and foaming in electrolyte solutions and seawater. Int. J. Miner. Process. 2013, 124, 8–14. [Google Scholar] [CrossRef]

- Gorain, B.K.; Napier-Munn, T.J.; Franzidis, J.-P.; Manlapig, E.V. Studies on impeller type, impeller speed and air flow rate in an industrial scale flotation cell. Part 5: Validation of k-Sb relationship and effect of froth depth. Miner. Eng. 1998, 11, 615–626. [Google Scholar] [CrossRef]

- Vinnett, L.; Yianatos, J.; Arismendi, L.; Waters, K.E. Assessment of two automated image processing methods to estimate bubble size in industrial flotation machines. Miner. Eng. 2020, 159, 106636. [Google Scholar] [CrossRef]

- Riquelme, A.; Desbiens, A.; Bouchard, J.; del Villar, R. Parameterization of Bubble Size Distribution in Flotation Columns. IFAC Proc. Vol. 2013, 46, 128–133. [Google Scholar] [CrossRef]

- Fitzgibbon, A.W.; Pilu, M.; Fisher, R.B. Direct Least Squares Fitting of Ellipses. In Proceedings of the 13th International Conference on Pattern Recognition, Vienna, Austria, 25–29 August 1996; Volume 251, pp. 253–257. [Google Scholar]

- Acuña, C.; Vinnett, L.; Kuan, S.H. Improving image analysis of online bubble size measurements with enhanced algorithms. In Proceedings of the 12th International Mineral Processing Conference (Procemin), Santiago, Chile, 26–28 October 2016. [Google Scholar]

- The MathWorks Inc. Image Processing Toolbox: User’s Guide; The MathWorks Inc.: Natick, MA, USA, 2021. [Google Scholar]

- Finch, J.A.; Dobby, G.S. Column Flotation; Pergamon Press: Oxford, UK, 1990. [Google Scholar]

- Clift, R.; Grace, J.; Weber, M. Bubbles, Drops, and Particles; Academic Press: New York, NY, USA, 1978. [Google Scholar]

- Yianatos, J.B.; Henríquez, F. Boundary conditions for gas rate and bubble size at the pulp-froth interface in flotation equipment. Miner. Eng. 2007, 20, 625–628. [Google Scholar] [CrossRef]

- Vinnett, L.; Yianatos, J.; Alvarez-Silva, M. Gas Dispersion Measurements in Industrial Flotation Equipment. In Proceedings of the 8th Copper International Conference (Copper 2013), Santiago, Chile, 1–4 December 2013. [Google Scholar]

- Hernandez-Aguilar, J.; Gomez, C.; Finch, J. A technique for the direct measurement of bubble size distributions in industrial flotation cells. In Proceedings of the 34th Annual Meeting of the Canadian Mineral Processors, Ottawa, ON, Canada, 22–24 January 2002; pp. 389–402. [Google Scholar]

- Grau, R.A. An Investigation of the Effect of Physical and Chemical Variables on Bubble Generation and Coalescence in Laboratory Scale Flotation Cells. Ph.D. Thesis, Helsinki University of Technology, Helsinki, Finland, 2006. [Google Scholar]

- Vinnett, L.; Alvarez-Silva, M. Indirect estimation of bubble size using visual techniques and superficial gas rate. Miner. Eng. 2015, 81, 5–9. [Google Scholar] [CrossRef]

- Vinnett, L.; Yianatos, J.; Alvarez, M. Gas dispersion measurements in mechanical flotation cells: Industrial experience in Chilean concentrators. Miner. Eng. 2014, 57, 12–15. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vinnett, L.; Yianatos, J.; Acuña, C.; Cornejo, I. A Method to Detect Abnormal Gas Dispersion Conditions in Flotation Machines. Minerals 2022, 12, 125. https://doi.org/10.3390/min12020125

Vinnett L, Yianatos J, Acuña C, Cornejo I. A Method to Detect Abnormal Gas Dispersion Conditions in Flotation Machines. Minerals. 2022; 12(2):125. https://doi.org/10.3390/min12020125

Chicago/Turabian StyleVinnett, Luis, Juan Yianatos, Claudio Acuña, and Iván Cornejo. 2022. "A Method to Detect Abnormal Gas Dispersion Conditions in Flotation Machines" Minerals 12, no. 2: 125. https://doi.org/10.3390/min12020125

APA StyleVinnett, L., Yianatos, J., Acuña, C., & Cornejo, I. (2022). A Method to Detect Abnormal Gas Dispersion Conditions in Flotation Machines. Minerals, 12(2), 125. https://doi.org/10.3390/min12020125