The Meso-Structural Characteristics of Crack Generation and Propagation during Rock Fracturing

Abstract

:1. Introduction

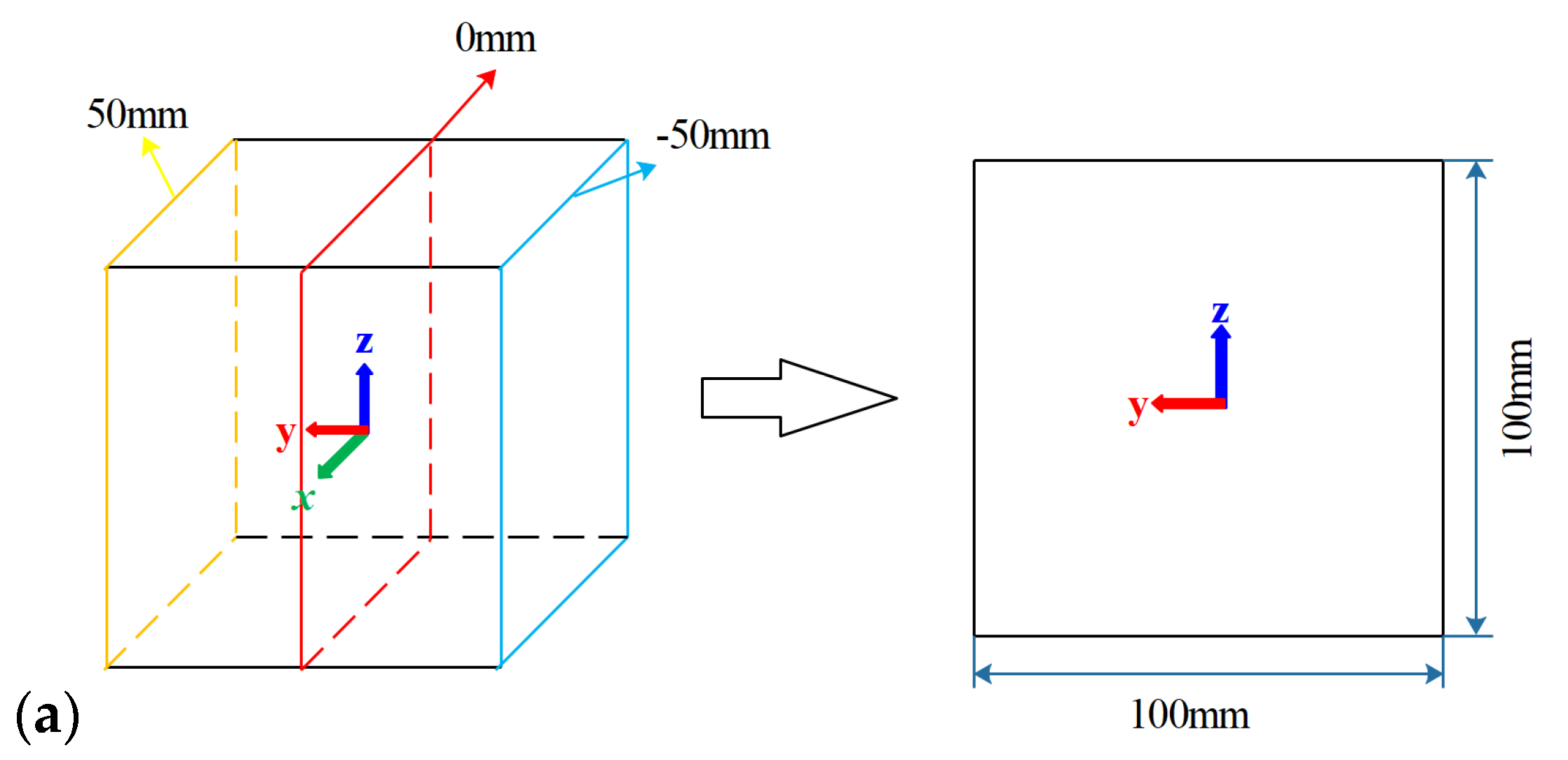

2. Experimental Design

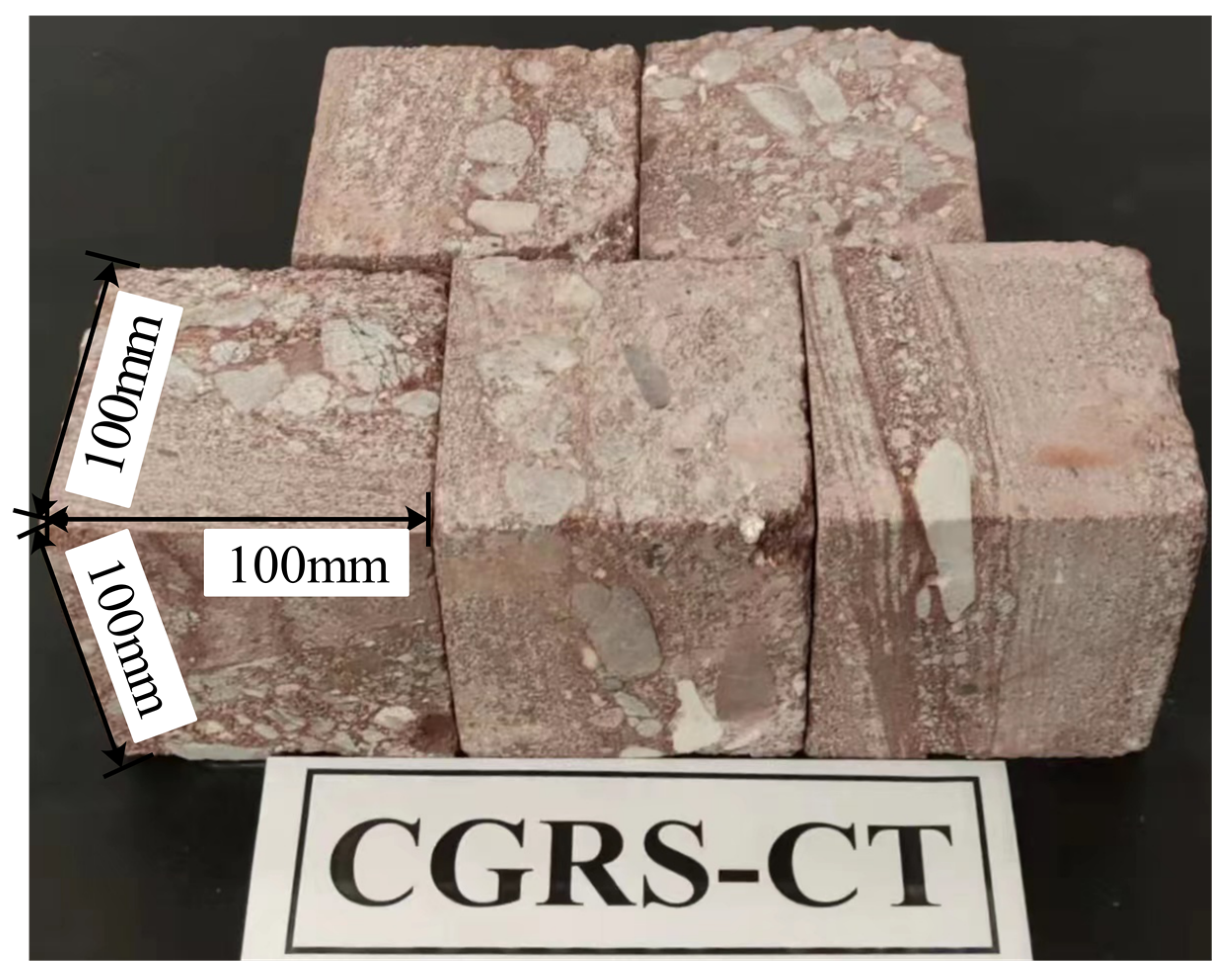

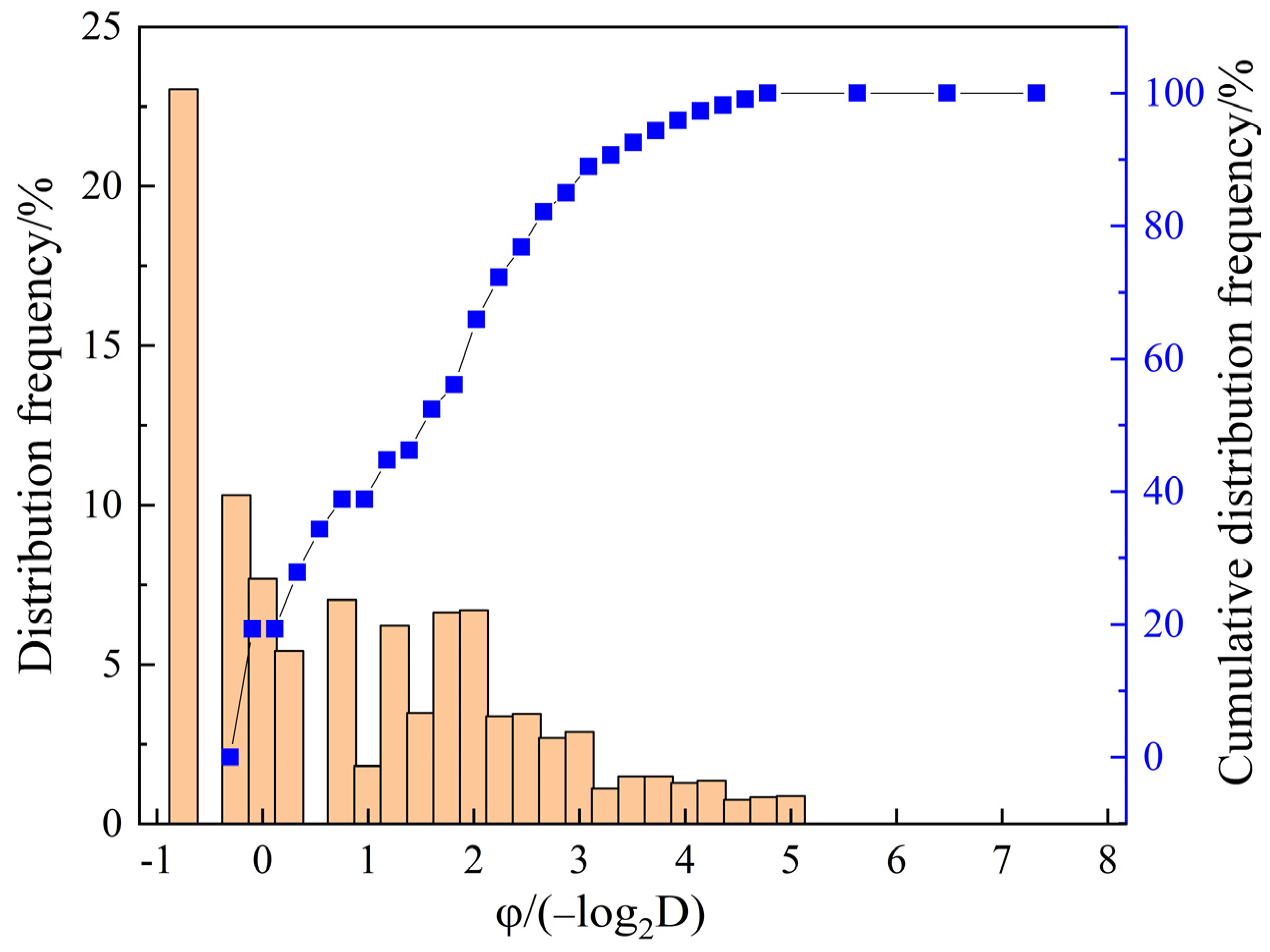

2.1. Specimen Selection

2.2. Test System

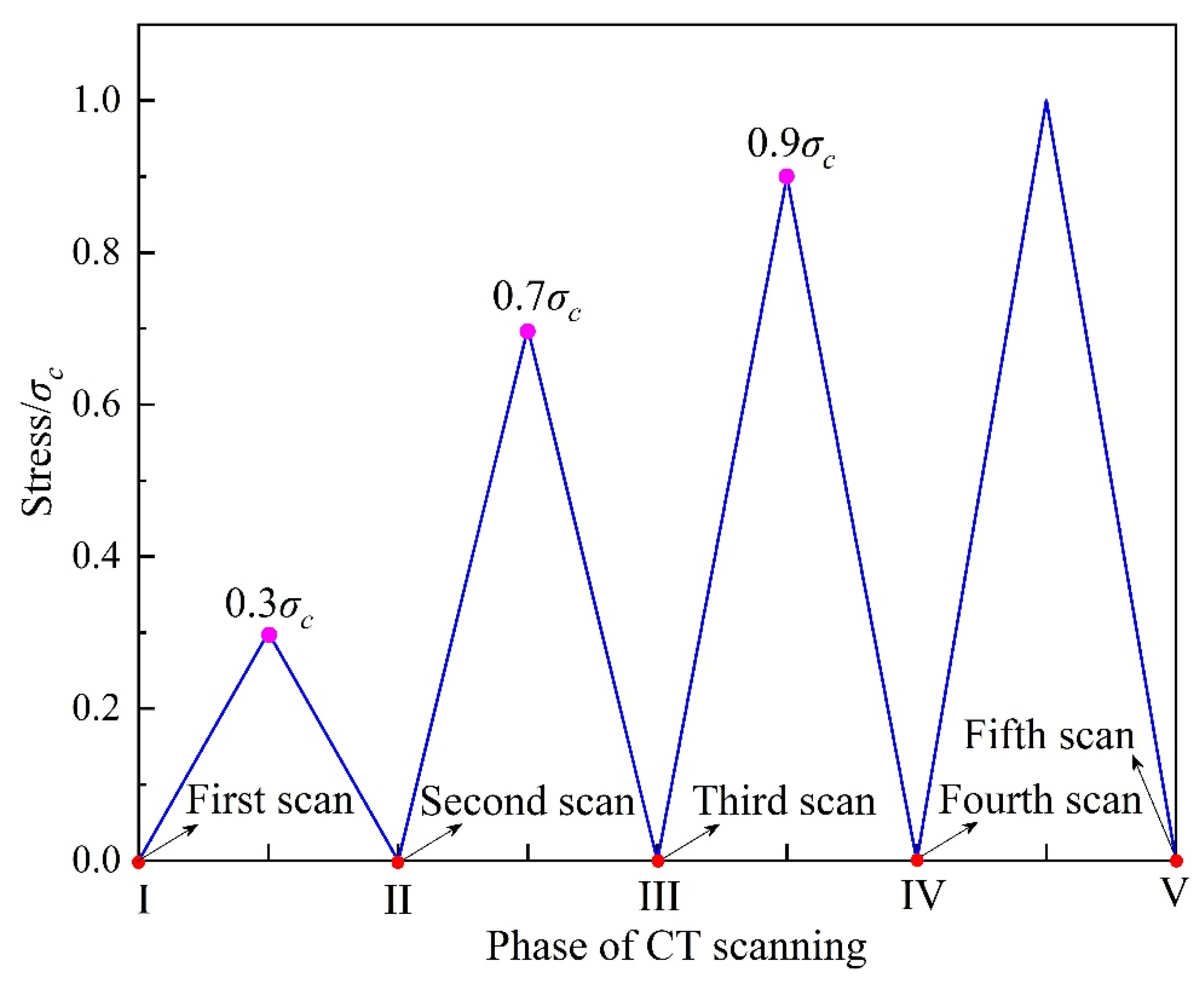

2.3. Experimental Process

3. Experimental Results

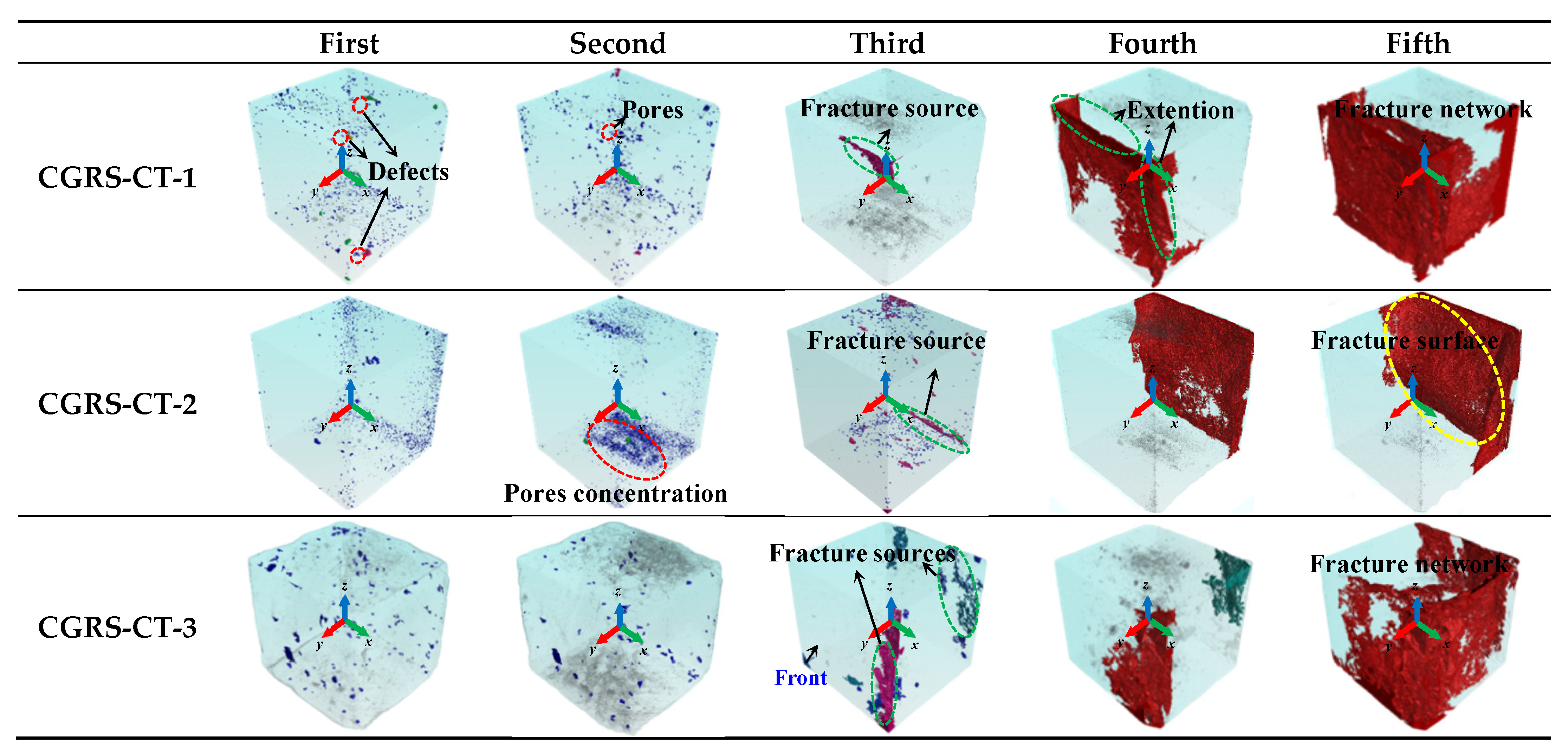

3.1. Location of Fracture Sources

3.2. Crack Propagation during Rock Fracturing Process

- -

- -

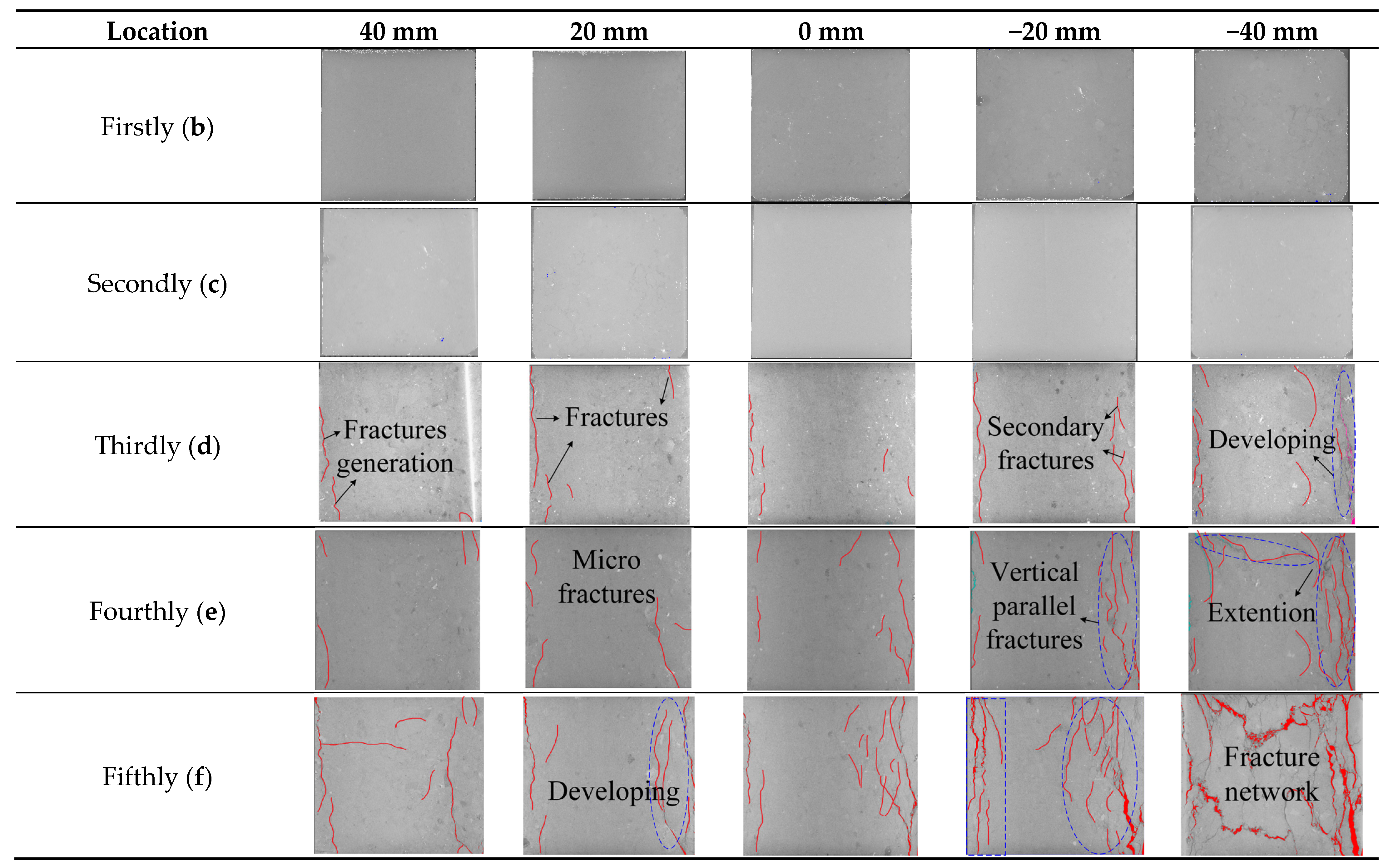

- Third scan (Figure 7d): In the corresponding elastic phase, fractures could be found in all slices. On the slice at 40 mm, the fracture occurred at the edge of the specimen. On the slices at 20 and 0 mm, the number of microfractures gradually increased. On the slice at −20 mm, evidence of secondary fracture production can be found in a vertical distribution parallel to the end of the specimen. On the slice at −40 mm, the fracture on the right-hand side of the sample penetrated both end surfaces and extended to the middle area.

- -

- Fourth scan (Figure 7e): After the unstable fracture stage, the generation and expansion of microfractures could be found on the slices at 40 and 20 mm, and compared with the previous stage, the distribution of fractures did not change much. On the slice at 0 mm, the number of fractures on the right-hand side of the sample gradually increased with a tendency to penetrate the upper and lower end surfaces. On the slice at −20 mm, the fractures on the right-hand side were approximately vertically parallel, with the upper and lower end surfaces connected. On the slice at −40 mm, the transverse fracture on the left-hand side and the vertical fracture on the right were connected to each other.

- -

- Fifth scan (Figure 7f): After the final fracture, compared with the previous stage, on the slices at 40 and 20 mm, both the length of the fracture and the degree of fracture propagation were increased. On the slice at −20 mm, there were many more branching fractures, which were distributed on both sides of the sample. On the slice at −40 mm, the branching fractures were inter-connected, and a more complex fracture network was formed.

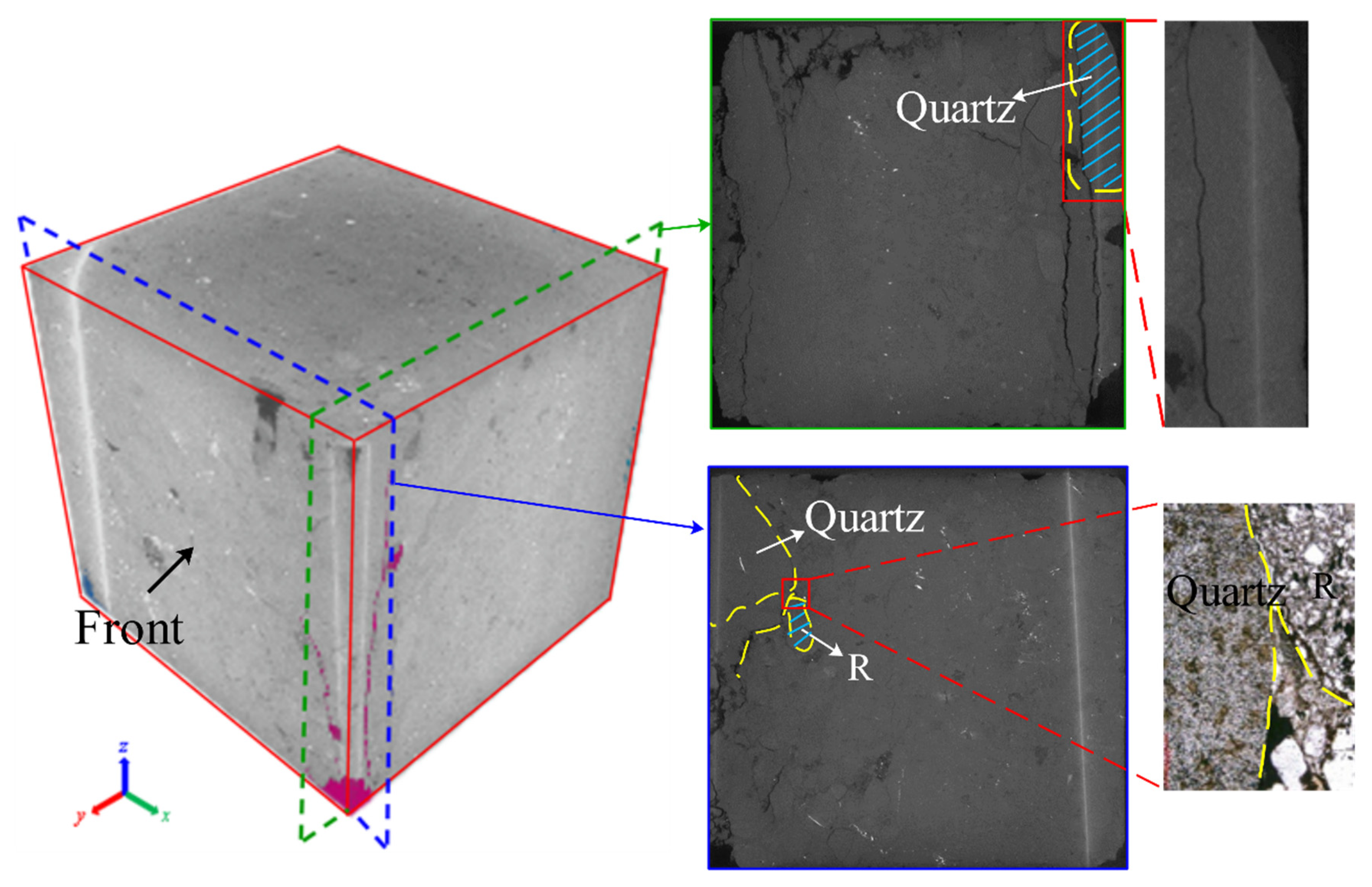

3.3. Types of Fracture Sources Based on Meso-Structure Scale

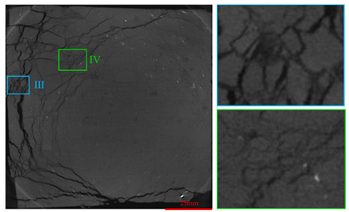

3.3.1. Fracture Sources of Pore Structure

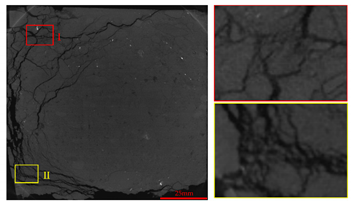

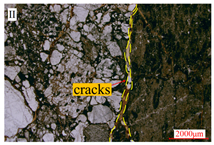

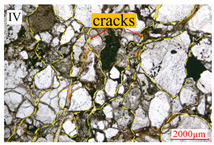

3.3.2. Fracture Sources of Micro-Cracks

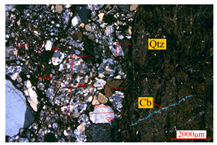

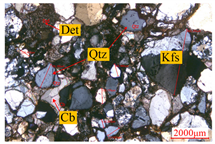

3.3.3. Fracture Sources of Mineral Particles

4. Discussion

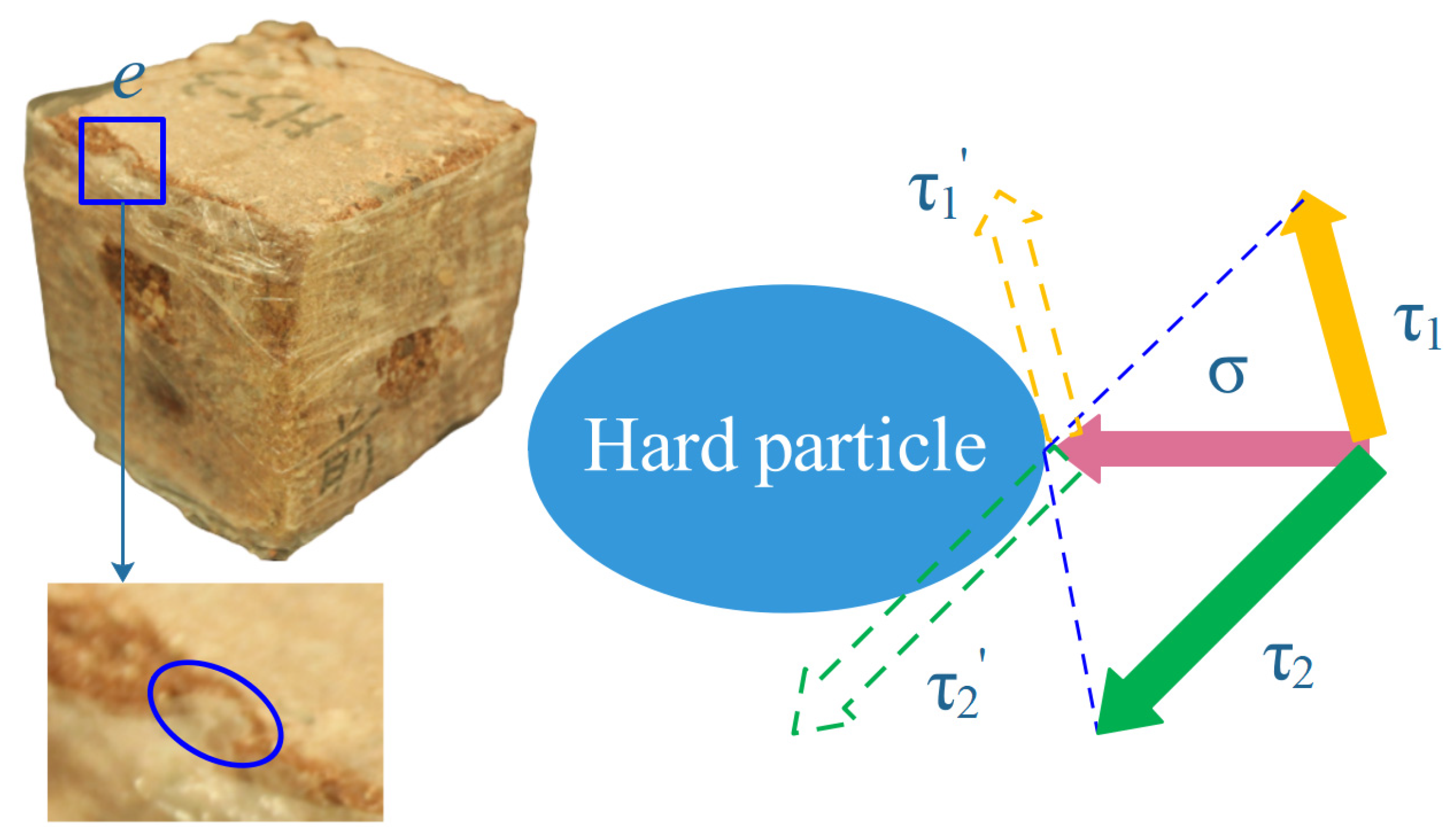

4.1. Physical Mechanisms of Fracture Source Classification

4.2. Influence of Rock Physical Properties on Crack Propagation

4.2.1. Mineral Particle Strength

4.2.2. Mineral Spatial Distributions

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xu, S.J.; Yin, X.T.; Dang, F.N. Mechanical characteristics of rock and soil affected by particle size of crystal and mineral. Rock Soil Mech. 2009, 30, 2581–2587. [Google Scholar] [CrossRef]

- Qin, Y.D.; Wang, H.; Wang, Z.X. Failure mechanism and control analysis of fractured and easily weathered roadway in deep mining. China Min Mag. 2020, 29, 388–393. [Google Scholar] [CrossRef]

- Anders, M.H.; Laubach, S.E.; Scholz, C.H. Microfractures: A review. J. Struct. Geol. 2014, 69, 377–394. [Google Scholar] [CrossRef] [Green Version]

- Wittmann, F.H.; RoelfstraP, E.; Sadouki, H. Simulation and analysis of composite structures. Mater. Sci. Eng. 1985, 68, 239–248. [Google Scholar] [CrossRef]

- Yu, Q.; Yang, T.; Zheng, C.; Tang, C.A.; Wang, P.T. Numerical analysis of influence of rock mesostructure on its deformation and strength. Rock Soil Mech. 2011, 32, 3468–3472. [Google Scholar] [CrossRef]

- Zhao, B.; Wang, Z.Y.; Wu, J.P. Relation between mineralogical composition and microstructure to the mechanical properties of rock materials. Coal Geol. Explor. 2013, 41, 59–63, 67. [Google Scholar] [CrossRef]

- Zhang, G.K.; Li, H.B.; Xia, X.; Li, J.R.; Li, X.F.; Song, T. Effects of microstructure and micro parameters on macro mechanical properties and failure of rock. Chin. J. Rock Mech. Eng. 2016, 35, 1341–1352. [Google Scholar] [CrossRef]

- Deng, C.F.; Liu, J.F.; Chen, L.; Li, Y.; Xiang, G. Fracture mechanical behaviors and acoustic emission characteristics of Beishan granites with different particle sizes. Rock Soil Mech. 2016, 37, 2313–2320. [Google Scholar] [CrossRef]

- Zhao, Y.C.; Liu, H.L.; Yang, T.H.; Xu, T.; Li, Y.; Hou, X.G.; Qin, Y. Effect of mesozoic sandstone meso structure on strength and energy dissipation characteristic. J. China Coal Soc. 2017, 42, 452–459. [Google Scholar] [CrossRef]

- Zhao, K.; Zhou, Y.T.; Zeng, P.; Yang, Z.Y.; Liu, C.F. Experimental study on acoustic emission characteristics of rock-like materials with different particle sizes under three-point bending. J. China Coal Soc. 2018, 43, 3107–3114. [Google Scholar] [CrossRef]

- Li, J.; Yilmaz, E.; Cao, S. Minerals influence of solid content, cement/tailings ratio, and curing time on rheology and strength of cemented tailings backfill. Minerals 2020, 10, 922. [Google Scholar] [CrossRef]

- Cao, S.; Xue, G.L.; Yilmaz, E.; Yin, Z.Y.; Yang, F.D. Utilizing concrete pillars asan environmental mining practice in underground mines. J. Clean. Prod. 2021, 278, 123433. [Google Scholar] [CrossRef]

- Cao, S.; Yilmaz, E.; Yin, Z.Y.; Xue, G.L.; Song, W.D.; Sun, L.J. CT scanning of internal crack mechanism and strength behavior of cement-fibertailings matrix composites. Cem. Concr. Compos. 2020, 116, 103865. [Google Scholar] [CrossRef]

- Ji, H.G.; Jiang, H.; Song, C.Y.; Liu, Z.Q.; Tan, J.; Liu, Y.J.; Wu, Y.F. Analysis on the microstructure evolution and fracture morphology during the softning process of weakly cemeted sandstone. J. China Coal Soc. 2018, 43, 993–999. [Google Scholar] [CrossRef]

- Song, C.Y.; Ning, F.B. Progress on the Association between Mesostructural Parameters and Macromechanical Behaviors of Weakly Cemented Rocks. Met. Mine. 2018, 12, 1–9. [Google Scholar] [CrossRef]

- Hasanipanah, M.; Meng, D.; Keshtegar, B.; Behrooz, K.; Nguyen, T.T.; Duc, K.T. Nonlinear models based on enhanced Kriging interpolation for prediction of rock joint shear strength. Neural Comput. Appl. 2021, 33, 4205–4215. [Google Scholar] [CrossRef]

- Huang, J.D.; Zhang, J.; Gao, Y. Intelligently predict the rock joint shear strength using the support vector regression and Firefly Algorithm. Lithosphere 2021, 2021, 2467126. [Google Scholar] [CrossRef]

- Ge, Y.F.; Tang, H.M.; Eldin, M.A.; Wang, L.Q.; Wu, Q.; Xiong, C.R. Evolution process of natural rock joint roughness during direct shear tests. Int. J. Geo. 2016, 17, E4016013. [Google Scholar] [CrossRef]

- Han, Q.; Feng, X.T.; Yang, C.X.; Kong, R.; Zhao, J.; Zhang, Y. Evaluation of the crack propagation capacity of hard rock based on stress-induced deformation anisotropy and the propagation angle of volumetric strain. Rock. Mech. Rock. Eng. 2021, 54, 6585–6603. [Google Scholar] [CrossRef]

- Sun, W.; Wu, A.; Hou, K.; Yang, Y.; Liu, L.; Wen, Y. Real-time observation of meso-fracture process in backfill body during mine subsidence using X-ray CT under uniaxial compressive conditions. Constr. Build. Mater. 2016, 113, 153–162. [Google Scholar] [CrossRef]

- Liu, S.; Wang, Z.; Zhang, L. Experimental study on the cracking process of layered shale using X-ray microCT. Energy Explor. Exploit. 2018, 36, 297–313. [Google Scholar] [CrossRef] [Green Version]

- Duan, Y.; Li, X.; Zheng, B.; He, J.; Hao, J. Cracking Evolution and Failure Characteristics of Longmaxi Shale Under Uniaxial Compression Using Real-Time Computed Tomography Scanning. Rock. Mech. Rock. Eng. 2019, 52, 3003–3015. [Google Scholar] [CrossRef]

- Wang, M.; Wan, W.; Zhao, Y. Experimental study on crack propagation and the coalescence of rock-like materials with two preexisting fissures under biaxial compression. Bull. Eng. Geol. Environ. 2020, 79, 3121–3144. [Google Scholar] [CrossRef]

- Pu, C.Z.; Cao, P. Failure characteristics and its influencing factors of rock-like material with multi-fissures under uniaxial compression. Trans. Nonferrous Met. Soc. China 2012, 22, 185–191. [Google Scholar] [CrossRef]

- Wang, D.J.; Tang, H.M.; Elsworth, D.; Wang, C.Y. Fracture evolution in artificial bedded rocks containing a structural flaw under uniaxial compression. Eng. Geol. 2019, 250, 130–141. [Google Scholar] [CrossRef]

- Du, M.R.; Jing, H.W.; Su, H.J.; Zhu, T.T. Experimental study of strength and failure characteristics of sandstone containing prefabricated elliptical hole. J. China Univ. Min. Technol. 2016, 45, 1164–1171. [Google Scholar] [CrossRef]

- Zhu, T.T.; Jing, H.W.; Su, H.J.; Yin, Q. Experimental investigation on mechanical behavior of sandstone with coupling effects under uniaxial compression. J. China Coal Soc. 2015, 40, 1518–1525. [Google Scholar] [CrossRef]

- Han, G.S.; Jing, H.W.; Su, H.J.; Zhu, T.T.; Du, M.R.; Xiong, F.; Wu, J.Y. Experimental study on compressive strength and fracture characteristics of sandstone containing double circular cavities. J. China Coal Soc. 2017, 42, 871–878. [Google Scholar] [CrossRef]

- Laubach, S.E.; Lander, R.H.; Criscenti, L.J.; Anovitz, L.M.; Urai, J.L.; Pollyea, R.M.; Hooker, J.N.; Narr, W.; Evans, M.A.; Kerisit, S.N.; et al. The role of chemistry in fracture pattern development and opportunities to advance interpretations of geological materials. Rev. Geophys. 2019, 57, 1065–1111. [Google Scholar] [CrossRef] [Green Version]

- Karfakis, M.G.; Akram, M. Effects of chemical solutions on rock fracturing. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1993, 30, 1253–1259. [Google Scholar] [CrossRef]

- Miao, S.J.; Cai, M.F.; Guo, Q.F.; Wang, P.T.; Liang, M.C. Damage effects and mechanisms in granite treated with acidic chemical solutions. Int. J. Rock Mech. Min. Sci. 2016, 88, 77–86. [Google Scholar] [CrossRef]

- Přikryl, R. Some microstructural aspects of strength variation in rocks. Int. J. Rock Mech. Rock. Eng. 2001, 38, 671–682. [Google Scholar] [CrossRef]

- Han, Z.H.; Zhang, L.Q.; Zhou, J. Effect of mineral particle size heterogeneity on mechanical properties in PFC2D simulation. J. Eng. Geol. 2019, 27, 706–716. [Google Scholar] [CrossRef]

- Han, Z.H.; Zhang, L.Q.; Zhou, J.; Yuan, G.X.; Wang, P.J. Uniaxial compression test and numerical studies of grain size effect on mechanical properties of granite. J. Eng. Geol. 2019, 27, 497–504. [Google Scholar] [CrossRef]

- Sun, C.; Ao, Y.H.; Zhang, J.M.; Wang, S. Particle flow of meso-fracture characteristics and macro-scale effect of granites. Chin. J. Geotech. Eng. 2020, 42, 1687–1695. [Google Scholar] [CrossRef]

- Ye, G.; Cao, H.; Gao, Q.; Zhang, Z.; Wang, T.Y. Numerical simulation study on the influence of particle proportion on rock mechanics characteristics. J. Mech. 2019, 25, 1129–1137. [Google Scholar] [CrossRef]

- Bai, Q.; Tu, S.; Zhang, C. DEM investigation of the fracture mechanism of rock disc containing hole(s) and its influence on tensile strength. Theor. Appl. Fract. Mech. 2016, 86, 197–216. [Google Scholar] [CrossRef]

- Yu, Q.L.; Ranjith, P.G.; Liu, H.Y.; Yang, T.H.; Tang, C.A.; Yang, S.Q. A Mesostructure-based Damage Model for Thermal Cracking Analysis and Application in Granite at Elevated Temperatures. Rock. Mech. Rock. Eng. 2015, 48, 2263–2282. [Google Scholar] [CrossRef]

- Cai, M. Rock Mechanics and Engineering, 2nd ed.; Science Press: Beijing, China, 2018; pp. 44–46. [Google Scholar]

- Liu, X.X.; Wu, L.X.; Zhang, Y.B.; Wang, S.Z.; Yao, X.L.; Wu, X.Z. The characteristics of crack existence and development during rock shear fracturing evolution. Bull. Eng. Geol. Environ. 2020, 80, 1–12. [Google Scholar] [CrossRef]

- Li, J.; Kong, X.C.; Song, M.S.; Wang, Y.; Wang, H.; Liu, X.L. Study on the influence of reservoir rock micro-pore structure on rock mechanical properties and crack propagation. Rock Soil Mech. 2019, 40, 4149–4156, 4164. [Google Scholar] [CrossRef]

- Wang, H.; Li, Y.; Cao, S.G.; Pan, R.K.; Yang, H.Y.; Zhang, K.W.; Liu, Y.B. Brazilian splitting test study on crack propagation process and macroscopic failure mode of pre-cracked black shale. Chin. J. Rock Mech. Eng. 2020, 39, 912–926. [Google Scholar] [CrossRef]

- Li, M.; Guo, Y.; Wang, H.; Li, Z.; Hu, Y. Effects of mineral composition on the fracture propagation of tight sandstones in the Zizhou area, east Ordos Basin, China. J. Nat. Gas. Sci. Eng. 2020, 78, 103334. [Google Scholar] [CrossRef]

- Li, B.F.; Zuo, Y.J.; Li, W.; Cao, J. Analysis on fracture mechanics of granite containing flaws based on digital image processing. Mech Pract. 2016, 38, 262–268. [Google Scholar] [CrossRef]

- Zhang, C.; Yang, Q.J.; Cao, W.G. Simulation method of rock deformation and failure process considering initial imperfection and elastic modulus. Chin. J. Appl. Mech. 2020, 37, 286–292. [Google Scholar] [CrossRef]

- David, C.; Menéndez, B.; Bernabé, Y. The mechanical behaviour of synthetic sandstone with varying brittle cement content. Int. J. Rock Mech. Min. Sci. 1998, 35, 759–770. [Google Scholar] [CrossRef]

- Song, C.Y.; Ji, H.G.; Zeng, P.; Sun, L.H.; Tan, J. Phase-like transition characteristics of uniaxial compression failure of weakly cemented coarse-grained sandstone in western china. J. Min. Saf. Eng. 2020, 37, 1027–1036. [Google Scholar] [CrossRef]

- Song, C.Y. The Analysis and Application of mesoscopic Structure Characteristic and Deformation and Failure Mechanism of Weak Cemeted Sandstone. Ph.D. Thesis, Beijing University of Science and Technology, Beijing, China, 2017. [Google Scholar]

| Scan Times | Stress Level | Corresponding Load Value/kN | Deformation Stage |

|---|---|---|---|

| First | 0 | 0.00 | Initial stage |

| Second | 0.3σc | 125.80 | Compaction stage |

| Third | 0.7σc | 293.50 | Stable fracture stage |

| Fourth Fifth | 0.9σc -- | 377.4.0 -- | Unstable fracture stage After rupture |

| Sample Number | Pore Volume at Fracture Source/mm3 | Proportion of Total Pore Volume /% |

|---|---|---|

| CGRS-CT-1 | 906.1 | 18.75 |

| CGRS-CT-2 | 386.8 | 23.56 |

| CGRS-CT-3 | 362.75 | 34.09 |

| Critical Area of Fracture Path | Single Polarized Slice | Orthogonal Polarizing Sheet |

|---|---|---|

|  |  |

|  | |

|  |  |

|  |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Gao, G.; Yan, S.; Yao, X.; Liu, X.; Liang, P.; Xu, Y. The Meso-Structural Characteristics of Crack Generation and Propagation during Rock Fracturing. Minerals 2022, 12, 94. https://doi.org/10.3390/min12010094

Zhang Y, Gao G, Yan S, Yao X, Liu X, Liang P, Xu Y. The Meso-Structural Characteristics of Crack Generation and Propagation during Rock Fracturing. Minerals. 2022; 12(1):94. https://doi.org/10.3390/min12010094

Chicago/Turabian StyleZhang, Yanbo, Guangyu Gao, Shaohong Yan, Xulong Yao, Xiangxin Liu, Peng Liang, and Yuedong Xu. 2022. "The Meso-Structural Characteristics of Crack Generation and Propagation during Rock Fracturing" Minerals 12, no. 1: 94. https://doi.org/10.3390/min12010094

APA StyleZhang, Y., Gao, G., Yan, S., Yao, X., Liu, X., Liang, P., & Xu, Y. (2022). The Meso-Structural Characteristics of Crack Generation and Propagation during Rock Fracturing. Minerals, 12(1), 94. https://doi.org/10.3390/min12010094