ECORE: A New Fast Automated Quantitative Mineral and Elemental Core Scanner

Abstract

:1. Introduction

1.1. The Future of Scarce Elements Mining in Need of a New Type of Sensor

1.2. Hyperspectral Imaging as a Solution to Better Mining Exploration Analyzers

1.3. Fast and Robust Hyperspectral Imagers on the Market and Their Limitations

1.4. A Technique of Interest for Providing the Elemental Content

1.5. Combining Multiple Techniques: A Solution?

1.6. Recent Progresses in LIBS

1.7. A LIBS Analyzer Providing a Supervised Mineral Content

1.8. A LIBS Core Scanner Reaching the kHz

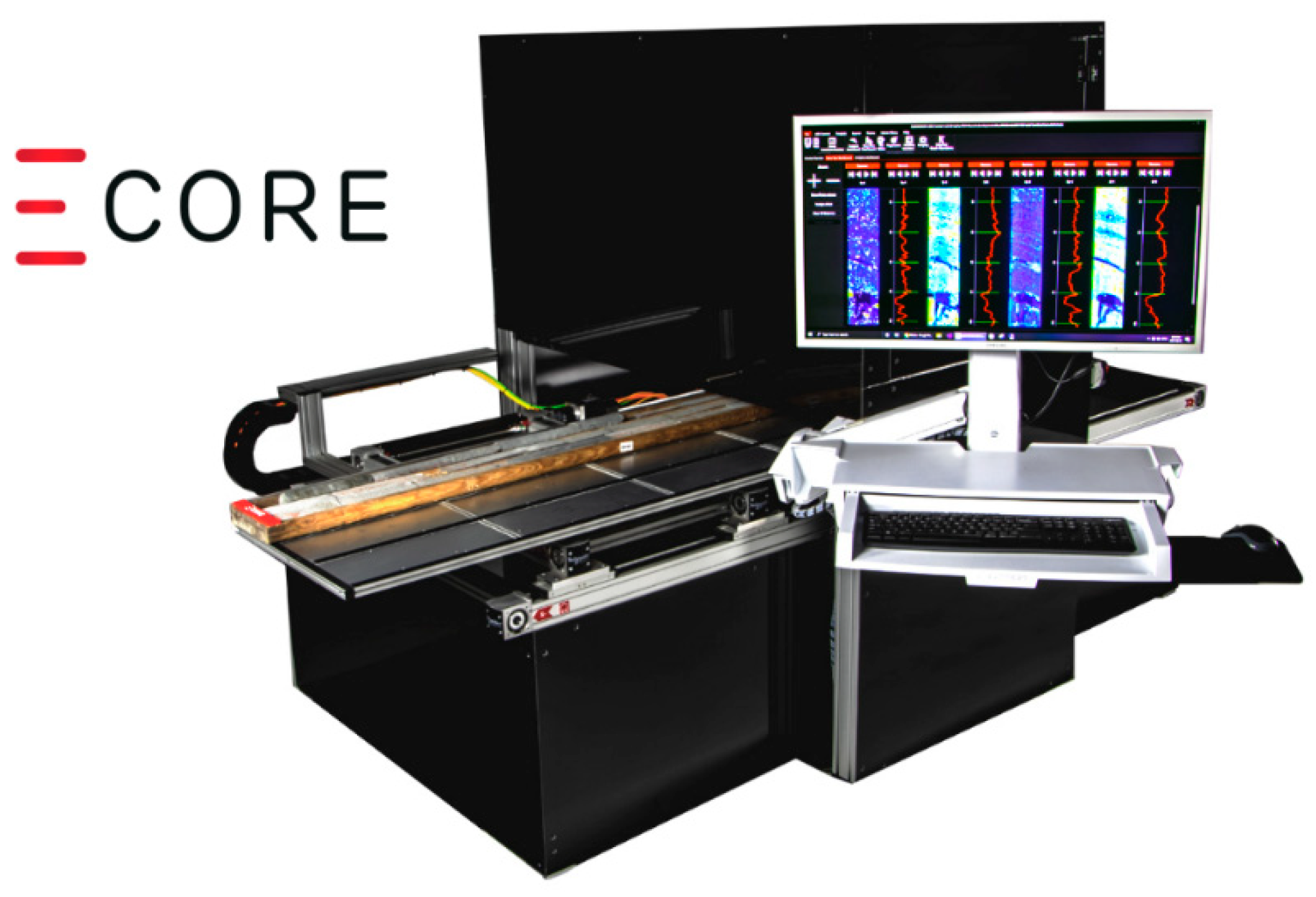

2. Method

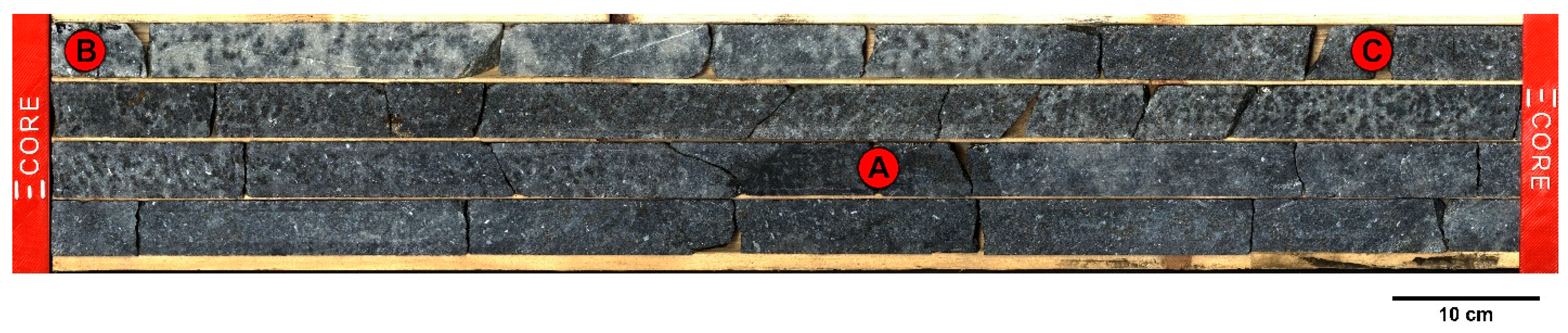

2.1. Drill Core Samples and Sample Preparation

2.2. LIBS Technical Overview

2.3. LIBS Procedure

2.4. TIMA-X Procedure

2.5. Drill Core Samples and Supervised Method

3. Discussion

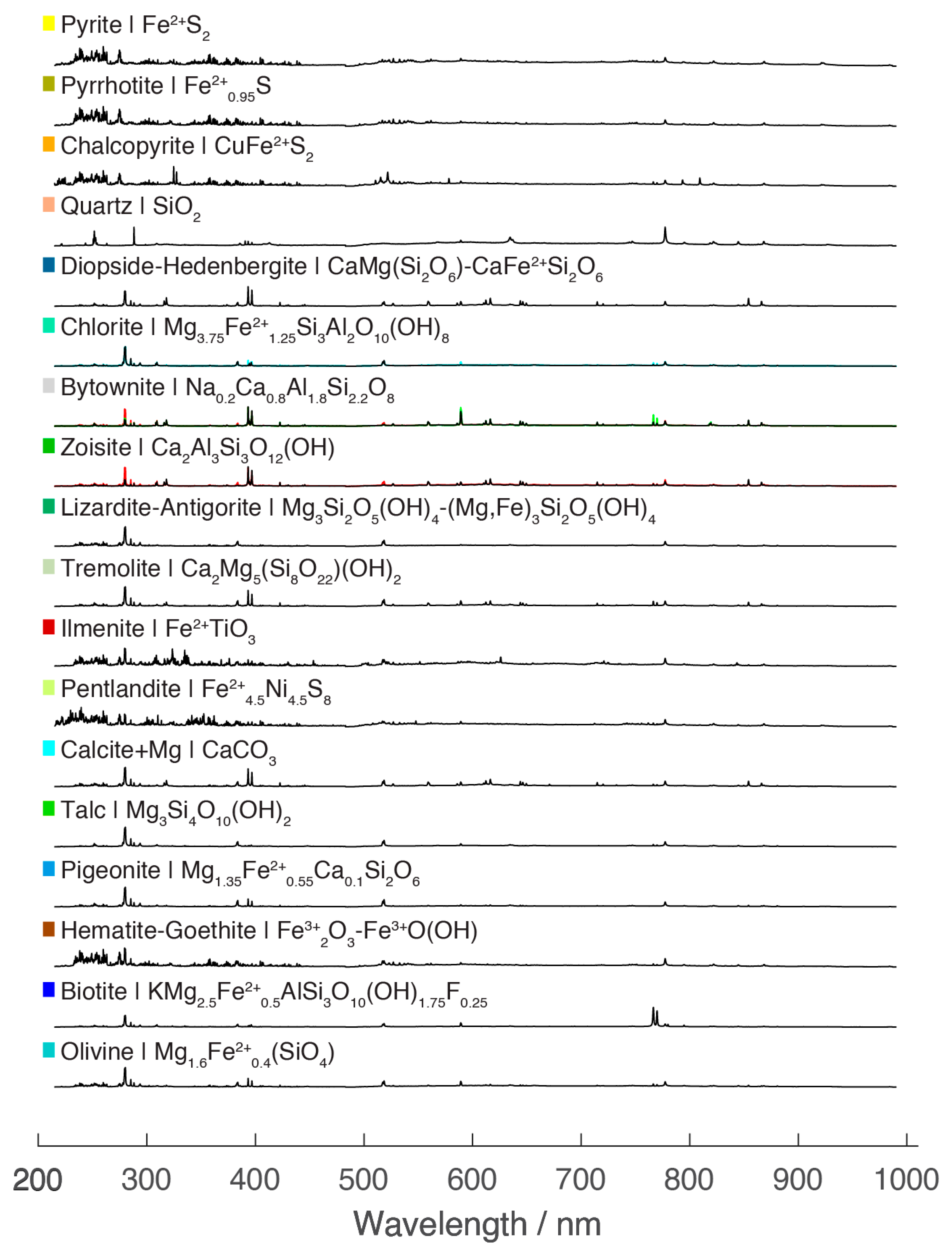

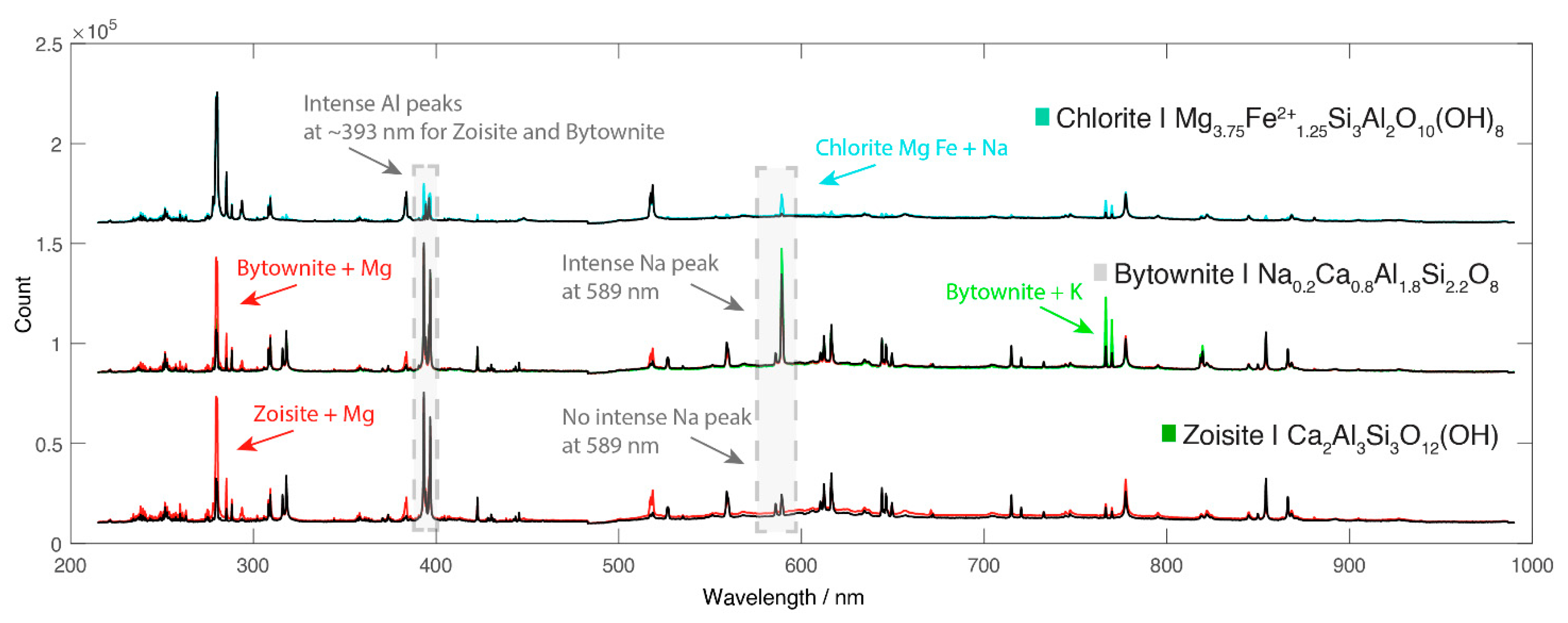

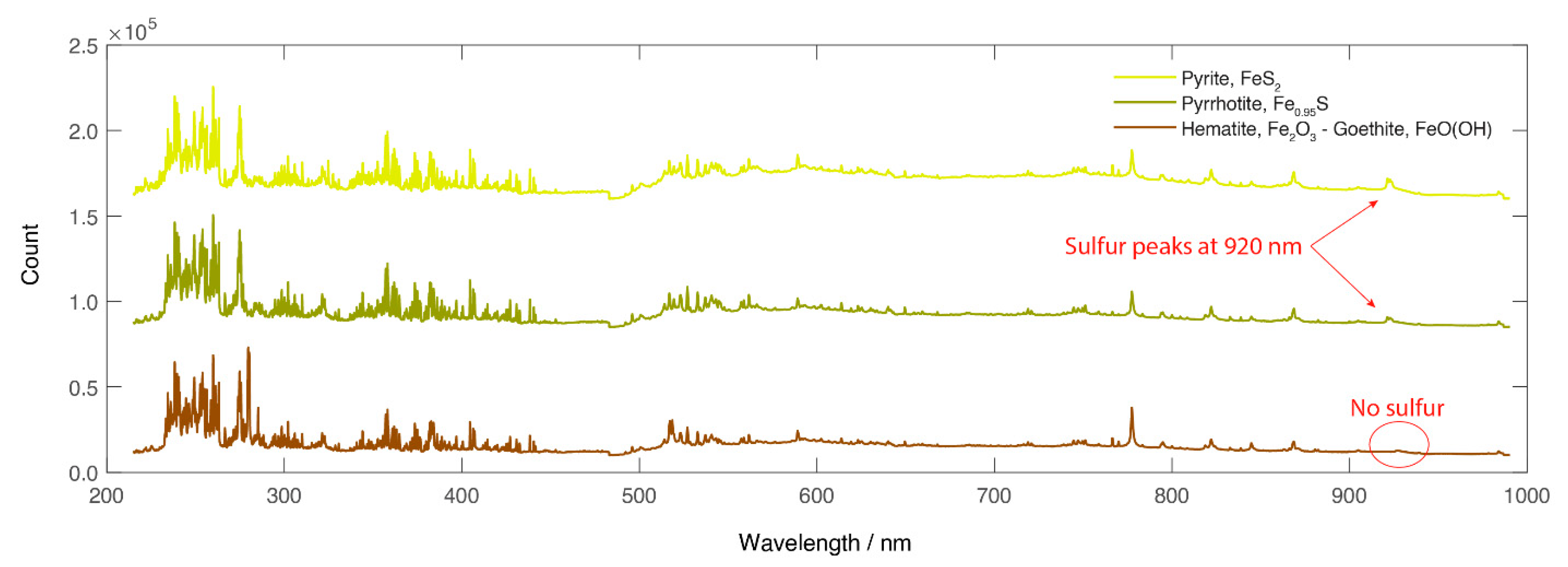

3.1. Mineral Classes and Their Spectra

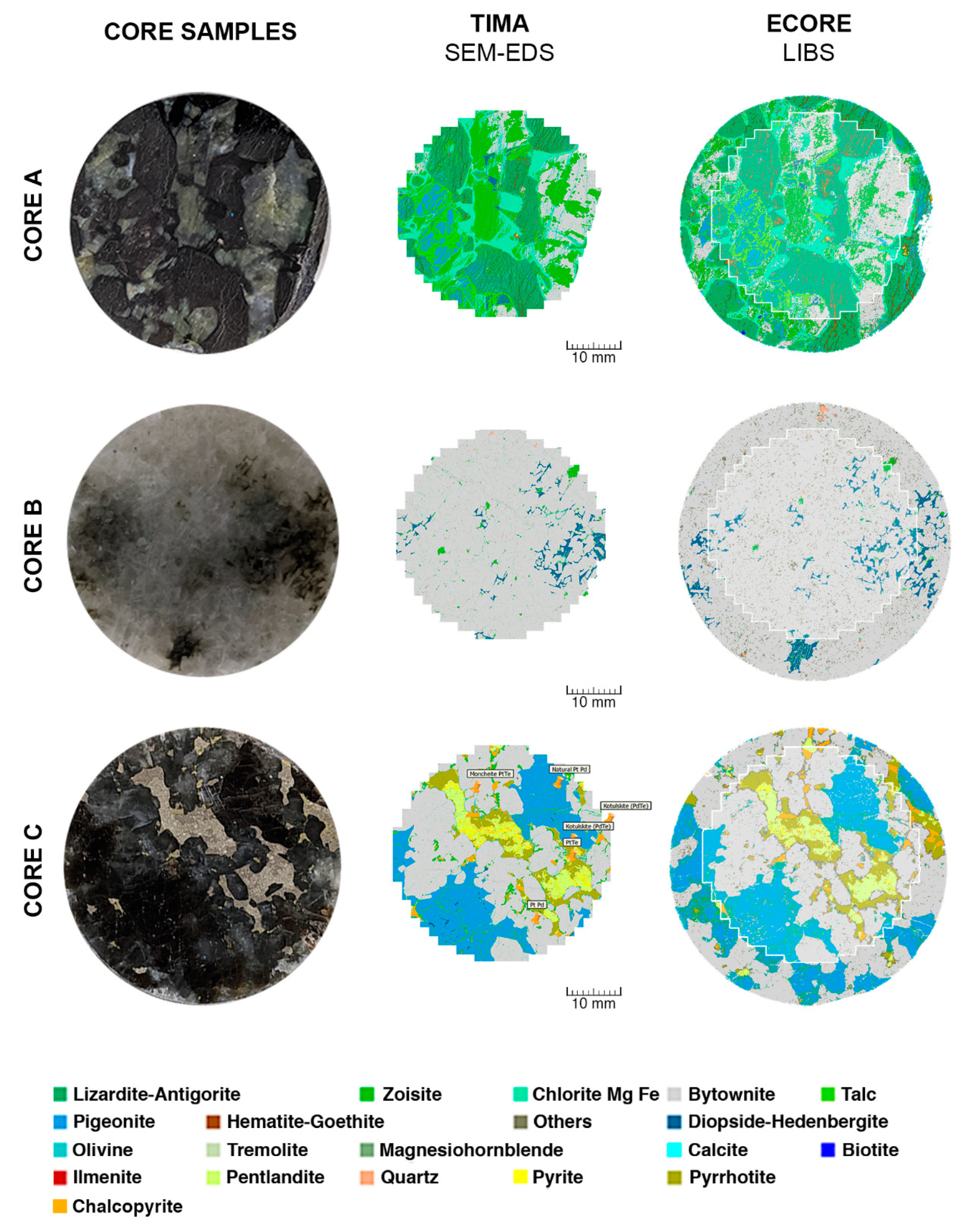

3.2. Newly Generated Maps of the Core Samples

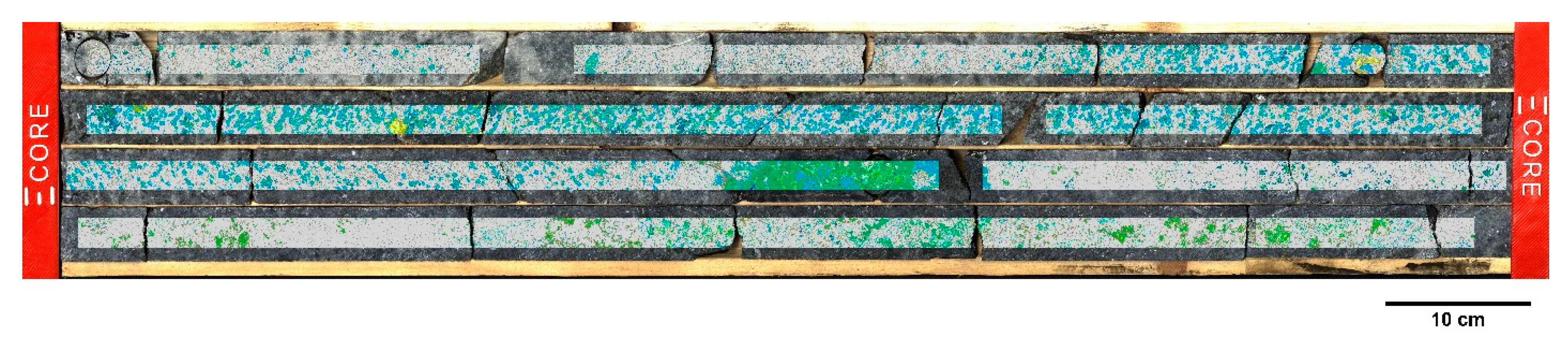

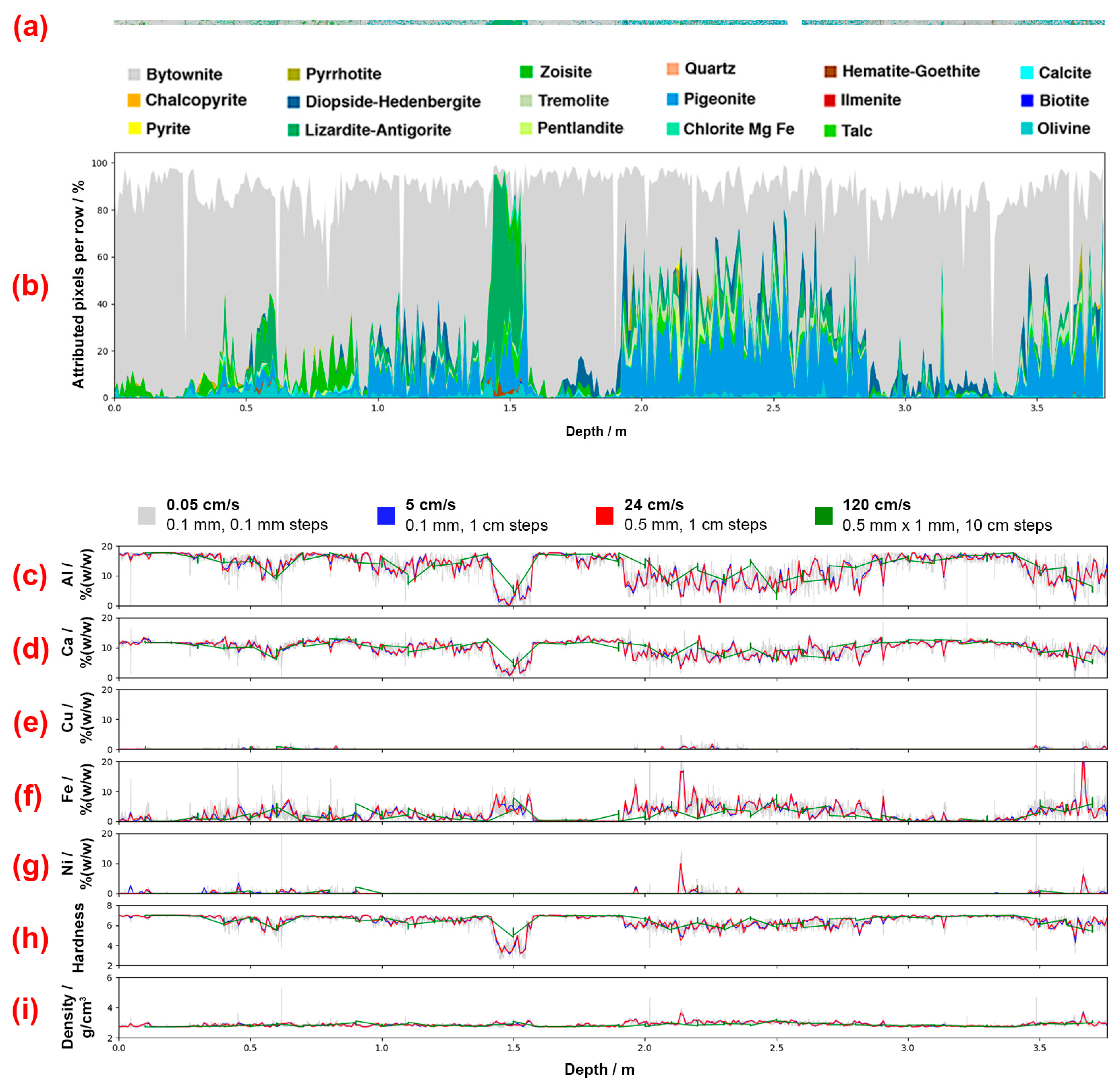

3.3. Automated Mineralogy of the Full Tray

3.4. Elemental Content

3.5. Comparison of Analysis Speeds with Other Techniques

3.6. Analysis Selectivity Comparison to Other Techniques

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Burlakovs, J.; Vincevica-Gaile, Z.; Krievans, M.; Jani, Y.; Horttanainen, M.; Pehme, K.-M.; Dace, E.; Setyobudi, R.H.; Pilecka, J.; Denafas, G.; et al. Platinum Group Elements in Geosphere and Anthroposphere: Interplay among the Global Reserves, Urban Ores, Markets and Circular Economy. Minerals 2020, 10, 558. [Google Scholar] [CrossRef]

- Zientek, M.L.; Loferski, P.J.; Parks, H.L.; Schulte, R.F.; Seal Ii, R.R. Platinum-Group Elements; 1802N; USGS: Reston, VA, USA, 2017; p. 106. [Google Scholar]

- ElMasry, G.; Sun, D.-W. CHAPTER 1—Principles of Hyperspectral Imaging Technology. In Hyperspectral Imaging for Food Quality Analysis and Control; Sun, D.-W., Ed.; Academic Press: San Diego, CA, USA, 2010; pp. 3–43. [Google Scholar]

- Goetz, A.F.H.; Vane, G.; Solomon, J.E.; Rock, B.N. Imaging Spectrometry for Earth Remote Sensing. Science 1985, 228, 1147–1153. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.W.; Reder, N.P.; Kang, S.; Glaser, A.K.; Liu, J.T.C. Multiplexed Optical Imaging of Tumor-Directed Nanoparticles: A Review of Imaging Systems and Approaches. Nanotheranostics 2017, 1, 369–388. [Google Scholar] [CrossRef] [PubMed]

- Abdo, M.; Badilita, V.; Korvink, J. Spatial scanning hyperspectral imaging combining a rotating slit with a Dove prism. Opt. Express 2019, 27, 20290–20304. [Google Scholar] [CrossRef] [PubMed]

- Johnson, C.L.; Browning, D.A.; Pendock, N.E. Hyperspectral Imaging Applications to Geometallurgy: Utilizing Blast Hole Mineralogy to Predict Au-Cu Recovery and Throughput at the Phoenix Mine, Nevada. Econ. Geol. 2019, 114, 1481–1494. [Google Scholar] [CrossRef]

- SPECIM. SWIR. Available online: https://www.specim.fi/products/swir/ (accessed on 18 May 2021).

- SPECIM. LWIR HS. Available online: https://www.specim.fi/products/lwir-hs/ (accessed on 18 May 2021).

- Lypaczewski, P.; Rivard, B.; Gaillard, N.; Perrouty, S.; Piette-Lauzière, N.; Bérubé, C.L.; Linnen, R.L. Using hyperspectral imaging to vector towards mineralization at the Canadian Malartic gold deposit, Québec, Canada. Ore Geol. Rev. 2019, 111, 102945. [Google Scholar] [CrossRef]

- Sun, L.; Khan, S.; Shabestari, P. Integrated Hyperspectral and Geochemical Study of Sediment-Hosted Disseminated Gold at the Goldstrike District, Utah. Remote Sens. 2019, 11, 1987. [Google Scholar] [CrossRef] [Green Version]

- Huang, J.-J.; Löwemark, L.; Chang, Q.; Lin, T.-Y.; Chen, H.-F.; Song, S.-R.; Wei, K.-Y. Choosing optimal exposure times for XRF core-scanning: Suggestions based on the analysis of geological reference materials. Geochem. Geophys. Geosyst. 2016, 17, 1558–1566. [Google Scholar] [CrossRef] [Green Version]

- Sjöqvist, A.S.L.; Arthursson, M.; Lundström, A.; Calderón Estrada, E.; Inerfeldt, A.; Lorenz, H. An innovative optical and chemical drill core scanner. Sci. Drill. 2015, 19, 13–16. [Google Scholar] [CrossRef] [Green Version]

- SPECTRAL INDUSTRIES. DRILL CORE SCANNER—LIBS ENGINE. Available online: https://www.spectralindustries.com/products/ (accessed on 31 May 2021).

- Fabre, C.; Devismes, D.; Moncayo, S.; Pelascini, F.; Trichard, F.; Lecomte, A.; Bousquet, B.; Cauzid, J.; Motto-Ros, V. Elemental imaging by laser-induced breakdown spectroscopy for the geological characterization of minerals. J. Anal. At. Spectrom. 2018, 33, 1345–1353. [Google Scholar] [CrossRef]

- Kuhn, K.; Meima, J.A.; Rammlmair, D.; Ohlendorf, C. Chemical mapping of mine waste drill cores with laser-induced breakdown spectroscopy (LIBS) and energy dispersive X-ray fluorescence (EDXRF) for mineral resource exploration. J. Geochem. Explor. 2016, 161, 72–84. [Google Scholar] [CrossRef]

- Khajehzadeh, N.; Kauppinen, T.K. Fast mineral identification using elemental LIBS technique. IFAC-PapersOnLine 2015, 48, 119–124. [Google Scholar] [CrossRef]

- Rifai, K.; Doucet, F.; Özcan, L.; Vidal, F. LIBS core imaging at kHz speed: Paving the way for real-time geochemical applications. Spectrochim. Acta Part B At. Spectrosc. 2018, 150, 43–48. [Google Scholar] [CrossRef]

- Rifai, K.; Michaud Paradis, M.-C.; Doucet, F.; Swierczek, Z.; Özcan, L.; Fayad, A.; Li, J.; Vidal, F. Emergences of new technology for ultrafast automated mineral phase identification and quantitative analysis using CORIOSITY Laser-Induced Breakdown Spectroscopy (LIBS) system. Minerals 2020, 10, 918. [Google Scholar] [CrossRef]

- Mohamed, N.; Rifai, K.; Selmani, S.; Constantin, M.; Doucet, F.R.; Özcan, L.Ç.; Sabsabi, M.; Vidal, F. Chemical and Mineralogical Mapping of Platinum-Group Element Ore Samples Using Laser-Induced Breakdown Spectroscopy and Micro-XRF. Geostand. Geoanal. Res. 2021. [Google Scholar] [CrossRef]

- Mineral Database. Available online: http://www.webmineral.com/ (accessed on 3 September 2020).

- Acosta, I.C.C.; Khodadadzadeh, M.; Tusa, L.; Ghamisi, P.; Gloaguen, R. A Machine Learning Framework for Drill-Core Mineral Mapping Using Hyperspectral and High-Resolution Mineralogical Data Fusion. IEEE J. Sel. Top. Appl. Earth Obs. Remote Sens. 2019, 12, 4829–4842. [Google Scholar] [CrossRef]

| Core Scanning/Logging Technique | |||

|---|---|---|---|

| Technique | IR-HSI | SXRF | LIBS-HSI |

| Analysis type | Hyperspectral imaging | Elemental content | Hyperspectral imaging and elemental content |

| Instrument in peer-reviewed article | SisuROCK AisaFENIX (VNIR-SWIR) | Minalyze CS | ECORE ELEMISSION |

| Resolution †, step size, analysis time reported by manufacturer | 65–560 μm, ≥65–560 μm, up to 50 mm/s | 1 mm/2 cm, 0.1 m, 1 cm/s | 50 μm, ≥50 μm, 1 pixel/ms |

| Spatial resolution (beam width) | Ø 1.5 mm/pixel | 1 mm/2 cm [13] | Ø 50 μm |

| Step size | 1.5 mm/pixel | 0.1 m | 500 μm |

| Real spatial resolution | 1.5 mm/pixel [22] | 0.1 m [13] | 500 μm |

| Dwell time | 4 ms (VNIR) [22] 15 ms (SWIR) [22] | 10 s [13] | 1 ms |

| Reported analysis speed | 25.06 mm/s [22] | 1 cm/s [13] | 1 pixel/ms |

| Analysis speed at 10 cm steps | 14 pixels in 1 mm/2 cm >13 cm/s | 1 cm/s | 82 pixels in 1 mm/2 cm 120 cm/s |

| Laser Energy | 1 mJ/Pulse |

|---|---|

| Laser source wavelength | 1064 nm |

| Acquisition rate | 1000 Hz |

| Spatial resolution | 50 µm |

| Rayleigh zone (depth of field) | 6 mm |

| Working distance (optical window-sample surface) | 250 mm |

| Dwell time | 1 ms |

| Step size (adjustable) | 0.1 mm |

| Core width to be scan (adjustable) | 20 mm |

| Drill core length | 3.81 m |

| Surface analyzed | 762 cm2 |

| Number of pixels (LIBS) | 7.62 megapixels |

| Total duration | 2.1 h |

| Scanning speed in real-time | 1 pixel/ms |

| Core Scanning Technique | ||||||

|---|---|---|---|---|---|---|

| Technique | IR-HSI (e.g., SisuROCK, HySpex, etc.) | SEM-EDS (e.g., TIMA) | SXRF (e.g., Minalyze CS, ITRAX, etc.) | LIBS-HSI (e.g., ECORE) | ||

| Sample sizes | Drill core trays | Small core cross-sections | Drill core trays | All types | ||

| Elemental assay | Diagnostic (good or non-diagnostic) | |||||

| Light elements (H-Mg) | ND | Diagnostic | ND | Good | ||

| Other elements (Al-Lr) | ND | Diagnostic | Good | Good | ||

| Mineral structure | Mineral group | Example | Diagnostic (poor, moderate, good or non-diagnostic) | |||

| Ino-silicates | Pyroxene | Diopside | Good (VNIR, LWIR) [7] Moderate (SWIR) [7] | Good | ND | Good |

| Pigeonite | Good (VNIR, LWIR) [7] Moderate (SWIR) [7] | Good | ND | Good | ||

| Soro-silicates | Epidote | Zoisite | Good (SWIR) [7,22] Moderate (LWIR) [7,22] | Good | ND | Good |

| Phyllo-silicates | Chlorite | Fe/Mg-Chlorite | Good (SWIR) [7,22] Moderate (LWIR) [7,22] | Good | ND | Good |

| Mica | Talc | Good (SWIR) [7] Moderate (LWIR) [7] | Good | ND | Good | |

| Tecto-silicates | Feldspar | Bytownite | Good (LWIR) [22] | Good | ND | Good |

| Silica | Quartz | Good (LWIR) [7,22] | Good | ND | Good | |

| Non-silicates | Oxides | Hematite | Good (VNIR) [7,22] | Good | ND | Good |

| Sulfides | Pyrite | Moderate (LWIR) [22] ND [7] | Good | ND | Good | |

| Chalcopyrite | ND [7] | Good | ND | Good | ||

| Pentlandite | ND [7] | Good | ND | Good | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paradis, M.-C.M.; Doucet, F.R.; Rifai, K.; Özcan, L.Ç.; Azami, N.; Vidal, F. ECORE: A New Fast Automated Quantitative Mineral and Elemental Core Scanner. Minerals 2021, 11, 859. https://doi.org/10.3390/min11080859

Paradis M-CM, Doucet FR, Rifai K, Özcan LÇ, Azami N, Vidal F. ECORE: A New Fast Automated Quantitative Mineral and Elemental Core Scanner. Minerals. 2021; 11(8):859. https://doi.org/10.3390/min11080859

Chicago/Turabian StyleParadis, Marie-Chloé Michaud, François R. Doucet, Kheireddine Rifai, Lütfü Ç. Özcan, Nawfel Azami, and François Vidal. 2021. "ECORE: A New Fast Automated Quantitative Mineral and Elemental Core Scanner" Minerals 11, no. 8: 859. https://doi.org/10.3390/min11080859

APA StyleParadis, M.-C. M., Doucet, F. R., Rifai, K., Özcan, L. Ç., Azami, N., & Vidal, F. (2021). ECORE: A New Fast Automated Quantitative Mineral and Elemental Core Scanner. Minerals, 11(8), 859. https://doi.org/10.3390/min11080859