Abstract

The possibility of replacing the traditional components of the filling mass with man-made waste and the need for the use of mechanical activation of the components of the filling composite in order to improve its rheological characteristics and the strength of the mass after solidification are proved. The demand for resource-reproducing technologies that allow the most complete use of the industrial mineral resource potential of the mining and processing enterprise, which will lead to a multiplicative ecological and economic effect, is confirmed. It is necessary to introduce the re-processing of man-made waste in order to further extract the useful component to a level that meets the standards of environmental safety and economic feasibility, which would create conditions for the actual sustainable development and give some perspectives for extending the operating time of mining regions. It is established that the sustainable development of the mining and processing region is impossible without a highly efficient exploitation of natural deposits and man-made georesources in combination with an integrated approach to the development of subsurface resources.

1. Introduction

Due to the development of modern societies, technological progress and the constant widening of the availability of goods, it can be concluded that along with the exponentially growing population of the Earth, the level of consumption of mineral resources is also close to exponential [1]. The consumption of goods is also growing in countries where mineral resources (raw material base) are limited [2] or close to exhaustion [3]. At the same time, growing awareness of societies and pressure from environmental organizations mean that more and more importance is attached to sustainable development [4]. This also applies to mining regions, where less environmentally invasive means of continuing mining activities are sought or, after the mine has been extinguished, revaluation through cultural landscapes of industrial heritage is being carried out [5].

In this regard, there is a depletion of available reserves and a sharp increase in the depth of mine field development. In the last century, the depth of the exploited seams in deep mines rarely exceeded 1.5 km. The depletion of shallow seams and the combination of demand on the raw materials market with the need to maintain the economic foundations of the functioning of communities related to mining activities force the use of ever deeper, regularly documented seams. The maximum depth of extraction in some mining fields (“Mponeng Mine”, “TauTona Mine”, “Bambanani Mine”—all in South Africa, “Kidd Mine”—Canada) is approaching 4 km. In the Russian Federation and the countries of Eastern Europe, the extraction of mineral resources takes place at depths exceeding 1.5 km (the “Czeremukhovskaya-Glubokaja” mine, the “Taimyrsky” mine—both in Russia, the Lenin mine, the “Rodina” mine—both in Ukraine). Increasing the depth of mineral extraction leads not only to an increase in the maintenance costs of the technological process, but also to an increased risk of rock pressure in unpredictable forms [6], which entails the need for backfilling [7,8]. Exploring deep or hardly accessible deposits is associated with the occurrence of man-made disasters and the decrease in the safety of underground mining operations [9], including global risk of operations and local risk for employees due to machine (vehicle) operation [10] and severe climatic conditions [11]. Some researchers tend to analyze so-called “well-being at work” by means of sustainable performance in the workplace [12].

The increase in the depth of development leads to the increase in the volume of overburden rocks. The frequency of man-made disasters in various manifestations: hard rock blasting activities; man-made earthquakes; the formation of sinkholes on the surface [13]; water sinking into the mine, and others, increases during the extraction of minerals [14]. Hard rock blasting activities and man-made earthquakes (paraseismic activities) cause vibrations that affect underground and ground structures and the environment. Methods for monitoring that kind of vibrations were considered in [15]. Other significant problems and challenges for the mining regions are related to excessive mineral extraction, proper management of sulfide-bearing waste [16], and control of groundwater balance [17].

In addition, the development involves reserves that were previously classified as off-balance sheet: the development of which at the time of evaluation, according to technical and economic calculation, is not economically efficient (with low content of extracted minerals); located within water protection zones, causing potential risk of excessive settlements of buildings and structures, influencing badly on agricultural facilities, nature reserves or natural, historical and cultural monuments. The involvement in the development of deposit areas with a low content of the useful component in the ore increases the costs of extraction, transportation and processing, as well as the formation of more man-made waste. The last-mentioned aspect has a double potential impact as deposits in tailing ponds not only destroy local landscape, but may also bring serious risks intensified by paraseismic activities caused by mining production. Industrial waste from overburden operations, formed in the process of enrichment and metallurgical processing, is stored on the surface and occupies vast territories. This leads to changes not only in the horizontal landscape environment, but also in the vertical one. Experiences gathered in Russia prove that 2.5 to 4.8 billion tons of mining and processing waste is generated annually, and 1 billion tons of solid waste is accumulated in the dumps and storage facilities of the country’s mining industry [18]. Industrial waste stored on the surface has a significant impact on the ecosphere. This is expressed in increased dust formation and subsequent entrainment of fine fractions from the surface of industrial storage facilities, and in the decrease in soil quality, and groundwater deterioration. All that involves the degradation of flora and fauna, up to the degeneration of historically established plant and animal species.

Equation (1) presented by Golik [19] is presented just to show the complexity of ecosystem degradation as a result of the impact of man-made waste from mining and processing industries. Understanding of this mathematical model that considers a long list of influencing factors helps to emphasize cumulative effects of threats for the environment and makes it possible to determine the reserve of man-made damage [19].

where —reserve of industrial damage; —the total volume of industrial waste; Σ—the quantity of components of industrial waste migrating to the ecosystem; —the concentration of individual components of industrial waste; —time; —is the number of enterprises processing/disposing of industrial waste; —the number of hazardous components in industrial waste; —the number of recycling operations; , , —the number of pollutants in the lithosphere, hydrosphere, atmosphere; , —the initial and final concentration of components of man-made waste that pollute the ecosystem; —the coefficient of self-organization of polluting components in man-made storage facilities; —the coefficient of leakage of polluting components into the ecosystem; —the coefficient of the radius of distribution of polluting components; —the coefficient of the influence of polluting components on the biosphere; —the coefficient of the probability of an environmental disaster; —the coefficient of the risk of an environmental disaster from unaccounted factors.

If the technology of deposit developing with the collapse of ores and host rocks at sufficiently low losses does not allow to preserve the pristine landscape, then the technology with the natural support of the stope is characterized by high losses.

All this indicates that rational geotechnology [20] is already at this stage obliged to create a foundation and to start the advanced development of science with the integration of mining experience and scientific and technological knowledge. It is necessary to introduce technologies that ensure the completeness of the minerals’ extraction, safe mining operations with minimal impact on the environment and allow for the sustainable development of the region. In further paragraphs, the authors are willing to guide the reader through the idea of reuse of industrial waste in the laying composite, process of backfill composite preparation with regard to the possibility of additional mineral extraction, presenting the efficiency of this extraction and achieved strength of composed backfill composites, defining the paradigm of sustainable development of mining regions and finally creating and proposing a road map (scheme) of sustainable development of the mining region, followed by conclusions.

2. Industrial Waste in the Laying Composite—A Method for Their Disposal

Reuse of industrial waste and efficient use of by-products are two main principles of sustainable industrial processes. Contemporary research is focused on concrete modifications [21,22], forming of the man-made ground embankments [23] and even evolutionary game theory study for construction and demolition waste recycling [24]. The main way to ensure the sustainable development of the mining region is to use mineral deposit development systems with a hardening backfill and to include man-made waste in a closed production cycle [25,26]. In addition to solving the issue of safe mining operations [8], the use of geotechnology with a backfill helps to improve the completeness and quality of deposit extraction (presented in further sections), protects the hydrogeological regime and reduces the degree of crack development in the mined-out mass. That leads to the preservation of the water-protective layer and protects the daylight surface from collapse. Geotechnology with a backfill allows to mine—out previously abandoned pillars. This technology increases the mineral resource base of the mining enterprise and increases the life of the mine, as well as solves the social issue of the region, where the mining enterprise has a city-forming role at the same time.

The use of man-made waste from mining and processing enterprises in the preparation of the fill composite leads to their disposal [25]. Utilization of industrial waste in geotechnology with the backfill leads to a reduction in the volume of industrial storage facilities (tailings), which reduces the cost of their creation, maintenance [27] and provides a certain level of security [28]. All this contributes to the implementation of the waste-free production concept [27], comprehensive exploitation of mineral resources, sustainable development [29] and reducing the impact of mining and processing industries on the environment [30]. It must be pointed here that mineral extraction in the course of mining waste activation significantly increases the metal yield during the reprocessing of man-made waste from tailings. It emphasizes the synergetic effect of waste activation, and using it as backfill, and simultaneously lowering the risks for environment, and last but not least, giving some perspectives for extending the operating time of mining regions.

The backfill of the mined-out space is the process of constructing an artificial mass in the stopes. This process involves the creation of various composite mixtures, which, under the influence of hydrolysis and hydration of the binder, crystallization through ongoing chemical reactions, form a monolithic mass with the specified characteristics [31].

Over the past 40 years, the evolution of geotechnology with backfill has undergone significant changes from dry rock to hydraulic backfill based on complex composite materials. Despite the main drawback, high cost, geotechnology with the backfill has a fairly broad application prospects due to the fact that it allows to avoid the shortcomings of other systems to a greater extent, to ensure high completeness of the extraction of minerals, and the safety of mining operations. However, due to the relatively high cost, this technology has a dominant application in the extraction of high-value ore or during the deposit’s development in heavy mining. At coal enterprises, the backfill was used in powerful mine fields and fields with a high risk of gas emissions [32]. The blocks were mined by dead-end stopes with their subsequent expansion in a straight line and with the backfill [33]. The use of backfill in coal deposits was abandoned due to the high cost of backfill, which increased the cost of production.

Creating a solid artificial mass allows to fully use the advantages of a hardening backfill. It is because during the construction of a solid fill mass, a number of conditions are considered: the parameters of the mined blocks; the seismic impact on the explosion mass; the height and area of the outcrop; the standard strength and other conditions. These conditions are quite strict and reflect the ability of the created fill mass to carry the load. The creation of an artificial mass with high regulatory characteristics does not allow reducing the cost of fill composite preparing and the cost of delivering it to the laying site [34].

For a wider application of the technology with artificial support of the mined-out void, it is necessary to reduce the cost of filling operations: reducing the cost of the backfill mixture components by completely eliminating or partially reducing the use of expensive binders and using industrial waste as aggregates; changing the approach to the formation of a continuous artificial mass through the use of new innovative solutions.

3. Preparation of the Backfill Composite Based on Industrial Waste

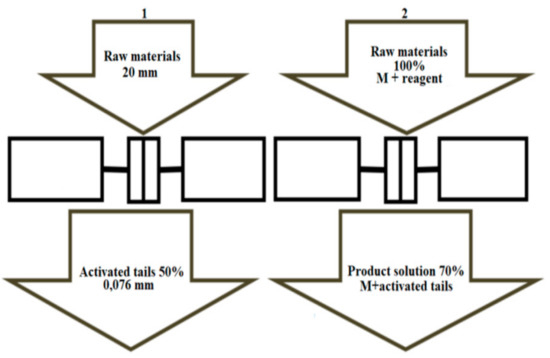

The creation of new composite materials based on man-made waste from mining and processing industries is currently a priority research in the field of the artificial mass formation during the extraction of minerals. Modern composite materials are produced by changing the internal material structure by creating new or secondary crystal structures, which leads to a significant increase in the strength characteristics of the mass after complete solidification. The activation of the individual components of the backfill composite or the finished mixture is the cheapest and easiest way to influence them in order to change the properties of the material. In addition to improving the strength characteristics and uniformity of the created mass, the activation of the finished composite mixture improves its rheological properties, which significantly increases its transportability from the place of preparation to the place of laying. Mechanical activation in the disintegrator is a rather promising method of activation processing of the components of the backfill composite (Figure 1).

Figure 1.

Activation installation (disintegrator). 1—cap; 2—fingers; 3—discs; 4—nozzles; 5—pump; 6—drain; 7—feed funnel. (A-A—cross section).

During the experiment, separate processing of industrial waste was performed before mixing it with other components. Before feeding the waste to the working body of the disintegrator, it is necessary to pre-grind it. When using the processing waste and slags of the metallurgical plant, with fine composition, preliminary grinding is not required. But in some cases, due to the high-water content of the processing tailings, it is necessary to remove the excess moisture. However, it should be considered that the compositions of man-made waste are very diverse and may include useful components necessary for re-development [35,36,37,38]. The use of some man-made waste is limited due to the presence of components that have a long-term negative impact on the environmental situation or have a negative effect on the created mass (heating, softening, expansion, etc.). Therefore, the presence of various components in man-made waste (both useful and harmful) can be an obstacle to their direct use in the preparation of the backfill composite.

International experience demonstrates the high efficiency of non-traditional technologies for extracting useful components from man-made waste, ranging up to 40% of the consumed volume of copper, up to 35% of gold and significant amounts of other precious and rare earth metals that are extracted. Industrial waste accumulated on the territory of Russia has a mineral and raw material value since the average content of the useful component in them is comparable to the content in natural deposits [39].

Currently, various technologies for the re-processing of man-made waste, which allow for additional profit, have been created. It is also necessary to create technologies that neutralize the negative impact of individual components on the environment and exclude the negative impact on the created mass. That will make it possible to use all the man-made waste in a closed production cycle without any restrictions. Depending on the composition of man-made waste, it is necessary to take a differentiated approach to their use as a part of the backfill material. In the absence of a useful component sufficient for extraction in industrial waste, it is used only after the processing. If there is a useful component, it is necessary to initially ensure its extraction from the disposed waste, and then use it in the backfill composite after activation (Figure 2).

Figure 2.

Using the disintegrator. 1—simple activation; 2—extraction and activation treatment.

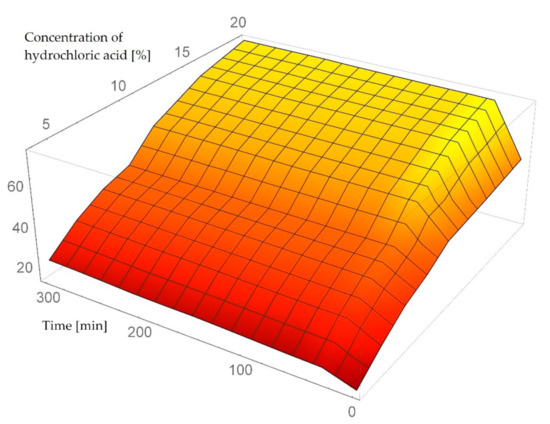

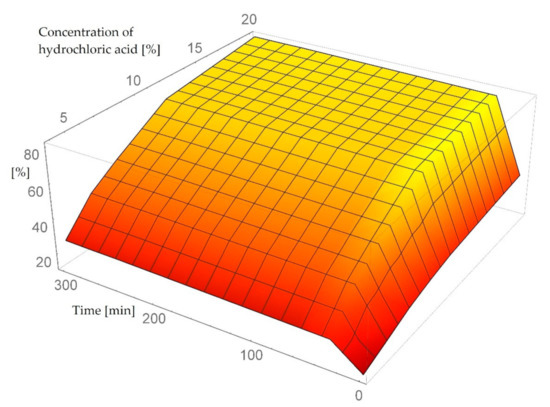

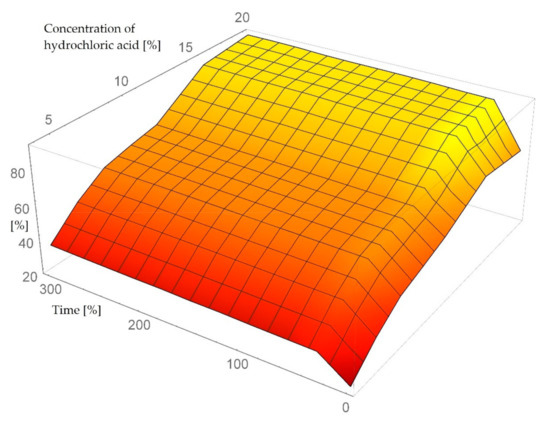

Studies on the additional extraction of a useful component from man-made waste (waste from the processing of the Gaya mining and Processing Plant) were carried out with different activation times and irrigation of the working solution with hydrochloric acid of differential concentration. The results of the study of the useful component extraction from the enrichment waste showed positive results and demonstrated a decrease in the final metal content in the tailings (Table 1, Table 2 and Table 3 and Figure 3, Figure 4 and Figure 5). It is worth observing that the efficiency of extraction can be effectively mounted by any range of activation treatments. Optimal concentration of hydrochloric acid in solution can also be determined experimentally for any kind of material from tailings.

Table 1.

Extraction of zinc from tailings.

Table 2.

Extraction of iron from tailings.

Table 3.

Extraction of copper from tailings.

Figure 3.

Extraction of zinc from tailings. Efficiency of extraction in % vs. concentration of hydrochloric acid in solution and duration of activation treatment.

Figure 4.

Extraction of iron from tailings. Efficiency of extraction vs. concentration of hydrochloric acid in solution and duration of activation treatment.

Figure 5.

Extraction of copper from tailings. Efficiency of extraction vs. concentration of hydrochloric acid in solution and duration of activation treatment.

The presented research results imply that the use of mechanical activation significantly increases the metal yield during the re-processing of man-made waste.

The vector aimed at the additional extraction of useful components from man-made waste from mining and processing industries before their use as a part of the backfill composite fully complies with the rules of human interaction with nature and becomes particularly relevant when solving the problems of diversification of mining and metallurgical industries in the context of globalization and high competition. The extraction of a useful component from man-made waste before its reuse in a closed cycle of main and auxiliary production allows the introduction of a single technological cycle of non-waste (low-waste) production. This will strengthen the present and future potential to meet human needs and aspirations to prepare backfill material. The study was conducted using cement M500 or metallurgical slag of Chusovoy Metallurgical Plant as a binder and tailings of the Gaysky Mining Plant as an aggregate (Table 4). From experimental results, it can be concluded that in the preparation of backfill composite for geotechnology with backfill, it is possible to completely replace the traditionally produced components with industrial wastes which were subject to activation treatment.

Table 4.

Testing the fill materials.

Activation treatment of the backfill composite components:

- increases the strength of the fill mass;

- adjusts the rheological properties of the backfill composite, which improves its transportability.

4. Discussion on Non-Waste (Low-Waste) Production as the Paradigm of Sustainable Development of Mining Regions

The innovative idea of the proposed technology is that the increase in the mineral resource base of the mining enterprise occurs due to the involvement in the development of off-balance reserves left in the blocks and due to the use of geotechnology with the backfill and extraction of useful components from man-made waste before their application in a closed production cycle. The impact of mining and processing industries on the ecosystem of the region is usually considered as a complex dynamic system. In such system each individual impact has a multifactorial and multi-criteria character, which are difficult to simply measure, describe and manage. But at the same time, it should be considered that in any, even most complex systems (not only in the ecological and economic field), very ordered patterns often appear. On the basis of the identified patterns, it is possible to identify certain rules with clear relationships. One of the elementary rules that establish the order in the functioning of such complex systems is the multiplication effect, where there are increasing effects (negative and positive) on the final value of the controlled system. The cumulative multiplicative effect from implementation of waste-free technology according to the maximum profit criterion, considering the economic component of the industrial mineral resource base circulation, can be represented by the following expression [40]. It is a very complex issue (see the size of the Equation (2) [40]).

where:

—industrial waste to be recycled;

—types of industrial waste;

M—methods of processing industrial waste;

—time of industrial waste utilization;

—terms of existence of the mining and processing plant;

—stage of industrial waste utilization;

—volume of a valuable component obtained from industrial raw materials;

—price per unit volume of a valuable component in industrial raw materials, %;

—volume of products production from industrial raw materials,

—price per unit of products made from industrial raw materials,

—costs of utilization and processing of industrial waste;

—capital costs of utilization and processing of industrial waste;

EНУ—discount rate;

Еq—discounted operating costs,

—discounted capital costs,

Y—economic damage from the impact of the project on the environment

—volume of a valuable component not extracted from industrial raw materials,

—price per unit volume of a valuable component that has not been extracted,

—volume of products made from industrial raw materials not purified to zero

—price per unit of products made from unrefined industrial raw materials,

—volume of buried (utilized) industrial raw materials

—price per unit volume of a valuable component in buried (utilized) industrial raw materials

—coefficient of industrial dump’s self-organization;

—coefficient of solutions’ influence on the system;

—distribution radius of solutions’ coefficient;

—coefficient of influence of industrial waste components on the biosphere;

—risk coefficient;

—time coefficient;

—coefficient of unaccounted factors.

Same comment may be provided considering Equation (3) [10] dealing with safety pricing in mining industry. Equations (2) and (3) were included just to show the complexities of the implementation of waste-free technology and environmental protection.

The effectiveness of environmental protection measures is expressed by the ratio of the probabilistic consequences of the environmental disasters’ occurrence, expressed in monetary terms, to the costs associated with the prevention of their development and occurrence [10]:

where —profit from the use of technologies that reduce the load on the ecosystem; Σ—the sum of factors affecting the ecosystem; —the time of impact; —the number of factors affecting the ecosystem; —the total amount of work related to the elimination of the environmental disasters’ consequences; . . —the number of pollutants in the lithosphere. hydrosphere. atmosphere; —the amount of compensation work; —the cost of compensation work; —the amount of work related to the protection of the ecosystem; —the cost of work. related to the protection of the ecosystem; —time coefficient that considers the increased impact on the system; —the coefficient of the influence of polluting components on the biosphere; —the coefficient of the accuracy of predicting an environmental disaster; —the coefficient of the risk of an environmental disaster from unaccounted factors.

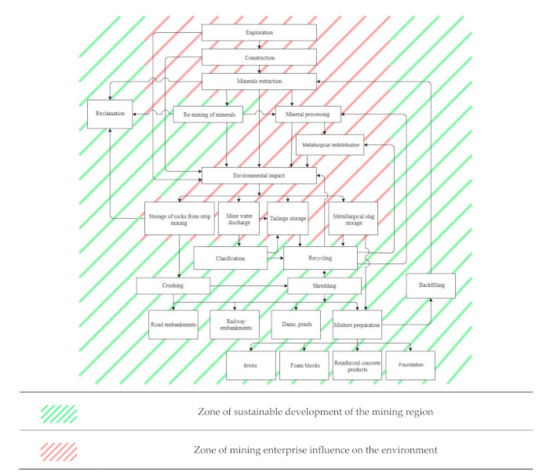

It is impossible to implement the requirements of sustainable development of the mining region without an integrated approach to the development of resources. Comprehensive resource exploitation implies engagement of man-made waste in a closed cycle of main and auxiliary production. It can be implemented based on a systematic approach to the development and implementation of technological schemes. in which a single technological task is a discrete element of a single scheme of a mining enterprise (Figure 6). At the same time, the profitability of individual design and technical solutions based on the involvement of man-made waste in the processing should be evaluated from the point of view of the effectiveness of the entire field development project within the mining complex.

Figure 6.

Scheme of sustainable development of the mining region.

The introduction of resource-producing technologies allows one to extract the economic effect of obtaining additional products and improves the environmental situation in the region of the mining enterprise. At the same time, an indispensable condition for the sustainable development of the mining region is not so much the improvement of the technical and economic indicators of the development of its mineral resource base but its increase due to the involvement in the highly efficient production operation of man-made waste generated as a result of the long-term activities of mining enterprises and mining the blocks by applying geotechnology with backfill.

Consequently, the introduction of a full cycle of comprehensive resource exploitation ensures the sustainable development of the mining region and causes positive economic effects:

- increase in the mineral resource base of mining and processing enterprises;

- reduction of production costs;

- increase in quality indicators during production and processing;

- reduction of losses of minerals during extraction and useful component during processing;

- reducing the cost of mining operations by replacing specially extracted components of the fill composite with man-made waste;

- reducing the cost of storing man-made waste by involving it in a closed cycle of main and auxiliary production.

In addition to the economic effects, the sustainable development of the mining region provides the following environmental and social effects:

- improving the health and life quality of the mining regions’ population by significantly reducing the impact on the ecosystem, and as a result, significantly improving the environmental situation by reducing the amount of man-made waste stored on the surface;

- increasing the effective operation life of the mining enterprise due to the development of the blocks, involvement in the industrial use of substandard and poor ores, including the processing of man-made waste in the production cycle;

- more complete use of the mineral resource base of the region, due to the implementation of the useful components’ extraction from low-value and off-balance ores, as well as man-made waste and complex processing of mineral raw materials;

- reduction of costs for the operation and construction of man-made storage facilities, as well as for environmental deductions;

- creation of innovative production facilities for new types of products that are not typical for a mining enterprise;

- increasing the competitive position and improving financial stability in the context of globalization through the introduction of high-performance physical, chemical and physical-technical technologies at mining enterprises with natural and man-made raw materials.

5. Conclusions

Studies have proved that the preparation of the backfill composite can completely replace the traditional, specially extracted components, and partially binders with man-made waste from mining and processing industries. Activation of industrial waste used in the fill composite significantly (up to 40%) increases the strength of the mass after solidification.

The use of man-made waste in the fill composite must be carried out after their re-processing, which allows to additionally extract the remaining useful components and neutralize the negative impact of harmful ones. Presented results can also prove that the activation process (concerning its duration time and concentration of hydrochloric acid in solution) may also increase the efficiency of mineral extractions from tailings. The full use of natural and man-made georesources increases the mineral resource base of the mining enterprise, which will allow for the achievement of sustainable development of the mining region.

It must be underlined here, that sustainable development is costly and any additional profit from technological processes (mineral extraction) increases the motivation for cleaner and safer mining production.

Proposed “Scheme of sustainable development of the mining region” (Figure 6) with red (bad) and green zones of process description emphasizes the importance of the creation of backfill materials based on industrial waste.

6. Final Remarks and Prospects for Further Studies

Sustainable development of the mining region is possible through the introduction of resource-reproducing technologies, considering a comprehensive approach to the depth development and the transition to an innovative principle of production organization [40]. The principle excludes the formation of waste and determines the use of intermediate products (man-made waste) in cyclic production. The maximum ecological, economic and social effect in the mining industry is possible with deep exploitation along with natural resources of man-made waste [41].

For highly efficient exploitation of natural deposits and man-made georesources, it is necessary to include physical-technical and physical-chemical technologists in the unified technological process of resource development at the design stage of a mining and processing enterprise. It is important to consider the gradual depletion of natural resources and the attenuation of physical-technical geotechnologies and the increase in physical-chemical geotechnologies, and to ensure optimal, phased commissioning of operational thickness.

Author Contributions

Conceptualization. J.R., C.K.-S., Y.T. and A.M.K.; methodology. C.K.-S. and Y.T.; software. A.M.K.; validation. C.K.-S., Y.T. and A.M.K.; formal analysis. C.K-S.; investigation. C.K.-S. and Y.T.; resources. C.K.-S. and Y.T.; data curation. A.M.K.; writing—original draft preparation. C.K.-S., Y.T. and J.R.; writing—review and editing. J.R.; visualization. A.M.K.; supervision. J.R.; project administration. Y.T.; funding acquisition. J.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Samarina, V.P. Mineral resource industry of Russia in the world market: Current developments. Min. Inf. Anal. Bull. 2017, 3, 209–216. [Google Scholar]

- Resniovam, E.; Ponomarenko, T. Sustainable Development of the Energy Sector in a Country Deficient in Mineral Resources: The Case of the Republic of Moldova. Sustainability 2021, 13, 3261. [Google Scholar] [CrossRef]

- Ponomarenko, T.; Nevskaya, M.; Jonek-Kowalska, I. Mineral Resource Depletion Assessment: Alternatives. Problems. Results. Sustainability 2021, 13, 862. [Google Scholar] [CrossRef]

- Grayson, R.L. Addressing the Dual Challenges of Meeting Demand for Minerals and Sustainable Development. Minerals 2011, 1, 1. [Google Scholar] [CrossRef] [Green Version]

- Tost, M.; Ammerer, G.; Kot-Niewiadomska, A.; Gugerell, K. Mining and Europe’s World Heritage Cultural Landscapes. Resources 2021, 10, 18. [Google Scholar] [CrossRef]

- Khayrutdinov, A.M.; Kongar-Syuryun, C.B.; Kowalik, T.; Tyulyaeva, Y.S. Stress-strain behavior control in rock mass using different-stregth backfill. Min. Inf. Anal. Bull. 2020, 10, 42–55. [Google Scholar] [CrossRef]

- Rybak, J.M.; Kongar-Syuryun, C.; Tyulyaeva, Y.; Khayrutdinov. A, M.; Akinshin, I. Geomechanical substantiation of parameters of technology for mining salt deposits with a backfill. Min. Sci. 2021, 28, 19–32. [Google Scholar] [CrossRef]

- Golik, V.I.; Burdzieva, O.G. Increase of work safety by enlargement of field of application of hardening mixtures from processing waste. Occup. Saf. Ind. 2016, 8, 45–50. [Google Scholar]

- Zeqiri, K. Investigation of the mining accidents at “Stan Terg” mine. Min. Sci. 2020, 27, 39–46. [Google Scholar] [CrossRef]

- Sukhorukova, M.; Ivannikov, A. Vehicle accident risk assessment in mines. Min. Inf. Anal. Bull. 2020, 6, 224–232. [Google Scholar] [CrossRef]

- Gendler, S.; Prokhorova, E. Risk-Based Methodology for Determining Priority Directions for Improving Occupational Safety in the Mining Industry of the Arctic Zone. Resources 2021, 10, 20. [Google Scholar] [CrossRef]

- Amrani, M.; Rachid, C.; Azzedine, B.; Verzea, I. Well-being at work: A lever for sustainable performance in workplace. Min. Sci. 2020, 27, 89–104. [Google Scholar] [CrossRef]

- Yu, L.; Ignatov, Y.; Ivannikov, A.; Khotchenkov, E.; Krasnoshtanov, D. Common features in the manifestation of natural and induced geodynamic events in the eastern regions of Russia and China. IOP Conf. Ser. Earth Environ. Sci. 2019, 324, 012004. [Google Scholar] [CrossRef]

- Golik, V.I.; Gabaraev, O.Z.; Maslennikov, S.A.; Khasheva, Z.M.; Shulgaty, L.P. The provision of development conversion perspectives into undeground one for Russian iron ore deposits development. Soc. Sci. 2016, 11, 4348–4351. [Google Scholar]

- Parkasiewicz, B.; Kadela, M.; Bȩtkowski, P.; Sieńko, R.; Bednarski, Ł. Application of Structure Monitoring Systems to the Assessment of the Behaviour of Bridges in Mining Areas. IOP Conf. Ser. Mat. Sci. Eng. 2017, 245, 032018. [Google Scholar] [CrossRef]

- Öhlander, B.; Chatwin, T.; Alakangas, L. Management of Sulfide-Bearing Waste, a Challenge for the Mining Industry. Minerals 2012, 2, 1–10. [Google Scholar] [CrossRef]

- Menshikova, E.; Fetisov, V.; Karavaeva, T.; Blinov, S.; Belkin, P.; Vaganov, S. Reducing the Negative Technogenic Impact of the Mining Enterprise on the Environment through Management of the Water Balance. Minerals 2020, 10, 1145. [Google Scholar] [CrossRef]

- Eron’ko, S.P.; Danilov, V.L.; Kuklev, A.V.; Tkachev, M.Y.; Tinyakov, V.V.; Mechik, S.V. Experience of Design and Industrial Application of Systems for the Driven Feed of Slag-Forming Mixtures into the Crystallizers of Slab CCM. Metallurgist 2020, 64, 214–222. [Google Scholar] [CrossRef]

- Golik, V.; Komaschenko, V.; Morkun, V.; Khasheva, Z. The effectiveness of combining the stages of ore fields development. Metall. Min. Ind. 2015, 7, 401–405. [Google Scholar]

- Golik, V.I.; Razorenov, Y.I.; Lukyanov, V.G. Environmental and economic aspects of resource saving in mining. Bull. Tomsk Polytech. Univ. Geo Assets Eng. 2017, 328, 18–27. [Google Scholar]

- Kowalik, T.; Ubysz, A. Waste basalt fibers as an alternative component of fiberconcrete. Mater. Today Proc. 2021, 38, 2055–2058. [Google Scholar] [CrossRef]

- Pizoń, J.; Gołaszewski, J.; Alwaeli, M.; Szwan, P. Properties of Concrete with Recycled Concrete Aggregate Containing Metallurgical Sludge Waste. Materials 2020, 13, 1448. [Google Scholar] [CrossRef] [Green Version]

- Kawalec, J.; Kwiecień, S.; Pilipenko, A.; Rybak, J. Application of crushed concrete in geotechnical engineering-selected issues. IOP Conf. Ser. Earth Environ. Sci. 2017, 95, 022057. [Google Scholar] [CrossRef]

- Long, H.; Liu, H.; Li, X.; Chen, L. An Evolutionary Game Theory Study for Construction and Demolition Waste Recycling Considering Green Development Performance under the Chinese Government’s Reward–Penalty Mechanism. Int. J. Environ. Res. Public Health 2020, 17, 6303. [Google Scholar] [CrossRef] [PubMed]

- Khayrutdinov, M.M.; Kongar-Syuryun, C.B.; Tyulyaeva, Y.S.; Khayrutdinov, A.M. Cementless backfill mixtures based on water-soluble manmade waste. Bull. Tomsk Polytech. Univ. Geo Assets Eng. 2020, 331, 30–36. [Google Scholar] [CrossRef]

- Noui, A.; Bouglada, M.S.; Belagraa, L.; Achour, Y.; Abderazak, B. Study of the mechanical behavior and durability of mortars based on prepared sand. Min. Sci. 2020, 27, 47–59. [Google Scholar] [CrossRef]

- Golik, V.; Dmytrak, Y.; Sergeev, V.; Vernigor, V. Impact of Tailing Dumps on the Environment of the Mining Region. Ecol. Ind. Russ. 2018, 22, 44–48. [Google Scholar] [CrossRef]

- Bac-Bronowicz, J.; Kowalczyk, P.; Bartlewska-Urban, M. Risk Reduction of a Terrorist Attack on a Critical Infrastructure Facility of LGOM Based on the Example of the Żelazny Most Tailings Storage Facility (OUOW Żelazny Most). Studia Geotech. Mech. 2020, 42, 376–387. [Google Scholar] [CrossRef]

- Sidorova, E. Modern strategic decisions in the field of waste as a basis of development of circular economy and greening of industrial production. In Proceedings of the 19th International Multidisciplinary Scientific Geo Conference (SGEM 2019), Albena, Bulgaria, 28 June–6 July 2019; pp. 531–538. [Google Scholar]

- Radyuk, A.G.; Gorbatyuk, S.M.; Tarasov, Y.S.; Titlyanov, A.E.; Aleksakhin, A.V. Improvements to Mixing of Natural Gas and Hot-Air Blast in the Air Tuyeres of Blast Furnaces with Thermal Insulation of the Blast Duct. Metallurgist 2019, 63, 433–440. [Google Scholar] [CrossRef]

- Ermolovich, O.V.; Ermolovich, E.A. Composite backfilling materials with the addition of of mechanically activated beneficiation tailings. Bull. Tula State Univ. Earth Sci. 2016, 3, 24–30. [Google Scholar]

- Melnik, V.V.; Vasyuchkov, Y.F. Principles of Increasing Safety at the Development of Coal Deposits. Occup. Saf. Ind. 2016, 8, 51–53. [Google Scholar]

- Sarychev, V.I.; Melnik, V.V.; Golodov, M.A.; Zubakov, I.N.; Zhukov, S.S. Technological schemes of mining by cells with widening and backfilling open areas. Bull. Tula State Univ. Earth Sci. 2011, 2, 203–206. [Google Scholar]

- Melnik, V.V.; Kozlov, V.V. Analysis of research and state of the hydraulic technology and process of coal mining. Russ. Coal J. 2017, 2, 16–17. [Google Scholar] [CrossRef]

- Golik, V.I. Metal leaching technologies-the way of reanimation of mining Ossetia. Sustain. Dev. Mt. Territ. 2020, 12, 273–282. [Google Scholar] [CrossRef]

- Szyszka, D. Frother critical coalescence concentration and dose in flotation of copper-bearing carbonaceous shale. Min. Sci. 2019, 26, 289–295. [Google Scholar] [CrossRef]

- Szyszka, D. Critical coalescence concentration (Ccc) for surfactants in aqueous solutions. Minerals 2018, 8, 431. [Google Scholar] [CrossRef] [Green Version]

- Zglinicki, K.; Szamałek, K.; Wołkowicz, S. Critical Minerals from Post-Processing Tailing. A Case Study from Bangka Island, Indonesia. Minerals 2021, 11, 352. [Google Scholar] [CrossRef]

- Kaplunov, D.R. Comprehensive exploitation of mineral resources is a major trend in design of ore mines. Min. Inf. Anal. Bull. 2014, S1, 347–357. [Google Scholar]

- Golik, V.I.; Razorenov, Y.I.; Maslennikov, S.A. Protection of natural geological environment by utilizing ore tailings. Bull. Tomsk Polytech. Univ. Geo Assets Eng. 2015, 326, 6–15. [Google Scholar]

- Hefni, M.; Ahmed, H.A.M.; Omar, E.S.; Ali, M.A. The Potential Re-Use of Saudi Mine Tailings in Mine Backfill: A Path towards Sustainable Mining in Saudi Arabia. Sustainability 2021, 13, 6204. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).