Influence of Weak Interlayer on the Mechanical Performance of the Bolted Rock Mass with a Single Free Surface in Deep Mining

Abstract

1. Introduction

2. Experimental Arrangement

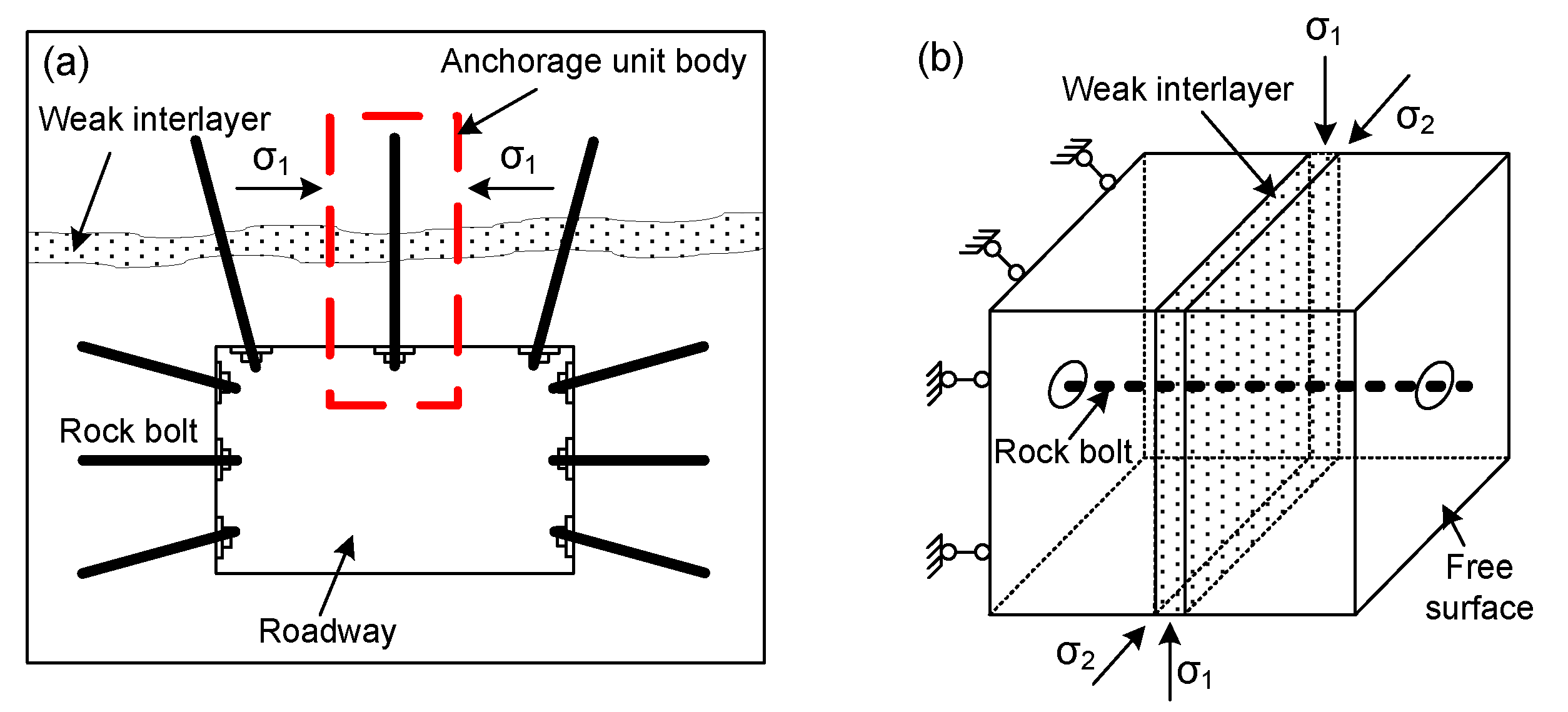

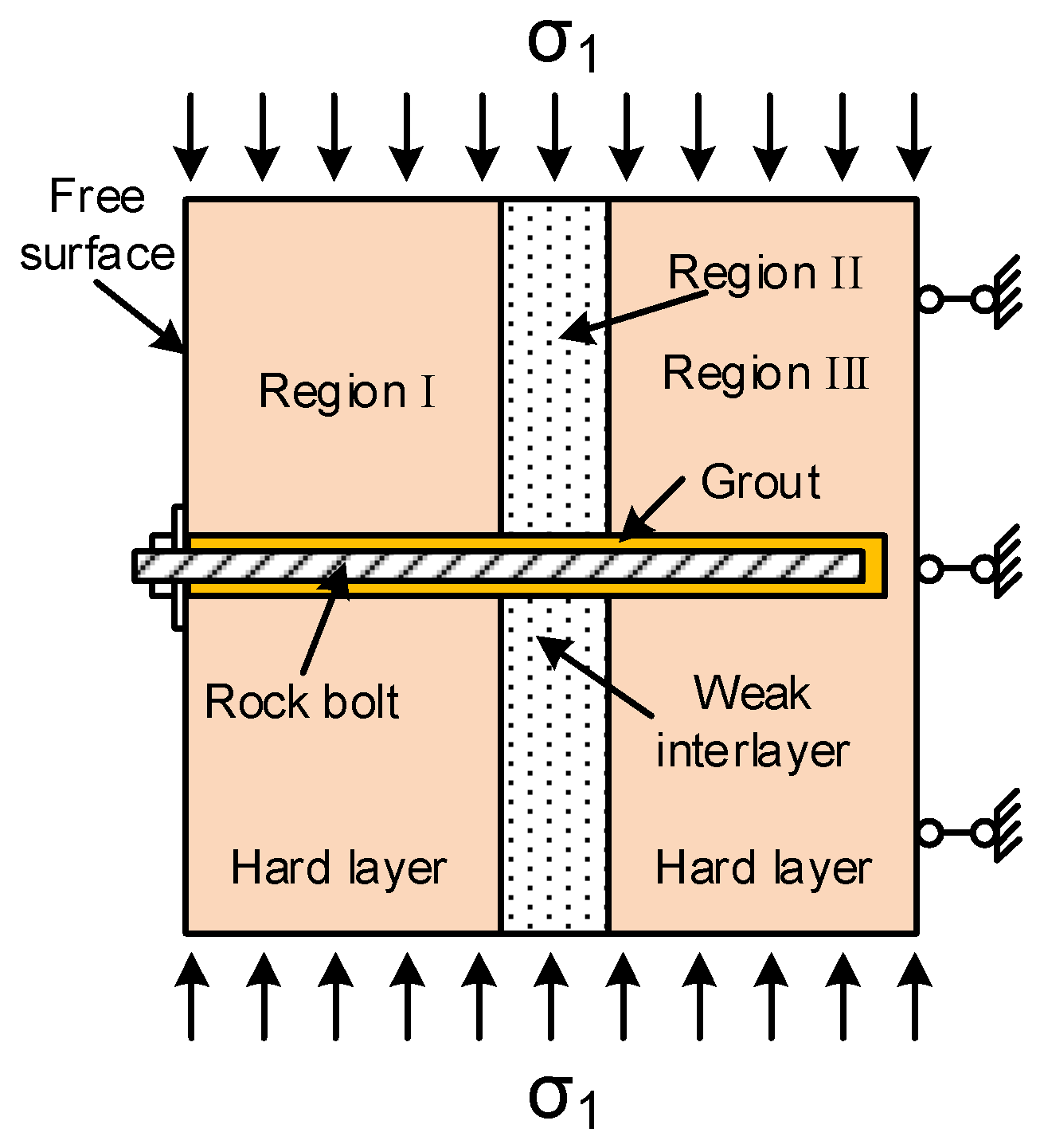

2.1. Test Prototype and Mechanical Model

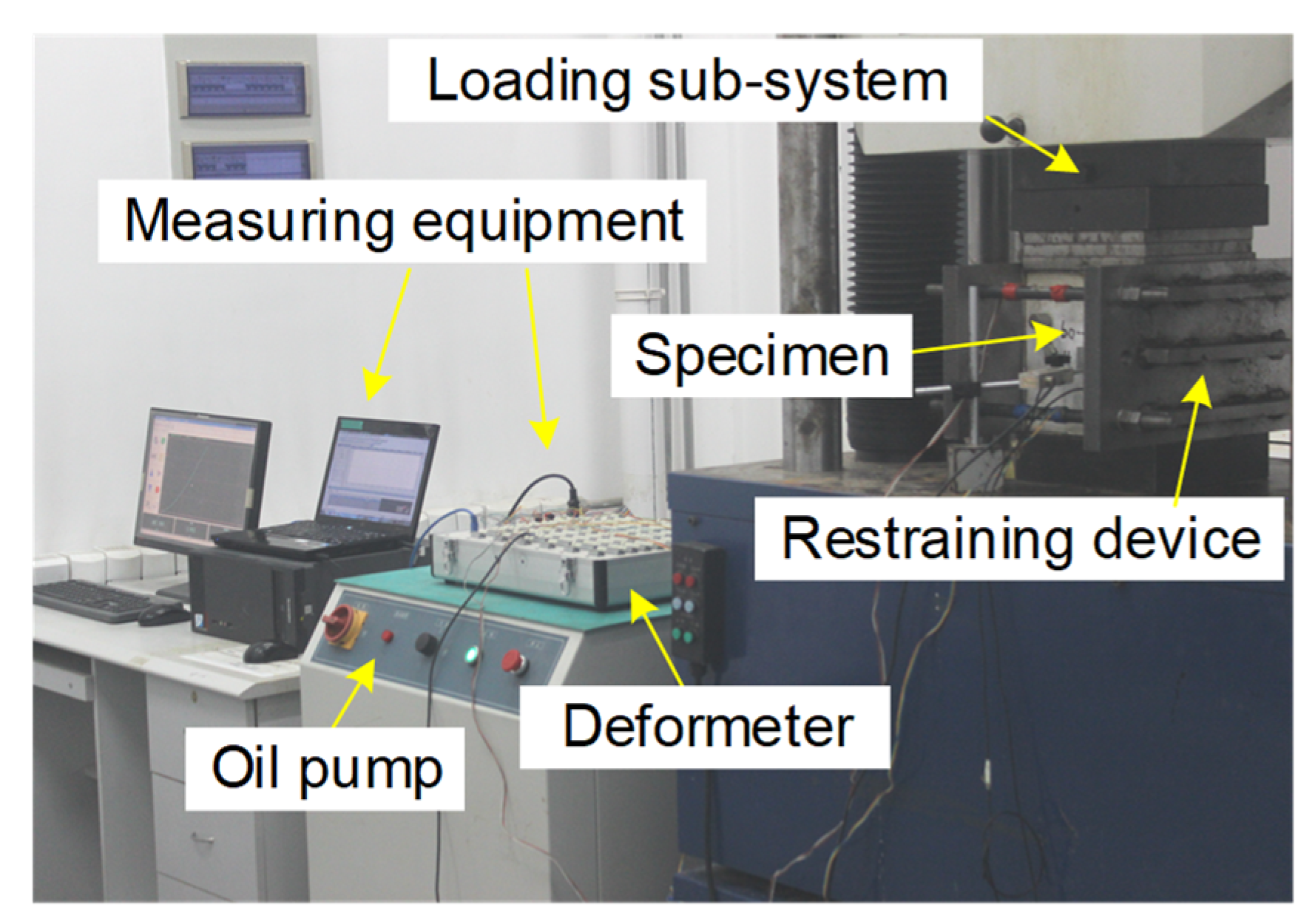

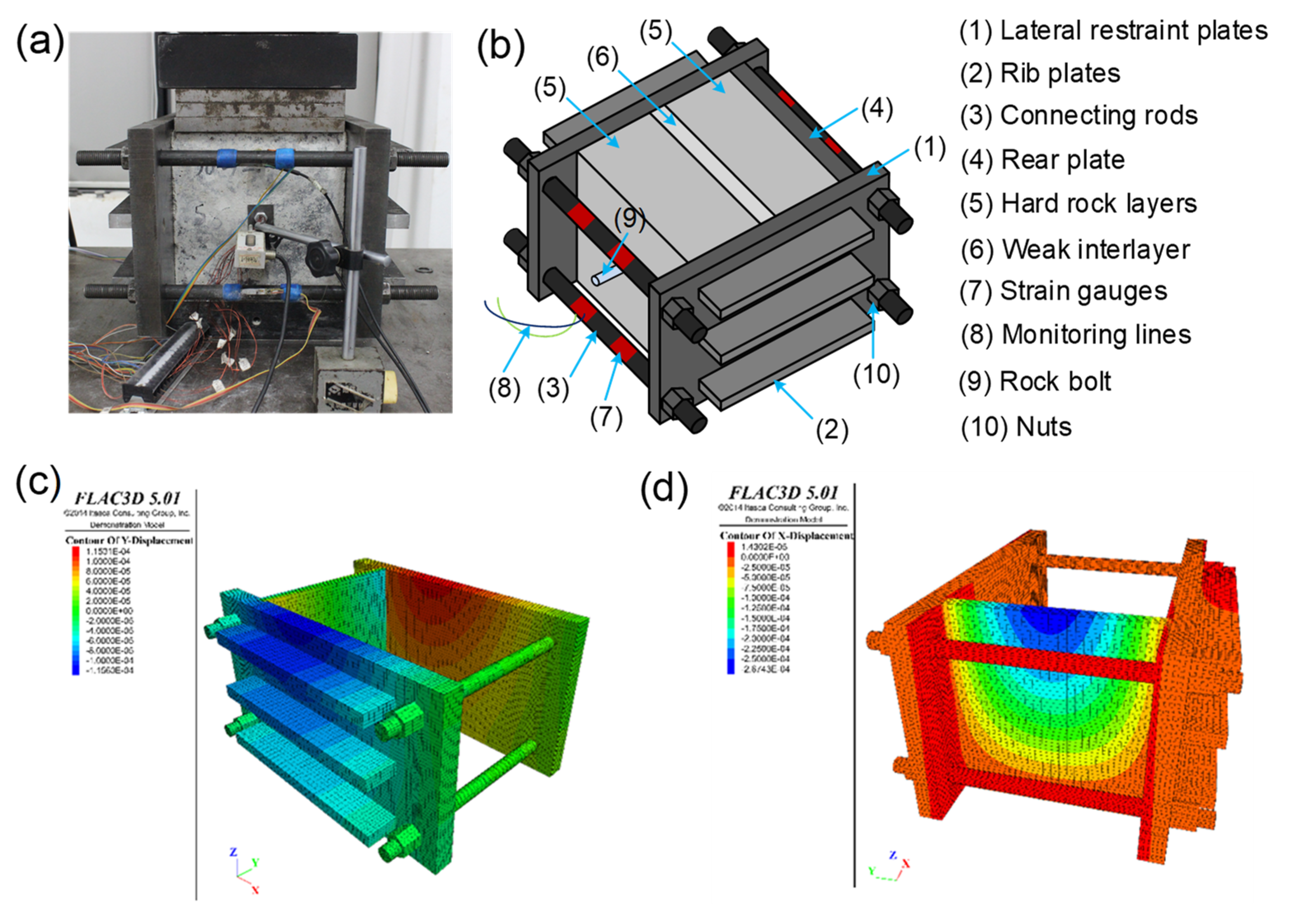

2.2. Test System

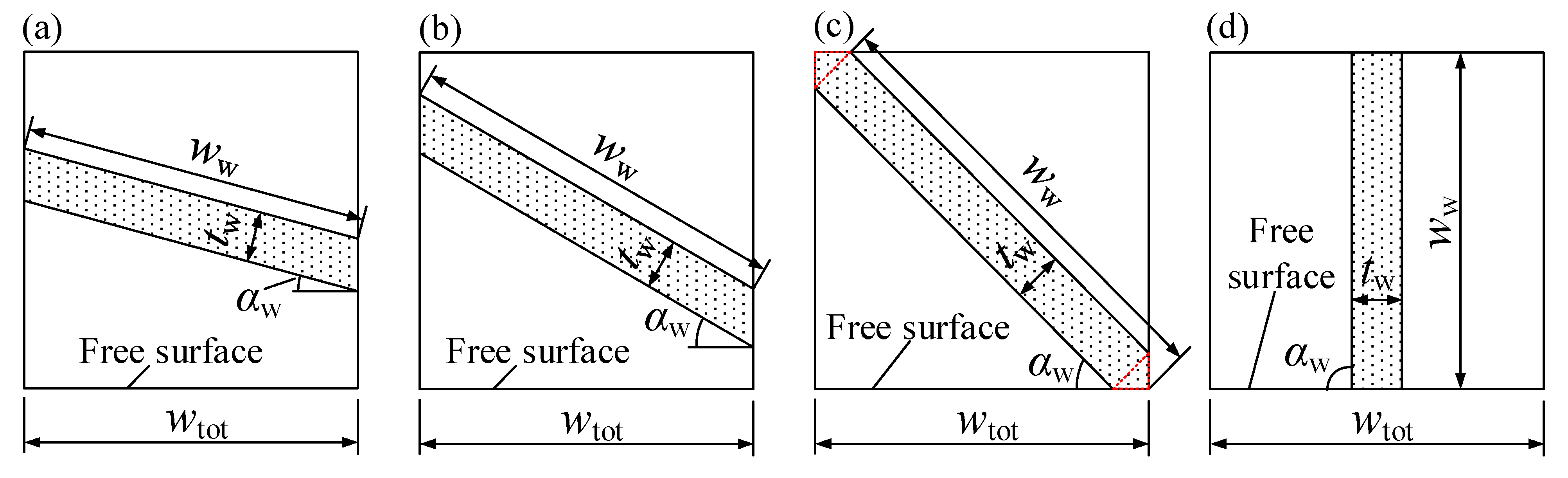

2.3. Specimens Preparation

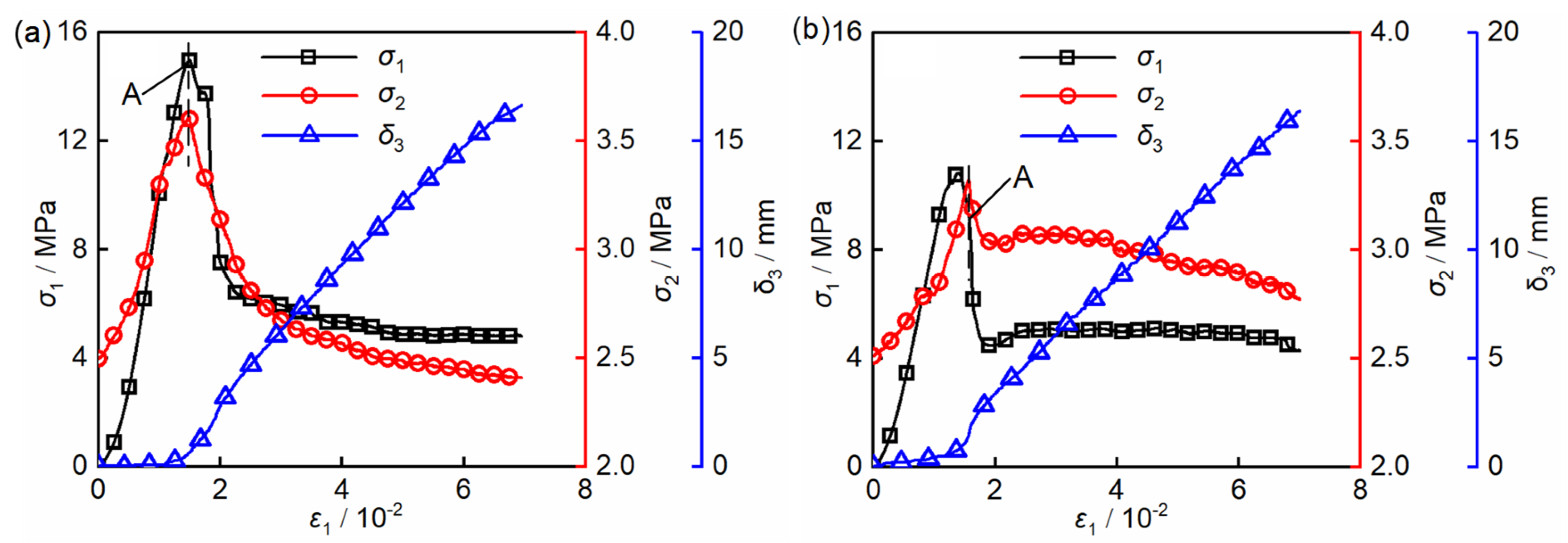

3. Strength and Deformation Behavior of Bolted Specimens Containing Weak Interlay-ER

3.1. Typical Whole Stress–Strain Curve of Bolted Specimens

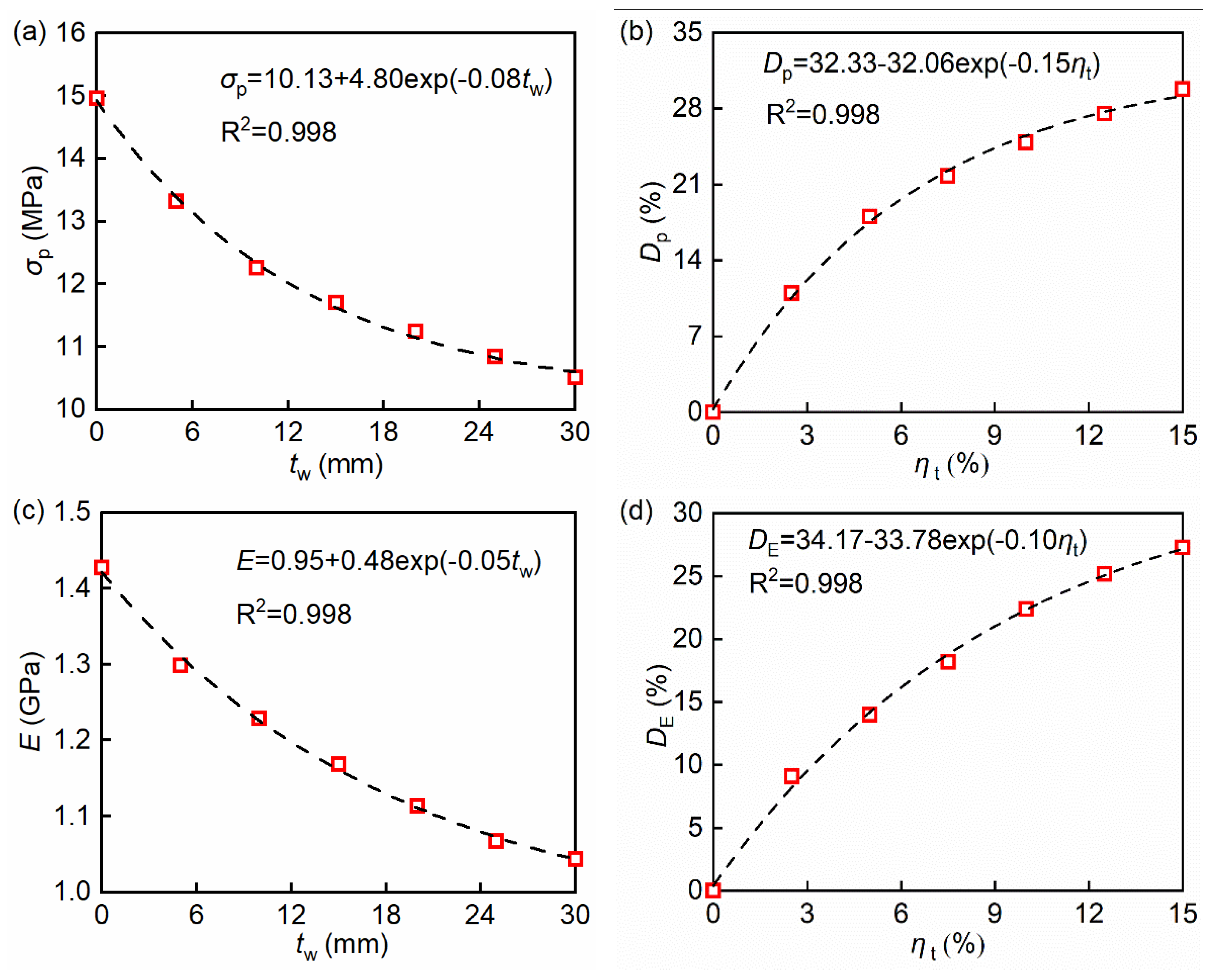

3.2. Effect of Weak Interlayer Thickness

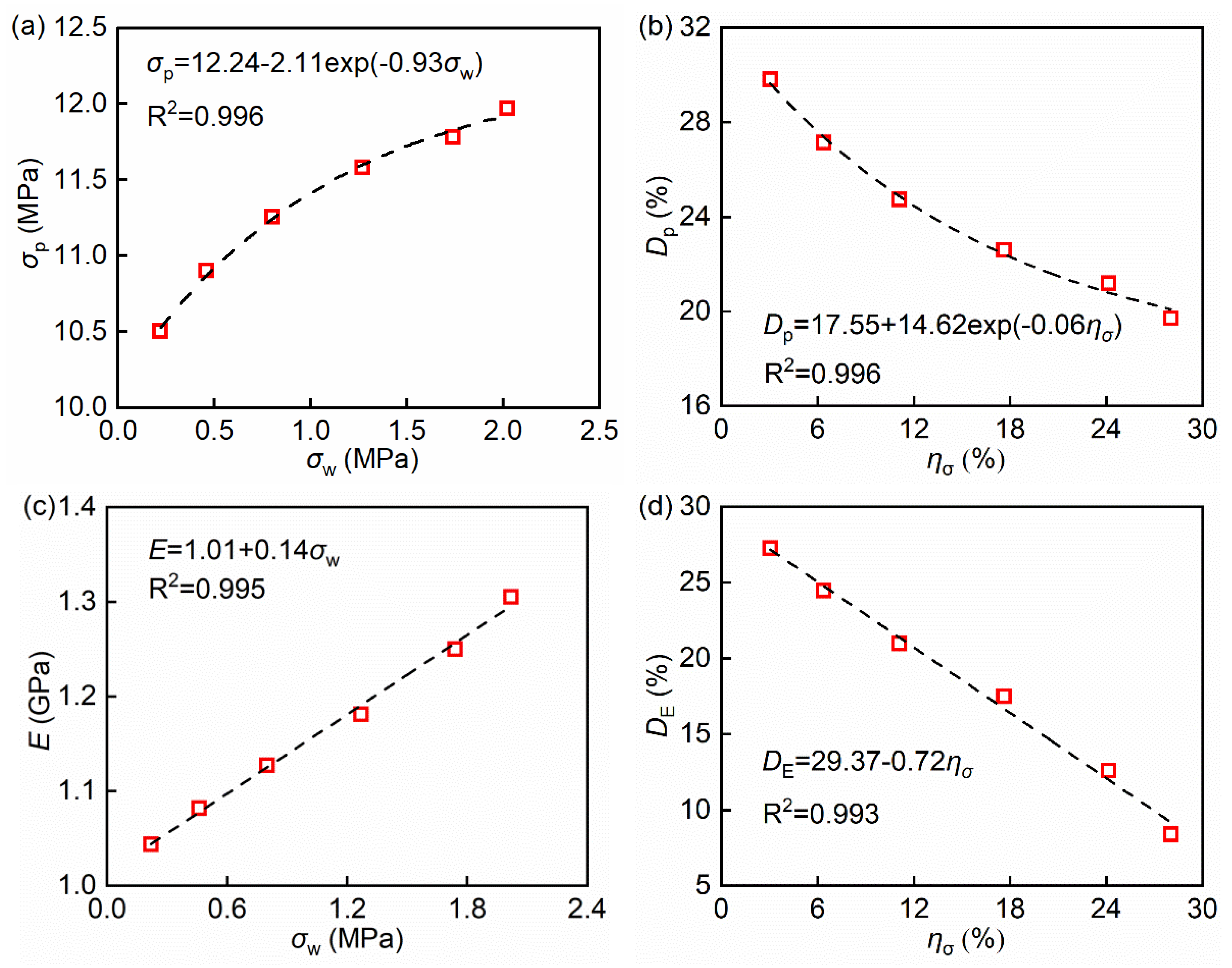

3.3. Effect of the Uniaxial Compressive Strength of Weak Interlayer

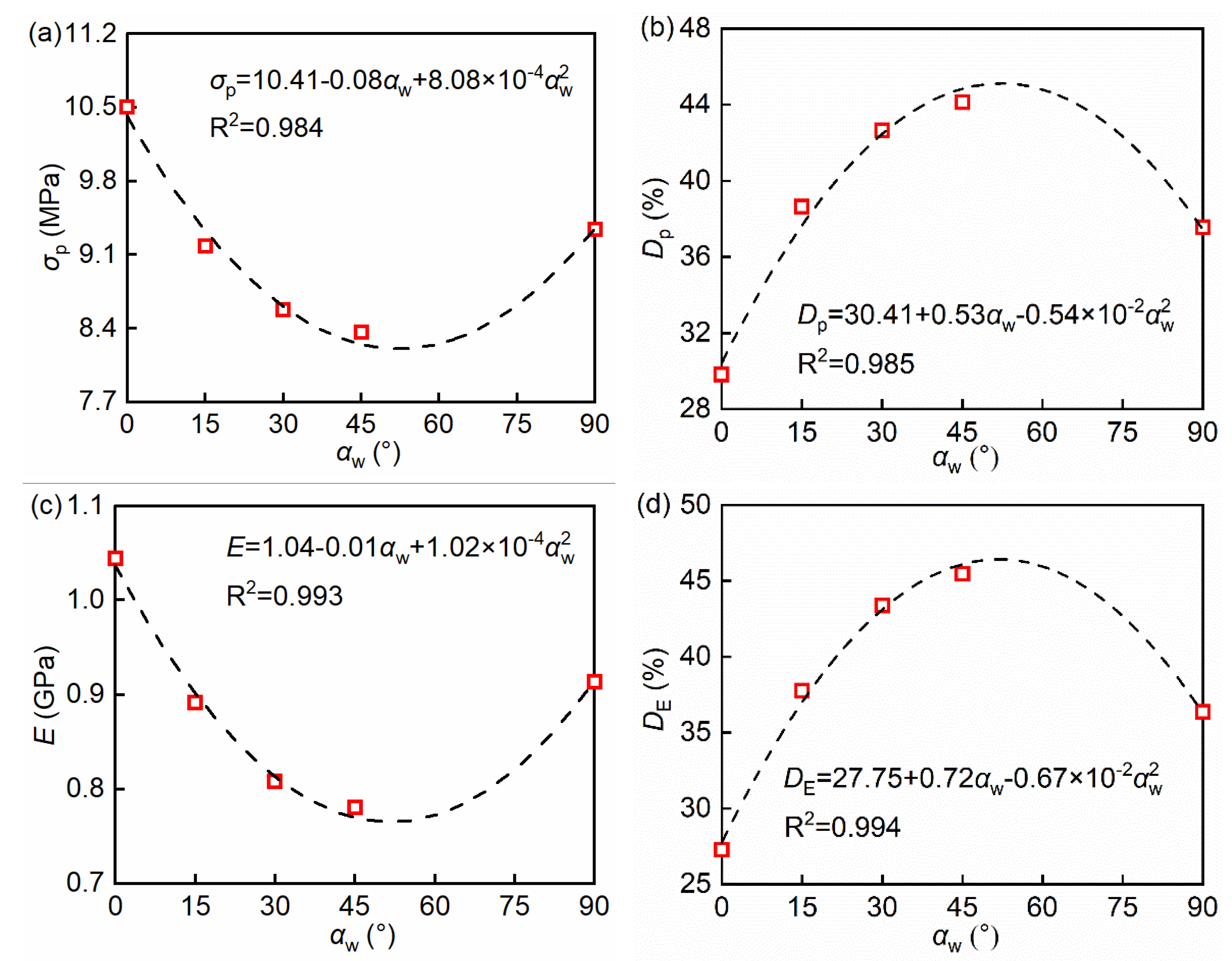

3.4. Effect of Weak Interlayer Dip Angle

3.5. Mechanism of Weakening Effect of Weak Interlayer

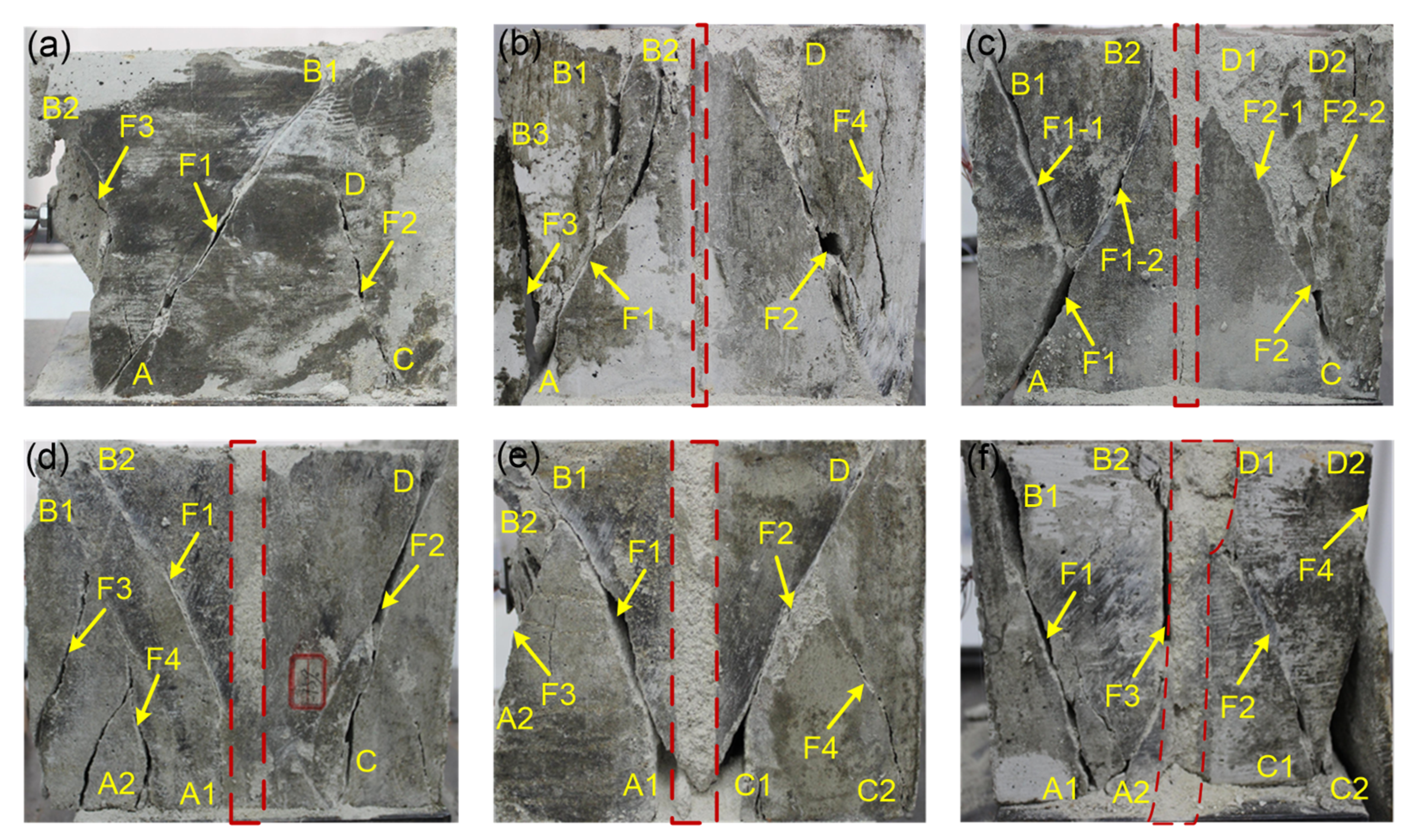

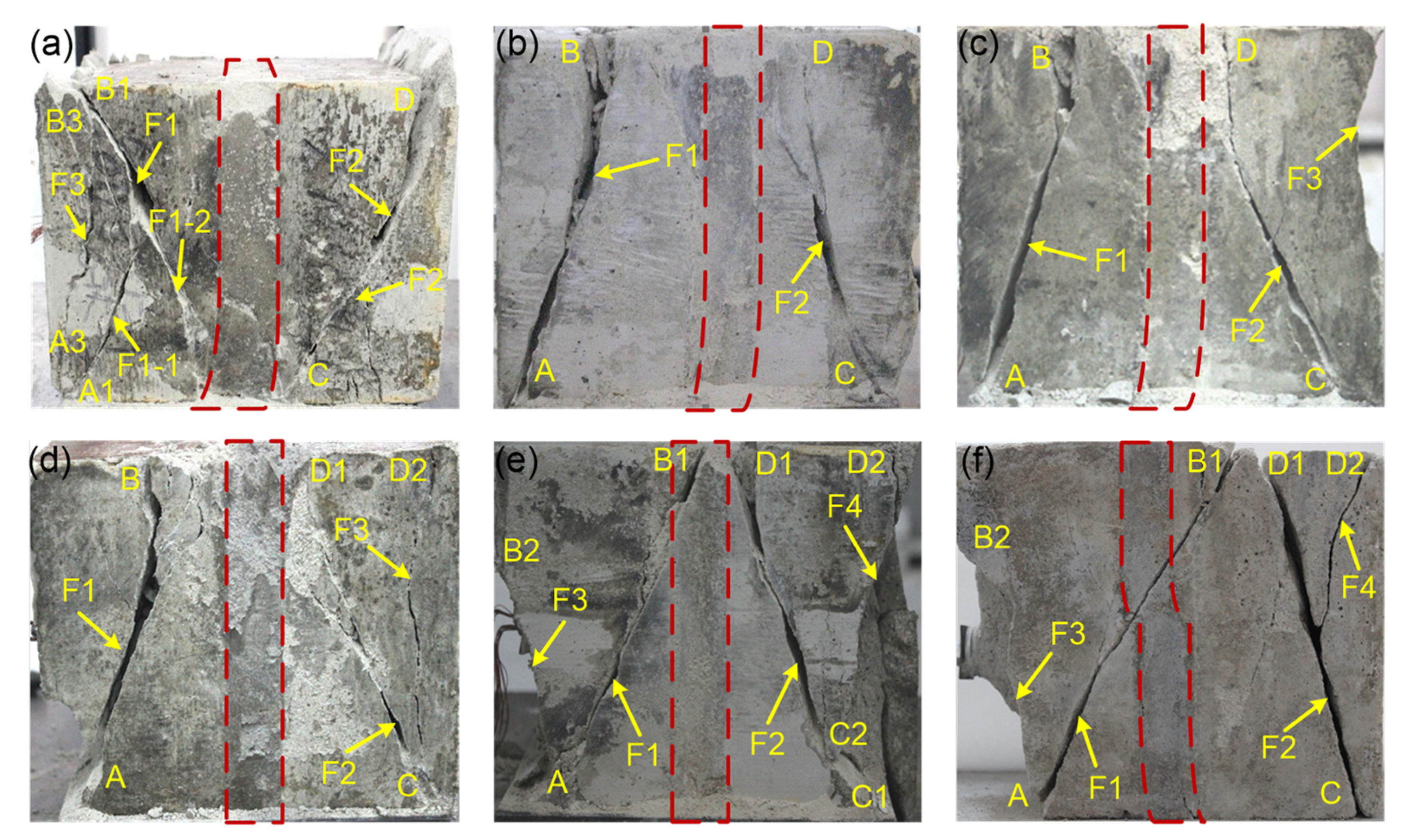

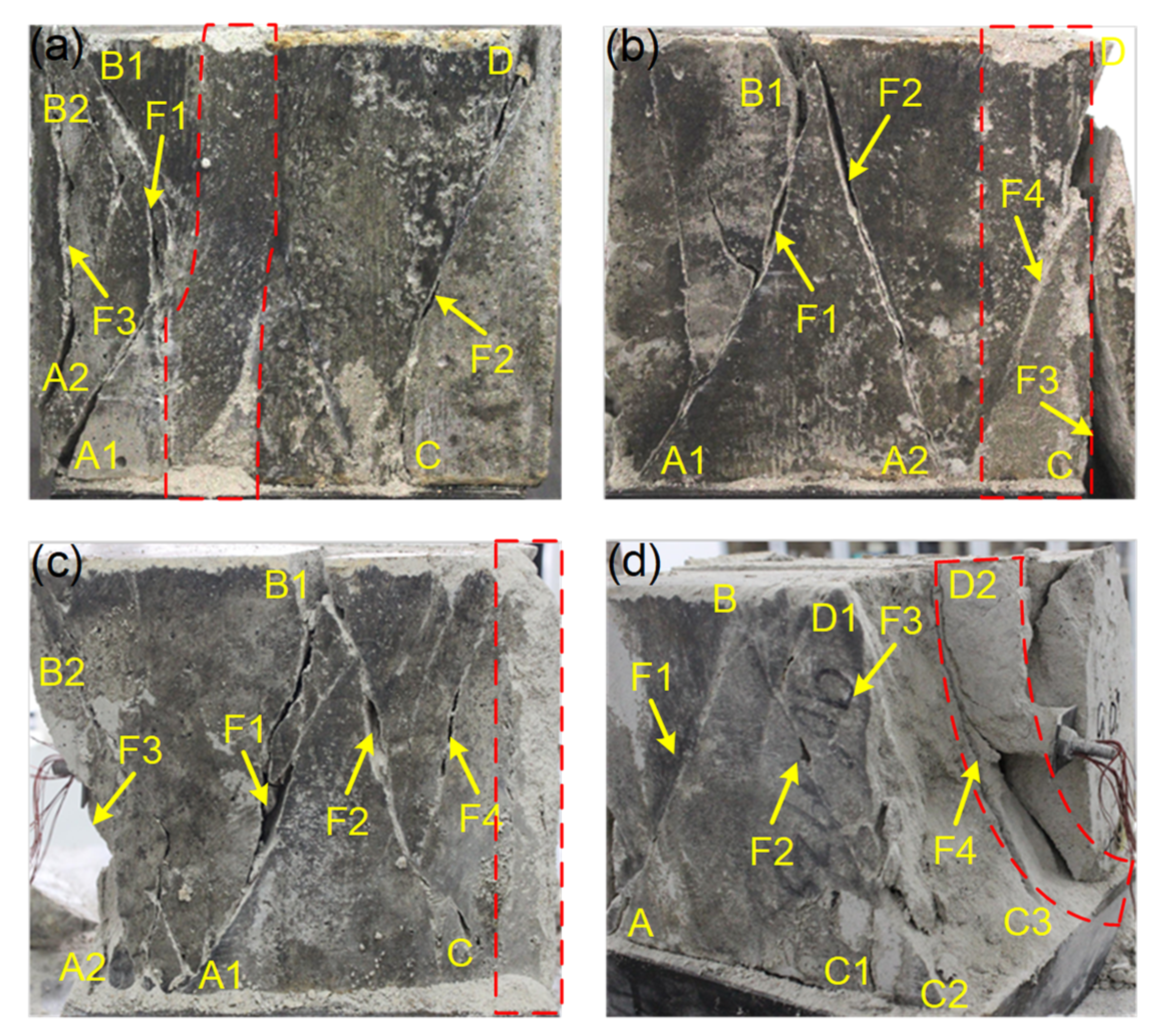

4. Influence of Weak Interlayer on the Failure Modes of the Bolted Samples

4.1. Analysis of the Effect of Weak Interlayer Thickness

4.2. Analysis of the Effect of the Uniaxial Compressive Strength of Weak Interlayer

4.3. Analysis of the Effect of Weak Interlayer Dip Angle

4.4. Analysis on the Synergistic Bearing Effect between Hard Rock and Weak Interlayer

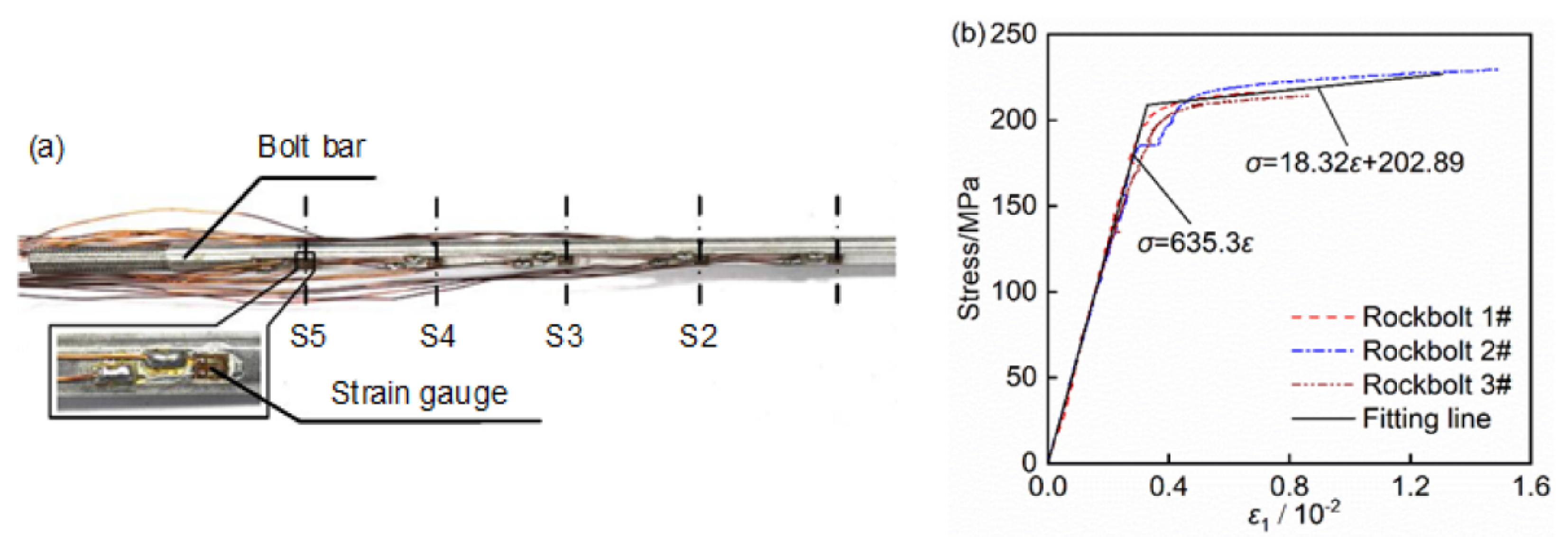

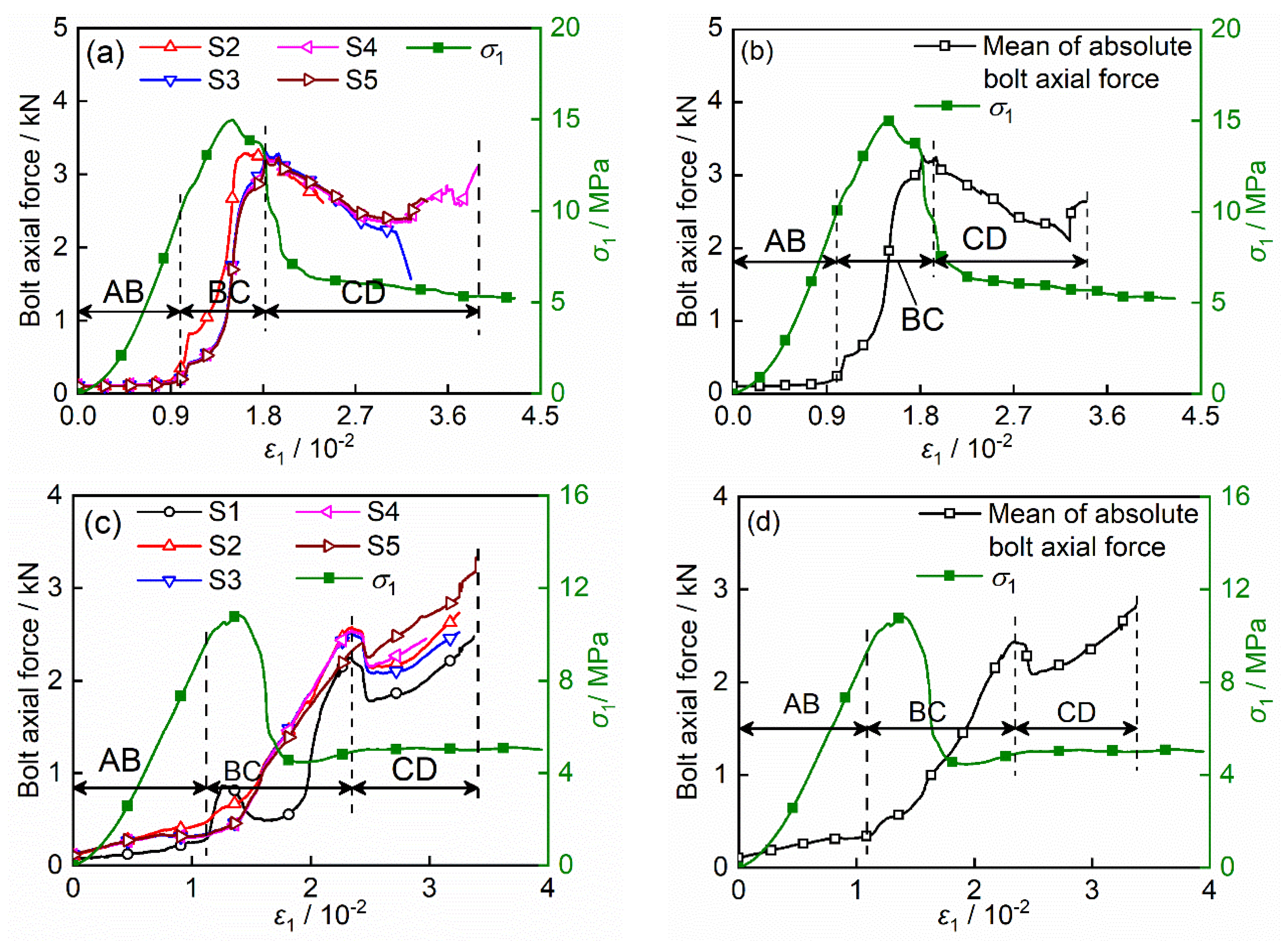

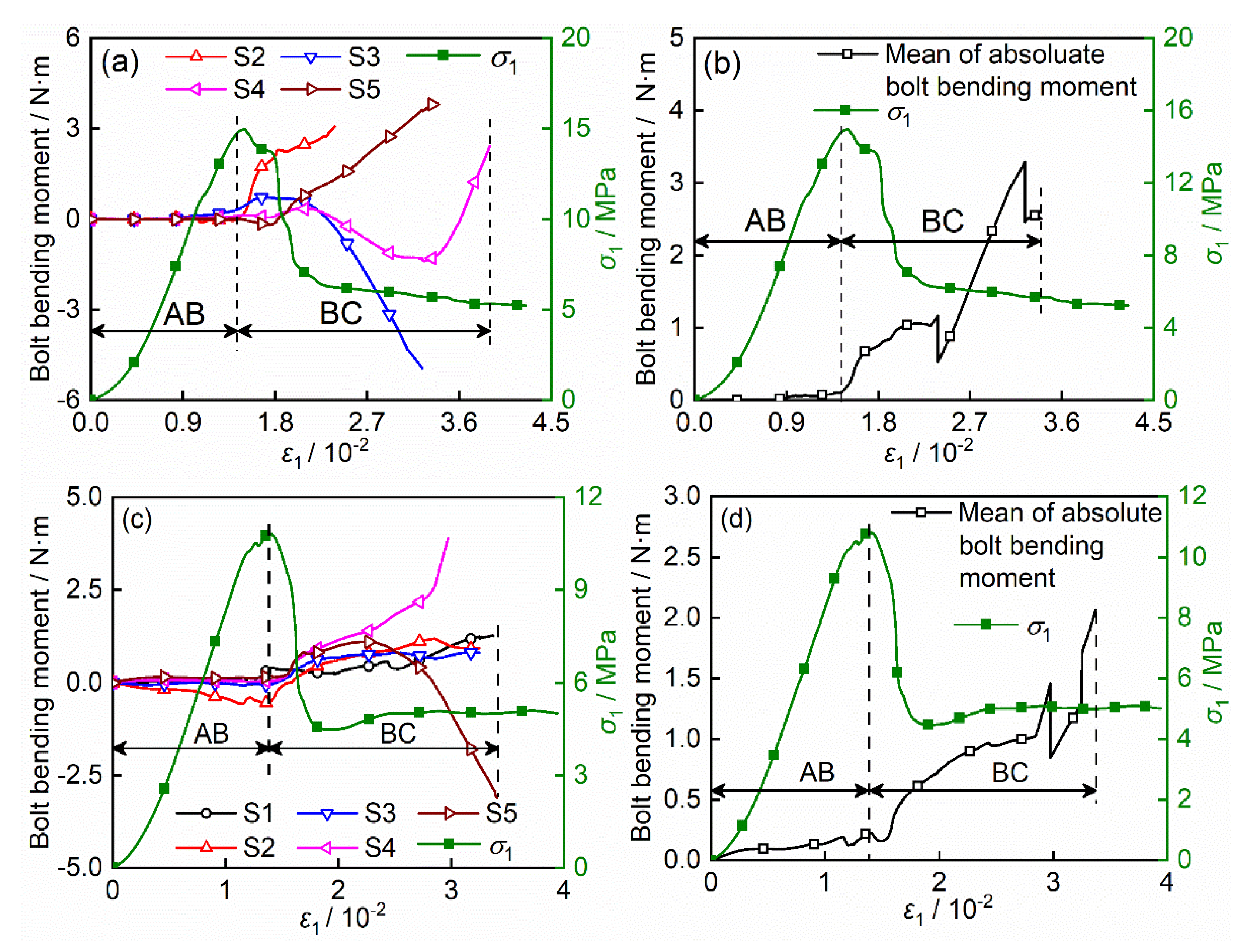

5. Analysis on Bolt Performance during the Deformation Process of the Specimens

5.1. Evolution of Bolt Axial Force

5.2. Evolution of Bolt Bending Moment

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, C.; Li, Y. Analytical study of the mechanical behavior of fully grouted bolts in bedding rock slopes. Rock Mech. Rock Eng. 2017, 50, 2413–2423. [Google Scholar] [CrossRef]

- Kang, H.; Wu, Y.; Gao, F.; Jiang, P.; Cheng, P.; Meng, X.; Li, Z. Mechanical performances and stress states of rock bolts under varying loading conditions. Tunn. Undergr. Space Technol. 2016, 52, 138–146. [Google Scholar] [CrossRef]

- Ning, J.; Wang, J.; Bu, T.; Hu, S.; Liu, X. An innovative support structure for gob-side entry retention in steep coal seam mining. Minerals 2017, 7, 75. [Google Scholar] [CrossRef]

- Yang, H.; Cao, S.; Li, Y.; Sun, C.; Guo, P. Soft roof failure mechanism and supporting method for gob-side entry retaining. Minerals 2015, 5, 707–722. [Google Scholar] [CrossRef]

- Wang, J.; Qiu, P.; Ning, J.; Zhuang, L.; Yang, S. A numerical study of the mining-induced energy redistribution in a coal seam adjacent to an extracted coal panel during longwall face mining: A case study. Energy Sci. Eng. 2020, 8, 817–835. [Google Scholar] [CrossRef]

- Peng, S.S.; Tang, D. Roof bolting in underground mining: A state-of-the-art review. Int. J. Min. Eng. 1984, 2, 1–42. [Google Scholar] [CrossRef]

- Song, G.; Li, W.; Wang, B.; Ho, S.C.M. A review of rock bolt monitoring using smart sensors. Sensors 2017, 17, 776. [Google Scholar] [CrossRef]

- Li, W.; Li, S.; Feng, X.; Li, S.; Yuan, C. Study of post-peak strain softening mechanical properties of rock based on Mohr-Coulomb criterion. Chin. J. Rock Mech. Eng. 2011, 7, 1460–1466. [Google Scholar]

- Bjurstrom, S. Shear strength of hard rock joints reinforced by grouted untensioned bolts. In Proceedings of the Third Congress of the International Society for Rock Mechanics, Denver, CO, USA, 1–7 September 1974; Volume 2, pp. 1194–1199. [Google Scholar]

- Wu, X.; Jiang, Y.; Li, B. Influence of joint roughness on the shear behaviour of fully encapsulated rock bolt. Rock Mech. Rock Eng. 2018, 51, 953–959. [Google Scholar] [CrossRef]

- Chen, N.; Zhang, X.; Jiang, Q.; Feng, X.; Wei, W.; Yi, B. Shear behavior of rough rock joints reinforced by bolts. Int. J. Geomech. 2018, 18, 04017130. [Google Scholar] [CrossRef]

- Grasselli, G. 3D behaviour of bolted rock joints: Experimental and numerical study. Int. J. Rock Mech. Min. Sci. 2005, 42, 13–24. [Google Scholar] [CrossRef]

- Jalalifar, H.; Aziz, N.; Hadi, M. The effect of surface profile, rock strength and pretension load on bending behaviour of fully grouted bolts. Geotech. Geol. Eng. 2006, 24, 1203–1227. [Google Scholar] [CrossRef]

- Jalalifar, H.; Aziz, N. Experimental and 3D numerical simulation of reinforced shear joints. Rock Mech. Rock Eng. 2010, 43, 95–103. [Google Scholar]

- Li, L.; Hagan, P.; Saydam, S.; Hebblewhite, B.; Li, Y. Parametric study of rockbolt shear behaviour by double shear test. Rock Mech. Rock Eng. 2016, 49, 4787–4797. [Google Scholar]

- Li, X.; Aziz, N.; Mirzaghorbanali, A.; Nemcik, J. Behavior of fiber glass bolts, rock bolts and cable bolts in shear. Rock Mech. Rock Eng. 2016, 49, 2723–2735. [Google Scholar] [CrossRef]

- Shi, X.; Jing, H.; Zhao, Z.; Gao, Y.; Zhang, Y.; Bu, R. Physical Experiment and Numerical Modeling on the Failure Mechanism of Gob-Side Entry Driven in Thick Coal Seam. Energies 2020, 13, 5425. [Google Scholar] [CrossRef]

- Yang, X.-X.; Qiao, W.-G. Numerical investigation of the shear behavior of granite materials containing discontinuous joints by utilizing the flat-joint model. Comput. Geotech. 2018, 104, 69–80. [Google Scholar] [CrossRef]

- Narr, W.; Suppe, J. Joint spacing in sedimentary rocks. J. Struct. Geol. 1991, 13, 1037–1048. [Google Scholar]

- Li, Y.; Liu, W.; Yang, C.; Daemen, J.J. Experimental investigation of mechanical behavior of bedded rock salt containing inclined interlayer. Int. J. Rock Mech. Min. Sci. 2014, 69, 39–49. [Google Scholar]

- Jing, H.-W.; Yang, S.-Q.; Zhang, M.-L.; Xu, G.; Chen, K. An experimental study on anchorage strength and deformation behavior of large-scale jointed rock mass. Tunn. Undergr. Space Technol. 2014, 43, 184–197. [Google Scholar]

- Srivastava, L.P.; Singh, M. Effect of fully grouted passive bolts on joint shear strength parameters in a blocky mass. Rock Mech. Rock Eng. 2015, 48, 1197–1206. [Google Scholar] [CrossRef]

- Zhang, B.; Li, S.; Xia, K.; Yang, X.; Zhang, D.; Wang, S.; Zhu, J. Reinforcement of rock mass with cross-flaws using rock bolt. Tunn. Undergr. Space Technol. 2016, 51, 346–353. [Google Scholar] [CrossRef]

- Su, H.; Jing, H.; Zhao, H.; Yu, L.; Wang, Y. Strength degradation and anchoring behavior of rock mass in the fault fracture zone. Environ. Earth Sci. 2017, 76, 179. [Google Scholar] [CrossRef]

- Zhu, W.; Jing, H.; Yang, L.; Pan, B.; Su, H. Strength and deformation behaviors of bedded rock mass under bolt reinforcement. Int. J. Min. Sci. Technol. 2018, 28, 593–599. [Google Scholar] [CrossRef]

- Teng, J.; Tang, J.; Zhang, Y.; Li, X. CT experimental study on the damage characteristics of anchored layered rocks. KSCE J. Civ. Eng. 2018, 22, 3653–3662. [Google Scholar] [CrossRef]

- Boon, C. Study of reinforcement support mechanisms for wide-span horse-shoe-shaped openings in horizontally layered jointed rock using the distinct element method. Rock Mech. Rock Eng. 2019, 52, 1179–1191. [Google Scholar] [CrossRef]

- Liu, X.; Han, Y.; Li, D.; Tu, Y.; Deng, Z.; Yu, C.; Wu, X. Anti-pull mechanisms and weak interlayer parameter sensitivity analysis of tunnel-type anchorages in soft rock with underlying weak interlayers. Eng. Geol. 2019, 253, 123–136. [Google Scholar] [CrossRef]

- Duan, S.-Q.; Feng, X.-T.; Jiang, Q.; Liu, G.-F.; Pei, S.-F.; Fan, Y.-L. In situ observation of failure mechanisms controlled by rock masses with weak interlayer zones in large underground cavern excavations under high geostress. Rock Mech. Rock Eng. 2017, 50, 2465–2493. [Google Scholar] [CrossRef]

- Xing, Y.; Kulatilake, P.; Sandbak, L. Effect of rock mass and discontinuity mechanical properties and delayed rock supporting on tunnel stability in an underground mine. Eng. Geol. 2018, 238, 62–75. [Google Scholar] [CrossRef]

- Xie, H.; Ju, Y.; Gao, F.; Gao, M.; Zhang, R. Groundbreaking theoretical and technical conceptualization of fluidized mining of deep underground solid mineral resources. Tunn. Undergr. Space Technol. 2017, 67, 68–70. [Google Scholar] [CrossRef]

- Mudd, G.M. The environmental sustainability of mining in Australia: Key mega-trends and looming constraints. Resour. Policy 2010, 35, 98–115. [Google Scholar] [CrossRef]

- Ulusay, R. The ISRM Suggested Methods for Rock Characterization, Testing and Monitoring: 2007–2014; Springer International Publishing: Cham, Switzerland, 2015. [Google Scholar]

- Huang, F.; Zhu, H.; Xu, Q.; Cai, Y.; Zhuang, X. The effect of weak interlayer on the failure pattern of rock mass around tunnel–Scaled model tests and numerical analysis. Tunn. Undergr. Space Technol. 2013, 35, 207–218. [Google Scholar] [CrossRef]

- Shan, R.; Kong, X.; Wei, Z.; Li, M.; Yang, S.; TIAN, L. Theory and application of strong support for coal roadway sidewall. Chin. J. Rock Mech. Eng. 2013, 32, 1304–1314. [Google Scholar]

- GUO, F.-L.; ZHANG, D.-L.; SU, J.; NIU, X.-K. Change of strength of surrounding rock system induced by weak interlayer. Chin. J. Geotech. Eng. 2009, 31, 720–726. [Google Scholar]

- Wu, W.; Feng, X.; Zhang, C.; Qiu, S. Classification of failure modes and controlling measures for surrounding rock of deep tunnel in hard rock. Chin. J. Rock Mech. Eng. 2011, 30, 1782–1802. [Google Scholar]

- Li, C.; Stillborg, B. Analytical models for rock bolts. Int. J. Rock Mech. Min. Sci. 1999, 36, 1013–1029. [Google Scholar] [CrossRef]

- Pellet, F.; Egger, P. Analytical model for the mechanical behaviour of bolted rock joints subjected to shearing. Rock Mech. Rock Eng. 1996, 29, 73–97. [Google Scholar] [CrossRef]

- Freeman, T. The behaviour of fully-bonded rock bolts in the Kielder experimental tunnel. Tunn. Tunn. Int. 1978, 10, 37–40. [Google Scholar]

- He, L.; An, X.; Zhao, Z. Fully grouted rock bolts: An analytical investigation. Rock Mech. Rock Eng. 2015, 48, 1181–1196. [Google Scholar] [CrossRef]

- Li, C.C. Field observations of rock bolts in high stress rock masses. Rock Mech. Rock Eng. 2010, 43, 491–496. [Google Scholar] [CrossRef]

- Saadat, M.; Taheri, A. Effect of contributing parameters on the behaviour of a bolted rock joint subjected to combined pull-and-shear loading: A DEM approach. Rock Mech. Rock Eng. 2020, 53, 383–409. [Google Scholar] [CrossRef]

- Saadat, M.; Taheri, A. Modelling micro-cracking behaviour of pre-cracked granite using grain-based distinct element model. Rock Mech. Rock Eng. 2019, 52, 4669–4692. [Google Scholar] [CrossRef]

| Lithology | E/GPa | σc/MPa | σt/MPa | c/MPa | φ/° | γ/(kN/m3) |

|---|---|---|---|---|---|---|

| Sandstone | 20.26~32.85 | 53.85~79.53 | 3.50~5.35 | 5.35~8.83 | 38.4~45.0 | 25 |

| Mudstone | 4.04~10.25 | 9.78~12.80 | 1.20~2.00 | 1.25~2.34 | 19.8~22.5 | 25 |

| Type | Sand: Cement: Gypsum | E/MPa | σc/MPa | σt/MPa | c/MPa | ϕ/° |

|---|---|---|---|---|---|---|

| Hard rock | 4.5:1:0 | 940 | 7.21 | 0.99 | 2.64 | 27.77 |

| Weak interlayer | 3: 0.5: 0.5 | 360 | 2.02 | 0.25 | 0.49 | 16.88 |

| 4: 0.6: 0.4 | 310 | 1.74 | 0.22 | 0.45 | 18.19 | |

| 4: 0.5: 0.5 | 190 | 1.27 | 0.17 | 0.36 | 24.56 | |

| 4: 0.4: 0.6 | 110 | 0.80 | 0.12 | 0.16 | 31.10 | |

| 6: 0.5: 0.5 | 70 | 0.46 | 0.06 | 0.12 | 28.61 | |

| 6: 0.4: 0.6 | 20 | 0.22 | 0.03 | 0.08 | 26.06 |

| Case No. | Sample | σw/MPa | tw/mm | αw/° |

|---|---|---|---|---|

| I | S-1 | 0.22 | 30 | 0 |

| S-2 | 0.46 | |||

| S-3 | 0.80 | |||

| S-4 | 1.27 | |||

| S-5 | 1.74 | |||

| S-6 | 2.02 | |||

| II | T-1 | 0.22 | 0 | 0 |

| T-2 | 5 | |||

| T-3 | 10 | |||

| T-4 | 15 | |||

| T-5 | 20 | |||

| T-6 | 25 | |||

| T-7 | 30 | |||

| III | A-1 | 0.22 | 30 | 0 |

| A-2 | 15 | |||

| A-3 | 30 | |||

| A-4 | 45 | |||

| A-5 | 90 |

| Thickness of Weak Interlayer tw (mm) | 0 | 5 | 10 | 15 | 20 | 25 | 30 |

|---|---|---|---|---|---|---|---|

| Peak strength of the sample σp (MPa) | 14.96 | 13.32 | 12.26 | 11.70 | 11.24 | 10.84 | 10.50 |

| Elastic modulus of the sample E (GPa) | 1.43 | 1.30 | 1.23 | 1.17 | 1.11 | 1.07 | 1.04 |

| Weakening effect index of WI on sample peak strength Dp (%) | 0 | 10.96 | 18.05 | 21.79 | 24.87 | 27.54 | 29.81 |

| Weakening effect index of WI on sample elastic modulus DE (%) | 0 | 9.09 | 13.99 | 18.18 | 22.3 | 25.17 | 27.27 |

| Uniaxial Compressive Strength of Weak Interlayer σw (MPa) | 0.22 | 0.46 | 0.80 | 1.27 | 1.74 | 2.02 |

|---|---|---|---|---|---|---|

| Peak strength of the sample σp (MPa) | 10.50 | 10.90 | 11.26 | 11.58 | 11.79 | 12.01 |

| Elastic modulus of the sample E (GPa) | 1.04 | 1.08 | 1.13 | 1.18 | 1.25 | 1.31 |

| Weakening effect index of weak interlayer on sample peak strength Dp (%) | 29.81 | 27.14 | 24.73 | 22.59 | 21.19 | 19.72 |

| Weakening effect index of weak interlayer on sample elastic modulus DE (%) | 27.27 | 24.48 | 20.98 | 17.48 | 12.59 | 8.39 |

| Dip angle of weak interlayer αw (°) | 0 | 15 | 30 | 45 | 90 |

|---|---|---|---|---|---|

| Peak strength of the sample σp (MPa) | 10.50 | 9.18 | 8.58 | 8.36 | 9.34 |

| Elastic modulus of the sample E (GPa) | 1.04 | 0.89 | 0.81 | 0.78 | 0.91 |

| Weakening effect index of weak interlayer on sample peak strength Dp (%) | 29.81 | 38.64 | 42.65 | 44.12 | 37.57 |

| Weakening effect index of weak interlayer on sample elastic modulus DE (%) | 27.27 | 37.76 | 43.36 | 45.45 | 36.36 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, S.; Gao, Y.; Jing, H.; Shi, X.; Qi, Y.; Guo, J. Influence of Weak Interlayer on the Mechanical Performance of the Bolted Rock Mass with a Single Free Surface in Deep Mining. Minerals 2021, 11, 496. https://doi.org/10.3390/min11050496

Ding S, Gao Y, Jing H, Shi X, Qi Y, Guo J. Influence of Weak Interlayer on the Mechanical Performance of the Bolted Rock Mass with a Single Free Surface in Deep Mining. Minerals. 2021; 11(5):496. https://doi.org/10.3390/min11050496

Chicago/Turabian StyleDing, Shuxue, Yuan Gao, Hongwen Jing, Xinshuai Shi, Yanjun Qi, and Jiaqi Guo. 2021. "Influence of Weak Interlayer on the Mechanical Performance of the Bolted Rock Mass with a Single Free Surface in Deep Mining" Minerals 11, no. 5: 496. https://doi.org/10.3390/min11050496

APA StyleDing, S., Gao, Y., Jing, H., Shi, X., Qi, Y., & Guo, J. (2021). Influence of Weak Interlayer on the Mechanical Performance of the Bolted Rock Mass with a Single Free Surface in Deep Mining. Minerals, 11(5), 496. https://doi.org/10.3390/min11050496