Real-Time Electrical Conductivity Monitoring and Correlation with Sulfate Release and Acid Mine Drainage Potential from a Gold/Silver Paste Tailing Storage

Abstract

:1. Introduction

2. Materials and Methods

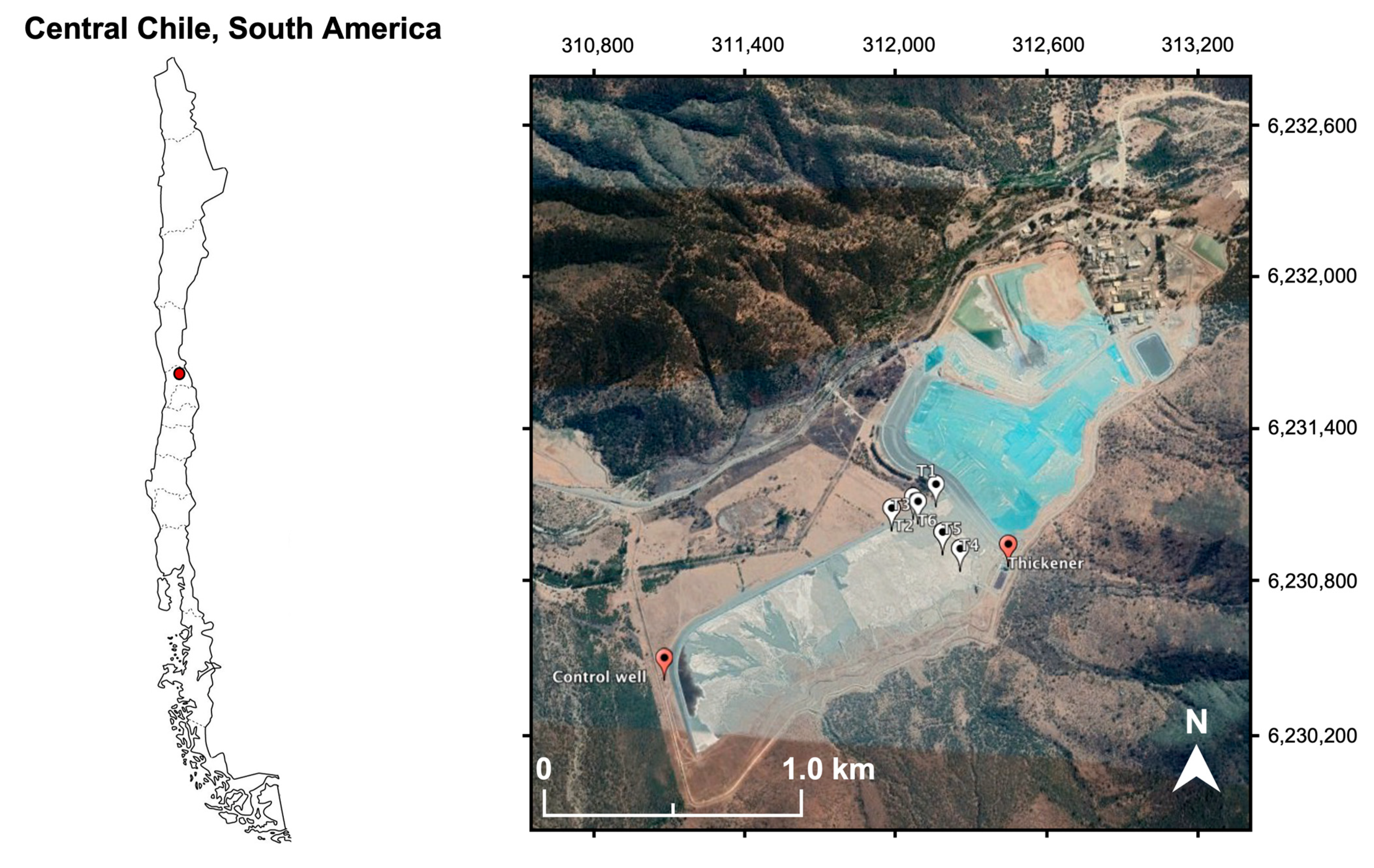

2.1. Site Description

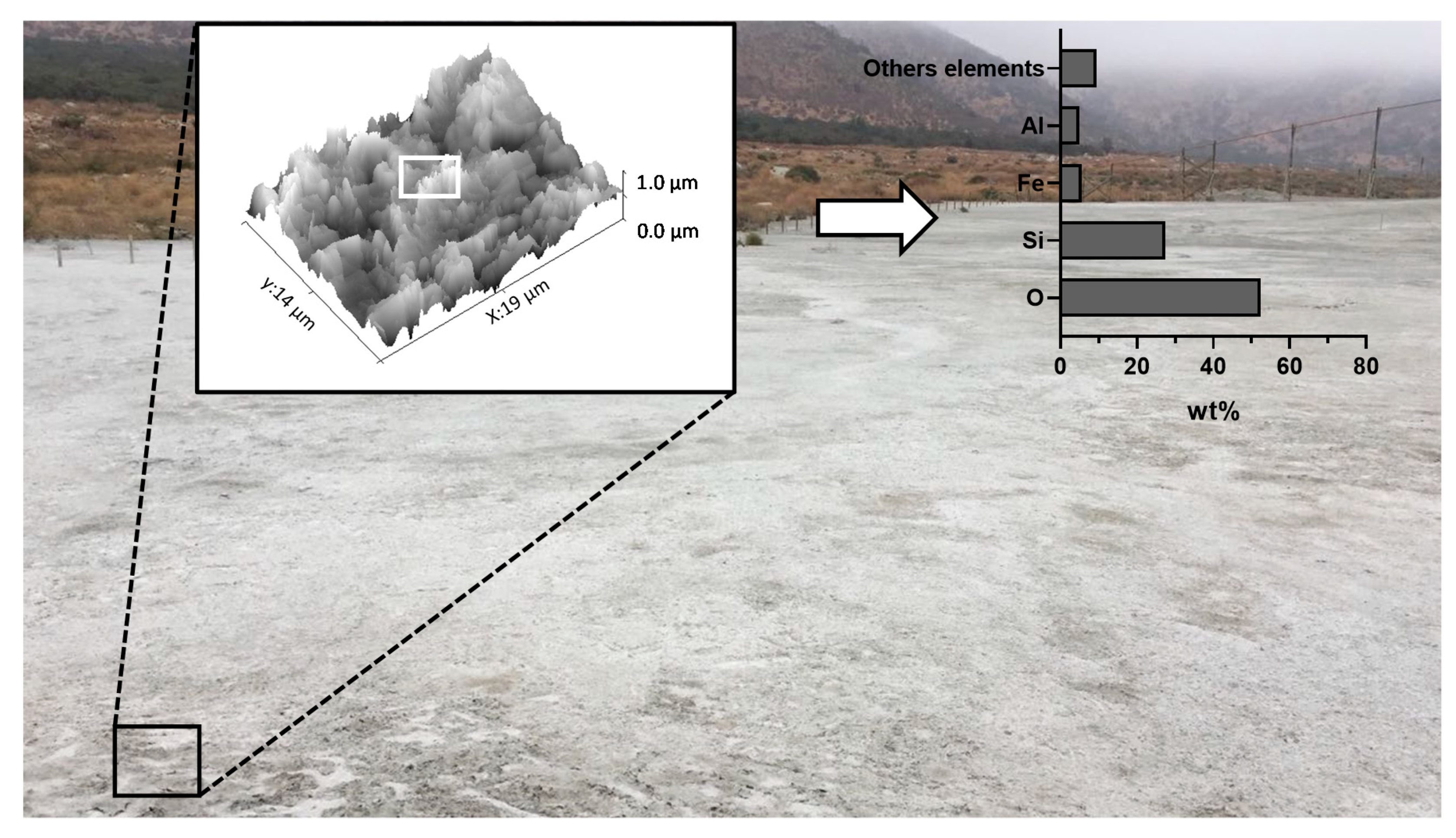

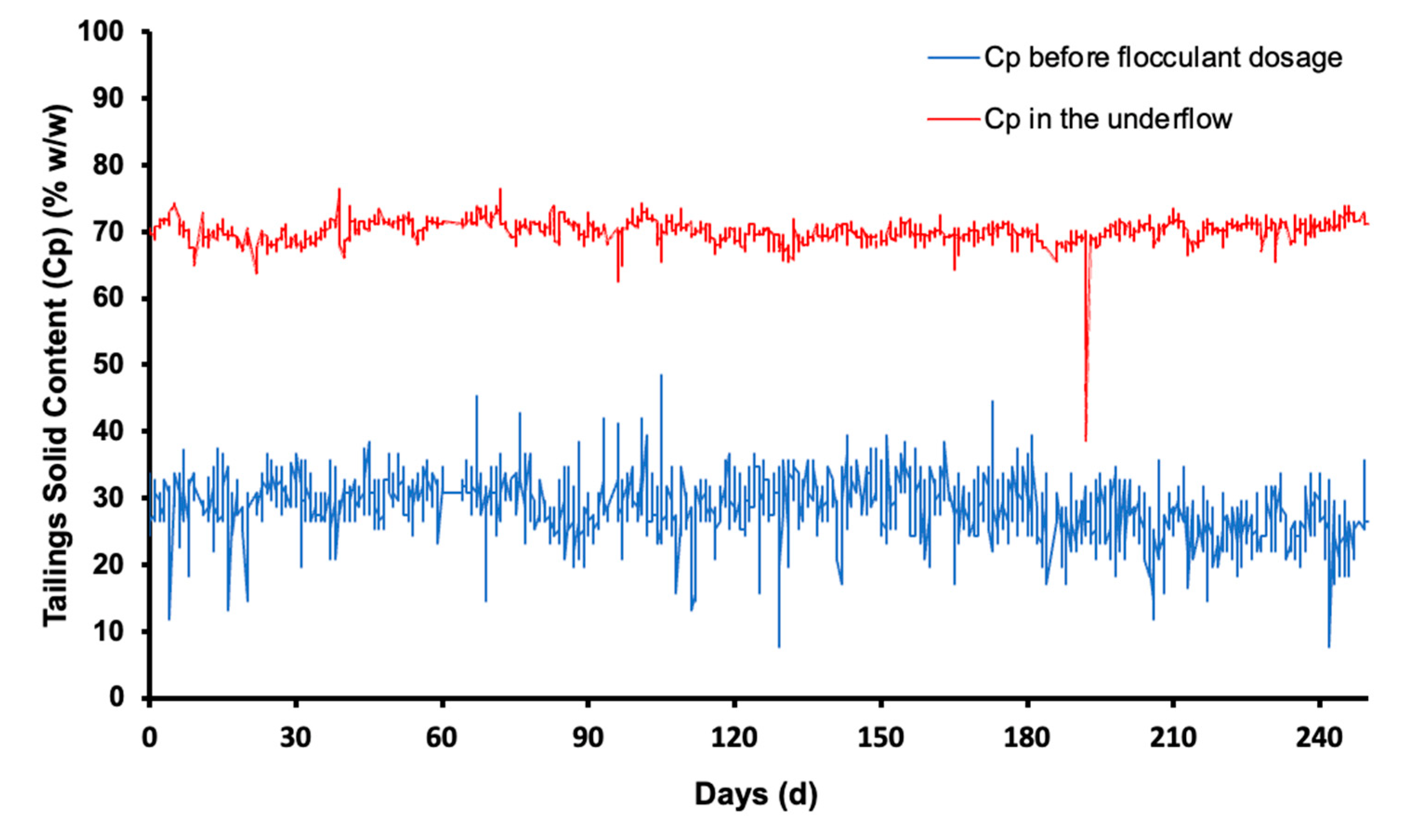

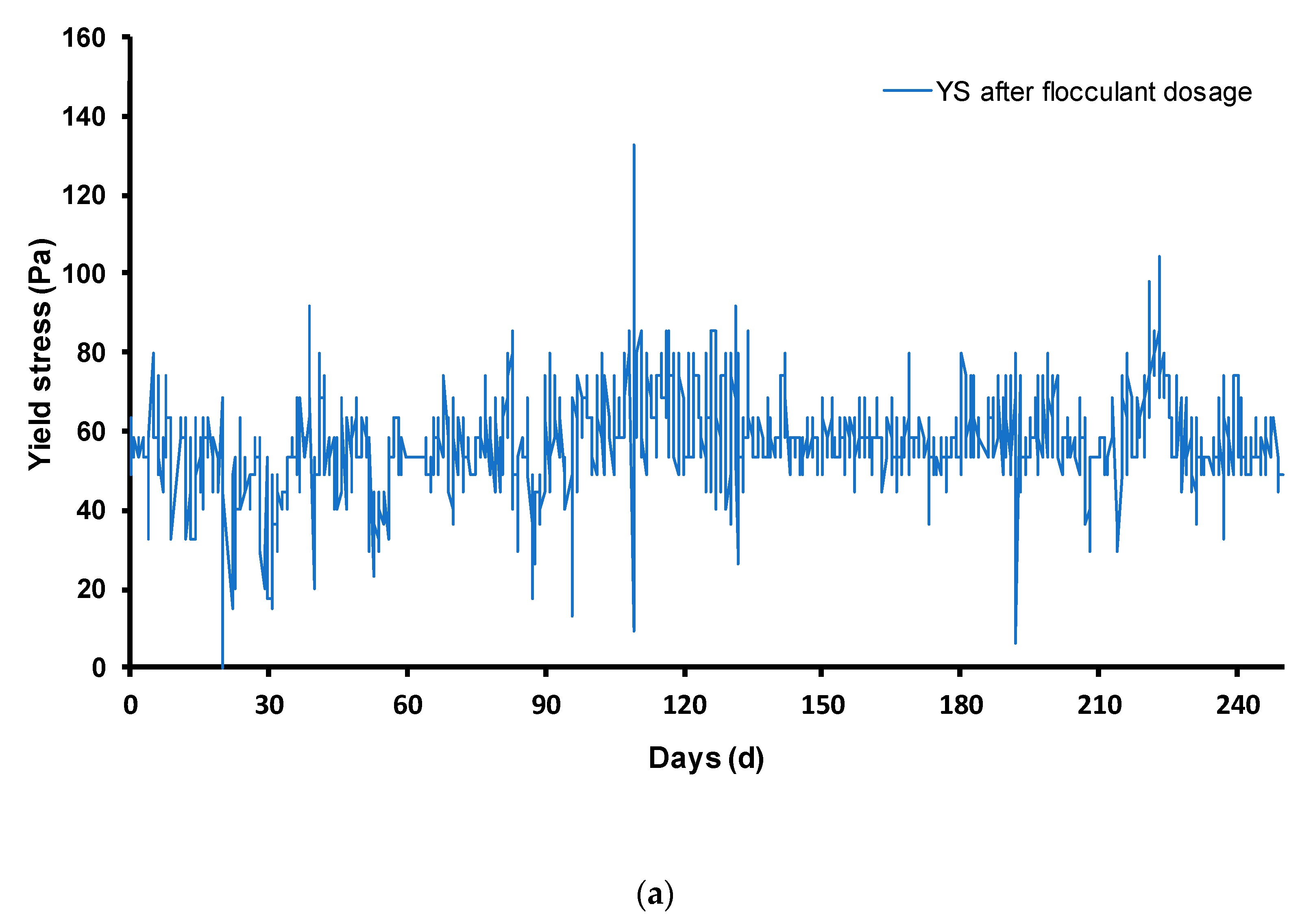

2.2. Paste Characterization

2.3. Tailings Analysis

2.4. Acid Potential Tests

2.4.1. Net Acid Generation (NAG) Tests

2.4.2. Acid Base Accounting (ABA)

2.4.3. Paste pH

2.4.4. Kinetic Test: Humidity Cells

2.5. Real-Time Monitoring of Chemical Parameters

2.6. Time Series Analysis of Real-Time Monitoring of Chemical Parameters

2.7. Quality Assurance/Quality Control (QA/QC)

2.8. Statistical Analysis

3. Results and Discussion

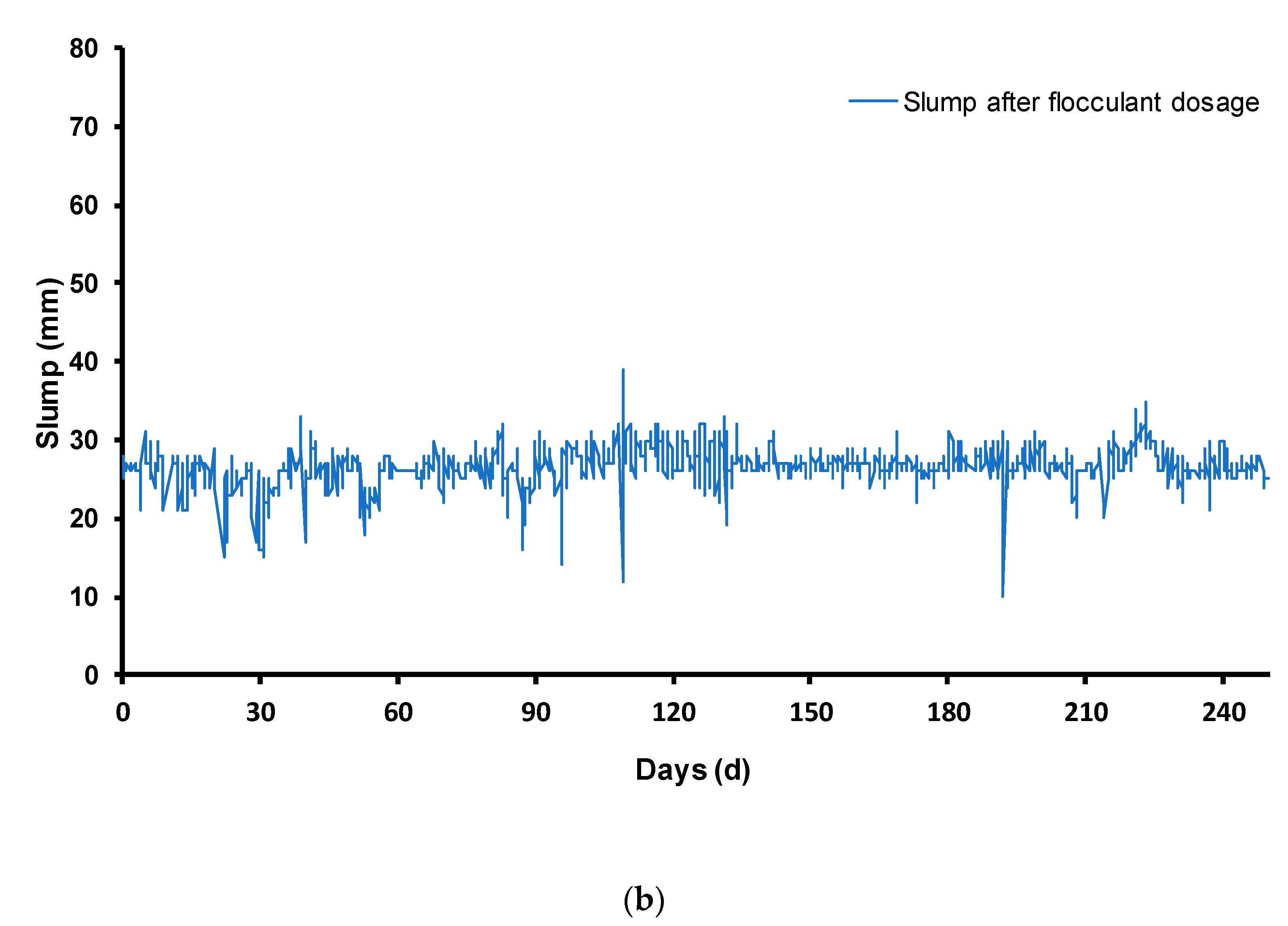

3.1. Paste Tailings Characterization

3.2. Chemical Analysis of Tailings Samples

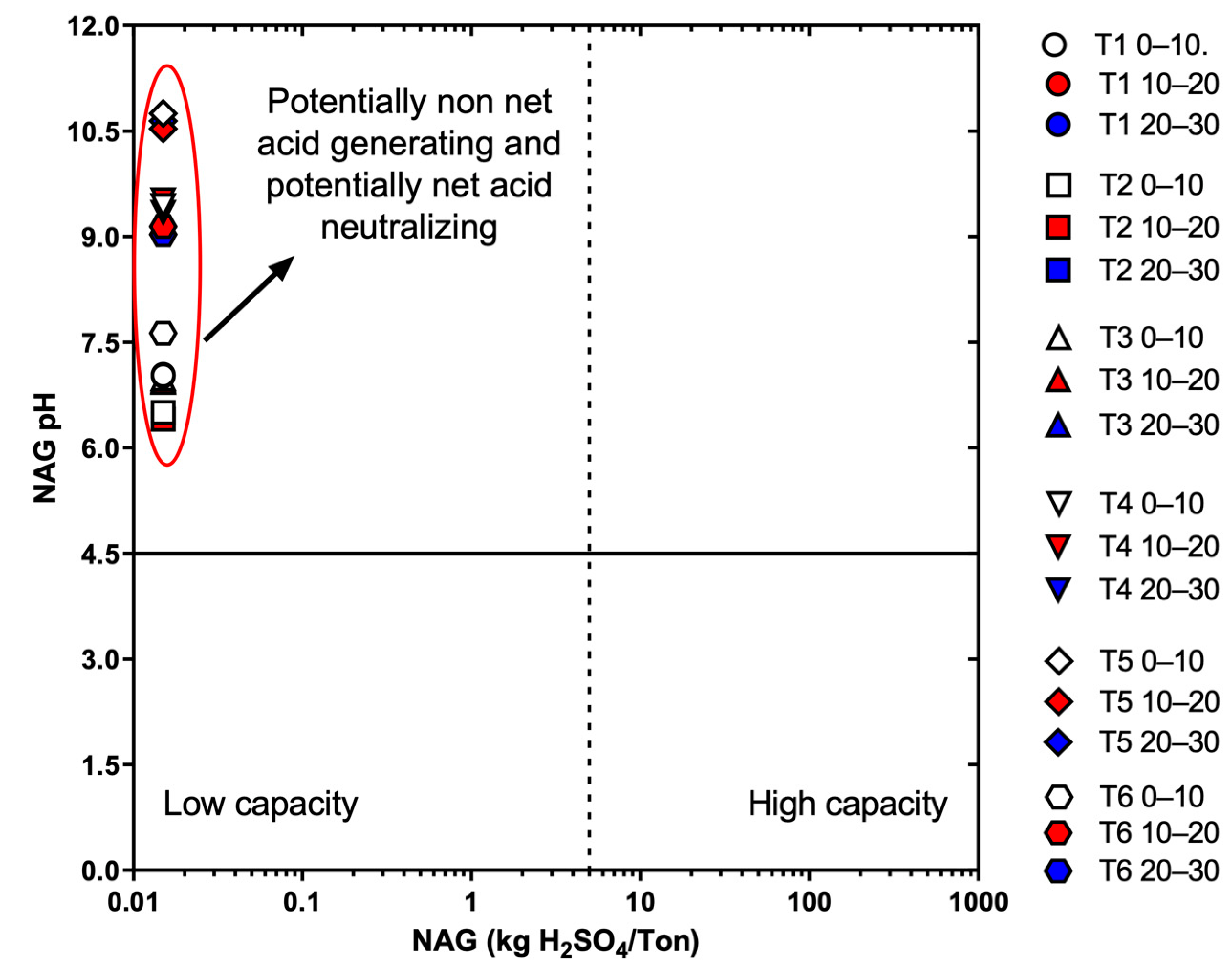

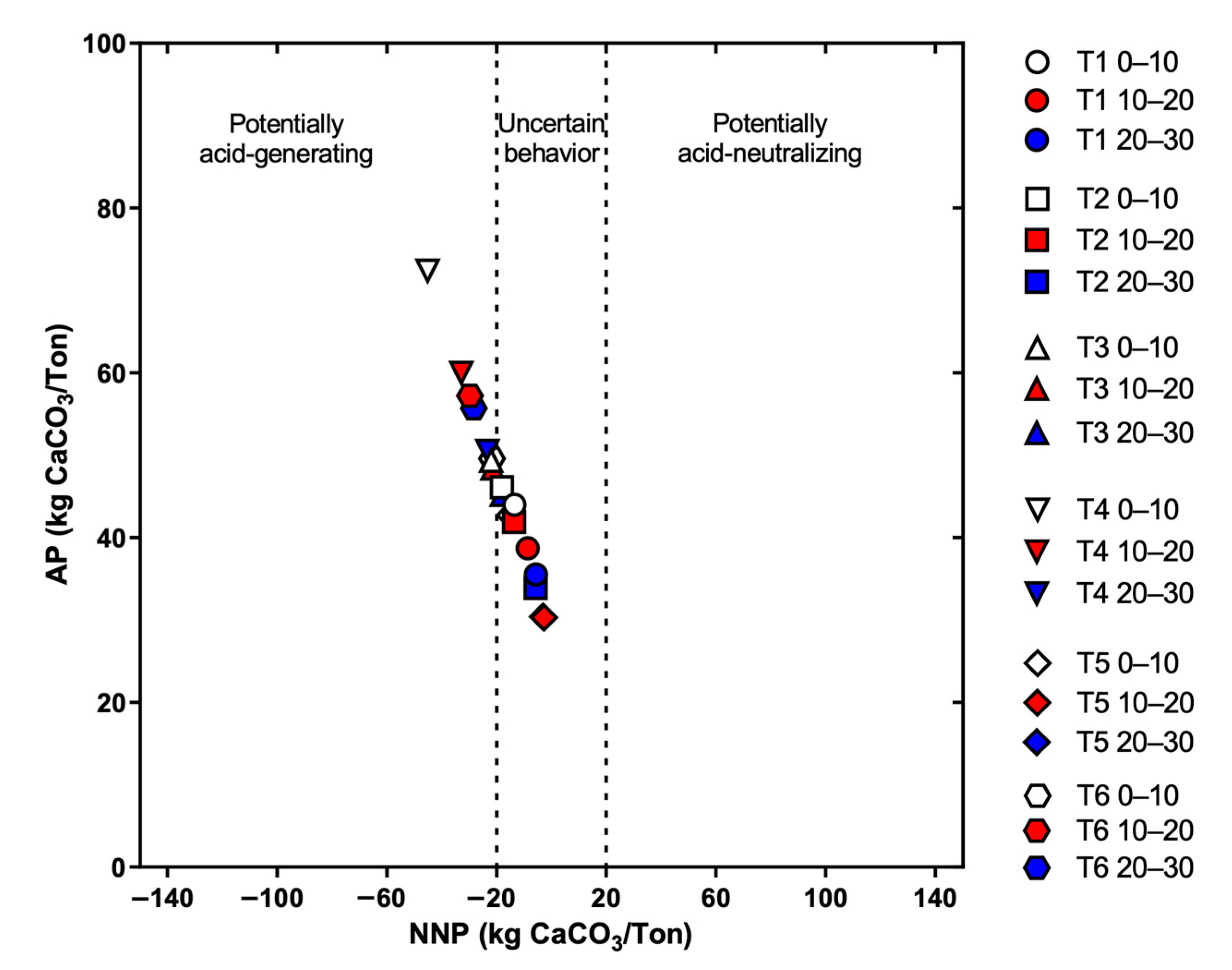

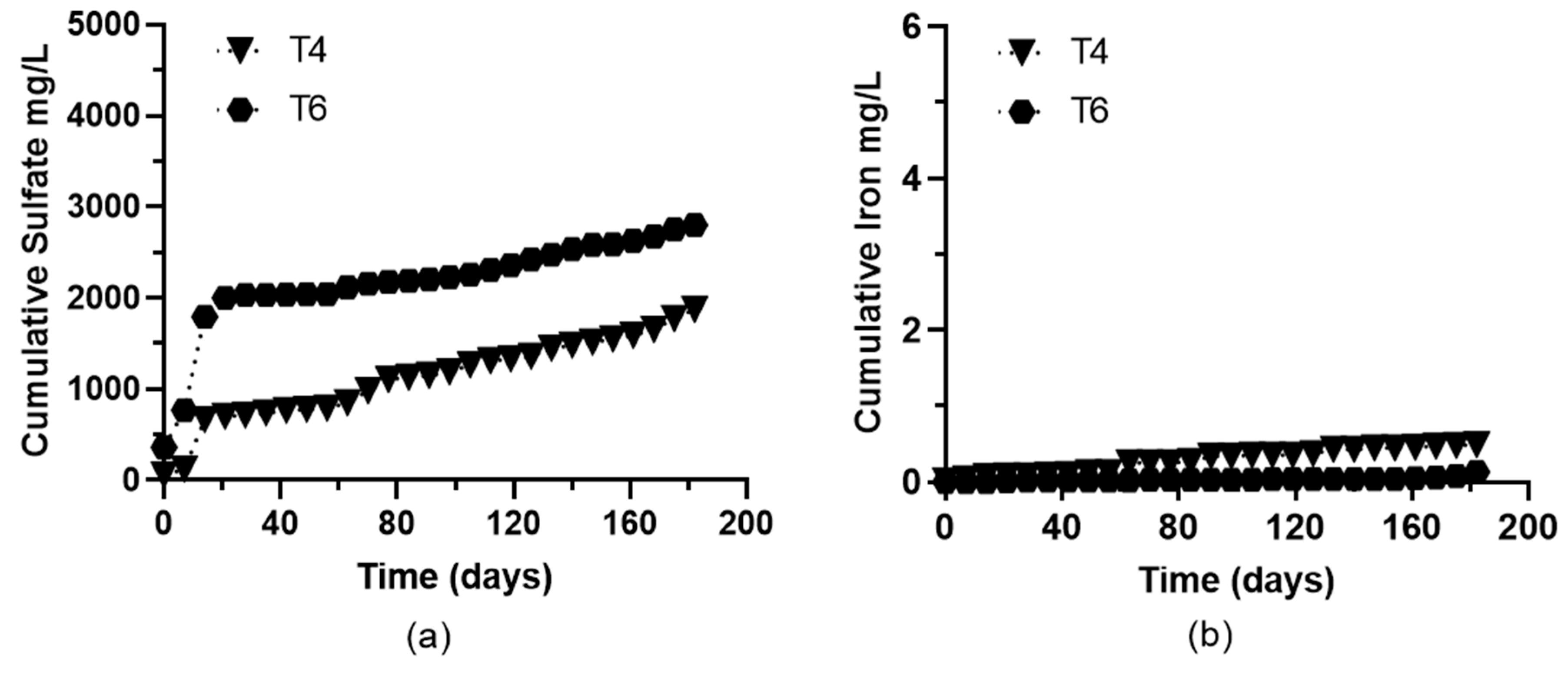

3.3. Assessment of Acid Mine Drainage Potential

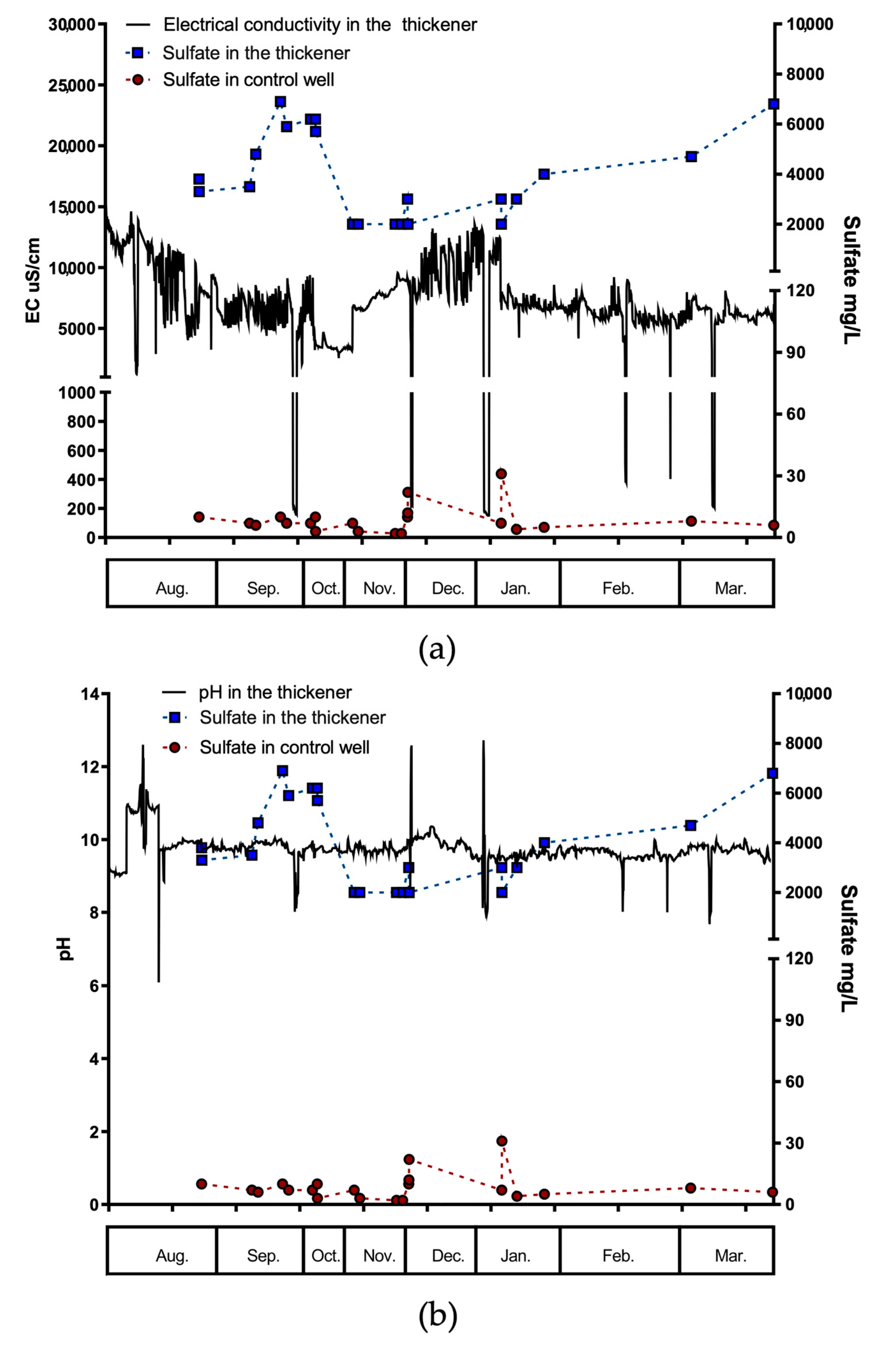

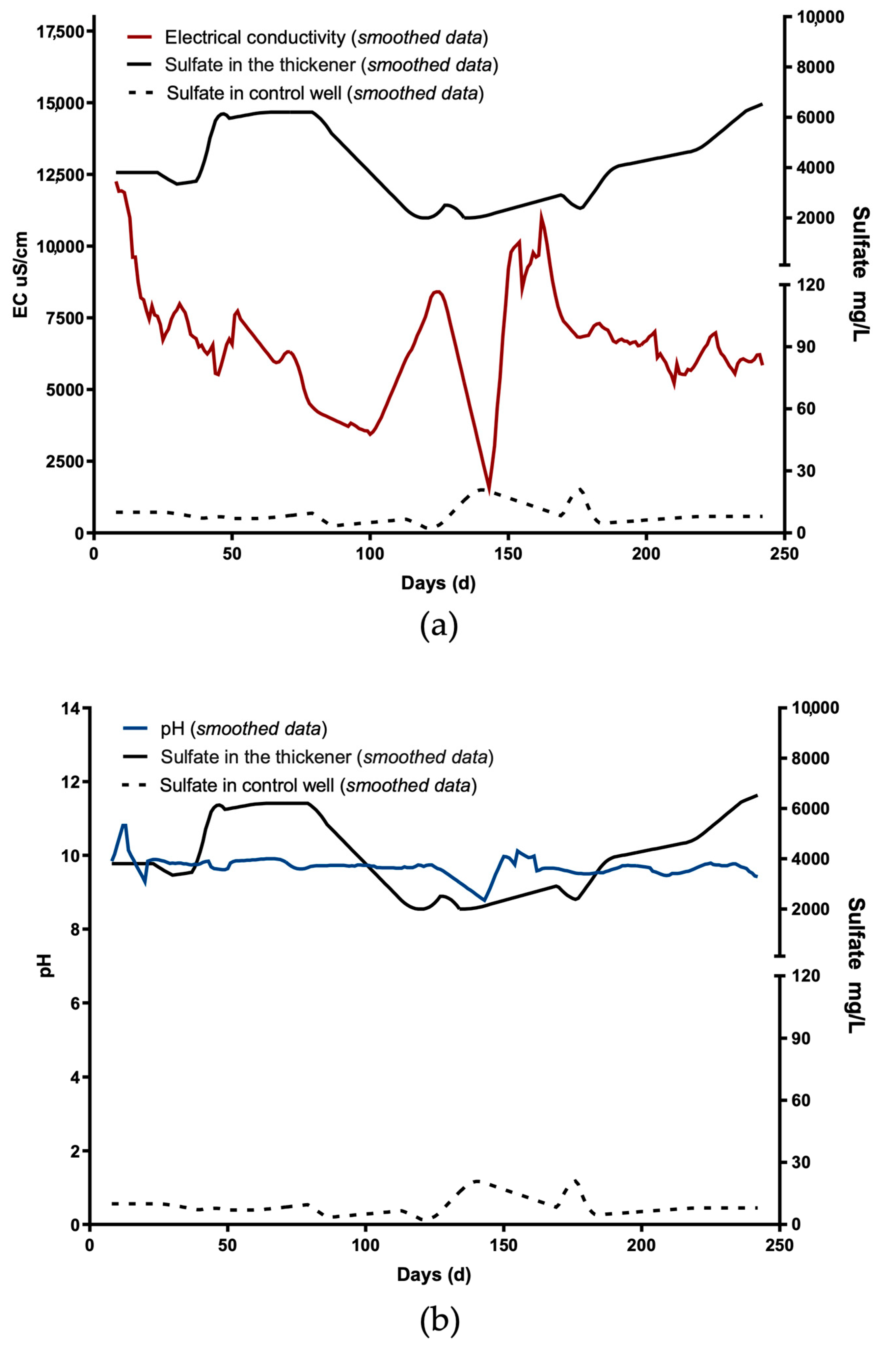

3.4. Electrical Conductivity and pH Time-Series

3.5. Correlation Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- SERNAGEOMIN. Datos Públicos Deposito de Relaves [WWW Document]. 2018. Available online: https://www.sernageomin.cl/datos-publicos-deposito-de-relaves/ (accessed on 6 October 2021).

- Araya, N.; Kraslawski, A.; Cisternas, L.A. Towards mine tailings valorization: Recovery of critical materials from Chilean mine tailings. J. Clean. Prod. 2020, 263, 121555. [Google Scholar] [CrossRef]

- Nasrabadi, T.; Nabi Bidhendi, G.R.; Karbassi, A.R.; Hoveidi, H.; Nasrabadi, I.; Pezeshk, H.; Rashidnejad, F. Infuence of Sungun copper mine on groundwater quality, NW Iran. Environ. Geol. 2009, 58, 693–700. [Google Scholar] [CrossRef]

- Blowes, D.; Ptacek, C.; Jambor, J.; Weisener, C. The Geochemistry of Acid Mine. Environ. Geochem. 2005, 9, 149. [Google Scholar]

- Johnson, D.B.; Hallberg, K.B. Acid mine drainage remediation options: A review. Sci. Total Environ. 2005, 338, 3–14. [Google Scholar] [CrossRef]

- Nishimoto, N.; Yamamoto, Y.; Yamagata, S.; Igarashi, T.; Tomiyama, S. Acid Mine Drainage Sources and Impact on Groundwater at the Osarizawa Mine, Japan. Minerals 2021, 11, 998. [Google Scholar] [CrossRef]

- Yamaguchi, K.; Tomiyama, S.; Igarashi, T.; Yamagata, S.; Ebato, M.; Sakoda, M. Improvement in pH and Total Iron Concentration of Acid Mine Drainage after Backfilling: A Case Study of an Underground Abandoned Mine in Japan. Minerals 2021, 11, 1297. [Google Scholar] [CrossRef]

- Elghali, A.; Benzaazoua, M.; Bouzahzah, H.; Bussière, B. Laboratory Study on the Effectiveness of Limestone and Cementitious Industrial Products for Acid Mine Drainage Remediation. Minerals 2021, 11, 413. [Google Scholar] [CrossRef]

- Elghali, A.; Benzaazoua, M.; Bussière, B.; Genty, T. In Situ Effectiveness of Alkaline and Cementitious Amendments to Stabilize Oxidized Acid-Generating Tailings. Minerals 2019, 9, 314. [Google Scholar] [CrossRef] [Green Version]

- Leiva, E.; Leiva-Aravena, E.; Vargas, I. Acid water neutralization using microbial fuel cells: An alternative for acid mine drainage treatment. Water 2016, 8, 536. [Google Scholar] [CrossRef] [Green Version]

- Rodríguez, C.; Leiva, E. Enhanced heavy metal removal from acid mine drainage wastewater using double-oxidized multiwalled carbon nanotubes. Molecules 2020, 25, 111. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rodríguez, C.; Tapia, C.; Leiva-Aravena, E.; Leiva, E. Graphene oxide–ZnO nanocomposites for removal of aluminum and copper ions from acid mine drainage wastewater. Int. J. Environ. Res. Public Health 2020, 17, 6911. [Google Scholar] [CrossRef]

- Chen, J.; Li, X.; Jia, W.; Shen, S.; Deng, S.; Ji, B.; Chang, J. Promotion of bioremediation performance in constructed wetland microcosms for acid mine drainage treatment by using organic substrates and supplementing domestic wastewater and plant litter broth. J. Hazard. Mater. 2021, 404, 124125. [Google Scholar] [CrossRef] [PubMed]

- Kefeni, K.K.; Msagati, T.A.M.; Mamba, B.B. Acid mine drainage: Prevention, treatment options, and resource recovery: A review. J. Clean. Prod. 2017, 151, 475–493. [Google Scholar] [CrossRef]

- Liu, W.; Chen, X.; Li, W.; Yu, Y.; Yan, K. Environmental assessment, management and utilization of red mud in China. J. Clean. Prod. 2014, 84, 606–610. [Google Scholar] [CrossRef]

- Mymrin, V.; Alekseev, K.; Fortini, O.M.; Aibuldinov, Y.K.; Pedroso, C.L.; Nagalli, A.; Winter, E., Jr.; Catai, R.E.; Costa, E.B.C. Environmentally clean materials from hazardous red mud, ground cooled ferrous slag and lime production waste. J. Clean. Prod. 2017, 161, 376–381. [Google Scholar] [CrossRef]

- Davies, M. Filtered dry stacked tailings e the fundamentals. In Proceedings of the Tailings and Mine Waste, Vancouver, BC, Canada, 6–9 November 2011. [Google Scholar]

- Hua, Y.; Heal, K.V.; Friesl-Hanl, W. The use of red mud as an immobiliser for metal/metalloid-contaminated soil: A review. J. Hazard. Mater. 2017, 325, 17–30. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cincilla, W.A.; Landriault, D.A.; Verburg, R. Application of paste technology to surface disposal of mineral wastes. In Proceedings of the Fourth International Conference on Tailings and Mine Waste, Fort Collins, CO, USA, 13–17 January 1997; pp. 343–356. [Google Scholar]

- Henriquez, J.; Simms, P. Dynamic imaging and modelling of multilayer deposition of gold paste tailings. Miner. Eng. 2009, 22, 128–139. [Google Scholar] [CrossRef]

- Brackebusch, F.; Shillabeer, J. Use of paste for tailings disposal. In Proceedings of the Sixth International Symposium on Mining with Backfill; Bloss, M., Ed.; The Australasian Institute of Mining and Metallurgy: Brisbane, Australia, 1998; pp. 53–58. [Google Scholar]

- Newman, P.; Landriault, D. The Use of Paste Technology in the Surface Disposal of Mineral Waste; Waste Minimisation and Recycle: Birmingham, UK, 1997. [Google Scholar]

- Trampus, B.C.; Franca, S.C. Performances of two flocculants and their mixtures for red mud dewatering and disposal based on mineral paste production. J. Clean. Prod. 2020, 257, 120534. [Google Scholar] [CrossRef]

- Arslan, S.; Ucbeyiay, H.; Celikel, B.; Baygul, M.; Avcu, S.; Demir, G.K. ETI aluminum red mud characteristics and evaluation of dewatering performance. In Proceedings of the Bauxite Residue Valorization and Best Practices Conference, Leuven, Belgium, 4–7 October 2015. [Google Scholar]

- Meggyes, T.; Debreczeni, A. Paste technology for tailings management. Land Contam. Reclamat. 2006, 14, 815–827. [Google Scholar] [CrossRef]

- Trampus, B.C.; França, S.C.A. Reologia aplicada ao desaguamento de lama vermelha como suporte para a produçao de pasta mineral. In Proceedings of the XXVII Encontro Nacional de Tratamento de Minerios e Metalurgia Extrativa, Belém, Pará, Brasil, 23–27 October 2017. [Google Scholar]

- Hogg, R. Flocculation and dewatering. Int. J. Miner. Process. 2000, 58, 223–236. [Google Scholar] [CrossRef]

- Guezennec, A.G.; Michel, C.; Bru, K.; Touze, S.; Desroche, N.; Mnif, I.; Motelica-Heino, M. Transfer and degradation of polyacrylamide based flocculants in hydrosystems: A review. Environ. Sci. Pollut. Res. 2015, 22, 6390–6406. [Google Scholar] [CrossRef] [Green Version]

- Bortoleto, D.A.; Camargos, M.A.; Davo, J.B. Powder flocculant application for Bayer residue sedimentation in the aluminium industry. Holos 2017, 6, 217–223. [Google Scholar] [CrossRef] [Green Version]

- Gregory, J.; Barany, S. Adsorption and flocculation by polymers and polymer mixtures. Adv. Colloid Interface Sci. 2011, 169, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Boger, D.V. Rheology of slurries and environmental impacts in the mining industry. Annu. Rev. Chem. Biomol. Eng. 2013, 4, 239–257. [Google Scholar] [CrossRef] [PubMed]

- Uhlherr, P.H.T.; Guo, J.; Fang, T.N.; Tiu, C. Static measurement of yield stress using a cylindrical penetrometer. Korea Aust. Rheol. J. 2002, 14, 17–23. [Google Scholar]

- Bhattacharya, S. Yield stress and time-dependent rheological properties of mango pulp. J. Food Sci. 1999, 64, 1029–1033. [Google Scholar] [CrossRef]

- Cooke, R. Thickened and paste tailings pipeline systems: Design procedure–Part 1. In Proceedings of the Ninth International Seminar on Paste and Thickened Tailings; Australian Centre for Geomechanics: Crawley, Australia, 2006; pp. 371–381. [Google Scholar]

- Clayton, S.; Grice, T.G.; Boger, D.V. Analysis of the slump test for on-site yield stress measurement of mineral suspensions. Int. J. Min. Process. 2003, 70, 3–21. [Google Scholar] [CrossRef]

- Leiva, E.; Cayazzo, M.; Dávila, L.; Torres, M.; Ledezma, C. Acid Mine Drainage Dynamics from a Paste Tailing Deposit: Effect of Sulfate Content on the Consistency and Chemical Stability after Storage. Metals 2021, 11, 860. [Google Scholar] [CrossRef]

- USEPA. Method 3050B. Acid digestion of sediments, sludges, and soils. In Test Methods for Evaluating Solid Waste; USEPA: Washington, DC, USA, 1996. [Google Scholar]

- Miller, S.D. Predicting Acid Drainage. Groundwork; Australian Minerals and Energy Environment Foundation: Melbourne, Australia, 1998; Volume 2, pp. 8–9.

- Sobek, A.A. Field and Laboratory Methods Applicable to Overburdens and Minesoils; Industrial Environmental Research Laboratory, Office of Research and Development, US Environmental Protection Agency: Washington, DC, USA, 1978. [Google Scholar]

- Elghali, A.; Benzaazoua, M.; Bouzahzah, H.; Bussière, B.; Villarraga-Gómez, H. Determination of the available acid-generating potential of waste rock, part I: Mineralogical approach. Appl. Geochem. 2018, 99, 31–41. [Google Scholar] [CrossRef]

- Bouzahzah, H.; Benzaazoua, M.; Plante, B.; Bussiere, B. A quantitative approach for the estimation of the “fizz rating” parameter in the acid-base accounting tests: A new adaptations of the Sobek test. J. Geochem. Explor. 2015, 153, 53–65. [Google Scholar] [CrossRef]

- MEND. Prediction Manual for Drainage Chemistry from Sulphidic Geological Materials. MEND Report 1.20.1; Report Prepared by Price, W.A. December 2009, p. 579. Available online: http://mend-nedem.org/wp-content/uploads/1.20.1_PredictionManual.pdf (accessed on 14 June 2021).

- Morin, K.A.; Hutt, N.M. Observed preferential depletion of neutralization potential over sulfide minerals in kinetic tests: Site-specific criteria for safe NP/AP ratios. In Proceedings of the Third International Conference on the Abatement of Acidic Drainage, Pittsburgh, PA, USA, 24–29 April 1994. [Google Scholar]

- Mudd, G.M.; Boger, D.V. The ever growing case for paste and thickened tailings—towards more sustainable mine waste management. J. Aust. Inst. Min. Metall. 2013, 2, 56–59. [Google Scholar]

- Edraki, M.; Baumgartl, T.; Manlapig, E.; Bradshaw, D.; Franks, D.M.; Moran, C.J. Designing mine tailings for better environmental, social and economic outcomes: A review of alternative approaches. J. Clean. Prod. 2014, 84, 411–420. [Google Scholar] [CrossRef]

- Sofra, F.; Boger, D.V. Environmental rheology for waste minimisation in the minerals industry. Chem. Eng. J. 2002, 86, 319–330. [Google Scholar] [CrossRef]

- Sofra, F.; Boger, D.V. Rheology for thickened tailings and paste e history, stateof-the-art and future directions. In Proceedings of the 14th International Seminar on Paste and Thickened Tailings, Perth, Australia, 5–7 April 2011; pp. 121–133. [Google Scholar]

- Kwak, M.; James, D.F.; Klein, K.A. Flow behaviour of tailings paste disposal. Int. J. Miner. Process. 2005, 77, 139–153. [Google Scholar] [CrossRef]

- Crowder, J.J. Deposition, Consolidation, and Strength of a Non-Plastic Tailings Paste for Surface Disposal. Ph.D. Thesis, University of Toronto, Toronto, ON, Canada, 2004. [Google Scholar]

- Liddell, P.V.; Boger, D.V. Yield Stress Measurements with the vane. J. Nonnewton. Fluid Mech. 1996, 63, 235–261. [Google Scholar] [CrossRef]

- Blowes, D.W.; Ptacek, C.J.; Jambor, J.L.; Weisener, C.G. The Geochemistry of Acid Mine Drainage. In Treatise on Geochemistry; Elsevier Inc.: Amsterdam, The Netherlands, 2003; Volume 9, pp. 149–204. [Google Scholar]

- Bryan, R. Drying and Oxidation of Surface-Disposed Paste Tailings. Ph.D. Thesis, Carleton University, Ottawa, ON, Canada, 2009. [Google Scholar]

- Chafy, A.; Tidswell, M.; Lane, C. Case study: Project start-up for thickened graphite tailings, storage and water recovery strategies. In Proceedings of the 21st International Seminar on Paste and Thickened Tailings; Australian Centre for Geomechanics: Crawley, Australia, 2018; pp. 531–544. [Google Scholar]

- Deschamps, T.; Benzaazoua, M.; Bussiere, B.; Aubertin, M.; Belem, T. Microstructural and geochemical evolution of paste tailings in surface disposal conditions. Miner. Eng. 2008, 21, 341–353. [Google Scholar] [CrossRef]

- Simms, P.; Grabinsky, M.; Zhan, G. Modelling evaporation of paste tailings from the Bulyanhulu mine. Can. Geotech. J. 2007, 44, 1417–1432. [Google Scholar] [CrossRef]

- Yanful, E.K. Oxygen diffusion through soil covers on sulphidic mine tailings. J. Geotech. Eng. 1993, 119, 1207–1228. [Google Scholar] [CrossRef]

- Dold, B.; Fontboté, L. Element cycling and secondary mineralogy in porphyry copper tailings as a function of climate, primary mineralogy, and mineral processing. J. Geochem. Explor. 2001, 74, 3–55. [Google Scholar] [CrossRef]

- Ruan, Z.; Wu, A.; Bürger, R.; Betancourt, F.; Wang, Y.; Wang, Y.; Jiao, H.; Wang, S. Effect of interparticle interactions on the yield stress of thickened flocculated copper mineral tailings slurry. Powder Technol. 2021, 392, 278–285. [Google Scholar] [CrossRef]

- Fourie, A.B. Material Characteristics. In Proceedings of the High Density & Paste Seminar, Santiago, Chile, 9–11 April 2002. [Google Scholar]

- Verburg, R.; Johnson, B.; Fordham, M.; Logsdon, M. A rapid and costeffective method for bench screening of geochemical performance and disposal options for high-sulphide tailings. In Proceedings of the 6l International Conference on Acid Rock Drainage, Cairns, Australia, 12–18 July 2003. [Google Scholar]

- Ran, A.; Pérez, N.; Dahan, O. Real Time Monitoring of Infiltration and contamination from Paste Tailing Site. In Proceedings of the 23rd International Conference on Paste, Thickened and Filtered Tailings—PASTE 2020; Gecamin Publications: Santiago, Chile, 2020. [Google Scholar]

- Theron, M.; Addis, P.C.; Wates, J.A.; Martin, V. Bulyanhulu mine (Tanzania) paste tailings facility: Relating the unsaturated properties of gold tailings to rate of rise. In Proceedings of the International Seminar on Paste and Thickened Tailings 2005; Australian Centre for Geomechanics: Crawley, Australia, 2005; pp. 219–229. [Google Scholar]

- Theriault, J.A.; Frostiak, J.; Welch, D. Surface disposal of past tailings at the Bulyanhulu gold mine, Tanzania. In Proceedings of Sudbury Mining and Environment Conference; Spiers, G., Beckett, P., Conroy, H., Eds.; Centre for Environmental Monitoring, Laurentian University: Sudbury, ON, Canada, 2003; p. 149. [Google Scholar]

- Chamberlain, C.M.; Wilkinson, J.J.; Herrington, R.J.; Boyce, A.J. The Bulyanhulu enigma: An atypical Archaean lode gold deposit—Evidence for a pre-ore magmatic input. Trans. Inst. Min. Metall. 2003, 112B, 112–113. [Google Scholar]

- Nkuli, G. Effects of Mining at Bulyanhulu Gold Mine (BGM) on the Water Quality of Bulyanhulu River: Shinyanga-Tanzania. 2012. Available online: https://ir.uz.ac.zw/handle/10646/1021 (accessed on 10 October 2021).

- Khoeurn, K.; Sasaki, A.; Tomiyama, S.; Igarashi, T. Distribution of zinc, copper, and iron in the tailings dam of an abandoned mine in Shimokawa, Hokkaido, Japan. Mine Water Environ. 2019, 38, 119–129. [Google Scholar] [CrossRef]

- Valente, T.; Ferreira, M.J.; Grande, J.A.; de la Torre, M.L.; Borrego, J. pH, electric conductivity and sulfate as base parameters to estimate the concentration of metals in AMD using a fuzzy inference system. J. Geochem. Explor. 2013, 124, 22–28. [Google Scholar] [CrossRef]

- Olıas, M.; Nieto, J.M.; Sarmiento, A.M.; Cerón, J.C.; Cánovas, C.R. Seasonal water quality variations in a river affected by acid mine drainage: The Odiel River (Activities South West Spain). Sci. Total Environ. 2004, 333, 267–281. [Google Scholar] [CrossRef]

| Element | T1 0–10 cm | T1 10–20 cm | T1 20–30 cm | T2 0–10 cm | T2 10–20 cm | T2 20–30 cm | T3 0–10 cm | T3 10–20 cm | T3 20–30 cm |

| S (wt%) | 1.49 | 1.36 | 123 | 1.43 | 1.55 | 1.31 | 1.41 | 1.67 | 1.52 |

| Fe (wt%) | 2.81 | 2.84 | 2.87 | 2.84 | 2.91 | 2.87 | 2.82 | 2.84 | 2.88 |

| Si (wt%) | 16.61 | 16.72 | 16.51 | 15.67 | 15.81 | 15.94 | 17.25 | 17.37 | 17.49 |

| Al (wt%) | 124 | 1.34 | 1.43 | 1.31 | 1.21 | 1.11 | 123 | 1.33 | 1.41 |

| Mn (wt%) | 1.81 | 1.83 | 1.87 | 1.93 | 1.90 | 1.86 | 1.90 | 1.93 | 1.86 |

| Ca (wt%) | 2.48 | 2.42 | 2.39 | 2.40 | 2.44 | 2.47 | 2.38 | 2.44 | 246 |

| Zn (ppm) | 6379 | 6443 | 6508 | 6291 | 6228 | 6164 | 6499 | 6441 | 6379 |

| Pb (ppm) | 3273 | 3307 | 3343 | 3162 | 3196 | 3233 | 3164 | 3130 | 3098 |

| Cu (ppm) | 399 | 412 | 385 | 483 | 471 | 461 | 392 | 380 | 364 |

| Cr (ppm) | 50 | 54 | 45 | ND | 41 | 32 | 56 | 41 | 25 |

| Ni (ppm) | ND * | ND | ND | ND | ND | ND | ND | ND | ND |

| Sn (ppm) | 8 | 12 | 20 | 25 | 31 | 10 | S | ND | ND |

| Cd (ppm) | 7 | ND | ND | ND | ND | ND | 40 | 26 | 14 |

| Ag (ppm) | ND | ND | 24 | 31 | ND | ND | ND | 18 | 14 |

| Element | T4 0–10 cm | T4 10–20 cm | T4 20–30 cm | T5 0–10 cm | T5 10–20 cm | T5 20–30 cm | T6 0–10 cm | T6 10–20 cm | T6 20–30 cm |

| S (wt%) | 2.25 | 1.86 | 1.57 | 1.33 | 0.94 | 0.94 | 1.54 | 1.77 | 1.73 |

| Fe (wt%) | 3.83 | 3.65 | 297 | 4.68 | 3.82 | 3.58 | 3.69 | 3.67 | 3.60 |

| Si (wt%) | 19.9 | 16.8 | 18.4 | 20.8 | 17.8 | 19.3 | 18.0 | 17.0 | 17.0 |

| Al (wt%) | 1.61 | 1.36 | 1.52 | 1.46 | 1.38 | 1.44 | 1.60 | 1.47 | 1.41 |

| Mn (wt%) | 2.98 | 3.32 | 278 | 2.97 | 2.90 | 2.78 | 1.88 | 2.23 | 225 |

| Ca (wt%) | 3.27 | 2.96 | 2.84 | 4.02 | 3.70 | 3.77 | 2.52 | 3.13 | 3.07 |

| Zn (ppm) | 7302 | 9385 | 4767 | 5378 | 3441 | 3225 | 5761 | 8218 | 8253 |

| Pb (ppm) | 4343 | 5841 | 2964 | 1768 | 2172 | 2444 | 3933 | 4610 | 4480 |

| Cu (ppm) | 526 | 532 | 355 | 419 | 372 | 361 | 540 | 545 | 628 |

| Cr (ppm) | 51 | 53 | 43 | 66 | 100 | 79 | 53 | 45 | 46 |

| Ni (ppm) | ND | ND | ND | ND | ND | ND | ND | ND | ND |

| Sn (ppm) | 8 | 31 | ND | ND | 14 | 23 | ND | ND | 5 |

| Cd (ppm) | 46 | 85 | 10 | 19 | 7 | 12 | 40 | 44 | 25 |

| Ag (ppm) | 29 | 41 | 31 | 41 | ND | ND | 34 | 15 | ND |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leiva, E.; Cayazzo, M.; Torres, M. Real-Time Electrical Conductivity Monitoring and Correlation with Sulfate Release and Acid Mine Drainage Potential from a Gold/Silver Paste Tailing Storage. Minerals 2021, 11, 1436. https://doi.org/10.3390/min11121436

Leiva E, Cayazzo M, Torres M. Real-Time Electrical Conductivity Monitoring and Correlation with Sulfate Release and Acid Mine Drainage Potential from a Gold/Silver Paste Tailing Storage. Minerals. 2021; 11(12):1436. https://doi.org/10.3390/min11121436

Chicago/Turabian StyleLeiva, Eduardo, María Cayazzo, and Mario Torres. 2021. "Real-Time Electrical Conductivity Monitoring and Correlation with Sulfate Release and Acid Mine Drainage Potential from a Gold/Silver Paste Tailing Storage" Minerals 11, no. 12: 1436. https://doi.org/10.3390/min11121436

APA StyleLeiva, E., Cayazzo, M., & Torres, M. (2021). Real-Time Electrical Conductivity Monitoring and Correlation with Sulfate Release and Acid Mine Drainage Potential from a Gold/Silver Paste Tailing Storage. Minerals, 11(12), 1436. https://doi.org/10.3390/min11121436