Recent Advancements in Metallurgical Processing of Marine Minerals

Abstract

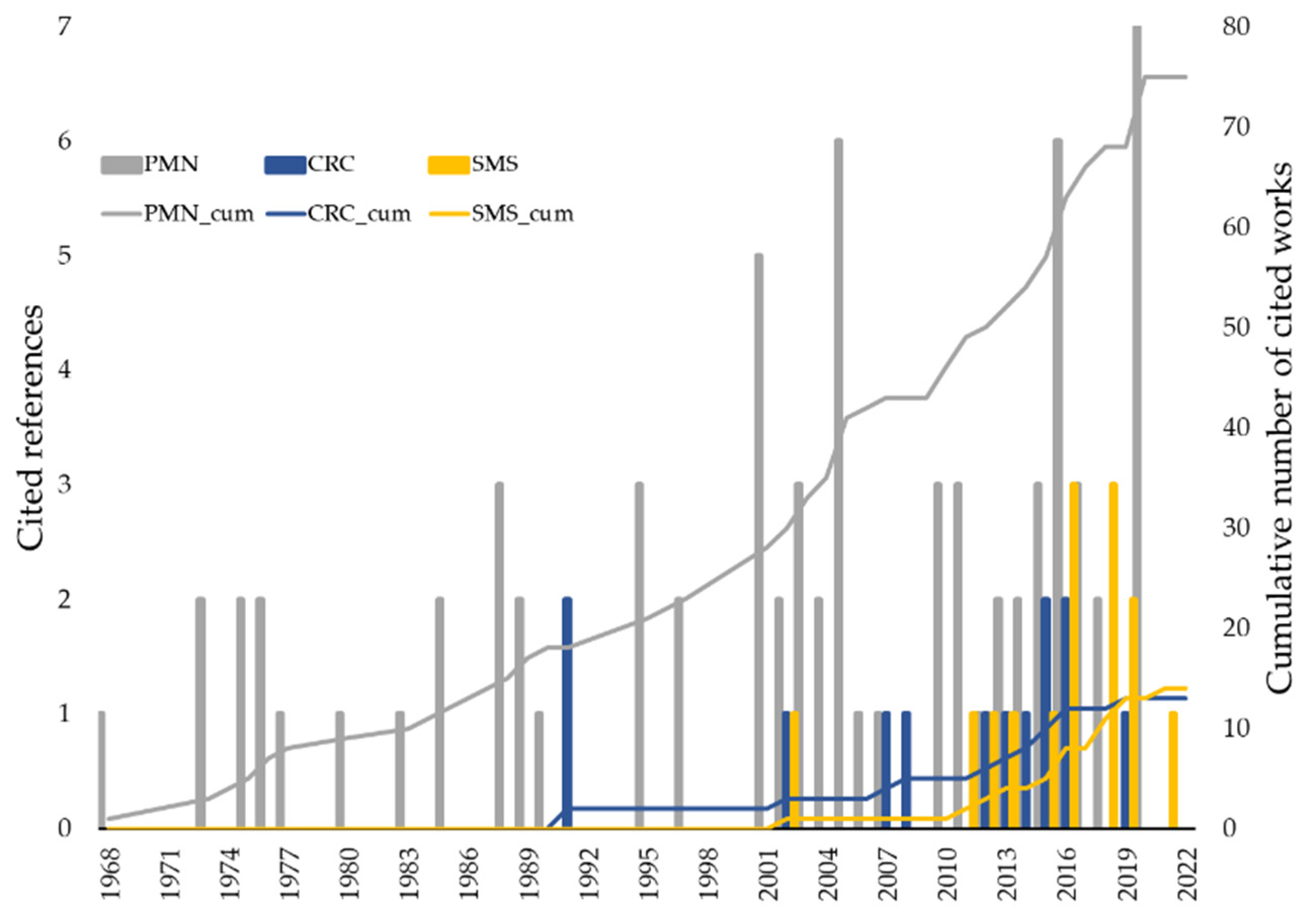

:1. Introduction

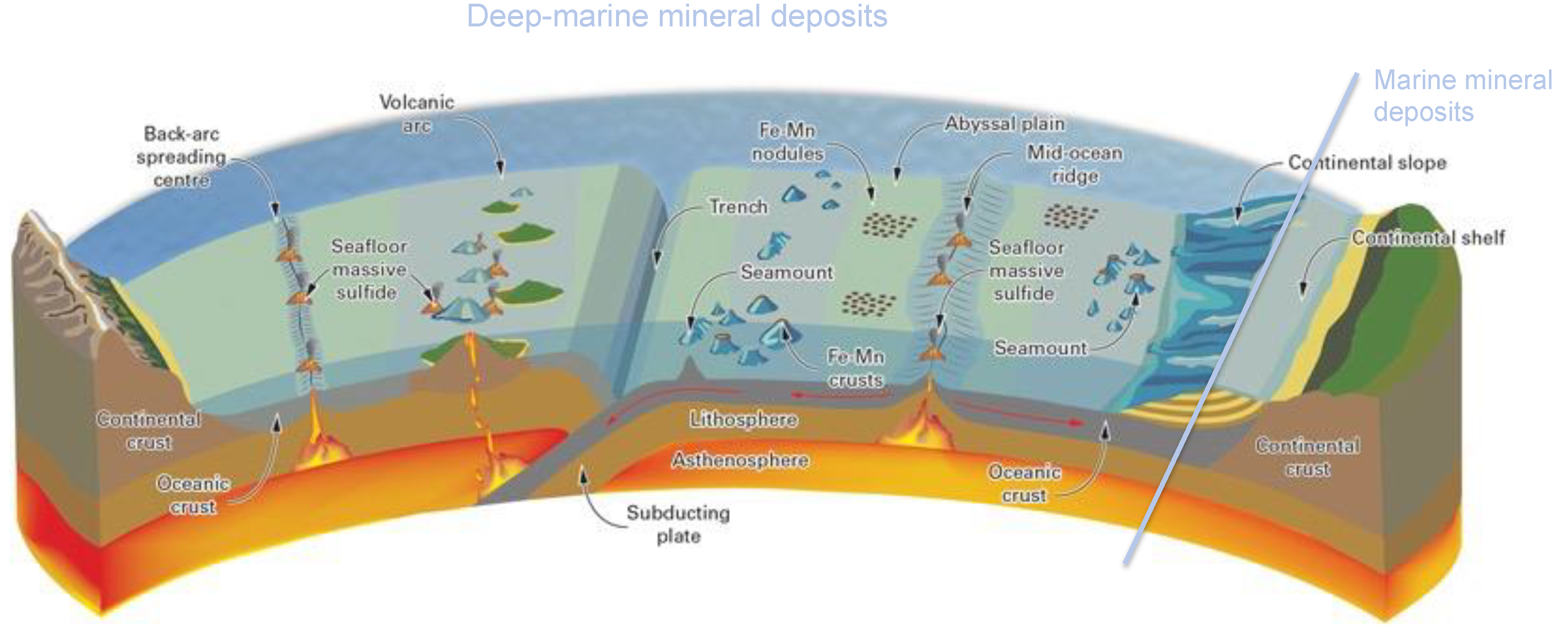

2. Brief Characteristics of Marine Resources

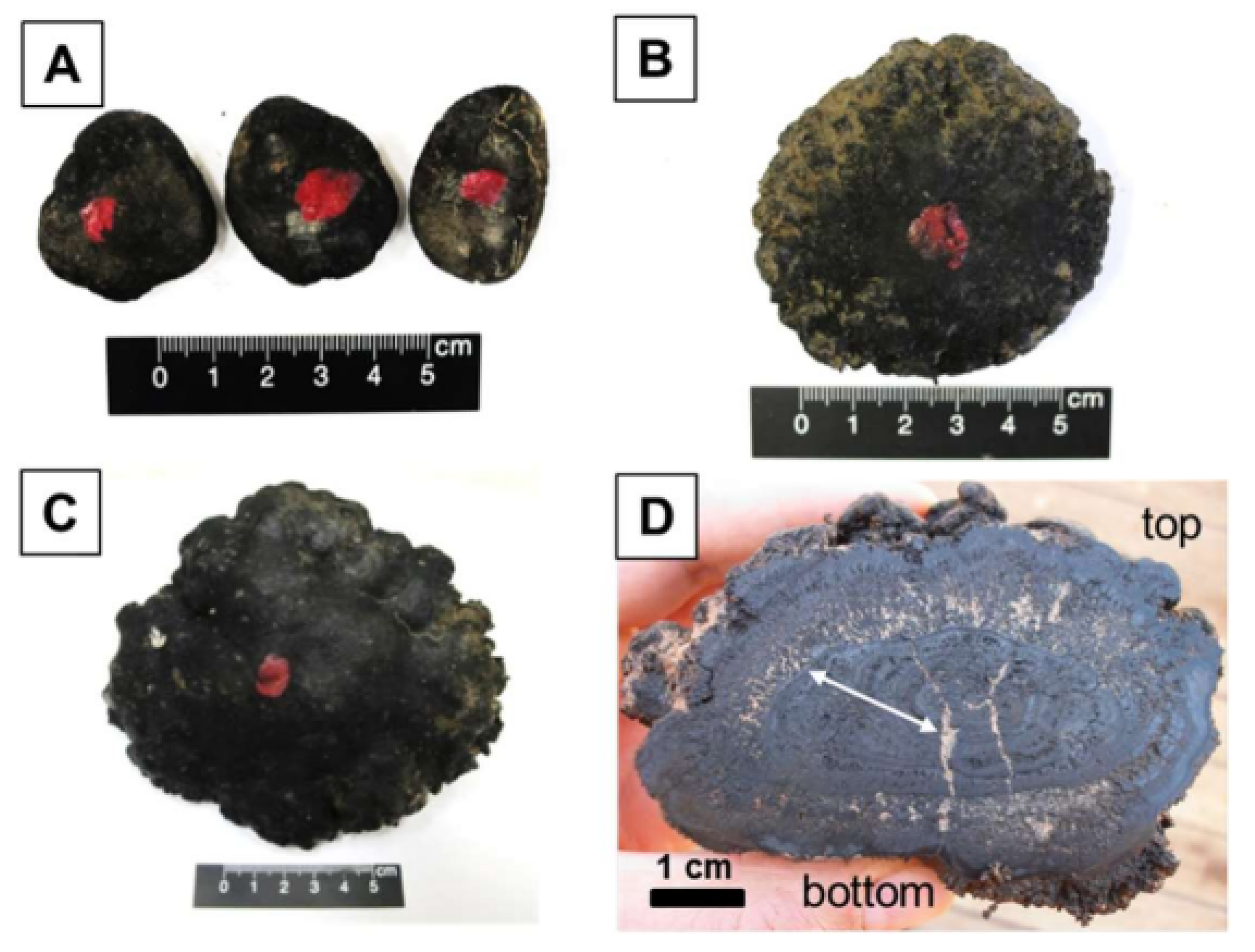

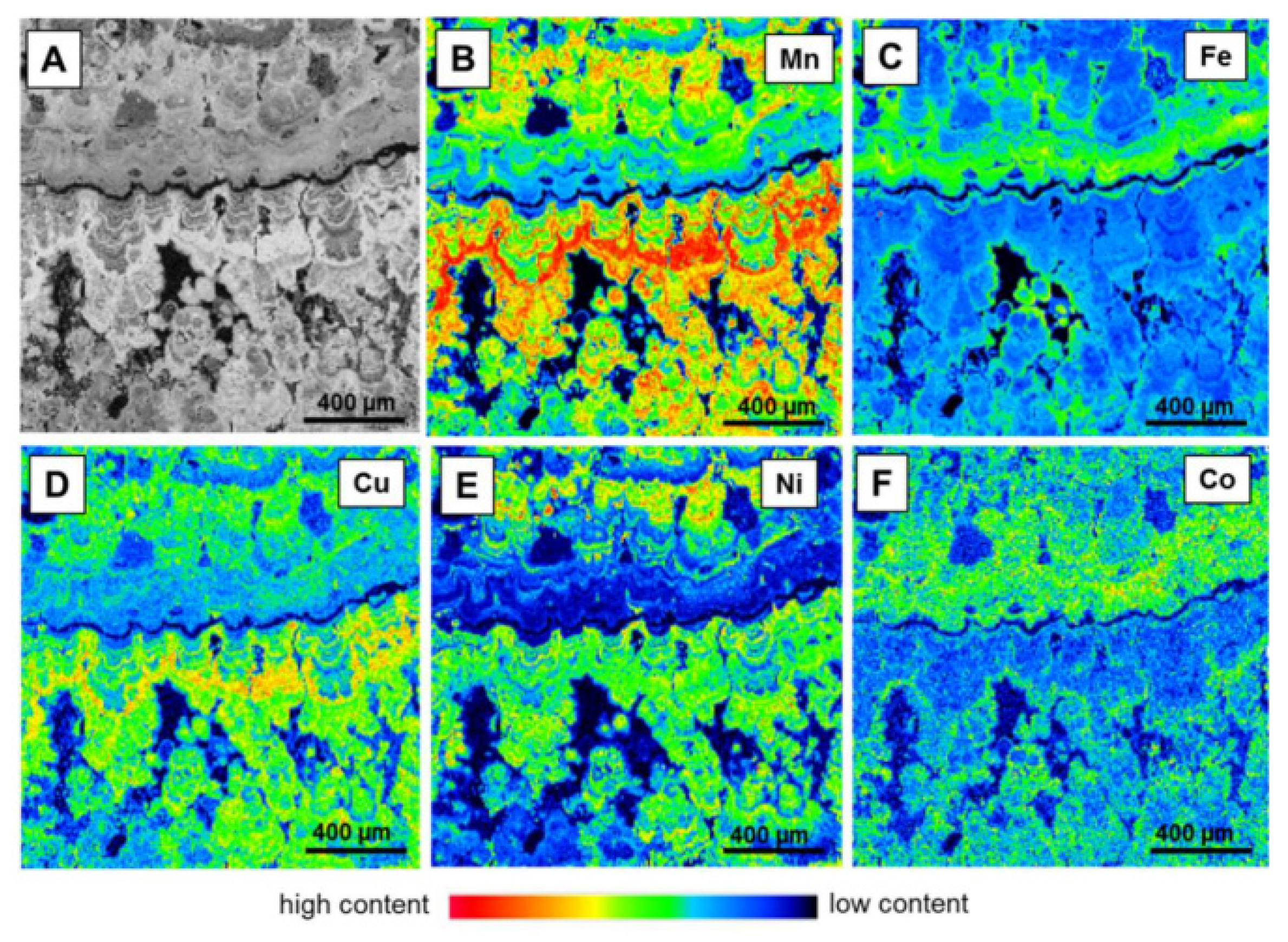

2.1. Polymetallic Manganese Nodules (PMN)

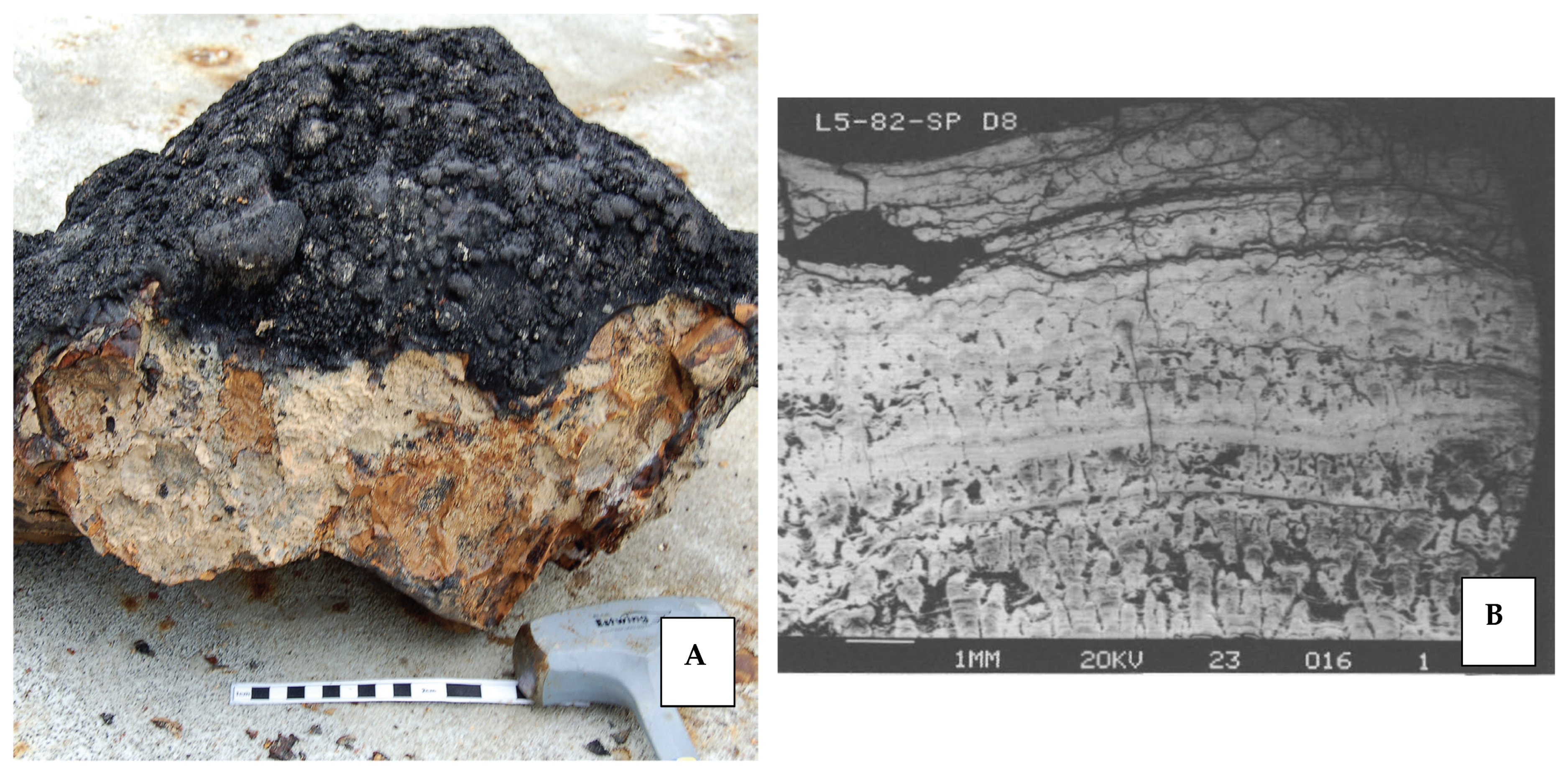

2.2. Cobalt-Rich Manganese Crusts (CRC)

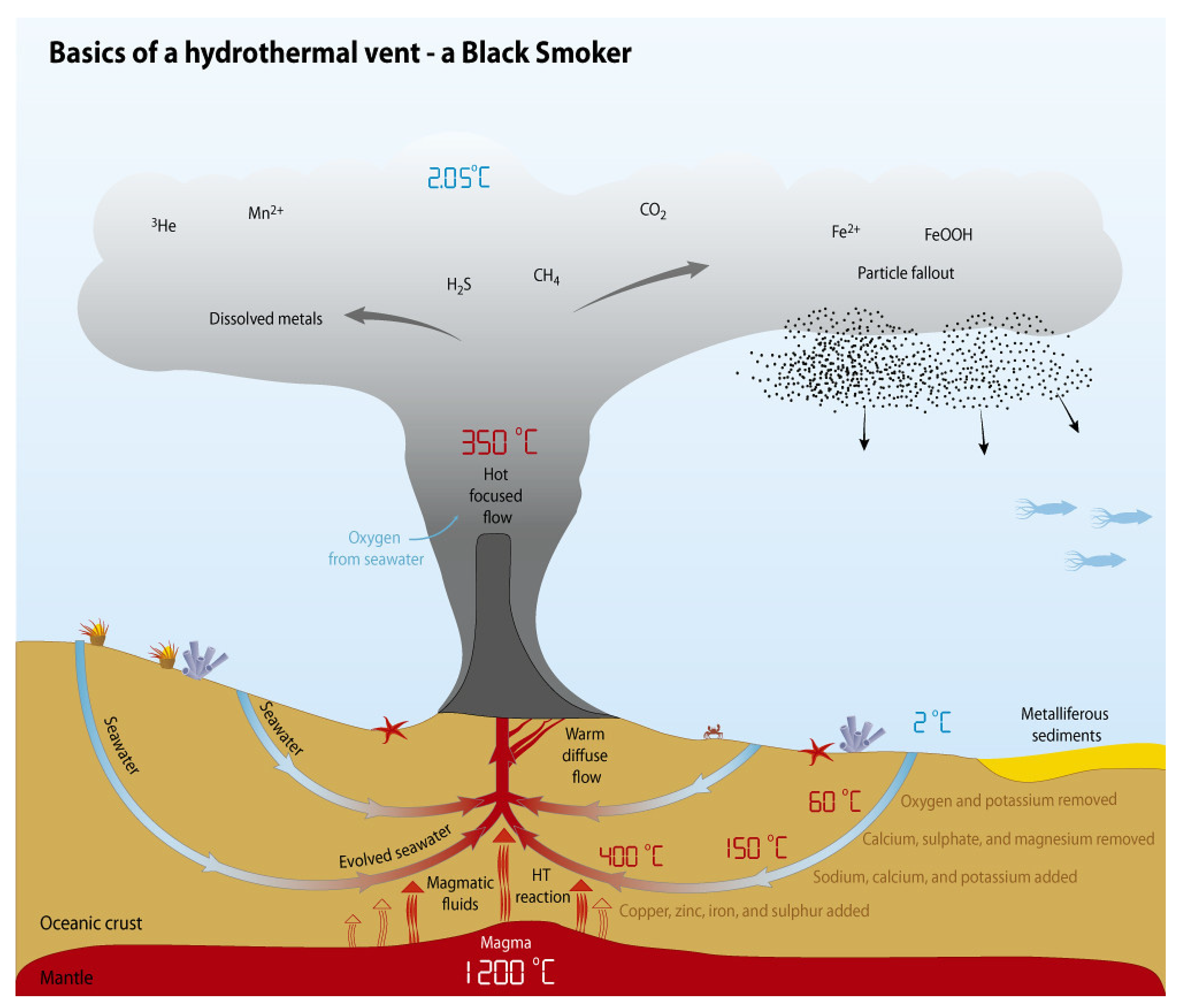

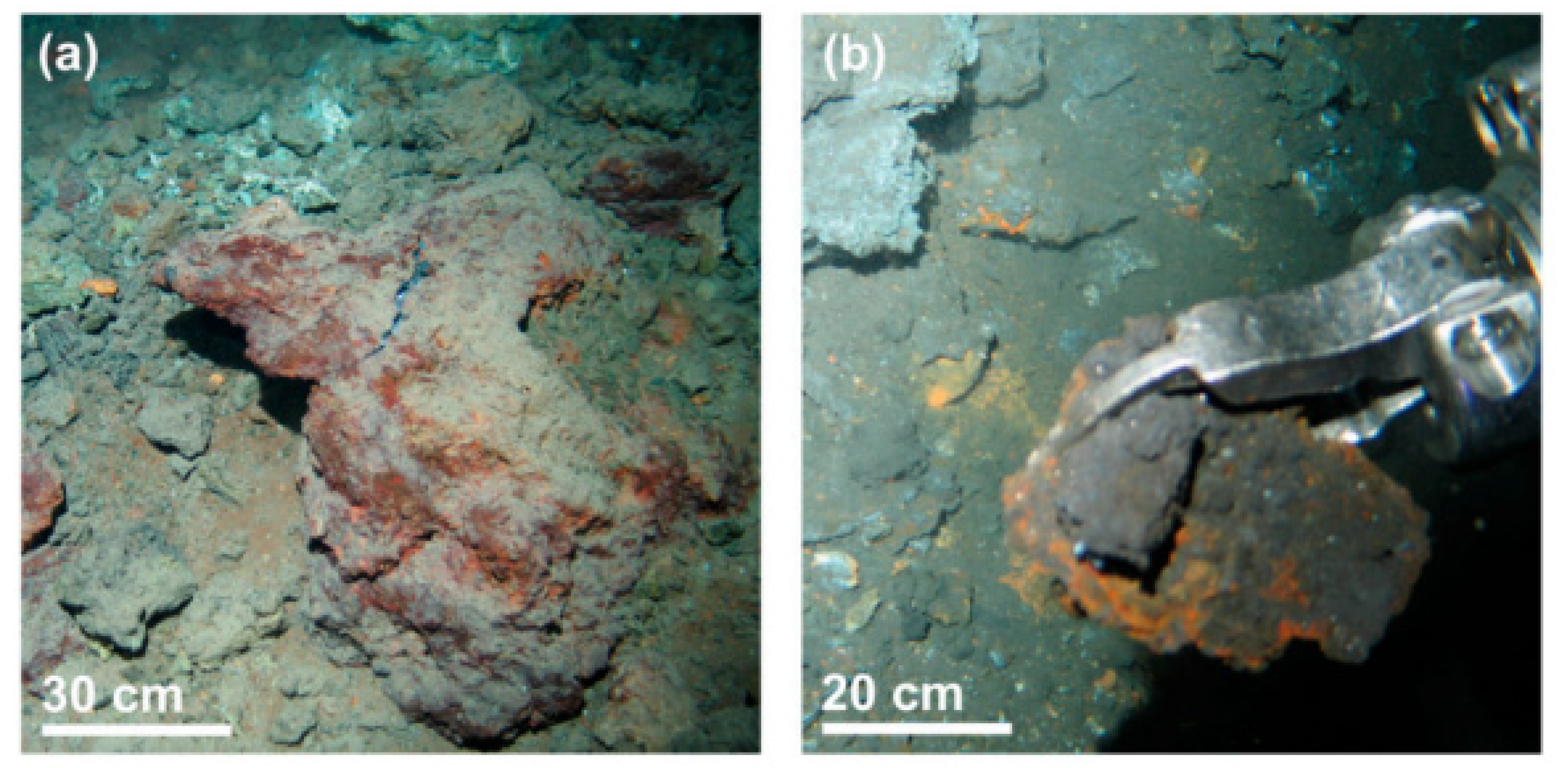

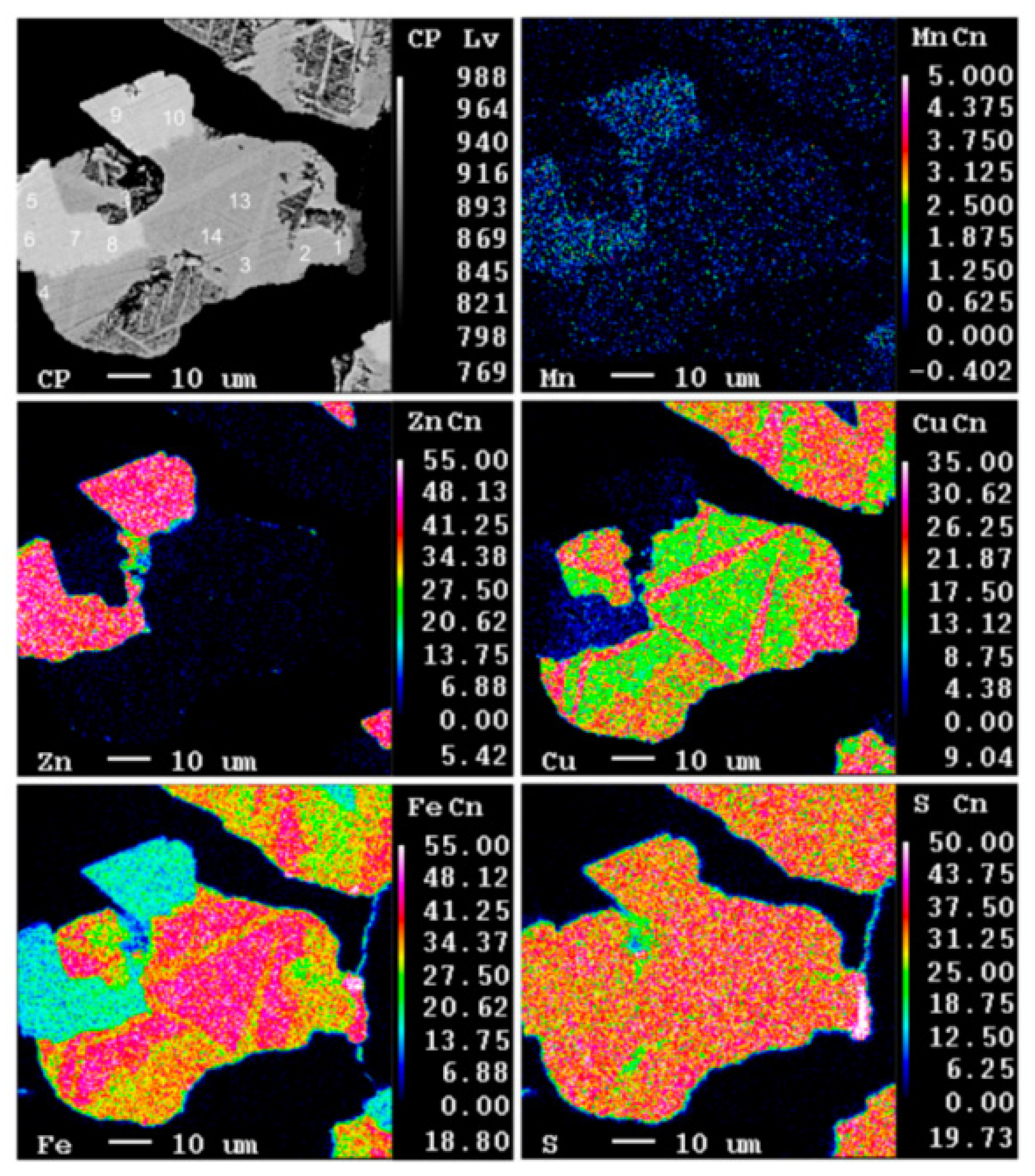

2.3. Seafloor Massive Sulfides (SMS)

2.4. Comparison of Different Ore Types

3. Processing of Marine Minerals

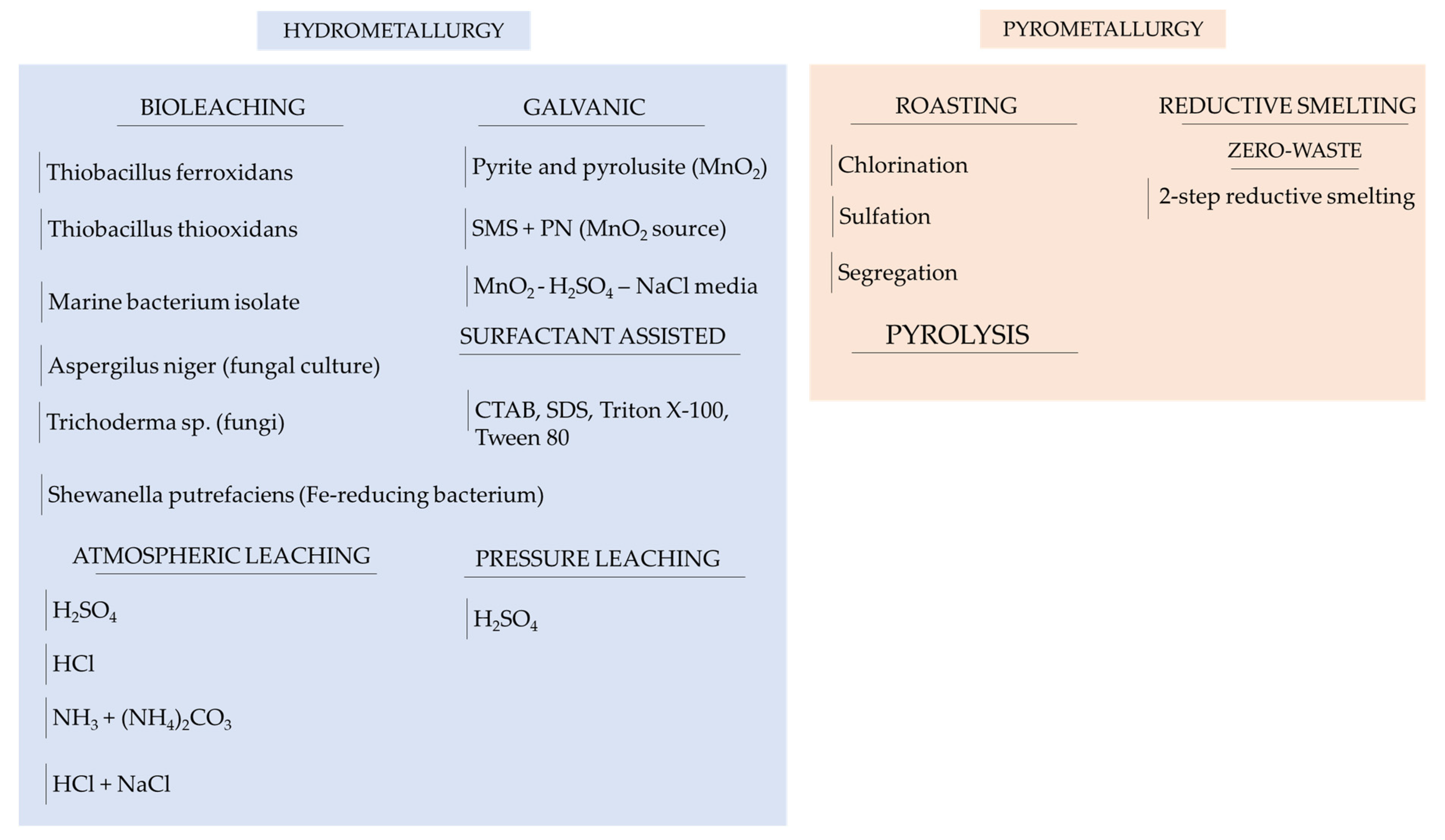

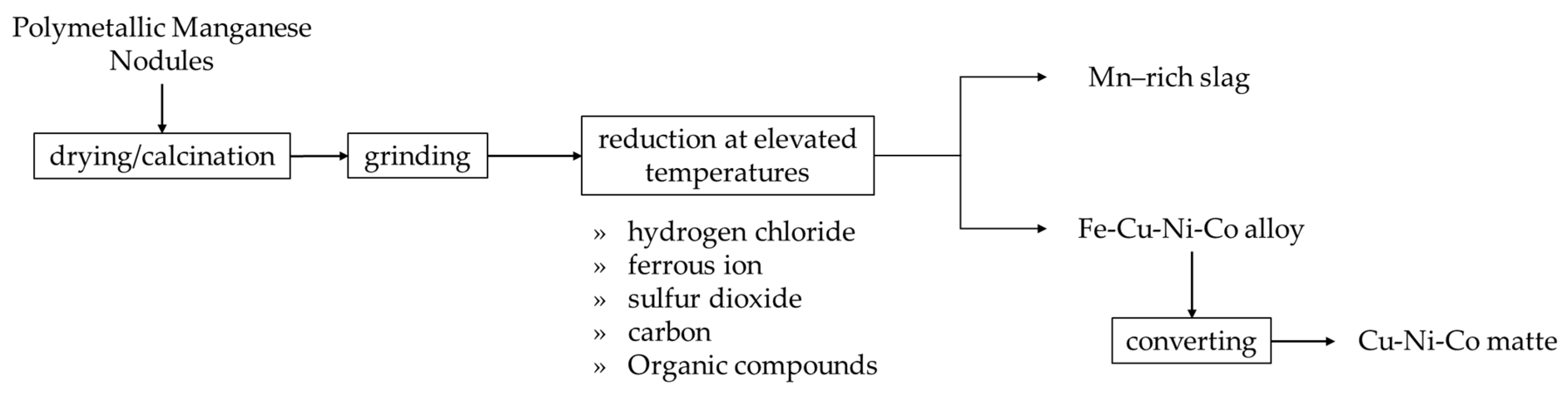

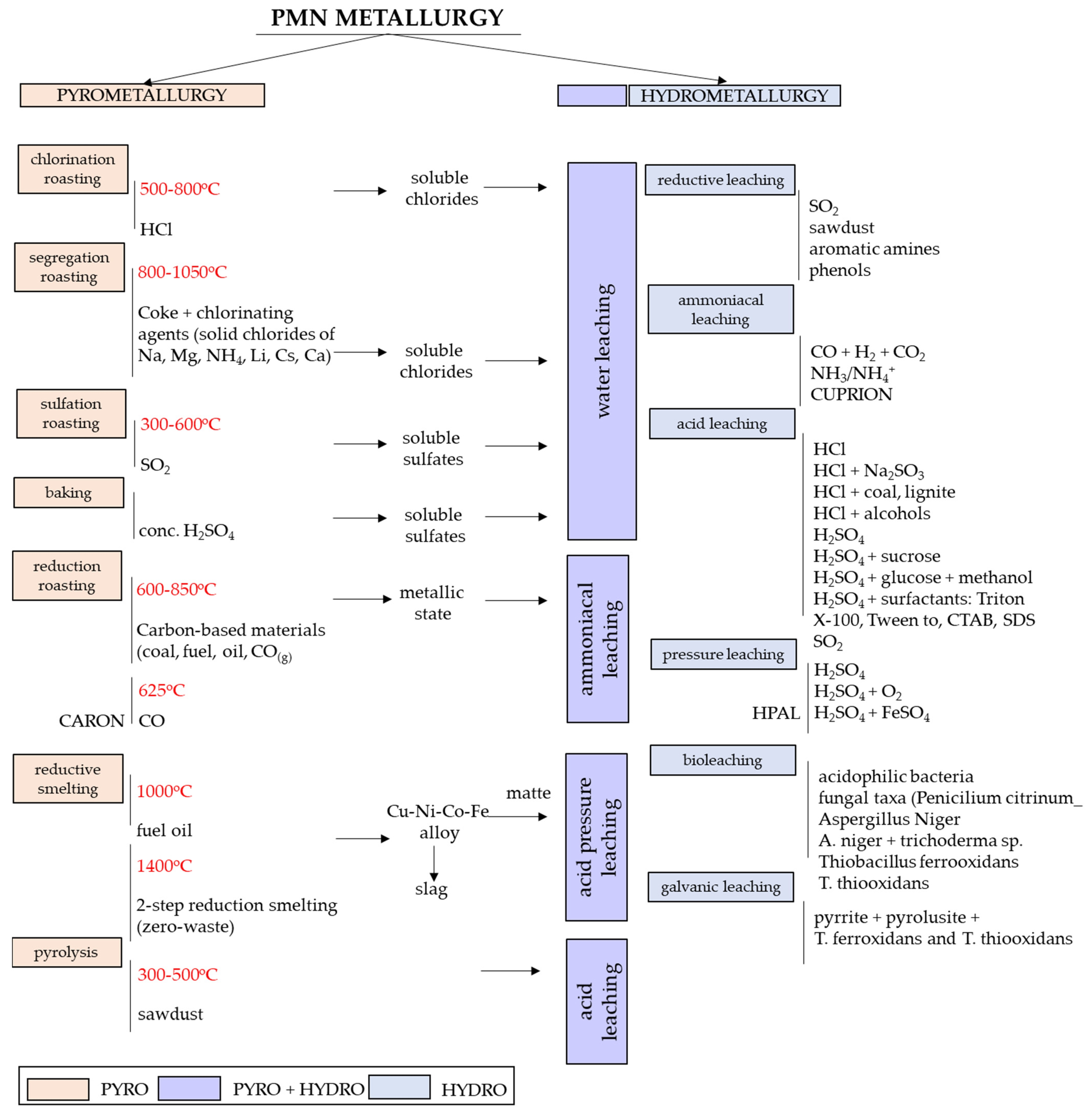

3.1. Polymetallic Manganese Nodules (PMN)

3.2. Cobalt-Rich Manganese Crusts (CRC)

3.3. Seafloor Massive Sulfides (SMS)

4. Downstream Processing

5. Conclusions and Future Perspectives

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Glasby, G.P.; Li, J.; Sun, Z. Deep-Sea Nodules and Co-rich Mn Crusts. Mar. Georesources Geotechnol. 2015, 33, 72–78. [Google Scholar] [CrossRef]

- Molemaker, R.-J.; Gille, J.; Kantor, E.; van Schijndel, M.; Pauer, A.; von Schickfus, M.-T.; van Elswijk, J.; Beerman, R.; Hodgson, S.; Beaudoin, Y.; et al. Study to Investigate the State of Knowledge of Deep-Sea Mining; ECORYS: Brussel, Belgium, 2014. [Google Scholar]

- Georgiou, D.; Papangelakis, V.G. Behavior of cobalt during sulphuric acid pressure leaching of a limonitic laterite. Hydrometallurgy 2009, 100, 34–40. [Google Scholar] [CrossRef]

- ISA brochure, Seabed Technology. Available online: https://isa.org.jm/files/files/documents/ENG10.pdf (accessed on 14 November 2021).

- Sharma, R. Environmetal Issues of Deep-Sea Mining. Proced. Earth Plan. Sc. 2015, 11, 204–211. [Google Scholar] [CrossRef] [Green Version]

- Mestre, N.C.; Rocha, T.L.; Canals, M.; Cardoso, C.; Danovaro, R.; Dell’Anno, A.; Gambi, C.; Regoli, F.; Sanchez-Vidal, A.; João Bebianno, M. Environmental hazard assessment of a marine mine tailings deposit site and potential implications for deep-sea mining. Environ. Pollut. 2017, 228, 169–178. [Google Scholar] [CrossRef]

- Abramowski, T. Environment Protection Policy and Monitoring Systems for Polymetallic Nodules Exploitation. New Trends Prod. Eng. 2018, 1, 523–529. [Google Scholar] [CrossRef] [Green Version]

- Monhemius, J. The extractive metallurgy of deep-sea manganese nodules. In Topics in Non-ferrous Extractive Metallurgy; Burkin, A.R., Ed.; Blackwell Scientific Publications: Oxford, UK, 1980; pp. 42–69. [Google Scholar]

- Spearman, J.; Taylor, J.; Crossouard, N.; Cooper, A.; Turnbull, M.; Manning, A.; Lee, M.; Murton, B. Measurement and modelling of deep sea sediment plumes and implications for deep sea mining. Sci. Rep. 2020, 10, 5075. [Google Scholar] [CrossRef] [Green Version]

- Petersen, S.; Krätschell, A.; Augustin, N.; Jamieson, J.; Hein, J.R.; Hannington, M.D. News from the seabed—Geological characteristics and resource potential of deep-sea mineral resources. Mar. Policy 2016, 70, 175–187. [Google Scholar] [CrossRef]

- Fuerstenau, D.W.; Han, K.N. Metallurgy and Processing of Marine Manganese Nodules. Miner. Process. Extr. Metall. Rev. 1983, 1, 1–83. [Google Scholar] [CrossRef]

- Lusty, P.A.J.; Murton, B.J. Deep-ocean mineral deposits could make a significant contribution to future raw material supply. Elements 2018, 14, 301–306. [Google Scholar] [CrossRef] [Green Version]

- Hein, J.R.; Koschinsky, A. Deep-Ocean Ferromanganese Crusts and Nodules, in Treatise on Geochemistry; Elsevier: Amsterdam, The Netherlands, 2014; pp. 273–291. [Google Scholar] [CrossRef]

- Navneet, S.; Randhawa, J.; Hait, R.; Kumar, J. A brief overview on manganese nodules processing signifying the detail in the Indian context highlighting the international scenario. Hydrometallurgy 2016, 165 Pt 1, 166–181. [Google Scholar]

- Hein, J.R.; Koschinsky, A.; Kuhn, T. Deep- ocean polymetallic nodules as a resource for critical materials. Nat. Rev. Earth Environ. 2020, 1, 158–169. [Google Scholar] [CrossRef]

- The Manganese Nodule Belt of the Pacific Ocean. In Geological Environment, Nodule Formation, and Mining Aspects; Halbach, P.; Friedrich, G.; Von Stackelberg, U. (Eds.) Ferdinand Enke: Stuttgart, Germany, 1988; ISBN 3 432 96381 5. [Google Scholar]

- Hoover, M.; Han, K.N.; Fuerstenau, D.W. Segregation roasting of nickel, copper and cobalt from manganese nodules. Int. J. Miner. Process. 1975, 2, 173–185. [Google Scholar] [CrossRef]

- Cruickshank, M.J. Marine mining. In General Geology. Encyclopedia of Earth Science; Springer: Boston, MA, USA, 1988. [Google Scholar] [CrossRef]

- Haynes, B.W.; Law, S.L.; Barron, D.C.; Kramer, G.W.; Maeda, R.; Magyar, J. Pacific manganese nodules: Characterization and processing. Bull. United States Bur. Mines 1985, 674, 43. [Google Scholar]

- Wegorzewski, A.V.; Köpcke, M.; Kuhn, T.; Sitnikova, M.A.; Wotruba, H. Thermal Pre-Treatment of Polymetallic Nodules to Create Metal (Ni, Cu, Co)-Rich Individual Particles for Further Processing. Minerals 2018, 8, 523. [Google Scholar] [CrossRef] [Green Version]

- Hein, J. Cobalt-rich ferromanganese crusts: Global distribution, composition, origin and research activities. In ISA Technical Study: No.2 Polymetallic Massive Sulphides and Cobalt-Rich Ferromanganese Crusts: Status and Prospects; International Seabed Authority: Kingston, Jamaica, 2002. [Google Scholar]

- Hein, J.R. Co-Rich Manganese Crusts. In Encyclopedia of Marine Geosciences; Springer: Dordrecht, The Netherlands. [CrossRef]

- SPC. Deep Sea Minerals: Cobalt-Rch Ferromanganese Crusts, a Physical, Biological, Environmental, and Technical Review; Baker, E., Beaudoin, Y., Eds.; Secretariat of the Pacific Community: Nouméa, NC, USA, 2013; Volume 1C. [Google Scholar]

- Hein, J.R.; Schulz, M.S.; Kang, J.-K. Insular and Submarine Ferromanganese Mineralization of the Tonga-Lau Region. Mar. Min. 1990, 9, 305–354. [Google Scholar]

- Hannington, M.D.; De Ronde, C.E.J.; Petersen, S. Sea-Floor Tectonics and Submarine Hydrothermal Systems. In One Hundredth Anniversary Volume; Society of Economic Geologists: Littleton, CO, USA, 2005. [Google Scholar]

- Boschen, R.E.; Rowden, A.A.; Clark, M.R.; Gardner, J.P.A. Mining of deep-sea seafloor massive sulfides: A review of the deposits, their benthic communities, impacts from mining, regulatory frameworks and management strategies. Ocean Coast. Manag. 2013, 84, 54–67. [Google Scholar] [CrossRef] [Green Version]

- Hannington, M.; Jamieson, J.; Monecke, T.; Petersen, S.; Beaulieu, S. The abundance of seafloor massive sulfide deposits. Geology 2011, 39, 1155–1158. [Google Scholar] [CrossRef]

- Spagnoli, G.; Jahnb, A.; Halbach, P. First results regarding the influence of mineralogy on the mechanical properties of seafloor massive sulfide samples. Eng. Geol. 2016, 214, 127–135. [Google Scholar] [CrossRef]

- GRID- Arendal. 2014. Available online: https://www.grida.no/resources/8166 (accessed on 17 December 2021).

- Snook, B.; Drivenes, K.; Rollinson, G.K.; Aasly, K. Characterisation of Mineralised Material from the Loki’s Castle Hydrothermal Vent on the Mohn’s Ridge. Minerals 2018, 8, 576. [Google Scholar] [CrossRef] [Green Version]

- Cherkashov, G. Prospecting. In Deep-Sea Mining: Resource Potential, Technical and Environmental Considerations; Sharma, R., Ed.; Springer International Publishing: Cham, Switzerland, 2017; pp. 143–164. [Google Scholar] [CrossRef]

- The Norwegian Petroleum Directorate, Det første funnet i Norskehavet. Nor. Sokkel 2020, 6. (In Norwegian)

- Nozaki, T.; Tokumaru, A.; Takaya, Y.; Kato, Y.; Suzuki, K.; Urabe, T. Major and trace element compositions and resource potential of ferromanganese crust at Takuyo Daigo Seamount, Northwestern Pacific Ocean. Geochem. J. 2016, 50, 527–537. [Google Scholar] [CrossRef] [Green Version]

- Hannington, M.; Jamieson, J.; Monecke, T.; Petersen, S. Modern Sea-Floor Massive Sulfides and Base Metal Resources Toward an Estimate of Global Sea-Floor Massive Sulfide Potential. In The Challenge of Finding New Mineral Resources. Global Metallogeny, Innovative Exploration, and New Discoveries; Society of Economic Geologists: Littleton, CO, USA, 2010. [Google Scholar]

- Su, K.; Ma, X.; Parianos, J.; Zhao, B. Thermodynamic and Experimental Study on Efficient Extraction of Valuable Metals from Polymetallic Nodules. Minerals 2020, 10, 360. [Google Scholar] [CrossRef] [Green Version]

- Drakshayani, D.N.; Sankar, C.; Mallya, R.M. The Reduction Of Manganese Nodules By Hydrogen. Thermochim. Acta 1989, 144, 313–328. [Google Scholar] [CrossRef]

- Zhao, F.; Jiang, X.; Wang, S.; Feng, L.; Li, D. The Recovery of Valuable Metals from Ocean Polymetallic Nodules Using Solid-State Metalized Reduction Technology. Minerals 2020, 10, 20. [Google Scholar] [CrossRef] [Green Version]

- Sommerfeld, M.; Friedmann, D.; Kuhn, T.; Friedrich, B. “Zero-Waste”: A Sustainable Approach on Pyrometallurgical Processing of Manganese Nodule Slags. Minerals 2018, 8, 544. [Google Scholar] [CrossRef] [Green Version]

- Kmetova, D.; Stofko, M.; Kmet, S. Ammoniacal Leaching For Extraction Of Non-Ferrous Metals From Deep-Sea Nodules. Int. J. Miner. Process. 1985, 15, 145–153. [Google Scholar] [CrossRef]

- Jana, R.K.; Akerkar, D.D. Studies of the metal–ammonia–carbondioxide–water system in extraction metallurgy of polymetallic sea nodules. Hydrometallurgy 1989, 22, 363–378. [Google Scholar] [CrossRef]

- Wilder, T.C. Two Stage Selective Leaching of Copper and Nickel from Complex Ore. U.S. Patent 3,736,125, 29 May 1973. [Google Scholar]

- Mishra, D.; Srivastava, R.R.; Sahu, K.K.; Singh, T.B.; Jana, R.K. Leaching of roast-reduced manganese nodules in NH3–(NH4)2CO3 medium. Hydrometallurgy 2011, 109, 215–220. [Google Scholar] [CrossRef]

- Deng, X.-Y.; He, D.-S.; Chi, R.-A.; Xiao, C.-Q.; Hu, J.-G. The Reduction Behavior of Ocean Manganese Nodules by Pyrolysis Technology Using Sawdust as the Reductant. Minerals 2020, 10, 850. [Google Scholar] [CrossRef]

- Kohga, T.; Imamura, M.; Takahashi, J.; Tanaka, N.; Nishizawa, T. Recovering iron, manganese, copper, cobalt, and high-purity nickel from sea nodules. JOM 1995, 47, 40–43. [Google Scholar] [CrossRef]

- Kane, W.S.; Cardwell, P.H. Recovery of Metal Values from Ocean Floor Nodules. U.S. Patent 3,950,486, 14 August 1973. [Google Scholar]

- Sridhar, R.; Jones, W.E.; Warner, J.S. Extraction of copper, nickel and cobalt from sea nodules. J. Met. 1976, 32–37. [Google Scholar] [CrossRef]

- Keber, S.; Brückner, L.; Elwert, T.; Kuhn, T. Concept for a Hydrometallurgical Processing of a Copper-Cobalt-Nickel Alloy Made from Manganese Nodules. Chem. Ing. Tech. 2020, 92, 1–9. [Google Scholar]

- UNOET. Analysis of Processing Technology for Manganese Nodules, Sea Bed Mineral Series; Graham & Trotman Limited: London, UK, 1968; Volume 3, pp. 31–39. [Google Scholar]

- Barik, R.; Sanjay, K.; Mishra, B.K.; Mohapatra, M. Micellar mediated selective leaching of manganese nodule in high temperature sulfuric acid medium. Hydrometallurgy 2016, 165 Pt 1, 44–50. [Google Scholar] [CrossRef]

- Anand, S.; Das, S.C.; Das, R.P.; Jena, P.K. Leaching of Manganese Nodules at Elevated Temperature and Pressure in the Presence of oxygen. Hydrometallurgy 1988, 20, 155–168. [Google Scholar] [CrossRef]

- Han, K.N.; Fuerstenau, D.W. Acid leaching of ocean manganese nodules at elevated temperatures. Int. J. Miner. Process. 1975, 2, 63–171. [Google Scholar] [CrossRef]

- Vua, H.; Jandova, J.; Lisa, K.; Vranka, F. Leaching of manganese deep ocean nodules in FeSO4–H2SO4–H2O solutions. Hydrometallurgy 2005, 77, 147–153. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, Q.; Sun, C. Sulfuric acid leaching of ocean manganese nodules using aromatic amines as reducing agents. Miner. Eng. 2001, 14, 539–542. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, Q.; Sun, C. Sulfuric acid leaching of ocean manganese nodules using phenols as reducing agents. Miner. Eng. 2001, 14, 525–537. [Google Scholar] [CrossRef]

- Pahlman, J.E.; Khalafalla, S.E. Selective Recovery of Nickel, Cobalt, Manganese from Sea Nodules with Sulfurous Acid. U.S. Patent US 4, 138, 465 (US 860249 (771213)), 6 February 1979. [Google Scholar]

- Kanungo, S.B.; Jena, P.K. Studies on the dissolution of metal values in manganese nodules of Indian Ocean origin in dilute hydrochloric acid. Hydrometallurgy 1988, 21, 23–39. [Google Scholar] [CrossRef]

- Parhi, P.K.; Park, K.H.; Nam, C.W.; Park, J.T.; Barik, S.P. Extraction of rare earth metals from deep sea nodule using H2SO4 solution. Int. J. Miner. Process. 2013, 119, 89–92. [Google Scholar] [CrossRef]

- Gupta, B.; Deep, A.; Singh, V.; Tandon, S.N. Recovery of cobalt, nickel, and copper from sea nodules by their extraction with alkylphosphines. Hydrometallurgy 2003, 70, 121–129. [Google Scholar] [CrossRef]

- Kumari, A.; Natarajan, K.A. Electroleaching of polymetallic ocean nodules to recover copper, nickel and cobalt. Miner. Eng. 2001, 14, 877–886. [Google Scholar] [CrossRef]

- Wang, C.-Y.; Qiu, D.-F.; Chen, Y.-Q. Slurry electrolysis of ocean polymetallic nodule. Trans. Nonferrous Met. Soc. China 2010, 20, 60–64. [Google Scholar] [CrossRef]

- Mittal, N.K.; Sen, P.K. India’s first medium scale demonstration plant for treating poly-metallic nodules. Miner. Eng. 2003, 16, 865–868. [Google Scholar] [CrossRef]

- Wang, Y.; Li, Z.; Li, H. A new process for leaching metal values from ocean polymetallic nodules. Miner. Eng. 2005, 18, 1093–1098. [Google Scholar] [CrossRef]

- Asai, S.; Konishi, Y.; Takasaka, Y. Bioleaching of rare metals from manganese nodules by Thiobacillus ferrooxidans. Miner. Process. Extr. Metall. Rev. 1995, 15, 140–141. [Google Scholar] [CrossRef]

- Konishi, Y.; Asai, S.; Sawada, Y. Leaching of marine manganese nodules by acidophilic bacteria growing on elemental sulfur. Metall. Mater. Trans. B 1997, 28, 25–32. [Google Scholar] [CrossRef]

- Li, H.; Feng, Y.; Lu, S.; Du, Z. Bioleaching of valuable metals from marine nodules under anaerobic condition. Miner. Eng. 2005, 18, 1421–1422. [Google Scholar] [CrossRef]

- Mukherjee, A.; Raichur, A.M.; Modak, J.M.; Natarajan, K.A. Bioprocessing of polymetallic Indian Ocean nodules using a marine isolate. Miner. Process. Extr. Metall. Rev. 2004, 25, 91–127. [Google Scholar] [CrossRef]

- Kumari, A.; Natarajan, K.A. Development of a clean bioelectrochemical process for leaching of ocean manganese nodules. Miner. Eng. 2002, 15, 103–106. [Google Scholar]

- Kumari, A.; Natarajan, K.A. Electrochemical aspects of leaching of ocean nodules in the presence and absence of microorganisms. Int. J. Miner. Process. 2002, 66, 29–47. [Google Scholar] [CrossRef]

- Fujimoto, J.; Tanaka, K.; Watanabe, N.; Takahashi, Y. Simultaneous recovery and separation of rare earth elements in ferromanganese nodules by using Shewanella putrefaciens. Hydrometallurgy 2016, 166, 80–86. [Google Scholar] [CrossRef]

- Aishvarya, V.; Mishra, G.; Pradhan, N.; Ghosh, M.K. Bioleaching of Indian Ocean nodules with in situ iron precipitation by anaerobic Mn reducing consortia. Hydrometallurgy 2016, 166, 130–135. [Google Scholar] [CrossRef]

- Mehta, K.D.; Das, C.; Kumar, R.; Pandey, B.D.; Mehrotra, S.P. Effect of mechano-chemical activation on bioleaching of Indian Ocean nodules by a fungus. Miner. Eng. 2010, 23, 1207–1212. [Google Scholar] [CrossRef]

- Mehta, K.D.; Das, C.; Pandey, B.D. Leaching of copper, nickel and cobalt from Indian Ocean manganese nodules by Aspergillus Niger. Hydrometallurgy 2010, 105, 89–95. [Google Scholar] [CrossRef]

- Beolchini, F.; Becci, A.; Barone, G.; Amato, A.; Hekeu, M.; Danovaro, R.; Dell’Anno, A. High fungal-mediated leaching efficiency of valuable metals from deep-sea polymetallic nodules. Environ. Technol. Innov. 2020, 20. [Google Scholar] [CrossRef]

- Marino, E.; González, F.J.; Kuhn, T.; Madureira, P.; Wegorzewski, A.V.; Mirao, J.; Medialdea, T.; Oeser, M.; Miguel, C.; Reyes, J.; et al. Hydrogenetic, Diagenetic and Hydrothermal Processes Forming Ferromanganese Crusts in the Canary Island Seamounts and Their Influence in the Metal Recovery Rate with Hydrometallurgical Methods. Minerals 2019, 9, 439. [Google Scholar] [CrossRef] [Green Version]

- Lugovskaya, I.G.; Dubinchuk, V.T.; Baturin, G.N. Composition of technological sample of ferromanganese crusts from seamounts and products of its processing. Lithol. Miner. Resour. 2007, 42, 515–522. [Google Scholar] [CrossRef]

- Allen, J.P.; Abercrombie, H.L.; Rice, D.A. Leaching and recovery of metals from cobalt-rich manganese ocean crust. Mining Metall. Explor. 1991, 8, 97–104. [Google Scholar] [CrossRef]

- Kowalczuk, P.B.; Snook, B.; Kleiv, R.A.; Aasly, K. Efficient extraction of copper and zinc from seafloor massive sulphide rock samples from the Loki’s Castle area at the Arctic Mid-Ocean Ridge. Miner. Eng. 2018, 115, 106–116. [Google Scholar] [CrossRef]

- Kowalczuk, P.B.; Oliric Manaig, D.; Drivenes, K.; Snook, B.; Aasly, K.; Kleiv, R.A. Galvanic Leaching of Seafloor Massive Sulphides Using MnO2 in H2SO4-NaCl Media. Minerals 2018, 8, 235. [Google Scholar] [CrossRef] [Green Version]

- Kowalczuk, P.B.; Bouzahzah, H.; Kleiv, R.A.; Aasly, K. Simultaneous Leaching of Seafloor Massive Sulfides and Polymetallic Nodules. Minerals 2019, 9, 482. [Google Scholar] [CrossRef] [Green Version]

- Fallon, E.K.; Niehorster, E.; Brooker, R.A.; Scott, T.B. Experimental leaching of massive sulphide from TAG active hydrothermal mound and implications for seafloor mining. Mar. Pollut. Bull. 2018, 126, 501–515. [Google Scholar] [CrossRef] [Green Version]

- Nakajima, Y.; Sato, T.; Thornton, B.; Dodbina, G.; Fujita, T. Development of Seafloor Mineral Processing for Seafloor Massive Sulfides; IEEE: Kobe, Japan, 2016; pp. 119–126. [Google Scholar]

- Aikawa, K.; Ito, M.; Kusano, A.; Park, I.; Oki, T.; Takahashi, T.; Furuya, H.; Hiroyoshi, N. Flotation of Seafloor Massive Sulfide Ores: Combination of Surface Cleaning and Deactivation of Lead-Activated Sphalerite to Improve the Separation Efficiency of chalcopyrite and Sphalerite. Metals 2021, 11, 253. [Google Scholar] [CrossRef]

- Lipton, I. Mineral Resource Estimate, Solwara project, Bismarck Sea, PNG, Nautilus Minerals Nuigini Limited 2012, SL01-NSG-RPT-7020-001 Rev 1—Golden Resource Report; 2012.

- Agarwal, J.C.; Beecher, N.; Davies, D.S.; Hubred, G.L.; Kakaria, V.K.; Kust, R.N. Processing of ocean nodules: A technical and economic review. JOM 1976, 28, 24–31. [Google Scholar] [CrossRef]

- Parida, K.M.; Mallick, S.; Mohapatra, B.K.; Misra, V.N. Studies on manganese-nodule leached residues: Physicochemical characterization and its adsorption behavior toward Ni2+ in aqueous system. J. Colloid Interf. Sci. 2004, 277, 48–54. [Google Scholar] [CrossRef] [PubMed]

- Mallick, S.; Dash, S.S.; Parida, K.M. Adsorption of hexavalent chromium on manganese nodule leached residue obtained from NH3–SO2 leaching. J. Colloid Interf. Sci. 2006, 297, 419–425. [Google Scholar] [CrossRef] [PubMed]

- Parida, K.M.; Dash, S.S.; Mallik, S.; Das, J. Effect of heat treatment on the physico-chemical properties and catalytic activity of manganese nodules leached residue towards decomposition of hydrogen peroxide. J. Colloid Interf. Sci. 2005, 290, 431–436. [Google Scholar] [CrossRef] [PubMed]

- Bhattacharjee, S.; Chakrabarty, S.; Maity, S.; Kar, S.; Thakur, P.; Bhattacharyya, G. Removal of lead from contaminated water bodies using sea nodule as an adsorbent. Water Res. 2003, 37, 3954–3966. [Google Scholar] [CrossRef]

- Pan, L.; Zhang, A.-B.; Sun, J.; Ye, Y.; Chen, X.-G.; Xia, M.-S. Application of ocean manganese nodules for the adsorption of potassium ions from seawater. Miner. Eng. 2013, 49, 121–127. [Google Scholar] [CrossRef]

- Havlik, T.; Laubertova, M.; Miskufova, A.; Kondas, J.; Vranka, F. Extraction of copper, zinc, nickel and cobalt in acid oxidative leaching of chalcopyrite at the presence of deep-sea manganese nodules as oxidant. Hydrometallurgy 2005, 77, 51–59. [Google Scholar] [CrossRef]

- Toro, N.; Pérez, K.; Saldaña, M.; Jeldres, R.I.; Jeldres, M.; Cánovas, M. Dissolution of pure chalcopyrite with manganese nodules and waste water. J. Mater. Rest. Technol. 2020, 9, 798–805. [Google Scholar] [CrossRef]

- Devi, N.B.; Madhuchhanda, M.; Rath, P.C.; Srinivasa Rao, K.; Paramguru, R.K. Simultaneous leaching of a deep-seamanganese nodule and chalcopyrite in hydrochloric acid. Metall. Mater. Trans. B 2001, 32, 778–784. [Google Scholar] [CrossRef]

- Das, R.P.; Anand, S. Aqueous Reduction of Polymetallic Nodule For Metal Extraction, Proceedings of the Second Ocean Mining Symposium; ISOPE: Seoul, Korea, 1997; pp. 165–171. [Google Scholar]

- Das, R.P.; Anand, S. Metallurgical Processing of Polymetallic Ocean Nodules. In Deep-Sea Mining; Sharma, R., Ed.; Springer, Resource Potential, Technical and Environmental Considerations: Cham, Switzerland, 2017. [Google Scholar] [CrossRef]

- Charewicz, W.A.; Chaoyin, Z.; Chmielewski, T. The leaching behavior of ocean polymetallic nodules in chloride solutions. Physicochem. Probl. Miner. Process. 2001, 35, 55–66. [Google Scholar]

- Jana, R.K.; Singh, D.D.N.; Roy, S.K. Alcohol modified hydrochloric acid leaching of sea nodules. Hydrometallurgy 1995, 38, 289–298. [Google Scholar] [CrossRef]

- Abramovski, T.; Stefanova, V.; Causse, P.R.; Romanchuk, A. Technologies for the processing of polymetallic nodules from Clarion Clipperton Zone in the Pacific Ocean. J. Chem. Technol. Metall. 2017, 52, 2. [Google Scholar]

- Hirt, W.C.; Rice, D.A.; Shirts, M.B. Flotation of cobalt-rich ferromanganese crust from the pacific ocean. Miner. Eng. 1991, 4, 535–551. [Google Scholar]

- Ito, M.; Tsunekawa, M.; Yamaguchi, E.; Sekimura, K.; Kashiwaya, K.; Hori, K.; Hiroyoshi, N. Estimation of degree of liberation in a coarse crushed product of cobalt-rich ferromanganese crust/nodules and its gravity separation. Int. J. Miner. Process. 2008, 87, 100–105. [Google Scholar] [CrossRef]

- Majima, H.; Peters, E. Electrochemistry of sulphide dissolution in hydrometallurgical systems. Int. Miner. Processing Congr. 1968, 8, 13–14. [Google Scholar]

- Hiskey, J.; Wadsworth, M. Galvanic conversion of chalcopyrite. Metall. Trans. B 1975, 184, 183–190. [Google Scholar] [CrossRef]

- Mehta, A.P.; Murr, L.E. Fundamental studies of the contribution of galvanic interaction to acid-bacterial leaching of mixed metal sulfides. Hydrometallurgy 1983, 9, 235–256. [Google Scholar] [CrossRef]

- Dixon, D.G.; Mayne, D.D.; Baxter, K.G. GALVANOXTM—A novel galvanically-assisted atmospheric leaching technology for copper concentrates. Can. Metall. Q. 2008, 47, 327–336. [Google Scholar] [CrossRef]

- Sommerfeld, M.; Friedmann, D.; Friedrich, B.; Schwarz-Schampera, U. Mineralogical Characterization and Metallurgical Processing of Seafloor Massive Sulphides from The German License Area In The Indian Ocean. In Proceedings of the 58th Annual Conference of Metallurgists (COM) Hosting Copper 2019, Vancouver, BC, Canada, 18–21 August 2019. [Google Scholar]

- Sridhar, V.; Verma, J.K. Extraction of copper, nickel and cobalt from the leach liquor of manganese-bearing sea nodules using LIX 984N and ACORGA M5640. Miner. Eng. 2011, 24, 959–962. [Google Scholar] [CrossRef]

- Parhi, P.K.; Park, K.H.; Nam, C.W.; Park, J.T. Liquid-liquid extraction and separation of total rare earth (RE) metals from polymetallic manganese nodule leaching solution. J. Rare Earths 2015, 33, 207. [Google Scholar] [CrossRef]

- Padhan, E.; Sarangi, K.; Subbaiah, T. Recovery of manganese and nickel from polymetallic manganese nodule using commercial extractants. Int. J. Miner. Process. 2014, 126, 55–61. [Google Scholar] [CrossRef]

- Parhi, P.K.; Park, K.-H.; Kim, H.-I.; Park, J.-T. Recovery of molybdenum from the sea nodule leach liquor by solvent extraction using Alamine 304-I. Hydrometallurgy 2011, 105, 195–200. [Google Scholar] [CrossRef]

- Shen, Y.-F.; Xue, W.-Y.; Li, W.; Li, S.-D.; Liu, X.-H. Recovery of Mn2+, Co2+ and Ni2+ from manganese nodules by redox leaching and solvent extraction. T. Nonferr. Metal. Soc. 2007, 17, 1105–1111. [Google Scholar] [CrossRef]

- Kumar, V.; Pandey, B.D.; Akerkar, D.D. Electrowinning of nickel in the processing of polymetallic sea nodules. Hydrometallurgy 1990, 24, 189–201. [Google Scholar] [CrossRef]

- Zhang, Z.; Du, Y.; Gao, L.; Zhang, Y.; Shi, G.; Liu, C.; Zhang, P.; Duan, X. Enrichment of REEs in polymetallic nodules and crusts and its potential for exploitation. J. Rare Earths 2012, 30, 621–626. [Google Scholar] [CrossRef]

- Pak, S.-J.; Seo, I.; Lee, K.-Y.; Hyeong, K. Rare Earth Elements and Other Critical Metals in Deep Seabed Mineral Deposits: Composition and Implications for Resource Potential. Minerals 2019, 9, 3. [Google Scholar] [CrossRef] [Green Version]

| Cu | Mn | Fe | Ni | Co | Mo | Al | Moisture |

|---|---|---|---|---|---|---|---|

| (wt%) | |||||||

| 0.74 | 26.0 | 8.9 | 1.0 | 0.19 | 0.05 | 2.0 | 13.8 |

| Mn Minerals | (1) Todorokite: oxides of manganese, magnesium, calcium, sodium, and potassium which may be chemically stated as (Ca, Na, Mn2+, K) (Mn4+, Mn2+, Mg)6O12·3H2O (2) Buserite or 10 Å manganite: a sodium manganese oxide hydrate Na4Mn14O27 · 21H2O (3) Birnessite or 7 Å manganite: (Na7Ca3)Mn7O140·28H2O (4) Vernadite (Mn4+,Fe3+,Ca,Na)(O,OH)2 · nH2O or MnO |

| Fe Minerals | Goethite α-FeOOH Feroxyhyte δ-Fe3+O(OH) |

| Mn | Fe | Co | Ni | Cu | Pt |

|---|---|---|---|---|---|

| (wt%) | (ppm) | ||||

| 28.4 | 14.3 | 1.18 | 0.5 | 0.03 | 0.5 |

| Mn-Minerals: | Vernadite (Mn4+,Fe3+,Ca,Na)(O,OH)2 · nH2O |

| Fe-Minerals: | Amorphous Fe-oxyhydroxides; Ferroxyhyte δ-Fe3+O(OH); Ferrihydrite (Fe3+)2O3·0.5H2O; Goethite α-FeO(OH) |

| Others: | Quartz SiO2; Feldspars (KAlSi3O8-NaAlSi3O8-CaAl2Si2O8); Phosphates; Carbonates |

| Setting | N | Cu | Zn | Pb | Fe | Au | Ag |

|---|---|---|---|---|---|---|---|

| (wt%) | (ppm) | ||||||

| Sediment-free MOR | 51 | 4.5 | 8.3 | 0.2 | 27 | 1.3 | 94 |

| Ultramafic-hosted MOR | 12 | 13.4 | 7.2 | <0.1 | 24.8 | 6.9 | 69 |

| Sediment-hosted MOR | 3 | 0.8 | 2.7 | 0.4 | 18.6 | 0.4 | 64 |

| Intraoceanic back arc | 36 | 2.7 | 17 | 0.7 | 15.5 | 4.9 | 202 |

| Transitional back-arcs | 13 | 6.8 | 17.5 | 1.5 | 8.8 | 13.2 | 326 |

| Intracontinental rifted arc | 5 | 2.8 | 14.6 | 9.7 | 5.5 | 4.1 | 1260 |

| Volcanic arcs | 17 | 4.5 | 9.5 | 2 | 9.2 | 10.2 | 197 |

| Value Minerals: | Chalcopyrite CuFeS2; Isocubanite CuFe2S3; Sphalerite ZnS; Wurtzite (Zn,Fe)S; Chalcocite Cu2S |

| Gangue Minerals: | Pyrite/marcasite FeS2; Pyrrhotite Fe1−xS (x = 0 to 0.2) |

| Baryte BaSO4; Anhydrite CaSO4; Quartz SiO2; Aragonite/calcite CaCO3 |

| CCZ | Global Land-Based Reserves | PPCZ | |

|---|---|---|---|

| 106 metric tons | |||

| Mn | 5929 | 5200 | 1718 |

| Cu | 224 | 1300 | 7.4 |

| Ti | 59 | 900 | 87 |

| Zn | 29 | 480 | 5 |

| REO * | 17 | 150 | 20 |

| Ni | 278 | 150 | 32 |

| Zr | 6 | 57 | 4.1 |

| Mo | 12 | 19 | 3.5 |

| Li | 2.7 | 14 | 0.02 |

| Co | 42 | 13 | 50 |

| W | 1.3 | 6.3 | 0.67 |

| Nb | 0.4 | 3.0 | 0.4 |

| Bi | – | 0.68 | 0.32 |

| Y | 1.9 | 0.48 | 1.7 |

| Te | 0.07 | 0.05 (0.022) | 0.45 |

| Method | Concept | Results and Main Conclusions | Ref. | ||

|---|---|---|---|---|---|

| PYROMETALLURGY | Reduction smelting | Prereduction at 1000 °C for 1 h; smelting with pure graphite powder → Fe-Cu-Co-Ni alloy + Mn-rich slag | 4 wt% graphite at MnO/SiO2 ratio = 1.6, 1350 °C | [35] | |

| Segregation roasting | Roasting at 800–1000 °C, 1 h with coke + chlorinating agents (solid chlorides of Na, Mg, NH4, Li, Cs, Ca) | 46–88% Cu, 22.5–32% Ni, 7–21.5% Co, 0–9% Mn, 0–9% Fe. Best temp for Cu–850 °C, for Ni and Co–1050 | [17] | ||

| Reduction with hydrogen | Reduction at 130–500 °C, 1 h, or at 400 °C for 8 h | Reduction of PMN in H2 proceeds in 4 stages: 1st—loss of water (up to 130 °C); 2nd—decomposition of ferric oxyhydroxide (up to 320 °C), 2nd and 3rd—reduction of oxides and hydroxides of Cu, Ni and Co; 4th—reduction of α-Fe2O3 to metallic Fe | [36] | ||

| Reduction roasting | Reduction at 1000–1150 °C with anthracite and additives (CaF2, SiO2, FeS) + magnetic separation | 1100 °C, 2.5 h, 4% CaF2, 7% anthracite, 5% SiO2, 6% FeS metals in concentrates: 86.48% Ni, 86.74% Co, 5.63% Mn, 83.91 Cu, 91.46% Fe | [37] | ||

| Reductive smelting | Zero-waste 2-step smelting → Cu-Co-Ni alloy + HC FeMn | Smelting at 1400 °C with 9.4% SiO2, yielding over 90 and up to 100% for Cu, Co, Mo, and Ni, 97% of Mn in final slag | [38] | ||

| PYROMETALLURGY + HYDROMETALLURGY | Reduction roasting + ammoniacal leaching | Reduction at 750–1150 K with wood charcoal and natural gas; Leaching in 1 M (NH4)2CO3 in 10% NH3 | Roasting at 1073 K, 2 h, 6% reduction agent, leaching for 210 min at 318 K: for Co roasting temp. 1123 K 90% Ni, >70% Cu, >60% Mo, 90% Co | [39] | |

| Reduction at 700 °C, 2 h with 10% low-sulfur fuel oil; precipitation of Fe and Mn before leaching; leaching with NH3 + CO2 | 3.5 h leaching time 10% Cu, 22% Ni, 62% Co | [40] | |||

| Reduction at 650–800 °C with coal; leaching (2 stages) with ammonium salt + ammonium hydroxide sol. | 1st leaching step (0.05–1 M NH3) at RT for Cu recovery, 2nd leaching step (up to 2 M NH3) at ~50 °C for Ni dissolution in residue. Leaching time 0.5–4 h. | [41] | |||

| Reduction at 800 °C with coal; preconditioning with NH3 + (NH4)2CO3 + surfactant solution; precipitation of Fe and Mn by air purging; residue leaching in NH3 + (NH4)2CO3 | 95% Cu, 94% Ni, 80% Co | [42] | |||

| Pyrolysis + acidic leaching | Reduction at 300–500 °C with sawdust ground <1mm under N2; Leaching with 1 M H2SO4 at 60 °C for 1 h | 10% sawdust, reduction temp. 500 °C, reduction time 6 min. 96.1% Mn, 91.7% Cu, 92.5% Co, 94.4% Ni | [43] | ||

| Reduction and smelting + chlorine leach | Reduction at 900 °C with coal + SiO2 + CaO for 2 h; Smelting at 1400 °C for 2 h; Leaching of sulfided Cu-Co-Ni alloy with chlorine gas; SX + EW for Fe, Cu, Co, and Ni | Silicomanganese obtained from slag phase chlorine leach is preferable to an oxygen-pressure leach. 99% Cu, Co, Ni in 3 h | [44] | ||

| Hydrochlorination + water leach | Hydrochlorination with HCl gas at 550 °C and water vapour at 300 °C; Leaching of dissolved chloride products with water; Separation of Fe2O3 precipitate; SX of Cu, Co, and Ni from PLS; electrolysis. | US Patent | [45] | ||

| Reduction + smelting + acidic pressure leaching | Reduction with fuel oil + air at 1000 °C; smelting in electric furnace; oxidative pressure leaching of matte; slag treatment for Mn recovery; | Ground matte leached at 1 MPa, 110 °C, 2 h, 100 g/L H2SO4 99% Cu, Co, Ni, only 0.01 g/L Fe (after sulfidization of matte) | [46] | ||

| Reduction + smelting + POX | Reduction with fuel oil + air at 1000 °C; smelting in electric furnace; oxidative pressure leaching of FeNiCoCu alloy (no conversion to matte) with H2SO4 + CuSO4; FeOOH precipitation; SX + EW Of Cu, Co, and Ni | Addition of CuSO4 prevents H2 formation during leaching, Cu is cemented by less noble metals and leached by sulfuric acid. 1.5 excess of acid, 2–3 excess of CuSO4, 10 bar, 6 h, solid conc. 25–45 g/L | [47] | ||

| Baking + water leaching | Baking with conc. H2SO4; water leaching of Cu, Co, Ni, Mn soluble sulfates | N/A | [48] | ||

| HYDROMETALLURGY | Acidic | Pressure leaching micellar mediated | Pressure leaching of ground nodules (<100 μm) with H2SO4 and surfactants: CTAB, SDS, Triton X 100, Tween 80; conditions: 110–160 °C, S/L 1/10, 2 h. | CTAB, 160 °C, 10% pulp density, 2 h, 5% H2SO4 99% Mn, Cu, Co, Ni | [49] |

| Pressure leaching/+charcoal | Leaching of ground nodules with H2SO4 at 150 °C and 0,55 MPa, 4 h Charcoal addition to remove Fe dissolve MnO2 | 150 °C, 0.66 g H2SO4 per g of nodule, pO2 = 0.55 MPa, 4 h or the same conditions + 0.05 g charcoal/g of nodule 77%Cu, 99,8% Ni, 88% Co, 99,8% Mn, 4,5%Fe | [50] | ||

| Atmospheric/Pressure leaching | Comparative leaching with H2SO4 at 100 °C and 200 °C | 200 °C, 3 h, 0.3 g H2SO4/g of nodules, 90% Ni, 91% Cu, 44% Co, 6% Mn, 2% Fe Higher leaching at 100 °C for Co (70%) and Fe (65%) | [51] | ||

| Atmospheric leaching | Leaching with H2SO4 + FeSO4·7H2O at 80 °C, 90 °C | 90 °C, 1.6 excess of H2SO4, L/S 7–15. Solution contains FeSO4 in stoichiometric amount to MnO2. >90% Ni, Cu and Mn, 85% Co | [52] | ||

| Atmospheric leaching + amines | Leaching with H2SO4 and aromatic amines (as reductants) at ambient temp. aniline, o-phenylene diamine, o-aminobenzoic acid, o-nitroaniline, p-amino toluene, p-aminobenzene sulfonic acid, 1-naphtylamine | 84–99.6% Mn, 23–97.7% Cu, 74–99.3% Ni, 89–99.7% Co | [53] | ||

| Atmospheric leaching + phenols | Leaching with H2SO4 and phenols (as reductants) at ambient temp. hydroxybenzene, o-dihydroxybenzene, m-dihydroxybenzene, p-dihydroxybenzene, o-trihydroxybenzene and m-trihydroxybenzene | 95% Mn, Cu, Ni, Co | [54] | ||

| Atmospheric leaching | Leaching of ground nodules with H2SO3 (dilute aq. solution of SO2) at ambient temp. | SO2 ratio to the total weight of nodules (g): 0.94·10−2 —1.25·10−2. Concentration of 6–8% SO2 in water is satisfactory. Temp 25 °C, p = 1 atm. >90% Ni, Co, Mn in ~10 min. | [55] | ||

| Atmospheric leaching | Leaching of ground nodules with SO2 or SO2 + H2SO4 at 30 °C | Particle size −150: +76 μm. 30–40 °C, leaching with SO2 (only) 89% Mn, 60% Cu, 82,5% Ni, 90% Co, 75% Zn | [56] | ||

| Atmospheric leaching | Leaching of REE in H2SO4, 500rpm, 30 °C, 2 h | 3 M H2SO4 90 °C >90% REE but high co-extraction of Fe, Co, Ni, Cu or 0.2 M H2SO4 at 45 °C total extraction of REE 58% low co-extraction (0.3% Mn, 4.63% Fe, 23.7% Cu, 0.2% Co, 31.8% Ni). | [57] | ||

| Atmospheric leaching | Leaching of ground nodules with HCl, at 90–100 °C | 1–1.5 M HCl, Grain size ~35 μm. Non-selective towards Fe. >80%Ni, Cu and Zn with 30–35% Fe, Mn, and Co < 20%. | [56] | ||

| Atmospheric leaching + SX | Leaching of powdered nodules in HCl; Solvent extraction of Cu, Co, and Ni | 4 M HCl; Cyanex 923 and Cyanex 301 at 25 °C A/O = 1 >90% Cu, Co, Ni | [58] | ||

| Cathodic electroleaching + adsorption | Electrolytic reduction of Cu, Mn, Co, and Ni from acidic slurry sltn on Pt electrodes at 30 °C; Adsorption of metals from lean electrolyte on nodules | Copper leached and deposited on a cathode, MnO2 deposited on the anode. Adsorption: 1g of nodules mix with 100mL of sltn Cu, Ni, Co, Mn (single or grouped), size fraction −75 and +53 μm 100% Cu, Co, Ni. 50% Mn | [59] | ||

| Slurry electrolysis | Electrolysis in HCl-NaCl medium cathodic reduction at the cathode; anodic oxidation and deposition of MnO2 | Anode: Ti/MnO2 strip; Cathode: graphite stick, diaphragm; 120 g/L NaCl, 40–70 g/L Mn, 70 °C, pH 0.5–1.5, 200 min, current density: 200 A/m2 Cu 96–99%, Co 99%, Ni 98–99%, Fe 54–79%, Mn 96–99% | [60] | ||

| Basic | Pressure leaching + SX-EW Medium-scale plant | Ammoniacal leaching with reductants: SO2, CO, Fe(II), Mn(II), thiosulfate, glucose, carbon, Demanganisation step (prec. MnO2), ammonia stripping and recycling; Cu SX-EW Sulfides precipitation of Co, Ni, and minor impurities (Cu, Zn, Fe), dissolution in H2SO4; Co-Ni SX-EW | 5 m3 autoclave, medium temp and pressure. Scale: 500 kg/day avg. 85% Cu, 90% Ni, 80% Co | [61] | |

| Liquid phase oxidation + Atmospheric leaching | Molten KOH + air to oxidize MnO2 in nodules and for dissociation of nodules structure; conversion of K2MnO4 to KMnO4 and MnO2 Pure MnO2 from KMnO4 decomposition; separation of Fe2O3 through gravity classification, reductive leaching with (NH4)2SO3 | 50 g/L residue conc., 200 rpm, 100 g/L NH3, 70 °C 95%Cu, 65% Co, 84% Ni | [62] | ||

| Microorganisms assisted | Bacterial leaching | Leaching of REE from nodules with thiobacillus ferroxidans | ~100% for Cu and Ni (2 weeks), <5% Fe and Mn, 50% Co | [63] | |

| Bacterial leaching | Leaching of ground PMN with thermophile Acidianus brierleyi at 65 °C or mesophile Thiobacillus species at 30 °C | A. brierleyi more effective; 100% Cu, Zn (4 days) and 85% Ni, 70% Co, 55% Mn (10 days) | [64] | ||

| Bacterial leaching + pyrite | Thiobacillus ferroxidans + pyrite at 30 °C pyrite as reductant | pH 2, pulp 10%, 3 days leaching, pyrite:nodules ratio 1:1 95% Co, 94% Ni, 97% Mn, 80% Cu Higher leaching rate at anaerobic conditions | [65] | ||

| Bioleaching with marine bacterium isolate | Comparison of acidic leaching and bioleaching; 2.5 M H2SO4 + Na2S2O3 or 2.5 M HCl + glucose or 2.5 M HNO3 vs. marine isolate; 30 °C | 30–50% Co (HCl), 85% Cu, 85% Ni (HCl), 80%Mn. Bioleahing with marine isolate was much less efficient < 45% Co, ~30% Cu and Ni | [66] | ||

| Electrobioleaching/galvanic leaching | Thiobacillus ferrooxidans, Thiobacillus thiooxidans, 30 °C; Galvanic leaching with pyrite/pyrolusite (MnO2) | voltage range −600:-1400 mV, 4–5 h; −75 to +53 μm size fraction; galvanic leachingat nodule:pyrite ratio = 2:10 100% Cu, Ni, Co | [67,68] | ||

| Leaching with Fe-reducing bacterium | Decomposition of nodules with Shewanella putrefaciens and NaCl solution | 0.5 M NaCl, pH 7, necessary daily addition of 1mmol sodium lactate, leaching of REE with 0,01M HCl | [69] | ||

| Bioleaching with bacteria consortia and reductants | Anaerobic leaching with bacteria consortia and glucose or sodium acetate as reductants, 30 °C, no agitation | Glucose (30% recovery of Mn) 90 days only 42 ppm of Fe was leached, only 30% of Cu, and 30% of Ni | [70] | ||

| Bioleaching with fungi | Aspergillus niger (fungal culture) realeses organic acids such as oxalic or citric acid which help reduce host metal oxides/hydroxides in nodules | Activation: 10 min, size <10 μm; Leaching with A. niger, 15 days, 35 °C. (25 days for not-activated material) 95% Cu, Ni, and Co | [71] | ||

| Bioleaching more effective than chemical leaching by carboxylic acids or by fungal metabolites. 97%Cu, 98% Ni, 86% Co, 91% Mn, 36% Fe, 30 days, initial pH 4.5, 35°C, 5% pulp density, particle size <300 μm | [72] | ||||

| Aspergillus niger and Trichoderma sp. | 11 days with A. Niger >80% Mn, Cu, Ni, 70% Co, 30% Fe | [73] | |||

| HYDROMETALLURGY | Acidic | Atmospheric leaching | 2.75 M HCl with the addition of 18.5 mL of ethanol (reductant) initial pH: 1.5 | Mixed diagenetic/hydrogenetic crust shows lower recovery than lower diagenetic or pure hydrogenetic crusts. Mn 75–81%, Fe 49–58%, Co 63–108%, Ni 53–85%, Cu 50–74%, V 58–85% | [74] |

| 1st stage—leaching with H2SO4 at 80–90 °C; 2nd stage—leaching of residue with HNO3 | 50 g of sample + H2SO4 (20–25%), S/L = 1/4 or HNO3 (10–30%) 74–85% Mn, Co, Ni, Cu, Zn, Y, HREE, U, and Hf >90% of elements extracted from the residue | [75] | |||

| Beneficiation of crust sample by froth flotation and magnetic separation(separation from the substrate); leaching with H2SO4-H2O2; precipitation of Fe with CaO; precipitation with H2S under pressure removal of Co-Ni mixed sulfides Mn recovery by carbonation at neutral pH precipitation of MnCO3 | 25 °C, 1 h, 13% solids, 5.9% H2SO4, 1.2% H2O2 96% MNm 43% Fe, 95% Co, 91%Ni | [76] |

| PYROMETALLURGY | Zero-waste process: 2-stage reductive smelting | Modification of INCO process; The slag phase from 1st smelting step was directed to the next stage to increase Mn recovery in the form of high carbon ferromanganese (HC FeMn). | 1400 °C with 9.4% SiO2, yielding 90–100% for Cu, Co, Mo, and Ni. The final slag: 97% of Mn and low concentrations of Cr, Cu, V, and Ni. | [38] | |

| HYDROMETALLURGY | Acidic | Atmospheric leaching | Leaching with HNO3 | 10% HNO3 90 °C, 2 h, S/L 1/10 >90% Cu, Zn, Fe | [77] |

| Galvanic leaching using MnO2-H2SO4-NaCl media. | 24 h, temp 30–80 °C, 0–1.5 M H2SO4, 0–1 M NaCl, 0–19.5 g/L MnO2 | [78] | |||

| Simultaneous leaching of SMS and PMN-pure or at different ratios | 1 M H2SO4 and 1 M NaCl, 700 rpm, 80 °C, 48 h, S/L 50 g/L PMN dosage from 30–100% Cu, Mn, Ni ~100, Zn ~85% | [79] | |||

| Artificial seawater leaching | 12 °C, 0.6–1 g SMS to 500 mL of seawater ppb levels for Cu and Pb | [80] | |||

| CONVENTIONAL PROCESSING | Application of ball mill grinding and column flotation to SMS processing; LIBS technology applied for in situ measurement of the metal grade of ore particles | Water-filled grinding at high pressure had an almost comparable grinding performance to wet grinding at the atmospheric pressure; concentrates of Cu and Zn obtained in column flotation | [81] | ||

| Flotation of SMS to separate chalkopyrite and galena as froth, and sphalerite, pyrite, and remaining gangue minerals as tailings. | Flotability of sphalerite increases in the presence of Pb minerals (PbS, PbSO4) and soluble compounds: Cu2+, Zn2+, Pb2+, and Fe2+/3+ High separation of chalkopyrite and sphalerite is possible through the combination of surface cleaning with EDTA and depression of lead-activated sphalerite by zinc sulfate | [82] | |||

| SMS grinding and flotation of Cu-minerals (mainly chalkopyrite) | >25% Cu concentrates (~85–90% Cu recovery) ready for Cu smelter ~25% gold recovered in Cu concentrate ~65–70% of Au can be recovered into a pyrite concentrate. Extraction of Au by the conventional technologies of roasting/cyanidation or pressure oxidation/cyanidation | [83] | |||

| Method | Conditions | Results/Main Conclusions | Ref. |

|---|---|---|---|

| Ammonia leaching with SO2 → precipitation of Mn(aq), recovery and recycle of ammonia → Cu SXandEW → precipitation of Ni, Co sulfides from Cu raffinate → dissolution of Ni(Co) sulfides in H2SO4, O2 → Ni, Co SXandEW | Cu SX with LIX 84I, Ni SX with D2EHPA Co SX with PC-88A | Medium scale demonstration plant 500 kg/day Metals recoveries: Cu: 85% Ni: 90% Co: 80% | [61] |

| Leaching with 50% H2SO4 → precipitation of Fe and Mn at pH 4.5 → co-extraction of Cu and Ni → selectie stripping of Ni and Cu | Leaching at 80–90 °C; SX: Organic phase: LIX 984N + kerosene Acorga M5640 + kerosene, 5 min., A/O = 1 | Quantitative and selective stripping of Cu and Ni; Co in raffinate | [105] |

| Leach liquor → precipitation of Fe → SX of REE | Fe precipit. with Ca(OH)2, at pH = 3.95 SX: 0,1M sols of D2EHPA, PC88A and Cyanex 272, 5 min, A/O = 1; Stripping with 2M HCl | Highly selective extraction of REE with D2EHPA, in the presence of base metals (Cu, Ni, Co, Mn) | [106] |

| PMN leach liqor → Fe precipitation → Cu SX → Zn SX → Mn SX, Co scrubbing from loaded organic → Ni SX | Fe(II) oxidation with 0.5% H2O2, precipit. With Ca(OH)2; Cu SX: 10% LIX84I + kerosene, A/O = 6/1; Zn SX: 0.02 MD2EHPA + kerosene, A/O = 1 Mn SX: 1M NaD2EHPA + kerosene Ni SX: 0.15 M NaD2EHPA + kerosene 30oC, A/O = 1, 5 min; stripping with H2SO4 | Metals recoveries: Cu: ~100% Zn(II): 99.6% Mn(II): 99.9% Ni(II): 99.3% | [107] |

| Synthetic solution (equivalent to sea nodule leach liquor) → Mo SX → crystallization → thermal decomposition | Mo SX: 10% v/v Alamine 304–1 + kerosene, 5 min., 25 °C, stripping with NH4OH + (NH4)2CO3; Crystallization of (NH4)4Mo2O6; decomposition at 400 °C to MoO3 | purity of (NH4)4Mo2O6 and MoO3—99.9% | [108] |

| PMN leaching liquor → Precipitation of Fe → * precipitation of Co, Ni sulfides → dissolution in H2SO4 → Co, Ni SX → Co precipitation → roasting → Co2O3 → Ni recovery → NiSO4·7H2O precipitation of Mn from * → dissolution in 0.5 M H2SO4 and crystallization of MnSO4·H2O | Impurities (Mn, Fe, Cu, Zn) SX: 15% D2EHPA + kerosene Co, Ni SX: 25% P507 (neutralized) kerosene, 27 °C, Co precipitation with oxalic acid and ammonium oxalate at 65 °C; Roasting at 700 °C → Co2O3 | Fe precipitates as jarosite Metals recoveries: Mn: 85%; Co: 75%; Ni: 78% | [109] |

| PMN leach liquor → Cu SX → Co, Ni SX from Cu raffinate → Co SX and stripping → Ni SX and stripping | 1st stage: Cu SX: 0.3 M Cyanex 923; 2nd stage: Co SX: 0.6 M Cyanex 923; 3rd stage: Ni SX: 0.1M Cyanex 301 | Metals recoveries: Co(II), Cu(II), Ni(II): 90% | [58] |

| PMN leach liquor →Co-extraction of Cu and Ni → selective stripping of Ni → Ni SX-EW | Cu,Ni SX: LIX 64N + kerosene, A/O = 1; scrubbing with ammonia, Ni stripping in 6 stages, Ni EW 12h, 61 °C | Purity of electrocrystallized Ni: 99.82% The effect of organic phase deletorious for the quality of electrowinning product | [110] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ochromowicz, K.; Aasly, K.; Kowalczuk, P.B. Recent Advancements in Metallurgical Processing of Marine Minerals. Minerals 2021, 11, 1437. https://doi.org/10.3390/min11121437

Ochromowicz K, Aasly K, Kowalczuk PB. Recent Advancements in Metallurgical Processing of Marine Minerals. Minerals. 2021; 11(12):1437. https://doi.org/10.3390/min11121437

Chicago/Turabian StyleOchromowicz, Katarzyna, Kurt Aasly, and Przemyslaw B. Kowalczuk. 2021. "Recent Advancements in Metallurgical Processing of Marine Minerals" Minerals 11, no. 12: 1437. https://doi.org/10.3390/min11121437

APA StyleOchromowicz, K., Aasly, K., & Kowalczuk, P. B. (2021). Recent Advancements in Metallurgical Processing of Marine Minerals. Minerals, 11(12), 1437. https://doi.org/10.3390/min11121437