Effect of Nano-Additives on the Strength and Durability Characteristics of Marl

Abstract

:1. Introduction

2. Materials

3. Experimental Program and Methods

4. Results and Discussion

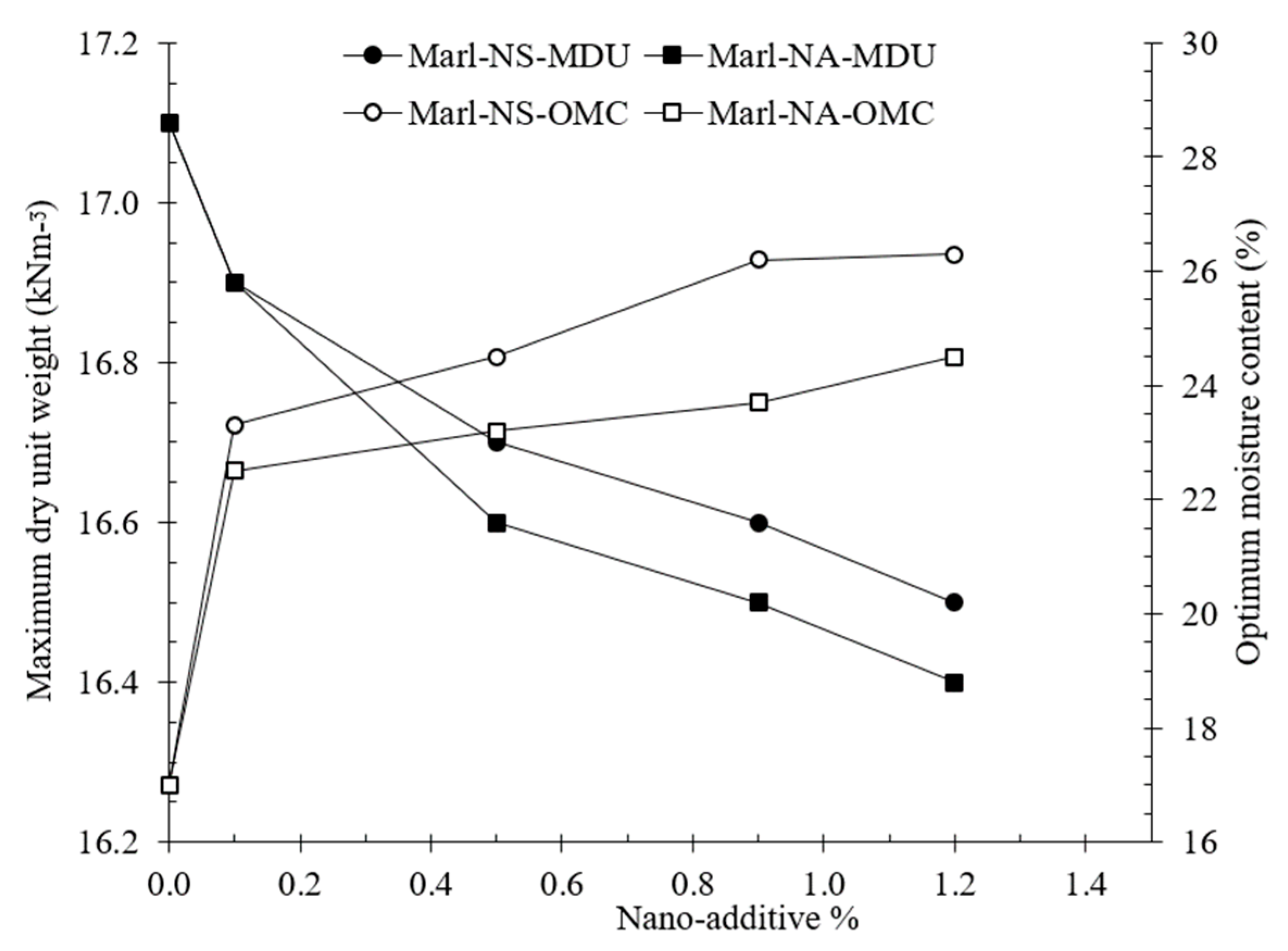

4.1. Effect of Nano-Additives on the Compaction Properties of Marl

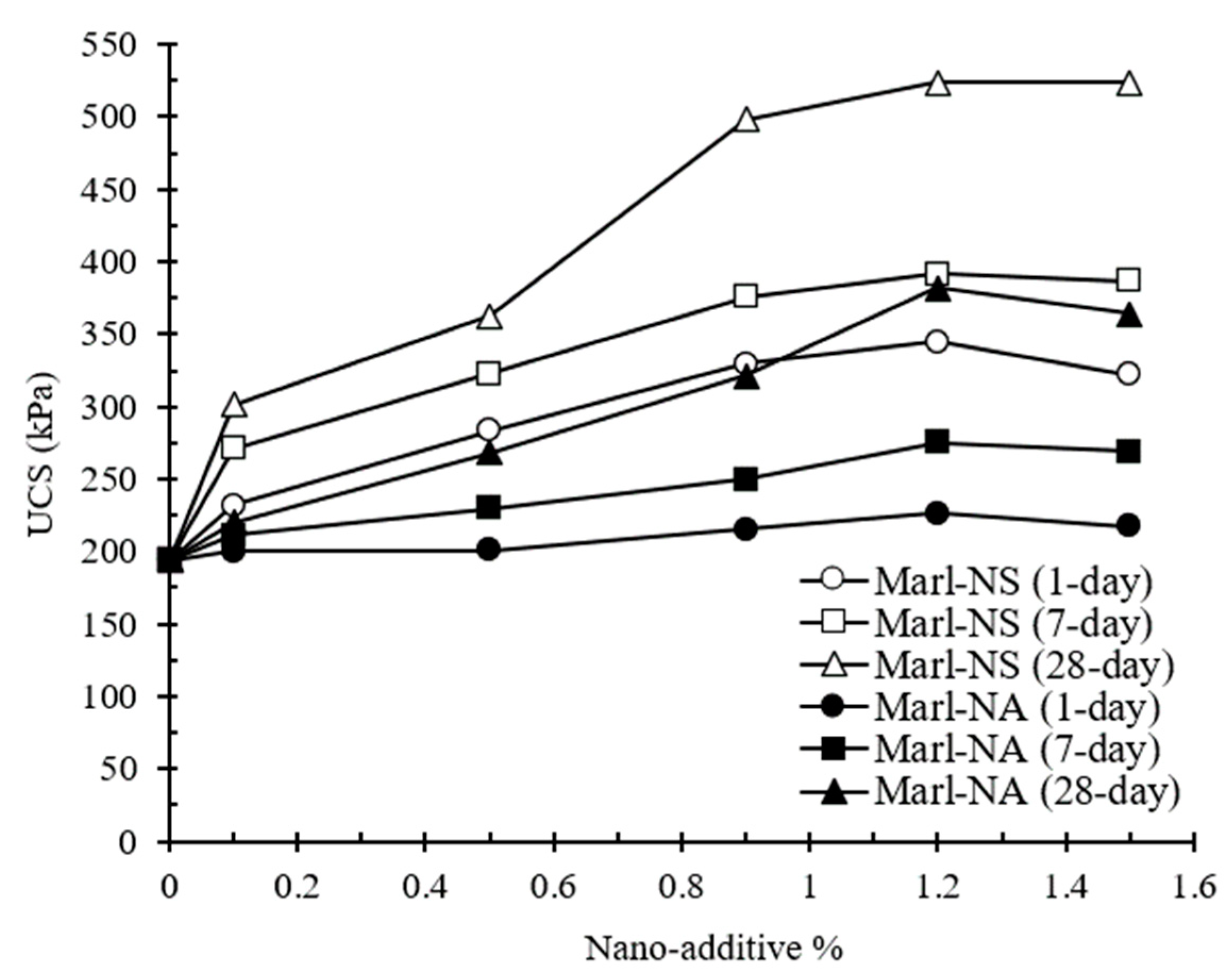

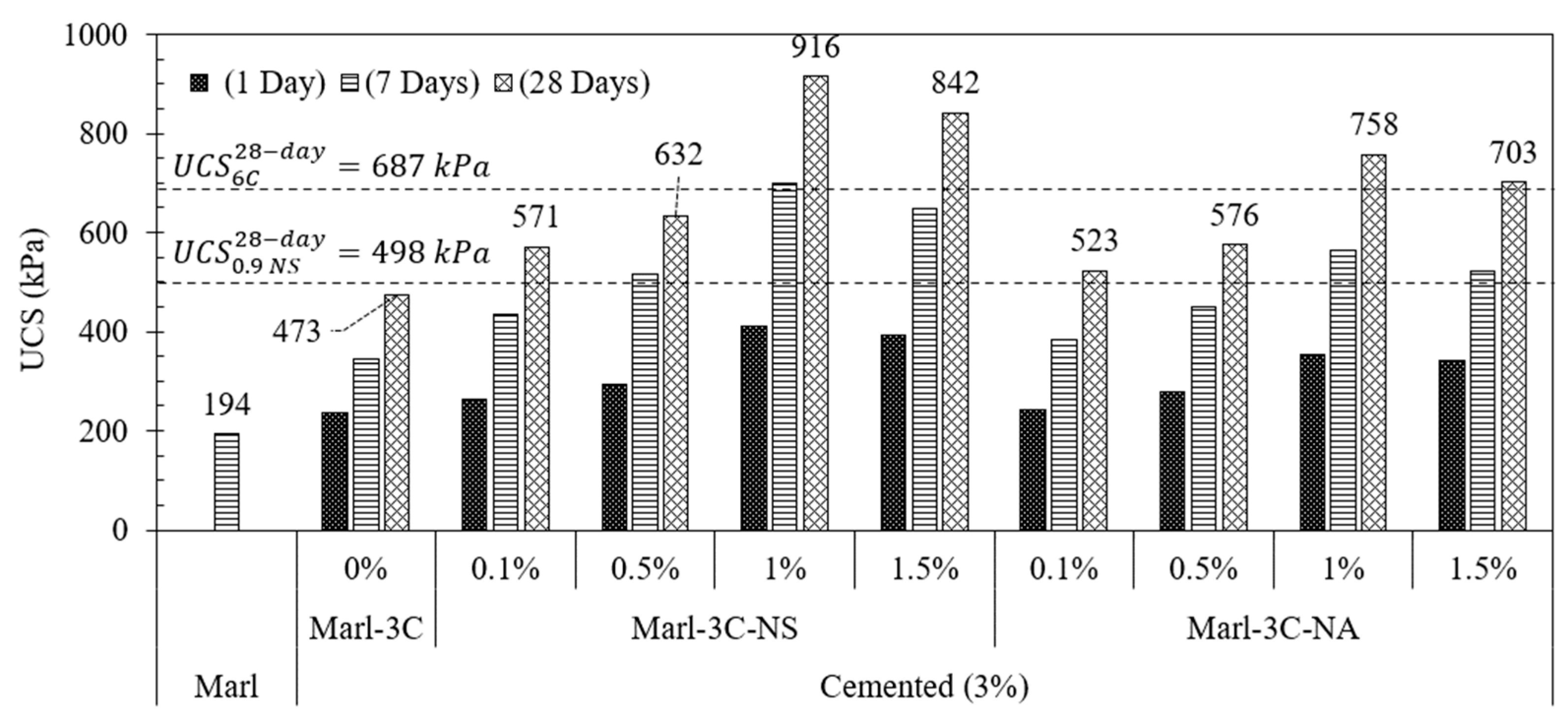

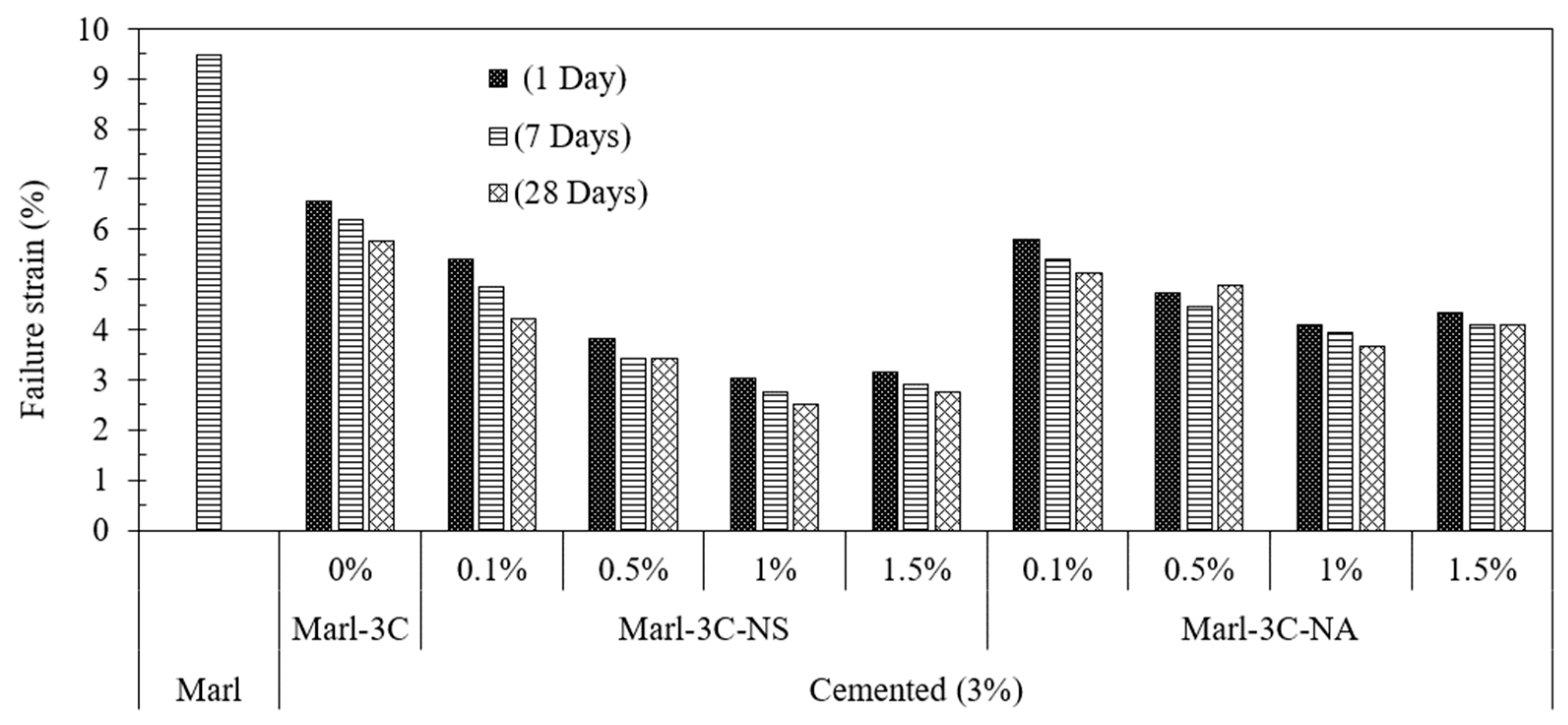

4.2. Effect of Nano-Additives on the UCS of Marl

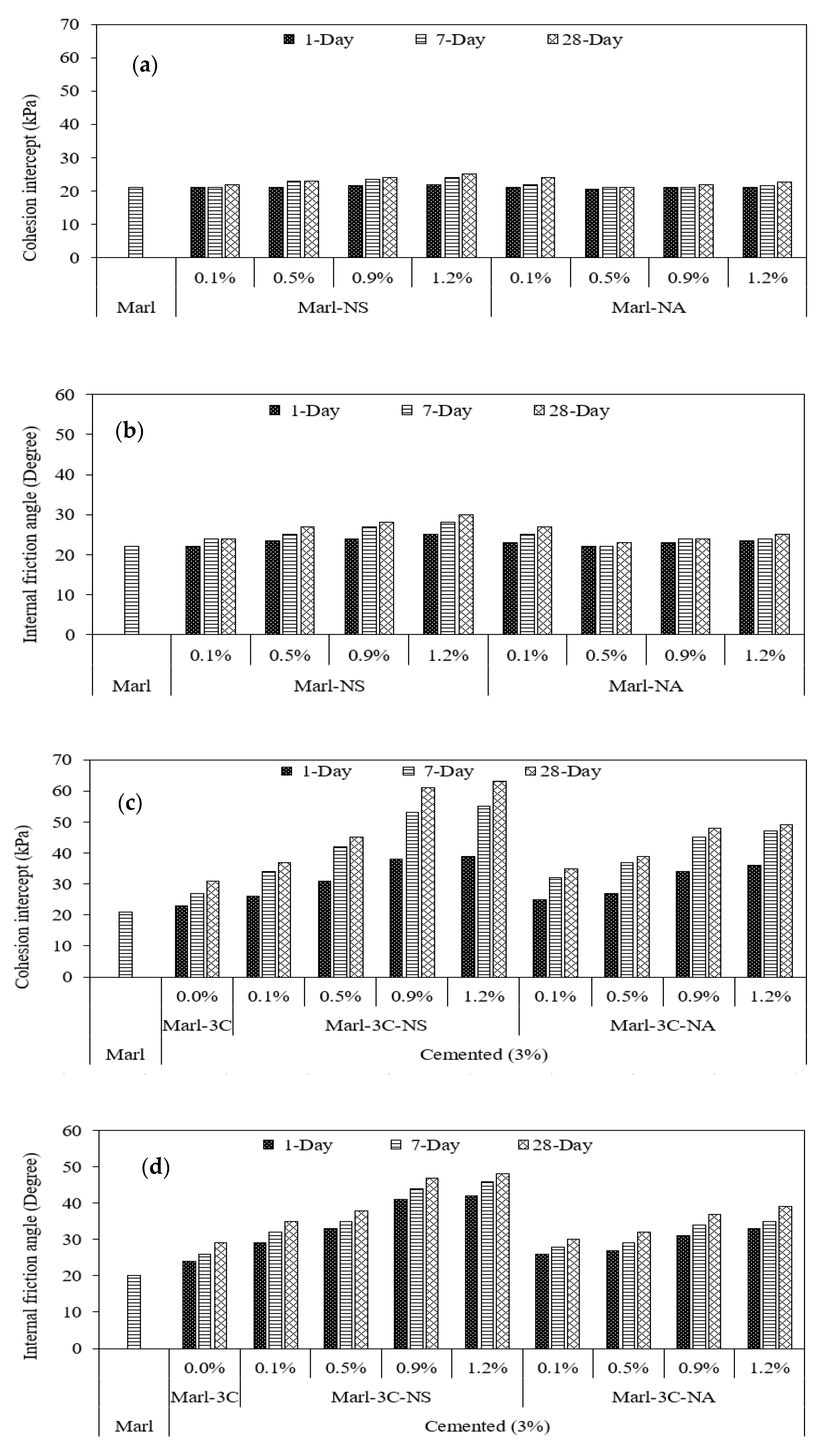

4.3. Effect of Nano-Additives on the Shear Strength of Marl

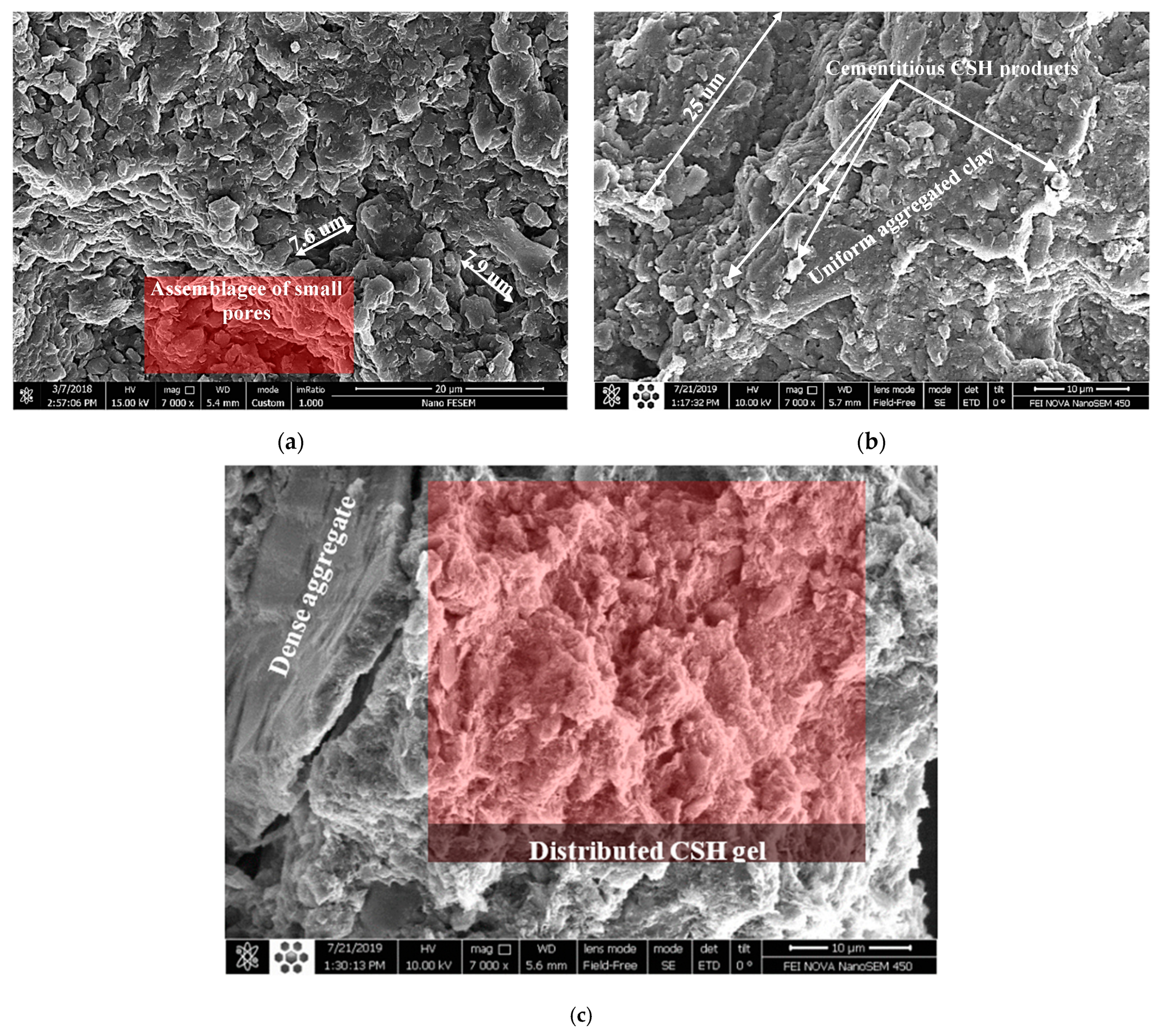

4.4. Microfabric of Nano-Additive Stabilized Marl

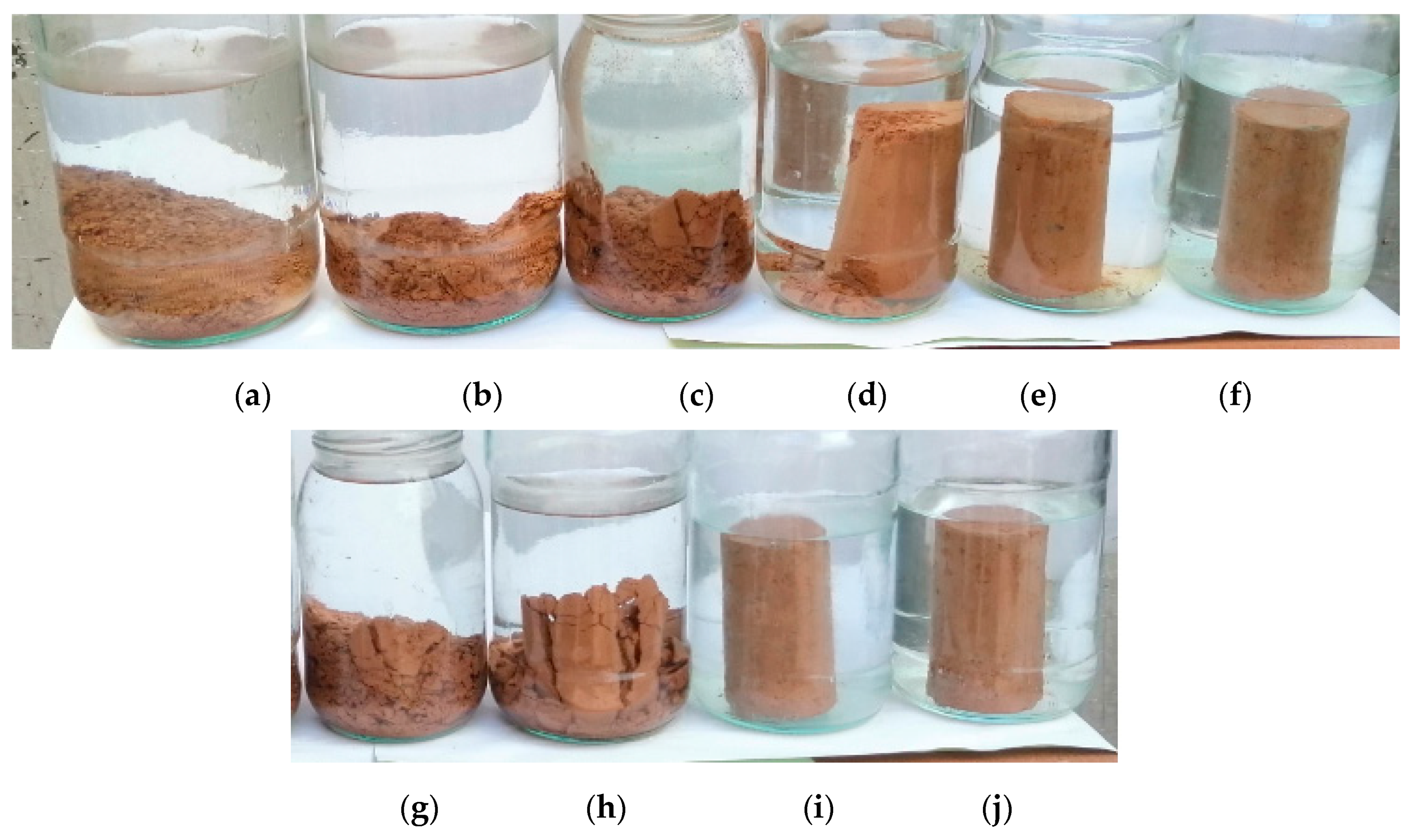

4.5. Durability of Nano-Additive Stabilized Marl

5. Conclusions

- The addition of nano-additives resulted in an increase in the optimum moisture content and a decrease in the dry unit weight of the marl due to the hydrophilicity and high specific surface of nano-additives used in this study.

- The UCS of the nano-additive treated marl increased with an increase in the concentration of both nano-additives to a threshold nano-additive content of 1%.

- The 28-day UCS of 3% cemented marl was slightly less than the 28-day UCS of treated marl with 0.9% nano-silica, which suggests 3% cement can be replaced with 0.9% nano-silica for achieving similar improvement results.

- Stabilizing marl with combined 3% cement and 1% nano-silica achieved 94% surplus UCS to the 3% cement stabilized marl. Nano-additives accelerate the hydration of cement due to the fact of their high surface energy. Therefore, although cement is primarily a common additive for soil stabilization projects, the combination of cement and nano-additives can yield nearly double UCS of the cemented clay (i.e., at 28 days of curing).

- The 28-day UCS values of 3% cement stabilized marl with 0.5% and 1% nano-silica were 0.92 and 1.32 times that of the 6% cement stabilized marl. Therefore, nano-additives can replace cement partially to achieve similar or higher UCS values.

- Stabilizing marl with 1% nano-silica and cement resulted in an intensified secant modulus that was 18.8 times that of the marl. However, cemented marl achieved only a secant modulus four times that of the marl.

- Stabilizing the marl with nano-additives or with a combined mix of cement and nano-additives improved the shear strength parameters (i.e., cohesion intercept and internal friction angle) of the marl. The 28-day cohesion intercept and internal friction angle of cemented marl treated with 1.2% nano-silica were 3 and 2.4 times those of the uncemented marl, respectively. Although, the effect of individual additives (either cement or nano-additives) on the shear strength parameters of the marl was insignificant, the combination of both additives improved the shear strength parameters of the marl significantly.

- Nano-alumina treated marl yielded lower UCS and shear strength than nano-silica treated marl at all curing times.

- SEM micrographs of the stabilized marl showed an increase in the growth of CSH products within the microfabric of the clay with the addition of nano-silica.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chew, S.H.; Kamruzzaman, A.H.M.; Lee, F.H. Physicochemical and engineering behavior of cement treated clays. J. Geotech. Geoenviron. Eng. 2004, 130, 696–706. [Google Scholar] [CrossRef]

- Sariosseiri, F.; Muhunthan, B. Effect of cement treatment on geotechnical properties of some Washington State soils. Eng. Geol. 2009, 104, 119–125. [Google Scholar] [CrossRef]

- Mirzababaei, M.; Arulrajah, A.; Ouston, M. Polymers for Stabilization of Soft Clay Soils. Procedia Eng. 2017, 189, 25–32. [Google Scholar] [CrossRef]

- Yong, L.L.; Perera, S.V.A.D.N.J.; Syamsir, A.; Emmanuel, E.; Paul, S.C.; Anggraini, V. Stabilization of a Residual Soil Using Calcium and Magnesium Hydroxide Nanoparticles: A Quick Precipitation Method. Appl. Sci. 2019, 9, 4325. [Google Scholar] [CrossRef] [Green Version]

- Shenal Jayawardane, V.; Anggraini, V.; Emmanuel, E.; Yong, L.L.; Mirzababaei, M. Expansive and Compressibility Behavior of Lime Stabilized Fiber-Reinforced Marine Clay. J. Mater. Civ. Eng. 2020, 32, 04020328. [Google Scholar] [CrossRef]

- Rastegarnia, A.; Lashkaripour, G.R.; Sharifi Teshnizi, E.; Ghafoori, M. Evaluation of engineering characteristics and estimation of static properties of clay-bearing rocks. Environ. Earth Sci. 2021, 80, 621. [Google Scholar] [CrossRef]

- Pani, A.; Singh, S.P. Geo-engineering Properties of Sedimented Flyash Bed Stabilized by Chemical Columns. In Ground Improvement Techniques and Geosynthetics; Thyagaraj, T., Ed.; Springer: Singapore, 2019; pp. 363–371. ISBN 978-981-13-0558-0. [Google Scholar]

- Pani, A.; Singh, S.P. Strength and compressibility of sedimented ash beds treated with chemical columns. Soils Found. 2020, 60, 573–591. [Google Scholar] [CrossRef]

- Yazdi, A.; Sharifi Teshnizi, E. Effects of contamination with gasoline on engineering properties of fine-grained silty soils with an emphasis on the duration of exposure. SN Appl. Sci. 2021, 3, 704. [Google Scholar] [CrossRef]

- Saride, S.; Dutta, T.T. Effect of Fly-Ash Stabilization on Stiffness Modulus Degradation of Expansive Clays. J. Mater. Civ. Eng. 2016, 28, 04016166. [Google Scholar] [CrossRef]

- Soltani, A.; Raeesi, R.; Taheri, A.; Deng, A.; Mirzababaei, M. Improved shear strength performance of compacted rubberized clays treated with sodium alginate biopolymer. Polymers 2021, 13, 764. [Google Scholar] [CrossRef]

- Amadi, A.A.; Osu, A.S. Effect of curing time on strength development in black cotton soil—Quarry fines composite stabilized with cement kiln dust (CKD). J. King Saud Univ.-Eng. Sci. 2018, 30, 305–312. [Google Scholar] [CrossRef] [Green Version]

- Miller, G.A.; Azad, S. Influence of soil type on stabilization with cement kiln dust. Constr. Build. Mater. 2000, 14, 89–97. [Google Scholar] [CrossRef]

- Yilmaz, I.; Civelekoglu, B. Gypsum: An additive for stabilization of swelling clay soils. Appl. Clay Sci. 2009, 44, 166–172. [Google Scholar] [CrossRef]

- Lu, S.G.; Sun, F.F.; Zong, Y.T. Effect of rice husk biochar and coal fly ash on some physical properties of expansive clayey soil (Vertisol). Catena 2014, 114, 37–44. [Google Scholar] [CrossRef]

- Poltue, T.; Suddeepong, A.; Horpibulsuk, S.; Samingthong, W.; Arulrajah, A.; Rashid, A.S.A. Strength development of recycled concrete aggregate stabilized with fly ash-rice husk ash based geopolymer as pavement base material. Road Mater. Pavement Des. 2020, 21, 2344–2355. [Google Scholar] [CrossRef]

- Rahgozar, M.A.; Saberian, M.; Li, J. Soil stabilization with non-conventional eco-friendly agricultural waste materials: An experimental study. Transp. Geotech. 2018, 14, 52–60. [Google Scholar] [CrossRef]

- Ghasemzadeh, H.; Mehrpajouh, A.; Pishvaei, M.; Mirzababaei, M. Effects of Curing Method and Glass Transition Temperature on the Unconfined Compressive Strength of Acrylic Liquid Polymer–Stabilized Kaolinite. J. Mater. Civ. Eng. 2020, 32, 04020212. [Google Scholar] [CrossRef]

- Mohammadinia, A.; Arulrajah, A.; Phummiphan, I.; Horpibulsuk, S.; Mirzababaei, M. Flexural fatigue strength of demolition aggregates stabilized with alkali-activated calcium carbide residue. Constr. Build. Mater. 2019, 199, 115–123. [Google Scholar] [CrossRef]

- Biswal, D.R.; Sahoo, U.C.; Dash, S.R. Fatigue Characteristics of Cement-Stabilized Granular Lateritic Soils. J. Transp. Eng. Part B Pavements 2020, 146, 04019038. [Google Scholar] [CrossRef]

- Nasiri, H.; Khayat, N.; Mirzababaei, M. Simple yet quick stabilization of clay using a waste by-product. Transp. Geotech. 2021, 28, 100531. [Google Scholar] [CrossRef]

- Lemos, S.G.F.P.; Almeida, M.D.S.S.; Consoli, N.C.; Nascimento, T.Z.; Polido, U.F. Field and Laboratory Investigation of Highly Organic Clay Stabilized with Portland Cement. J. Mater. Civ. Eng. 2020, 32, 04020063. [Google Scholar] [CrossRef]

- Wang, Y.; Guo, P.; Li, X.; Lin, H.; Liu, Y.; Yuan, H. Behavior of fiber-reinforced and lime-stabilized clayey soil in triaxial tests. Appl. Sci. 2019, 9, 900. [Google Scholar] [CrossRef] [Green Version]

- Hataf, N.; Ghadir, P.; Ranjbar, N. Investigation of soil stabilization using chitosan biopolymer. J. Clean. Prod. 2018, 170, 1493–1500. [Google Scholar] [CrossRef]

- Rashid, A.S.A.; Latifi, N.; Meehan, C.L.; Manahiloh, K.N. Sustainable Improvement of Tropical Residual Soil Using an Environmentally Friendly Additive. Geotech. Geol. Eng. 2017, 35, 2613–2623. [Google Scholar] [CrossRef]

- Smitha, S.; Rangaswamy, K. Effect of Biopolymer Treatment on Pore Pressure Response and Dynamic Properties of Silty Sand. J. Mater. Civ. Eng. 2020, 32, 04020217. [Google Scholar] [CrossRef]

- Zhang, T.; Cai, G.; Liu, S. Application of lignin-based by-product stabilized silty soil in highway subgrade: A field investigation. J. Clean. Prod. 2017, 142, 4243–4257. [Google Scholar] [CrossRef]

- Canakci, H.; Güllü, H.; Alhashemy, A. Performances of using geopolymers made with various stabilizers for deep mixing. Materials 2019, 12, 2542. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bayesteh, H.; Sharifi, M.; Haghshenas, A. Effect of stone powder on the rheological and mechanical performance of cement-stabilized marine clay/sand. Constr. Build. Mater. 2020, 262, 120792. [Google Scholar] [CrossRef]

- Ismail, M.A.; Joer, H.A.; Sim, W.H.; Randolph, M.F. Effect of cement type on shear behavior of cemented calcareous soil. J. Geotech. Geoenvironmental Eng. 2002, 128, 520–529. [Google Scholar] [CrossRef]

- Yang, X.; Nie, A.; Elsworth, D.; Zhou, J. The influence of the structural distribution and hardness of mineral phases on the size and shape of rock drilling particles. Mar. Georesour. Geotechnol. 2020, 38, 511–517. [Google Scholar] [CrossRef]

- Sadaoui, O.; Bahar, R. Field measurements and back calculations of settlements of structures founded on improved soft soils by stone columns. Eur. J. Environ. Civ. Eng. 2019, 23, 85–111. [Google Scholar] [CrossRef]

- Faro, V.P.; Consoli, N.C.; Schnaid, F.; Thomé, A.; da Silva Lopes, L. Field Tests on Laterally Loaded Rigid Piles in Cement Treated Soils. J. Geotech. Geoenviron. Eng. 2015, 141, 06015003. [Google Scholar] [CrossRef]

- Hozatlıoğlu, D.T.; Yılmaz, I. Shallow mixing and column performances of lime, fly ash and gypsum on the stabilization of swelling soils. Eng. Geol. 2021, 280, 105931. [Google Scholar] [CrossRef]

- Tsampali, E.; Tsardaka, E.C.; Pavlidou, E.; Paraskevopoulos, K.M.; Stefanidou, M. Comparative study of the properties of cement pastes modified with nano-silica and Nano-Alumina. Solid State Phenom. 2019, 286, 133–144. [Google Scholar] [CrossRef]

- Changizi, F.; Haddad, A. Strength properties of soft clay treated with mixture of nano-SiO2 and recycled polyester fiber. J. Rock Mech. Geotech. Eng. 2015, 7, 367–378. [Google Scholar] [CrossRef]

- Bahmani, S.H.; Farzadnia, N.; Asadi, A.; Huat, B.B.K. The effect of size and replacement content of nanosilica on strength development of cement treated residual soil. Constr. Build. Mater. 2016, 118, 294–306. [Google Scholar] [CrossRef]

- Baziar, M.H.; Saeidaskari, J.; Alibolandi, M. Effects of nanoclay on the treatment of core material in earth dams. J. Mater. Civ. Eng. 2018, 30. [Google Scholar] [CrossRef]

- Yao, K.; An, D.; Wang, W.; Li, N.; Zhang, C.; Zhou, A. Effect of nano-MgO on mechanical performance of cement stabilized silty clay. Mar. Georesour. Geotechnol. 2020, 38, 250–255. [Google Scholar] [CrossRef]

- Thomas, G.; Rangaswamy, K. Strengthening of cement blended soft clay with nano-silica particles. Geomech. Eng. 2020, 20, 505–516. [Google Scholar] [CrossRef]

- Choobbasti, A.J.; Samakoosh, M.A.; Kutanaei, S.S. Mechanical properties soil stabilized with nano calcium carbonate and reinforced with carpet waste fibers. Constr. Build. Mater. 2019, 211, 1094–1104. [Google Scholar] [CrossRef]

- Karimiazar, J.; Mahdad, M.; Teshnizi, E.S.; Karimizad, N. Assessing the geotechnical properties of soils treated with cement and nano-Silica additives. JOJ Sci. 2020, 2, 56–59. [Google Scholar] [CrossRef]

- Lang, L.; Liu, N.; Chen, B. Strength development of solidified dredged sludge containing humic acid with cement, lime and nano-SiO2. Constr. Build. Mater. 2020, 230, 116971. [Google Scholar] [CrossRef]

- Farzadnia, N.; Abang Ali, A.A.; Demirboga, R.; Anwar, M.P. Effect of halloysite nanoclay on mechanical properties, thermal behavior and microstructure of cement mortars. Cem. Concr. Res. 2013, 48, 97–104. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, L. Experimental studies on nanomaterials for soil improvement: A review. Environ. Earth Sci. 2016, 75, 497. [Google Scholar] [CrossRef]

- Wang, D.; Wang, H.; Wang, X. Compressibility and strength behavior of marine soils solidified with MgO, A green and low carbon binder. Mar. Georesour. Geotechnol. 2017, 35, 878–886. [Google Scholar] [CrossRef]

- Naqi, A.; Jang, J.G. Recent progress in green cement technology utilizing low-carbon emission fuels and raw materials: A review. Sustainability 2019, 11, 537. [Google Scholar] [CrossRef] [Green Version]

- Bahmani, S.H.; Huat, B.B.K.; Asadi, A.; Farzadnia, N. Stabilization of residual soil using SiO2nanoparticles and cement. Constr. Build. Mater. 2014, 64, 350–359. [Google Scholar] [CrossRef]

- Farzadnia, N.; Bahmani, S.H.; Asadi, A.; Hosseini, S. Mechanical and microstructural properties of cement pastes with rice husk ash coated with carbon nanofibers using a natural polymer binder. Constr. Build. Mater. 2018, 175, 691–704. [Google Scholar] [CrossRef]

- Majeed, Z.H.; Taha, M.R.; Jawad, I.T. Stabilization of soft soil using nanomaterials. Res. J. Appl. Sci. Eng. Technol. 2014, 8, 503–509. [Google Scholar] [CrossRef]

- Feng, R.; Wu, L.; Liu, D.; Wang, Y.; Peng, B. Lime- and Cement-Treated Sandy Lean Clay for Highway Subgrade in China. J. Mater. Civ. Eng. 2020, 32, 04019335. [Google Scholar] [CrossRef]

- Al-Rawas, A.A.; Goosen, M.F.A. Expansive Soils: Recent Advances in Characterization and Treatment; Taylor & Francis: Leiden, The Netherlands, 2006; ISBN 978-0-415-39681-3. [Google Scholar]

- Sobolev, K.; Flores, I.; Torres-Martinez, L.M.; Valdez, P.L.; Zarazua, E.; Cuellar, E.L. Engineering of SiO2 Nanoparticles for Optimal Performance in Nano Cement-Based Materials. In Nanotechnology in Construction 3; Springer: Berlin/Heidelberg, Germany, 2009; pp. 139–148. [Google Scholar] [CrossRef]

- Anggraini, V.; Asadi, A.; Farzadnia, N.; Jahangirian, H.; Huat, B.B.K. Reinforcement benefits of nanomodified coir fiber in lime-treated marine clay. J. Mater. Civ. Eng. 2016, 28, 1–8. [Google Scholar] [CrossRef]

- Krzywiński, K.; Sadowski, Ł.; Szymanowski, J.; Zak, A.; Piechówka-Mielnik, M. Attempts to improve the subsurface properties of horizontally-formed cementitious composites using tin(ii) fluoride nanoparticles. Coatings 2020, 10, 83. [Google Scholar] [CrossRef] [Green Version]

- Zhang, T.; Cai, G.; Liu, S. Application of lignin-stabilized silty soil in highway subgrade: A macroscale laboratory study. J. Mater. Civ. Eng. 2018, 30, 1–16. [Google Scholar] [CrossRef]

- Gallagher, P.M.; Mitchell, J.K. Influence of colloidal silica grout on liquefaction potential and cyclic undrained behavior of loose sand. Soil Dyn. Earthq. Eng. 2002, 22, 1017–1026. [Google Scholar] [CrossRef]

- Taha, M.R.; Taha, O.M.E. Influence of nano-material on the expansive and shrinkage soil behavior. J. Nanopart. Res. 2012, 14, 1190. [Google Scholar] [CrossRef]

- Edil, T.B.; Benson, C.H.; Bin-Shafique, M.; Tanyu, B.F.; Kim, W.-H.; Senol, A. Field Evaluation of Construction Alternatives for Roadways over Soft Subgrade. Transp. Res. Rec. J. Transp. Res. Board 2002, 1786, 36–48. [Google Scholar] [CrossRef]

- Hooshmand, A.; Aminfar, M.H.; Asghari, E.; Ahmadi, H. Mechanical and Physical Characterization of Tabriz Marls, Iran. Geotech. Geol. Eng. 2012, 30, 219–232. [Google Scholar] [CrossRef]

- Bahadori, H.; Hasheminezhad, A.; Taghizadeh, F. Experimental Study on Marl Soil Stabilization Using Natural Pozzolans. J. Mater. Civ. Eng. 2018, 31, 04018363. [Google Scholar] [CrossRef]

- Pakbaz, M.S.; Alipour, R. Influence of cement addition on the geotechnical properties of an Iranian clay. Appl. Clay Sci. 2012, 67–68, 1–4. [Google Scholar] [CrossRef]

- Ebrahimnezhad Sadigh, E.; Moradi, G. Geotechnical Properties Improvement of Disturbed Tabriz Marl By Chemical Method. Electron. J. Geotech. Eng. 2017, 22, 3787–3796. [Google Scholar]

- Mahouti, A.; Katebi, H.; Akhlaghi, T. Ultimate Bond Stress between the Cement Grout and Tabriz Marl Soil Measured by Laboratory and Full-scale Experiments. Electron. J. Geotech. Eng. 2017, 22, 2881–2892. [Google Scholar]

- Sadrekarimi, J.; Zekri, A.; Majidpour, H. Geotechnical Features of Tabriz Marl; The Geological Society of London: London, UK, 2006; pp. 1–9. [Google Scholar]

- Zahedi, P.; Rezaei-Farei, A.; Soltani-Jigheh, H. Performance Evaluation of the Screw Nailed Walls in Tabriz Marl. Int. J. Geosynth. Gr. Eng. 2021, 7, 1. [Google Scholar] [CrossRef]

- Azarafza, M.; Ghazifard, A. Urban geology of Tabriz City: Environmental and geological constraints. Adv. Environ. Res. 2016, 5, 95–108. [Google Scholar] [CrossRef] [Green Version]

- Asghari-Kaljahi, E.; Barzegari, G.; Jalali-Milani, S. Assessment of the swelling potential of Baghmisheh marls in Tabriz, Iran. Geomech. Eng. 2019, 18, 267–275. [Google Scholar] [CrossRef]

- ASTM C150/C150M-21, Standard Specification for Portland Cement; ASTM International: West Conshohocken, PA, USA, 2021; Volume 4, pp. 134–138. [CrossRef]

- Taha, M.R. Geotechnical Properties of Soil-Ball Milled Soil Mixtures. In Nanotechnology in Construction 3; Springer: Berlin/Heidelberg, Germany, 2009; pp. 377–382. [Google Scholar] [CrossRef]

- ASTM, D. 3080--4: 2004, Standard Test Method for Direct Shear Test of Soils under Consolidated Drained Conditions; ASTM International: West Conshohocken, PA, USA, 2004. [Google Scholar] [CrossRef]

- Karimiazar, J.; Sharifi Teshnizi, E.; Mirzababaei, M.; Mahdad, M.; Arjmandzadeh, R. California bearing ratio of a reactive clay treated with nano-additives and cement. ASCE J. Mater. Civ. Eng. 2021. [Google Scholar] [CrossRef]

- Choobbasti, A.J.; Kutanaei, S.S. Microstructure characteristics of cement-stabilized sandy soil using nanosilica. J. Rock Mech. Geotech. Eng. 2017, 9, 981–988. [Google Scholar] [CrossRef]

- Arabani, M.; Haghi, A.K.; Mohammadzade, S.A.; Kamboozia, N. Use of Nanoclay for Improvement the Microstructure and Mechanical Properties of Soil. In Proceedings of the 4th International Conference on Nanostructures (ICNS4), Kish Island, Iran, 12–14 March 2012; pp. 1552–1554. [Google Scholar]

- Taylor, H.F.W. Nanostructure of CSH: Current status. Adv. Cem. Based Mater. 1993, 1, 38–46. [Google Scholar] [CrossRef]

- Emmanuel, E.; Lau, C.C.; Anggraini, V.; Pasbakhsh, P. Stabilization of a soft marine clay using halloysite nanotubes: A multi-scale approach. Appl. Clay Sci. 2019, 173, 65–78. [Google Scholar] [CrossRef]

- Hou, P.; Wang, K.; Qian, J.; Kawashima, S.; Kong, D.; Shah, S.P. Effects of colloidal nanoSiO2 on fly ash hydration. Cem. Concr. Compos. 2012, 34, 1095–1103. [Google Scholar] [CrossRef] [Green Version]

- Bowles, J.E. Foundation Analysis and Design, 3rd ed.; Wiley-Interscience: Hoboken, NJ, USA, 1996. [Google Scholar]

- Holtz, R.D.; Kovacs, W.D.; Sheahan, T.C. An Introduction to Geotechnical Engineering, 2nd ed.; Prentice-Hall: Englewood Cliffs, NJ, USA, 2011. [Google Scholar]

| Physical Properties | Value |

|---|---|

| Gravel (%) | 0 |

| Sand (%) | 4 |

| Silt (%) | 55 |

| Clay (%) | 41 |

| Liquid limit (LL) (%) | 42.0 |

| Plastic limit (%) | 17.0 |

| Plasticity index (%) | 25.0 |

| Shrinkage limit (%) | 12.7 |

| Specific gravity (Gs) | 2.73 |

| Soil classification (USCS) | CI |

| Activity (%) | 0.61 |

| Physical State | APS * (nm) | SSA ** (m2g−1) | Color | Particle Density (gcm−3) | Morphology | |

|---|---|---|---|---|---|---|

| Nano-silica (SiO2) | Solid | 11–13 | 200 | white | 2.40 | Amorphous |

| Nano-alumina (Al2O3) | Solid | 20 | 138 | white | 3.89 | Nearly spherical |

| Chemical Properties | Value | Physical Properties | Value |

|---|---|---|---|

| SiO2 (%) | 23.13 | Fineness (%) | 1.54 |

| Al2O3 (%) | 5.53 | Specific gravity | 3.00 |

| Fe2O3 (%) | 3.51 | ||

| CaO (%) | 58.95 | ||

| MgO (%) | 1.18 | ||

| Na2O (%) | 0.33 | ||

| K2O (%) | 0.85 | ||

| SO3 (%) | 2.19 | ||

| Insoluble Residue | |||

| LOI | 6.36 | ||

| Free Lime | 3.41 |

| Mix Name | Cement (%) | Nano-Silica (%) | Nano-Alumina (%) | OMC * (%) | MDU ** (kNm−3) |

|---|---|---|---|---|---|

| Marl | 0 | 0.0 | 0.0 | 17.0 | 17.1 |

| Marl-3C | 3 | 0.0 | 0.0 | 19.6 | 17.2 |

| Marl-3C-0.1NS | 3 | 0.1 | 0.0 | 21.6 | 16.8 |

| Marl-3C-0.5NS | 3 | 0.5 | 0.0 | 22.2 | 16.7 |

| Marl-3C-1.0NS | 3 | 1.0 | 0.0 | 22.4 | 16.4 |

| Marl-3C-1.5NS | 3 | 1.5 | 0.0 | 23.8 | 16.3 |

| Marl-3C-0.1NA | 3 | 0.0 | 0.1 | 22.3 | 16.9 |

| Marl-3C-0.5NA | 3 | 0.0 | 0.5 | 23.0 | 16.7 |

| Marl-3C-1.0NA | 3 | 0.0 | 1.0 | 25.0 | 16.6 |

| Marl-3C-1.5NA | 3 | 0.0 | 1.5 | 26.0 | 16.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mirzababaei, M.; Karimiazar, J.; Sharifi Teshnizi, E.; Arjmandzadeh, R.; Bahmani, S.H. Effect of Nano-Additives on the Strength and Durability Characteristics of Marl. Minerals 2021, 11, 1119. https://doi.org/10.3390/min11101119

Mirzababaei M, Karimiazar J, Sharifi Teshnizi E, Arjmandzadeh R, Bahmani SH. Effect of Nano-Additives on the Strength and Durability Characteristics of Marl. Minerals. 2021; 11(10):1119. https://doi.org/10.3390/min11101119

Chicago/Turabian StyleMirzababaei, Mehdi, Jafar Karimiazar, Ebrahim Sharifi Teshnizi, Reza Arjmandzadeh, and Sayed Hessam Bahmani. 2021. "Effect of Nano-Additives on the Strength and Durability Characteristics of Marl" Minerals 11, no. 10: 1119. https://doi.org/10.3390/min11101119

APA StyleMirzababaei, M., Karimiazar, J., Sharifi Teshnizi, E., Arjmandzadeh, R., & Bahmani, S. H. (2021). Effect of Nano-Additives on the Strength and Durability Characteristics of Marl. Minerals, 11(10), 1119. https://doi.org/10.3390/min11101119