AI4R2R (AI for Rock to Revenue): A Review of the Applications of AI in Mineral Processing

Abstract

:1. Introduction: Pain-Points in Mineral Processing

- 1.

- Ore preparation, which consists of steps, including selective mining (for various reasons), ore blending, and other pre-concentration techniques.

- 2.

- Comminution, where the size of the ore is reduced.

- 3.

- Sizing, where particles of certain sizes are passed on to the next stage.

- 4.

- Concentration, where particles with higher concentration are filtered out in stages so that the mineral concentration in the overall material goes up.

- 5.

- Dewatering, where the water from the particles is removed.

1.1. Some of the Current Challenges in Mineral Processing

- There is a need to extract multiple minerals (complex composition) from the same ore. Or, there is a need to extract minerals of various concentrations from the same ore.

- The quality of the deposit is high but the size or accumulation is low.

- The quality of the deposit is low but the accumulation is high.

- Lastly, due to the recent interest in green and sustainable development, there is increasing importance on ethical and green mining with minimized climate and material footprint of the whole process chain [6]. This has also created a scarcity in ores.

- 1.

- No One Size Fits All: Traditionally, mineral processing techniques and machines have been uniform across operations. Even if there is fine-tuning involved for each site, the process parameters are not often changed. Ores were more or less consistent in their properties. When we are (figuratively) scraping the bottom of our deposit barrels, the properties of the ores are no longer consistent. This requires the real-time fine-tuning of process parameters. This is a domain where the application of ML and AI has shown considerable success in many domains [7,8,9]. This is expected to be one of the major applications of ML and AI in mineral processing shortly. These applications of AI would mostly not require major installation changes.

- 2.

- Reducing Human Error: Mineral processing plants are well-oiled processes. A small mistake can stop the process, and each hour costs an exorbitant amount of losses. Often, these mistakes are human-errors. There has always been a need to automate systems to avoid these. The need, now, is more acute. With the quality of ore diminishing, mineral processing plants are becoming more sophisticated. They come with numerous sensors whose values should be interpreted in real-time. These sensors are not human-perceivable. This means that these are not pictures or sounds for which humans have well-established sensory facilities. Interpreting data from these sensors requires a great deal of training and experience. This increases the chances of human error.This is where ML and AI can really make a difference. Current generation deep learning (DL) algorithms are extremely good correlation extractors [10]. In terms of extracting correlations, they are better than humans [11,12], especially for non-optical and non-audio types of sensory data. With a human in the loop (to make the executive decisions) and AI algorithms to interpret the sensory data, the chances of human-error can be reduced substantially. Sensors and AI are integral parts of most AI solutions. Hence, sensor and AI (SensAI) developments should always be done in a co-development model.

1.2. Ever Expanding Meaning of Mineral Processing

- Mineral Processing for Urban Mining: Recycling and the circular economy (CE) have been taking an increasingly central position in the world order. Extracting metals and materials from urban waste can be called urban mining. The processing needed for this new kind of mining can also be called mineral processing. For example, harvesting Lithium from Lithium ion batteries, which is a prominent e-waste. Another interesting example is the use of living organisms to harvest metals from waste [13] (like the use of microorganisms to recover metal from discarded printed circuit boards [14]).Recycling, especially in the case of certain metals, such as aluminium, is a well established business. The mineral processing needed for this traditional recycling is mostly simple. However, shortly, we will need to extract metals that are in very low concentrations from waste. This will require sophisticated mineral processing. AI has a major role to play in this. New companies, like Zen Robotics, are already pushing the boundaries in terms of sophisticated waste sorting using AI [15].Secondly, in a circular economy, where there is no real beginning and end of materials, it will be difficult to exactly pinpoint the processes that can be called mineral processing. The preparation of ores for comminution is an integral part of mineral processing. In a circular economy, tracing the possible materials that will become a resource for the next slot of mining would also be a part of mineral processing. The role of SensAI is pivotal in tracing metals in circulation. For example, a group from Sweden has done made interesting innovations on the use of embedded sensors to trace metals in circulation [16].

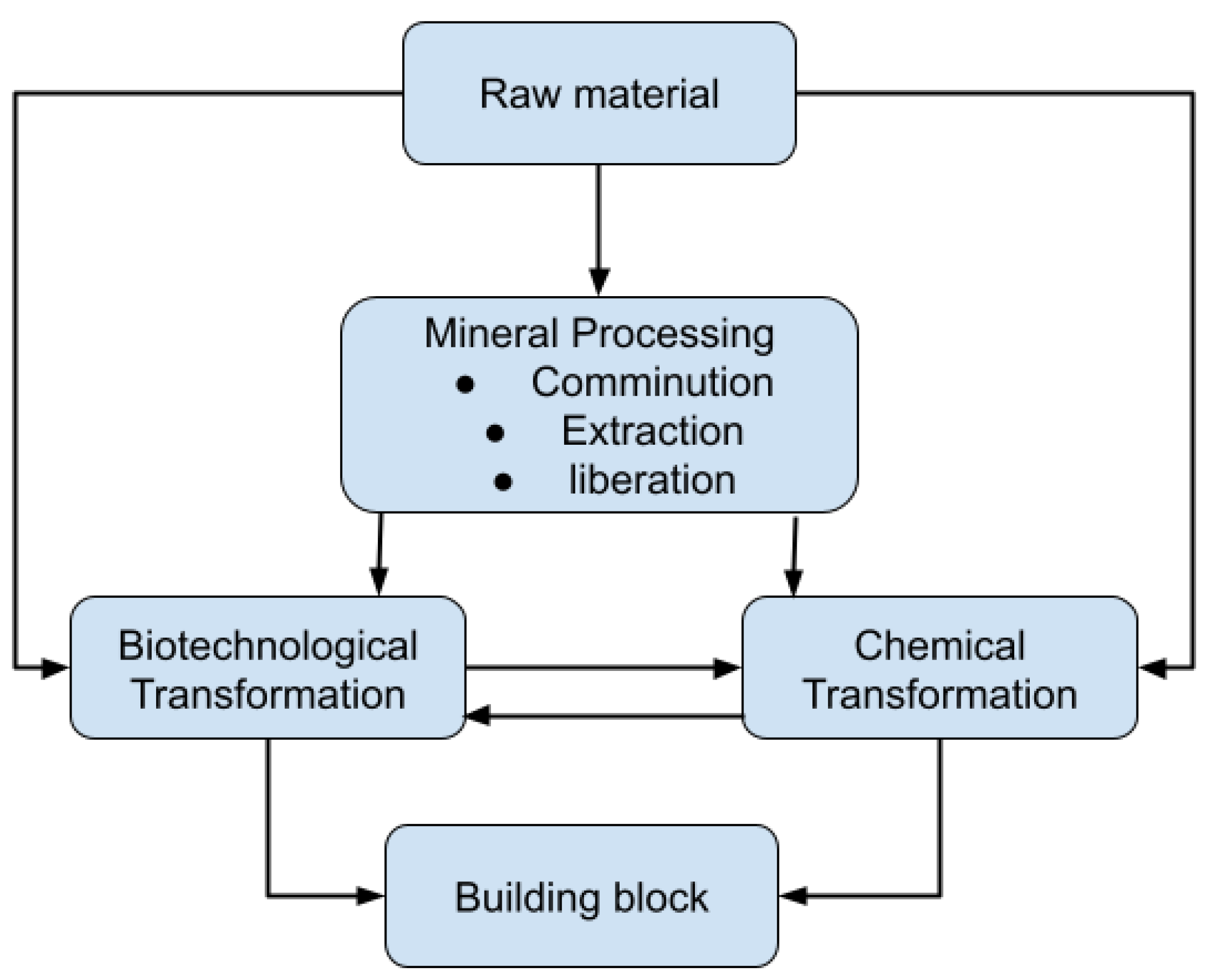

- Renewable Mining: Renewables providing fuels and raw materials will become more common soon. If we can term the process of extracting materials and fuels from renewables as renewable mining then the preprocessing involved in these plants can also be termed as mineral processing. For example, work towards the use of biomass to produce polymeric materials, organic chemicals, and fuel [17,18] has been going on since the 1970s. Bio-diesel [19] is one of the many materials, currently being produced from renewables.The process chain of renewables (refer Figure 1 [20]) mostly involves steps that are the same as some of the steps followed in traditional mineral processing. SensAI will, again, play a pivotal role in these processes. AI can also be useful in recommending refined process chains for new kinds of renewable materials [16].

2. A Review of AI and ML Algorithms

- Artificial Intelligence (AI): The wish to create something intelligent is as old as human intelligence itself. The endeavours were formalized by Turing in his elegant work [23] that gave us the famous Turing Test. I strongly suggest this work to anyone interested in AI. However, the Turing test is based on the concept of a universal Turing machine [24].The meaning of “intelligence” itself is a hot field of research [25,26,27]. If and when intelligence can be defined analytically, implementing it using a Turing machine will be an easy follow-up step. Hence, some in the AI field are trying to approach the challenge from another angle. What if there is no mathematical framework to capture intelligence? The machine to implement AI need not be a Turing machine [28].With this extremely short historical summary of the domain of AI, I note that AI is the super-set of all the pertinent endeavours. I, now, discuss ML and DL, which are subsets of AI.

- Machine Learning (ML): Machine learning, as a domain, involves algorithms that can use experiences and learn from them. Experiences, are mostly in the form of data that the ML algorithm uses to build models. These models are, in turn, used to perform a range of actions, such as pattern classification, recognition, anomaly detection, prediction, and regression. Arthur Samuel was the person who first used the phrase machine learning in his interesting work on modelling checkers [29].

- Deep Learning (DL): Deep learning is a subset of artificial neural networks (ANN), which is a subset of ML. ANNs have been around for more than seven decades. Hebbian networks [30] were one of the initial ANNs to be studied. Cybenko’s work on the universal approximation capabilities of a sigmoid-based ANN [31] gave strong mathematical reason to expect a great deal from ANNs. However, there have been many brick walls that did not give traditional ANNs as many successes. With a few interesting innovations, deeper ANNs became more practical. One of the biggest advantages of deeper ANN was the fact that they can learn features on their own from data. Readers are suggested to refer to an excellent introduction to deep learning written by some of its founding fathers [10].

- 1.

- Generative ML: This is the more traditional approach to ML. The underlying hypothesis is that measured data is always noisy. Hence, we cannot trust data! A model was needed that could describe the data and noise together. Traditionally, statistical models fit the requirements. Hence, in Generative ML, it is assumed that there is an underlying model that is generating the data. The more we understand this model, the more we know about the data. Statistical models are characterized by model parameters. Hence, statistical ML focuses on estimating these parameters and is also called ML. There are excellent textbooks on this subject [36,37].The second revolution of generative ML came after the invention of the generative adversarial network (GAN) [38], which is a semi-parametric generative ML algorithm. The reason it is semi-parametric is that, even though it does not intend to build a statistical model, it still uses parametric statistics in comparing the generative and adversarial branches.

- 2.

- Discriminative ML: In discriminative ML the data is trusted! The data is used to build ML models. The reason these algorithms are called discriminative is that in this the boundary that discriminates two classes or a class-limits is directly learned using the data.Some of the oldest ML algorithms, like [36], are discriminative in nature. Most ANN-based algorithms are discriminative in nature. One of the classic non-ANN discriminative ML algorithm is a support vector machine [37].Some of the most successful discriminative ML algorithms include convolutional neural network (CNN) and recurrent neural network (RNN). The readers are referred to one of the classic reviews in DNN to learn more about these algorithms [10].

2.1. A Thumb-Rule to Choose AI/ML Algorithms

- 1.

- The classic algorithm can always be taken as a starting point. It is easy to implement and can be used as a standard to compare other algorithms against.

- 2.

- Support Vector Machines (SVMs) are very powerful. Unlike most ANN-based algorithms, SVMs are analytically well-founded. In other words, they are not black-box solutions. Many times, when one does not have a sufficient amount of representative data for a problem, SVMs outperform DNNs. SVMs are also often faster than DNNs. In using SVMs, it is advisable to use as much domain knowledge as possible to extract useful features from the data. Feature engineering is not a forte of SVM.

- 3.

- In exploring DNNs, it is advisable to start with a CNN with a small number of convolutional units (CUs). This helps in analysing the filters learned by the CUs. This builds some amount of explainability into the solution.

- 4.

- If the problem at hand is time-based (e.g., predicting the output of a flotation cell) then recurrent networks, such as Long Short-term Memory (LSTM) networks, could be useful.

- 5.

- CNNs are very effective in feature learning. Hence, often, the architecture may have a CNN followed by an LSTM. A CNN followed by an SVM is also a potential solution.

- 6.

2.2. Future Tends

- eAI: AI algorithms need to be explainable, ethical, and empathetic. Explainable AI (xAI) is a major stream of development in the AI fraternity. One of the greatest developments in this direction has been the recent work toward bridging the gap between discriminative and generative AI. The development of generative AI models (GAN [38] being one of the most popular and powerful versions of it) started using neural networks not only to predict the discriminative boundaries of a given data-point but also to generate the data itself. Thus far, this has been the forte of statistical machine learning. This, for me, is the starting point of xAI. The readers can refer to one of my informal articles [44] on interpretable AI for some further light discussion around xAI.

- Perception in the Loop: The importance of human perception is receiving a great deal of attention of late. Any real-life AI system will need to take this into account. I am not talking about making AI systems perceive things, such as humans [45]. That is a great goal for hard-AI scientists. I am talking about quantifying human perception and using it in training neural network models. Such perception-centric AI [46] systems will be crucial towards the adoption of AI in complex systems, such as industries and smart cities.

- Intuition-Based AI: The lack of a sufficient amount of data and the lack of generalized transferability are two challenges that I discussed above. Bio-inspired computational approaches have always given us new ways to look at problems. One brain-inspired approach that may enable AI algorithms to solve both the data and the transferability challenges is “intuition”. Intuition-centered AI models [47] can use less amount of “right kind” of data to build robust models. It can also give directions to have an architecture that can leverage fusing symbolic and non-symbolic AI [48] to have a modus operandi to enable better transferability of models in the industrial ecosystem.

3. Existing Research, Development & Innovation (RDI) on the Use of ML and AI in Mineral Processing

3.1. ML and AI in Comminution and Sizing

3.2. ML and AI in Concentration and Dewatering

3.3. ML and AI in Operations

3.4. ML and AI in Ethical and Green Mineral Processing

- Tailing: Tailing is a major harmful effect of mineral processing that can severely affect the safety of the local community, the local water resources, vegetation, and biodiversity. They can also affect the rainwater flow and hence affect the courses of the nearby rivers. A recent standard [87] by by the United Nations Environment Programme (UNEP), the Principles for Responsible Investment (PRI) and the International Council on Mining and Metals (ICMM) sets strict standards in terms of tailing management. This has resulted in the acceleration of research in this domain [88].

- Wastewater Management: Most mineral processing operations are severely water-intensive. This affects the local water resources in two ways. It stresses the limited water resources. Wastewater from the plant can detrimentally affect the local reserves in detrimental way. Measurement is the key. The use of Internet of Things (IoT) based sensor-network as well as remote sensing would help in making sure that the both the water usage of the plant as well as quality (and quantity) of wastewater disposed of by the plant is strictly monitored.It is encouraging to note that, of late, multiple earth-observing satellites have been launched with specialized sensors, such as multi-band synthetic aperture radar (SAR) [95,96], soil-moisture mapping (SMAP) sensors [97] and hyperspectral sensors [98]. For mineral processing, hyperspectral sensors with AI hold tremendous possibilities [99].

- Hazardous Gas and Dust Emissions: Gases emitted by mineral processing can be dangerous when the concentration goes beyond a certain limit. For the safety of the workers and of the people living in the immediate vicinity, close monitoring of the levels of gas and dust would be highly advisable. Recent pieces of work have shown the potential of using SensAI for dust level monitoring [100,101,102]. Similarly, research in the domain of the use of SensAI for hazardous gas detection is growing rapidly [103,104,105]. The use of SensAI for gas and dust monitoring in a mineral processing plant is deemed to bear good results.

4. The Futuristic Use-Cases

4.1. Chemical Discovery

4.2. Process Diagnosis, Recommendation and Modification

- 1.

- End to End Modelling: In this approach, the complete process is modelled as a black-box. Depending on how well sampled the data-space is (depending on strategically placed sensors and sensing-timing), deep learning networks can learn a process quite well. Especially in industrial processes where the chances of abrupt changes are lower, deep learning can be a powerful solution.

- 2.

- Latent Parameter Modelling: In this approach, the machine learning algorithm endeavours to model not only the end-to-end characteristics of a process but also its latent causes. The Bayesian mixture model has been particularly successful in modelling latent factors (which may or may not have phenomenological interpretation) [111,112].

5. Suggested Modus Operandi to Investigate AI for a Specific Mineral Processing Challenge

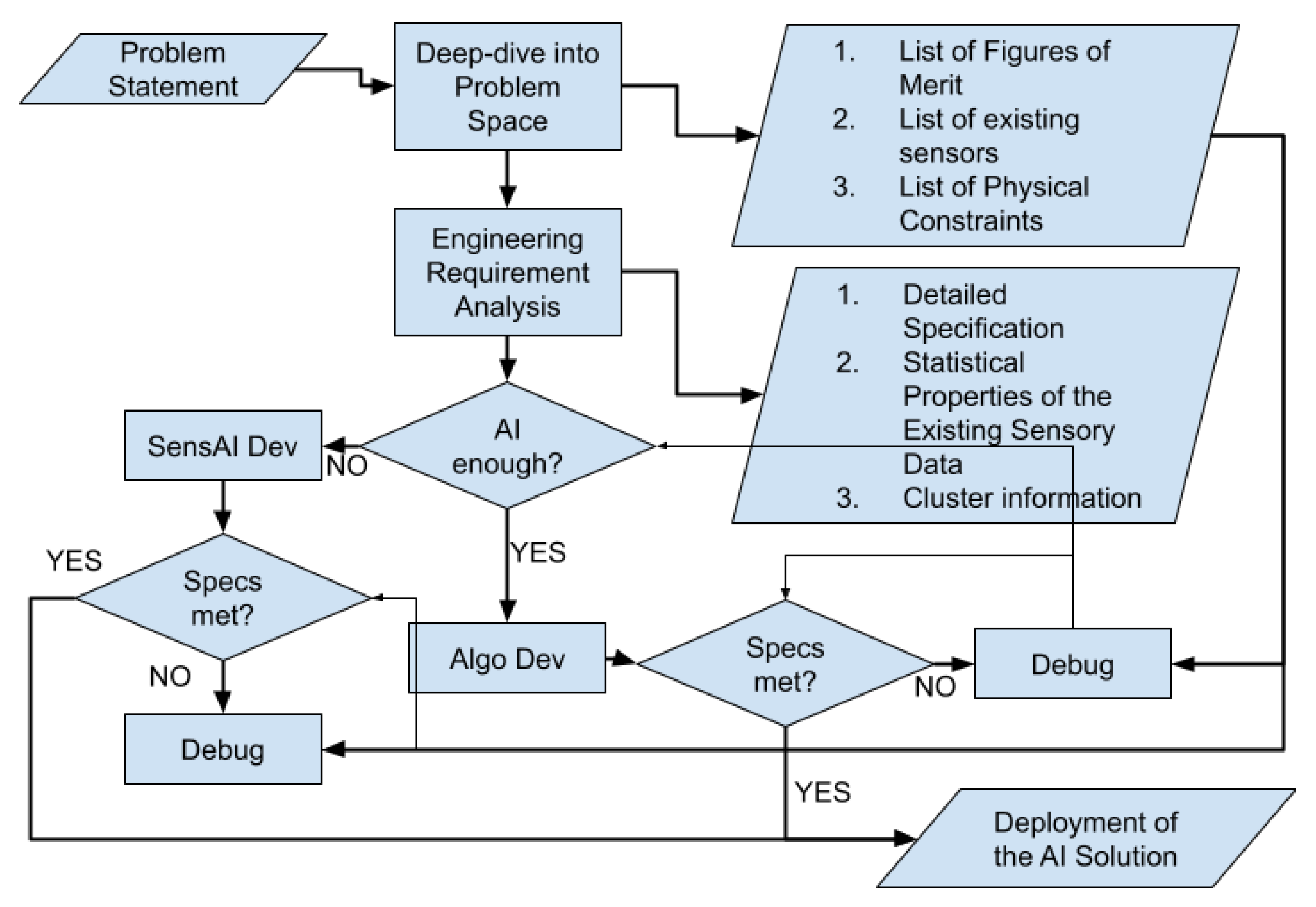

- 1.

- Immersion in the Problem Space (data): Design thinking [122] methodologies strongly suggest one to spend as much time as one can in the problem space. This is of particular importance in industrial AI innovation projects. The following are some of the important steps one can take in this phase.Figures of Merit: The famous theorem of “no free lunch” [123,124] roughly tells us that there is no universal algorithm that can solve all the problems. An algorithm can be good at a certain task but will not perform as well in other problems. The corollary of this is that, to find an algorithm that performs very well, the problem needs to be defined very well.Defining the problem, invariably, means finding the best set of figures of merits. A classic example is target detection algorithm design in radar systems [125]. For a radar systems, the probability of a false alarm is more important than the probability of detection.Given an AI-challenge in mineral processing, we need, first of all, to list how the decision of the proposed AI system will affect the operations.In ML, it is relatively easy to take care of a set of figures of merit each of which has different importance. One of the ways to achieve this is by using a weighted sum of loss function [126,127,128,129].The Data Space: Exploratory data analysis [130,131] is always recommended as a step to spend some time in. Irrespective of the problem at hand, some data can always be obtained from the process plant. Analysis of the statistics of the data and the clustering of the data from different sources are some of the recommended steps. First of all, most ML algorithms work the best with Gaussian data. Hence, it is always useful to know if the data distribution is going to deviate substantially from a normal distribution [132]. Secondly, even using simple principal component analysis (PCA) [133] to visualize the data in three dimensions can lead to interesting data models [134].At this stage, it is also advisable to endeavour to find out as much as possible about pertinent statistical bounds [135], viz. Cramér–Rao bound (CRB) [136], Fisher Information [137] etc.The Physical Space: While investigating the feasibility of AI for any industrial application it is highly recommended to visit the physical space. The more we know about the actual physical space and operation, the better equipped we will be to take care of interesting bugs that may arise later. An infamous case study is the mysterious signal detected by radio astronomers in Australia, which was later identified as radio frequency interference coming from an old microwave oven [138]!The end of this phase should also give a list of detailed specifications that have to be met by the AI-solution.

- 2.

- AI or SensAI?: After having a deep dive into the problem space, one needs to decide on the next important choice. AI systems can be implemented either using existing sensory data or by using new sensors. The first case where we already have the sensors in place will involve innovations in the algorithm space only and can be called AI-only development. In the second case where the most informative data is not available, we can go for the installation of new sensors. In this case, the sensors and AI algorithms are co-innovated and co-developed. For example, hyperspectral imaging [139] and high-energy ultrasound sensors [140] have shown good potential in ore quality analysis. Combined with ML, hyperspectral imaging can be used in many stages of mineral processing to customize the process parameters depending on the ore quality [141].However, in most heavy industries, any change to the existing setup is extremely costly (especially as it can lead to down time). Hence, the engineers are highly encouraged to thoroughly investigate what can be achieved by using the existing sensory-data. The use of AI can also, in some cases, aid us in generating secondary data that correlates well to a non-existing sensor using data from existing sensors. This is sometimes called soft-sensors [142].

- 3.

- Development, Debug and Deployment: This last step is not common to any engineering development. Depending on the route chosen in the previous step the development would either be algorithm development or a co-development of a SensAI system. If the performance of the solution meets the specifications, then it can be taken to commissioning. However, this rarely happens in the first iteration. In the debug process, the insights gathered in the deep-dive phase can be used effectively. At times, there might be statistical limits preventing us from achieving the specifications. In that case, we would need to change the sensors or the setup or need to adjust the specifications.

6. Conclusions

Funding

Conflicts of Interest

Nomenclature

| AI | Artificial Intelligence |

| ML | Machine Learning |

| CE | Circular Economy |

| SensAI | Sensing and AI |

| DL | Deep Learning |

| ANN | Artificial Neural Network |

| CNN | Convolutional Neural Network |

| GAN | Generative Adversarial Network |

| RNN | Recursive Neural Network |

| SVM | Support Vector Machine |

| CU | Convolutional Unit |

| LSTM | Long Short-Term Memory |

| RDI | Research, Development and Innovation |

| UNEP | United Nations Environment Programme |

| ICMM | International Council on Mining and Metals |

| PRI | Principles for Responsible Investment |

| SAR | Synthetic Aperture Radar |

| SMAP | Soil-Moisture Mapping |

| LVSR | Large Vocabulary Speech Recognition |

| PCA | Principal Component Analysis |

| CRB | Cramèr–Rao bound |

| ASIN | Application-Specific Instrumentation |

| IoT | Internet of Things |

References

- Kelly, E.G.; Spottiswood, D.J. Introduction to Mineral Processing; John Wiley & Sons Inc.: Hoboken, NJ, USA, 1982. [Google Scholar]

- Gupta, A.; Yan, D.S. Mineral Processing Design and Operations: An Introduction; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Mudd, G.M. Sustainable/responsible mining and ethical issues related to the Sustainable Development Goals. Geol. Soc. Lond. Spec. Publ. 2021, 508, 187–199. [Google Scholar] [CrossRef]

- Trends and Challenges for Technology in Mineral Processing. Available online: https://www.australianmining.com.au/news/trends-challenges-technology-mineral-processing/ (accessed on 17 September 2021).

- Evolving to Meet Future Challenges in Mining and Minerals Processing. Available online: https://www.hatch.com/About-Us/Publications/Blogs/2020/02/Evolving-to-meet-future-challenges-in-mining-and-minerals-processing (accessed on 17 September 2021).

- Jiskani, I.M.; Cai, Q.; Zhou, W.; Shah, S.A.A. Green and climate-smart mining: A framework to analyze open-pit mines for cleaner mineral production. Resour. Policy 2021, 71, 102007. [Google Scholar] [CrossRef]

- Ali, D.; Frimpong, S. Artificial intelligence, machine learning and process automation: Existing knowledge frontier and way forward for mining sector. Artif. Intell. Rev. 2020, 53, 6025–6042. [Google Scholar] [CrossRef]

- Min, Q.; Lu, Y.; Liu, Z.; Su, C.; Wang, B. Machine learning based digital twin framework for production optimization in petrochemical industry. Int. J. Inf. Manag. 2019, 49, 502–519. [Google Scholar] [CrossRef]

- Kwame Osei, E. Machine Learning-Based Quality Prediction in the Froth Flotation Process of Mining. Master’s Thesis, Dalarna University, Falun, Sweden, 2019. [Google Scholar]

- Hinton, G.; LeCun, Y.; Bengio, Y. Deep learning. Nature 2015, 521, 436–444. [Google Scholar]

- Froomkin, A.M.; Kerr, I.; Pineau, J. When AIs outperform doctors: Confronting the challenges of a tort-induced over-reliance on machine learning. Ariz. Law Rev. 2019, 61, 33. [Google Scholar]

- Sejnowski, T.J. The unreasonable effectiveness of deep learning in artificial intelligence. Proc. Natl. Acad. Sci. USA 2020, 117, 30033–30038. [Google Scholar] [CrossRef] [Green Version]

- Staicu, L.C.; Stolz, J.F. Microbes vs. metals: Harvest and recycle. FEMS Microbiol. Ecol. 2021, 97, fiab056. [Google Scholar] [CrossRef]

- Argumedo-Delira, R.; Díaz-Martínez, M.E.; Gómez-Martínez, M.J. Microorganisms and plants in the recovery of metals from the printed circuit boards of computers and cell phones: A mini review. Metals 2020, 10, 1120. [Google Scholar] [CrossRef]

- Lukka, T.J.; Tossavainen, T.; Kujala, J.V.; Raiko, T. Zenrobotics recycler–robotic sorting using machine learning. In Proceedings of the International Conference on Sensor-Based Sorting (SBS), Aachen, Germany, 11–13 March 2014; pp. 1–8. [Google Scholar]

- Carlsson, R.; Elmquist, L.; Johansson, C. Cast metal with intelligence–from passive to intelligent cast components. In Proceedings of the VIII ECCOMAS Thematic Conference on Smart Structures and Materials (SMART), Madrid, Spain, 5–8 June 2017. [Google Scholar]

- Sarkanen, K.V. Renewable resources for the production of fuels and chemicals. Science 1976, 191, 773–776. [Google Scholar] [CrossRef]

- Narayan, R. Biomass (renewable) resources for production of materials, chemicals, and fuels: A paradigm shift. In Emerging Technologies for Materials and Chemicals from Biomass; American Chemical Society: Washington, DC, USA, 1992. [Google Scholar]

- Amin, A. Review of diesel production from renewable resources: Catalysis, process kinetics and technologies. Ain Shams Eng. J. 2019, 10, 821–839. [Google Scholar] [CrossRef]

- Peuker, U.; Kwade, A.; Teipel, U.; Mütze, T. Mineral Processing Mineral, Renewable and Secondary Raw Material Processing—Current Engineering Challenges; ProcessNet Subject Divisions: Frankfurt, Germany, 2012. [Google Scholar]

- Fu, Y.; Aldrich, C. Deep Learning in Mining and Mineral Processing Operations: A Review. IFAC-PapersOnLine 2020, 53, 11920–11925. [Google Scholar] [CrossRef]

- McCoy, J.T.; Auret, L. Machine learning applications in minerals processing: A review. Miner. Eng. 2019, 132, 95–109. [Google Scholar] [CrossRef]

- Turing, A.M.; Haugeland, J. Computing Machinery and Intelligence; MIT Press: Cambridge, MA, USA, 1950. [Google Scholar]

- Turing, A.M. On computable numbers, with an application to the Entscheidungsproblem. Proc. Lond. Math. Soc. 1937, 2, 230–265. [Google Scholar] [CrossRef]

- Pfeifer, R.; Scheier, C. Understanding Intelligence; MIT Press: Cambridge, MA, USA, 2001. [Google Scholar]

- Sternberg, R.J. Intelligence; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2013. [Google Scholar]

- Haier, R.J. The Neuroscience of Intelligence; Cambridge University Press: Cambridge, UK, 2016. [Google Scholar]

- Blum, M.; Blum, L. A theoretical computer science perspective on consciousness. J. Artif. Intell. Conscious. 2021, 8, 1–42. [Google Scholar] [CrossRef]

- Samuel, A.L. Some studies in machine learning using the game of checkers. IBM J. Res. Dev. 1959, 3, 210–229. [Google Scholar] [CrossRef]

- Hebb, D.O. The Organisation of Behaviour: A Neuropsychological Theory; Science Editions: New York, NY, USA, 1949. [Google Scholar]

- Cybenko, G. Approximation by superpositions of a sigmoidal function. Math. Control Signals Syst. 1989, 2, 303–314. [Google Scholar] [CrossRef]

- Available online: https://pytorch.org/ (accessed on 15 April 2021).

- Available online: https://www.tensorflow.org (accessed on 15 April 2021).

- Riesenhuber, M.; Poggio, T. Hierarchical models of object recognition in cortex. Nat. Neurosci. 1999, 2, 1019–1025. [Google Scholar] [CrossRef]

- Bengio, Y.; Lecun, Y.; Hinton, G. Deep learning for AI. Commun. ACM 2021, 64, 58–65. [Google Scholar] [CrossRef]

- Fukunaga, K. Introduction to Statistical Pattern Recognition; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- James, G.; Witten, D.; Hastie, T.; Tibshirani, R. An Introduction to Statistical Learning; Springer: New York, NY, USA, 2013; Volume 112. [Google Scholar]

- Goodfellow, I.; Pouget-Abadie, J.; Mirza, M.; Xu, B.; Warde-Farley, D.; Ozair, S.; Courville, A.; Bengio, Y. Generative adversarial nets. In Advances in Neural Information Processing Systems; Morgan Kaufmann Publishers Inc.: Burlington, MA, USA, 2014; Volume 27. [Google Scholar]

- Nguyen, H.; La, H. Review of deep reinforcement learning for robot manipulation. In Proceedings of the 2019 Third IEEE International Conference on Robotic Computing (IRC), Naples, Italy, 25–27 February 2019; pp. 590–595. [Google Scholar]

- Nian, R.; Liu, J.; Huang, B. A review on reinforcement learning: Introduction and applications in industrial process control. Comput. Chem. Eng. 2020, 139, 106886. [Google Scholar] [CrossRef]

- Levine, S.; Kumar, A.; Tucker, G.; Fu, J. Offline reinforcement learning: Tutorial, review, and perspectives on open problems. arXiv 2020, arXiv:2005.01643. [Google Scholar]

- Taylor, L.; Nitschke, G. Improving deep learning with generic data augmentation. In Proceedings of the 2018 IEEE Symposium Series on Computational Intelligence (SSCI), Bangalore, India, 18–21 November 2018; pp. 1542–1547. [Google Scholar]

- Wen, Q.; Sun, L.; Yang, F.; Song, X.; Gao, J.; Wang, X.; Xu, H. Time series data augmentation for deep learning: A survey. arXiv 2020, arXiv:2002.12478. [Google Scholar]

- Interpretable AI: The Zing-Thing to Bolster the Adoption of AI in Industries. Available online: https://www.linkedin.com/pulse/interpretable-ai-zing-thing-bolster-adaptability-mishra-phd/ (accessed on 6 August 2021).

- AI vs. Human: A Comparison of Human Perception with Artificial Intelligence (AI). Available online: https://thinkml.ai/ai-vs-human-comparison-of-human-perception-with-artificial-intelligence/ (accessed on 6 August 2021).

- Perception Centric AI: Project Rear-View Mirror. Available online: https://amit-india.medium.com/perception-centric-ai-project-rear-view-mirror-df0627aa2030 (accessed on 6 August 2021).

- Mishra, A.K. ICABiDAS: Intuition centred architecture for big data analysis and synthesis. arXiv 2017, arXiv:1706.00638. [Google Scholar] [CrossRef]

- Son, J.; Mishra, A.K. A survey of brain inspired technologies for engineering. In Proceedings of the 2016 Pattern Recognition Association of South Africa and Robotics and Mechatronics International Conference (PRASA-RobMech), Stellenbosch, South Africa, 30 November–2 December 2016; pp. 1–6. [Google Scholar]

- Kalashnikov, A.; Pakhomovsky, Y.A.; Bazai, A.; Mikhailova, J.; Konopleva, N. Rock-chemistry-to-mineral-properties conversion: Machine learning approach. Ore Geol. Rev. 2021, 136, 104292. [Google Scholar] [CrossRef]

- Patel, A.K.; Chatterjee, S.; Gorai, A.K. Development of machine vision-based ore classification model using support vector machine (SVM) algorithm. Arab. J. Geosci. 2017, 10, 107. [Google Scholar] [CrossRef]

- Rajabinasab, B.; Asghari, O. Geometallurgical domaining by cluster analysis: Iron ore deposit case study. Nat. Resour. Res. 2019, 28, 665–684. [Google Scholar] [CrossRef]

- Lishchuk, V.; Lund, C.; Ghorbani, Y. Evaluation and comparison of different machine-learning methods to integrate sparse process data into a spatial model in geometallurgy. Miner. Eng. 2019, 134, 156–165. [Google Scholar] [CrossRef]

- Chauhan, S.; Rühaak, W.; Khan, F.; Enzmann, F.; Mielke, P.; Kersten, M.; Sass, I. Processing of rock core microtomography images: Using seven different machine learning algorithms. Comput. Geosci. 2016, 86, 120–128. [Google Scholar] [CrossRef]

- Okada, N.; Maekawa, Y.; Owada, N.; Haga, K.; Shibayama, A.; Kawamura, Y. Automated Identification of Mineral Types and Grain Size Using Hyperspectral Imaging and Deep Learning for Mineral Processing. Minerals 2020, 10, 809. [Google Scholar] [CrossRef]

- Deo, A.J.; Sahoo, A.; Behera, S.K.; Das, D.P. Machine Learning based Image Processing for Iron Ore Pellet Size Analysis. In Proceedings of the 2021 4th Biennial International Conference on Nascent Technologies in Engineering (ICNTE), Navi Mumbai, India, 15–16 January 2021; pp. 1–5. [Google Scholar]

- Tessier, J.; Duchesne, C.; Bartolacci, G. A machine vision approach to on-line estimation of run-of-mine ore composition on conveyor belts. Miner. Eng. 2007, 20, 1129–1144. [Google Scholar] [CrossRef]

- Petersen, K.; Aldrich, C.; Van Deventer, J. Analysis of ore particles based on textural pattern recognition. Miner. Eng. 1998, 11, 959–977. [Google Scholar] [CrossRef]

- Tungol, Z.; Kawamura, Y.; Kitahara, I.; Jang, H.D. Development of a Remote Rock Fragmentation Size Distribution Measurement System for Surface Mines Using 3D Photogrammetry. In Proceedings of the 10th International Conference on Explosives and Blasting, Chengdu, China, 27–30 October 2019. [Google Scholar]

- Das, S.; Das, D.P.; Sarangi, C.K.; Bhoi, B. Estimation of hydrogen flow rate in atmospheric Ar: H2 plasma by using artificial neural network. Neural Comput. Appl. 2020, 32, 1357–1365. [Google Scholar] [CrossRef]

- Nayak, D.K.; Das, D.P.; Behera, S.K.; Das, S.P. Monitoring the fill level of a ball mill using vibration sensing and artificial neural network. Neural Comput. Appl. 2020, 32, 1501–1511. [Google Scholar] [CrossRef]

- Van Duijvenbode, J.R.; Buxton, M.W.; Shishvan, M.S. Performance improvements during mineral processing using material fingerprints derived from machine learning—A conceptual framework. Minerals 2020, 10, 366. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Y.; Sun, W. Tool wear condition monitoring in milling process based on current sensors. IEEE Access 2020, 8, 95491–95502. [Google Scholar] [CrossRef]

- Ostasevicius, V.; Karpavicius, P.; Paulauskaite-Taraseviciene, A.; Jurenas, V.; Mystkowski, A.; Cesnavicius, R.; Kizauskiene, L. A Machine Learning Approach for Wear Monitoring of End Mill by Self-Powering Wireless Sensor Nodes. Sensors 2021, 21, 3137. [Google Scholar] [CrossRef] [PubMed]

- Yilmaz, E. Field monitoring and performance evaluation of crushing plant operation. Physicochem. Probl. Miner. Process. 2014, 50, 615–630. [Google Scholar]

- Nielsen, K.; Kristiansen, J. Blasting-crushing-grinding: Optimisation of an integrated comminution system. In Rock Fragmentation by Blasting; CRC Press: Boca Raton, FL, USA, 2020; pp. 269–277. [Google Scholar]

- Horn, Z.; Auret, L.; McCoy, J.; Aldrich, C.; Herbst, B. Performance of convolutional neural networks for feature extraction in froth flotation sensing. IFAC-PapersOnLine 2017, 50, 13–18. [Google Scholar] [CrossRef]

- Pu, Y.; Szmigiel, A.; Chen, J.; Apel, D.B. FlotationNet: A hierarchical deep learning network for froth flotation recovery prediction. Powder Technol. 2020, 375, 317–326. [Google Scholar] [CrossRef]

- Pu, Y.; Szmigiel, A.; Apel, D.B. Purities prediction in a manufacturing froth flotation plant: The deep learning techniques. Neural Comput. Appl. 2020, 32, 13639–13649. [Google Scholar] [CrossRef]

- Cook, R.; Monyake, K.C.; Hayat, M.B.; Kumar, A.; Alagha, L. Prediction of flotation efficiency of metal sulfides using an original hybrid machine learning model. Eng. Rep. 2020, 2, e12167. [Google Scholar]

- Tuşa, L.; Kern, M.; Khodadadzadeh, M.; Blannin, R.; Gloaguen, R.; Gutzmer, J. Evaluating the performance of hyperspectral short-wave infrared sensors for the pre-sorting of complex ores using machine learning methods. Miner. Eng. 2020, 146, 106150. [Google Scholar] [CrossRef]

- Cisternas, L.A.; Lucay, F.A.; Botero, Y.L. Trends in modelling, design, and optimization of multiphase systems in minerals processing. Minerals 2020, 10, 22. [Google Scholar] [CrossRef] [Green Version]

- Tohry, A.; Jafari, M.; Farahani, M.; Manthouri, M.; Chelgani, S.C. Variable importance assessments of an innovative industrial-scale magnetic separator for processing of iron ore tailings. Miner. Process. Extr. Metall. 2020, 1–8. [Google Scholar] [CrossRef]

- Raman, G.S.; Klima, M.S. Application of statistical and machine learning techniques for laboratory-scale pressure filtration: Modeling and analysis of cake moisture. Miner. Process. Extr. Metall. Rev. 2019, 40, 148–155. [Google Scholar] [CrossRef]

- Tripathy, S.K.; Murthy, Y.R.; Farrokhpay, S.; Filippov, L.O. Design and analysis of dewatering circuits for a chromite processing plant tailing slurry. Miner. Process. Extr. Metall. Rev. 2021, 42, 102–114. [Google Scholar] [CrossRef]

- Ali, D.; Frimpong, S. DeepHaul: A deep learning and reinforcement learning-based smart automation framework for dump trucks. Prog. Artif. Intell. 2021, 10, 157–180. [Google Scholar] [CrossRef]

- Olivier, L.E.; Craig, I.K. A survey on the degree of automation in the mineral processing industry. In Proceedings of the 2017 IEEE AFRICON, Cape Town, South Africa, 18–20 September 2017; pp. 404–409. [Google Scholar]

- Chai, T.; Ding, J.; Yu, G.; Wang, H. Integrated optimization for the automation systems of mineral processing. IEEE Trans. Autom. Sci. Eng. 2014, 11, 965–982. [Google Scholar] [CrossRef]

- Hosseini, S.H.; Samanipour, M. Prediction of final concentrate grade using artificial neural networks from Gol-E-Gohar iron ore plant. Am. J. Min. Metall. 2015, 3, 58–62. [Google Scholar]

- Feng, Q.; Zhang, J.; Zhang, X.; Wen, S. Proximate analysis based prediction of gross calorific value of coals: A comparison of support vector machine, alternating conditional expectation and artificial neural network. Fuel Process. Technol. 2015, 129, 120–129. [Google Scholar] [CrossRef]

- Wang, J.S.; Han, S. Feed-Forward neural network soft-sensor modelling of flotation process based on particle swarm optimization and gravitational search algorithm. Comput. Intell. Neurosci. 2015, 2015, 147843. [Google Scholar] [CrossRef]

- Jorjani, E.; Poorali, H.A.; Sam, A.; Chelgani, S.C.; Mesroghli, S.; Shayestehfar, M. Prediction of coal response to froth flotation based on coal analysis using regression and artificial neural network. Miner. Eng. 2009, 22, 970–976. [Google Scholar] [CrossRef]

- Jahedsaravani, A.; Marhaban, M.; Massinaei, M. Application of statistical and intelligent techniques for modelling of metallurgical performance of a batch flotation process. Chem. Eng. Commun. 2016, 203, 151–160. [Google Scholar] [CrossRef]

- Pan, X.W.; Metzner, G.; Selby, N.; Visser, C.; Letwaba, T.; Coleman, K. Development of weightometer soft sensor. J. S. Afr. Inst. Min. Metall. 2004, 104, 291–296. [Google Scholar]

- Ko, Y.D.; Shang, H. A neural network-based soft sensor for particle size distribution using image analysis. Powder Technol. 2011, 212, 359–366. [Google Scholar] [CrossRef]

- Ebid, A.M. 35 Years of (AI) in geotechnical engineering: State of the art. Geotech. Geol. Eng. 2021, 39, 637–690. [Google Scholar] [CrossRef]

- Bergen, K.J.; Johnson, P.A.; Maarten, V.; Beroza, G.C. Machine learning for data-driven discovery in solid Earth geoscience. Science 2019, 363, eaau0323. [Google Scholar] [CrossRef] [PubMed]

- Global Industry Standard on Tailings Management; Standard, UNEP, ICM and PRI: Nairobi, Kenya, 2020.

- Morrison, K.F. Preface to the MME Special Focus Issue on Tailings Management. Mining, Metall. Explor. 2021, 38, 1287–1288. [Google Scholar]

- Qi, C.; Ly, H.B.; Chen, Q.; Le, T.T.; Le, V.M.; Pham, B.T. Flocculation-dewatering prediction of fine mineral tailings using a hybrid machine learning approach. Chemosphere 2020, 244, 125450. [Google Scholar] [CrossRef]

- Nasategay, F.F.U. Detection and Monitoring of Tailings Dam Surface Erosion Using UAV and Machine Learning. Ph.D. Thesis, University of Nevada, Reno, NV, USA, 2020. [Google Scholar]

- Betrie, G.D.; Tesfamariam, S.; Morin, K.A.; Sadiq, R. Predicting copper concentrations in acid mine drainage: A comparative analysis of five machine learning techniques. Environ. Monit. Assess. 2013, 185, 4171–4182. [Google Scholar] [CrossRef] [PubMed]

- Tousi, E.G.; Duan, J.G.; Gundy, P.M.; Bright, K.R.; Gerba, C.P. Evaluation of E. coli in sediment for assessing irrigation water quality using machine learning. Sci. Total Environ. 2021, 799, 149286. [Google Scholar] [CrossRef]

- Hao, L.; Zhang, Z.; Yang, X. Mine tailing extraction indexes and model using remote-sensing images in southeast Hubei Province. Environ. Earth Sci. 2019, 78, 493. [Google Scholar] [CrossRef] [Green Version]

- Yan, D.; Li, G.; Li, X.; Zhang, H.; Lei, H.; Lu, K.; Cheng, M.; Zhu, F. An Improved Faster R-CNN Method to Detect Tailings Ponds from High-Resolution Remote Sensing Images. Remote Sens. 2021, 13, 2052. [Google Scholar] [CrossRef]

- Rosen, P.A.; Kumar, R. NASA-ISRO SAR (NISAR) Mission Status. In Proceedings of the 2021 IEEE Radar Conference (RadarConf21), Atlanta, GA, USA, 7–14 May 2021; pp. 1–6. [Google Scholar]

- Ignatenko, V.; Laurila, P.; Radius, A.; Lamentowski, L.; Antropov, O.; Muff, D. ICEYE Microsatellite SAR Constellation Status Update: Evaluation of first commercial imaging modes. In Proceedings of the IGARSS 2020—2020 IEEE International Geoscience and Remote Sensing Symposium, Waikoloa, HI, USA, 26 September–2 October 2020; pp. 3581–3584. [Google Scholar]

- Colliander, A.; Reichle, R.; Crow, W.; Cosh, M.; Chen, F.; Chan, S.; Das, N.; Bindlish, R.; Chaubell, J.; Kim, S.; et al. Validation of Soil Moisture Data Products from the NASA SMAP Mission. TechRxiv 2021. [Google Scholar] [CrossRef]

- Vangi, E.; D’Amico, G.; Francini, S.; Giannetti, F.; Lasserre, B.; Marchetti, M.; Chirici, G. The new hyperspectral satellite PRISMA: Imagery for forest types discrimination. Sensors 2021, 21, 1182. [Google Scholar] [CrossRef]

- Qin, P.; Cai, Y.; Wang, X. Small waterbody extraction with improved U-Net using Zhuhai-1 hyperspectral remote sensing images. IEEE Geosci. Remote Sens. Lett. 2021, 1–5. [Google Scholar] [CrossRef]

- Xiong, R.; Tang, P. Machine learning using synthetic images for detecting dust emissions on construction sites. Smart Sustain. Built Environ. 2021. [Google Scholar] [CrossRef]

- Kavitha, N.; Madhumathy, P. Development of an IOT-Based Atmospheric Fine Dust Monitoring System. In Internet of Things, Smart Computing and Technology: A Roadmap Ahead; Springer: New York, NY, USA, 2020; pp. 263–279. [Google Scholar]

- Bozdağ, A.; Dokuz, Y.; Gökçek, Ö.B. Spatial prediction of PM10 concentration using machine learning algorithms in Ankara, Turkey. Environ. Pollut. 2020, 263, 114635. [Google Scholar] [CrossRef]

- Jiao, Z.; Hu, P.; Xu, H.; Wang, Q. Machine Learning and Deep Learning in Chemical Health and Safety: A Systematic Review of Techniques and Applications. ACS Chem. Health Saf. 2020, 27, 316–334. [Google Scholar] [CrossRef]

- Fan, Y.; Zhu, X.; Sui, H.; Sun, H.; Wang, Z. Design and application of toxic and harmful gas monitoring system in fire fighting. Sensors 2019, 19, 369. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Qiu, S.; Chen, B.; Wang, R.; Zhu, Z.; Wang, Y.; Qiu, X. Atmospheric dispersion prediction and source estimation of hazardous gas using artificial neural network, particle swarm optimization and expectation maximization. Atmos. Environ. 2018, 178, 158–163. [Google Scholar] [CrossRef]

- Luco, J.; Ferretti, F. QSAR Based on Multiple Linear Regression and PLS Methods for the Anti-HIV Activity of a Large Group of HEPT Derivativess. J. Chem. Inf. Comput. Sci. 1997, 37, 392–401. [Google Scholar] [CrossRef]

- Jalali-Heravi, M.; Parastar, F. Use of artificial neural networks in a QSAR study of anti-HIV activity for a large group of HEPT derivatives. J. Chem. Inf. Comput. Sci. 2000, 40, 147–154. [Google Scholar] [CrossRef]

- Mishra, A.K.; Patri, O.P. A structure-motivated hybrid machine for prediction of biological activity of chemical compounds. In Proceedings of the 2010 Annual IEEE India Conference (INDICON), Kolkata, India, 17–19 December 2010; pp. 1–4. [Google Scholar]

- Quintanilla, P.; Neethling, S.J.; Brito-Parada, P.R. Modelling for froth flotation control: A review. Miner. Eng. 2020, 162, 106718. [Google Scholar] [CrossRef]

- von Rueden, L.; Mayer, S.; Sifa, R.; Bauckhage, C.; Garcke, J. Combining machine learning and simulation to a hybrid modelling approach: Current and future directions. In International Symposium on Intelligent Data Analysis; Springer: Cham, Switzerland, 2020; pp. 548–560. [Google Scholar]

- Blei, D.M.; Ng, A.Y.; Jordan, M.I. Latent dirichlet allocation. J. Mach. Learn. Res. 2003, 3, 993–1022. [Google Scholar]

- Moser, G.; Lee, S.H.; Hayes, B.J.; Goddard, M.E.; Wray, N.R.; Visscher, P.M. Simultaneous discovery, estimation and prediction analysis of complex traits using a Bayesian mixture model. PLoS Genet. 2015, 11, e1004969. [Google Scholar] [CrossRef]

- Ren, J.; Ni, D. A batch-wise LSTM-encoder decoder network for batch process monitoring. Chem. Eng. Res. Des. 2020, 164, 102–112. [Google Scholar] [CrossRef]

- Liu, K.; Zhang, J. A Dual-Layer Attention-Based LSTM Network for Fed-batch Fermentation Process Modelling. In Computer Aided Chemical Engineering; Elsevier: Amsterdam, The Netherlands, 2021; Volume 50, pp. 541–547. [Google Scholar]

- Halle, M.; Stevens, K. Speech recognition: A model and a program for research. IRE Trans. Inf. Theory 1962, 8, 155–159. [Google Scholar] [CrossRef]

- Reddy, D.R. Speech recognition by machine: A review. Proc. IEEE 1976, 64, 501–531. [Google Scholar] [CrossRef]

- Juang, B.H.; Rabiner, L.R. Automatic Speech Recognition—A Brief History of the Technology Development; Georgia Institute of Technology; Atlanta Rutgers University and the University of California: Santa Barbara, CA, USA, 2005; p. 67. [Google Scholar]

- Jaitly, N.; Nguyen, P.; Senior, A.; Vanhoucke, V. Application of Pretrained Deep Neural Networks to Large Vocabulary Speech Recognition. In Proceedings of the Interspeech 2012, Portland, OR, USA, 9–13 September 2012. [Google Scholar]

- Eirinakis, P.; Kalaboukas, K.; Lounis, S.; Mourtos, I.; Rožanec, J.M.; Stojanovic, N.; Zois, G. Enhancing cognition for digital twins. In Proceedings of the 2020 IEEE International Conference on Engineering, Technology and Innovation (ICE/ITMC), Cardiff, UK, 15–17 June 2020; pp. 1–7. [Google Scholar]

- Zobel-Roos, S.; Schmidt, A.; Uhlenbrock, L.; Ditz, R.; Köster, D.; Strube, J. Digital Twins in Biomanufacturing. In Digital Twins; Springer: New York, NY, USA, 2020; pp. 181–262. [Google Scholar]

- Schilling, D.R. Knowledge doubling every 12 months, soon to be every 12 hours. Industry Tap, 19 April 2013. [Google Scholar]

- Brown, T. Design thinking. Harv. Bus. Rev. 2008, 86, 84. [Google Scholar]

- Gómez, D.; Rojas, A. An empirical overview of the no free lunch theorem and its effect on real-world machine learning classification. Neural Comput. 2016, 28, 216–228. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Adam, S.P.; Alexandropoulos, S.A.N.; Pardalos, P.M.; Vrahatis, M.N. No free lunch theorem: A review. Approx. Optim. 2019, 145, 57–82. [Google Scholar]

- Marcum, J. A statistical theory of target detection by pulsed radar. IRE Trans. Inf. Theory 1960, 6, 59–267. [Google Scholar] [CrossRef]

- Rengasamy, D.; Jafari, M.; Rothwell, B.; Chen, X.; Figueredo, G.P. Deep learning with dynamically weighted loss function for sensor-based prognostics and health management. Sensors 2020, 20, 723. [Google Scholar] [CrossRef] [Green Version]

- Beygelzimer, A.; Dasgupta, S.; Langford, J. Importance weighted active learning. In Proceedings of the 26th Annual International Conference on Machine Learning, Montreal, QC, Canada, 14–18 June 2009; pp. 49–56. [Google Scholar]

- Zhang, W.; Du, Y.; Yoshida, T.; Yang, Y. DeepRec: A deep neural network approach to recommendation with item embedding and weighted loss function. Inf. Sci. 2019, 470, 121–140. [Google Scholar] [CrossRef]

- Czech, D.; Mishra, A.; Inggs, M. A CNN and LSTM-based approach to classifying transient radio frequency interference. Astron. Comput. 2018, 25, 52–57. [Google Scholar] [CrossRef] [Green Version]

- Bezerra, A.; Silva, I.; Guedes, L.A.; Silva, D.; Leitão, G.; Saito, K. Extracting value from industrial alarms and events: A data-driven approach based on exploratory data analysis. Sensors 2019, 19, 2772. [Google Scholar] [CrossRef] [Green Version]

- Taboada, G.L.; Han, L. Exploratory data analysis and data envelopment analysis of urban rail transit. Electronics 2020, 9, 1270. [Google Scholar] [CrossRef]

- Czech, D.; Mishra, A.; Inggs, M. Characterizing transient radio-frequency interference. Radio Sci. 2017, 52, 841–851. [Google Scholar] [CrossRef]

- Jolliffe, I.T.; Cadima, J. Principal component analysis: A review and recent developments. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2016, 374, 20150202. [Google Scholar] [CrossRef]

- Czech, D.; Mishra, A.K.; Inggs, M. A canonical interferencelet-based approach to RFI identification. In Proceedings of the 2016 Radio Frequency Interference (RFI), Socorro, NM, USA, 17–20 October 2016; pp. 16–20. [Google Scholar]

- Loh, P.L. On lower bounds for statistical learning theory. Entropy 2017, 19, 617. [Google Scholar] [CrossRef] [Green Version]

- Piou, J.E. Computation of Posterior Cramer-Rao Bounds for Deep Learning Networks. In Proceedings of the 2020 11th IEEE Annual Ubiquitous Computing, Electronics & Mobile Communication Conference (UEMCON), New York, NY, USA, 28–31 October 2020; pp. 0240–0244. [Google Scholar]

- Hannun, A.; Guo, C.; van der Maaten, L. Measuring Data Leakage in Machine-Learning Models with Fisher Information. arXiv 2021, arXiv:2102.11673. [Google Scholar]

- Petroff, E.; Keane, E.; Barr, E.; Reynolds, J.; Sarkissian, J.; Edwards, P.; Stevens, J.; Brem, C.; Jameson, A.; Burke-Spolaor, S.; et al. Identifying the source of perytons at the Parkes radio telescope. Mon. Not. R. Astron. Soc. 2015, 451, 3933–3940. [Google Scholar] [CrossRef] [Green Version]

- Schneider, S.; Murphy, R.J.; Melkumyan, A. Evaluating the performance of a new classifier–the GP-OAD: A comparison with existing methods for classifying rock type and mineralogy from hyperspectral imagery. ISPRS J. Photogramm. Remote Sens. 2014, 98, 145–156. [Google Scholar] [CrossRef] [Green Version]

- Morkun, V.; Tron, V.; Goncharov, S. Automation of the ore varieties recognition process in the technological process streams based on the dynamic effects of highenergy ultrasound. Metall. Min. Ind. 2015, 2, 31–34. [Google Scholar]

- Gewali, U.B.; Monteiro, S.T.; Saber, E. Machine learning based hyperspectral image analysis: A survey. arXiv 2018, arXiv:1802.08701. [Google Scholar]

- Jiang, Y.; Yin, S.; Dong, J.; Kaynak, O. A review on soft sensors for monitoring, control and optimization of industrial processes. IEEE Sens. J. 2021, 21, 12868–12881. [Google Scholar] [CrossRef]

- Sardar, S.; Mishra, A.K. ASIN-based UWB radar for sludge monitoring. IEEE Access 2014, 2, 290–300. [Google Scholar] [CrossRef]

- Mishra, A.K. Application Specific Instrumentation (ASIN): A Bio-inspired Paradigm to Instrumentation using recognition before detection. arXiv 2016, arXiv:1611.00228. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mishra, A.K. AI4R2R (AI for Rock to Revenue): A Review of the Applications of AI in Mineral Processing. Minerals 2021, 11, 1118. https://doi.org/10.3390/min11101118

Mishra AK. AI4R2R (AI for Rock to Revenue): A Review of the Applications of AI in Mineral Processing. Minerals. 2021; 11(10):1118. https://doi.org/10.3390/min11101118

Chicago/Turabian StyleMishra, Amit Kumar. 2021. "AI4R2R (AI for Rock to Revenue): A Review of the Applications of AI in Mineral Processing" Minerals 11, no. 10: 1118. https://doi.org/10.3390/min11101118

APA StyleMishra, A. K. (2021). AI4R2R (AI for Rock to Revenue): A Review of the Applications of AI in Mineral Processing. Minerals, 11(10), 1118. https://doi.org/10.3390/min11101118