Flow and Tableting Behaviors of Some Egyptian Kaolin Powders as Potential Pharmaceutical Excipients

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Preparation

2.2. Powder Characterization

2.2.1. XRD/XRF Composition and Microstructure

2.2.2. SEM/TEM Microtexture and Micromorphology

2.2.3. Laser Granulometry

2.2.4. Porosity

2.2.5. Bulk and Tapped Density

2.2.6. Thermogravimetric Analysis (TGA)

2.2.7. Powder Flowability

2.3. Tablets Manufacturing and Testing Data Analysis

3. Results and Discussion

3.1. Powder Characteristics

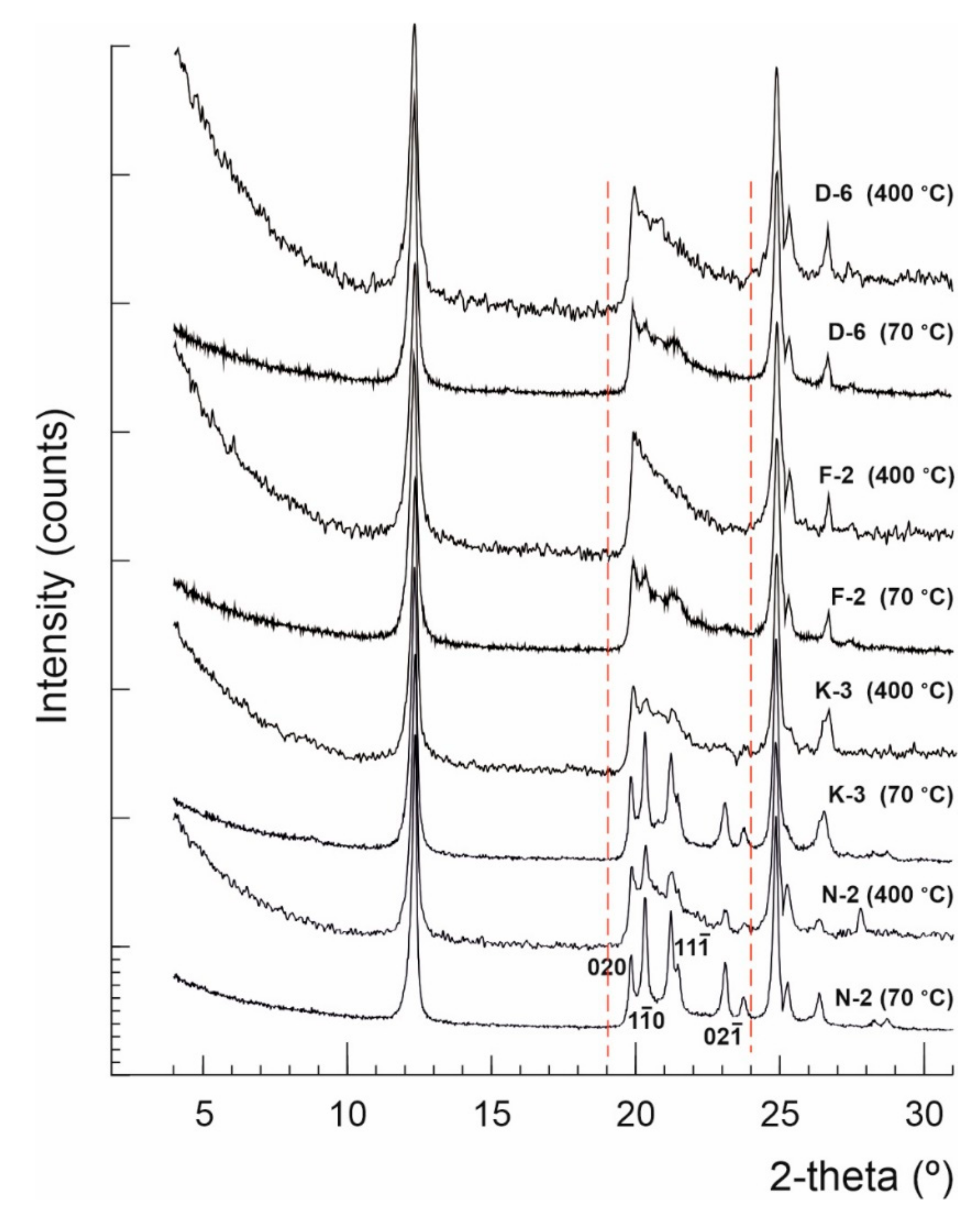

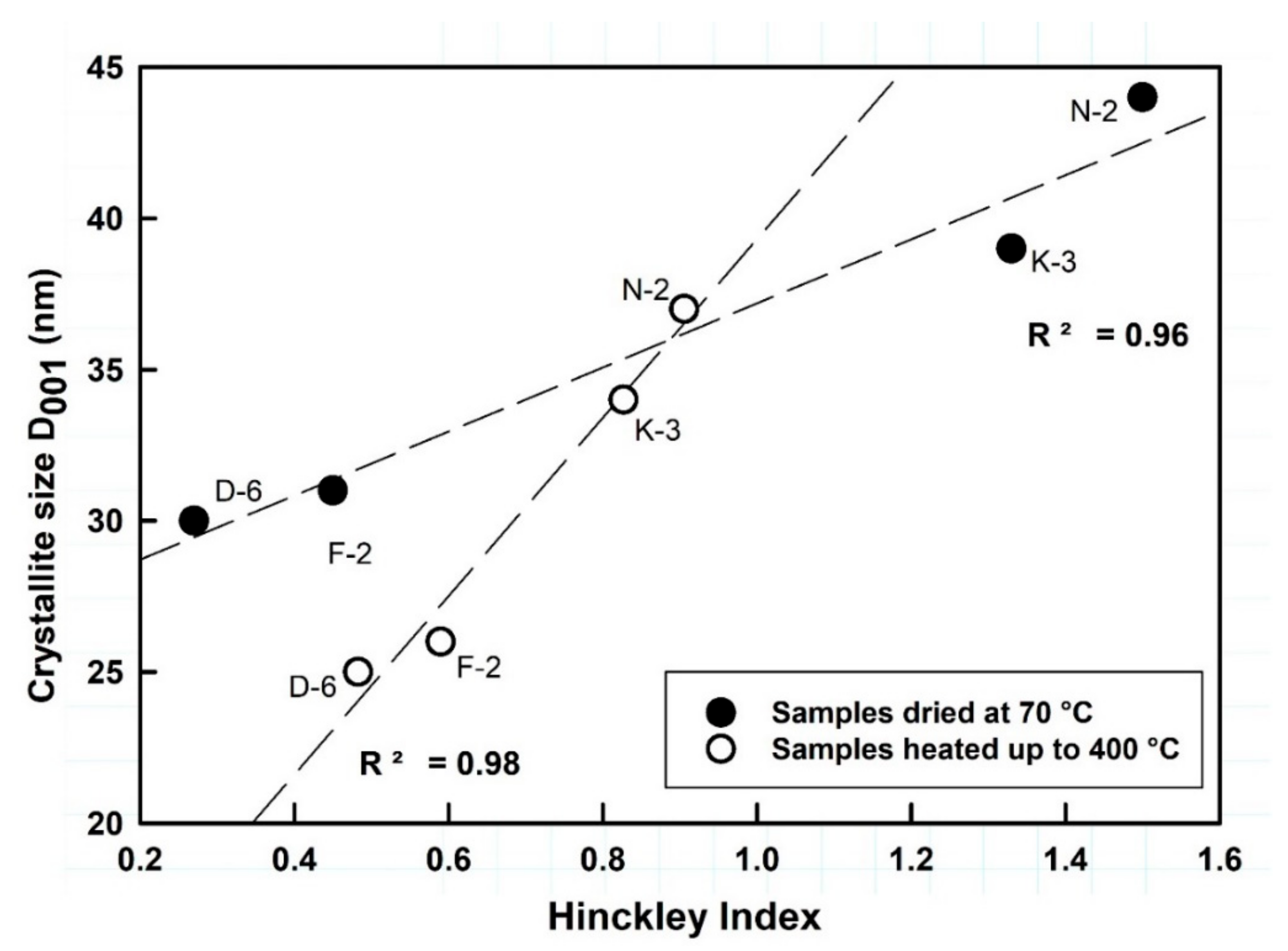

3.1.1. Compostion and Microstructure

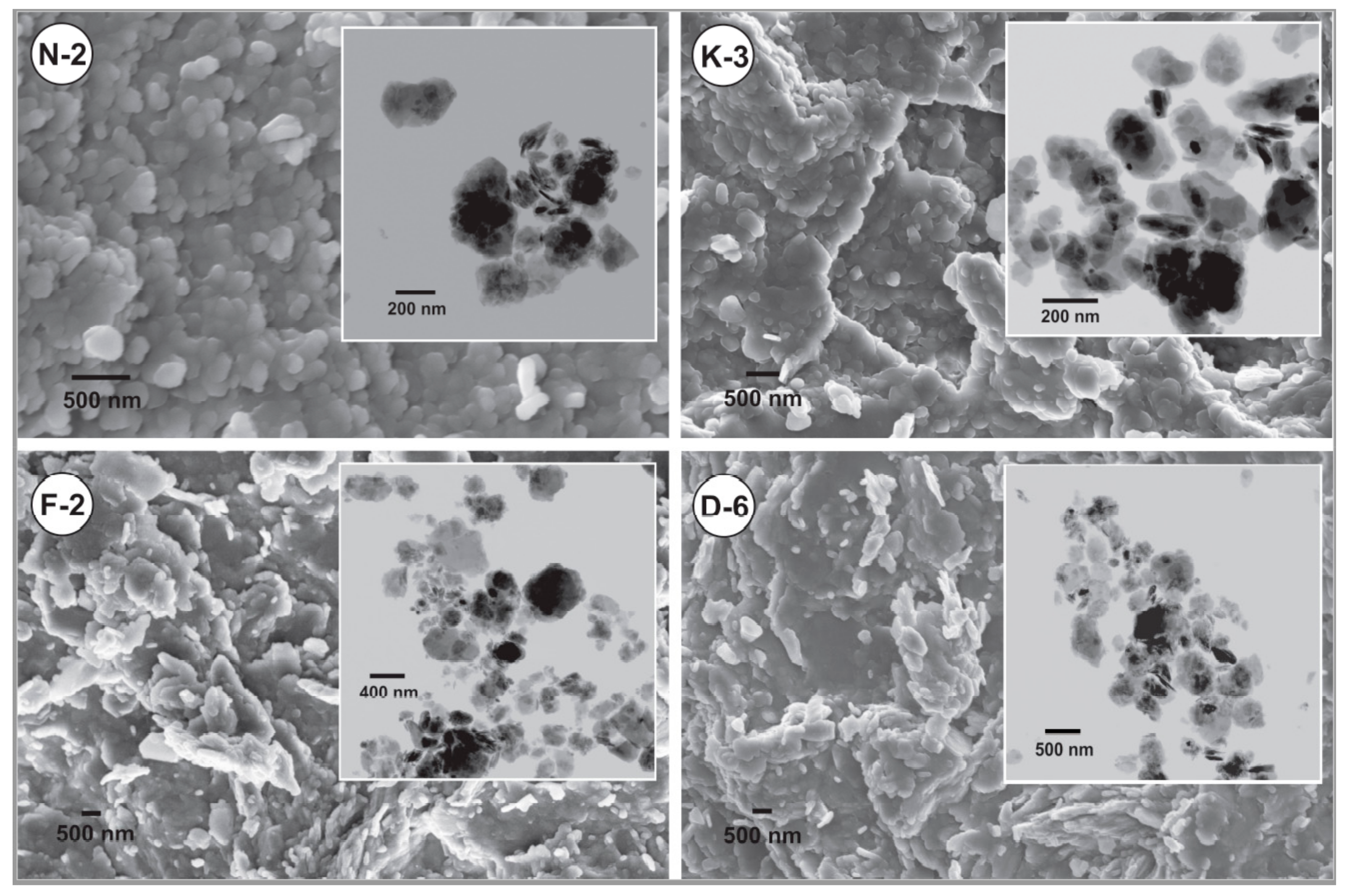

3.1.2. Microtexture and Micromorphology

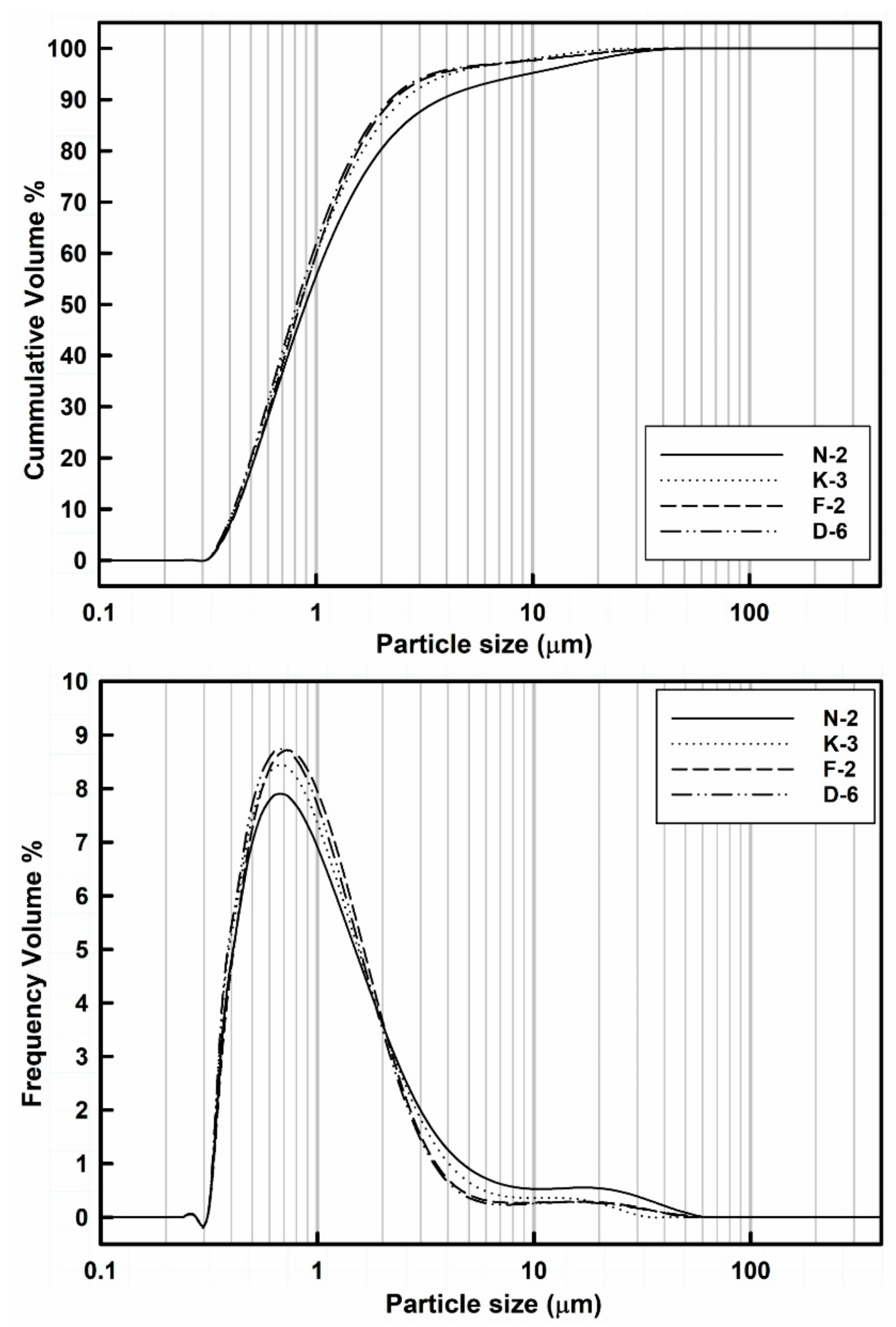

3.1.3. Particle Size Distribution

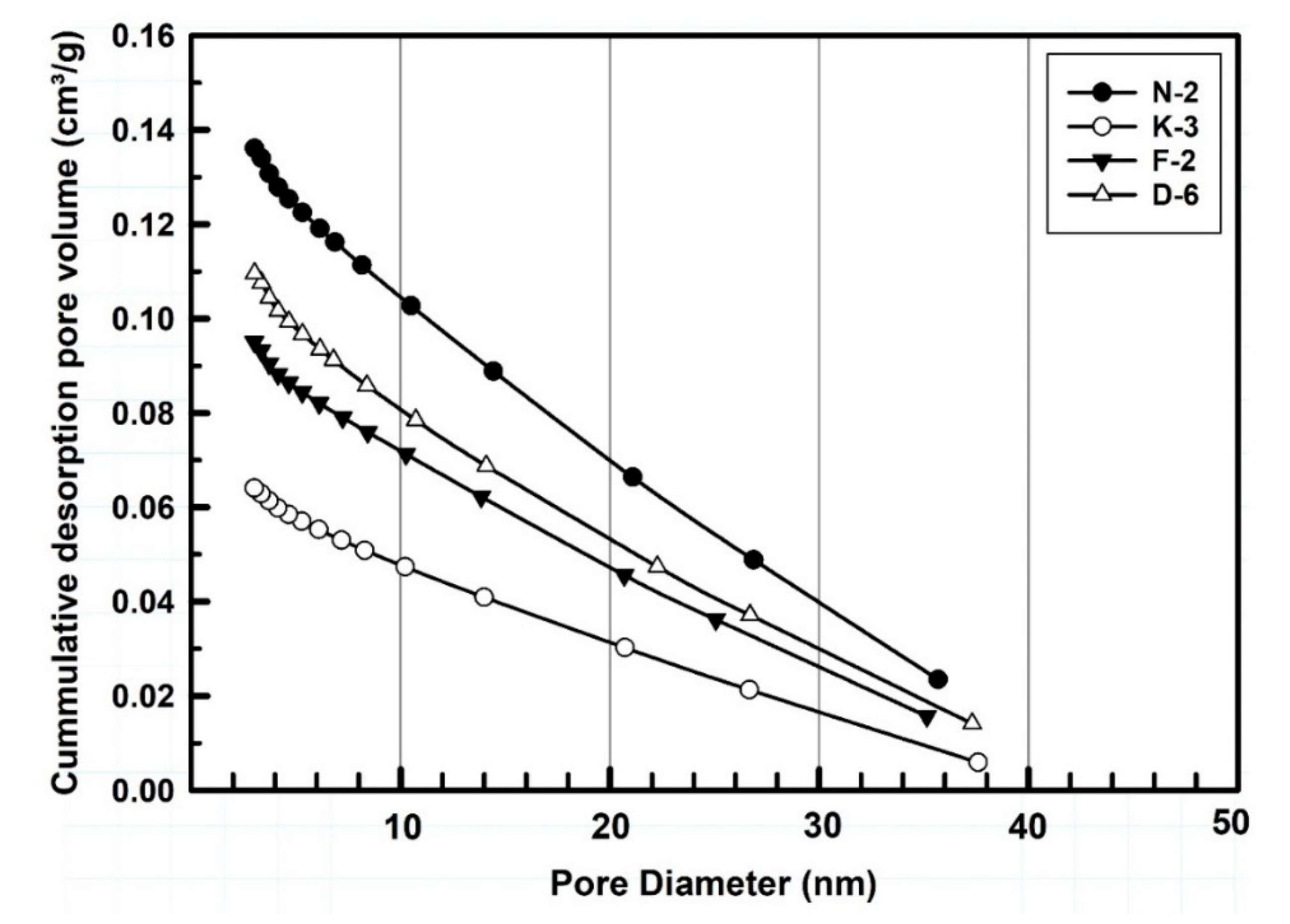

3.1.4. Porosity and Pore Size Distribution

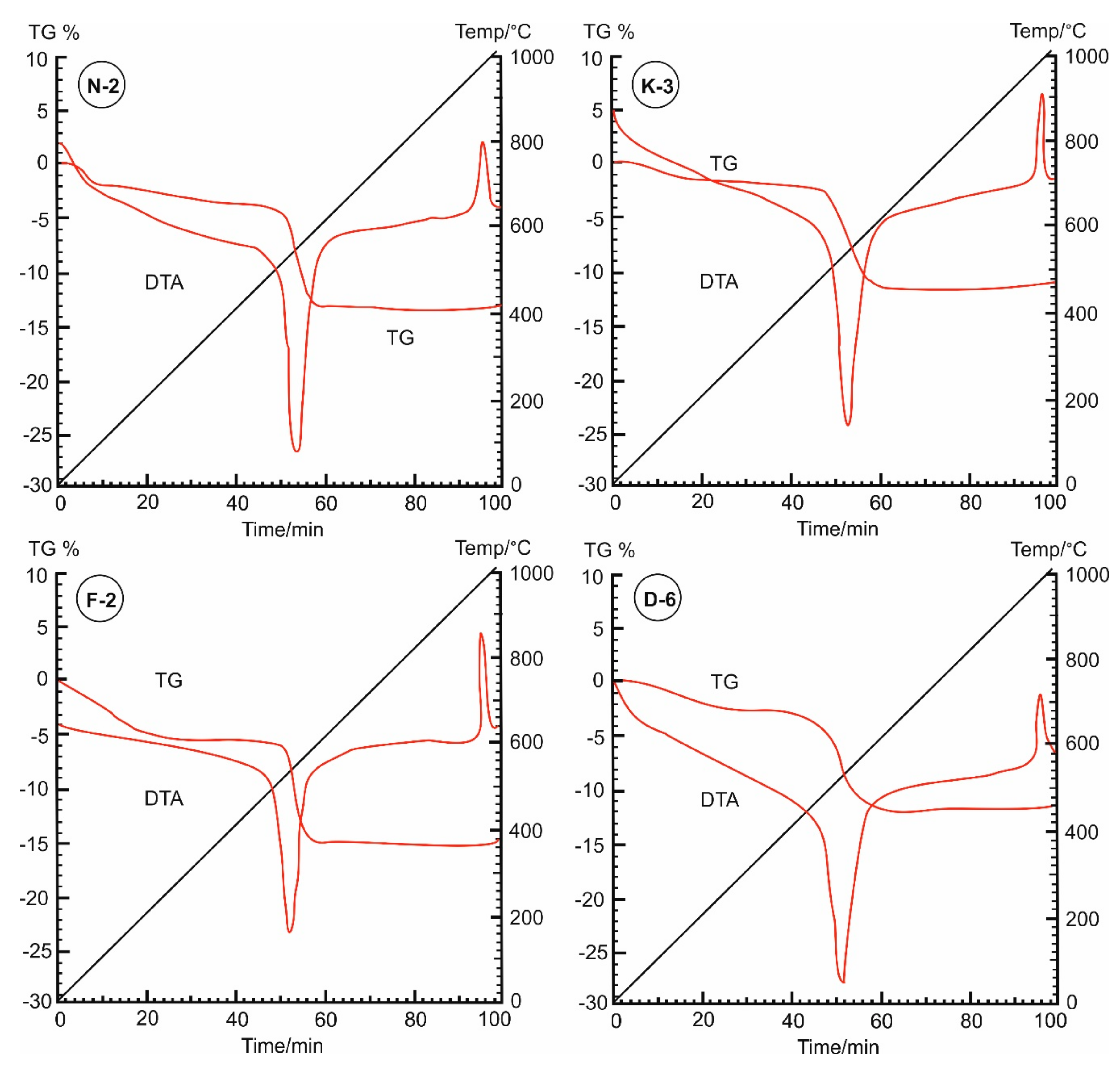

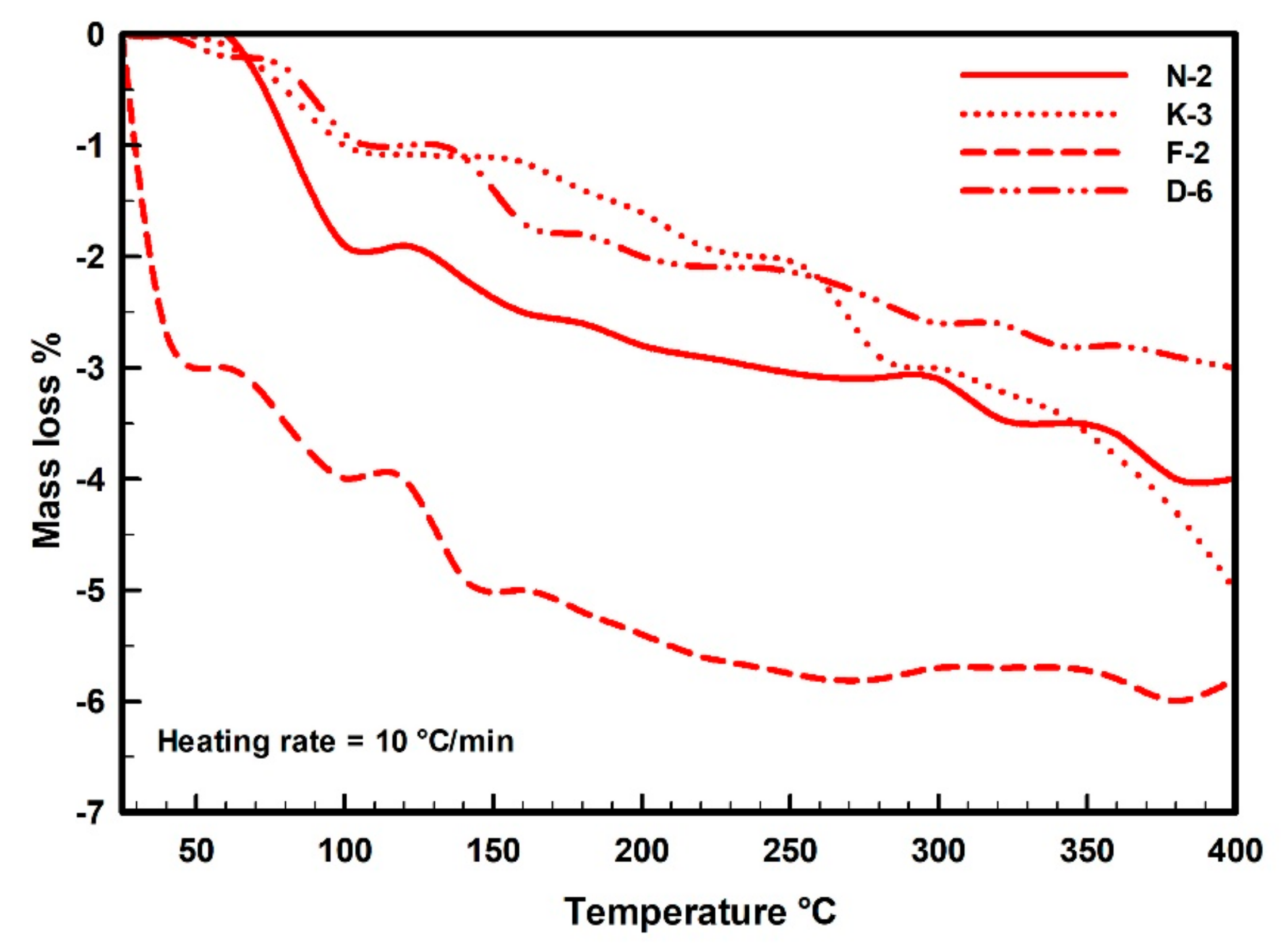

3.1.5. Moisture Content by Thermogravimetry

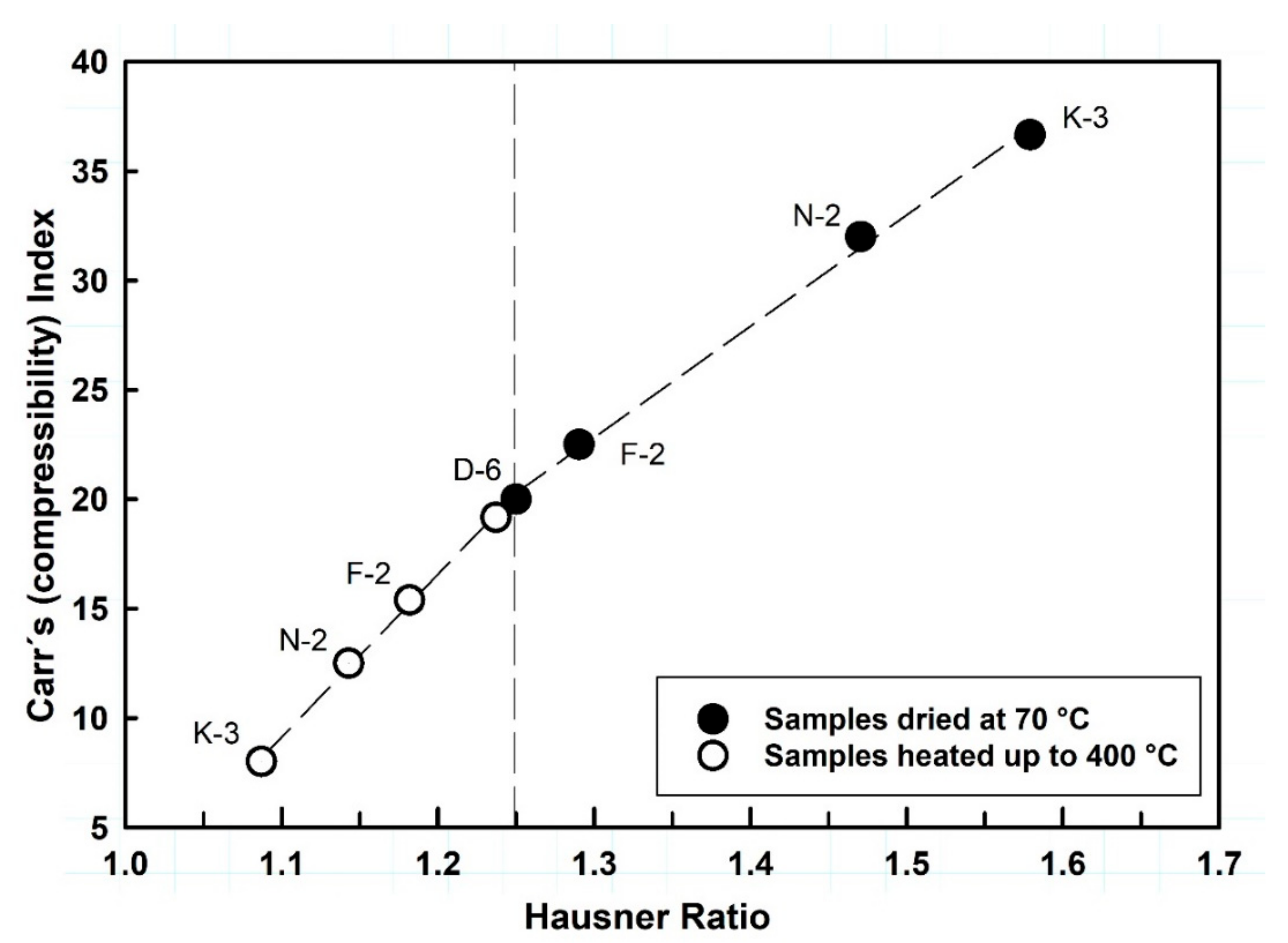

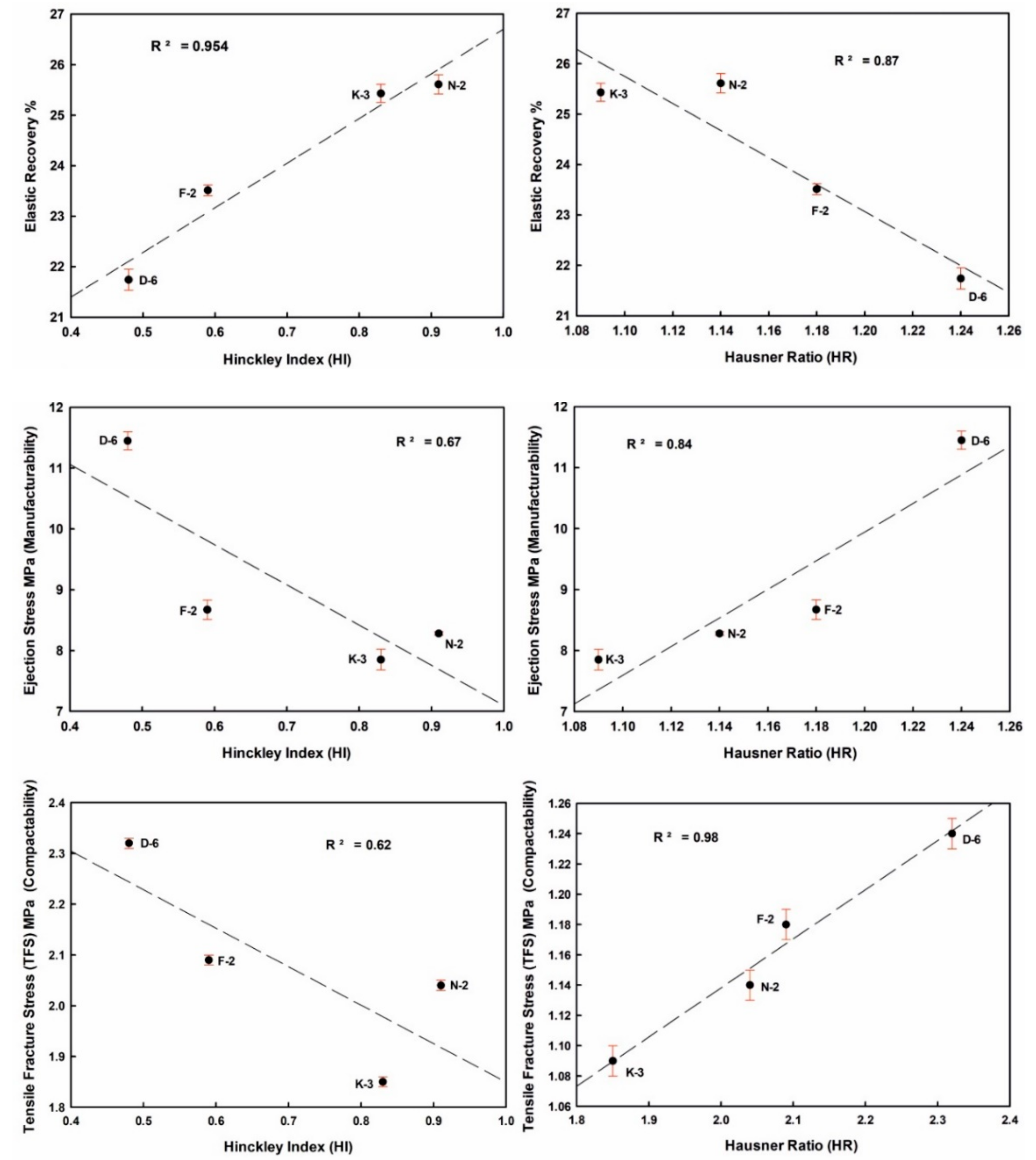

3.1.6. Flow Characteristics

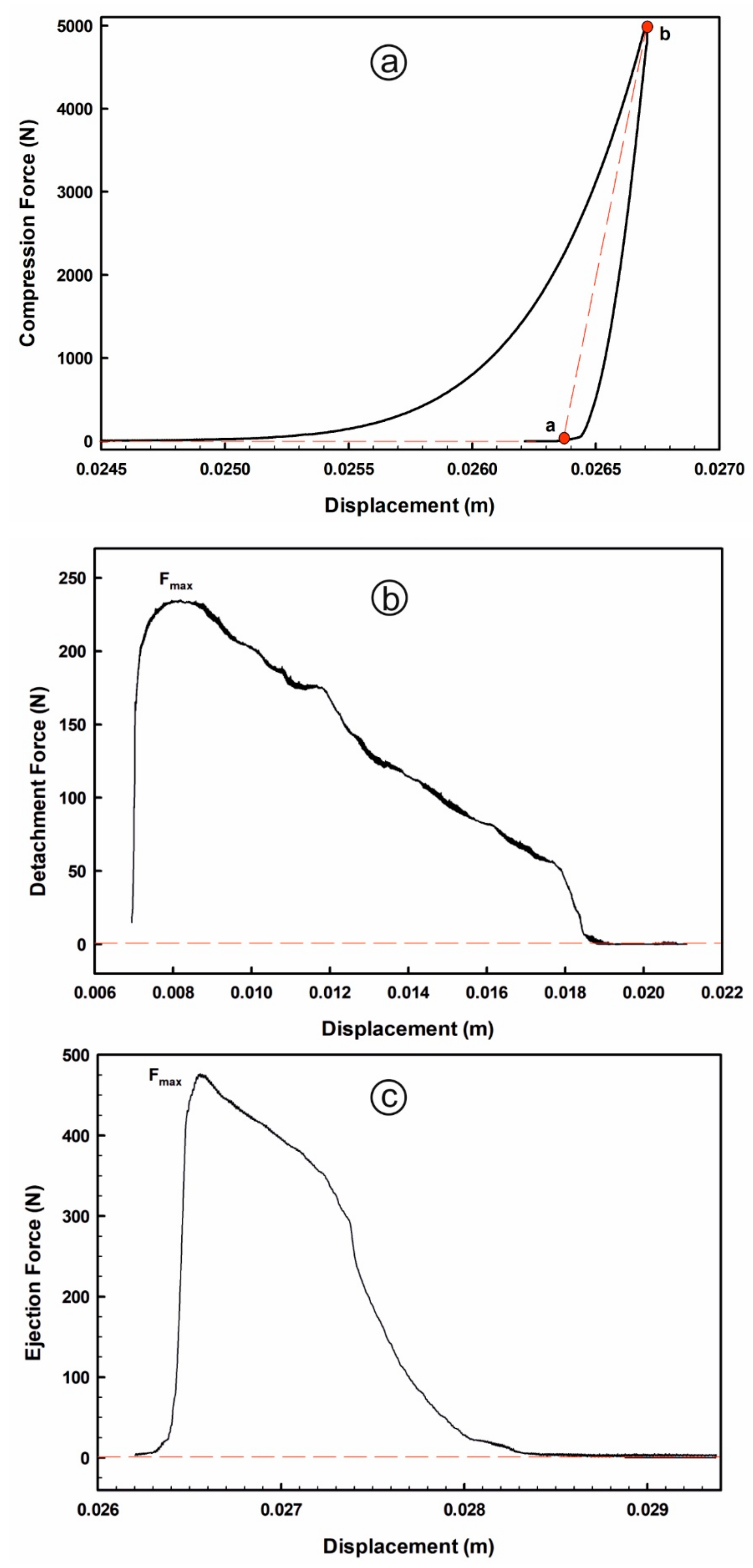

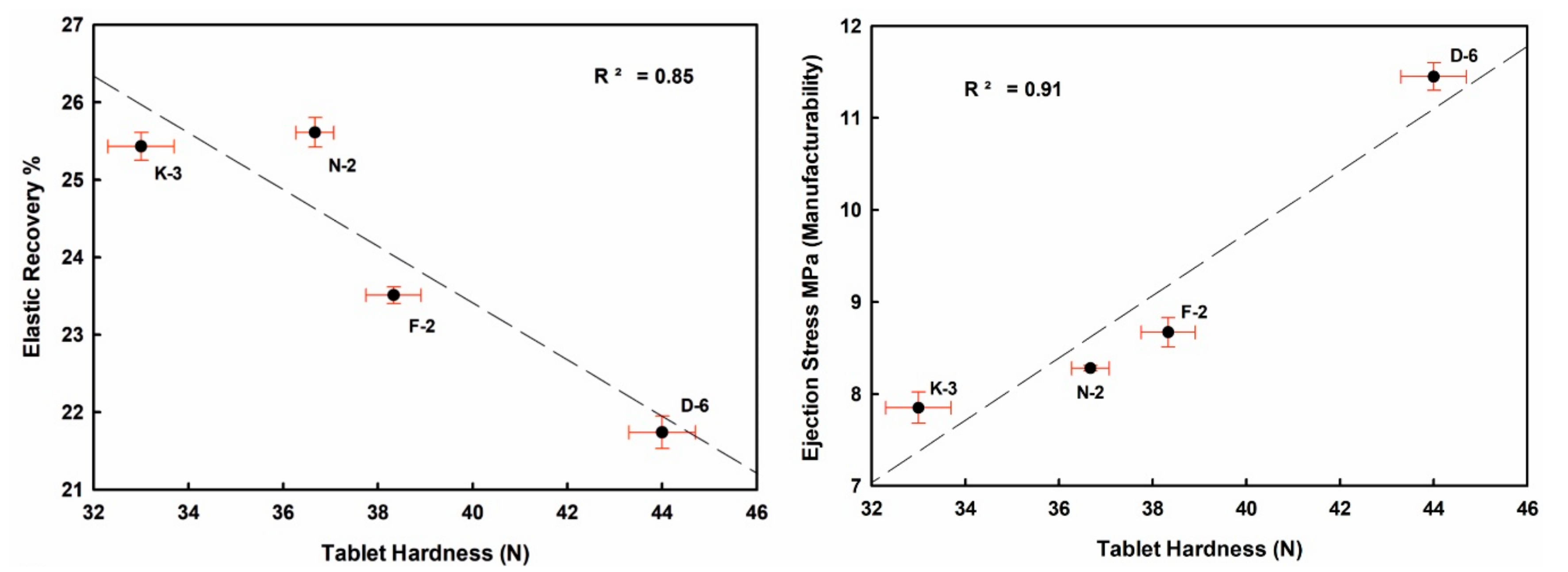

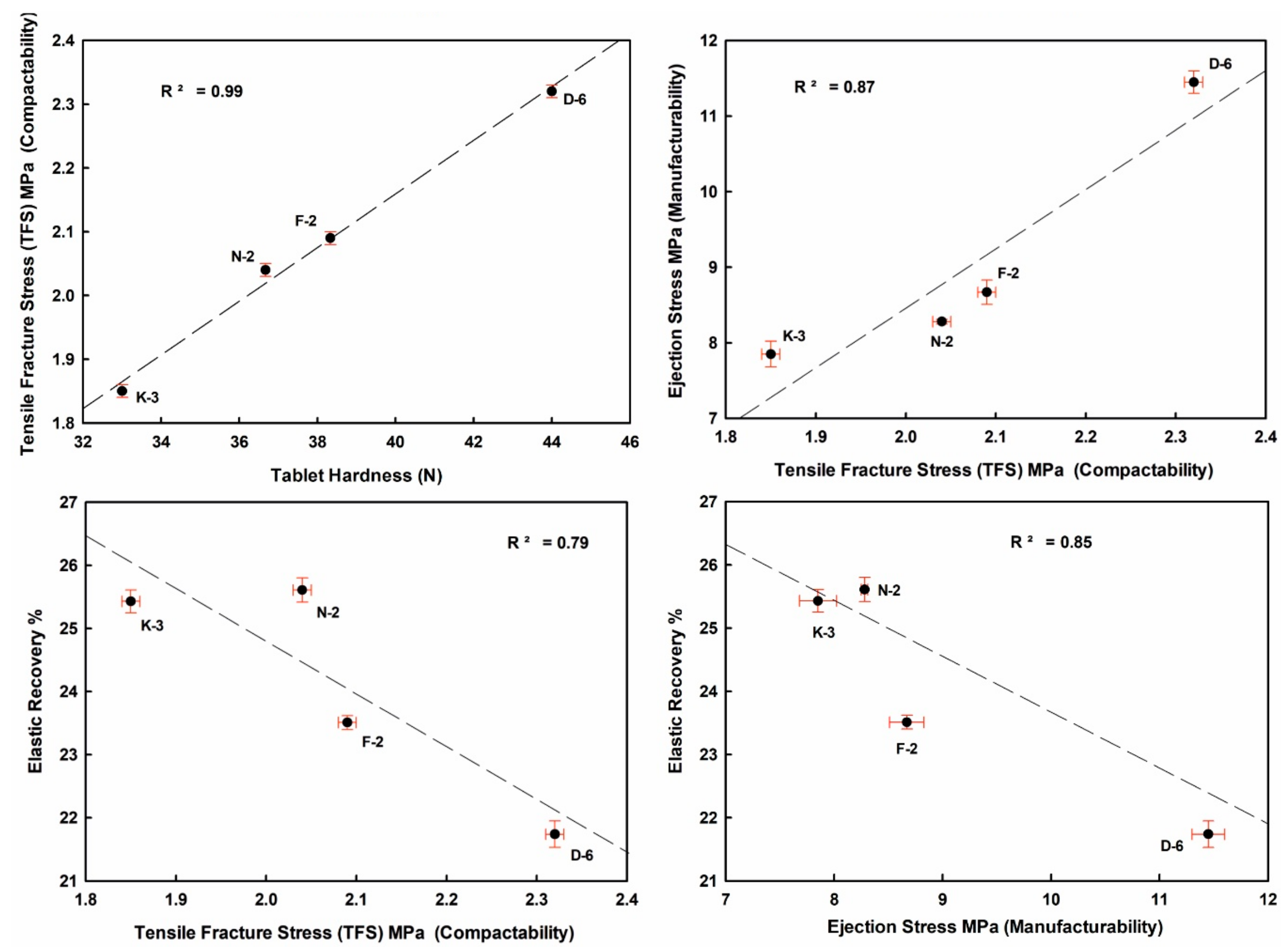

3.2. Tableting Characteristics

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Augsburger, L.L.; Hoag, S.W. (Eds.) Pharmaceutical Dosage Forms: Tablets, Volume 1: Unit Operations and Mechanical Properties, 3rd ed.; Informa Healthcare: London, UK; CRC Press: Boca Raton, FL, USA, 2008; p. 656. [Google Scholar]

- Viseras, C.; Aguzzi, C.; Cerezo, P.; Lopez-Galindo, A. Uses of clay minerals in semisolid health care and therapeutic products. Appl. Clay Sci. 2007, 36, 37–50. [Google Scholar] [CrossRef]

- Carretero, M.I.; Pozo, M. Clay and non-clay minerals in the pharmaceutical industry: Part I. excipients and medical applications. Appl. Clay Sci. 2009, 46, 73–80. [Google Scholar] [CrossRef]

- Carretero, M.I.; Pozo, M. Clay and non-clay minerals in the pharmaceutical and cosmetic industries Part II. Active ingredients. Appl. Clay Sci. 2010, 47, 171–181. [Google Scholar] [CrossRef]

- Williams, L.B.; Hillier, S. Kaolins and health: From first grade to first aid. Elements 2014, 10, 207–211. [Google Scholar] [CrossRef]

- Khurana, I.S.; Kaur, S.; Kaur, H.; Khurana, R.K. Multifaceted role of clay minerals in pharmaceuticals. Future Sci. OA 2015, 1. [Google Scholar] [CrossRef] [PubMed]

- Kim, M.H.; Choi, G.; Elzatahry, A.; Vinu, A.; Bin Choy, Y.; Choy, J.H. Review of clay-drug hybrid materials for biomedical applications: Administration routes. Clays Clay Miner. 2016, 64, 115–130. [Google Scholar] [CrossRef]

- Awad, M.E.; López-Galindo, A.; Setti, M.; El-Rahmany, M.M.; Iborra, C.V. Kaolinite in pharmaceutics and biomedicine. Int. J. Pharm. 2017, 533, 34–48. [Google Scholar] [CrossRef]

- Rautureau, M.; Gomes, C.F.; Liewig, N.; Katouzian-Safadi, M. Clays and Health: Properties and Therapeutic Uses; Springer: Berlin/Heidelberg, Germany, 2017; p. 217. [Google Scholar]

- Detellier, C. Functional kaolinite. Chem. Rec. 2018, 18, 868–877. [Google Scholar] [CrossRef]

- Massaro, M.; Colletti, C.; Lazzara, G.; Riela, S. The Use of some clay minerals as natural resources for drug carrier applications. J. Funct. Biomater. 2018, 9, 58. [Google Scholar] [CrossRef]

- Viseras, C.; Carazo, E.; Borrego-Sánchez, A.; García-Villén, F.; Sánchez-Espejo, R.; Cerezo, P.; Aguzzi, C. Clay minerals in skin drug delivery. Clays Clay Miner. 2019, 67, 59–71. [Google Scholar] [CrossRef]

- Williams, L.B. Natural antibacterial clays: Historical uses and modern advances. Clays Clay Miner. 2019, 67, 7–24. [Google Scholar] [CrossRef]

- Tan, D.; Yuan, P.; Annabi-Bergaya, F.; Liu, D.; He, H. Methoxy-modified kaolinite as a novel carrier for high-capacity loading and controlled-release of the herbicide amitrole. Sci. Rep. 2015, 5, 8870. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Long, M.; Huang, P.; Yang, H.; Chang, S.; Hu, Y.; Tang, A.; Mao, L. Intercalated 2D nanoclay for emerging drug delivery in cancer therapy. Nano Res. 2017, 10, 2633–2643. [Google Scholar] [CrossRef]

- Zhang, Y.; Huang, P.; Long, M.; Liu, S.; Yang, H.; Yuan, S.; Chang, S. Intercalated kaolinite as an emerging platform for cancer therapy. Sci. China Chem. 2018, 62, 58–61. [Google Scholar] [CrossRef]

- Nizam, N.; Ramli, N.I. Preparation and antibacterial properties of cetylpyridinium bromide-modified silver-loaded kaolinite. Mater. Res. Express 2019, 6, 094006. [Google Scholar]

- Tan, D.; Yuan, P.; Bergaya, F.A.; Liu, D.; He, H. High-capacity loading of 5-fluorouracil on the methoxy modified kaolinite. Appl. Clay Sci. 2014, 100, 60–65. [Google Scholar] [CrossRef]

- Dey, S.C.; Al-Amin, M.; Rashid, T.U.; Ashaduzzaman, M.; Shamsuddin, S.M. pH induced fabrication of kaolinite-chitosan biocomposite. Int. Lett. Chem. Phys. Astron. 2016, 68, 1–9. [Google Scholar] [CrossRef]

- Detellier, C.; Schoonheydt, R.A. From platy kaolinite to nanorolls. Elements 2014, 10, 201–206. [Google Scholar] [CrossRef]

- Schroeder, P.A.; Erickson, G. Kaolin: From ancient porcelains to nanocomposites. Elements 2014, 10, 177–182. [Google Scholar] [CrossRef]

- Reddy, O.S.; Subha, M.C.S.; Jithendra, T.; Madhavi, C.; Rao, K.C.; Mallikarjuna, B. Sodium alginate/gelatin microbeads-intercalated with kaolin nanoclay for emerging drug delivery in wilson’s disease. Int. J. App. Pharm. 2019, 11, 71–80. [Google Scholar] [CrossRef]

- Cerri, G.; Farina, M.; Brundu, A.; Daković, A.; Giunchedi, P.; Gavini, E.; Rassu, G. Natural zeolites for pharmaceutical formulations: Preparation and evaluation of a clinoptilolite-based material. Microporous Mesoporous Mater. 2016, 223, 58–67. [Google Scholar] [CrossRef]

- De Gennaro, B.; Mercurio, M.; Cappelletti, P.; Catalanotti, L.; Daković, A.; De Bonis, A.; Grifa, C.; Izzo, F.; Kraković, M.; Monetti, V.; et al. Use of surface modified natural zeolite (SMNZ) in pharmaceutical preparations. Part 2. A new approach for a fast functionalization of zeolite-rich carriers. Microporous Mesoporous Mater. 2016, 235, 42–49. [Google Scholar] [CrossRef]

- Pasquino, R.; Di Domenico, M.; Izzo, F.; Gaudino, D.; Vanzanella, V.; Grizzuti, N.; de Gennaro, B. Rheology-sensitive response of zeolite-supported anti-inflammatory drug systems. Colloids Surf. B Biointerfaces 2016, 146, 938–944. [Google Scholar] [CrossRef] [PubMed]

- Cappelletti, P.; Colella, A.; Langella, A.; Mercurio, M.; Catalanotti, L.; Monetti, V.; de Gennaro, B. Use of surface modified natural zeolite (SMNZ) in pharmaceutical preparations Part 1. Mineralogical and technological characterization of some industrial zeolite-rich rocks. Microporous Mesoporous Mater. 2017, 250, 232–244. [Google Scholar] [CrossRef]

- De Gennaro, B.; Izzo, F.; Catalanotti, L.; Langella, A.; Mercurio, M. Surface modified phillipsite as a potential carrier for NSAIDs release. Adv. Sci. Lett. 2017, 23, 5941–5943. [Google Scholar] [CrossRef]

- Mercurio, M.; Izzo, F.; Langella, A.; Grifa, C.; Germinario, C.; Daković, A.; Aprea, P.; Pasquino, R.; Cappelletti, P.; Graziano, F.S.; et al. Surface-modified phillipsite-rich tuff from the Campania region (southern Italy) as a promising drug carrier: An ibuprofen sodium salt trial. Am. Miner. 2018, 103, 700–710. [Google Scholar] [CrossRef]

- Izzo, F.; Mercurio, M.; de Gennaro, B.; Aprea, P.; Cappelletti, P.; Daković, A.; Germinario, C.; Grifa, C.; Smiljanic, D.; Langella, A. Surface modified natural zeolites (SMNZs) as nanocomposite versatile materials for health and environment. Colloids Surf. B Biointerfaces 2019, 182, 110380. [Google Scholar] [CrossRef]

- Callahan, J.C.; Cleary, G.W.; Elefant, M.; Kaplan, G.; Kensler, T.; Nash, R.A. Equilibrium moisture content of pharmaceutical excipients. Drug Dev. Ind. Pharm. 1982, 8, 355–369. [Google Scholar] [CrossRef]

- Gerhardt, A.H. Moisture effects on solid dosage forms-formulation, processing, and stability. J. GXP Compliance 2009, 13, 58–66. [Google Scholar]

- Shalini, Y.; Annapurneswari, T.S.; Sundari, C.B.T.; Rao, V.J.; Nath, A.R. Method development and validation for simultaneous estimation of propranolol hydrochloride and flunarizine dihydrochloride in bulk and pharmaceutical dosage form by RP-HPLCY. Int. Res. J. Pharm. Appl. Sci. 2012, 2, 143–148. [Google Scholar]

- Huertas, F.J.; Chou, L.; Wollast, R. Mechanism of kaolinite dissolution at room temperature and pressure. Part II: Kinetic study. Geochim. Cosmochim. Acta. 1999, 63, 3261–3275. [Google Scholar] [CrossRef]

- Rozalen, M.; Huertas, F.J.; Brady, P.V. Experimental study of the effect of pH and temperature on the kinetics of montmorillonite dissolution. Geochim. Cosmochim. Acta. 2009, 73, 3752–3766. [Google Scholar] [CrossRef]

- Sheth, A.R.; Grant, D.J.W. Relationship between the structure and properties of pharmaceutical crystals. KONA Powder Part. J. 2005, 23, 36–48. [Google Scholar] [CrossRef]

- Hlinak, A.J.; Kuriyan, K.; Morris, K.R.; Reklaitis, G.V.; Basu, P.K. Understanding critical material properties for solid dosage form design. J. Pharm. Innov. 2006, 1, 12–17. [Google Scholar] [CrossRef]

- Mirza, S.; Miroshnyk, I.; Heinämäki, J.; Antikainen, O.; Rantanen, J.; Vuorela, P.; Vuorela, H.; Yliruusi, J. Crystal morphology engineering of pharmaceutical solids: Tabletting performance enhancement. AAPS PharmSciTech 2009, 10, 113–119. [Google Scholar] [CrossRef]

- Awad, M.E.; López-Galindo, A.; El Rahmany, M.M.; El-Desoky, H.M.; Viseras, C. Characterization of Egyptian kaolins for health-care uses. Appl. Clay Sci. 2017, 135, 176–189. [Google Scholar] [CrossRef]

- Awad, M.E.; López-Galindo, A.; Sánchez-Espejo, R.; Sainz-Díaz, C.I.; El-Rahmany, M.M.; Viseras, C. Crystallite size as a function of kaolinite structural order-disorder and kaolin chemical variability: Sedimentological implication. Appl. Clay Sci. 2018, 162, 261–267. [Google Scholar] [CrossRef]

- Gamlen, M. An instrumental process: Tablet compaction. Innov. Pharm. Technol. 2013, 44, 54–58. [Google Scholar]

- Yendluri, R.; Otto, D.P.; De Villiers, M.M.; Vinokurov, V.; Lvov, Y.M. Application of halloysite clay nanotubes as a pharmaceutical excipient. Int. J. Pharm. 2017, 521, 267–273. [Google Scholar] [CrossRef]

- Osamura, T.; Takeuchi, Y.; Onodera, R.; Kitamura, M.; Takahashi, Y.; Tahara, K.; Takeuchi, H. Characterization of tableting properties measured with a multi-functional compaction instrument for several pharmaceutical excipients and actual tablet formulations. Int. J. Pharm. 2016, 510, 195–202. [Google Scholar] [CrossRef]

- Maynard, R.N. A method for removing titanium dioxide impurities from kaolin. Clays Clay Miner. 1969, 17, 59–62. [Google Scholar] [CrossRef]

- Conley, R.F. Practical Dispersion: A Guide to Understanding and Formulating Slurries; John Wiley & Sons: Hoboken, NJ, USA, 1996; p. 464. [Google Scholar]

- Hammouda, I.; Mihoubi, D. Thermodynamic and mechanical characterisation of kaolin clay. Pol. J. Chem. Technol. 2014, 16, 28–35. [Google Scholar] [CrossRef]

- Moore, D.M.; Reynolds, R.C. X-ray Diffraction and the Identification and Analysis of Clay Minerals; Oxford University Press: Oxford, UK, 1989; p. 332. [Google Scholar]

- López-Galindo, A.; Torres-Ruiz, J.; Gonzalez-López, J.M. Mineral quantification in sepiolite-palygorskite deposits using X-ray diffraction and chemical data. Clay Miner. 1996, 31, 217–224. [Google Scholar] [CrossRef]

- Hinckley, D.N. Mineralogical and chemical variations in the kaolin deposits of the coastal plain of Georgia and South Carolina. Am. Mineral. 1965, 50, 1865–1883. [Google Scholar]

- Martín-Ramos, J.D. X-Powder, a Software Package for Powder X-ray Diffraction Analysis. Legal Deposit GR. 1001/04. 2004. Available online: http://www.xpowder.com (accessed on 10 November 2019).

- Rodriguez-Navarro, C.; Ruiz-Agudo, E.; Ortega-Huertas, M.; Hansen, E. Nanostructure and irreversible colloidal behavior of Ca(OH)2: Implications in cultural heritage conservation. Langmuir 2005, 21, 10948–10957. [Google Scholar] [CrossRef]

- QAS/11-450. Bulk Density and Tapped Density of Powders. World Health Organization Monograph on Specifications for Pharmaceutical Preparations. 2012. Available online: https://www.who.int/medicines/publications/pharmacopoeia/Bulk-tapped-densityQAS11_450FINAL_MODIFIEDMarch2012.pdf (accessed on 21 November 2019).

- Djuris, J.; Medarevic, D.; Krstic, M.; Djuric, Z.; Ibric, S. Application of quality by design concepts in the development of fluidized bed granulation and tableting processes. J. Pharm. Sci. 2013, 102, 1869–1882. [Google Scholar] [CrossRef]

- Hausner, H.H. Friction conditions in a mass of metal powder. Int. J. Powder Metall. 1967, 3, 7–13. [Google Scholar]

- Carr, R.L. Evaluating flow properties of solids. Chem. Eng. J. 1965, 72, 163–168. [Google Scholar]

- Osamura, T.; Takeuchi, Y.; Onodera, R.; Kitamura, M.; Takahashi, Y.; Tahara, K.; Takeuchi, H. Formulation design of granules prepared by wet granulation method using a multi-functional single-punch tablet press to avoid tableting failures. Asian J. Pharm. Sci. 2018, 13, 113–119. [Google Scholar] [CrossRef]

- Kotłowska, H.; Sznitowska, M. Development of orodispersible minitablets with lorazepam using Gamlen Tablet Press. Int. J. Pharm. 2018, 536, 502. [Google Scholar] [CrossRef]

- Osamura, T.; Takeuchi, Y.; Onodera, R.; Kitamura, M.; Takahashi, Y.; Tahara, K.; Takeuchi, H. Prediction of effects of punch shapes on tableting failure by using a multi-functional single-punch tablet press. Asian J. Pharm. Sci. 2017, 12, 412–417. [Google Scholar] [CrossRef]

- Adamis, Z.; Williams, R.B. International Programme on Chemical Safety. Bentonite, Kaolin and Selected Clay Minerals. World Health Organization, 2005. Available online: https://apps.who.int/iris/handle/10665/43102 (accessed on 21 November 2019).

- ICH-Q3D. ICH Guideline Q3D on Elemental Impurities. European Medicines Agency, 2014. Available online: https://www.ema.europa.eu/en/documents/scientific-guideline/international-conference-harmonisation-technical-requirements-registration-pharmaceuticals-human-use_en-13.pdf (accessed on 21 November 2019).

- Kakali, G.; Perraki, T.; Tsivilis, S.; Badogiannis, E. Thermal treatment of kaolin: The effect of mineralogy on the pozzolanic activity. Appl. Clay Sci. 2001, 20, 73–80. [Google Scholar] [CrossRef]

- Wardhana, Y.W.; Hasanah, A.N.; Primandini, P. Deformation and adsorption capacity of kaolin that is influenced by temperature variation on calcination. Int. J. Pharm. Pharm. Sci. 2014, 6, 78–5867. [Google Scholar]

- York, P. Particle slippage and rearrangement during compression of pharmaceutical powders. J. Pharm. Pharmacol. 1978, 30, 6–10. [Google Scholar] [CrossRef] [PubMed]

- Goh, H.P.; Heng, P.W.S.; Liew, C.V. Comparative evaluation of powder flow parameters with reference to particle size and shape. Int. J. Pharm. 2018, 547, 133–141. [Google Scholar] [CrossRef]

- Rowe, R.C.; Sheskey, P.J.; Cook, W.G.; Fenton, M.E. (Eds.) Handbook of Pharmaceutical Excipients, 7th ed.; APhA/Pharmaceutical Press: London, UK, 2012; p. 1064. [Google Scholar]

- Chandrasekhar, S.; Ramaswamy, S. Influence of mineral impurities on the properties of kaolin and its thermally treated products. Appl. Clay Sci. 2002, 21, 133–142. [Google Scholar] [CrossRef]

- Bayor, M.T.; Tuffour, E.; Lambon, P.S. Evaluation of starch from new sweet potato genotypes for use as a pharmaceutical diluent, binder or disintegrant. J. Appl. Pharm. Sci. 2013, 3, S17–S23. [Google Scholar]

- Sun, C.C. True density of microcrystalline cellulose. J. Pharm. Sci. 2005, 94, 2132–2134. [Google Scholar] [CrossRef]

- Capece, M.; Silva, K.R.; Sunkara, D.; Strong, J.; Gao, P. On the relationship of inter-particle cohesiveness and bulk powder behavior: Flowability of pharmaceutical powders. Int. J. Pharm. 2016, 511, 178–189. [Google Scholar] [CrossRef]

- Neumann, B.S. The flow properties of powders. In Advances in Pharmaceutical Sciences; Bean, H.S., Beckett, A.H., Carless, J.E., Eds.; Academic Press: London, UK, 1967; Volume II, pp. 181–221. [Google Scholar]

- Sun, C.; Grant, D.J. Effects of initial particle size on the tableting properties of l-lysine monohydrochloride dihydrate powder. Int. J. Pharm. 2001, 215, 221–228. [Google Scholar] [CrossRef]

- Shah, U.V.; Karde, V.; Ghoroi, C.; Heng, J.Y.Y. Influence of particle properties on powder bulk behaviour and processability. Int. J. Pharm. 2017, 518, 138–154. [Google Scholar] [CrossRef] [PubMed]

- Rouquerol, J.; Avnir, D.; Fairbridge, C.W.; Everett, D.H.; Haynes, J.M.; Pernicone, N.; Ramsay, J.D.F.; Sing, K.S.W.; Unger, K.K. Recommendations for the characterization of porous solids. Pure Appl. Chem. 1994, 66, 1739–1758. [Google Scholar] [CrossRef]

- Keleṣ, Ö.; Barcenas, N.P.; Sprys, D.H.; Bowman, K.J. Effect of porosity on strength distribution of microcrystalline cellulose. AAPS PharmSciTech 2015, 16, 1455–1464. [Google Scholar] [CrossRef] [PubMed]

- Gong, X.; Chang, S.Y.; Osei-Yeboah, F.; Paul, S.; Perumalla, S.R.; Shi, L.; Sun, W.; Zhou, Q.; Sun, C.C. Dependence of tablet brittleness on tensile strength and porosity. Int. J. Pharm. 2015, 493, 208–213. [Google Scholar] [CrossRef] [PubMed]

- Ford, J. Thermal analysis of hydroxypropylmethylcellulose and methylcellulose: Powders, gels and matrix tablets. Int. J. Pharm. 1999, 179, 209–228. [Google Scholar] [CrossRef]

- Pirayavaraporn, C.; Rades, T.; Tucker, I.G. Determination of moisture content in relation to thermal behaviour and plasticization of Eudragit RLPO. Int. J. Pharm. 2012, 422, 68–74. [Google Scholar] [CrossRef]

- Krok, A.; Vitorino, N.; Zhang, J.; Frade, J.R.; Wu, C.Y. Thermal properties of compacted pharmaceutical excipients. Int. J. Pharm. 2017, 534, 119–127. [Google Scholar] [CrossRef]

- Mielenz, R.C.; Schieltz, N.C.; King, M.E. Thermogravimetric analysis of clay and clay-like minerals. Clays Clay Miner. 1953, 2, 285–314. [Google Scholar] [CrossRef]

- Koopman, D.E. Thermal analysis of kaolin clays: Correlation with X-ray crystallinity data. In Analytical Calorimetry; Porter, R.S., Johnson, J.F., Eds.; Springer: Berlin/Heidelberg, Germany, 1968; pp. 189–194. [Google Scholar]

- Tomasetta, I.; Barletta, D.; Poletto, M. The effect of temperature on flow properties of fine powders. Chem. Eng. Trans. 2011, 24, 655–660. [Google Scholar]

| Sample | SiO2 | Al2O3 | TiO2 | Fe2O3 | MgO | CaO | Na2O | K2O | LOI | Al2O3/ SiO2 | Kaolinite % | Illite % | Quartz % | Anatase % |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| N-2 | 43.11 | 36.82 | 1.1 | 0.60 | 0.13 | 0.04 | 0.26 | 0.01 | 17.91 | 0.85 | 99 | - | - | 1 |

| K-3 | 43.13 | 35.85 | 0.5 | 0.54 | 0.18 | 0.04 | 0.26 | 0.44 | 18.99 | 0.83 | 95 | 3 | 1 | 1 |

| F-2 | 43.04 | 36.84 | 1.2 | 0.74 | 0.06 | 0.06 | 0.04 | 0.01 | 17.92 | 0.85 | 98 | - | 1 | 1 |

| D-6 | 42.86 | 36.41 | 1.12 | 0.71 | 0.06 | 0.04 | 0.08 | 0.02 | 18.57 | 0.85 | 98 | - | 1 | 1 |

| Sample Code | Heating Conditions | Crystallite Size D001 (nm) | Hinckley Index | Bulk Density (g/mL) ± 0.01 | Tapped Density (g/mL) ± 0.01 | Direct Flowability (g/s) ± 0.1 | Carr’s Index ± 0.01 | Hausner Ratio ± 0.01 | Flow Character |

|---|---|---|---|---|---|---|---|---|---|

| N-2 | 70 °C (2 h) | 44 | 1.50 | 0.55 | 0.81 | 2.64 | 32.00 | 1.47 | Poor |

| 400 °C (10 °C/min) | 37 | 0.91 | 0.66 | 0.76 | 3.74 | 12.50 | 1.14 | Good | |

| K-3 | 70 °C (2 h) | 39 | 1.33 | 0.51 | 0.81 | 2.05 | 36.67 | 1.58 | Poor |

| 400 °C (10 °C/min) | 34 | 0.83 | 0.66 | 0.71 | 2.56 | 8.00 | 1.09 | Excellent | |

| F-2 | 70 °C (2 h) | 31 | 0.45 | 0.64 | 0.83 | 2.06 | 22.50 | 1.29 | Very poor |

| 400 °C (10 °C/min) | 26 | 0.59 | 0.64 | 0.75 | 3.51 | 15.38 | 1.18 | Good | |

| D-6 | 70 °C (2 h) | 30 | 0.27 | 0.54 | 0.67 | 2.04 | 20.00 | 1.25 | Very poor |

| 400 °C (10 °C/min) | 25 | 0.48 | 0.50 | 0.62 | 3.85 | 19.17 | 1.24 | Fair |

| Sample Code | Particle Size Distribution | Cumulative Pore Volume (BJH) cm3/g | Mass Loss TG % (at 400 °C) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| <1 μm | 1–4 μm | 4–10 μm | >10 μm | D10 μm | D50 μm | D90 μm | Span | |||

| N-2 | 55.22 | 35.87 | 4.46 | 4.45 | 0.42 | 0.87 | 3.67 | 3.74 | 0.1360 | −3.98 |

| K-3 | 59.93 | 35.11 | 3.18 | 1.78 | 0.42 | 0.83 | 2.50 | 2.51 | 0.0640 | −4.95 |

| F-2 | 60.08 | 35.45 | 2.23 | 2.24 | 0.42 | 0.84 | 2.25 | 2.18 | 0.0951 | −5.82 |

| D-6 | 62.24 | 34.01 | 1.89 | 1.86 | 0.42 | 0.81 | 2.15 | 2.14 | 0.1096 | −2.98 |

| Tableting and Tablet Parameters | N-2 | K-3 | F-2 | D-6 | Commercial Kaolin |

|---|---|---|---|---|---|

| Elastic Recovery (%) “Compressibility” | 25.61 ± 0.19 | 25.43 ± 0.18 | 23.51 ± 0.11 | 21.74 ± 0.21 | 30.92 ± 0.21 |

| Ejection Stress ES (MPa) “Manufacturability” | 8.28 ± 0.03 | 7.85 ± 0.17 | 8.67 ± 0.16 | 11.45 ± 0.15 | 4.01 ± 0.17 |

| Tensile Fracture Stress TFS (MPa) “Compactability” | 2.04 ± 0.02 | 1.85 ± 0.02 | 2.09 ± 0.02 | 2.32 ± 0.02 | 1.16 ± 0.04 |

| Compression Energy Ec (N.m) | 1.88 ± 0.01 | 1.83 ± 0.01 | 1.81 ± 0.01 | 1.99 ± 0.04 | 1.58 ± 0.02 |

| Detachment Stress DS (MPa) | 8.19 ± 0.02 | 7.61 ± 0.03 | 9.56 ± 0.04 | 8.65 ± 0.03 | 8.24 ± 0.07 |

| Detachment Energy ED (N.m) | 1.80 ± 0.01 | 1.71 ± 0.02 | 1.93 ± 0.04 | 1.80 ± 0.03 | 0.76 ± 0.06 |

| Ejection Energy (N.m) | 0.26 ± 0.01 | 0.23 ± 0.03 | 0.34 ± 0.03 | 0.43 ± 0.05 | 0.07 ± 0.01 |

| Tablet Hardness H (N) | 36.67 ± 0.4 | 33.00 ± 0.7 | 38.33 ± 0.58 | 44.00 ± 0.7 | 18.67 ± 0.58 |

| Tablet Diameter (mm) | 6.02 ± 0.01 | 6.04 ± 0.03 | 6.04 ± 0.01 | 6.05 ± 0.02 | 6.03 ± 0.02 |

| Tablet Thickness (mm) | 1.9 ± 0.01 | 1.88 ± 0.03 | 1.93 ± 0.06 | 2.00 ± 0.01 | 1.70 ± 0.01 |

| Parameters | ER | ES | TFS | H | Ec | HR | CI | D50 | Span | PSD < 1 μ % | HI | D001 | TG% | BJH |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ER | 1.00 | |||||||||||||

| ES | −0.92 | 1.00 | ||||||||||||

| TFS | −0.89 | 0.93 | 1.00 | |||||||||||

| H | −0.92 | 0.95 | 1.00 | 1.00 | ||||||||||

| Ec | −0.65 | 0.89 | 0.80 | 0.80 | 1.00 | |||||||||

| HR | −0.93 | 0.92 | 0.99 | 0.99 | 0.71 | 1.00 | ||||||||

| CI | −0.90 | 0.88 | 0.98 | 0.98 | 0.68 | 0.99 | 1.00 | |||||||

| D50 | 0.75 | −0.68 | −0.42 | −0.49 | −0.47 | −0.48 | −0.40 | 1.00 | ||||||

| Span | 0.72 | −0.47 | −0.32 | −0.38 | −0.09 | −0.44 | −0.39 | 0.88 | 1.00 | |||||

| PSD < 1 μ % | −0.79 | 0.63 | 0.43 | 0.50 | 0.33 | 0.51 | 0.45 | −0.97 | −0.96 | 1.00 | ||||

| HI | 0.98 | −0.82 | −0.79 | −0.83 | −0.47 | −0.86 | −0.84 | 0.77 | 0.83 | −0.84 | 1.00 | |||

| D001 | 0.93 | −0.72 | −0.71 | −0.75 | −0.33 | −0.80 | −0.78 | 0.73 | 0.86 | −0.84 | 0.99 | 1.00 | ||

| TG% | 0.39 | −0.72 | −0.61 | −0.61 | −0.95 | −0.50 | −0.46 | 0.27 | −0.17 | −0.09 | 0.19 | 0.03 | 1.00 | |

| BJH | −0.08 | 0.28 | 0.52 | 0.46 | 0.44 | 0.43 | 0.49 | 0.52 | 0.62 | −0.55 | 0.07 | 0.15 | −0.50 | 1.00 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Awad, M.E.; López-Galindo, A.; Medarević, D.; Đuriš, J.; El-Rahmany, M.M.; Ibrić, S.; Viseras, C. Flow and Tableting Behaviors of Some Egyptian Kaolin Powders as Potential Pharmaceutical Excipients. Minerals 2020, 10, 23. https://doi.org/10.3390/min10010023

Awad ME, López-Galindo A, Medarević D, Đuriš J, El-Rahmany MM, Ibrić S, Viseras C. Flow and Tableting Behaviors of Some Egyptian Kaolin Powders as Potential Pharmaceutical Excipients. Minerals. 2020; 10(1):23. https://doi.org/10.3390/min10010023

Chicago/Turabian StyleAwad, Mahmoud E., Alberto López-Galindo, Djordje Medarević, Jelena Đuriš, Mahmoud M. El-Rahmany, Svetlana Ibrić, and César Viseras. 2020. "Flow and Tableting Behaviors of Some Egyptian Kaolin Powders as Potential Pharmaceutical Excipients" Minerals 10, no. 1: 23. https://doi.org/10.3390/min10010023

APA StyleAwad, M. E., López-Galindo, A., Medarević, D., Đuriš, J., El-Rahmany, M. M., Ibrić, S., & Viseras, C. (2020). Flow and Tableting Behaviors of Some Egyptian Kaolin Powders as Potential Pharmaceutical Excipients. Minerals, 10(1), 23. https://doi.org/10.3390/min10010023