Abstract

This paper presents a comprehensive review and theoretical analysis of integrating Cyclic Solvent Injection (CSI) with multilateral well (MLW) technologies to enhance heavy oil recovery. Given that many MLW configurations inherently exhibit symmetrical geometries, CSI–MLW integration offers structural advantages for fluid distribution. CSI offers a non-thermal mechanism for oil production through viscosity reduction, oil swelling, and foamy oil behaviour, but its application is often limited by poor sweep efficiency and non-uniform solvent distribution in conventional single-well configurations. In contrast, MLW configurations are effective in increasing reservoir contact and improving flow control but lack solvent-based enhancement mechanisms. In particular, symmetrical MLW configurations, such as dual-opposing laterals and evenly spaced fishbone laterals, can facilitate balanced solvent distribution and pressure profiles, thereby improving sweep efficiency and mitigating early breakthrough. By synthesizing experimental findings and theoretical insights from the existing literature, laboratory studies have reported that post-CHOPS CSI using a 28% C3H8–72% CO2 mixture can recover about 50% of the original oil in place after six cycles, while continuous-propagation CSI (CPCSI) has achieved up to ~85% OOIP in 1D physical models. These representative values illustrate the performance spectrum observed across different CSI operational modes, underscoring the importance of operational parameters in governing recovery outcomes. Building on this foundation, this paper synthesizes key operational parameters, including solvent composition, pressure decline rate, and well configuration, that influence CSI performance. While previous studies have extensively reviewed CSI and MLW as separate technologies, systematic analyses of their integration remain limited. This review addresses that gap by providing a structured synthesis of CSI–MLW interactions, supported by representative quantitative evidence from the literature. The potential synergy between CSI and MLW is highlighted as a promising direction to overcome current limitations. By leveraging geometric symmetry in well architecture, the integrated CSI–MLW approach offers unique opportunities for optimizing solvent utilization, enhancing recovery efficiency, and guiding future experimental and field-scale developments. Such symmetry-oriented designs are also central to the experimental framework proposed in this study, in which potential methods, such as the microfluidic visualization of different MLW configurations, spanning small-scale visualization studies, bench-scale experiments on fluid and chemical interactions, and mock field setups with pipe networks, are proposed as future avenues to further explore and validate this integrated strategy.

1. Introduction

Heavy oil resources account for a significant share of global petroleum reserves, making their efficient development essential to meet growing energy demand. Owing to their high viscosity and geological complexity, Enhanced Oil Recovery (EOR) methods are widely used to improve production beyond primary and secondary stages.

Within EOR applications, multilateral wells (MLW) have proven effective in increasing reservoir contact and improving flow control. Their ability to influence fluid movement and expand swept volume makes them a potential complement to solvent-based recovery processes. Combining such well configurations with solvent-based methods could leverage the strengths of both approaches to improve recovery performance in challenging reservoirs.

Solvent-based methods have emerged as an attractive non-thermal alternative, particularly suited for heavy oil reservoirs where thermal methods may be constrained by heat loss, energy cost, or environmental impact. Within this category, CSI has gained increasing attention due to its ability to lower viscosity, swell oil, and sustain foamy-oil flow without the need for steam or combustion. These advantages make CSI a promising option for enhancing recovery in both onshore and offshore heavy oil developments.

However, CSI faces challenges such as poor vertical solvent distribution in heterogeneous reservoirs, causing low sweep efficiency, early breakthrough, and reduced recovery. Although previous reviews have examined CSI and MLW separately, systematic evaluations that integrate both technologies, quantify potential performance improvements, and address implementation challenges are scarce. This review addresses this gap by exploring the integration of CSI with MLW to improve distribution by enlarging reservoir contact and optimizing flow paths. Based on recent experimental, theoretical, and numerical studies, key operational parameters are identified and the potential of MLW to address current limitations is demonstrated, offering guidance for future research and applications. The main contributions of this review are the following:

- Introducing the novel concept of integrating CSI with MLW systems to enhance sweep efficiency and reduce early solvent breakthrough;

- Identifying and categorizing critical operational parameters affecting CSI efficiency using insights from recent experimental, theoretical, and simulation-based studies;

- Proposing practical MLW-based strategies to optimize fluid flow and solvent contact within heterogeneous reservoirs;

- Highlighting potential future research directions and practical considerations for the field application of hybrid CSI–MLW technologies, aimed at promoting higher recovery factors in challenging geological settings.

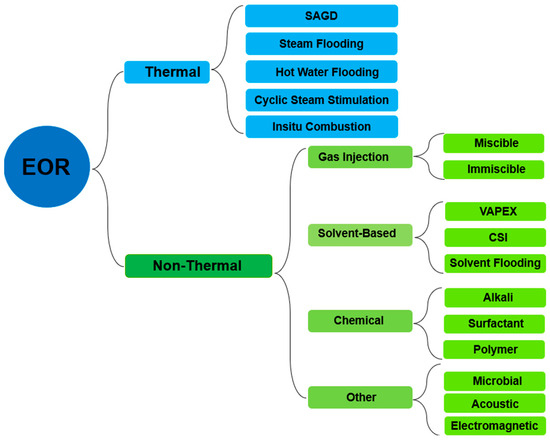

2. Cyclic Solvent Injection

EOR methods include thermal, gas injection, chemical, and other innovative techniques, as illustrated in Figure 1. The diagram presents a hierarchical classification: the top-level divides EOR into thermal and non-thermal categories. Thermal methods, such as SAGD, Cyclic Steam Stimulation, Steam Flooding, Hot Water Flooding, and In Situ Combustion, reduce oil viscosity through heat [1] but often require high energy and raise environmental concerns. Non-thermal methods are further divided into gas injection, solvent-based processes, chemical methods, and other emerging technologies. Gas injection can be miscible or immiscible, while chemical methods include alkali, surfactant, and polymer flooding. Other techniques involve microbial, acoustic, and electromagnetic processes. Within solvent-based EOR, Vapor Extraction (VAPEX), CSI, and solvent flooding are key subtypes. This structure situates CSI as a distinct non-thermal method that relies on solvent–oil interactions to enhance recovery. MLW, while not shown as a separate category in the EOR classification, functions as a flexible well configuration strategy that can complement multiple EOR processes, including CSI, by improving reservoir contact and controlling fluid flow. This integrated perspective forms the conceptual basis of this review.

Figure 1.

Classification of EOR Methods.

Against this background, the focus is placed on CSI within the solvent-based category, which has gained attention for its simplicity, lower environmental impact, and effectiveness in heavy oil recovery. CSI cyclically injects solvent, followed by soaking and production, reducing oil viscosity, inducing oil swelling, and generating stable foamy oil, thereby improving reservoir fluid mobility and recovery efficiency [2,3].

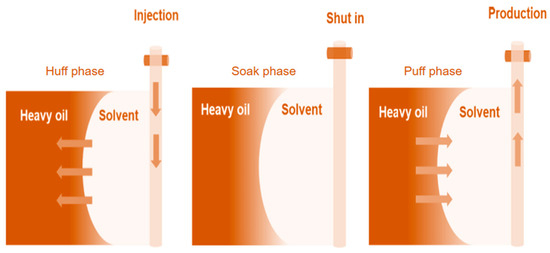

As shown in Figure 2, CSI follows a cyclic three-phase production process: Injection (Huff phase), Soaking (Soak phase), and Production (Puff phase), all completed within a single well [4]. CSI relies entirely on the physicochemical interactions of solvents to reduce crude oil viscosity, without heat input, making it a non-thermal recovery technique [5].

Figure 2.

Schematic Diagram of Three Periods of a CSI cycle [4].

In the Huff phase (Injection phase), a high-pressure solvent, such as propane, butane, or CO2, or a tailored mixture, is injected into the reservoir at pressures typically below the minimum miscibility pressure (MMP) to avoid excessive gas channeling. The injected solvent penetrates the pore network, displaces in situ fluids, and establishes contact with the heavy oil. Solvent dissolution into the oil phase initiates viscosity reduction through molecular dilution and promotes swelling, which increases the oil’s relative volume and drives it toward adjacent lower-pressure regions. The degree of penetration and contact efficiency during this phase is strongly influenced by reservoir heterogeneity, permeability anisotropy, and the solvent injection rate.

In the Soak phase, the well is shut in for a predetermined duration, allowing sufficient time for solvent–oil mass transfer. This period enables the diffusion and dispersion of the solvent deeper into the formation, facilitating more uniform contact with the oil. The solvent–oil interaction not only reduces viscosity but may also alter asphaltene stability, resulting in improved mobility. Additionally, dissolved gases within the oil may expand when pressure is subsequently reduced, setting the stage for gas-driven production in the next phase. The duration of the soak phase must balance mass transfer optimization with operational efficiency, as excessively long soak times may yield diminishing returns.

In the Puff phase (Production phase), the well is reopened, and the reservoir pressure is lowered, triggering exsolution of dissolved gases from the oil phase. The expansion of these gases provides a drive mechanism, pushing the mobilized oil–solvent mixture toward the production wellbore. This phase is characterized by high initial production rates, which decline as the solvent is recovered and the oil saturation decreases. Recovered solvent can be separated at the surface and reinjected in subsequent cycles, enhancing process economics. The cycle is repeated until the incremental oil production from additional cycles becomes uneconomic, typically due to reduced solvent effectiveness and increasing gas–oil ratios.

2.1. Fundamental Principles of CSI

In the CSI process, mass transfer is the key mechanism for enhancing oil recovery (EOR) [6]. CSI operates using a Huff-n-Puff approach, where solvent diffusion and convection drive solvent penetration into heavy oil, improving rheological properties, reducing flow resistance, and enhancing recovery efficiency [7]. During this process, solvent-oil interactions trigger a series of physicochemical changes, primarily involving the following mechanisms:

- Interfacial Tension Reduction

When the solvent diffuses into the reservoir, it interacts with the crude oil and dissolves its lighter hydrocarbon components, weakening intermolecular forces at the oil–gas or oil–solvent interface, thereby reducing interfacial tension (IFT) [8]. A reduction in IFT decreases capillary trapping, making oil droplets more easily detached from the rock surface, thereby enhancing fluid mobilization. Additionally, lower IFT facilitates a more uniform solvent-oil mixing zone, improving two-phase flow characteristics and ultimately increasing oil recovery efficiency.

- Viscosity Reduction

The high viscosity of heavy oil primarily results from strong intermolecular forces and the entanglement of large hydrocarbon molecules such as asphaltenes and resins [9]. When solvents such as CH4, C3H8, and CO2 penetrate heavy oil, they weaken intermolecular interactions, reducing cohesion and allowing oil molecules to move more freely, thereby significantly lowering crude oil viscosity [10]. As viscosity decreases, oil mobility improves, reducing fluid flow resistance in porous media and lowering the pressure gradient required for production, ultimately enhancing overall reservoir utilization. The viscosity of the oil–solvent mixture is commonly estimated using the logarithmic mixing rule, expressed as follows [11]:

where

- : The viscosity of solvent-saturated oil;

- : The mole fraction of component i in the oil phase;

- : The apparent viscosity of component i.

- Oil Swelling Effect

When a solvent dissolves into crude oil, it induces oil volume expansion (a swelling effect) [12]. As the oil volume increases, the proportion of recoverable oil in the reservoir rises, leading to an increase in oil saturation (So) and consequently improving oil recovery efficiency. Additionally, the swelling effect enhances the relative permeability of fluids, reduces residual oil saturation, and improves reservoir fluid mobility.

- Foamy Oil Flow

Foamy oil flow is a critical mechanism in heavy oil recovery, particularly under non-thermal and solution gas drive conditions. Unlike conventional gas-oil two-phase flow, foamy oil behaves as a dispersed system consisting of microbubbles suspended in the continuous oil phase. This unique flow regime provides significant mobility reduction and pressure support, contributing to sustained oil production and enhanced solvent utilization. During the production phase, the solvent gradually precipitates from crude oil, forming gas bubbles and generating foamy oil. Unlike conventional gas drive, microbubbles in foamy oil are uniformly distributed, ensuring more stable displacement pressure and delaying gas breakthrough to the production well, thereby improving solvent utilization efficiency [13]. Additionally, the presence of foam reduces gas channeling risks, allowing for more uniform pressure depletion, which helps maintain a prolonged period of high oil production and enhances overall recovery efficiency. Early foundational studies clarified the fundamental mechanism of foamy oil formation as involving non-equilibrium gas dissolution and dispersed microbubble formation within the viscous oil phase [14,15,16]. For instance, when methane is used as a solvent, the foamy oil formation process involves a nonequilibrium gas release mechanism [17], which can be expressed as

where

- : Methane dissolved in the oil phase;

- : Methane microbubbles in the oil phase;

- : Methane in the gas phase.

Theoretical models have quantitatively described bubble coalescence and breakup in foamy oil flow, introducing key concepts such as the critical capillary number and shear-induced bubble dispersion. These concepts effectively explain the observed mobility reduction and foam texture evolution during pressure depletion [18,19].

These classical models have laid the theoretical foundation for understanding foam structure dynamics in porous media. Building upon these insights, numerous experimental and numerical studies have been conducted to further advance the understanding of foamy oil behavior under CSI conditions. These include visual micromodel experiments, non-equilibrium phase behavior modeling, and pressure-decline optimization frameworks, which collectively deepen the mechanistic understanding and provide practical design guidance for field-scale applications. For example, Zhao and Torabi, in 2019, found that specific surfactants can effectively stabilize CO2 foams, significantly increasing oil recovery efficiency [20]. Zhou et al. [21] conducted sandpack depletion experiments on heavy oil–solvent systems, showing that appropriate solvent proportions and controlled pressure decline rates can prolong the foamy oil stage, reduce gas–oil ratios, and enhance recovery, thereby offering practical guidance for optimizing CSI operations. Jia et al. [22] developed a numerical simulation framework for foamy-oil flow in CSI processes, incorporating phase change, gas exsolution, and bubble coalescence dynamics. The model, validated against laboratory depletion tests, successfully captured multi-stage production behavior and identified key operational parameters influencing foamy-oil stability. Similarly, Rahman and Torabi (2023) developed comprehensive non-equilibrium bubble dynamics models, effectively capturing microbubble interactions and stability factors [23]. Cheperli et al. in 2024 introduced the concept of a diffusion-controlled foam stability window, systematically analyzing interactions between CO2 injection and foamy oil behavior, providing a robust theoretical basis for enhancing CSI performance [3]. In addition, other studies have examined foam behavior under CSI from both pore-scale modeling and experimental perspectives. Zhao et al., in 2022, developed a pore-scale foam flow model that incorporates viscous drag forces and bubble coalescence behavior, enabling improved prediction of steady-state foam transport in porous media [24]. The model successfully captured flow resistance characteristics and pressure profiles under various gas–liquid flow regimes, offering insights into foam propagation under CSI conditions. Li et al. [25] performed sandpack and micromodel depletion experiments with Orinoco Belt heavy oil to evaluate the effects of permeability, temperature, and pressure decline rate on foamy oil behavior. They identified critical supersaturation and bubble activation pressures as key parameters controlling foam texture evolution and stability, offering valuable insights for optimizing foam-assisted CSI processes. Their work effectively described foam texture evolution in the presence and absence of residual oil, providing a comprehensive correlation between foam strength, capillary pressure, and porous structure. Zhao and Torabi, in 2021, employed a coupled microfluidic and numerical framework to investigate the impact of CO2 injection rates and surfactant concentrations on foam texture and mobility control in CSI [26]. Their results revealed clear trends in bubble stabilization, lamellae thickness, and gas mobility reduction across different depletion scenarios. Wu et al. [27] conducted a series of sandpack pressure depletion experiments to examine the effects of temperature on foamy oil flow in CO2–heavy oil systems. They observed that increasing temperature reduces oil viscosity and weakens foamy oil stability, leading to lower recovery factors, while also identifying a secondary foamy oil flow regime at later production stages that enhances oil recovery through renewed gas entrapment. Zhao and Torabi further investigated the diffusion-controlled foam stability framework, identifying the conditions under which foamy oil structures remain intact under CSI [28]. By integrating experimental visualization with multiphase flow modeling, they also established a quantitative link between interfacial mass transfer and foam breakdown time. Rahman et al., in 2024, extended pore network modeling by incorporating dynamic film thinning and surfactant transport mechanisms to simulate foam rupture timing and spatial heterogeneity [29]. Their findings emphasized the sensitivity of CSI performance to local capillary film stability and bubble–bubble interaction dynamics, providing a refined framework for future CSI process design.

Overall, foamy oil flow plays a pivotal role in enhancing CSI effectiveness by enabling delayed gas breakthrough, improved solvent utilization, and sustained oil production through its non-equilibrium multiphase behavior. Comprehensive theoretical and experimental studies, including detailed pore-scale and core-scale investigations under CSI conditions, have significantly deepened the mechanistic understanding of foamy oil formation, evolution, and stability. These collective efforts provide essential guidance for optimizing CSI processes and further enhancing heavy oil recovery in heterogeneous reservoirs.

- Asphaltene Precipitation

Asphaltenes are high-molecular-weight components in heavy oil, and their solubility is influenced by oil phase polarity and solvent interaction [30]. When a solvent is injected into the reservoir, it may alter the phase equilibrium of the oil, leading to asphaltene precipitation. Moderate precipitation can reduce the proportion of heavy components in heavy oil, thereby enhancing oil mobility. However, excessive precipitation may block reservoir pores, reducing permeability. Therefore, in the CSI process, solvent type and injection volume must be carefully optimized to balance the benefits of improved recovery while mitigating the risk of pore blockage.

Therefore, CSI enhances reservoir fluid mobility and improves oil recovery through interfacial tension reduction, viscosity reduction, oil swelling, foamy oil flow, and asphaltene precipitation. These mechanisms work synergistically, ensuring that solvents fully interact with crude oil during the soaking phase, optimizing displacement efficiency, and increasing reservoir utilization during the production phase.

2.2. Experimental Studies of CSI

CSI evolved from the CO2 Huff-n-Puff technique, which was initially applied in heavy oil regions in Canada and the United States. In 1984, Sayegh and Maini demonstrated that CO2 Huff-n-Puff effectively reduces heavy oil viscosity and enhances oil recovery [31]. In 1989, Haskin and Alston further validated the oil swelling effect and viscosity reduction mechanism of CO2 Huff-n-Puff through field trials in Texas [32]. However, CO2 Huff-n-Puff has several limitations, including significant heat loss, solvent retention, excessively high saturation pressure, and insufficient displacement efficiency, which restrict its widespread application [33]. These challenges led to the development of CSI, which optimizes solvent selection and injection strategies to significantly improve solvent utilization and adaptability, making it one of the most effective techniques for heavy oil recovery.

Research on CSI began with solvent-driven experimental studies. Firouz and Torabi in 2012 investigated the performance of CO2, CH4, C3H8, and C4H10 in CSI and found that supercritical CO2 significantly reduces oil viscosity and enhances recovery under high-pressure conditions, while the use of mixed solvents can improve the economic feasibility of CSI [34]. Mahinpey et al. in 2012 proposed an Enhanced Cyclic Solvent Process (ECSP). Their experiment utilized stepwise injection of methane and propane, which increased solvent solubility in oil, effectively reducing viscosity and achieving higher recovery rates compared to conventional CSI [35].

Subsequently, Ivory et al., in 2010, conducted CSI experiments in post-cold production reservoirs at the Cold Lake and Lloydminster fields, using a mixed solvent of 28% C3H8 and 72% CO2 over six injection cycles, achieving a final recovery factor of 50%, thereby validating the application potential of CSI in post-cold production stages [11]. Jiang et al. in 2014 proposed a Continuous Production Cyclic Solvent Injection (CPCSI) method and experimentally verified its feasibility, showing that this approach can further improve recovery efficiency over conventional CSI [36].

Lin et al. in 2014 conducted a comprehensive review of solvent-based heavy oil recovery methods, highlighting CSI’s advantages over other solvent techniques such as VAPEX and summarizing key factors affecting CSI performance, including solvent type, injection pressure, and foamy oil stability [37]. Du et al. in 2016 systematically studied the effect of pressure decline rates on CSI recovery efficiency, finding that during the foamy oil flow-dominated phase, an optimal pressure decline rate of 5 kPa/min was identified, while in the two-phase flow-dominated phase, a faster pressure decline rate improved crude oil production rates [38].

Ahadi and Torabi in 2018 further investigated the effects of various C3H8/CH4/CO2 mixed solvents in CSI. Their experimental results indicated that increasing C3H8 concentration improved recovery, but when C3H8 exceeded 50%, the increase plateaued. Additionally, adding CO2 enhanced the apparent solubility of the solvent and improved foamy oil stability, enabling CSI to increase recovery while reducing solvent loss [39]. In the same year, Ahadi et al. in 2018 studied the impact of light hydrocarbons (C3H8, CH4) on CO2-based CSI and found that C3H8 contributed to the formation of stable foamy oil, enhancing recovery, whereas CH4 weakened the solvent effect [40]. Du et al. in 2018 explored the role of CO2-C3H8 mixed solvents in CSI, with a particular focus on asphaltene precipitation and its effect on solvent-driven recovery. Their findings showed that asphaltene precipitation reduced recovery efficiency, leading to recommendations for optimizing solvent composition in CSI [41].

Subsequent studies further refined the understanding of operational variables in CSI. Plata et al. in 2021 showed that vertical wells enhanced gravity drainage, and slower depletion rates improved efficiency, though no foamy oil was observed [42].

This observation contrasts with the findings of Ahadi et al. [39,40], who consistently reported the formation of stable foamy oil in propane–CO2 systems under CSI conditions. The discrepancy may arise from differences in experimental design, reservoir analogs, and monitoring techniques—Plata et al.’s work focused on gravity drainage in a vertical configuration with specific depletion controls, which may have suppressed foamy oil nucleation or made it less detectable [42]. Such contrasts highlight the influence of well orientation, pressure management, and observation scale on foamy oil occurrence and underscore the need to tailor CSI designs to reservoir-specific mechanisms.

Saman Mohammadi et al. in 2023 reported that higher pressure and faster depletion improved recovery, but soaking at high pressure led to efficiency loss due to asphaltene effects [43]. Lin et al. in 2024 found that CO2–N2 blends with ~17% N2 achieved the best trade-off between recovery, solubility, and cost, while higher N2 reduced performance [44]. Cartagena-Pérez, D in 2025 confirmed that a 5 kPa/min pressure decline rate led to the most stable foamy oil flow and the highest recovery in 2D visual models [45]. Compared with Plata et al.’s findings [42], which reported no foamy oil formation under slower depletion rates in vertical well configurations, Chen and Leung’s results highlight those differences in experimental setup, monitoring resolution, and reservoir analogue can strongly influence foamy oil detectability. This suggests that the absence of observed foamy oil in some studies does not necessarily indicate its absence in the reservoir but may reflect operational and diagnostic limitations. Le Van et al. in 2025 demonstrated that CO2 recovered up to 45% OOIP in tight sandstone cores, with final pressure having a strong positive effect [46]. Mohammadi, in 2025 reported that, in propane-CSI visualization tests conducted without an extended soaking stage, oil recovery increased with both injection pressure and depletion rate—reaching 18.2% IOIP at 210 psi and 5 psi/min—whereas at 113 psi the depletion rate had little effect [47]. Yang et al., in 2025, concluded that propane–methane mixtures improve sweep efficiency through synergistic dissolution and puffing mechanisms in solvent–steam systems [48]. Ogunkunle et al. in 2025 evaluated solvent-assisted low-salinity waterflooding in cyclic mode and confirmed improved oil recovery, offering insights for CSI applications [49]. Guo et al., in 2025, compared CO2 and hydrocarbon gas in cyclic injection tests, showing both enhance recovery and inform solvent selection in CSI design [50]. Yang et al., in 2025, reviewed solvent–steam co-injection and emphasized solvent choice based on volatility and phase behavior, supporting CSI solvent optimization [48].

To provide a more comprehensive overview of recent key research advancements in CSI, this study summarizes major research efforts in recent years, compiling them into Table 1. This table presents experimental variables, methodologies, and key findings from different studies, offering a clearer understanding of CSI technology trends and research priorities.

Table 1.

CSI Research Progress and Key Findings.

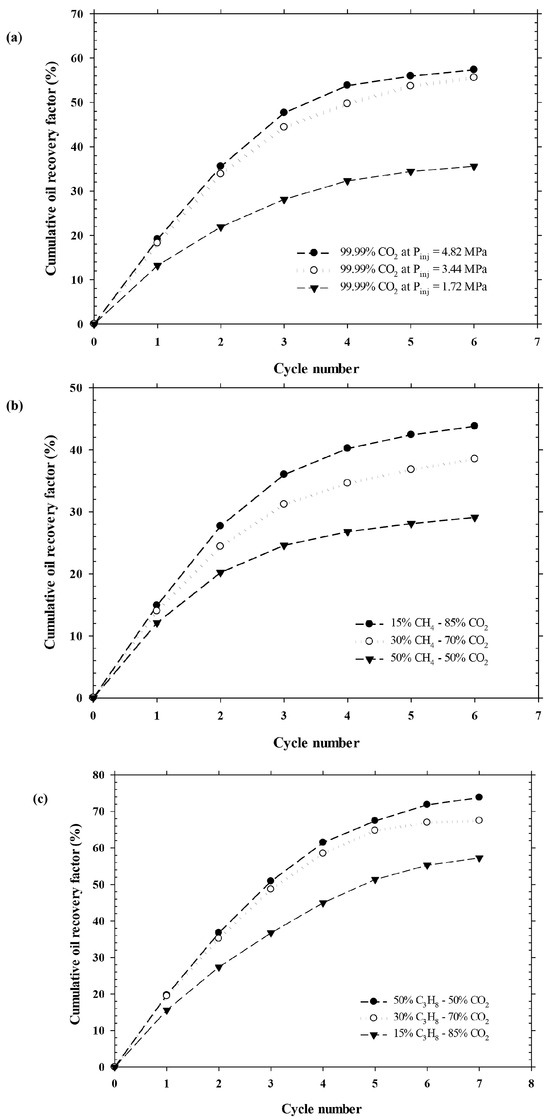

To more intuitively illustrate the parameter–performance relationships summarized in Table 1, Figure 3 highlights representative experimental results from the literature, focusing on the impact of key operational parameters on CSI recovery performance. Based on published data from Ahadi and Torabi [40], the three subplots compare (a) CO2 injection pressure, (b) CH4 content in CH4–CO2 blends, and (c) C3H8 content in C3H8–CO2 blends. The results indicate that increasing CO2 pressure enhances recovery up to an optimum value, beyond which asphaltene deposition may offset the benefits; moderate addition of C3H8 can achieve recovery comparable to higher CO2 pressures by improving solvent solubility and foamy oil stability; and excessive CH4 reduces recovery by weakening solvent–oil interactions. These quantitative findings align with the trends identified in Table 1 and underscore the importance of balancing pressure and solvent composition to maximize CSI performance, providing a practical parameter basis for future experimental and numerical studies under MLW configurations. While the experimental studies summarized in Table 1 provide valuable insights into CSI mechanisms and operational parameters, several limitations should be considered when assessing their scalability and applicability to MLW configurations.

Figure 3.

Effect of Key Operational Parameters on CSI Cumulative Oil Recovery: (a) CO2 injection pressure, (b) Concentration of CH4 in CH4/CO2 mixtures, and (c) Concentration of C3H8 in C3H8/CO2 mixtures [40].

While the experimental studies summarized in Table 1 provide valuable insights into CSI mechanisms and operational parameters, several limitations should be considered when assessing their scalability and applicability to MLW configurations:

- Geometric and Dimensional Constraints

Most experiments were performed in one-dimensional cores or two-dimensional visualization cells, which cannot fully capture the three-dimensional flow dynamics, gravity segregation, and crossflow effects expected in MLW systems. This dimensional limitation can lead to overestimation of sweep uniformity and underestimation of gravity-induced solvent override.

- Reservoir Heterogeneity Representation

Many laboratory models assume homogeneous porous media, neglecting the impact of permeability anisotropy, stratification, and connectivity variations that are critical in MLW applications. These heterogeneities strongly influence solvent distribution along multiple laterals and may diminish the synergistic effects observed in homogeneous models.

- Scale-Dependent Mass Transfer and Capillary Effects

Solvent dissolution, diffusion, and foamy oil stability are highly sensitive to pressure gradients and characteristic length scales. Laboratory-scale diffusion rates and capillary pressures may not translate directly to field-scale MLW operations, potentially leading to discrepancies in the predicted solvent utilization and recovery factor.

- Operational Coupling in MLW Systems

Most CSI experiments are based on single-well cyclic operation, without considering well-to-well interference, lateral-to-lateral pressure communication, or asynchronous cycling strategies inherent to MLW deployment. These interactions can alter injection–production dynamics, solvent breakthrough timing, and optimal depletion rates in ways not captured by conventional CSI experiments.

By acknowledging these constraints, future experimental designs should incorporate three-dimensional physical models, controlled heterogeneity, and MLW-specific injection–production schemes to more accurately evaluate the scalability and applicability of CSI mechanisms under multilateral well configurations. Addressing these aspects not only strengthens the applicability assessment of existing experimental results but also provides a solid foundation for advancing CSI research in more complex well architectures.

The above review reveals that significant progress has been made in CSI research, particularly in solvent optimization, pressure control, and foamy oil mechanisms. Studies indicate that proper solvent composition and pressure management can effectively enhance oil recovery. However, challenges such as low solvent utilization, uneven fluid distribution, and the limitations of conventional single-well CSI continue to affect its development efficiency. Therefore, it is proposed to conduct experiments to investigate the role of MLWS in CO2-based CSI, optimizing solvent selection, pressure decline rates, and other key variables to further improve recovery efficiency and enhance the overall performance of CSI development.

2.3. Numerical Simulation of CSI

Numerical simulation studies on CSI technology initially focused on the application of CO2 Huff-n-Puff in reservoirs. Yu et al. in 2014 used numerical simulation to investigate the performance of CO2 Huff-n-Puff in tight oil reservoirs, analyzing the effects of various operational parameters, including CO2 injection rate, soaking time, and cycle count. Their results indicated that the injection rate is the critical influencing factor [51]. Wang et al., in 2018, proposed a numerical simulation method for in situ CO2 Huff-n-Puff (ISCHP) technology, demonstrating that the synergistic effect of CO2 and chemical agents significantly enhances EOR. They also optimized process parameters, such as the optimal solvent concentration and soaking time [52]. Subsequently, Yu et al., in 2018, further investigated key factors influencing CO2 Huff-n-Puff in tight oil reservoirs, including CO2 molecular diffusion effects, nanopore confinement effects, and stress-sensitive deformation, all of which had a significant impact on recovery efficiency. Their study emphasized that numerical simulation models should fully account for these factors [53].

In the numerical simulation of CSI, Chang and Ivory in 2013 were the first to establish a field-scale CSI numerical simulation model. They proposed a nonequilibrium solvent dissolution and precipitation model, highlighting that ignoring nonequilibrium effects could significantly underestimate recovery predictions [17]. Moreover, Zhang et al., in 2014, conducted a numerical upscaling study on CSI, demonstrating that as model size increases, the influence of capillary pressure gradually diminishes. They suggested that capillary pressure could be neglected in field-scale applications [54]. Rangriz Shokri and Babadagli, in 2016, conducted numerical simulations to investigate the role of thermal-assisted solvent recovery during CSI, emphasizing that thermal assistance significantly enhances oil recovery. They suggested that proper control of thermal conditions is essential to optimizing CSI performance [55]. Soh et al., in 2018, analyzed the application of methane and propane in CSI through numerical simulation. Their study proposed that a high-pressure decline rate improves foamy oil formation, thereby increasing oil recovery [56]. Chen and Leung, in 2021, performed a numerical simulation of nonequilibrium foamy oil behavior in CSI, examining the impact of pressure decline rates on foamy oil effects. Their results showed that faster pressure decline rates enhance foamy oil formation, leading to higher recovery efficiency [57]. In the latest research, Jia et al., in 2023, further refined numerical simulations of foamy oil flow in CSI, discovering that foamy oil exhibits periodic fluctuations during the production phase. They proposed that a slower pressure decline rate and higher initial solvent content contribute to improved oil recovery [22]. Cheperli et al., in 2025, presented a comprehensive scaling framework for CSI by integrating material balance, mass transfer, and pseudo-chemical reaction equations to derive 11 key dimensionless groups using the Buckingham π Theorem. These terms capture essential CSI dynamics such as foamy oil behavior and solvent exsolution. To ensure scalability from lab to field, a method for adjusting permeability in laboratory models to reflect pressure propagation delays in larger reservoirs was proposed. CSI experiments conducted on two Sandpack models were successfully scaled up into synthetic reservoirs using CMG software, demonstrating good agreement in recovery factor, CGOR, and gas production trends. This study provides a robust foundation for scaling CSI processes and optimizing solvent-based recovery strategies in heavy oil reservoirs [58]. Existing CSI numerical simulation studies have made significant progress in solvent optimization, foamy oil mechanism modeling, pressure decline rate control, and nonequilibrium phase behavior analysis. However, most of these studies have focused on single-well systems, without fully considering the impact of MLW structures on CSI performance. Additionally, challenges such as solvent vaporization losses and reservoir heterogeneity remain insufficiently addressed in simulations. To overcome these limitations, this study innovatively introduces MLW structures and employs a combined experimental and numerical simulation approach to further optimize solvent selection, well configurations, and operational parameters, aiming to enhance the economic feasibility and adaptability of CSI technology. To address these challenges, particularly at the modelling stage, it is essential to leverage advanced numerical tools capable of capturing reservoir-, wellbore-, and junction-scale processes in an integrated manner.

Before delving into reservoir-scale simulation methods, it is necessary to review the evolution of CSI modeling over the past decade to highlight both the progression of techniques and the remaining shortcomings. When viewed collectively, these studies reveal a clear evolution in CSI modeling. Early frameworks, typified by Chang and Ivory in 2013, established field-scale CMG/STARS models with explicit non-equilibrium solvent dissolution and precipitation kinetics, enabling accurate history matches but relying on isothermal, geometry-agnostic formulations and extensive parameter tuning [17]. Mid-period developments [54,55,56] expanded the physics to include capillarity, thermal assistance, and solvent-specific foamy-oil behavior, yet still offered limited guidance for multi-well or MLW configurations. Recent advances, such as those by Chen and Leung (2021) [57] and Jia et al. (2023) [22], refined foamy-oil and pressure-decline modeling, capturing transient fluctuations and identifying operational windows for improved recovery. Cheperli et al. (2025) synthesized these advances into a Buckingham-π scaling framework with permeability rescaling, reducing parameter dependency, and providing explicit similarity criteria for lab-to-field extrapolation [58]. However, even the most recent models remain predominantly isothermal, assume homogeneity, and have yet to explicitly incorporate MLW geometry or fully resolve heterogeneity and solvent-loss mechanisms. Therefore, building upon the current approaches, there is still a need to develop modeling tools capable of simultaneously accounting for complex well geometries, reservoir heterogeneity, and multi-physics coupling effects to further enhance the accuracy and transferability of CSI–MLW simulations.

At the reservoir scale, commercial simulators such as ECLIPSE or CMG STARS serve as the primary tools for forecasting the long-term performance of CSI–MLW operations. These models can incorporate complex reservoir heterogeneities, compositional mass transfer, phase behaviour, and operational constraints, enabling detailed evaluation of solvent breakthrough timing, recovery efficiency, and ultimate recovery factors. Advanced features, such as compositional modelling, relative permeability hysteresis, and geomechanical coupling, allow these simulators to capture the multi-physics nature of CSI, which is essential for reliable field-scale predictions. When complemented by high-resolution insights from other modelling approaches, such as junction-scale CFD or wellbore-scale transient simulation, reservoir models can deliver more robust forecasts of production performance, solvent utilization efficiency, and economic indicators. However, while reservoir simulators provide robust field-scale predictions, capturing the intricate local interactions at MLW junctions and near-wellbore regions requires high-resolution approaches such as CFD.

In addition to reservoir-scale simulation, computational fluid dynamics (CFDs) provides a high-fidelity approach to resolve local flow physics in CSI under MLW geometries. By explicitly capturing multiphase flow patterns, phase transitions, and coupled heat/mass transfer in near-wellbore regions and junctions, CFD offers valuable insight into solvent distribution, foamy-oil behavior during pressure depletion, and geometry-induced flow instabilities.

CFD modelling for CSI typically involves multi-physics coupling of multiphase flow (Euler–Euler or interface-capturing methods), compositional mass transfer with diffusion/dispersion, and, in some cases, population-balance models to describe foamy-oil kinetics. Representative domains include lateral junctions and near-wellbore sections, with CSI cycles simulated through sequential injection, soaking, and pressure-decline phases. Appropriate boundary conditions and mesh resolution are essential to capture the relevant capillary–viscous interplay. While CFD is computationally intensive, it can complement reservoir-scale simulation by supplying junction-level split ratios, effective mobility modifiers, and rate-based mass-transfer coefficients derived from high-resolution studies. This hybrid approach allows pore- and well-scale phenomena observed in CFD to be incorporated into field-scale CSI–MLW models, thereby improving prediction accuracy and guiding operational strategies. In parallel with CFD analysis, modelling wellbore and surface network dynamics is also critical to achieving a complete understanding of system behaviour.

Alongside CFD and reservoir-scale simulation, one-dimensional transient multiphase flow simulators, such as OLGA, can be utilized to characterize wellbore and surface network dynamics during CSI–MLW operations. These tools are particularly effective in predicting transient pressure and temperature profiles, phase slip, and fluid holdup along MLW sections and junctions. By integrating outputs from CFD, such as junction-level flow distribution and phase change behaviour, into OLGA models, a system-level perspective can be achieved, linking detailed local phenomena with operational constraints and performance.

The integration of one-dimensional and two-/three-dimensional models offers a promising pathway for capturing both system-level dynamics and detailed local physics in CSI–MLW studies. In such a coupled framework, CFD can supply high-resolution junction-level flow and phase distribution data to refine OLGA wellbore simulations, while OLGA outputs, such as transient pressure and flow rate histories, can serve as dynamic boundary conditions for CFD domains. This bidirectional coupling enables a more realistic representation of multiscale interactions. Furthermore, the integration of model outputs with control algorithms could allow for real-time optimization of injection and production parameters, improving solvent utilization and overall recovery efficiency.

Overall, the integration of multi-scale numerical modelling approaches, ranging from reservoir-scale simulation with commercial tools (e.g., ECLIPSE, CMG STARS), to high-resolution CFD for junction- and near-wellbore-scale physics, to transient wellbore/network modelling with OLGA, and to coupled 1D–2D/3D frameworks with potential control strategies, provides a comprehensive toolkit for analyzing CSI–MLW systems. By bridging pore-, well-, and field-scale processes, these methods enable more reliable prediction of production performance, improved understanding of solvent transport and utilization, and informed optimization of operational parameters. Such an integrated modelling strategy not only complements experimental investigations but also serves as a decision-support framework for field deployment of CSI–MLW technology.

2.4. Challenges of CSI: Non-Uniform Solvent Distribution and Potential Solutions

Although CSI has demonstrated significant potential in improving heavy oil recovery, offering advantages such as lower energy consumption and reduced environmental impact, its practical implementation still faces critical technical challenges. Among these, the most prominent issue is the non-uniform distribution of the injected solvent within heterogeneous reservoirs. This issue arises from the combined effects of reservoir heterogeneity, gravity segregation, and adverse mobility ratios, all of which cause the injected solvent to follow preferential flow paths. Due to factors such as reservoir heterogeneity, unfavorable mobility ratios, and gravitational effects, the injected solvent tends to rapidly migrate through high-permeability channels, leaving large portions of oil-bearing zones unswept. Light solvents such as methane may rise and bypass mid- and lower-depth intervals, while heavier solvents like CO2 often accumulate near the base of the formation. Furthermore, once solvent breaks through early at the production well, local pressure drops quickly, further limiting solvent penetration into less-accessible zones. Laboratory studies have reported that in such cases, solvent utilization factors can drop sharply, with ultimate recovery factors reduced to 23–44% OOIP and apparent solvent solubility ranging from 0.12 to 0.53 g per 100 g of remaining oil, depending on solvent composition and operating conditions (Ahadi and Torabi, 2018) [39]. This uneven solvent distribution significantly reduces sweep efficiency, decreases solvent utilization, and ultimately limits overall oil recovery.

To overcome this critical challenge, recent studies have explored various approaches aimed at improving the uniformity of solvent propagation. Among these strategies, the application of MLWS has emerged as particularly promising. By creating multiple lateral branches within the reservoir, MLWs effectively enlarge the solvent–reservoir contact area, optimize the fluid flow paths, and mitigate early solvent breakthrough. Consequently, combining CSI with MLW technology offers a viable and practical solution to address the inherent limitation of non-uniform solvent distribution, significantly enhancing the overall performance and effectiveness of CSI operations.

In the following sections, the characteristics, classifications, and advantages of MLW technology will be comprehensively discussed, highlighting its synergistic potential when integrated with CSI processes.

3. Multilateral Wells in Heavy Oil Recovery

Well-designed MLW technologies are those that incorporate multiple lateral branches from a single main wellbore. Many MLW configurations inherently exhibit symmetrical geometries, such as dual-opposing laterals or evenly spaced branches, that can promote balanced reservoir contact and improved sweep efficiency. Compared to conventional vertical and horizontal wells, MLWs increase reservoir contact area, enhance oil recovery, and improve development economics [59]. Since the 1990s, MLW technology has been widely applied in conventional and unconventional reservoir development, demonstrating particular advantages in complex formations such as heavy oil and tight oil and gas reservoirs [60]. However, despite its progress in enhancing recovery and reducing drilling costs, MLW still faces challenges in wellbore stability, completion technology, and fluid flow control [61]. In particular, MLWs offer unique geometric advantages that can help mitigate non-uniform solvent distribution in CSI operations, making them especially attractive for integration with solvent-based recovery processes. Therefore, before delving into its applications, it is essential to first define MLW configurations and classifications to systematically understand its role in reservoir development.

3.1. Key Characteristics and Classification of MLW

The key characteristics of MLW technology lie in its structural design, fluid flow optimization, and completion methods, enabling it to adapt to various reservoir conditions and improve reservoir utilization efficiency. In many cases, these designs incorporate symmetrical geometries, such as mirrored or evenly spaced laterals, that can promote balanced reservoir contact, reduce flow interference, and enhance sweep efficiency. First, MLW consists of a main bore and one or more lateral wells, which can be drilled at different depths or directions to maximize reservoir contact area. This structural design allows for optimization based on reservoir characteristics. For example, in high-dip reservoirs, laterals can be aligned with the reservoir layers, while in low-permeability reservoirs, an increased number of lateral wells can enhance fluid flow efficiency [62]. Second, MLWs offer superior fluid flow control compared to conventional well types. Since laterals cover a broader reservoir area, MLWs reduce fluid flow resistance within a single wellbore, optimizing pressure distribution and improving fluid mobilization efficiency. Additionally, in high-water-cut reservoirs, MLWs can strategically place laterals to mitigate water or gas coning, thereby extending the stable production period [63]. Finally, MLW utilizes various completion techniques to adapt to different reservoir environments. Modern MLW technology often incorporates intelligent completion systems (ICD, AICD) to enable independent control of lateral wells, thereby enhancing recovery efficiency. In complex reservoirs, laterals can be mechanically isolated or equipped with packers to prevent interference between branches and improve production flexibility. With continued technological advancements, improvements in wellbore stability, lateral isolation techniques, and intelligent control systems have expanded the application of MLW technology in oilfield development [64].

MLW can be classified based on different technical characteristics, primarily into Wellbore Configuration and Completion Type categories.

3.1.1. Based on Wellbore Configuration

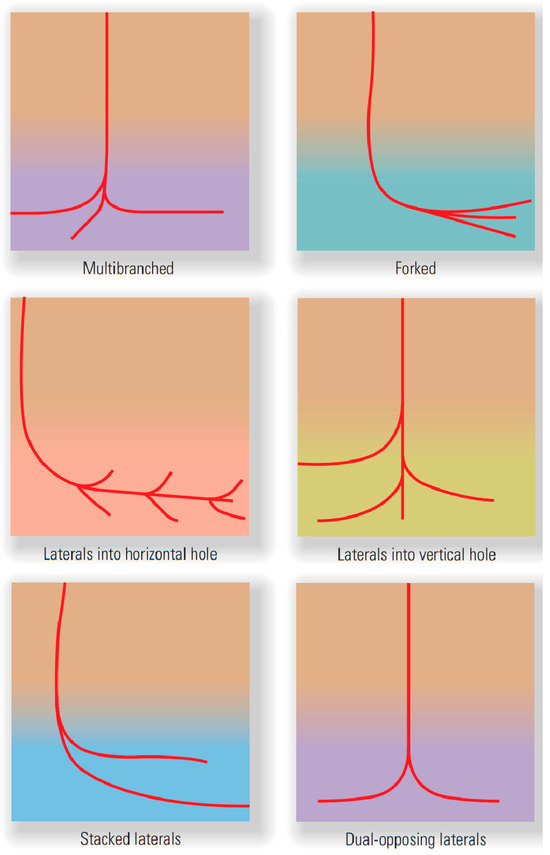

According to the arrangement of the main bore and lateral wells, MLWs can be categorized into six primary types as depicted in Figure 4 [65]:

Figure 4.

Symmetrical And Other MLW Configurations Based on Wellbore Structure [65].

Multibranched Wells: The main bore branches into multiple lateral wells at the same depth, increasing reservoir contact area and improving oil recovery in low-permeability reservoirs [66]; Forked Wells: The main bore splits into two or more branches at a specific depth, often in a symmetrical fork arrangement that enhances flow control and facilitates balanced drainage in heterogeneous reservoirs; Laterals into Horizontal Hole: Laterals are oriented along a horizontal well, improving reservoir utilization in ultra-low permeability formations [67]; Laterals into Vertical Hole: Designed for layered production, where laterals are drilled at different depths along a single main bore, enabling the co-development of multiple reservoir zones; Stacked Laterals: Multiple lateral wells are vertically stacked, improving fluid drainage efficiency, making it ideal for thick reservoirs or highly heterogeneous formations; Dual-Opposing Laterals: Laterals are symmetrically positioned on both sides of the main bore, optimizing fluid flow paths and reducing water or gas coning risks, making it suitable for high-water-cut or high gas breakthrough reservoirs [68].

Functionally, each MLW configuration imposes a distinct control on fluid movement during CSI. Multibranched and forked geometries multiply reservoir exposure and distribute drawdown among several entry points, which has been shown to improve sweep efficiency by delaying water/gas breakthrough through lower branch-level drawdown and more favorable drainage patterns; this effect arises precisely because multilateral drainage architectures increase the contact area at a given pad location. Stacked laterals and “laterals-into-vertical-hole” layouts extend access to multiple depths and connect isolated sand bodies, enhancing vertical pressure communication and enlarging the effective sweep of heterogeneous or thick formations. Fishbone/splayed branches help traverse laminated sands and smooth lateral flow non-uniformities, while dual-opposing laterals tend to create quasi-symmetric pressure fields that mitigate coning-prone inflow around the main bore; together, these configuration choices translate structural geometry into predictable differences in solvent propagation, pressure profiles, and the swept area at the pad scale.

3.1.2. Based on Completion Type

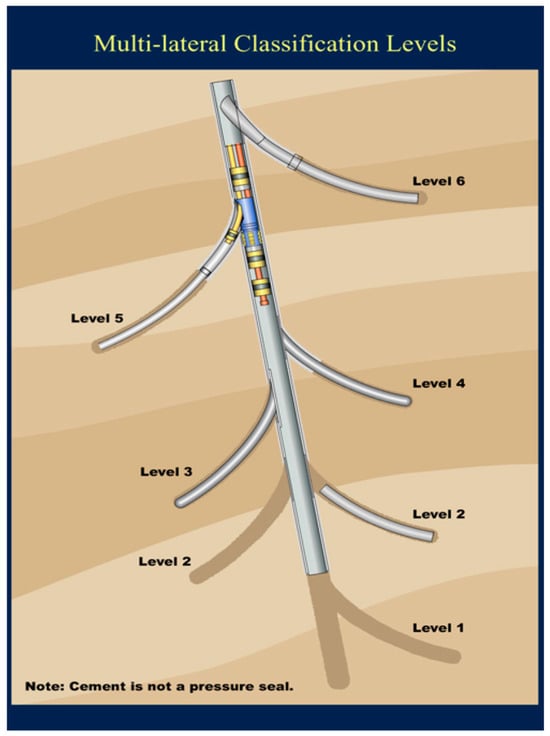

According to the complexity of the completion method and fluid control capability, MLW are classified into six levels (Level 1–Level 6) based on the API TAML standard. This classification is depicted in Figure 5 [69]. As the level increases, wellbore integrity, fluid control, and intervention capability are progressively enhanced [69]:

Figure 5.

TAML Classification of MLW [69].

Level 1 (Lowest Level)–Open-Hole Laterals: Open-hole laterals have no mechanical support or sealing system between the lateral wells and the main bore, leaving all wellbores fully open [70]. They are suitable for low-cost development, but fluid flow cannot be controlled, making it susceptible to water or gas coning breakthrough.; Level 2—Cased and Cemented Main Bore, Open Laterals: The main bore is fully completed, but laterals remain open [71]. They are suitable for reservoirs requiring some degree of wellbore stability, but lateral wells still lack independent fluid control; Level 3–Mechanically Supported Laterals: Mechanical tools such as liners or support rings are used at lateral connections to enhance structural stability [72]. They are suitable for reservoirs requiring improved lateral well integrity, but fluid flow from individual laterals cannot be controlled separately; Level 4—Laterals with Packers: Packers are used at lateral well interfaces to provide pressure isolation between the main bore and laterals [73]. They are suitable for reservoirs that require independent fluid control across different layers, such as aquifers or multilayer oil reservoirs; Level 5–Intelligent Completion: Remote-controlled adjustable valves (e.g., AICD, ICD) are integrated to monitor and optimize production from each lateral [74]. They are suitable for reservoirs that require flexible control over production fluids, improving oil recovery and operational efficiency; Level 6 (Highest Level)–Fully Sealed and Independently Controlled Laterals: Each lateral well is independently controlled, with remote intervention capability [75]. Each is suitable for complex reservoir development, including high-pressure and high-temperature formations, providing the highest level of production optimization.

From a completion standpoint, the TAML level governs how pressure profiles can be managed and how sweep can be expanded. Levels 1–2 provide no junction isolation, favoring commingled flow but limiting control of crossflow and branch-level drawdown; Level 3 ties back a supported lateral to the main bore for borehole stability and sand control, yet still lacks a hydraulic seal. By contrast, Level 4’s cemented tie-back blocks annular solids migration and preserves a full-drift ID that facilitates artificial-lift placement and more stable drawdown distribution; in Orinoco heavy-oil practice, production is commonly commingled, and Levels 3–4 are widely used. Structural improvements such as the junction-support tool (JST) further stabilize Level-4 junctions against drawdown and subsidence, sustaining long-term pressure communication and re-entry access. At the higher end, Levels 5–6 enable pressure-isolated junctions; when combined with intelligent completions, operators can monitor and choke individual branches in real time to tailor pressure gradients and maximize sweep in heterogeneous settings.

3.2. Advantages and Field Applications of MLW

3.2.1. Advantages of MLW

- Increased Reservoir Contact Area and Enhanced Recovery

MLW, especially those with symmetrical branch arrangements, significantly increase the wellbore-reservoir contact area by drilling multiple lateral branches from a single main bore [76]. This symmetry-oriented design allows fluids to flow more easily from the reservoir into the wellbore, thereby improving overall recovery efficiency. The advantage is particularly pronounced in low-permeability or heterogeneous reservoirs, where multiple laterals enable broader and more uniform reservoir drainage, effectively addressing the limited reservoir access often encountered with conventional well types.

- Reduced Development Costs and Surface Infrastructure Requirements

By drilling multiple laterals from a single wellhead, symmetrical MLW configurations effectively reduce the number of wells and completion operations required. This leads to lower drilling, completion, and maintenance costs, as well as a reduction in the scale and footprint of surface infrastructure [77]. This advantage is particularly significant in offshore fields or environmentally sensitive areas, where minimizing surface disturbance carries both economic and environmental benefits, thereby enhancing the overall cost-effectiveness of the development project.

- Enhanced Wellbore and Fluid Control Capability

MLW technologies are often combined with advanced completion technologies, such as intelligent completion systems, enabling independent monitoring and control of each lateral well’s production performance [78]. This allows for the precise management of production from individual branches and real-time adjustment of operational strategies to optimize reservoir performance. Compared to conventional wells, this flexible control capability, especially in symmetrical designs, significantly improves wellbore management efficiency, reduces the risk of water or gas coning, and effectively extends the stable production period.

- Improved Adaptability to Complex Reservoirs

In reservoirs with dense fault zones or complex geological structures, single-well development often suffers from unstable production due to reservoir heterogeneity. MLW can be flexibly configured in terms of lateral direction and length based on reservoir characteristics, including symmetrical patterns, providing targeted solutions for underperforming zones [79]. The adaptability of multiple laterals under varying geological conditions enhances reservoir utilization in complex formations and reduces inter-reservoir interference, thereby maintaining more stable productivity.

- Reduced Reservoir Damage and Improved Wellbore Stability

Through rational, well-designed, and optimized branch placement, including symmetry-based arrangements, MLW technologies can minimize reservoir damage caused by drilling fluid invasion. Additionally, with the application of mechanical supports or packer-based connections, the stability of lateral wellbores is significantly improved, effectively reducing the risk of borehole instability. These advantages ensure wellbore integrity during long-term production, extend the service life of MLW technologies, and reduce the need for costly workover operations [80].

- Suitable for Development in Constrained Areas

Because symmetrical MLW configurations can extend multiple branches from a single surface location, they reduce surface infrastructure and land use, making them especially suitable for space-limited or environmentally sensitive areas [81]. In offshore platforms, suburban fields, or ecologically protected zones, MLWs have demonstrated excellent adaptability, significantly enhancing the feasibility and economic viability of field development.

3.2.2. Field Applications of MLW Technologies

The world’s first successful application of an MLW occurred in 1953 at the Bashkiria oilfield in Russia, where turbine drilling tools were used to drill nine lateral branches, arranged in a generally symmetrical pattern. This increased the reservoir exposure area by 5.5 times, boosted production by 17 times, and incurred only 1.5 times the cost of a conventional single well, marking the first true MLW in history [62]. Since then, MLW technology has rapidly expanded. In 2004, a TAML Level 3 MLW was successfully implemented in a Canadian heavy oil sandstone reservoir. The well consisted of one main bore and three lateral branches, in a configuration that could be considered symmetrical, using slotted liners and external casing packers (ECP) for sand control. The total reservoir exposure area was approximately 15,000 feet [82]. In 2012, MLW technology was applied in the Achimov formation of Western Siberia, Russia, where a combination of TAML Level 4 and Level 5 designs was implemented. This significantly enhanced wellbore integrity and pressure control, potentially benefiting from balanced flow paths in certain symmetrical layouts, leading to improved reservoir drainage efficiency [83]. In 2019, the application of MLW technology in Abu Dhabi was further advanced by integrating intelligent completion systems, including interval control valves (ICV) and permanent downhole monitoring systems (PDHMSs). These systems enabled individual flow control for each branch via advanced surface control equipment, which in some configurations may reflect symmetrical spacing, achieving precise production optimization and improved economic returns [83]. In 2023, the first TAML Level 5 trilateral well in the Alvheim area of the Norwegian North Sea was successfully deployed. It marked the first instance of independent control and completion of a three-lateral well in the region. By combining autonomous inflow control devices (AICD) with an intelligent completion system, the well enabled independent monitoring and flow control for each branch, ensuring the economic and efficient development of thin oil zones [84]. In 2024, Halliburton introduced an innovative expandable multilateral anchoring system in the Middle East, which was successfully applied in a deep reservoir with a well depth of 14,578 feet. This operation achieved a reservoir contact area exceeding 32,769 feet, demonstrating the capability and potential of multilateral completions in deep and technically challenging wells [85].

In conclusion, with the continuous evolution of MLW technology, its successful global applications clearly demonstrate that this approach not only effectively increases reservoir contact area and recovery factor, reduces the number of surface wellheads, and lowers development costs but also, in some configurations incorporating symmetrical geometries, significantly enhances the economic performance and development efficiency of individual wells.

3.3. Challenges in MLW Implementation

Based on an in-depth analysis and synthesis of the literature, the following key challenges have been identified in the implementation of MLW:

Complexity of Junction Connections: The junction—where the lateral well connects to the main bore—is one of the most critical challenges in MLW implementation. The mechanical complexity of the junction directly affects the stability of the wellbore and the long-term reliability of production. This is particularly true for high-level junction structures (e.g., higher TAML grades), which require high-precision construction and significant cost investment, thereby increasing operational difficulty and economic risk [86]; Wellbore Stability Issues: During drilling, MLWs are susceptible to wellbore instability and collapse due to uneven in situ stress distribution, especially in high-inclination and horizontal lateral sections. These issues pose greater risks and complexity during the drilling process, particularly in challenging geological settings [87]; Completion and Production Control Challenges: MLW technologies typically require intelligent completion systems to enable independent monitoring and control of each lateral in symmetrical arrangements. However, issues related to the reliability, long-term stability, and maintenance of intelligent completion equipment pose significant technical challenges. Equipment failure and the difficulty of maintenance may lead to production interruptions [88]; Reservoir Heterogeneity Challenges: In geologically complex or highly heterogeneous reservoirs, optimizing the layout of MLW is particularly challenging. Variations in fluid properties, pressure differentials, and fracture development across different reservoir layers can lead to uneven production among laterals, even in symmetrical configurations, thereby reducing overall production efficiency and economic returns [89]; Drilling Tool and Equipment Limitations: Due to the unique structure of MLW bores and equipment limitations, such as coiled tubing length constraints and potential locking issues, the maximum lateral length is strictly limited. These constraints can limit the full potential of MLW technology, especially when ultra-long horizontal sections are desired [90]; Economic Cost and Risk Management: The implementation of high-level MLW technologies (e.g., TAML Level 5 and 6) involves substantial investment. The technical complexity of such systems makes risk management and cost control more difficult, particularly during the initial investment phase and in economically sensitive development projects [91]; Construction Complexity: The complexity of MLW construction, including certain symmetrical designs, imposes higher technical demands on personnel and precision requirements on equipment. Complicated procedures increase the risk of delays, equipment damage, and quality issues, especially in environmentally sensitive areas or offshore platforms, where operational conditions are more constrained [92]; Reservoir Evaluation and Production Forecasting Uncertainty: Reservoir evaluation and production forecasting for MLW involve high levels of uncertainty. The complex layout of lateral branches combined with strong reservoir heterogeneity makes it difficult for traditional forecasting methods to accurately predict actual well performance, thereby increasing the complexity of reservoir management and operational decision-making [93]; Inter-well Interference: Interference between multiple laterals within a MLW, particularly in symmetrical branch patterns, may occur, potentially leading to production decline, premature water or gas breakthrough, and a shortened effective production lifespan. Effectively addressing this issue requires careful spatial design of lateral wells and optimized control of fluid production, which remains a critical challenge [94].

In response to these challenges, the industry has introduced various measures to improve MLW feasibility and performance. Modular high-strength junction systems and junction support tools enhance mechanical stability and reduce installation time. Rotary steerable systems, optimized drilling fluids, and advanced PDC bits help control wellbore instability. Intelligent completions with ICVs and ICDs enable branch-level flow control and real-time monitoring. Reservoir heterogeneity is addressed through geo-steering, 3D seismic characterization, and digital well modeling to optimize lateral placement. Extended-reach drilling tools, improved coiled tubing designs, and modularized construction methods further extend lateral length and improve operational efficiency.

In summary, MLW technology faces a range of technical and economic challenges during implementation, which partially constrain its full potential. By integrating MLW technology with CSI, this study aims to further explore the application potential of MLWs in complex reservoir development, in pursuit of more efficient recovery strategies and improved production performance.

4. Integration of CSI and MLW in Heavy Oil Recovery

The advantages of CSI and MLW technologies in the development of heavy oil reservoirs have been extensively validated in previous studies; however, no research to date has reported on the integration of these two technologies. On this basis, this section aims to systematically examine the feasibility and potential benefits of combining CSI and MLW through an in-depth analysis of the existing literature related to both technologies. Additionally, it will identify the technical and operational challenges that may arise during implementation, with the goal of providing clear direction and a solid theoretical foundation for future research. One of the most critical limitations in CSI operations is the non-uniform distribution of injected solvent, which leads to inefficient sweep and early breakthrough. Integrating MLW technology directly addresses this issue by expanding the solvent–reservoir contact area and promoting more uniform solvent propagation throughout the reservoir. The use of multiple (often symmetrical) laterals allows for more distributed injection or production points, which can minimize preferential flow paths and mitigate gravity segregation effects. As such, the combination of CSI and MLW is not only structurally synergistic but also functionally complementary, particularly in heterogeneous heavy oil reservoirs.

4.1. Fundamental Basis for Integration

Cyclic Solvent Injection (CSI) is a non-thermal EOR technique that improves heavy oil recovery by periodically injecting and producing solvents from the reservoir. Its core mechanisms include the dissolution, swelling, and viscosity reduction in heavy oil by the solvent, as well as the formation and stabilization of foamy oil [95]. Specifically, CSI induces reservoir oil phase expansion and viscosity reduction through cyclical solvent injection and production, thereby enhancing oil mobility and drainage efficiency [96]. Studies have shown that CSI is particularly well-suited for heavy oil reservoirs that are thin, highly viscous, and economically unviable for thermal recovery methods. Recent research emphasizes that parameters such as solvent type (e.g., CO2, C3H8, and their mixtures), pressure decline rate, and soaking duration have a significant impact on CSI performance, and optimizing these factors can further enhance recovery efficiency [97]. On the other hand, MLW technology enhances oil recovery by drilling multiple lateral branches from a single wellbore, significantly increasing reservoir contact area and optimizing fluid flow paths within the reservoir, thereby effectively improving well productivity and recovery factor. MLW is particularly suitable for development scenarios involving pronounced geological heterogeneity, limited reservoir thickness, or a need to reduce drilling and surface facility costs. By selecting an appropriate well configuration—such as stacked laterals, fishbone wells, or symmetrical laterals—and integrating intelligent completion technologies, operators can independently monitor and precisely control each lateral’s production, greatly enhancing flexibility in well pattern design and overall production efficiency [98].

From an analytical perspective, CSI and MLW technologies exhibit strong complementarity and synergistic potential. While CSI excels at enhancing oil recovery in the near-wellbore region, its limited sweep area per well restricts its ability to effectively mobilize oil in far-field zones [99]. Field and laboratory observations indicate that the effective sweep radius of single-well CSI operations is typically confined to approximately 15–40 m from the wellbore, depending on reservoir permeability and solvent properties. In contrast, MLW configurations, particularly those with extended-reach or stacked laterals, can increase the contacted reservoir length to several thousand meters and expand the effective drainage envelope by 1.5–3 times compared with single-horizontal wells [69]. This quantitative difference underscores the complementary nature of the two technologies—CSI improves local displacement efficiency near the wellbore, while MLW significantly enlarges the reservoir volume that can be effectively contacted within a single well system. However, MLW technology significantly expands the reservoir drainage area of a single well yet still requires improvement in enhancing local flow efficiency near the wellbore [100]. Therefore, by leveraging the structural advantages of MLW, the injection and production of solvents in CSI operations can achieve broader and more uniform reservoir coverage, leading to more efficient solvent utilization. Simultaneously, the cyclical injection-production nature of CSI can help reduce pressure losses and production interference between lateral branches, thereby improving overall fluid distribution and enhancing recovery performance.

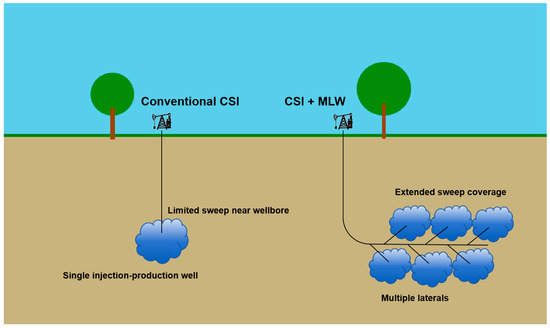

To further illustrate the contrast in reservoir, contact, and sweep patterns, Figure 6 provides a conceptual cross-sectional view comparing conventional single-well CSI with integrated CSI using MLW. The schematic depicts how multiple laterals can significantly expand solvent sweep coverage and promote more uniform propagation compared to the limited near-wellbore coverage of a single-well arrangement.

Figure 6.

Solvent Sweep Patterns in Conventional CSI and CSI + MLW.

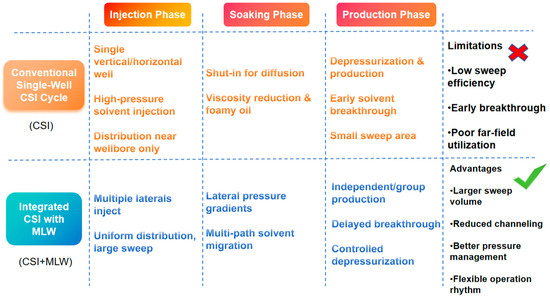

Building on the spatial distribution differences shown in Figure 6, Figure 7 summarizes the operational distinctions between conventional single-well CSI and integrated CSI with MLW across the injection, soaking, and production phases. This comparison outlines differences in injection strategies, soaking-phase dynamics, and production control, as well as the respective limitations and advantages of each configuration.

Figure 7.

Conceptual Scheme of Integrating CSI with MLW for Enhanced Heavy Oil Recovery.

In summary, from an analytical standpoint, the integration of CSI and MLW technologies holds significant synergistic potential. This combination not only helps to overcome the limitations inherent in the individual application of each technique but may also generate new technical advantages, thereby substantially enhancing the efficiency and economic viability of heavy oil development.

4.2. Potential Synergistic Benefits

Based on the respective mechanistic characteristics and application advantages of CSI and MLW technologies in heavy oil development, integrating these two techniques exhibits significant synergistic potential in theory. Their integration holds promise for complementarity at multiple levels—ranging from an expanded injection-production contact area and enhanced sweep efficiency to development pacing control and production system optimization—potentially forming a new technological breakthrough.

Firstly, as a non-thermal recovery method, CSI’s recovery efficiency is largely constrained by the diffusion range and sweep volume of the solvent within the reservoir. Traditional CSI operations often rely on a single wellbore structure for cyclic injection and production, which limits the sweep radius and leads to underutilization of far-field reservoir zones [101]. In contrast, MLW deploys multiple lateral branches within a single main bore, substantially expanding the spatial coverage for solvent injection and recovery. This structural advantage allows CSI to extend its effective range beyond the near-wellbore region [102], mitigating its limitations in large-scale reservoirs and enabling the solvent to penetrate more uniformly throughout the formation, thereby enhancing overall reservoir utilization.

This potential improvement in sweep efficiency has been corroborated by field evidence from other EOR processes employing MLW technology. For example, in a large-scale thermal recovery project in the Orinoco Belt reported by Petrozuata, TAML Level-4 multilateral wells were deployed in highly heterogeneous heavy-oil reservoirs with significant permeability barriers [69]. The multilateral configuration successfully connected isolated sand bodies, expanded the effective drainage area, and improved the uniformity of fluid contact compared with conventional horizontal wells. These enhancements led to higher ultimate recovery factors and better long-term economic performance. Although these results were achieved under steam-based operations, the underlying mechanism—reducing bypassed zones and improving displacement-front conformance—is directly relevant to solvent-based processes such as CSI. By analogy, applying MLW to CSI may help mitigate uneven solvent distribution and early breakthrough. While direct quantitative comparisons between conventional CSI and integrated CSI–MLW systems are not yet available in the literature, the consistent performance improvements observed in other EOR contexts provide a strong rationale for further targeted experimental and numerical modeling studies to evaluate and quantify this potential synergy.

Secondly, in addition to increasing reservoir contact area, MLW provides more pathways and entry points for solvent distribution and circulation within the reservoir, which theoretically allows for more rational injection-production configurations and dynamic control of operation timing. In the CSI process, the pressure decline rate is considered a key parameter influencing both foamy oil formation and solvent utilization efficiency [103]. By utilizing the structural layout of MLWs, it becomes possible to introduce differentiated injection-production rhythms among the various laterals, enabling pressure management and fluid organization at a broader spatial scale and offering greater flexibility to sustain the foamy oil displacement mechanism.

Furthermore, the technical advantages of MLWs in mitigating branch interference and extending the stable production period can further amplify the effectiveness of CSI. In conventional CSI, solvents may prematurely break through via low-resistance channels, resulting in reduced displacement efficiency. MLWs, however, can suppress early breakthrough and gas production issues by carefully designing the angle and length of each lateral and incorporating intelligent completion systems for independent injection-production control across branches, thereby improving solvent utilization [104]. In addition, the cyclical rhythm inherent to CSI operations may help to reduce pressure fluctuation between branches, contributing to lower inter-well interference risks in MLW configurations.

Finally, from a development strategy perspective, CSI inherently possesses flexible operational characteristics due to its cyclical and controllable nature, while MLW can further amplify this flexibility through structural expansion. In reservoirs with rapidly changing production dynamics, the integration of CSI and MLW can enable more precise, stratified, branched, and phase-specific control, providing a foundation for adaptive strategy transitions at different stages of development, thereby enhancing the stability and adaptability of the overall recovery process. In conclusion, CSI and MLW exhibit multi-dimensional synergistic potential from a technical logic standpoint. Their integration not only helps to extend the effective range of CSI but also offers a new approach for improving the overall development efficiency of heavy oil reservoirs.

4.3. Current Gaps and Future Directions