Modeling of Multifunctional Gas-Analytical Mine Control Systems and Automatic Fire Extinguishing Systems

Abstract

1. Introduction

- (1)

- Adaptive environmental compensation (Equation (2)) enabling 95% sensor accuracy under ±15 °C fluctuations;

- (2)

- Hybrid fire suppression (aerosol and powder modules) reducing CO concentration by 30% within 5 s;

- (3)

2. Materials and Methods

2.1. Overall System Design

2.1.1. System Framework

- Normal Operating Condition. In this condition, the gas environment inside the mine is within a safe range and a gas fire will not occur. The ventilation system equipment is operating normally. Sensor equipment should monitor the concentration of gases such as methane and carbon monoxide in real time to ensure that it is below the established safety thresholds. Under this mode of operation, the mine’s power generation can operate normally.

- Early Warning Condition. When the monitored gas concentration is close to or slightly above the safety threshold, the system automatically enters the early warning state. In this state, reduce non-critical tasks and investigate the cause of the system going into the warning state while ensuring that critical tasks are performed. Ventilation should be increased and emergency measures prepared. At the same time, miners and managers should be notified to remain alert and ready for further action.

- Emergency Operating Condition. If gas concentrations exceed safety standards or a fire is detected, the system shall immediately enter the emergency operating condition. In this state, all non-essential equipment shall immediately cease operation, the emergency ventilation subsystem and the fire prevention and suppression subsystem shall be activated to full capacity, and an emergency evacuation plan shall be implemented to ensure the safety of the miners. The general scheme of the system is shown below (Figure 1).

2.1.2. Designing the Overall Flow of Control System Operations

- Technical Specifications:

- PLC: Siemens S7-1200;

- Sampling Rate: 100 ms; protocol: RS-485 Modbus; sensors:

- SDTG-01 (CO: 0–1000 ppm), MMS-CH4 (CH4: 0–100% LEL), NTCR-Thermocouple;

- Actuation Thresholds: CH4 > 1.0% vol, CO > 50 ppm.

2.2. Selecting a Sensor

2.2.1. Stationary Toxic Gas Sensors

- 1

- —handle for carrying and fixing;

- 2

- —protective shell of the sensing element;

- 3

- —indicator of the supply voltage;

- 4

- —place for indicating the chemical formula of the controlled gas;

- 5

- —LCD;

- 6

- —fixing elements;

- 7

- —cover of the cable entry compartment;

- 8

- —cable entry;

- 9

- —cover of the hardware compartment;

- 10

- —housing;

- 11

- —label with marking.

2.2.2. Stationary Methane Sensors

2.3. Selecting a Sensor

Dynamic Environmental Compensation Algorithm

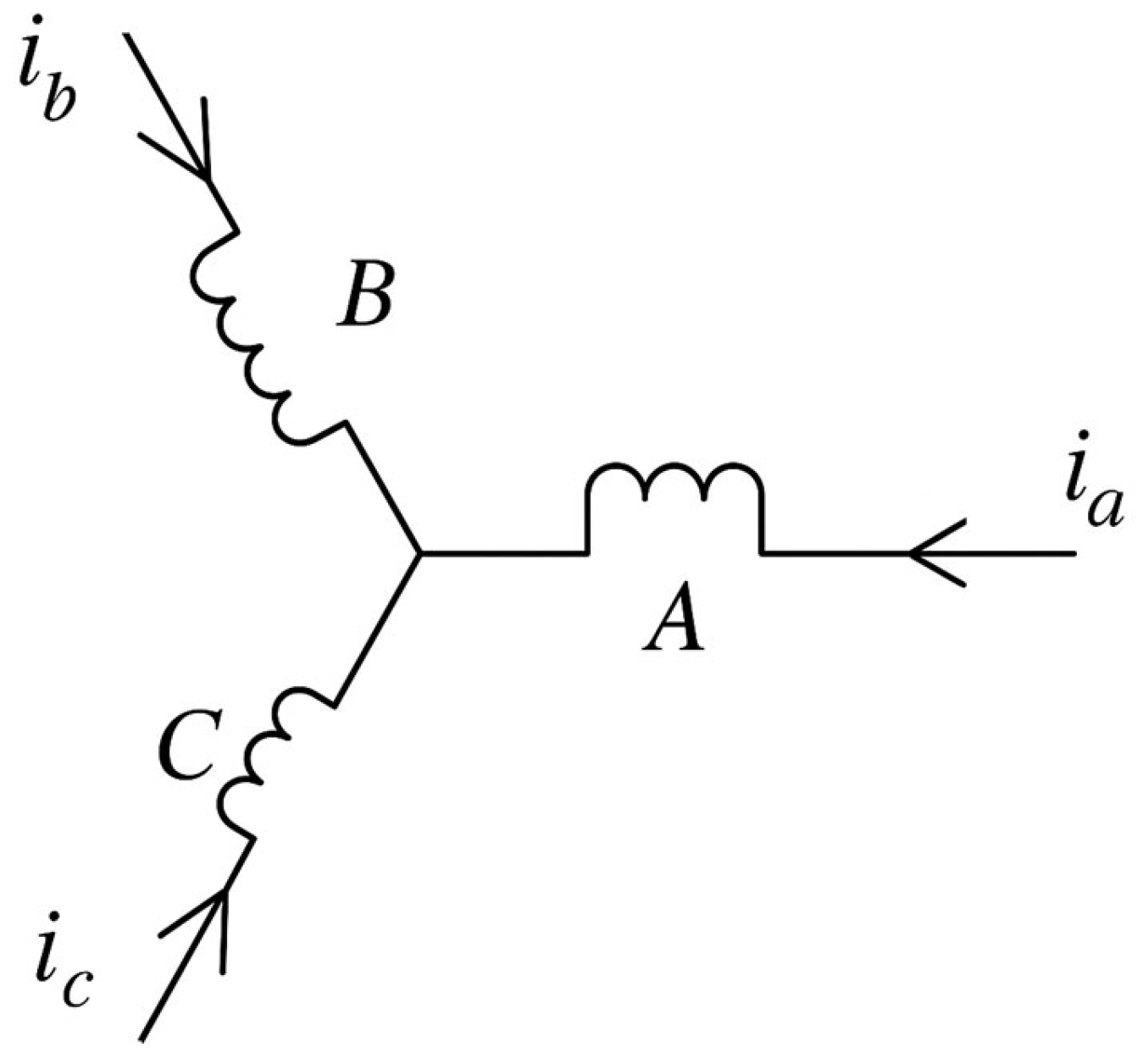

2.4. Motor Control and Modeling

Controller Tuning Methodology

- Controller: PID (Kₚ = 0.8, Kᵢ = 0.2, Kₔ = 0.05).

2.5. Powder Fire Extinguishing Module MPF

2.6. Development of a Wiring Diagram for the Programmable Logic Controller

- Industrial reliability: Operates under extreme conditions (−25 °C to +60 °C, 95% humidity) where microcontrollers fail.

- Real-time performance: Fixed 10 ms scan cycle ensures deterministic response for safety-critical systems.

- Long-distance communication: Built-in RS-485 supports 1.2 km cabling with noise immunity.

- Sensor delay: 50 ms (SDTG-01 datasheet);

- PLC processing: 10 ms (S7-1200 specifications);

- Actuator response: 30 ms (UAP-3 tests).

3. Results

- Response Time and Detection Accuracy

- 2.

- Comparative Analysis with Traditional Fire Suppression Methods

- 3.

- Validation of Theoretical Models (Equations (21) and (22))

Experimental Validation

4. Conclusions

Limitations

- Scope of Application:

- Advantages

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, Y.; Liu, X.; Patouillard, L.; Margni, M.; Bulle, C.; Hua, H.; Yuan, Z. Remarkable Spatial Disparity of Life Cycle Inventory for Coal Production in China. Environ. Sci. Technol. 2023, 57, 15443–15453. [Google Scholar] [CrossRef]

- Ivanov, N.A.; Sarychev, A.E.; Stoyanova, I.A. Role of coal in global energy transition. Russ. Min. Ind. 2023, 4, 102–108. [Google Scholar] [CrossRef]

- Kazanin, O.I. Promising technology trends in underground coal mining in Russia. Gorn. Zhurnal 2023, 9, 4–11. [Google Scholar] [CrossRef]

- Batugin, A.S.; Kobylkin, A.S.; Musina, V.R. Effect of geodynamic setting on spontaneous combustion of coal waste dumps. Eurasian Min. 2019, 2, 64–69. [Google Scholar] [CrossRef]

- Nehler, T.; Parra, R.; Thollande, P. Implementation of energy efficiency measures in compressed air systems: Barriers, drivers and non-energy benefits. Energy Effic. 2018, 11, 1281–1302. [Google Scholar] [CrossRef]

- Zubov, V.P.; Golubev, D.D. Prospects for the use of modern technological solutions in the flat-lying coal seams development, taking into account the danger of the formation of the places of its spontaneous combustion. J. Min. Inst. 2021, 250, 534–541. [Google Scholar] [CrossRef]

- Suksova, S.A.; Timofeeva, Y.V.; Dolkan, A.A.; Popov, E.V. Review of Methods for Identifying Spontaneous Combustion of Coal. Eurasian Sci. J. 2021, 1, 1–9. Available online: https://esj.today/PDF/19NZVN121.pdf (accessed on 19 March 2025).

- Govender, S.; du Plessis, J.J.L.; Webber-Youngman, R.C.W. A critical investigation into spontaneous combustion in coal storage bunkers. J. S. Afr. Inst. Min. Metall. 2021, 121, 251–260. [Google Scholar] [CrossRef]

- Biswal, S.S.; Gorai, A.K. Change detection analysis in coverage area of coal fire from 2009 to 2019 in Jharia Coalfield using remote sensing data. Int. J. Remote Sens. 2020, 41, 9545–9564. [Google Scholar] [CrossRef]

- Muduli, L.; Jana, P.K.; Mishra, D.P. Wireless sensor network based fire monitoring in underground coal mines: A fuzzy logic approach. Process Saf. Environ. Prot. 2018, 113, 435–447. [Google Scholar] [CrossRef]

- Starikov, A.N.; Kozunin, I.I. Comparative analysis of methods for sampling firedamp in the mines of the Verkhnekamye region. Min. Echo. 2022, 3, 104–110. [Google Scholar] [CrossRef]

- Gendler, S.G.; Kopachev, V.F.; Kovshov, S.V. Monitoring of compressed air losses in branched air flow networks of mining enterprises. J. Min. Inst. 2022, 253, 3–11. [Google Scholar] [CrossRef]

- Ostrowski, Р.; Pronobis, М.; Remiorz, L. Mine emissions reduction installations. Appl. Therm. Eng. 2015, 84, 390–398. [Google Scholar] [CrossRef]

- Rashid, H.A.; Najmaldin, E.H. Toxic Gases and Human Health: A Comprehensive Review of Sources, Health Effects, and Prevention Strategies. J. Mater. Sci. Res. Rev. 2024, 7, 612–622. [Google Scholar] [CrossRef]

- Kaledina, N.O.; Malashkina, V.A. Indicator assessment of the reliability of mine ventilation and degassing systems functioning. J. Min. Inst. 2021, 250, 553–561. [Google Scholar] [CrossRef]

- Tsai, W.-T. An overview of health hazards of volatile organic compounds regulated as indoor air pollutants. Rev. Environ. Health 2019, 34, 81–89. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.L.; Li, Z.H.; Xi, L.L.; Hou, S.S.; Zhou, Y.B.; Qi, K.K. Consolidating grouting technology for fire prevention in mined-out face and its application. Fire Mater. 2017, 41, 700–715. [Google Scholar] [CrossRef]

- Shi, D.; Liu, X.; He, L. A review on mine fire prevention technology and theory based on bibliometric analysis. Sustainability 2023, 15, 16639. [Google Scholar] [CrossRef]

- Tang, Y.B.; Hu, S.H.; Wang, H.E. Using P-Cl inorganic ultrafine aerosol particles to prevent spontaneous combustion of low-rank coal in an underground coal mine. Fire Saf. J. 2020, 115, 103140. [Google Scholar] [CrossRef]

- Xiang, Z.; Zhang, N.; Pan, D.; Xie, Z.; Zhao, Y. Development and performance characterization of a composite grouting material suitable for sealing and reinforcement of microcracked mudstone. J. Mater. Res. Technol. 2023, 26, 3726–3743. [Google Scholar] [CrossRef]

- Gao, F.; Bai, Q.; Jia, Z.; Zhang, X.; Li, Y. Influence and inerting mechanism of inert gas atmospheres on the characteristics of oxidative spontaneous combustion in coal. Energy 2024, 293, 130470. [Google Scholar] [CrossRef]

- Liu, H.; Wang, F. Thermal characteristics and kinetic analysis of coal-oxygen reaction under the condition of inert gas. Int. J. Coal Prep. Util. 2019, 42, 846–862. [Google Scholar] [CrossRef]

- Malashkina, V.A. Recent trends in efficiency improvement in application of degasification systems in coal mines. Min. Inf. Anal. Bull. 2019, 6, 206–214. [Google Scholar] [CrossRef]

- Kabanov, E.I. Analysis of accidents risk in coal mines taking into account human factor. Gorn. Zhurnal 2023, 9, 48–54. [Google Scholar] [CrossRef]

- Semin, M.A. Stability of air flows in mine ventilation networks. Process Saf. Environ. Prot. 2019, 24, 167–171. [Google Scholar] [CrossRef]

- Guenther, T.; Krol, A. Automated detection of compressed air leaks using a scanning ultrasonic sensor system. In Proceedings of the IEEE Sensors Applications Symposium (SAS), Catania, Italy, 20–22 April 2016. [Google Scholar] [CrossRef]

- Jana, R.; Hajra, S.; Rajaitha, P.M.; Mistewicz, K.; Kim, H.J. Recent advances in multifunctional materials for gas sensing applications. J. Environ. Chem. Eng. 2022, 10, 108543. [Google Scholar] [CrossRef]

- Kozhubaev, Y.N.; Belyaev, V.V.; Murashov, Y.V.; Prokofev, O.V. Controlling of unmanned underwater vehicles using the dynamic planning of symmetric trajectory based on machine learning for marine resources exploration. Symmetry 2023, 15, 1783. [Google Scholar] [CrossRef]

- Materova, E.S.; Aksenova, Z.A.; Sharafullina, R.R.; Galimova, G.A.; Shilov, M.L. Digitalization of operations in the Russian mining companies. Ugol 2024, 11, 117–121. Available online: https://ugolinfo.ru/artpdf/RU2411117.pdf (accessed on 19 March 2025).

- Nepsha, F.S.; Voronin, V.A.; Liven, A.S.; Korneev, A.S. Feasibility study of using cogeneration plants at Kuzbass coal mines. J. Min. Inst. 2023, 259, 141–150. [Google Scholar] [CrossRef]

- Kornev, A.V.; Spitsyn, A.A.; Korshunov, G.I.; Bazhenova, V.A. Preventing dust explosions in coal mines: Methods and current trends. Min. Inf. Anal. Bull. 2023, 3, 133–149. [Google Scholar] [CrossRef]

- Nevskaya, M.; Sharapova, A.; Kosovtseva, T.; Nikolaychuk, L. Applications of simulation modeling in mining project risk management: Criteria, algorithm, evaluation. J. Infrastruct. Policy Dev. 2024, 8, 5375. [Google Scholar] [CrossRef]

- Feteira, A. Negative temperature coefficient resistance (NTCR) ceramic thermistors: An industrial perspective. J. Am. Ceram. Soc. 2009, 92, 967–983. Available online: https://www.semanticscholar.org/paper/Negative-Temperature-Coefficient-Resistance-(NTCR)-Feteira/d1dcaef0da05862ce99525577d72342307539e61 (accessed on 1 May 2025). [CrossRef]

- Minakova, T.E.; Malarev, V.I.; Korzhev, A.A. Method to identify operating regimes of asynchronous drivers by subharmonic parameters in mining. Min. Inf. Anal. Bull. 2022, 11, 96–108. [Google Scholar] [CrossRef]

- Alkadhim, S.A.S. Three-phase Induction Motor: Types and Structure. Available online: https://ssrn.com/abstract=3647425 (accessed on 9 July 2020).

| Sensor Designation and Controlled Gas | Ku, Mln −1/V |

|---|---|

| SDTG 01—carbon monoxide CO | 31.25 |

| SDTG 02—hydrogen H2 (low concentration) | 31.25 |

| SDTG 04—hydrogen sulfide H2S | 12.50 |

| SDTG 05—nitrogen oxide NO | 6.25 |

| SDTG 06—nitrogen dioxide NO2 | 6.25 |

| SDTG 07—sulfur dioxide SO2 | 6.25 |

| SDTG 11—oxygen O2, %/V and %/mA | 15.625 |

| Specified Methane Volume Fraction Conversion Range, % | Current, mA Contact “1D” | Current, mA Contact “2D” |

|---|---|---|

| 0–2.5 | Iinp= 1.6*C + 1 | 0.875 ± 0.0625 |

| 0–5.0 | Iinp = 0.8*C + 1 | 0.875 ± 0.0625 |

| 2.5–100 | 5.25 ± 0.0625 | Iinp = 0.041*C + 0.897 |

| 5–100 | 5.25 ± 0.0625 | Iinp = 0.042*C + 0.789 |

| Parameters | UPTLK-30M | UPTLK-12M | UPTLK-12M | UPTLK-6M |

|---|---|---|---|---|

| Main location on the conveyor (with standard equipment) | Linear part | Drive, tensioning station | Drive, tensioning station | End drum |

| Number of protected drums | 2 | 3 | 2 | 1 |

| Operating water pressure, MPa | 0.35–2.4 | 0.35–2.4 | 0.35–2.4 | 0.35–2.4 |

| Maximum water pressure, MPa | 4.0 | 4.0 | 4.0 | 4.0 |

| Ambient temperature, °С | +2…+35 | +2…+35 | +2…+35 | +2…+35 |

| Sprinkler thermal lock failure temperature, °С | 68 ± 3 | 68 ± 3 | 68 ± 3 | 68 ± 3 |

| Length of protection using one set, m | 30 | 12 | 9 | 6 |

| Number of screw atomizers, pcs | 11 | 5 | 4 | 3 |

| Distance between screw atomizers, m | 3 | 3 | 3 | 3 |

| Water flow rate at 0.6 MPa, l/s | 26.3 | 10.6 | 10.6 | 8.0 |

| Weight, kg | 240 | 100 | 95 | 85 |

| Component | Response Time | Standard |

|---|---|---|

| Gas Sensors | 50 ms | EN 50270 |

| PLC Processing | 10 ms | IEC 61131-2 |

| Fire Extinguisher | 30 ms | ISO 7240-11 |

| Total System | 90 ms | ISO 13849-1 |

| Parameter | Simulation | Experiment | Error | Standard |

|---|---|---|---|---|

| CH4 reduction (2s) | 30.00% | 28.7 ± 0.8% | 4.30% | ISO 7240 |

| Response time (alarm) | 1.8 s | 2.05 ± 0.12 s | 13.90% | EN 54-29 |

| False positive rate | 0.10% | 0.9 ± 0.3% | 800% | IEC 61508 |

| Power consumption | 850 W | 910 ± 15W | 7.10% | AS/NZS 4871 |

| Parameter | Proposed System | Traditional Systems | Improvement |

|---|---|---|---|

| Response time (s) | 2.05 ± 0.12 | 8.2 ± 1.5 | 75% |

| Detection accuracy | 95% | 85% | 10% |

| CH4 reduction (2 s) | 28.7% | 12% | 139% |

| False alarm rate | 0.9% | 3.5% | 74% |

| Energy (kW) | 0.91 | 1.25 | 27% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ovchinnikova, E.; Kozhubaev, Y.; Wu, Z.; Sabbaghan, A.; Ershov, R. Modeling of Multifunctional Gas-Analytical Mine Control Systems and Automatic Fire Extinguishing Systems. Symmetry 2025, 17, 1432. https://doi.org/10.3390/sym17091432

Ovchinnikova E, Kozhubaev Y, Wu Z, Sabbaghan A, Ershov R. Modeling of Multifunctional Gas-Analytical Mine Control Systems and Automatic Fire Extinguishing Systems. Symmetry. 2025; 17(9):1432. https://doi.org/10.3390/sym17091432

Chicago/Turabian StyleOvchinnikova, Elena, Yuriy Kozhubaev, Zhiwei Wu, Aref Sabbaghan, and Roman Ershov. 2025. "Modeling of Multifunctional Gas-Analytical Mine Control Systems and Automatic Fire Extinguishing Systems" Symmetry 17, no. 9: 1432. https://doi.org/10.3390/sym17091432

APA StyleOvchinnikova, E., Kozhubaev, Y., Wu, Z., Sabbaghan, A., & Ershov, R. (2025). Modeling of Multifunctional Gas-Analytical Mine Control Systems and Automatic Fire Extinguishing Systems. Symmetry, 17(9), 1432. https://doi.org/10.3390/sym17091432