1. Introduction

In the automotive transmission system, the diaphragm spring is the ‘heart’ component of the clutch assembly [

1]. Especially for heavy commercial vehicles, the working performance, transmission efficiency, and operation reliability of the clutch depend entirely on the mechanical properties of the diaphragm spring [

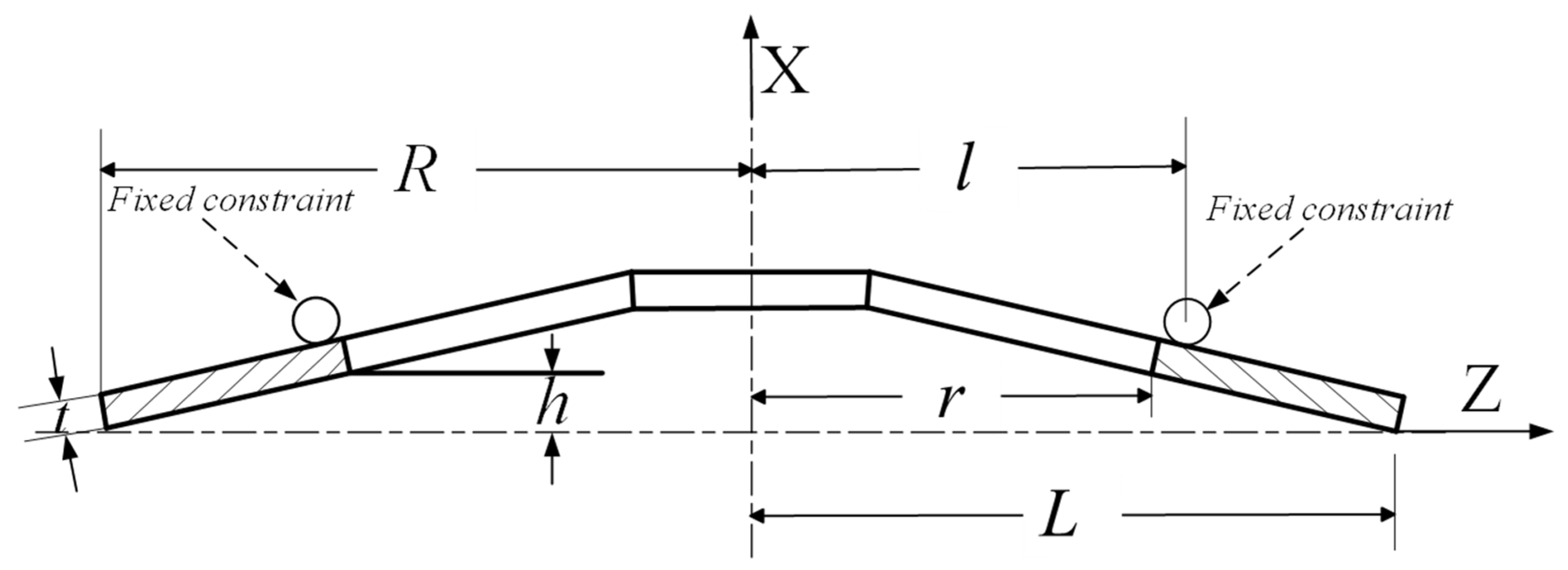

2]. The core design difficulty of the diaphragm spring lies in the nonlinear load–displacement characteristics presented at its large end. This characteristic stems from the large deformation behavior in the linear elastic range of the material, which belongs to the typical geometric nonlinear problem and poses stringent demands for the accuracy of the analysis method [

3]. This structural advantage stems from its inherent axisymmetry, which ensures uniform force distribution during clutch operation.

Early research on diaphragm springs focused on theoretical modeling and basic mechanical property analysis, laying the foundation for understanding their load–displacement behavior. Yasunori et al.’s research shows why and how the residual stress affects the P-δ curve. They established a formula and proposed an improved analysis method. By moving the coordinate origin, the P-δ curve can be easily predicted [

4]. Lin et al. considered the actual factors such as contact and friction between the diaphragm spring and the pressure plate and the support ring, established an accurate finite element model of the large end of the diaphragm spring, and analyzed the load–displacement characteristics and stress-displacement characteristics of the diaphragm spring [

5]. Yan conducted an in-depth analysis of the diaphragm spring, the buffer plate, and the friction plate and established a more complex model. They used the A-L method and the infinitesimal method to analyze the mechanical properties of the diaphragm spring and the buffer plate and verified the effectiveness of the established model through specific tests [

6]. SHI and Wang used the theoretical calculation formula of the diaphragm spring to analyze the main structurally sensitive factors affecting its load characteristics and established the finite element model of the diaphragm spring based on the nonlinear finite element method. By comparing the error between the finite element calculation results and the theoretical formula results and the experimental results, it is verified that the finite element analysis results are closer to the experimental results [

7,

8]. Further, Zhang et al. used ABAQUS finite element software to perform static loading tests on C-series disc springs with an outer diameter of 28 mm and obtained load–displacement characteristic curves under different working conditions [

9]. Hou et al. used the finite element method to simulate the force of the self-adjusting clutch force-sensing disc spring, obtained the load–displacement curve, and compared the results with the results calculated by the A-L theoretical formula and the test results [

10]. Shin et al. proposed a method for estimating the complex stiffness of an inflatable rubber diaphragm using a commercial finite element method (such as ABAQUS) [

11]. Bai and Lin used ANSYS to analyze the thermal stress and strain of the dry diaphragm spring clutch [

12]. These studies confirmed the superiority of finite element analysis (FEA) over traditional theoretical formulas but primarily focused on simplified disc spring models, leaving the influence of separation fingers under-explored.

Subsequent studies extended to thermal and structural coupling effects, which are critical for practical clutch operation under high-load conditions. In the field of theory and practice, the nonlinear characteristics of the diaphragm spring is an important research object [

13]. Shi and Huang et al. focus on the thermal-structural coupling characteristics of the diaphragm spring. The research results show that the temperature rise will reduce the maximum compressive stress of the diaphragm spring, reduce the working load, and increase the maximum separation force, thus affecting the wear life of the clutch friction plate. These studies provide an important theoretical basis for optimizing the design of diaphragm springs and improving the performance of clutches [

14]. Wang et al. found that the time-varying thermal characteristics of a dry clutch are related to its working time [

15]. Zhao et al. simulated the nonlinear characteristics of the diaphragm spring by Creo/Simulate and Workbench. The results show that the study further emphasizes the important influence of constraints on the nonlinear characteristics of the diaphragm spring and provides the basic principles for the simulation design and application of the diaphragm spring [

16]. While these works highlighted environmental factors (e.g., temperature) on diaphragm spring performance, they did not systematically investigate how separation finger geometry affects core load characteristics.

Recent research has emphasized optimization strategies and industrial applications, aiming to improve clutch performance through diaphragm spring design. Shangguan et al. proposed and used the finite element (FE) model to estimate the clutch separation characteristics, analyzed the influence of the nonlinear characteristics of the corrugated plate and the diaphragm spring on the clutch separation performance, and proposed how to use the nonlinear characteristics of the diaphragm spring and the corrugated plate to improve the clutch separation performance [

17]. Liu et al. used the periodic operation method and linear regression analysis method to analyze the variation law and trend of elastic properties and residual deformation of leaf springs with time during storage with different deformations and evaluated the storage life of products [

18]. Li and Chen optimized the basic parameters, diaphragm spring, and force-sensing spring of the self-adjusting diaphragm spring clutch and evaluated its life. The optimization results show that the basic parameter design is more compact than the original structure size design [

19]. Despite progress in optimization algorithms, the lack of quantitative analysis on separation finger parameters limits the precision of performance tuning for commercial vehicle clutches.

Intelligent algorithm-driven research on diaphragm spring optimization aims to enhance pressing stability and operational performance through multi-objective regulation. Zhou et al. established a multi-objective optimization model of the clutch diaphragm spring and proposed an improved particle swarm optimization algorithm (Improved PSO) based on dynamic weight and hierarchical penalty function to make the diaphragm spring have more stable pressing force and lighter operating characteristics [

20]. A Karaduman investigated the fatigue behavior of diaphragm springs by experimental and numerical methods. The study considers ten design variables, finger shape optimization with eight variables, and load and stress optimization targeting maximum fatigue resistance (two variables). Numerical analysis of 175 different designs [

21]. To improve fatigue strength, N. Kaya developed a method based on a genetic algorithm to optimize the window profile of a diaphragm spring with concentrated stress and used a local search algorithm to adjust the window profile parameters [

22]. While these algorithm optimizations improve fatigue strength and structural performance, they do not address the impact of separation finger geometric parameters on load characteristics, which is the key supplement of this study for commercial vehicle scenarios.

With the advancement of theory and optimization research, the landing of diaphragm spring-related technologies in industrial applications has become an important direction, covering many aspects such as design methods, system development, and control strategies. Hajavifard’s research found that shot peening can induce compressive stress in the stressed areas of diaphragm springs, thereby extending their operational limits under given yield strength and fatigue strength conditions [

23]. Qing et al. introduced the application of DFMEA (Design Failure Mode and Effects Analysis) in product design [

24]. From another point of view, Xu et al. proposed to use the secondary development function of Pro/Toolkit and VC as a development tool to establish a specific implementation process of a parametric system based on the parts of the diaphragm spring clutch [

25]. Li proposed an improved predictive functional control (mPFC) method, which has a small online calculation burden and a simple structure. It can be applied to other industrial control systems that require fast response [

26].

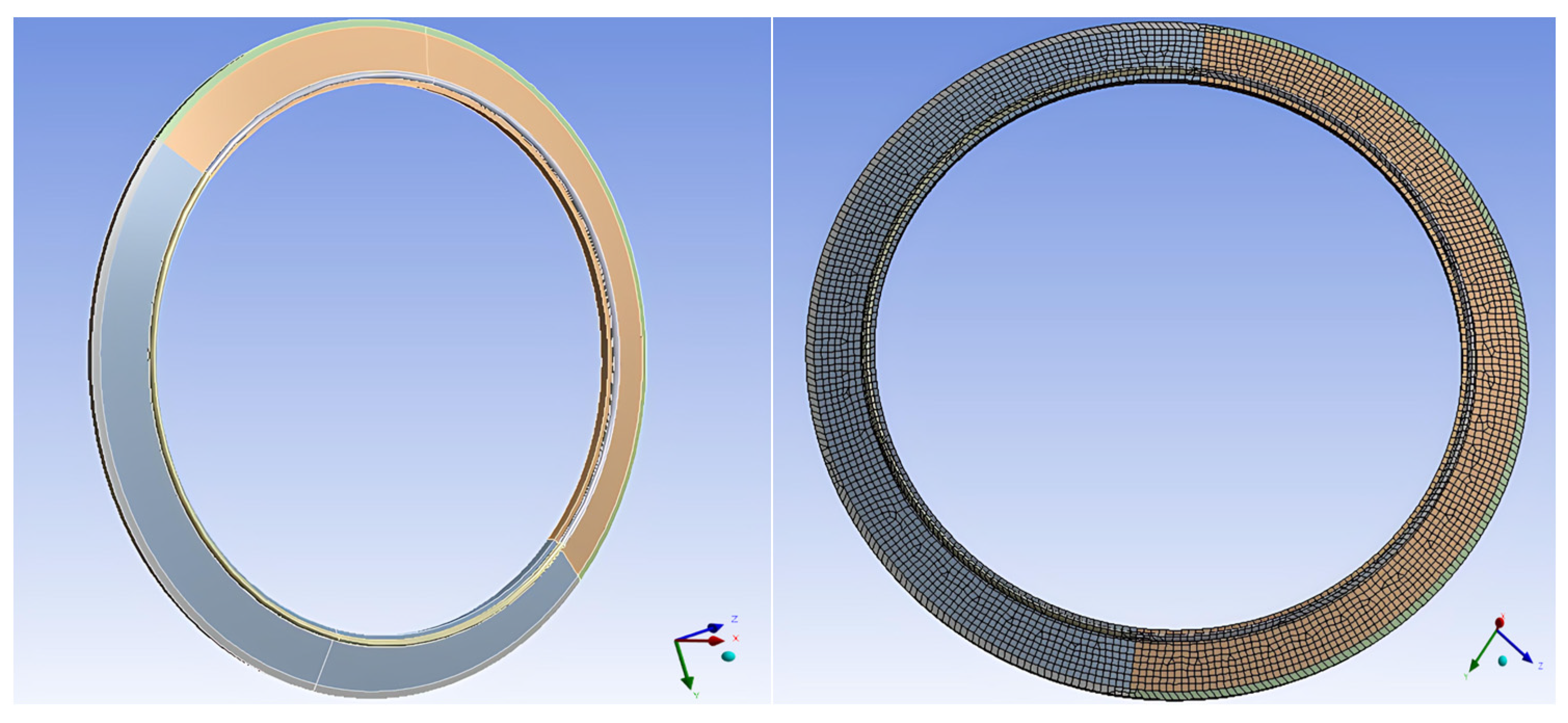

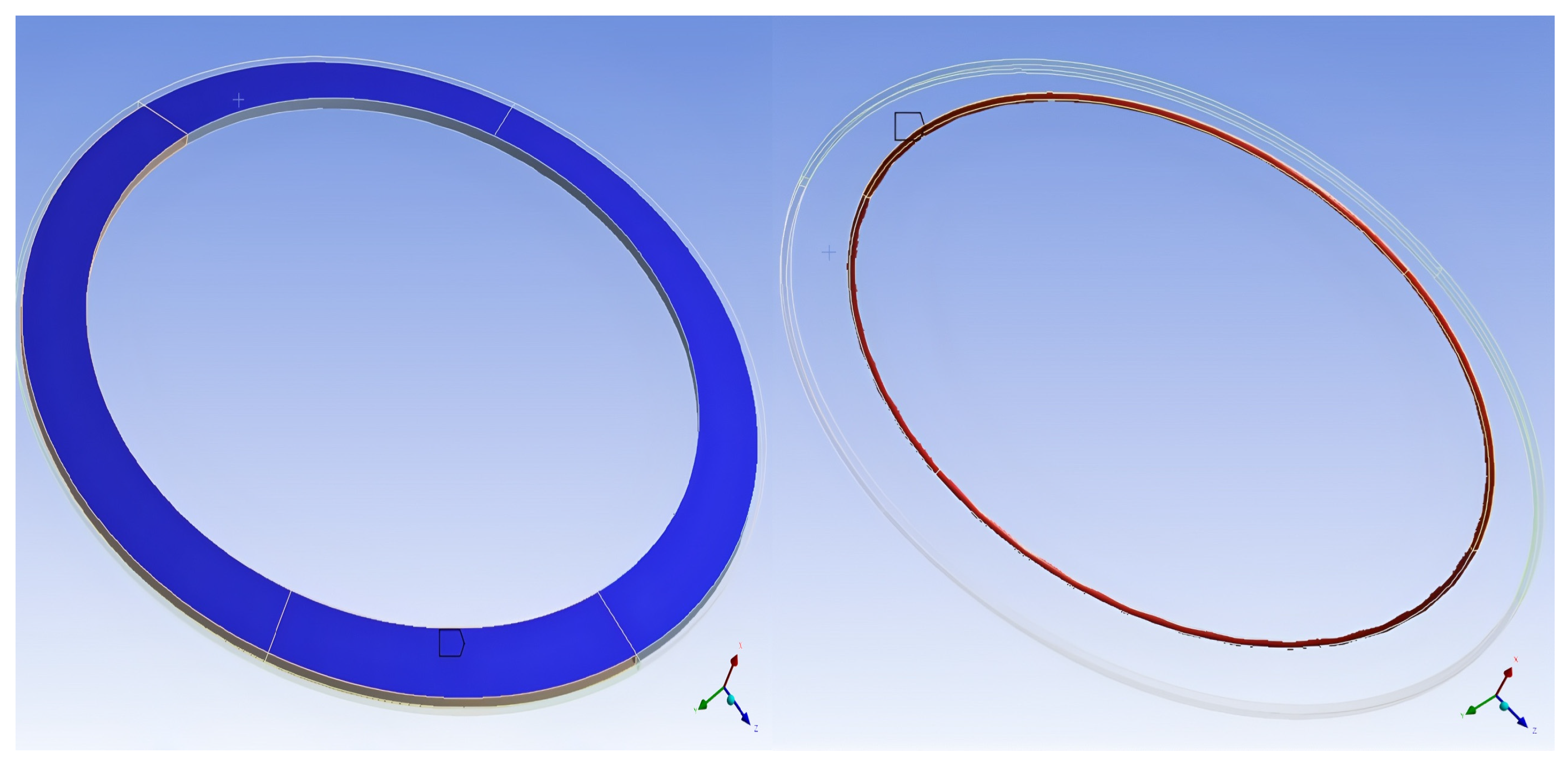

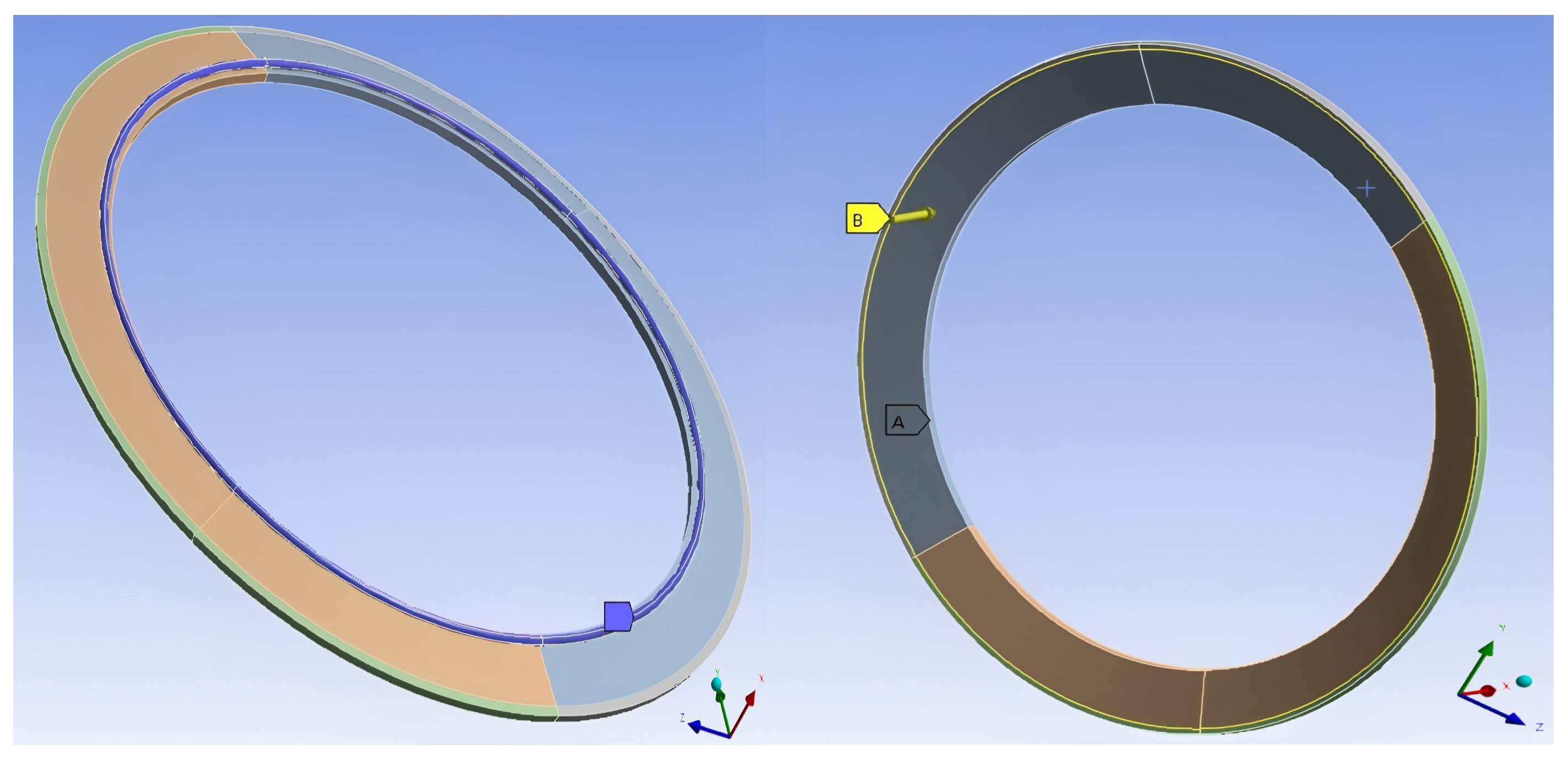

However, it is crucial to emphasize that diaphragm springs (industrial products integrated with separation fingers for commercial vehicle clutches) and disc springs (theoretical models without separation fingers, which the A-L formula is based on) differ fundamentally in structure—with the separation finger being their key distinguishing feature. Despite existing research revealing various characteristics of diaphragm springs, systematic quantitative analysis of how separation finger structural parameters (root hole size, shape, number, and length) influence the large-end load–displacement characteristics of commercial vehicle clutch diaphragm springs remains an insufficient critical gap for meeting the high performance and reliability demands of heavy vehicle clutches. To fill this gap, this study first establishes an FEA model of the diaphragm spring’s disc spring component (excluding separation fingers) and validates its accuracy against the A-L formula, laying a theoretical foundation for subsequent analysis. Then, a complete diaphragm spring model with separation fingers is constructed to systematically explore how separation finger root hole size, shape, number, and length affect large-end load–displacement characteristics. This research aims to provide a targeted theoretical basis and technical reference for the precise design and performance optimization of commercial vehicle diaphragm springs.

4. Discussion

In this study, the mechanical properties of the diaphragm spring obtained by finite element simulation can be analyzed in depth from the effectiveness of the simulation method and the influence mechanism of structural parameters.

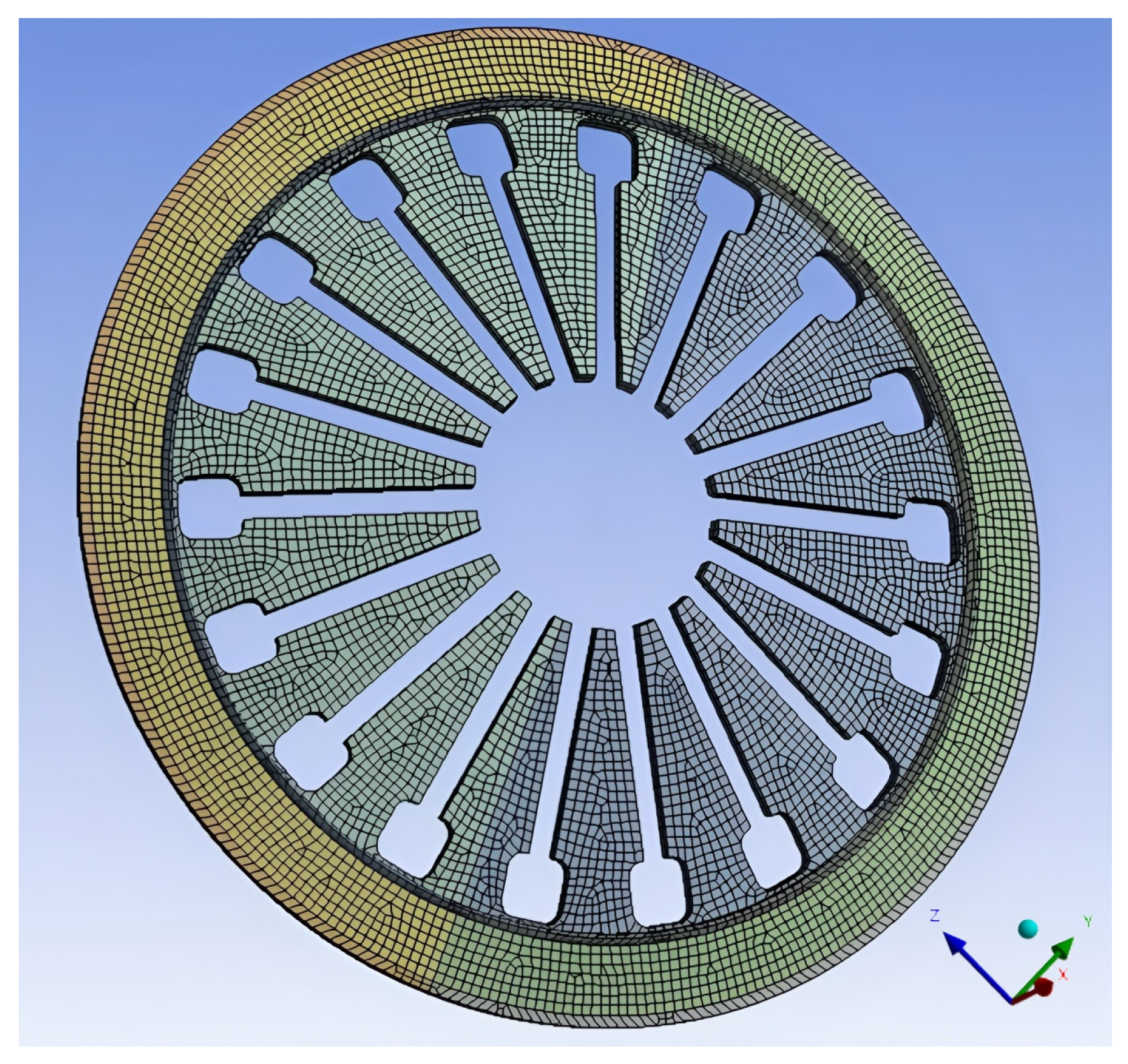

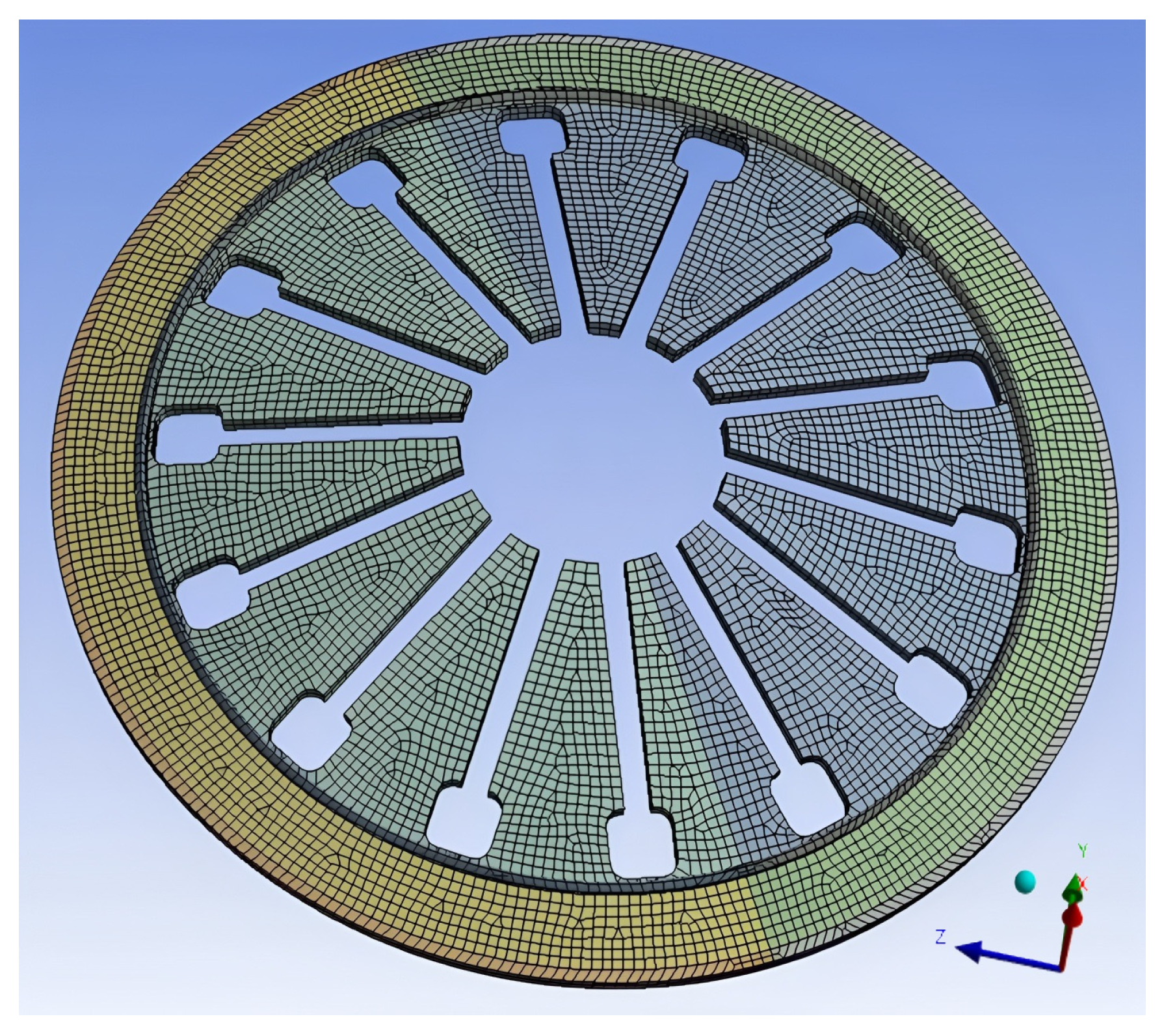

From the simulation method, the comparison between the finite element model and the A-L formula shows that the two trends are consistent and the difference is small (

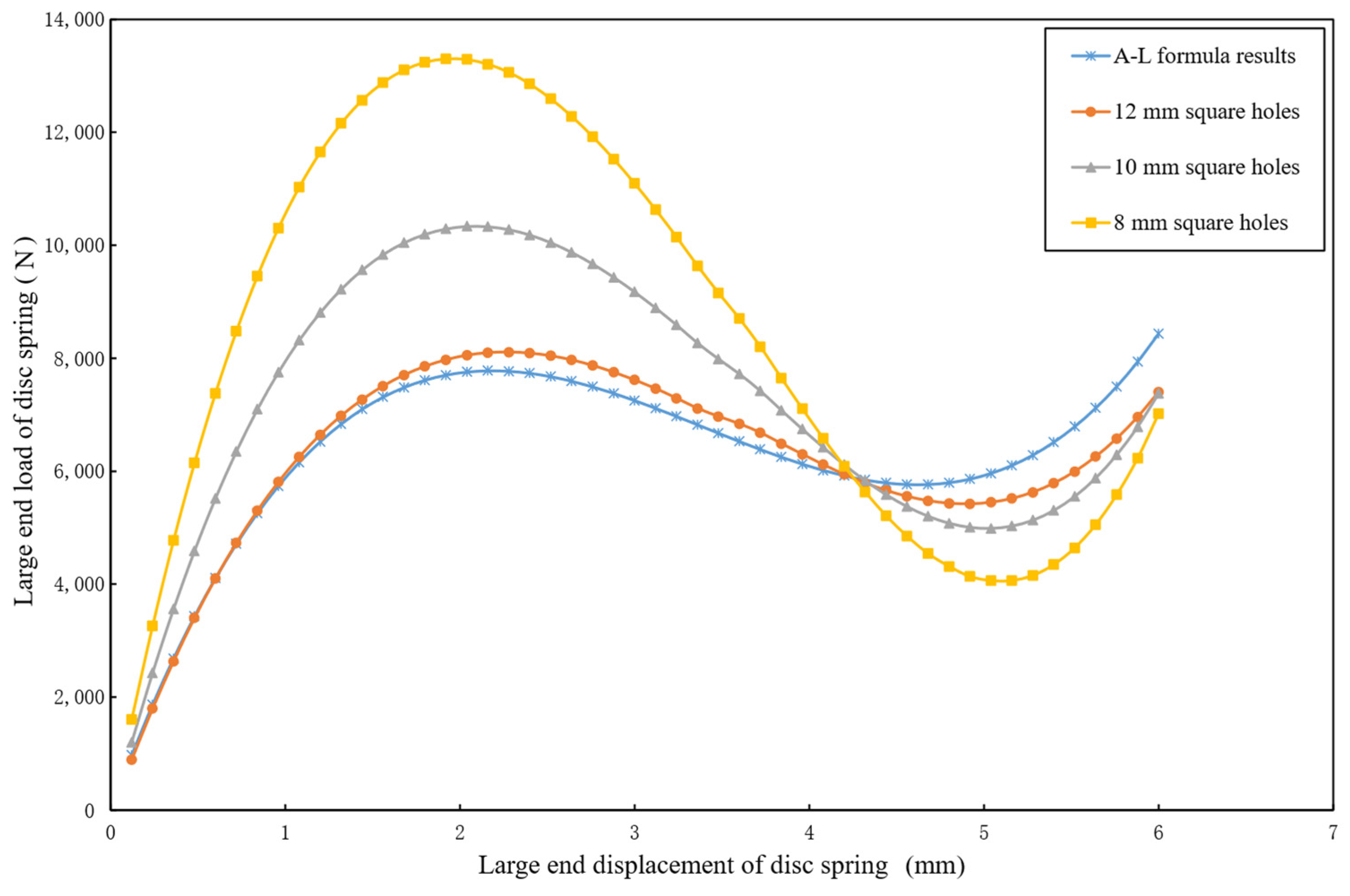

Figure 5), which verifies the applicability of the model to the large deformation nonlinear problem of the diaphragm spring. Compared with the traditional A-L formula, the advantage of finite element simulation is that it can accurately capture the subtle influence of the separation finger structure on the load–displacement characteristics, which is difficult to achieve by the A-L formula, because it is only applicable to the simplified disc spring model and cannot include the geometric effects of complex structures such as the separation finger. For example, when the size of the square hole at the root of the separation finger increases from 8 mm to 12 mm, the simulation results (

Table 3) clearly show that the load at 6 mm displacement increases from 7017.5 N to 7403.5 N, and the difference from the A-L formula results reduces from 16.8% to 12.3%, confirming that the load–displacement curve gradually approaches the theoretical model. This continuous change in stiffness, quantified by specific load values and deviation percentages, is difficult to capture through the A-L formula, while finite element simulation achieves precise tracking through mesh discretization.

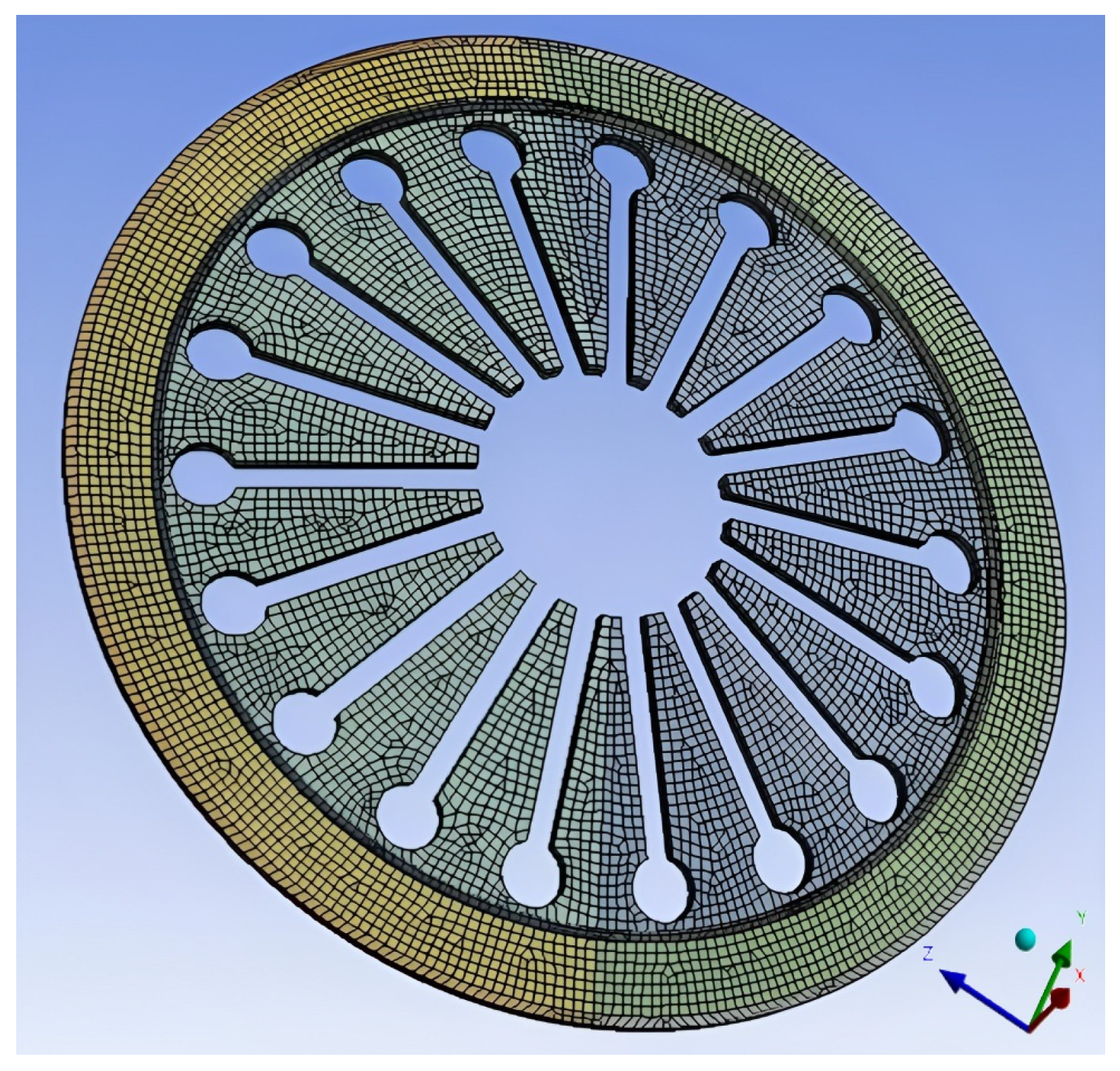

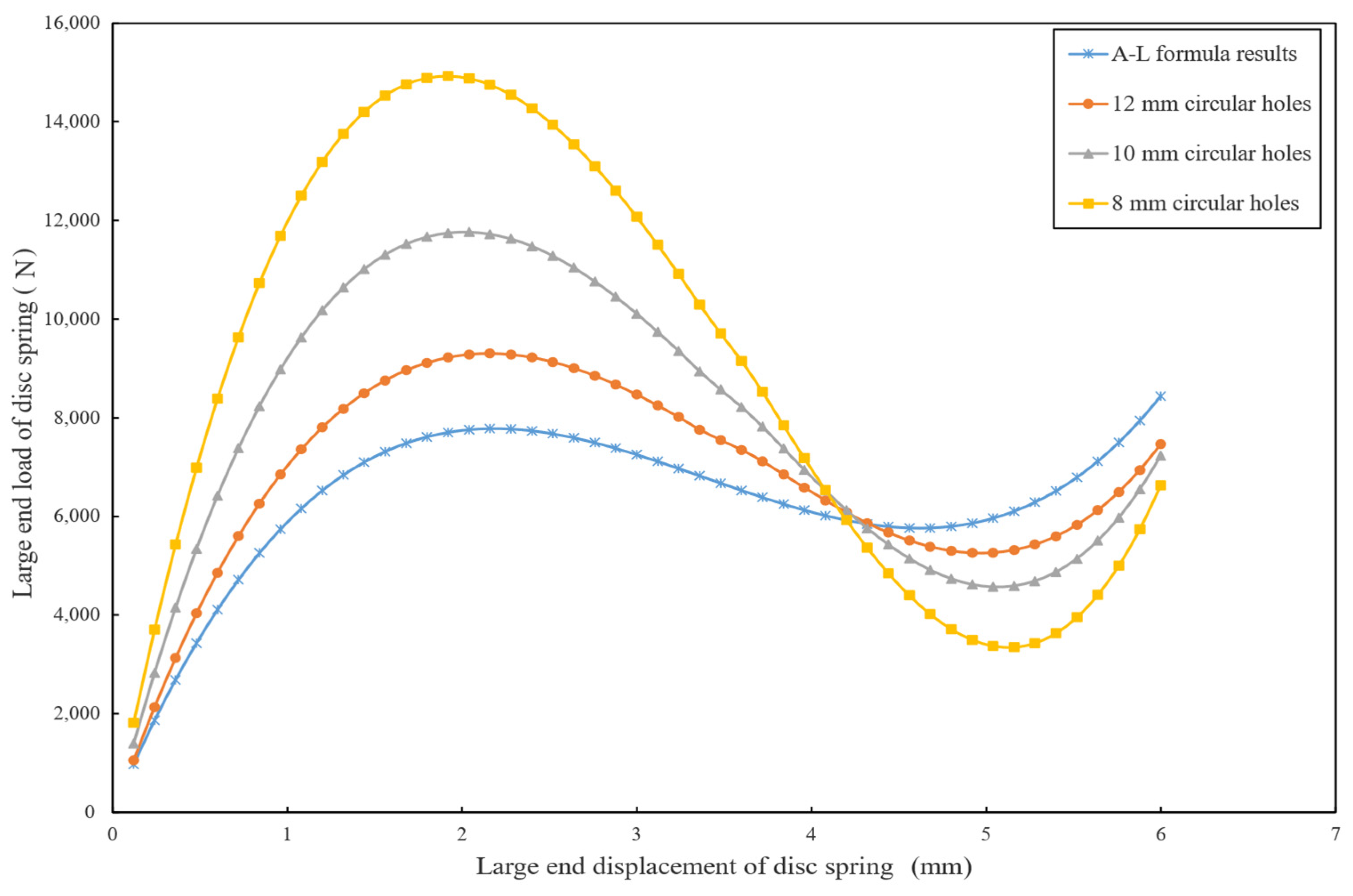

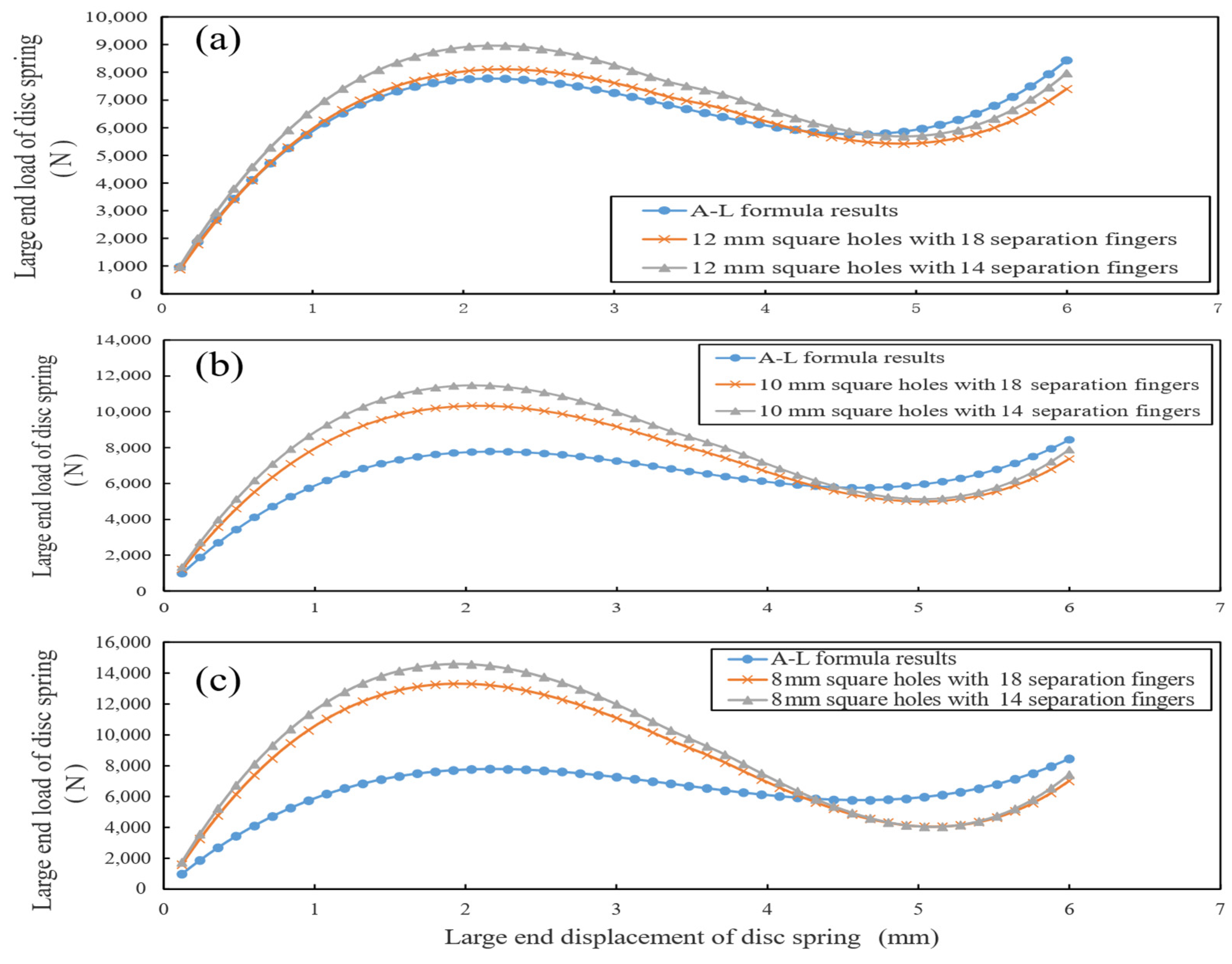

From the simulation results of the influence of structural parameters, the size and shape of the separation finger root hole are the core factors regulating the characteristic curve (

Figure 7,

Figure 9 and

Figure 10). For circular holes (

Table 4), when the size increases from 8 mm to 12 mm, the load at 6 mm displacement rises from 6627.0 N to 7462.5 N, and the difference from the A-L formula decreases from 24.5% to 11.6%, showing a similar trend to square holes in approaching the theoretical model but with a more significant load increase (12.6% vs. 5.5% for square holes). For hole shape (

Table 5), under the same aperture, the maximum load of square holes is consistently lower than that of circular holes by 10.9% (8 mm), 12.1% (10 mm), and 13.0% (12 mm). Notably, careful observation of

Figure 10 reveals a displacement-dependent relationship: before 4.32 mm displacement, the square hole load is smaller than the circular hole, while after this point, the trend reverses, which is closely related to the larger material removal area of square holes (15–20% larger than circular holes of the same size) and the stress redistribution in different deformation stages. In addition, the increase in the number of separation fingers (e.g., from 14 to 18) reduces stiffness (

Figure 14).

Table 7 shows that for 12 mm square holes, the maximum load decreases by 10.7% (from 8964.1 N to 8097.2 N) when the number increases, which is because more separation fingers disperse the load and reduce stress concentration per unit area, providing a quantitative basis for optimizing clutch operating force.

It is worth noting that the simulation results (

Table 6) confirm that “the length of the separation finger has no significant effect on the characteristic curve” (

Figure 12): under the same square hole size, the maximum load difference between long and short separation fingers is less than 0.1% (e.g., 13,302 N vs. 13,301 N for 8 mm aperture). Simulation shows that stress is mainly concentrated in the root area (over 90% of total stress), with negligible stress changes in the fingertip, so the impact on overall stiffness is weak. This provides flexibility for diaphragm spring adaptation—length can be adjusted according to assembly space without rechecking load characteristics. The symmetry of separation finger distribution is a key reason for balanced load–displacement curves, as asymmetric designs would introduce uneven stress concentrations.

5. Conclusions

This study systematically analyzed the mechanical properties of diaphragm springs for commercial vehicle clutches using the finite element method, focusing on the influence of separation finger structural parameters on large-end load–displacement characteristics. The finite element model was validated by comparison with the A-L formula, confirming its reliability in simulating large-deformation nonlinear behavior. Key findings include:

- (1)

The size, shape of the separation finger root hole, and the number of separation fingers are critical factors regulating the load–displacement curve—larger holes, square holes (vs. circular holes), and more separation fingers reduce stiffness effectively.

- (2)

Separation finger length has negligible impact on the characteristic curve, allowing flexible adjustment based on assembly space without affecting core load properties.

These results provide direct guidance for optimizing diaphragm spring design in commercial vehicle clutches. Notably, these findings underscore the critical role of structural symmetry, particularly axisymmetry and symmetrical distribution of separation fingers, in regulating load–displacement stability, offering a symmetry-based design framework for industrial applications.

However, there are still some limitations in this study: the model does not consider the influence of material nonlinearity (such as plastic deformation) and temperature on mechanical properties, while the temperature rise may lead to the degradation of material properties when the clutch of a heavy commercial vehicle works under long term high load; in addition, the influence of stress concentration at the root of the separation finger on the fatigue life is not involved, which is also a key issue to be concerned about in practical applications.

Future research can be expanded from three aspects: first, the introduction of a material elastic-plastic model and thermal-structural coupling analysis, closer to the actual working conditions; secondly, the simulation results are verified by experimental tests, and the fatigue life prediction is carried out. Thirdly, based on the multi-objective optimization algorithm, the global optimal design of the diaphragm spring is realized by considering the stiffness, stress distribution, and weight.