A Review of Vector Field-Based Tool Path Planning for CNC Machining of Complex Surfaces

Abstract

1. Introduction

2. Conventional Tool Path Planning Methods for Complex Surfaces

- (1)

- The isoparametric line method, first proposed by Loney et al. [18], is widely used in multi-coordinate machining due to its simplicity, as it generates paths along surface parametric lines [19]. However, its critical limitation lies in the non-linear mapping between parameter space and Euclidean space, leading to uneven path spacing and potential undercutting; this makes it unsuitable for highly curved surfaces. He et al. [20] addressed this by developing an adaptive mesh optimization method, which reduces transformation deviation but increases computational complexity, highlighting a trade-off between accuracy and efficiency that subsequent methods (e.g., the truncated plane method) sought to resolve.

- (2)

- The intercept plane method generates paths via intersections between parallel planes and the machined surface [21], showing strong applicability to sheared parametric surfaces. However, its reliance on solving nonlinear equations leads to high computational costs, and conservative line spacing (to ensure accuracy) reduces efficiency; this contrasts the isoparametric line method, which is simpler but less adaptable, revealing a fundamental tension between universality and computational feasibility in traditional path planning.

- (3)

- The equal illuminance line method was first proposed in 1984. There are many points on a surface with the same illuminance, and the curve formed by connecting these points is called the line of equal illuminance. Since the illuminance side reflects the smoothness of a surface, the method was initially used to check the continuity of surfaces. Later, Han et al. [22] proposed the following innovative idea: the complex surface of a workpiece surface is approximated as consisting of multiple piecewise straight curves. Under this assumption, we further connect points with the same illumination level to each other to form a series of boundary curves or localization buses located on the surface. More accurate positioning is achieved, so the method is also used in five-axis CNC machining with more and more accurate positioning coordinates.

- (4)

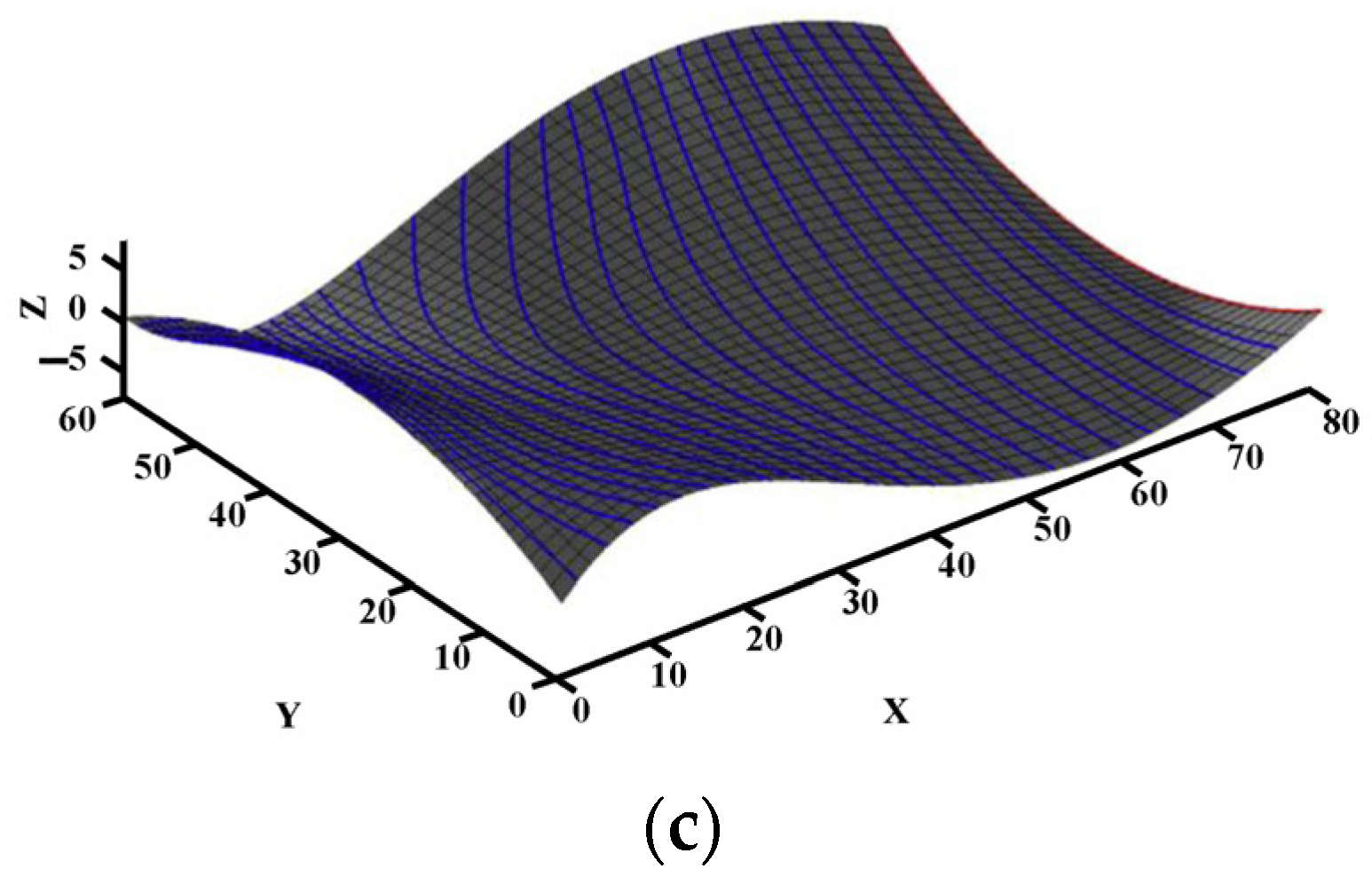

- The basic idea of the mapping method is to first map the three-dimensional surface to be machined into a two-dimensional plane, then calculate the tool trajectory for the two-dimensional plane. Following this, the tool position points of the obtained two-dimensional plane are corresponded to the three-dimensional surface one by one through the mapping to obtain the tool trajectory [23]. Han et al. [24] applied this method to complex impeller surfaces by mapping the trajectories from the parametric domain to the physical domain to obtain the tool path. For the mapping method, the direction of 3D parametric mapping directly affects the geometric fidelity and kinematic characteristics of the tool trajectory, which in turn determines the machining efficiency and molding accuracy of the method. Therefore, this method is widely used in tool path planning for curved cavity-like structures and multi-feature combination surfaces.

- (5)

- The equal residual height method is designed to improve machining efficiency, reduce machining time, and ensure machining accuracy by maintaining the machining residual height between adjacent tool paths within a preset maximum allowable value [25]. This method was first proposed by Suresh et al. [26] and is currently the most widely used method.

3. Vector Field-Based Tool Path Planning Methods for Complex Surfaces

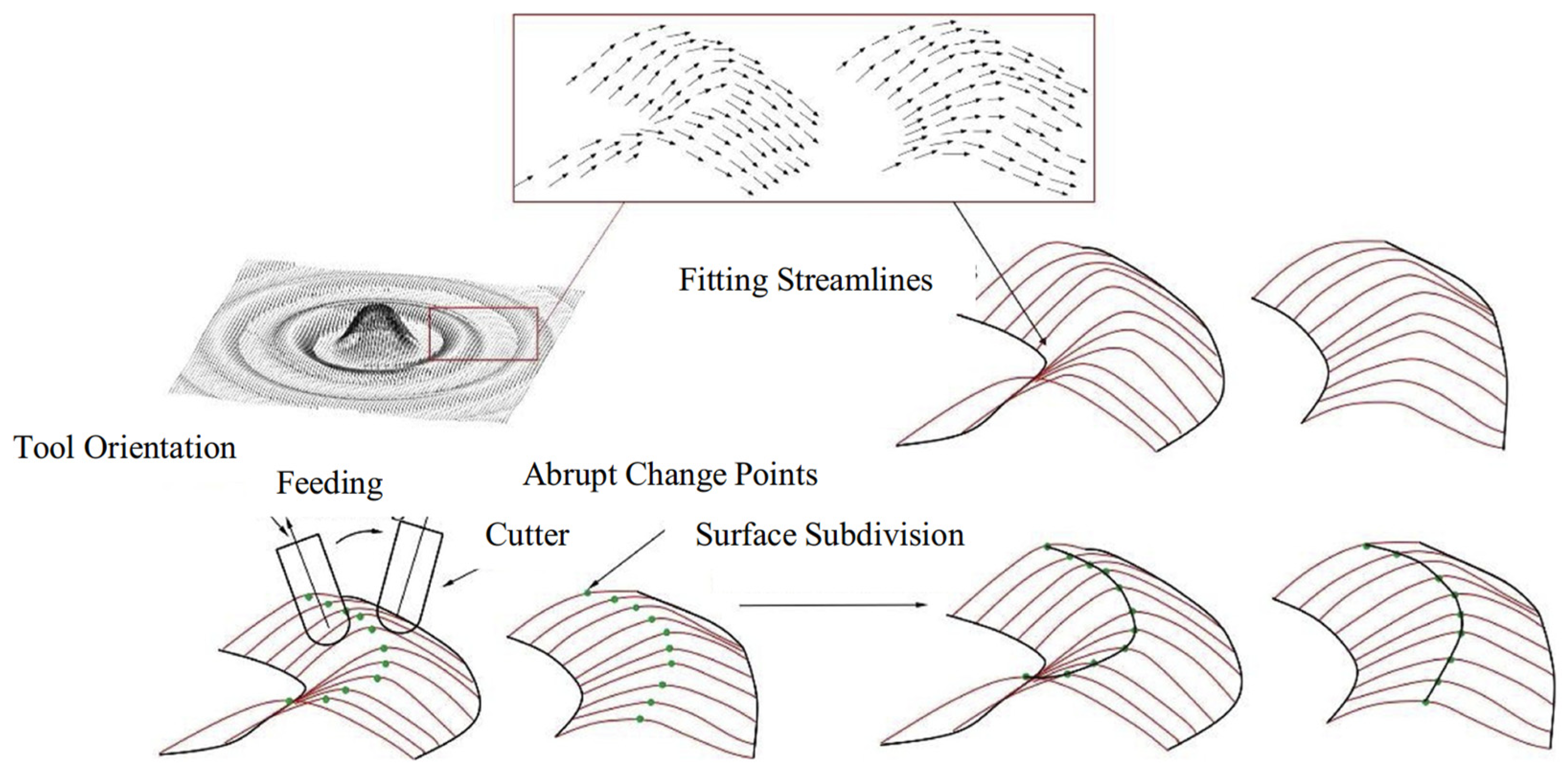

3.1. Vector Field-Based Tool Attitude Optimization

3.2. Vector Field-Based Tool Position Optimization

- (1)

- Maximum machining bandwidth [49]. In tool path planning, it is determined that the tool can move with the maximum machining bandwidth by considering the vectorial characteristics of the tool path (e.g, direction, speed, etc.) and the geometry of the machining area. However, it has high computational complexity and high equipment requirements, and it is more dependent on machining experience.

- (2)

- Optimized kinematic performance [50]. In the field of CNC machining, the kinematic characteristics of each feed axis of the machine tool are optimized by optimizing the direction and variation of the tool path and the tool axis vector field, thus ensuring speed smoothing, machining stability, and load balancing of the machine tool during the machining process.

- (3)

- Minimum energy consumption [51]. Under the premise of meeting the requirements of the machining task, the reasonable adjustment of the tool axis vector field to optimize the trajectory of the tool, so that the tool in the execution of the machining task requires a minimum of energy, thus reducing the production cost.

- (4)

- Maximum material removal rate [52]. This refers to the planning of the tool’s trajectory to achieve the optimization of the tool’s path, speed, acceleration, and other parameters through the planning of the tool axis vector field, so as to maximize the volume of material removed from the machined part per unit of time.

- (5)

- Optimal smoothness [53]. When performing CNC machining, the vector field is used to optimize the feed direction of the tool so that the machined surface achieves the optimum smoothness. This method not only reduces the roughness of the machined surface and improves the machining quality, but also reduces the tool wear and lowers the machining cost.

- (6)

- Area subdivision [54]. Area subdivision machining usually refers to the CNC machining of complex geometries. Based on the vector field, the entire machining area is subdivided into multiple sub-areas, and different machining strategies and parameter settings are formulated for the characteristics and needs of each sub-area to optimize the machining process and improve the quality of the product. In conclusion, area subdivision machining is an effective machining optimization method, which can improve production efficiency, reduce cost, improve product quality, adapt to market demand, and improve production safety.

3.2.1. Tool Position Optimization Based on Maximum Machining Bandwidth

3.2.2. Tool Position Optimization Based on Best Kinematic Performance

3.2.3. Tool Position Optimization Based on Minimum Energy Consumption

3.2.4. Tool Position Optimization Based on Maximum Material Removal

3.2.5. Smoothness-Based Optimal Tool Position Optimization

3.2.6. Tool Position Optimization Based on Area Segmentation

4. Conclusions and Outlook

- (1)

- The traditional tool path planning methods are still confined to the point-by-point trajectory design at the purely geometric level, and the layout form depends on the selection of the initial path. Additionally, there are fewer methods to consider the tool trajectory at the integrated level of geometry, kinematics, and dynamics, which are not able to take into account the physical characteristics of the surface geometry and have difficulty realizing the overall control of the tool trajectory. Therefore, it is necessary to consider from the perspective of geometry, kinematics, and dynamics.

- (2)

- Regarding the optimization of tool posture based on vector field, the current research mainly focuses on the smoothness of the feed vector; however, the consideration factors are too single. Therefore, the multimodal vector field data, such as the CAD model, feed speed curve, spindle torsion angle, vibration spectrum, etc., should be integrated to establish cross-modal correlation through models similar to the Contrastive Language–Image Pretraining model (CLIP-like model), to realize the comprehensive optimization of tool attitude.

- (3)

- In the optimization of tool position based on vector field, the current is mainly based on vector field from the machining bandwidth, the best motion performance, the minimum energy consumption, the maximum material removal rate, the maximum feed rate, and so on, as the goal to achieve the optimization of the tool path. However, the above optimization objectives are mainly for the optimization of the target offline value. In the future, with the development of artificial intelligence, digital twin, image processing technologies [81,82], and wireless sensing technology, based on the sensor feedback real-time correction vector field, dynamic adjustment of the tool position, our goal is to achieve the machining process of “perception—decision-making—execution” of the closed-loop optimization, and then realize the intelligent, real-time, multi-objective optimization of complex surfaces of high-precision machining.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, X.; Huang, T.; Zhao, H.; Zhang, X.; Yan, S.; Dai, X.; Ding, H. A review of recent advances in machining techniques of complex surfaces. Sci. China Technol. Sci. 2022, 65, 1915–1939. [Google Scholar] [CrossRef]

- Liu, H.; Xing, F. Tool axis vector optimization based on automatic smoothing rotary angles of five-axis machining for laser additive manufacturing. Int. J. Adv. Manuf. Technol. 2024, 134, 3481–3493. [Google Scholar] [CrossRef]

- Masood, A.; Siddiqui, R.; Pinto, M.; Rehman, H.; Khan, M.A. Tool Path Generation, for Complex Surface Machining, Using Point Cloud Data. Procedia CIRP 2015, 26, 397–402. [Google Scholar] [CrossRef]

- Behera, R.; Chan, T.-C.; Yang, J.-S. Innovative Structural Optimization and Dynamic Performance Enhancement of High-Precision Five-Axis Machine Tools. J. Manuf. Mater. Process. 2024, 8, 181. [Google Scholar] [CrossRef]

- Zhu, D.; Feng, X.; Xu, X.; Yang, Z.; Li, W.; Yan, S.; Ding, H. Robotic grinding of complex components: A step towards efficient and intelligent machining—Challenges, solutions, and applications. Robot. Comput. Manuf. 2020, 65, 101908. [Google Scholar] [CrossRef]

- Makhanov, S.S. Vector fields for five-axis machining. A survey. Int. J. Adv. Manuf. Technol. 2022, 122, 533–575. [Google Scholar] [CrossRef]

- Jignasu, A.; Rurup, J.D.; Secor, E.B.; Krishnamurthy, A. NURBS-based path planning for aerosol jet printing of conformal electronics. J. Manuf. Process. 2024, 118, 187–194. [Google Scholar] [CrossRef]

- Ma, J.W.; Hu, G.Q.; Qin, F.Z.; Li, G.-L.; Qu, Z.-W. Optimization method of tool axis vector based on kinematical characteristics of rotary feed axis for curved surface machining. Int. J. Adv. Manuf. Technol. 2019, 100, 2007–2020. [Google Scholar] [CrossRef]

- Ma, J.-W.; Hu, G.-Q.; Qin, F.-Z.; Li, G.-L.; Qu, Z.-W.; Liu, Y. Global tool axis vector optimization based on the minimum angular acceleration of rotary axes. Int. J. Adv. Manuf. Technol. 2020, 107, 2121–2136. [Google Scholar] [CrossRef]

- Zhao, P.; Liu, Z.; Li, Z.; Cao, Z. Research on tool axis vector optimization when face milling complex surfaces. Int. J. Adv. Manuf. Technol. 2023, 128, 5081–5099. [Google Scholar] [CrossRef]

- Gong, Z.; Li, B.; Zhang, H.; Ye, P. Tool orientation optimization method based on ruled surface using genetic algorithm. Int. J. Adv. Manuf. Technol. 2021, 118, 571–584. [Google Scholar] [CrossRef]

- Mi, Z.; Yuan, C.-M.; Ma, X.; Shen, L.-Y. Tool orientation optimization for 5-axis machining with C-space method. Int. J. Adv. Manuf. Technol. 2016, 88, 1243–1255. [Google Scholar] [CrossRef]

- Yuan, C.; Mi, Z.; Jia, X.; Lin, F.; Shen, L. Tool Orientation Optimization and Path Planning for 5-Axis Machining. J. Syst. Sci. Complex. 2020, 34, 83–106. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, Y.; Xu, K. Reinforcement learning–based tool orientation optimization for five-axis machining. Int. J. Adv. Manuf. Technol. 2022, 119, 7311–7326. [Google Scholar] [CrossRef]

- .Chu, M.; Bohez Erik, L.J.; Makhanov Stanlislav, S.; Munlin, M.; Phien, H.N.; Tabucanon, M.T. On 5-axis freeform surface machining optimization: Vector field clustering approach. Int. J. CAD/CAM 2005, 5, 1–10. [Google Scholar]

- Li, H.; Tutunea-Fatan, O.R.; Feng, H.-Y. An improved tool path discretization method for five-axis sculptured surface machining. Int. J. Adv. Manuf. Technol. 2006, 33, 994–1000. [Google Scholar] [CrossRef]

- Yao, Q. Five-Coordinate CNC Machining Space Cam CAD/CAM System. Master’s Thesis, Dalian University of Technology, Dalian, China, 2007. [Google Scholar] [CrossRef]

- Loney, G.C.; Ozsoy, T.M. NC machining of free form surfaces. Comput. Des. 1987, 19, 85–90. [Google Scholar] [CrossRef]

- Cho, J.H.; Kim, J.; Kim, K. CNC tool path planning for multi-patch sculptured surfaces. Int. J. Prod. Res. 2000, 38, 1677–1687. [Google Scholar] [CrossRef]

- He, W.; Lei, M.; Bin, H. Iso-parametric CNC tool path optimization based on adaptive grid generation. Int. J. Adv. Manuf. Technol. 2008, 41, 538–548. [Google Scholar] [CrossRef]

- Ding, S.; Mannan, M.; Poo, A.; Yang, D.; Han, Z. Adaptive iso-planar tool path generation for machining of free-form surfaces. Comput. Des. 2003, 35, 141–153. [Google Scholar] [CrossRef]

- Han, Z.; Yang, D.C.H.; Chuang, J.-J. Isophote-based ruled surface approximation of free-form surfaces and its application in NC machining. Int. J. Prod. Res. 2001, 39, 1911–1930. [Google Scholar] [CrossRef]

- Kim, B.; Choi, B. Guide surface based tool path generation in 3-axis milling: An extension of the guide plane method. Comput. Des. 2000, 32, 191–199. [Google Scholar] [CrossRef]

- Han, F.; Gu, Z.; Zhao, Y.; Zhang, C. Elliptic Cycloid Tool Path Optimization of Impeller Rough Machining Based on Parame-ter Maping. China Mech. Eng. 2024, 35, 438. [Google Scholar]

- Giri, V.; Bezbaruah, D.; Bubna, P.; Choudhury, A.R. Selection of master cutter paths in sculptured surface machining by employing curvature principle. Int. J. Mach. Tools Manuf. 2005, 45, 1202–1209. [Google Scholar] [CrossRef]

- Suresh, K.; Yang, D.C.H. Constant Scallop-height Machining of Free-form Surfaces. J. Eng. Ind. 1994, 116, 253–259. [Google Scholar] [CrossRef]

- Shi, B.G.; Lei, Y.; Yan, G.G. Surface mapping method for generating tool trajectories for equi-residual ring-cut machining. J. Eng. Graph. 2005, 3, 1217. [Google Scholar]

- Hauth, S.; Richterich, C.; Glasmacher, L.; Linsen, L. Constant cusp toolpath generation in configuration space based on offset curves. Int. J. Adv. Manuf. Technol. 2010, 53, 325–338. [Google Scholar] [CrossRef]

- Hao, S.Z.; Duroobi, A.A.; Chen, W.L.; He, L. Calculation of multi-axis machining stepover with equal residual heights for annular knives. J. Nanjing Univ. Aeronaut. Astronaut. 2012, 44, 538–542. [Google Scholar] [CrossRef]

- Zhao, S.T.; Zhao, D.B.; Fu, Y.Y.; Lu, Y.H.; Liu, K. Improved tool path generation algorithm for machining free-form surfaces with equal residual heights. J. Nanjing Univ. Aeronaut. Astronaut. 2012, 44, 240–245. [Google Scholar] [CrossRef]

- Ye, P.Q.; Chen, T.; Wang, J.S. Planning algorithms for tool trajectories in fivecoordinate CNC machining of complex surfaces. Mech. Sci. Technol. 2004, 8, 883–886. [Google Scholar]

- Feng, H.-Y.; Li, H. Constant scallop-height tool path generation for three-axis sculptured surface machining. Comput. Des. 2002, 34, 647–654. [Google Scholar] [CrossRef]

- Tournier, C.; Duc, E. Iso-scallop tool path generation in 5-axis milling. Int. J. Adv. Manuf. Technol. 2004, 25, 867–875. [Google Scholar] [CrossRef]

- Tournier, C.; Duc, E. A Surface Based Approach for Constant Scallop Height Tool-Path Generation. Int. J. Adv. Manuf. Technol. 2002, 19, 318–324. [Google Scholar] [CrossRef]

- Kim, T. Constant cusp height tool paths as geodesic parallels on an abstract Riemannian manifold. Comput. Des. 2007, 39, 477–489. [Google Scholar] [CrossRef]

- Wang, L.; Li, Y.; Yang, H.; Li, J. Surface-centric toolpath optimization via cutter location surface reconstruction for addressing neighboring inconsistency in CNC machining. J. Manuf. Process. 2025, 150, 933–948. [Google Scholar] [CrossRef]

- Raju, R.S.U.; Kumar, K.R.; Vargish, K.; Kumar, M.B. Machine learning based surface roughness assessment via CNC spindle bearing vibration. Int. J. Interact. Des. Manuf. (IJIDeM) 2024, 19, 477–494. [Google Scholar] [CrossRef]

- Chen, X.B.; Liao, W.H.; Wu, H.B.; Sun, Q.P.; Chen, Q.L. An algorithm for generating knife-rails with equal residual heights on triangular mesh surfaces. J. Comput. Aided Des. Graph. 2009, 21, 1800–1804. [Google Scholar]

- Jun, C.-S.; Cha, K.; Lee, Y.-S. Optimizing tool orientations for 5-axis machining by configuration-space search method. Comput. Des. 2003, 35, 549–566. [Google Scholar] [CrossRef]

- Lauwers, B.; Dejonghe, P.; Kruth, J.P. Optimal and collision free tool posture in five-axis machining through the tight integration of tool path generation and machine simulation. Comput. Aided Des. 2003, 35, 421–432. [Google Scholar] [CrossRef]

- Ho, M.-C.; Hwang, Y.-R.; Hu, C.-H. Five-axis tool orientation smoothing using quaternion interpolation algorithm. Int. J. Mach. Tools Manuf. 2003, 43, 1259–1267. [Google Scholar] [CrossRef]

- Wang, N.; Tang, K. Automatic generation of gouge-free and angular-velocity-compliant five-axis toolpath. Comput. Des. 2007, 39, 841–852. [Google Scholar] [CrossRef]

- Sun, Y.; Bao, Y.; Kang, K.; Guo, D. A cutter orientation modification method for five-axis ball-end machining with kinematic constraints. Int. J. Adv. Manuf. Technol. 2013, 67, 2863–2874. [Google Scholar] [CrossRef]

- Castagnetti, C.; Duc, E.; Ray, P. The Domain of Admissible Orientation concept: A new method for five-axis tool path optimisation. Comput. Des. 2008, 40, 938–950. [Google Scholar] [CrossRef]

- Jia, X.; Luo, J.; Li, K.; Wang, C.; Li, Z.; Wang, M.; Jiang, Z.; Veiko, V.P.; Duan, J. Ultrafast laser welding of transparent materials: From principles to applications. Int. J. Extrem. Manuf. 2025, 7, 032001. [Google Scholar] [CrossRef]

- Jia, X.; Lin, J.; Li, Z.; Wang, C.; Li, K.; Wang, C.; Duan, J. Continuous wave laser ablation of alumina ceramics under long focusing condition. J. Manuf. Process. 2025, 134, 530–546. [Google Scholar] [CrossRef]

- Li, Z.; Lin, J.; Jia, X.; Li, X.; Li, K.; Wang, C.; Sun, K.; Ma, Z.; Duan, J. High efficiency femtosecond laser ablation of alumina ceramics under the filament induced plasma shock wave. Ceram. Int. 2024, 50, 47472–47484. [Google Scholar] [CrossRef]

- Moodleah, S.; Bohez, E.; Makhanov, S. Five-axis machining of STL surfaces by adaptive curvilinear toolpaths. Int. J. Prod. Res. 2016, 54, 7296–7329. [Google Scholar] [CrossRef]

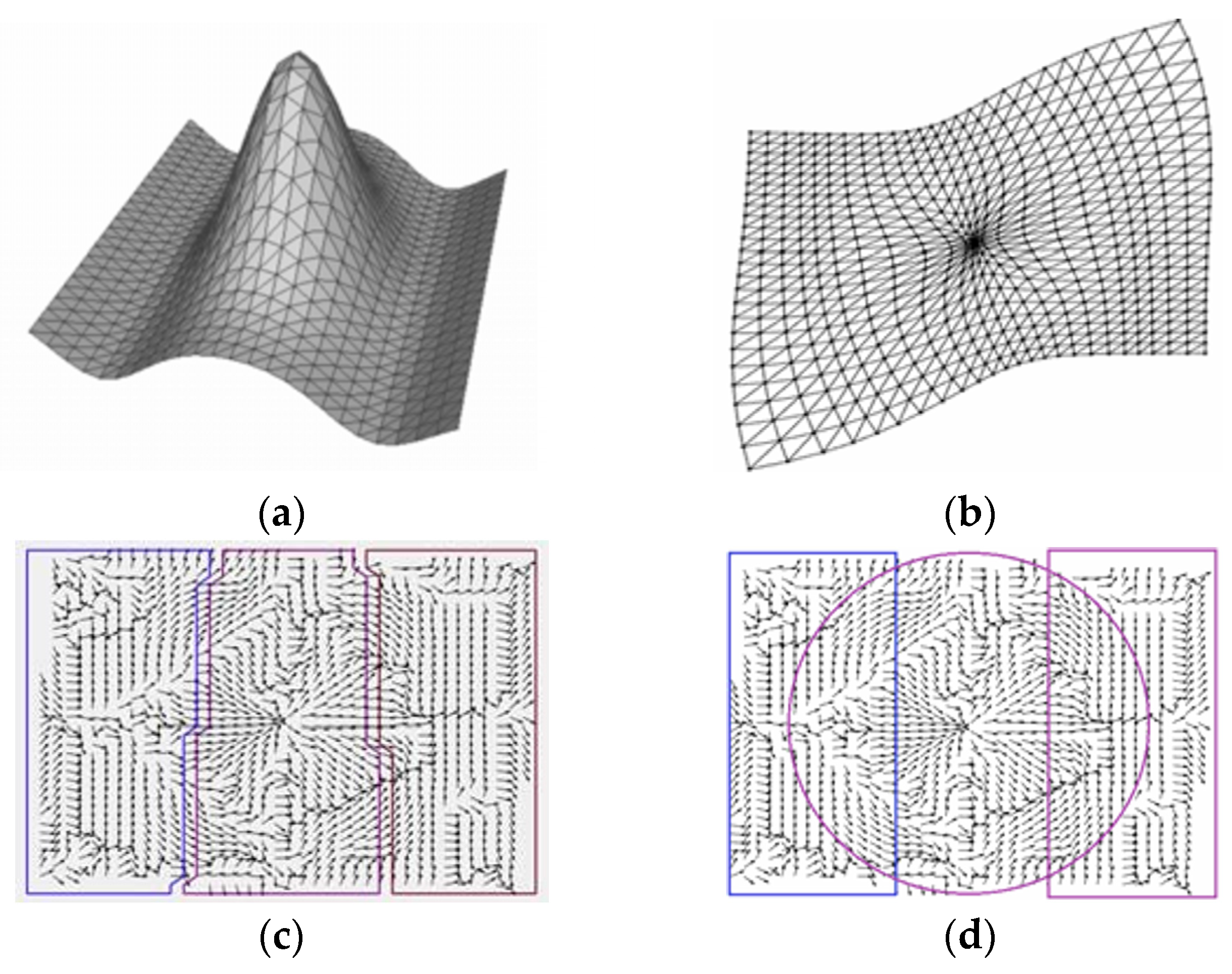

- Kumazawa, G.H.; Feng, H.Y.; Fard, M.J.B. Preferred feed direction field: A new tool path generation method for efficient sculptured surface machining. Comput. Aided Des. 2015, 67, 1–12. [Google Scholar] [CrossRef]

- Kim, T.; Sarma, S.E. Toolpath generation along directions of maximum kinematic performance; a first cut at machine-optimal paths. Comput. Des. 2002, 34, 453–468. [Google Scholar] [CrossRef]

- Xu, K.; Luo, M.; Tang, K. Machine based energy-saving tool path generation for five-axis end milling of freeform surfaces. J. Clean. Prod. 2016, 139, 1207–1223. [Google Scholar] [CrossRef]

- Ye, T.; Xiong, C.; Xiong, Y.; Zhao, C. Kinematics constrained five-axis tool path planning for high material removal rate. Sci. China Technol. Sci. 2011, 54, 3155–3165. [Google Scholar] [CrossRef]

- Huang, K.; Lee, C.-H.; Yan, C.; Gong, H. Study on a 2D field-based multi-objective tool-axis optimization algorithm based on covariant field theory for five-axis tool path generation. Int. J. Adv. Manuf. Technol. 2020, 108, 11–22. [Google Scholar] [CrossRef]

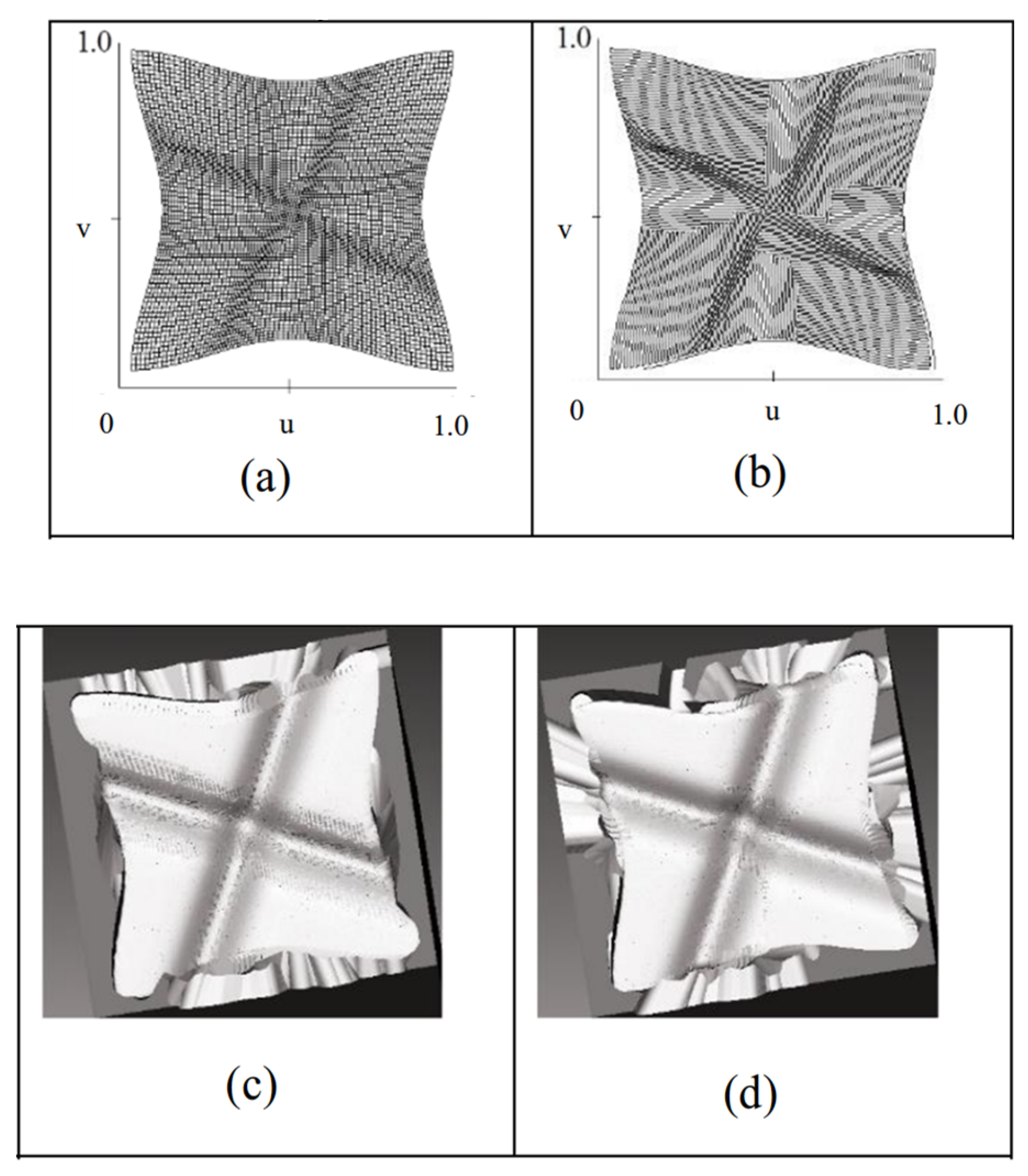

- He, S.P.; Xiao, Z.F.; Chen, J.J.; Xu, G.; Zheng, Y. Automatic Quad Mesh Generation of 2D Domain Based on Vector Field. J. Comput.-Aided Des. Comput. Graph. 2020, 32, 730–739. [Google Scholar]

- Zhang, K.; Tang, K. An efficient greedy strategy for five-axis tool path generation on dense triangular mesh. Int. J. Adv. Manuf. Technol. 2014, 74, 1539–1550. [Google Scholar] [CrossRef]

- Moodleah, S.; Makhanov, S.S. 5-axis machining using a curvilinear tool path aligned with the direction of the maximum removal rate. Int. J. Adv. Manuf. Technol. 2015, 80, 65–90. [Google Scholar] [CrossRef]

- Manav, C.; Bank, H.S.; Lazoglu, I. Intelligent toolpath selection via multi-criteria optimization in complex sculptured surface milling. J. Intell. Manuf. 2011, 24, 349–355. [Google Scholar] [CrossRef]

- Lamikiz, A.; López De Lacalle, L.N.; Sanchez, J.A.; Salgado, M.A. Cutting force integration at the CAM stage in the high-speed milling of complex surfaces. Int. J. Comput. Integr. Manuf. 2005, 18, 586–600. [Google Scholar] [CrossRef]

- Fard, M.J.B.; Feng, H.-Y. Effect of tool tilt angle on machining strip width in five-axis flat-end milling of free-form surfaces. Int. J. Adv. Manuf. Technol. 2008, 44, 211–222. [Google Scholar] [CrossRef]

- Fard, M.J.B.; Feng, H.-Y. Effective Determination of Feed Direction and Tool Orientation in Five-Axis Flat-End Milling. J. Manuf. Sci. Eng. 2010, 132, 061011. [Google Scholar] [CrossRef]

- Liu, X.; Li, Y.; Ma, S.; Lee, C.-H. A tool path generation method for freeform surface machining by introducing the tensor property of machining strip width. Comput. Des. 2015, 66, 1–13. [Google Scholar] [CrossRef]

- Wang, J.; Luo, M.; Zhang, D.H. A global space–based approach for wide strip flank milling of freeform surface with a barrel cutter. Int. J. Comput. Integr. Manuf. 2018, 32, 92–104. [Google Scholar] [CrossRef]

- Qian, L.; Zhang, L.; Gao, Q.; Yang, J. Optimization of tool axis vector for mirror milling of thin-walled parts based on kinematic constraints. Int. J. Adv. Manuf. Technol. 2022, 124, 847–861. [Google Scholar] [CrossRef]

- Dang, L.V.; Makhanov, S. Vector Field Analysis for optimization of the Tool Path of the Five-Axis Milling Machine. In Proceedings of the 2018 17th European Control Conference (ECC), Limassol, Cyprus, 12–15 June 2018; pp. 1–6. [Google Scholar]

- Shin, S.-J.; Woo, J.; Rachuri, S. Energy efficiency of milling machining: Component modeling and online optimization of cutting parameters. J. Clean. Prod. 2017, 161, 12–29. [Google Scholar] [CrossRef]

- Pavanaskar, S.; Pande, S.; Kwon, Y.; Hu, Z.; Sheffer, A.; McMains, S. Energy-efficient vector field based toolpaths for CNC pocketmachining. J. Manuf. Process. 2015, 20, 314–320. [Google Scholar] [CrossRef]

- Hu, P.; Tang, K. Five-axis tool path generation based on machine-dependent potential field. Int. J. Comput. Integr. Manuf. 2015, 29, 636–651. [Google Scholar] [CrossRef]

- Makhanov, S.S. Decomposition of the Vector Field of Preferred Directions for Optimization of Five-Axis Machining. In Proceedings of the 2020 4th International Conference on Materials Engineering and Nano Sciences (ICMENS), Pattaya, Thailand, 13–15 March 2020; Volume 840, p. 012005. [Google Scholar]

- Wang, Z.; Liu, S.; Liu, L.; Zou, Q.; Fu, X.-M. Computing smooth preferred feed direction fields with high material removal rates for efficient CNC tool paths. Comput. Des. 2023, 164, 103591. [Google Scholar] [CrossRef]

- Chiou, C.-J.; Lee, Y.-S. A machining potential field approach to tool path generation for multi-axis sculptured surface machining. Comput. Des. 2002, 34, 357–371. [Google Scholar] [CrossRef]

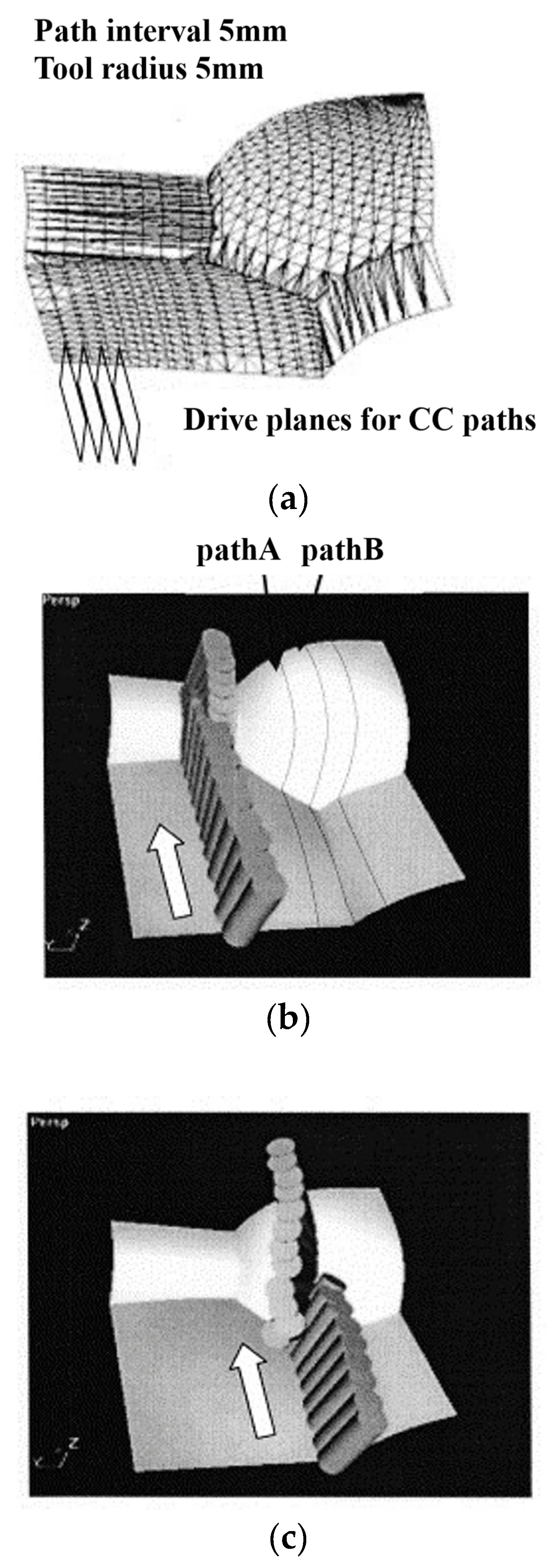

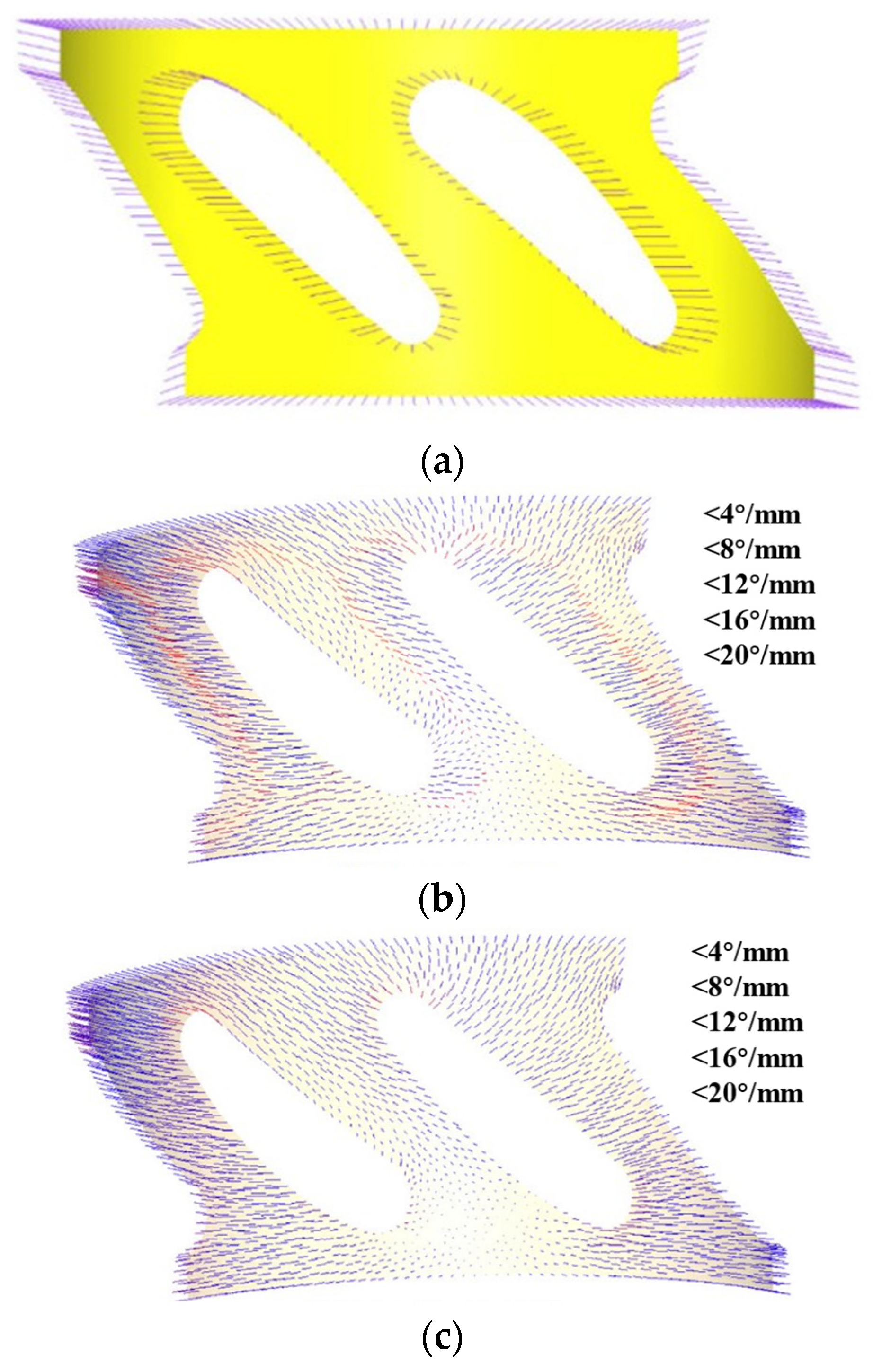

- Sun, S.; Sun, Y.; Xu, J.; Lee, Y.-S. Iso-Planar Feed Vector-Fields-Based Streamline Tool Path Generation for Five-Axis Compound Surface Machining With Torus-End Cutters. J. Manuf. Sci. Eng. 2018, 140, 071013. [Google Scholar] [CrossRef]

- Sun, Y.W.; Shu, C.L.; Liu, J. Research on CNC machining trajectory design method based on vector analysis. J. Mech. Eng. 2005, 41, 160–164, 170. [Google Scholar] [CrossRef]

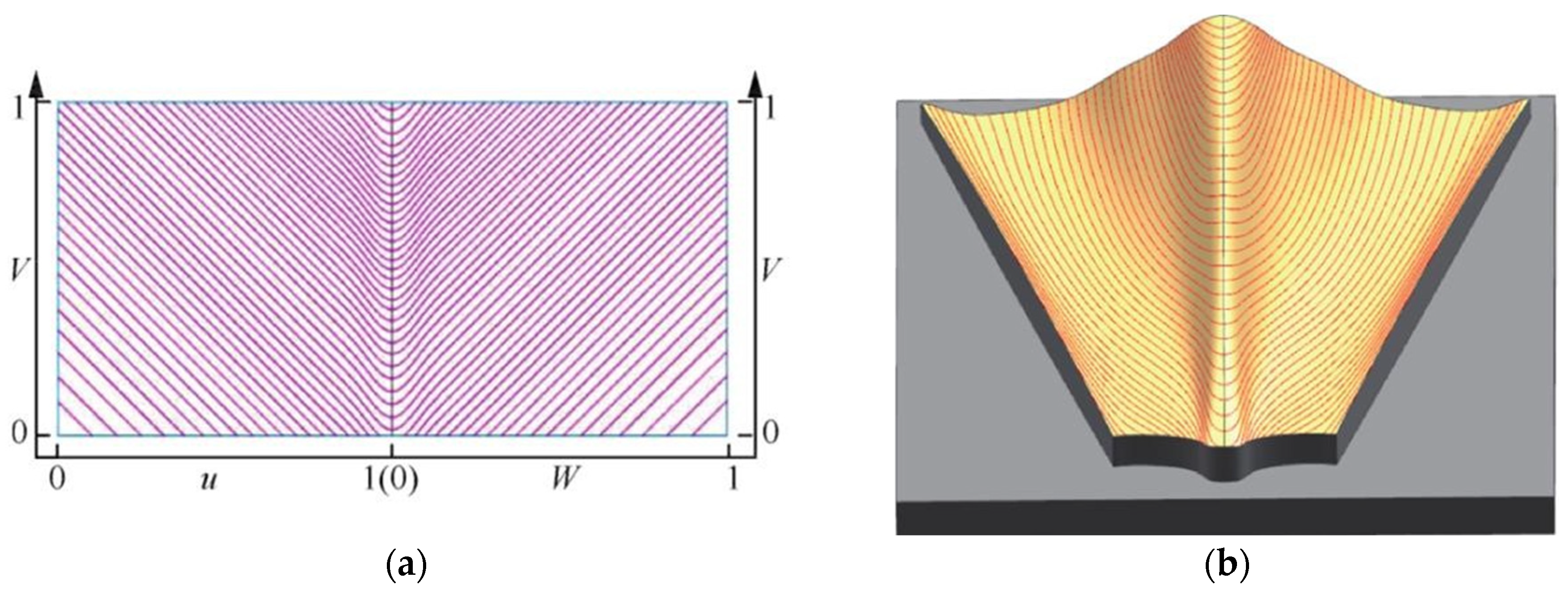

- Sun, Y.; Sun, S.; Xu, J.; Guo, D. A unified method of generating tool path based on multiple vector fields for CNC machining of compound NURBS surfaces. Comput. Des. 2017, 91, 14–26. [Google Scholar] [CrossRef]

- Shen, H.-Y.; Sun, Y.-F.; Zhang, L.-C.; Fu, J.-Z. A parameter zone subdivision method for rotary axes motion optimization in five-axis toolpath generation using inverse evaluation mechanism. Int. J. Adv. Manuf. Technol. 2018, 98, 3115–3131. [Google Scholar] [CrossRef]

- Li, Z.; Tang, K. Partition-based five-axis tool path generation for freeform surface machining using a non-spherical tool. J. Manuf. Syst. 2021, 58, 248–262. [Google Scholar] [CrossRef]

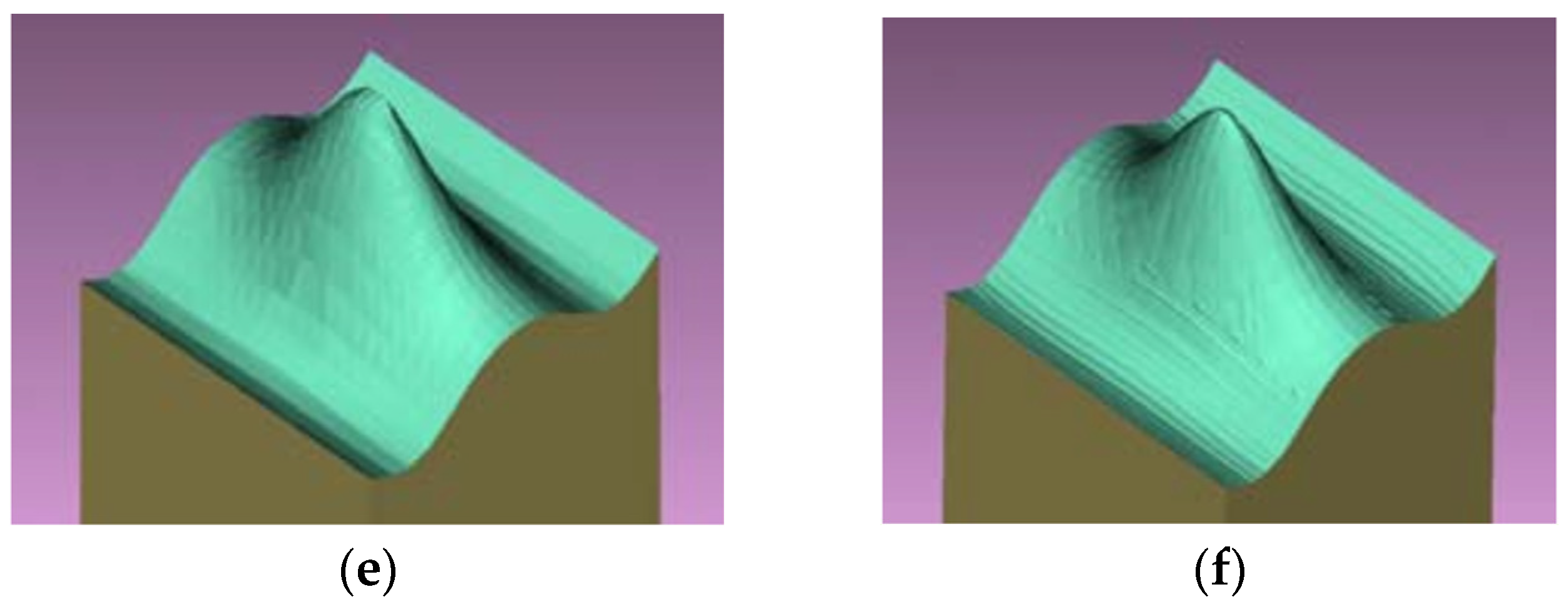

- Jia, Z.-Y.; Zhao, X.-X.; Ma, J.-W.; Chen, S.-Y.; Qin, F.-Z.; Liu, Z. Toolpath generation in sub-regional processing with constraint of constant scallop-height at boundary for complex curved surface. Precis. Eng. 2019, 55, 217–230. [Google Scholar] [CrossRef]

- Wang, Y.; Yan, C.; Yang, J.; Lee, C.-H. Tool path generation algorithm based on covariant field theory and cost functional optimization and its applications in blade machining. Int. J. Adv. Manuf. Technol. 2016, 90, 927–943. [Google Scholar] [CrossRef]

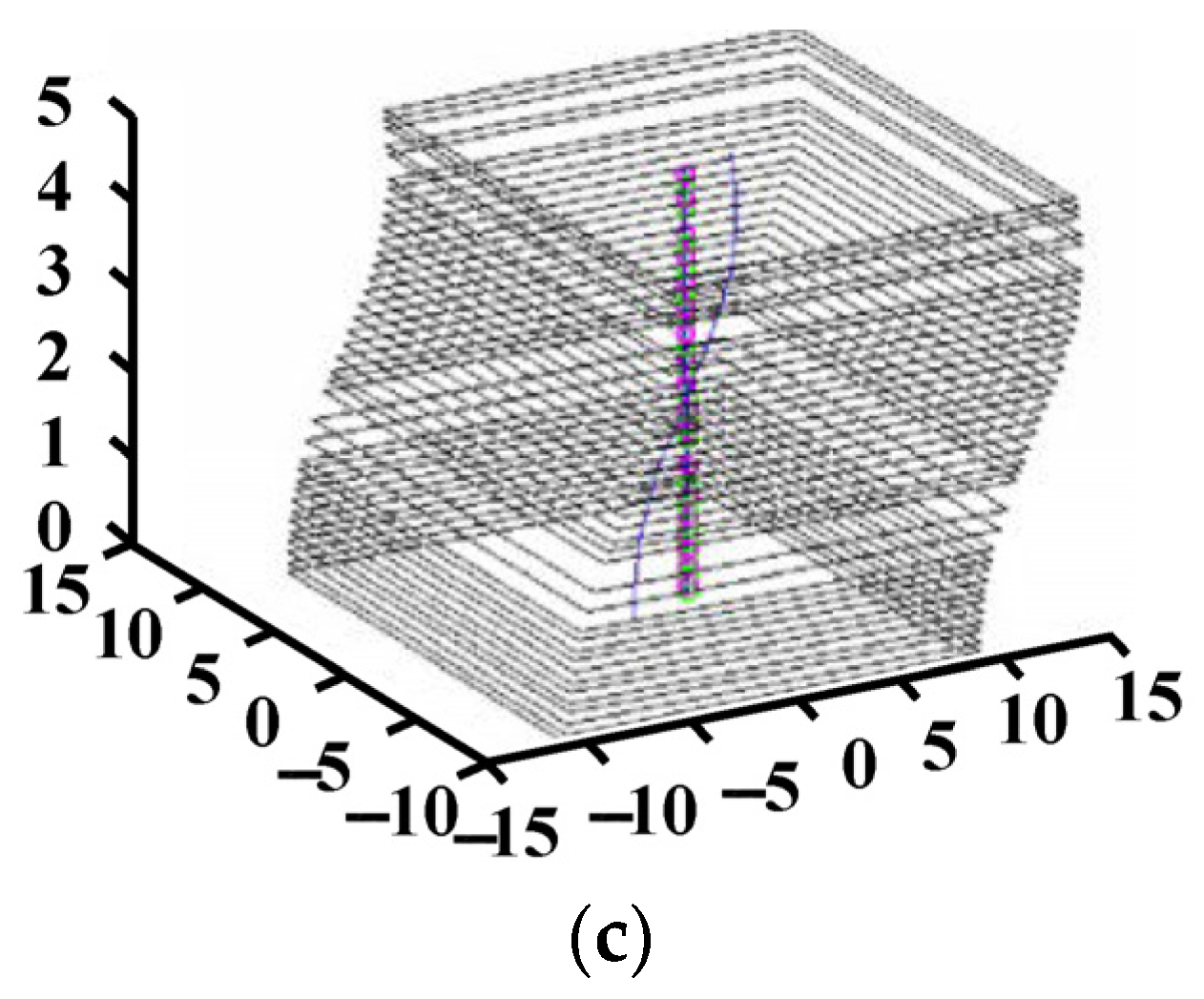

- Dutta, N.; Zhang, T.; Fang, G.; Yigit, I.E.; Wang, C.C.L. Vector Field-Based Volume Peeling for Multi-Axis Machining. J. Comput. Inf. Sci. Eng. 2023, 24, 051001. [Google Scholar] [CrossRef]

- Liu, X.; Li, Y.; Xu, X. A region-based tool path generation approach for machining freeform surfaces by applying machining strip width tensor. Int. J. Adv. Manuf. Technol. 2018, 98, 3191–3204. [Google Scholar] [CrossRef]

- Ma, J.-W.; Lu, X.; Li, G.-L.; Qu, Z.-W.; Qin, F.-Z. Toolpath topology design based on vector field of tool feeding direction in sub-regional processing for complex curved surface. J. Manuf. Process. 2020, 52, 44–57. [Google Scholar] [CrossRef]

- Pimenov, D.Y.; da Silva, L.R.R.; Ercetin, A.; Der, O.; Mikolajczyk, T.; Giasin, K. State-of-the-art review of applications of image processing techniques for tool condition monitoring on conventional machining processes. Int. J. Adv. Manuf. Technol. 2023, 130, 57–85. [Google Scholar] [CrossRef]

- Ercetin, A.; Der, O.; Akkoyun, F.; Chandrashekarappa, M.P.G.; Şener, R.; Çalışan, M.; Olgun, N.; Chate, G.; Bharath, K.N. Review of Image Processing Methods for Surface and Tool Condition Assessments in Machining. J. Manuf. Mater. Process. 2024, 8, 244. [Google Scholar] [CrossRef]

| Method Category | Specific Methods | Advantages | Disadvantages | Applicability |

|---|---|---|---|---|

| Conventional Tool Path Planning | Isoparametric Line Method | Simple and practical; widely used in multi-coordinate CNC machining. | Deviation between parameter space and Euclidean space; potential undercutting. | Parametric surfaces with relatively regular mesh structures. |

| Truncated Plane Method | Good applicability; suitable for sheared parametric surfaces. | Complex calculations (solving nonlinear equations); long tool path due to conservative line spacing. | General complex surfaces; widely used in CAD/CAM systems. | |

| Iso-Illumination Line Method | Accurate positioning; applicable to five-axis CNC machining. | Initially designed for surface continuity checking; limited in complex geometries. | Surfaces requiring high positioning accuracy. | |

| Mapping Method | Transforms 3D problems to 2D for easier calculation. | Mapping quality affects trajectory accuracy; challenging for highly complex surfaces. | Curved cavity-like structures and multi-feature combination surfaces. | |

| Equal Residual Height Method | Guarantees both machining efficiency and accuracy. | Large calculation volume; lower efficiency in the early stage (alleviated by modern computing). | Parametric surfaces and mesh surface models with high-precision requirements. | |

| Vector Field-Based Tool Path Planning | Tool Attitude Optimization | Improves machining smoothness and kinematic performance; reduces tool vibration. | Some methods ignore machine tool rotary axis performance; may cause servo tracking errors. | Scenarios requiring high smoothness, such as high-speed milling. |

| Tool Position Optimization (Maximum Bandwidth) | Enhances machining efficiency by maximizing cutting width. | High computational complexity; dependent on machining experience and equipment. | Large or structurally complex parts. | |

| Tool Position Optimization (Kinematic Performance) | Ensures speed smoothness, stability, and load balancing. | Requires comprehensive consideration of multi-axis constraints; complex parameter tuning. | High-speed and high-precision machining processes. | |

| Tool Position Optimization (Minimum Energy Consumption) | Reduces production cost by minimizing energy usage. | Limited by machining task requirements; needs balance with accuracy. | Energy-sensitive manufacturing environments. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, S.; Liu, Z. A Review of Vector Field-Based Tool Path Planning for CNC Machining of Complex Surfaces. Symmetry 2025, 17, 1300. https://doi.org/10.3390/sym17081300

Xie S, Liu Z. A Review of Vector Field-Based Tool Path Planning for CNC Machining of Complex Surfaces. Symmetry. 2025; 17(8):1300. https://doi.org/10.3390/sym17081300

Chicago/Turabian StyleXie, Shengchang, and Zhiping Liu. 2025. "A Review of Vector Field-Based Tool Path Planning for CNC Machining of Complex Surfaces" Symmetry 17, no. 8: 1300. https://doi.org/10.3390/sym17081300

APA StyleXie, S., & Liu, Z. (2025). A Review of Vector Field-Based Tool Path Planning for CNC Machining of Complex Surfaces. Symmetry, 17(8), 1300. https://doi.org/10.3390/sym17081300