Abstract

The rational design of high-performance microwave absorbers with broadband coverage, superior attenuation, and environmental durability is critical for addressing challenges in both defense and civilian technologies. High-entropy alloys (HEAs) exhibit atomic-scale asymmetric arrangements, demonstrating exceptional potential for microwave absorption through their unique lattice distortion, high entropy, sluggish diffusion, and “cocktail effect”. This critical review article provides an overview of the progress made in the development and understanding of HEA-based microwave absorbing materials. Initially, the microwave dissipation mechanisms for HEAs were analyzed, where atomic-scale distortions enhance polarization loss and broaden resonance bandwidth. Subsequently, key synthesis techniques like mechanical alloying and carbothermal shock are discussed, highlighting non-equilibrium processing for phase engineering. Building on these foundations, the discussion then progresses to evaluate four principal material design approaches: (1) compositionally-tuned powders, (2) multifunctional core–shell structures, (3) phase-controlled architectures, and (4) two-dimensional/porous configurations, each demonstrating distinct performance advantages. Finally, the discussion concludes by addressing current challenges in quantitative property modeling and industrial scalability while outlining future directions, including machine learning-assisted design and flexible integration, providing comprehensive guidance for developing next-generation high-performance microwave absorbing materials.

1. Introduction

The exponential growth of fifth-generation/sixth-generation (5G/6G) communication networks, internet of things devices, and artificial intelligence (AI) technologies has significantly intensified microwave pollution, which manifests through three interconnected challenges requiring urgent resolution [1,2]. As evidenced by World Health Organization studies, chronic radiofrequency/microwave exposure induces serious health consequences, including bioelectrical disruption, immune system impairment, and potential genetic damage, while microwave interference jeopardizes critical life-support medical devices and aviation systems with potentially disastrous outcomes [3,4,5]. Concurrently, modern defense systems demand sophisticated stealth technologies with precise microwave signature modulation capabilities [6]. To overcome these challenges, researchers should develop advanced microwave absorbing materials that combine high attenuation exceeding 90% with lightweight properties and environmental stability, as these characteristics are essential for protecting public health and enabling military operations in demanding electromagnetic environments.

Over decades of research, microwave absorbing materials have achieved substantial progress in theoretical models (e.g., transmission line theory [7,8], impedance matching models [9,10], and electromagnetic wave propagation simulations [11,12]) and engineering applications (including radar-absorbing structures [13,14], stealth coating technologies [15,16], and electromagnetic interference shielding for electronic devices [17,18]). Over the past decade, microwave absorbing materials have attracted significant research attention, with approximately 22,786 academic publications indexed in this field. Based on their distinct electromagnetic energy dissipation mechanisms, these materials are systematically classified into two primary categories. Specifically, magnetic loss materials (e.g., ferrites, Co/Ni-based magnetic metals) [19,20,21] primarily dissipate electromagnetic energy through hysteresis loss, natural resonance, and eddy current mechanisms. Among these, ferrites have been widely employed due to their cost-effectiveness and excellent stability [22]. However, their implementation in weight-sensitive systems remains fundamentally limited by two intrinsic material characteristics: excessive mass density and insufficient loss performance at elevated frequencies. In contrast, the dielectric loss materials, including carbon fibers and conductive polymers, operate primarily through polarization relaxation and conduction loss mechanisms [14,23,24,25]. Notably, carbon nanotube-based materials exhibit exceptional performance characteristics, including an extensive specific surface area and superior charge carrier mobility. However, their practical implementation faces significant challenges due to inherent impedance mismatch phenomena, necessitating strategic integration with magnetic components to achieve optimal impedance matching and enhanced microwave absorption performance. More recently, the emergence of 2D materials like graphene [26,27], MXenes [28,29,30], and hexagonal boron nitride (h-BN) [31,32,33,34] has expanded design possibilities, as graphene’s π-π conjugation enables strong interfacial polarization, while MXenes offer exceptional conductivity for conduction loss, and h-BN’s weak interlayer forces facilitate flexible heterostructure engineering. However, since single-component systems rarely satisfy all requirements for strong absorption, broadband response, and lightweight properties simultaneously, current research consequently focuses on multiscale designs including core–shell structures, hierarchical morphologies, and magnetic–dielectric hybrids to achieve optimal performance through synergistic loss mechanisms.

High-entropy alloys (HEAs) have emerged as a new class of microwave absorbing materials owing to their unique multi-principal-element compositions [35,36]. These alloys form single-phase solid solutions that generate four fundamental effects, including lattice distortion, high configurational entropy, sluggish diffusion, and the synergistic “cocktail” effect. Compared to traditional ferrites and carbon-based absorbers, these structural features offer three key advantages for microwave absorption. The atomic-scale lattice defects and strain fields in HEAs enhance microwave scattering, leading to substantially improved absorption efficiency. Moreover, the incorporation of ferromagnetic elements such as Fe, Co, and Ni contributes to superior soft magnetic properties, exhibiting high saturation magnetization along with low coercivity and excellent thermal stability [37,38]. The inherent lattice distortions in high-entropy materials-resulting from non-uniform elemental distribution, electronegativity variations, and atomic radius disparities-directly influence their dielectric and conductive loss properties by exacerbating electron scattering, altering electronic energy levels (e.g., via level splitting or band bending), and promoting localized/impurity energy levels between the conduction and valence bands [39,40,41]. These modifications enhance electron localization, impart semiconductor-like behavior, and critically modulate dielectric properties to optimize conductive loss for microwave absorption. Additionally, HEAs demonstrate remarkable mechanical durability, showing much higher fracture toughness and lower wear rates compared to conventional alloys while maintaining outstanding corrosion and oxidation resistance [42,43]. The ability to precisely tune these properties through compositional design and morphological control makes HEAs particularly valuable for extreme-environment applications, especially in aerospace and military systems requiring simultaneous microwave absorption and structural support. While current research focuses on microstructural optimization (including grain boundary engineering [44,45], defect control [46], and phase distribution tailoring [47] to enhance electromagnetic wave dissipation), future studies of composition–property relationships are expected to establish HEAs as next-generation broadband absorbers, offering innovative solutions for advanced stealth technologies and high-temperature electromagnetic shielding applications.

HEA-based microwave absorbers remain an emerging area, with only 115 publications to date in the last ten years. Notably, the number of HEA-related studies has shown a steady increase in recent years, reflecting growing recognition of their unique advantages in broadband absorption, environmental stability, and composition-dependent tunability. Despite significant progress in HEAs-based microwave absorbing materials, the scientific community still lacks a thorough understanding of the fundamental correlations between atomic configurations, phase engineering, nanoscale architectures, and their collective influence on electromagnetic wave dissipation. This knowledge gap underscores the critical need for a systematic and comprehensive review that addresses these interconnected aspects. In this review, we will provide a critical analysis of State-of-the-Art synthesis techniques and recent breakthroughs in material design. The review will conclude with a forward-looking perspective on emerging applications and key research directions that will shape the future development of this promising material system.

2. Microwave Absorption Mechanisms of HEAs

2.1. Interaction Between Microwave and Absorbing Materials

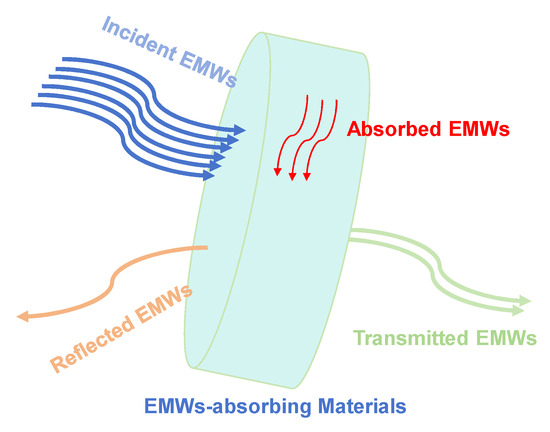

When microwaves interact with an absorbing material, their energy undergoes three fundamental transformation processes: reflection at the interface, absorption within the material bulk, and transmission through the medium (Figure 1), as described by classical electromagnetic wave theory [43]. The reflection behavior is primarily determined by the impedance mismatch between the material (Zin) and free space (Z0 ≈ 377 Ω), where the reflection coefficient scales inversely with the impedance matching degree. Optimal energy penetration occurs when the normalized material impedance (Zn = Zin/Z0) approaches unity, minimizing interfacial reflection and maximizing microwave absorption through bulk attenuation mechanisms [48,49]. The incident microwaves are subsequently attenuated through multiple microscopic energy conversion mechanisms (primarily to thermal energy), which constitute the fundamental working principle of microwave absorbing materials. The unabsorbed portion propagates as transmitted waves through the material thickness. For effective electromagnetic pollution control, the optimal microwave absorbing materials require simultaneous minimization of both reflection and transmission coefficients, achievable only through careful balancing of two critical material properties: (1) near-unity impedance matching (Zn ≈ 1) to maximize wave penetration, and (2) strong intrinsic dissipation capacity to ensure efficient energy conversion [50,51]. Typically, microwave absorption mechanisms are generally categorized into two fundamental types: magnetic loss and dielectric loss, which will be systematically discussed in subsequent sections [52].

Figure 1.

Schematic diagram of the principle in microwave absorbing materials.

2.2. Dielectric Loss Mechanisms in Microwave Absorption

Dielectric loss mechanisms fundamentally stem from a material’s dynamic interaction with alternating electric fields, governed primarily by polarization relaxation and conduction loss processes [53]. Within the polarization spectrum, electronic polarization dominates at optical frequencies while contributing minimally to microwave absorption, whereas ionic polarization becomes significant in the terahertz regime. For practical microwave applications, dipole orientation and interfacial polarization emerge as the dominant mechanisms. Ferroelectric materials like BaTiO3 exhibit particularly strong dipole polarization effects due to their characteristic relaxation times that naturally align with microwave frequencies [54]. Meanwhile, in multiphase composite systems, interfacial polarization prevails as space charge accumulation at material boundaries generates substantial additional polarization fields. These relaxation dynamics can be quantitatively characterized through Cole–Cole analysis, where ideal Debye-type behavior produces characteristic semicircular arcs in the complex permittivity plane (ε″ versus ε′), serving as a powerful diagnostic tool for understanding the underlying polarization processes [55].

Conduction loss dominates in highly conductive materials (σ = 102–105 S/m), including carbon-based systems like graphene and carbon nanotubes, where alternating electric fields induce resistive Joule heating through restricted charge carrier motion [31,56]. Although higher electrical conductivity generally enhances loss magnitude, excessive conductivity (>104 S/m) leads to detrimental impedance mismatch with free space, consequently reducing microwave absorption efficiency. Therefore, achieving optimal performance requires precise control of electrical conductivity through tailored doping or surface modification, establishing an optimal balance between electromagnetic loss capability and impedance matching efficiency.

2.3. Magnetic Loss Mechanisms in Microwave Absorption

Magnetic loss in microwave absorbing materials results from dynamic interactions with alternating magnetic fields through several principal mechanisms: hysteresis loss, eddy current loss, ferromagnetic resonance, natural resonance, and domain wall resonance [57]. Among these, natural resonance is considered to be a special form of ferromagnetic resonance. In addition, hysteresis loss becomes negligible due to the relatively weak magnetic field intensity, and domain wall resonance usually occurs in low-frequency ranges (f < 1 GHz). Thus, in the absence of an external magnetic field, eddy current loss and natural resonance emerge as the dominant contributors to electromagnetic wave absorbing materials (EWAMs) in the 1–18 GHz frequency band [58].

The eddy current contribution to reflection loss is governed by two key material parameters: electrical conductivity (σ) and sample thickness (d) [59]. This relationship is quantitatively described by the dimensionless coefficient C0, defined as follows [60]:

where μ′ and μ″ represent the real and imaginary components of complex permeability, f denotes frequency, μ0 stands for vacuum permeability, d corresponds to absorber thickness, and σ is the electric conductivity. A frequency-independent C0 value confirms eddy current loss as the dominant magnetic loss mechanism. Conversely, frequency-dependent C0 variations indicate the presence of additional loss mechanisms such as natural resonance or hysteresis. Effective suppression of eddy current effects requires strategic material design approaches, particularly through resistivity enhancement and thickness optimization below the skin depth limit.

C0 = μ″(μ′)−2f−1 = 2πμ0μ′2d2σf/3

Natural resonance emerges when an external field’s frequency synchronizes with a material’s intrinsic magnetic spin precession frequency, leading to significantly enhanced energy absorption—a phenomenon that critically governs the high-frequency electromagnetic response of materials [61,62,63]. The resonance behavior is determined by an intricate interplay of three parameter categories: (1) fundamental material properties (magnetization strength, magnetic anisotropy), (2) microstructural characteristics (domain size, crystalline arrangement), and (3) collective spin dynamics (spin–spin interactions, damping effects). This multidimensional parameter coupling creates substantial challenges in precisely engineering resonance intensity and frequency response ranges, particularly for developing optimized microwave-absorbing materials where tailored electromagnetic performance is required.

2.4. Microwave Absorption Advantages of HEAs

HEAs have emerged as a distinctive category of microwave absorbing materials, whose multi-principal-element composition (typically ≥ 5 equiatomic elements) confers exceptional functional properties [42,64]. The dielectric properties of HEAs are profoundly influenced by atomic-scale lattice distortion resulting from significant size mismatch among constituent elements [65]. X-ray diffraction analyses demonstrate this distortion through peak broadening compared to conventional alloys. These structural features produce two synergistic effects: (1) enhanced microwave scattering through lattice strain fields, and (2) formation of localized electronic states near the Fermi level, collectively contributing to superior dielectric loss performance.

For magnetic properties, the complex exchange interactions between ferromagnetic elements (Fe/Co/Ni) create unique magnetic configurations [66,67]. Mössbauer spectroscopy reveals substantially broader hyperfine field distributions in FeCoNiCrMn systems compared to conventional alloys, reflecting their more complex magnetic microstructures [68]. These unique configurations yield an unprecedentedly wide natural resonance frequency range (2–18 GHz), significantly exceeding the performance of traditional magnetic microwave absorbing materials. The inherent high configurational entropy (ΔS > 1.5 R) in HEAs provides exceptional thermal stability, as evidenced by FeCoNiAlTi exhibiting minimal variation in electromagnetic parameters after 500 °C thermal aging. This performance advantage becomes particularly apparent when compared to conventional materials, which typically suffer over 10% degradation under the same conditions [69].

The distinctive “cocktail effect” in HEAs enables simultaneous enhancement in mechanical and electromagnetic microwave absorbing properties. As a representative example, the CoCrFeCrCu system achieves fracture toughness values 200–300% greater than traditional microwave absorbers [70]. This remarkable mechanical performance, combined with tailored electromagnetic properties, makes these materials particularly suitable for demanding aerospace applications requiring multifunctional capability [71]. Through strategic compositional modifications and controlled microstructure design, HEAs offer unprecedented opportunities for developing next-generation broadband absorbers with superior stability in extreme operational environments.

3. Synthesis Methods for HEAs-Based Microwave Absorbing Materials

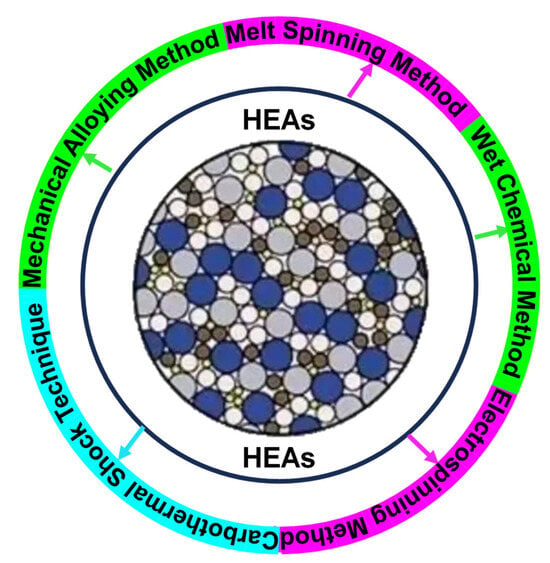

The fabrication of HEAs currently relies on several established synthesis routes, including mechanical alloying, melt spinning, wet chemical processing, electrospinning, and the emerging carbothermal shock technique (Figure 2). Each method will be analyzed systematically in subsequent sections.

Figure 2.

Synthesis methods for HEAs. Note: distinct colors and circle sizes correspond to different metal elements.

3.1. Mechanical Alloying Method

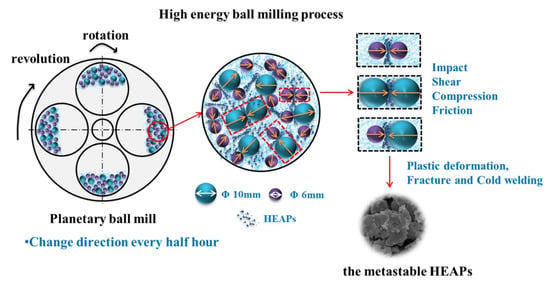

Mechanical alloying represents a well-established solid-state synthesis technique that achieves atomic-scale alloying through intense mechanical collisions and friction between grinding media and powder during high-energy ball milling [48,72,73,74]. Taking FeCoNiAlCrx high-entropy alloy powder synthesis as a representative example, this process demands precise optimization of several critical parameters (Figure 3) [51]. Specifically, employing a bimodal distribution of grinding balls (6 mm and 10 mm diameter) effectively balances impact energy with collision frequency, whereas maintaining a ball-to-powder ratio of 1:20 ensures sufficient energy input for homogeneous mixing. The judicious selection of process control agents, particularly anhydrous ethanol, plays a dual role by not only preventing excessive cold welding and particle agglomeration but also generating reactive species that fracture surface oxide layers. When subjected to prolonged cyclic milling, the powder undergoes successive deformation–fracture–rewelding cycles that ultimately produce flaky particles. These distinctive morphologies result from dynamic recrystallization processes wherein grain refinement reaches nanoscale dimensions and dislocation saturation promotes preferential cleavage along specific crystallographic orientations. Notably, this extended milling process simultaneously facilitates the formation of stable solid solution phases [75,76], which significantly enhance the phase stability and electromagnetic properties of medium/high entropy alloys. These high-aspect-ratio architectures markedly improve microwave absorption performance via dual synergistic effects: (1) the flake morphology substantially increases microwave scattering cross-sections, while (2) the solid solution phases optimize defect engineering and electronic structure tailoring, collectively achieving superior broadband absorption characteristics. Simultaneously, geometric anisotropy modifies magnetocrystalline anisotropy fields. Together, these mechanisms facilitate broadband absorption by systematically controlling resonance frequency shifts.

Figure 3.

Schematic diagram of the synthetic mechanism of the planetary ball mill to form HEA powders. Reproduced with permission from [51], Copyright 2019, Elsevier B.V.

3.2. Melt Spinning Method

The synthesis principle of melt spinning technology is based on achieving metallic glass or nanocrystalline structures via ultra-rapid solidification processes [77,78,79]. In a high-purity argon atmosphere, the metal or alloy is melted at high temperatures to form a uniform liquid metal, which is then rapidly thrown out through a nozzle and solidified on a cooling roller (usually a copper roller). The cooling rate of this process is extremely high, reaching up to 105–106 K/s, which facilitates the formation of microwave absorbing materials with amorphous or nanocrystalline structures. For example, a transmission electron microscopy analysis of FeCoNi(Si0.6Al0.2B0.2) HEAs ribbons reveals BCC-structured nanocrystals uniformly embedded in an amorphous matrix [80]. This unique microstructure generates significant interface polarization effects. During subsequent ball milling, the brittle fracture characteristics of amorphous ribbons facilitate the formation of flaky particles with sharp edges. This dual-phase structure with thicknesses of 1.2–2.0 mm possesses minimum reflection losses of −38.1 to −44.1 dB with effective absorption bandwidths (RL < 10 dB) of 2.5–3.8 GHz.

3.3. Wet Chemical Method

The core of wet chemical synthesis of HEAs lies in the kinetic control of co-reduction of metal ions in a liquid-phase environment [81,82,83,84]. Taking the FeCoNiCu quaternary system as an example [81], hydrazine hydrate acts as a strong reducing agent, with its reduction potential significantly differing from the standard electrode potentials of the metal ions (Fe2+: −0.44 V, Co2+: −0.28 V, Ni2+: −0.25 V, Cu2+: +0.34 V). To achieve uniform co-reduction, reaction kinetics must be precisely regulated: first, the pH value is stabilized within 10–11 to slow the reduction rate via OH− complexation with metal ions; second, a gradient heating strategy (50 °C → 70 °C → 90 °C) is adopted, allowing Cu2+ (with a more positive reduction potential) to nucleate preferentially as seeds, followed by epitaxial growth of Fe/Co/Ni ions on their surfaces. In situ X-ray diffraction studies indicate that this process follows a transformation path of amorphous precursor → metal hydroxide intermediate → alloy phase. The resulting powder exhibits a narrow particle size distribution and near-spherical morphology due to the isotropic nature of liquid-phase reactions. To achieve flaky morphology, subsequent surfactant-assisted mechanical flattening is required, increasing the particle aspect ratio to five–eight times and enhancing magnetocrystalline anisotropy.

3.4. Electrospinning Method

The electrospinning coupled with Joule heating technology represents a significant methodological advancement by integrating polymer templating with ultrafast thermal processing [85,86]. In fabricating HCNF/FeCoNiCuMn HEA composites, polyvinyl alcohol (PVA) performs dual functions: acting as both an electrospinning matrix and a carbon network precursor upon pyrolysis, thereby effectively preventing metal nanoparticle agglomeration [87]. This approach achieves three critical technological advances through precisely controlled processing parameters. First, multi-needle array electrospinning under optimized conditions produces fibers with highly uniform diameters. Second, a carefully programmed pre-oxidation stage induces PVA molecular chain cyclization, forming thermally stable ladder structures that prevent fiber coalescence during subsequent carbonization. Third, the implementation of ultra-rapid Joule heating simultaneously accomplishes two transformations: in situ reduction of metal salts into HEAs and graphitization of carbon fibers with controlled defect density. The resulting hierarchical architecture, featuring nanoalloy-embedded porous carbon fibers, exhibits synergistic electromagnetic wave dissipation through three complementary mechanisms: intrinsic dielectric loss from the carbon matrix, magnetic loss from HEAs nanoparticles, and interfacial polarization at their boundaries. This multifunctional design enables exceptional broadband absorption performance, achieving a minimum reflection loss of −65.8 dB and boasting a maximum absorption bandwidth of up to 7.68 GHz.

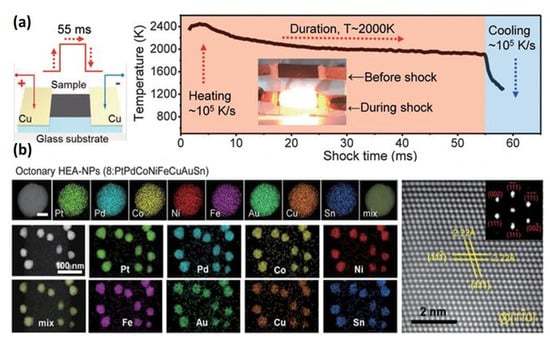

3.5. Carbothermal Shock Technology

Carbothermal shock technology (CST) represents a groundbreaking approach for synthesizing high-entropy materials by overcoming conventional alloy thermodynamic constraints through extreme non-equilibrium processing [88,89,90,91,92]. This technique initiates with the uniform deposition of metal precursors onto carbon-based carriers, where careful engineering of defects in the carbon matrix plays a pivotal role. Specifically, plasma treatment or chemical oxidation of carbon substrates such as graphene or carbon nanotubes generates oxygen vacancies or sp3 hybrid defects, which serve dual functions. These engineered defects not only strengthen the adsorption of metal precursors but also act as effective nucleation sites during subsequent thermal processing, thereby promoting homogeneous nanoparticle distribution. The thermal shock process, typically conducted at 2000–2500 K, progresses through three distinct stages that collectively enable unique material formation. In the initial millisecond-scale heating phase, metal salt precursors undergo rapid decomposition into their atomic constituents. As the system reaches peak temperatures, these atomic species achieve complete mixing in the liquid state, during which the high-entropy effect becomes thermodynamically dominant. Following Boltzmann’s entropy principle, this results in a configurational entropy of 1.61 R (where R represents the gas constant) for octonary alloy systems, which substantially lowers the Gibbs free energy and effectively suppresses phase segregation. The final quenching stage, characterized by cooling rates exceeding 104 K/s, preserves this high-entropy configuration as a metastable solid solution. Supporting this mechanism, in situ X-ray diffraction studies by Yao et al. demonstrated that the phase formation kinetics for a PtPdCoNiFeCuAuSn octonary alloy requires merely 50 milliseconds, representing a dramatic reduction compared to conventional furnace cooling processes that typically demand several hours (Figure 4) [92].

Figure 4.

(a) Sample preparation and the temporal evolution of temperature during the 55-ms thermal shock. (b) Individual and low-magnification elemental maps (left) and a high-resolution HAADF-STEM image with fast Fourier transform analysis (right) of octonary (PtPdCoNiFeCuAuSn) HEA-NPs, showing solid solutions with an fcc structure. The low-magnification elemental maps verify the structural and compositional uniformity of the HEA-NPs. Scale bar, 10 nm. Reproduced with permission from [92], Copyright 2018, The American Association for the Advancement of Science.

This ultrafast synthesis method creates materials with unique structural features. First, atomic-scale mixing produces single-phase solid solutions. HAADF-STEM analysis shows elemental distribution remains highly uniform, with deviations below 3%. Second, nanoparticles confined to carbon defects show controlled sizes of 2–10 nm. These structures achieve remarkably high surface areas exceeding 150 m2/g, creating abundant interfaces for electromagnetic scattering. More importantly, multicomponent electron clouds rearrange to form special band structures. Building upon these fundamental advances, the application scope of CST has progressively expanded beyond metallic alloys to encompass various compound systems through the strategic incorporation of different reactive precursors during synthesis, including sulfur sources such as thiourea for high-entropy sulfides, nitrogen donors like urea for nitrides, and phosphorus-containing compounds, including triphenylphosphine for phosphides. A representative example includes (CrMnFeCoNi)Sx systems that display remarkable dielectric loss performance, an effect primarily attributed to the polarization enhancement resulting from strategically engineered sulfur vacancies within the material structure [93].

3.6. Artificial Intelligence (AI)-Assisted Design of HEAs

The synergistic integration of machine learning with materials science has given rise to a vibrant and rapidly evolving interdisciplinary field, with HEAs emerging as particularly compelling model systems that effectively demonstrate machine learning’s transformative potential due to their exceptional mechanical properties, vast compositional space, and complex chemical interactions [94,95,96]. Current research encompasses diverse methodological approaches: data-driven optimizations of computational algorithms to enhance model performance coexist with materials-specific investigations that develop novel representations of short-range and long-range order to better capture the fundamental physics of HEAs, with these complementary efforts collectively advancing the practical application of machine learning in HEAs research while simultaneously leveraging machine learning’s inherent large-scale screening capabilities to provide new momentum for HEAs development through systematic exploration of their expansive composition–property landscape.

The existing synthesis methods collectively establish a comprehensive technical framework for preparing HEAs-based microwave absorbing materials, each exhibiting unique advantages and limitations. Mechanical alloying facilitates atomic-scale mixing through solid-state reactions, offering process simplicity and cost efficiency, though compromised by oxidation risks (leading to inhomogeneous phase distribution, controlled through argon/vacuum processing) and high energy demands (causing particle agglomeration, mitigated by optimized milling parameters). Melt spinning produces amorphous/nanocrystalline ribbons through ultra-rapid cooling (with potential surface defects addressed by laser-calibrated wheels), albeit requiring specialized equipment. Wet chemical approaches achieve molecular-level composition control but face challenges in process complexity (simplified via microfluidics) and production scale (improved by continuous-flow systems). The electrospinning-Joule heating technique integrates template synthesis with thermal processing (despite fiber consistency challenges controlled through voltage optimization), proving effective for hierarchical absorbers. AI’s capacity for large-scale screening has introduced fresh momentum to HEAs’ development, with oxidation propensity now predictable via ML-based thermodynamic calculators. Concurrently, interpretable machine learning models have emerged as a valuable innovation, offering new research directions. Generative models demonstrate particular promise by proposing potential elemental compositions and structures, effectively mitigating the challenges of predictive model exploration in high-dimensional spaces. CST overcomes thermodynamic limitations through millisecond heating-quenching (with inherent oxidation suppression), enabling novel multicomponent systems. These complementary techniques collectively address material requirements, including morphological control and compositional design, permitting tailored selection based on operational parameters, with ongoing progress in automation and scale-up promising enhanced performance–cost ratios for aerospace and telecommunication applications.

4. Research Progress on HEA Microwave Absorption Materials

In recent years, HEAs-based materials have demonstrated significant potential in microwave absorption due to their unique composition tunability, excellent mechanical properties, and diverse functional characteristics. Unlike conventional microwave absorption materials, HEAs achieve integrated broadband operation with strong attenuation, while simultaneously exhibiting exceptional environmental durability through corrosion resistance and thermal stability. These excellent properties originate from their multi-principal element chemistry and carefully engineered microstructures. These unparalleled capabilities have propelled HEAs to the forefront of electromagnetic materials research, driving the development of diverse material architectures including optimized powder systems, engineered core–shell configurations, phase-controlled composites, and two-dimensional (2D)/nanostructured porous designs. Through systematic composition optimization and advanced processing techniques, researchers have successfully enhanced key performance metrics such as electromagnetic response tuning, impedance matching characteristics, and loss mechanism efficiency, establishing HEAs as a versatile platform for next-generation absorption materials.

4.1. Powder-Based HEAs for Microwave Absorption

Powder-based HEAs have emerged as a promising class of microwave materials, where substantial performance enhancements have been achieved through strategic composition design, optimized synthesis protocols, and precise microstructure control. A representative example is the mechanically alloyed FeCoNiCr0.4Cux system, where controlled copper incorporation produces a pronounced “cocktail effect” that simultaneously enhances material plasticity and promotes the formation of high-aspect-ratio flaky particles [70]. These structurally anisotropic particles overcome conventional Snoek limit restrictions, exhibiting exceptional magnetic permeability characteristics in the MHz regime (μ′ = 2.7–7.5, with μ″ peaking at 2.7). The optimized material demonstrates remarkable microwave absorption performance, achieving a minimum reflection loss of −33.6 dB at 484 MHz while maintaining broadband effectiveness across the entire MHz frequency spectrum. Furthermore, the system retains excellent high-temperature stability, confirming its potential for demanding electromagnetic applications.

Similar to previous studies on modulating the microwave absorption properties of HEAs by adjusting copper content, researchers have found that the content of other key metals in HEAs also significantly influences microwave absorption performance. For instance, studies on FeCoNiCrxMn (x = 0.0–1.0) HEAs demonstrated that Cr doping in powder materials prepared via three-dimensional swing ball milling effectively optimizes impedance matching and enhances dielectric loss [97]. Among these, the FeCoNiCr0.8Mn sample exhibited outstanding microwave absorption performance, achieving a minimum reflection loss of −57.4 dB with an effective absorption bandwidth of 4.0 GHz, while also demonstrating excellent corrosion resistance. Similarly, research on FeCoNiCuTix alloys revealed that the introduction of Ti increased the material’s resistivity through lattice distortion [98]. The FeCoNiCuTi0.2 sample achieved a minimum reflection loss of −47.8 dB at 10.86 GHz, with an effective absorption bandwidth of 4.76 GHz, and its corrosion current density was significantly reduced by 55.7% (Figure 4).

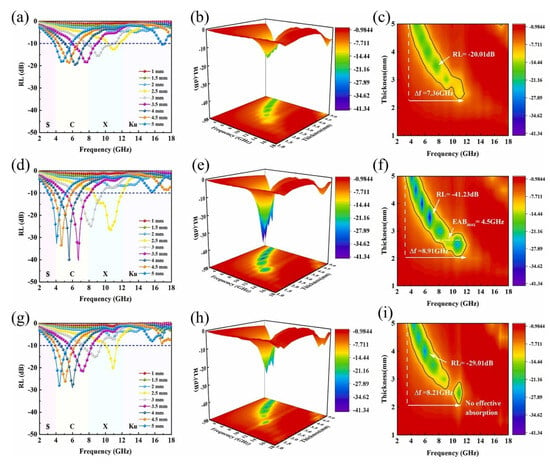

Beyond composition, optimizing the preparation process of powder-based HEAs is equally crucial, as demonstrated by several systematic studies. A nanocrystalline FeCoNiCr0.4Cu0.2 alloy, fabricated through precisely controlled multistage mechanical alloying combining dry and wet milling processes, developed both a highly crystalline FCC structure and flattened particle morphology [71]. The optimized D20 variant, processed with 20 h of dry milling followed by 5 h of wet milling, demonstrated exceptional electromagnetic properties including stable absorption across 523–600 MHz bandwidth at 5 mm thickness while maintaining a high Curie temperature of 774 °C. Parallel to these findings, research on high-energy ball-milled FeCoNiMn0.5Alx alloys revealed that Al doping effectively shifts Mn from antiferromagnetic to ferromagnetic behavior, resulting in reflection loss improvement from −38.414 dB (as-milled) to −42.851 dB (annealed) at 5.335 GHz [99]. Furthermore, the critical role of ball milling duration was confirmed in FeCoNiCuCr HEAs, where the 50 h-milled sample’s optimal size heterogeneity (3.15 μm average) enabled −41.23 dB minimum reflection loss at 6.4 GHz with 4.5 GHz bandwidth (Figure 5) [100]. Expanding on microstructure effects, comparative FeCoNiCrAl0.8 studies showed crystalline powder’s superior performance (−41.8 dB at 11.9 GHz) over amorphous phases (−35.5 dB), directly attributable to its enhanced saturation magnetization (67.52 emu/g) and coercivity (125.16 Oe) [72].

Figure 5.

The diagram of the relationship between reflection loss, frequency, and thickness at different ball milling times: (a) 40 h; (d) 50 h; (g) 60 h; 3D reflection loss curves: (b) 40 h; (e) 50 h; (h) 60 h and the corresponding projection: (c) 40 h; (f) 50 h; (i) 60 h. Reproduced with permission from [100], Copyright 2023, Elsevier B.V.

Innovative structural design has emerged as a pivotal approach for enhancing the microwave absorption properties of HEAs. Research on interstitial boron-doped FeCoNiCrBx alloys demonstrates that boron incorporation effectively induces an FCC-to-BCC phase transformation, significantly increasing lattice distortion and defect density [101]. Particularly, the FeCoNiCrB0.05 alloy exhibits outstanding comprehensive performance, achieving a remarkable minimum reflection loss of −62.5 dB at 11.74 GHz with an ultra-wide effective absorption bandwidth of 5.78 GHz. Similarly, studies on FeCoNiMnVx alloys reveal that vanadium doping not only enhances lattice distortion and defect concentration but also, after annealing treatment, enables the FeCoNiMnV0.5 alloy to attain exceptional absorption characteristics (−57.4 dB at 7.5 GHz with 6.2 GHz bandwidth) while maintaining superior hardness and corrosion resistance [102].

These significant findings collectively establish a systematic optimization framework through multidimensional strategies: compositional design via controlled doping of Cu, Cr, Ti, Al, V, and B elements; process optimization through precise ball milling duration and annealing treatments; and structural control by tuning crystalline/amorphous phases and flake morphology. Such integrated approaches provide comprehensive solutions for developing advanced HEA-based microwave absorption materials, demonstrating tremendous potential for broadband applications and harsh-environment operation due to their exceptional electromagnetic and mechanical properties.

4.2. Core–Shell-Based HEAs for Microwave Absorption

In recent years, core–shell-based HEA microwave absorption materials have demonstrated remarkable progress owing to their unique composition tunability and multiple loss mechanisms. Focusing on different design strategies for shell materials, we will systematically examine three representative systems (Ni-NiO shells, carbon shells, and PPy shells) to elucidate their respective regulatory mechanisms on microwave absorption performance.

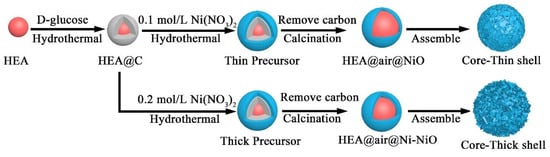

A breakthrough in core–shell design has been achieved with the development of an innovative HEA@air@Ni-NiO triple-layer structure featuring precisely controlled air gaps. The material was fabricated using a two-step process combining hydrothermal synthesis and calcination (Figure 6) [103]. Importantly, this work solved two key challenges simultaneously: it overcame the metal/oxide interfacial bonding issue through a glucose-derived carbon transition layer, while also enabling precise control of shell thickness (0.5–1 μm) via careful Ni2+ concentration regulation. The resulting structure demonstrates remarkable microwave absorption at an ultra-thin 1.3 mm thickness, achieving both a broad 4.0 GHz effective bandwidth (14–18 GHz) and an excellent minimum reflection loss of −41.4 dB. Detailed analysis shows this superior performance arises from three synergistic mechanisms: magnetic loss from the HEA core, dielectric loss from the Ni-NiO shell, and enhanced multiple reflections created by the carefully designed air gaps.

Figure 6.

A schematic illustration for the synthetic process of HEA@air@NiO and HEA@air@Ni-NiO microspheres. Reproduced with permission from [103], Copyright 2019, Elsevier B.V.

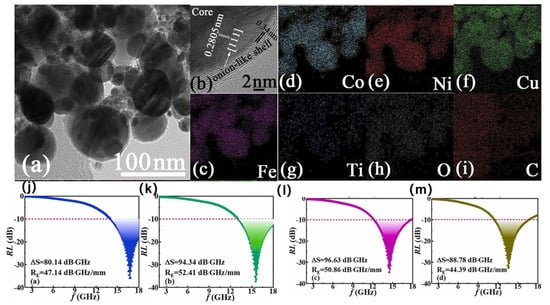

Recent advances in carbon-encapsulated HEAs represent a significant breakthrough in the design of high-performance microwave absorbing materials [104]. Using an arc-discharge method, Li’s research team developed two innovative core–shell systems: FeCoNiTiMn@C [105] and FeCoNiCuTi@C [106] (Figure 7). The first system achieves remarkable performance through Mn-modulated core resistivity, which dramatically enhances interfacial polarization to deliver an ultra-wide 5.45 GHz bandwidth (12.55–18.00 GHz) at just 1.9 mm thickness. Meanwhile, the second system demonstrates equally impressive results by combining Cu/Ti-optimized magnetic properties with a unique 3 nm onion-like carbon shell, enabling near-perfect impedance matching (|Zin/Z0| ≈ 1) at 1.8 mm thickness and exceptional absorption efficiency (52.41 dB·GHz/mm, Figure 7). Together, these findings reveal that engineered carbon shells not only provide vital oxidation protection for magnetic cores but, more crucially, enable precise control over the dielectric–magnetic loss balance, thereby maximizing microwave absorption performance.

Figure 7.

(a) TEM image of FeCoNiCuTi@C nanocapsules, (b) HRTEM image of a nanocapsule, (c–i) elemental mapping images. RL, ∆S, and RE of FeCoNiCuTi@C nanocapsules at some representative t. (j) 1.7 mm, (k) 1.8 mm, (l) 1.9 mm, and (m) 2.0 mm. Reproduced with permission from [106], Copyright 2022, Elsevier B.V.

Metal-organic chemical vapor deposition (MOCVD) has become a pivotal fabrication technique for core–shell-based HEAs, owing to its unparalleled composition control. Sibt ul Hassan’s team first applied this method to develop FeCoNiCuMnx@C core–shell nanoparticles (the “@” symbol denotes a core–shell structure), demonstrating how precise Mn content regulation could optimize electromagnetic properties to achieve −52.30 dB reflection loss at 2.35 mm thickness [67]. Expanding this approach, they subsequently combined MOCVD with thermal treatment (700–950 °C) to finely tune graphite crystallinity in CoNiFeCuV-C systems [107], with the 850 °C-treated HEA-850 sample exhibiting a remarkable 7.44 GHz bandwidth through synergistic dielectric–magnetic enhancement. In a complementary advancement, Wang’s team developed Cr-gradient-doped CoNiFeCuCrx@C core–shell structures with engineered multilayer architectures, where the sub-10 nm design and compositional control collectively enabled record-breaking microwave absorption performance. The resulting material achieved an unprecedented −63.9 dB reflection loss at just 2.1 mm thickness while maintaining an ultra-wide 12.22 GHz bandwidth, setting new standards for absorber materials [67].

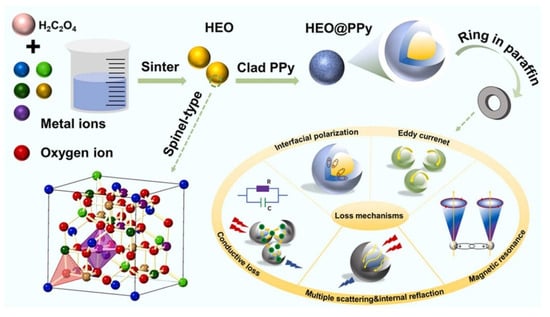

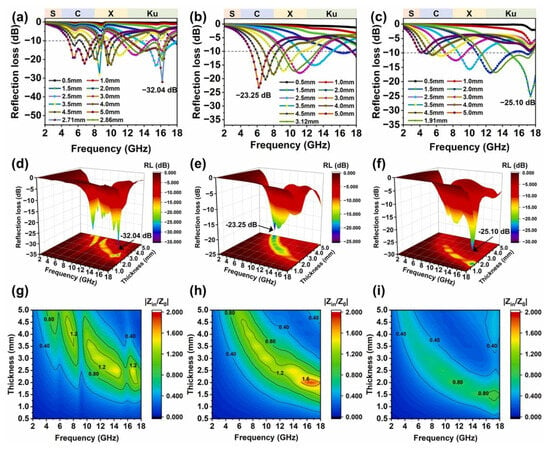

Beyond conventional metal/carbon systems, conductive polymer composites now offer innovative pathways for core–shell-based HEAs design. A prime example is the work by Sun’s group, who created a breakthrough PPy-coated high-entropy oxide (HEO@PPy) through an integrated liquid-phase and sintering process (Figure 8 and Figure 9) [108]. By strategically adjusting the magnetic elements (Fe, Ni, Co), they achieved optimal coupling between the PPy shell’s eddy current loss and the HEO core’s hysteresis loss. The optimized HEO(1)-FeNi@PPy composite demonstrates exceptional microwave absorption performance, achieving a remarkable −32.04 dB reflection loss at 2.71 mm thickness along with a broad 5.8 GHz bandwidth, while its outstanding thickness-normalized absorption reaches 5.3 GHz/mm. Beyond its practical performance, this work advances fundamental understanding by revealing the critical interplay between dielectric and magnetic losses, which provides essential guidance for designing next-generation lightweight and broadband absorbers.

Figure 8.

Preparation and electromagnetic wave absorption mechanism of core–shell structured HEO@PPy composite materials. Reproduced with permission from [108], Copyright 2024, Elsevier B.V.

Figure 9.

Two-dimensional RL curves: (a) HEO(1)-FeNi@PPy; (b) HEO(2)-FeCo@PPy; (c) HEO(3)-CoNi@PPy. Three-dimensional RL curves: (d) HEO(1)-FeNi@PPy; (e) HEO(2)-FeCo@PPy; (f) HEO(3)-CoNi@PPy. Impedance matching |Zin/Z0| contour plots: (g) HEO(1)-FeNi@PPy; (h) HEO(2)-FeCo@PPy; (i) HEO(3)-CoNi@PPy. Reproduced with permission from [108], Copyright 2024, Elsevier B.V.

The development of FeCoNiCrAl/AlN composite coatings with laser-induced pomegranate-like core–shell structures addresses the critical challenge of radar-infrared stealth performance degradation in high-temperature environments. Through laser cladding, we achieved in situ formation of TiN shells tightly encapsulating AlN cores via Marangoni convection-driven self-assembly, creating thermally stable heterointerfaces that enable simultaneous electromagnetic modulation and infrared suppression. At the optimal 8:2 mass ratio, these core–shell structured coatings exhibit exceptional high-temperature resilience, demonstrating −15.1 dB reflection loss at 14.75 GHz and 0.28 infrared emissivity (3–5 μm) with 2 mm thickness, while maintaining remarkable thermal stability at 500 °C (RL = −11 dB, ε = 0.33) and 700 °C (RL = −10 dB, ε = 0.328). The robust core–shell architecture not only enhances interfacial polarization for improved wave absorption but also prevents structural degradation under thermal stress, with the TiN protective shells ensuring consistent performance in extreme conditions [109]. This convection-engineered bionic design represents a significant advancement in high-temperature compatible stealth materials, combining tunable electromagnetic response with durable infrared suppression through its unique core–shell configuration.

Through systematic comparison of three core–shell architectures, researchers have established that while all achieve optimized impedance matching through carefully engineered composition and interfaces, each system possesses unique merits. Carbon-shell configurations excel in overall performance owing to their remarkable compositional, dimensional, and structural adaptability. In contrast, Ni-NiO-based systems offer unmatched ultra-thin absorption characteristics, whereas PPy-coated variants provide distinct advantages in processing simplicity and innovative loss mechanisms. With continuous advancements in fabrication precision and growing fundamental understanding of underlying mechanisms, these core–shell high-entropy alloys are poised to transform electromagnetic wave absorption technology, enabling tailored solutions for diverse operational requirements across multiple application domains.

4.3. Phase Structure Engineering in HEAs for Microwave Absorption

Phase structure engineering has emerged as a fundamental strategy to optimize microwave absorption in HEAs, where the established mechanistic insights have systematically advanced the field from initial single-phase modifications to complex multiphase architectures. The phase transition characteristics of Cs(PbFeCoNiMn)Br3 perovskite exemplify this progress, where high-energy ball milling precisely orchestrates cubic-to-orthorhombic-to-tetragonal transformations [110]. These transitions not only alter crystal symmetry but also induce significant lattice distortion, which becomes especially impactful at phase boundaries. Specifically, when orthorhombic and tetragonal phases coexist, their lattice mismatch produces intense localized strain fields that markedly strengthen interfacial polarization, ultimately enabling extraordinary absorption performance, including a −75 dB reflection loss and 8.8 GHz bandwidth at just 2.5 mm thickness. This case highlights how deliberate phase engineering can yield unprecedented electromagnetic wave absorption capabilities.

Building upon single-phase systems, researchers have pioneered an advanced multiphase strategy by developing FeCoNiCrMn33O44/Ni heterostructures through solid-state reaction and hydrogen annealing [111]. These engineered composites harness dual synergistic mechanisms by combining optimized impedance matching through electromagnetic contrast between the high-entropy oxide matrix and Ni-alloy phase with enhanced polarization loss arising from strategically designed heterointerfaces. The resulting architecture delivers exceptional broadband performance (11.8–18 GHz) with −54.1 dB reflection loss at just 1.55 mm thickness, coupled with improved thermal stability, demonstrating the significant advantages of deliberate multiphase design in microwave absorption materials.

Multicomponent FeCoNiAl0.4Si0.6Crx alloys (x = 0, 0.1, 0.3, 0.5) with high configurational disorder were synthesized via planetary ball milling, where precise Cr content adjustment effectively controlled the FCC-to-BCC phase ratio in these HEAs. Systematic characterization revealed that increasing Cr content reduces the VEC while augmenting the BCC phase proportion, inducing unconventional static magnetic and electromagnetic property variations, with FeCoNiAl0.4Si0.6Cr0.3 exhibiting exceptional electromagnetic performance—achieving −48.32 dB reflection loss at 3.5 mm thickness in C-band and 4.96 GHz effective absorption bandwidth at 1.5 mm. This work demonstrates that strategic VEC design can tailor the crystal structure of FeCoNiAl0.4Si0.6 HEAs to simultaneously enhance electromagnetic wave absorption and corrosion resistance [66].

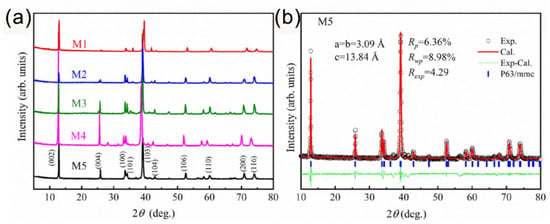

The optimization of phase ratios has emerged as an equally critical factor in enhancing performance, demonstrated by quantitative studies on the FeCoNiCr0.4Mnx system that reveal a direct correlation between controlled BCC/FCC phase ratios and tailored electromagnetic properties [112]. At optimal Mn concentrations, the tailored BCC phase fraction achieves ideal permittivity–permeability matching, which critically enables a strong reflection loss of −48.49 dB at 3 mm thickness. This principle extends to complex systems like high-entropy MAX phases, where Shen’s team demonstrated through (Ti0.2Zr0.2V0.2Nb0.2Ta0.2)2AlC synthesis that entropy engineering induces lattice distortion and defects [113]. These structural modifications simultaneously improve impedance matching while activating multiple polarization mechanisms and enhancing magnetic loss. The synergistic interplay of these mechanisms results in significantly enhanced performance characteristics, including a reflection loss of −47 dB at 11.92 GHz and an effective bandwidth of 3.92 GHz, demonstrating clear superiority over conventional MAX phases while highlighting the universal significance of phase regulation in diverse material systems (Figure 10 and Figure 11).

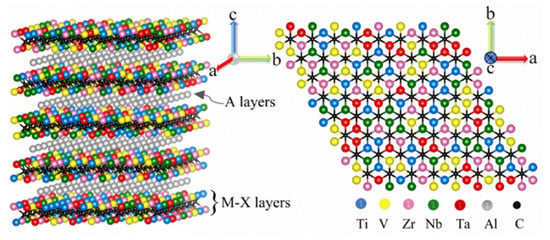

Figure 10.

The crystal structure diagram of high-entropy MAX phase M5 (left plot) with Ti (blue), V (yellow), Zr (pink), Nb (green), Ta (red), Al (gray), and C (black) atoms and its M-C layer (right plot) with five elements uniformly distributed. Reproduced with permission from [113], Copyright 2023, AIP Publishing.

Figure 11.

(a) XRD patterns for all our prepared MAX phases; (b) the Rietveld refinement results for M5. The Rietveld simulated results (red line), experimental data (black circle), and the difference between the above two (green line), Bragg positions of phases included for refinement (blue markers). Reproduced with permission from [113], Copyright 2023, AIP Publishing.

Nanoscale phase engineering has made significant progress through the FeCoNiSiₓAl0.4 system’s biphasic design [114]. By precisely controlling amorphization, researchers developed a nanocrystalline/nanoglass hybrid architecture. This structure uniquely combines crystalline-phase magnetic loss with glassy-phase dielectric loss. Moreover, it enhances wave attenuation while maintaining optimal impedance matching-a rare achievement in conventional absorbers. Progressing from bulk phase control, researchers have further advanced the field through innovative interface engineering in HEA/nitrogen-doped carbon heterojunctions [115]. Here, nitrogen segregation generates aligned electric dipoles at the interfaces, which not only enhance interfacial polarization but also improve electromagnetic wave scattering. As a result, these designed interfaces achieve a remarkable −56.38 dB reflection loss at just 1.80 mm thickness, demonstrating the transformative potential of atomic-level interface control in microwave absorbers.

Extending these interfacial design principles, the most significant advancement emerges from multiphase interface engineering, as demonstrated by comparative studies between Cu-based (multiphase) and Zn-based (single-phase) high-entropy sulfides. While the homogeneous Zn-system exhibits limited performance due to constrained lattice distortion, the reactive interfaces in Cu-system heterostructures (CuS/CuFe2S3/Fe0.5Ni0.5S2) enable strong polarization loss through interfacial charge accumulation [116]. Remarkably, thermal annealing at 400 °C transforms the Zn-system into an equally effective multiphase configuration (FeNi2S4/(ZnFe)S), with its bandwidth dramatically increasing to 4.83 GHz. Ultimately, the optimized Cu-system achieves a record 6.70 GHz bandwidth at 2.00 mm thickness, conclusively demonstrating how engineered multiphase interfaces can overcome conventional material limitations by maximizing polarization effects.

Collectively, these studies demonstrate that phase-structure engineering has evolved into a robust methodology for HEAs-based microwave absorbers, spanning precise atomic-scale lattice control to macroscopic interface design. To further advance the field, three key research directions emerge as critical: (1) in situ monitoring of phase transition dynamics, (2) atomic-scale interface analysis, and (3) quantitative modeling of structure–property relationships. Addressing these challenges will unlock new generations of tunable, high-performance absorbers for tailored electromagnetic applications.

4.4. Two-Dimensional and Porous Architecture HEAs for Microwave Absorption

Recent developments in two-dimensional (2D) nanostructures and porous architectures have significantly enhanced the microwave absorption capabilities of HEAs. Through precise microstructure engineering, researchers have fabricated novel material systems with exceptional electromagnetic wave attenuation properties.

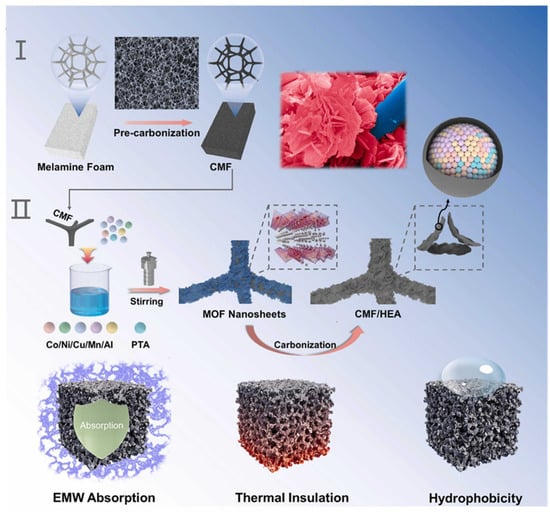

A notable advancement in 2D architectures was achieved by Gang’s research team, who developed an innovative 3D porous heterostructure (Figure 12 and Figure 13) [117]. Their approach involved embedding 2D nanosheets of CoMnNiCuAl HEA into carbonized melamine foam substrates through a combination of hydrothermal synthesis and controlled annealing processes. This sophisticated design effectively harnesses two complementary mechanisms by utilizing lattice distortion effects to optimize impedance matching while simultaneously leveraging multiscale interfaces to achieve synergistic loss phenomena. Impressively, this composite material demonstrates outstanding absorption performance with only 12 wt% filler content, achieving a minimum reflection loss of −74.86 dB and an effective absorption bandwidth of 7.94 GHz. In a complementary approach, Gui’s research group has pioneered high-temperature stable stealth materials utilizing ultra-thin HEA films [118]. Their methodology employs precision lithography and advanced deposition techniques to fabricate microscale-patterned HEA films on Al2O3 dielectric layers, forming optimized metal–insulator–metal (MIM) configurations. These engineered structures effectively combine magnetic resonance mechanisms with ohmic loss characteristics. The resulting materials achieve dual functional integration by combining broadband microwave absorption capabilities with well-preserved infrared stealth performance across operational frequency ranges. Most remarkably, these MIM structures show exceptional thermal stability, maintaining their performance characteristics even when exposed to temperatures as high as 600 °C.

Figure 12.

Schematic illustration for preparation of CMF and CMF/HEA-x. Reproduced with permission from [117], Copyright 2025, Elsevier B.V.

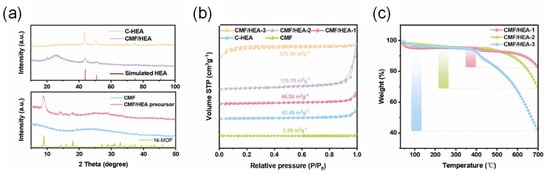

Figure 13.

(a) XRD patterns of CMF, CMF/HEA precursor, (b) C-HEA, and CMF/HEA. (c) BET surface area of CMF, C-HEA, CMF/HEA-1, CMF/HEA-2, and CMF/HEA-3. (c) TG curves of CMF, C-HEA, CMF/HEA-1, CMF/HEA-2, and CMF/HEA-3 with a heating rate of 10 °C min−1 in Ar. Reproduced with permission from [117], Copyright 2025, Elsevier B.V.

Recent advances in porous HEA architectures demonstrate innovative approaches to microwave absorption enhancement. Ma’s research team developed a breakthrough microwave-assisted synthesis method for in situ growth of FeCoNiCrAl nanoparticles on carbon nanofibers [119]. Their technique produces three-dimensional hierarchical porous networks where carefully engineered Al gradient distribution and controlled lattice distortion work together to significantly improve polarization loss. The optimized material achieves impressive −51.5 dB absorption at 5.4 mm thickness while offering excellent lightweight properties and environmental stability. In a complementary development, researchers have created porous FeCoNiCrCuAl0.3 alloys through an integrated ball-milling and selective etching process [120]. This approach creates abundant pore structures that simultaneously enhance specific surface area and optimize impedance matching characteristics through their unique architectural features. The resulting ultrathin 1.7 mm absorber delivers outstanding performance with 4.48 GHz bandwidth and −40.2 dB reflection loss, demonstrating exceptional efficiency for its thickness.

Recent studies have revealed that 2D and porous architectures can substantially improve the microwave absorption capabilities of HEAs by synergistically enhancing interfacial polarization through heterogeneous interfaces, optimizing impedance matching via multiscale porosity, and enabling coupled loss mechanisms through gradient compositions. These innovative designs have not only expanded the application potential of HEAs in electromagnetic wave absorption but also provided valuable insights for developing next-generation multifunctional absorbers.

Recent advances in microwave-absorbing materials highlight the critical importance of synergistic optimization across compositional design, structural engineering, and processing approaches. Researchers have developed various material architectures with tailored electromagnetic properties, including powder-based systems with controlled doping and morphology, core–shell configurations utilizing interfacial effects, and phase-engineered crystalline structures. Particularly noteworthy are two-dimensional and porous architectures that integrate multiple functional advantages. Collectively, these advancements establish a comprehensive materials design paradigm for developing high-performance electromagnetic wave absorbers with customizable protection capabilities.

5. Conclusions and Perspectives

As a new generation of microwave absorbing materials, HEAs demonstrate remarkable advantages in broadband absorption, lightweight design, and extreme environmental stability, owing to their unique composition tunability, lattice distortion effects, and excellent electromagnetic loss capabilities. Through composition optimization, structural design, and advanced preparation techniques, researchers have developed high-performance material systems with reflection loss as low as −74.86 dB and effective absorption bandwidth up to 12.22 GHz. These breakthroughs not only address the long-standing challenge of balancing impedance matching and loss capability in traditional absorbing materials but also provide innovative solutions for electromagnetic protection in military stealth, aerospace, and 5G/6G communication applications.

However, further development of HEA-based microwave absorbing materials still faces critical challenges. At the mechanistic level, the quantitative structure–property relationships between electron cloud rearrangement, lattice distortion, and electromagnetic parameters in multi-principal element systems remain incompletely understood, particularly regarding the synergistic mechanisms of dielectric/magnetic losses that require more in-depth in situ characterization and theoretical modeling. In terms of preparation technology, issues such as composition uniformity control in scaled-up production, interfacial stability of core–shell structures, and the balance between lightweight properties and mechanical strength need urgent breakthroughs. Moreover, most current research focuses on small-scale laboratory preparation, and achieving cost-effective mass production while meeting practical engineering requirements still demands process optimization and equipment upgrades.

Looking ahead, the integration of artificial intelligence (AI)-assisted design is poised to transform the development of high-entropy alloys, where machine learning algorithms can efficiently analyze composition–structure–property relationships to accelerate the discovery of optimal elemental combinations and processing parameters, thereby dramatically reducing experimental iteration cycles. Combined with first-principles calculations and molecular dynamics simulations, AI can further guide the development of novel HEA MAX phases or sulfide/nitride systems, extending the absorption bandwidth to terahertz frequencies. In advanced fabrication technology, emerging non-equilibrium synthesis methods are enabling precise control of nanocrystalline/amorphous architectures, whereas multi-material 3D printing now facilitates integrated manufacturing of gradient impedance–porous structures for performance-tailored applications in complex operational conditions.

At the application level, HEAs-based microwave absorbing materials will evolve toward multifunctional and intelligent designs. Representative applications demonstrate the versatility of these materials, ranging from flexible wearable HEA-polymer composites that integrate electromagnetic shielding with biocompatibility, to high-temperature resistant HEA carbide coatings enabling thermal-electromagnetic synergistic protection in hypersonic vehicle components, and further extending to metamaterial-based dynamically tunable absorbers designed for customized performance in complex operational environments. With the integration of AI-driven high-throughput computing and automated experimental platforms, HEAs-based microwave absorbing materials are expected to achieve the leap from laboratory research to industrial applications within the next decade, providing revolutionary solutions for electromagnetic pollution control and defense stealth technologies.

Author Contributions

Conceptualization, investigation, writing—original draft preparation, supervision, C.M.; Resources, writing—review and editing, Y.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Acknowledgments

The authors gratefully acknowledge Zao Yi for his invaluable insights into electromagnetic wave theory and constructive suggestions during manuscript preparation.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Akdeniz, M.R.; Liu, Y.; Samimi, M.K.; Sun, S.; Rangan, S.; Rappaport, T.S.; Erkip, E. Millimeter Wave Channel Modeling and Cellular Capacity Evaluation. IEEE J. Sel. Area Commun. 2014, 32, 1164–1179. [Google Scholar] [CrossRef]

- Lv, H.; Yang, Z.; Pan, H.; Wu, R. Electromagnetic absorption materials: Current progress and new frontiers. Prog. Mater. Sci. 2022, 127, 100946. [Google Scholar] [CrossRef]

- Belpomme, D.; Hardell, L.; Belyaev, I.; Burgio, E.; Carpenter, D.O. Thermal and non-thermal health effects of low intensity non-ionizing radiation: An international perspective. Environ. Pollut. 2018, 242, 643–658. [Google Scholar] [CrossRef] [PubMed]

- Galeev, A.L. The effects of microwave radiation from mobile telephones on humans and animals. Neurosci. Biobehav. Physiol. 2000, 30, 187–194. [Google Scholar] [CrossRef] [PubMed]

- Breckenkamp, J.; Berg, G.; Blettner, M. Biological effects on human health due to radiofrequency/microwave exposure: A synopsis of cohort studies. Radiat. Environ. Biophys. 2003, 42, 141–154. [Google Scholar] [CrossRef]

- Zuo, D.; Jia, Y.; Xu, J.; Fu, J. High-Performance Microwave Absorption Materials: Theory, Fabrication, and Functionalization. Ind. Eng. Chem. Res. 2023, 62, 14791–14817. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, Y.; Drew, M.G.B. Wave mechanics of microwave absorption in films: A short review. Opt. Laser Technol. 2024, 178, 111211. [Google Scholar] [CrossRef]

- Wang, T.G.; Gong, J.; Du, H.; Liu, J.G.; Sun, C.; Wen, L.S. Study on electromagnetic wave transmission performances of ultra-thin metallic films. Acta Metall. Sin. 2005, 41, 814–818. [Google Scholar]

- Duan, Y.; Ma, B.; Huang, L.; Ma, X.; Wang, M. Moth-Eye-Inspired Gradient Impedance Microwave Absorption Materials with Multiband Compatible Stealth Characteristic. Adv. Mater. Technol. 2023, 8, 202202172. [Google Scholar] [CrossRef]

- Hou, Z.-L.; Gao, X.; Zhang, J.; Wang, G. A perspective on impedance matching and resonance absorption mechanism for electromagnetic wave absorbing. Carbon 2024, 222, 118935. [Google Scholar] [CrossRef]

- Bao, R.; Peng, X.; Yang, Y.; Xiong, N.; Tao, Y.; Wu, J.; Liu, D. Investigation of Beat Wave Propagation along Lossy Dielectric Bar for Wind Tunnel Microwave Experiments. Appl. Sci. 2023, 13, 619. [Google Scholar] [CrossRef]

- Prihoda, M.; Hoffmann, K. Novel Multimode Planar Absorbing Structure. IEEE Microw. Wirel. Compon. Lett. 2013, 23, 7–9. [Google Scholar] [CrossRef]

- Mashadi; Winatapura, D.S.; Setiawan, J.; Mulyawan, A.; Yunasfi; Adi, W.A. Radar absorbing material of Co1-xCuxFe2O4: Structural, magnetic properties and absorption characteristic. Mater. Chem. Phys. 2025, 339, 130647. [Google Scholar] [CrossRef]

- Tian, H.; Guo, Q.; Liu, S.; Jiao, K.; Ren, X.; Liu, J.; Hao, H.; Yin, J.; Long, J.; Wang, Y.; et al. Robust Single-Walled Carbon Nanotube-Coated Aramid Fibers with Tunable Conductivities for Broadband Radar Absorption in Honeycomb Structures. ACS Nano 2025, 19, 21729–21738. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Hu, R.; Xiong, Z.; Wang, D.; Zhang, Z.; Liu, C.; Zeng, X.; Chen, D.; Che, R.; Nie, X. Metal-Organic Gel Leading to Customized Magnetic-Coupling Engineering in Carbon Aerogels for Excellent Radar Stealth and Thermal Insulation Performances. Nano-Micro Lett. 2024, 16, 42. [Google Scholar] [CrossRef] [PubMed]

- Liu, B.F.; Liu, Z.P.; Ren, J.N.; Fan, X.Y.; Zhou, H.M.; Oleksandr, M.; Zhu, M.W.; Li, W.; Lu, S.W. Fabrication and structural optimization of integrated gradient honeycombs with the conductive/absorbing coatings for ultra-wideband microwave absorption. Funct. Mater. Lett. 2025; accepted. [Google Scholar] [CrossRef]

- Mohapatra, P.P.; Singh, H.K.; Dobbidi, P. Advancements in electromagnetic microwave absorbers: Ferrites and carbonaceous materials. Sci. Adv. Colloid Interface Sci. 2025, 337, 103381. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, Y.; Wang, Y.; Huang, Y. Advances in conductive filler-integrated hydrogels and derived aerogels: Innovative strategies for electromagnetic interference shielding. Mater. Horiz. 2025, accepted. [Google Scholar] [CrossRef]

- Di, J.; Duan, Y.; Bo, L.; Gu, S.; Pang, H.; Jia, H. The Co/CoNi sequential configurations based on transparent basalt substrates toward excellent microwave absorption. Chem. Eng. J. 2024, 481, 148207. [Google Scholar] [CrossRef]

- Du, Z.; Zhou, C.; Zhang, H.; Zhao, R. Co-Ni doped lignin-derived carbon-based materials with “mosaic” structure for efficient microwave absorption. Mater. Lett. 2025, 386, 138215. [Google Scholar] [CrossRef]

- Zhou, L.; Hu, P.; Bai, M.; Leng, N.; Cai, B.; Peng, H.-L.; Zhao, P.-Y.; Guo, Y.; He, M.; Wang, G.-S.; et al. Harnessing the Electronic Spin States of Single Atoms for Precise Electromagnetic Modulation. Adv. Mater. 2025, 37, 2418321. [Google Scholar] [CrossRef] [PubMed]

- Shi, H.; Gao, H.; Qin, L.; Yuan, J.-T.; Tang, L.-X.; Wang, Z.-R.; Li, W.-J.; Feng, Z.-H.; Wang, Y.; Xie, A.M. High efficiency electromagnetic waves absorption of ferrite/polypyrrole composite based on precise structural control of rare earth doping. Rare Met. 2025, 44, 5621–5632. [Google Scholar] [CrossRef]

- Guo, Z.; Lan, D.; Jia, Z.; Gao, Z.; Shi, X.; He, M.; Guo, H.; Wu, G.; Yin, P. Multiple Tin Compounds Modified Carbon Fibers to Construct Heterogeneous Interfaces for Corrosion Prevention and Electromagnetic Wave Absorption. Nano-Micro Lett. 2025, 17, 23. [Google Scholar] [CrossRef]

- Guo, Y.; Ruan, K.; Wang, G.; Gu, J. Advances and mechanisms in polymer composites toward thermal conduction and electromagnetic wave absorption. Sci. Bull. 2023, 68, 1195–1212. [Google Scholar] [CrossRef]

- Thomassin, J.-M.; Jerome, C.; Pardoen, T.; Bailly, C.; Huynen, I.; Detrembleur, C. Polymer/carbon based composites as electromagnetic interference (EMI) shielding materials. Mater. Sci. Eng. R 2013, 74, 211–232. [Google Scholar] [CrossRef]

- Hu, H.; Zhao, Z.; Wan, W.; Gogotsi, Y.; Qiu, J. Ultralight and Highly Compressible Graphene Aerogels. Adv. Mater. 2013, 25, 2219–2223. [Google Scholar] [CrossRef]

- Zhang, Y.; Huang, Y.; Zhang, T.; Chang, H.; Xiao, P.; Chen, H.; Huang, Z.; Chen, Y. Broadband and Tunable High-Performance Microwave Absorption of an Ultralight and Highly Compressible Graphene Foam. Adv. Mater. 2015, 27, 2049–2053. [Google Scholar] [CrossRef]

- Cao, M.-S.; Cai, Y.-Z.; He, P.; Shu, J.-C.; Cao, W.-Q.; Yuan, J. 2D MXenes: Electromagnetic property for microwave absorption and electromagnetic interference shielding. Chem. Eng. J. 2019, 359, 1265–1302. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, Y.; Wu, N.; Han, M.; Liu, W.; Liu, J.; Zeng, Z. Diverse Structural Design Strategies of MXene-Based Macrostructure for High-Performance Electromagnetic Interference Shielding. Nano-Micro Lett. 2023, 15, 240. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, J.; Cui, J.; Chen, Z.; Zhang, Z.; Deng, N.; Zeng, Y.; Zhou, Z.; Zhou, Z. Broadband Microwave Absorption of Nb2CTxNanosheets by a One-Step Hydrothermal Method. Inorg. Chem. 2025, 64, 9435–9446. [Google Scholar] [CrossRef]

- Ren, J.; Shi, P.; Zu, X.; Ding, L.; Liu, F.; Wang, Y.; Wu, Y.; Shi, G.; Wu, Y.; Li, L. Challenges and future prospects of the 2D material-based composites for microwave absorption. Nanoscale 2025, 17, 13622–13645. [Google Scholar] [CrossRef]

- Zhu, S.; Zhang, Q.; Wang, W.; Gong, P.; Zhang, Y.; Wang, Q.; Han, G.; Zhang, J.; Zhang, W. Synthesis and electromagnetic wave absorption performance of h-BN composites. J. Mater. Sci. Mater. Electron. 2025, 36, 50. [Google Scholar] [CrossRef]

- Wang, F.; Bai, C.; Chen, L.; Yu, Y. Boron nitride nanocomposites for microwave absorption: A review. Mater. Today Nano 2021, 13, 100108. [Google Scholar] [CrossRef]

- Zhong, B.; Cheng, Y.; Wang, M.; Bai, Y.; Huang, X.; Yu, Y.; Wang, H.; Wen, G. Three dimensional hexagonal boron nitride nanosheet/carbon nanotube composites with light weight and enhanced microwave absorption performance. Compos. Part A Appl. Sci. Manuf. 2018, 112, 515–524. [Google Scholar] [CrossRef]

- George, E.P.; Raabe, D.; Ritchie, R.O. High-entropy alloys. Nat. Rev. Mater. 2019, 4, 515–534. [Google Scholar] [CrossRef]

- Miracle, D.B.; Senkov, O.N. A critical review of high entropy alloys and related concepts. Acta Mater. 2017, 122, 448–511. [Google Scholar] [CrossRef]

- Jin, J.; Zheng, Y.; Hu, J.; Jiang, L.; Jia, L.; Liu, H.; Zhou, H. Surface phosphating modification of FeCoNiMn high-entropy alloys for efficient electromagnetic-wave absorption performances. J. Alloys Compd. 2024, 1005, 175980. [Google Scholar] [CrossRef]

- Rajhi, A.A.; Duhduh, A.A. Rational construction of decorated CoFeCuNiCr HEA and hierarchical mesoporous Cu3P in gradient double-layer nanocomposite configuration with highly efficient microwave absorption performance. J. Alloys Compd. 2025, 1014, 175980. [Google Scholar] [CrossRef]

- Divilov, S.; Eckert, H.; Hicks, D.; Oses, C.; Toher, C.; Friedrich, R.; Esters, M.; Mehl, M.J.; Zettel, A.C.; Lederer, Y.; et al. Disordered enthalpy-entropy descriptor for high-entropy ceramics discovery. Nature 2024, 625, 66–73. [Google Scholar] [CrossRef]

- Li, C.; Liu, Y.; Li, B.; Yuan, Z.; Yang, T.; Liu, Y.; Gao, H.; Xu, L.; Yu, X.; Luo, Q.; et al. Enhanced energy storage in high-entropy ferroelectric polymers. Nat. Mater. 2025, 24, 1066–1073. [Google Scholar] [CrossRef]

- Zeng, Y.; Ouyang, B.; Liu, J.; Byeon, Y.-W.; Cai, Z.; Miara, L.J.; Wang, Y.; Ceder, G. High-entropy mechanism to boost ionic conductivity. Science 2022, 378, 1320–1324. [Google Scholar] [CrossRef]

- Shome, S.; Ray, N. High-Entropy Alloys for Next-Generation Electromagnetic Shielding Applications. Adv. Eng. Mater. 2025, 2500361. [Google Scholar] [CrossRef]

- Tian, J.; Yang, X.; Song, J.; Wei, L.; Tian, Q.; Wang, M.; Wu, S.; Feng, J.; Chen, Z. Research progress and future prospects of high-entropy alloys as microwave-absorbing materials: Review. J. Mater. Sci. Mater. Electron. 2025, 36, 92. [Google Scholar] [CrossRef]

- Liang, H.; Zhang, L.; Wu, H. Exploration of Twin-Modified Grain Boundary Engineering in Metallic Copper Predominated Electromagnetic Wave Absorber. Small 2022, 18, 2203620. [Google Scholar] [CrossRef] [PubMed]

- Shao, C.; Ding, C.; Liu, Y.; Ma, Y.; Zhang, L.; Ren, X.; Wu, S.; Zhong, B.; Wen, G.; Huang, X. Grain boundary capacitance effect in Iron-based magnetic composites for superior C-band microwave absorption. Chem. Eng. J. 2023, 466, 143162. [Google Scholar] [CrossRef]

- Li, P.; Feng, X.; Yu, H.; Liu, Y.; Huang, J.; Zhou, P.; Wu, S.; Li, H. Enhancing absorption performance of Nd-doped BaFe12O19/MWCNTs/PDMS composites through stress control and defect engineering via ultrasonic cavitation. Carbon 2025, 242, 120462. [Google Scholar] [CrossRef]

- Yao, P.; Qian, Y.; Li, W.; Li, C.; Zuo, J.; Xu, J.; Li, M. Exploration of dielectric and microwave absorption properties of quaternary MAX phase ceramic (Cr2/3Ti1/3)3AlC2. Ceram. Int. 2020, 46, 22919–22926. [Google Scholar] [CrossRef]

- Duan, Y.; Cui, Y.; Zhang, B.; Ma, G.; Wang, T. A novel microwave absorber of FeCoNiCuAl high-entropy alloy powders: Adjusting electromagnetic performance by ball milling time and annealing. J. Alloys Compd. 2019, 773, 194–201. [Google Scholar] [CrossRef]

- Yi, P.; Yao, Z.; Zhou, J.; Wei, B.; Lei, L.; Tan, R.; Fan, H. Facile synthesis of 3D Ni@C nanocomposites derived from two kinds of petal-like Ni-based MOFs towards lightweight and efficient microwave absorbers. Nanoscale 2021, 13, 3119–3135. [Google Scholar] [CrossRef]

- Zhang, M.; Han, C.; Cao, W.-Q.; Cao, M.-S.; Yang, H.-J.; Yuan, J. A Nano-Micro Engineering Nanofiber for Electromagnetic Absorber, Green Shielding and Sensor. Nano-Micro Lett. 2021, 13, 27. [Google Scholar] [CrossRef]

- Duan, Y.; Wen, X.; Zhang, B.; Ma, G.; Wang, T. Optimizing the electromagnetic properties of the FeCoNiAlCrx high entropy alloy powders by composition adjustment and annealing treatment. J. Magn. Magn. Mater. 2020, 497, 165947. [Google Scholar] [CrossRef]

- Zeng, X.; Cheng, X.; Yu, R.; Stucky, G.D. Electromagnetic microwave absorption theory and recent achievements in microwave absorbers. Carbon 2020, 168, 606–623. [Google Scholar] [CrossRef]

- Li, J.; Li, X.; He, L.; Guo, H.; Xia, W.; Sun, B.; Cao, C.; Sha, L.; Zhou, D. MoS2-Based Nanocomposites for Microwave Absorption: A Review. ACS Appl. Nano Mater. 2024, 7, 5761–5775. [Google Scholar] [CrossRef]

- Lv, Z.; Yang, W.; Yao, L.; Chen, X.; Zhou, J.; Li, R.; Mei, H.; Cheng, L.; Zhang, L. Electromagnetic response mechanism of BaTiO3-based metamaterials: Transition between microwave absorption and shielding capacity. Addit. Manuf. 2024, 95, 104558. [Google Scholar] [CrossRef]

- Verma, A.; Gotra, S.; Singh, D.; Das Varma, G.; Dhawan, N. Microwave absorption properties of CI and E-waste based heterogenous mixtures. Ceram. Int. 2024, 50, 20879–20893. [Google Scholar] [CrossRef]

- Li, J.; Zhou, D.; Wang, P.-J.; Du, C.; Liu, W.-F.; Su, J.-Z.; Pang, L.-X.; Cao, M.-S.; Kong, L.-B. Recent progress in two-dimensional materials for microwave absorption applications. Chem. Eng. J. 2021, 425, 131558. [Google Scholar] [CrossRef]

- Zhang, H.; Kuang, K.; Zhang, Y.; Sun, C.; Yuan, T.; Yin, R.; Fan, Z.; Che, R.; Pan, L. Multifunctional Carbon Foam with Nanoscale Chiral Magnetic Heterostructures for Broadband Microwave Absorption in Low Frequency. Nano-Micro Lett. 2025, 17, 133. [Google Scholar] [CrossRef]

- Ghasemi, A.; Liu, X.; Morisako, A. Effect of Additional Elements on the Structural Properties, Magnetic Characteristics and Natural Resonance Frequency of Strontium Ferrite Nanoparticles/Polymer Composite. IEEE Trans. Magn. 2009, 45, 4420–4423. [Google Scholar] [CrossRef]

- Xiong, X.; Zhang, H.; Lv, H.; Yang, L.; Liang, G.; Zhang, J.; Lai, Y.; Cheng, H.-W.; Che, R. Recent progress in carbon-based materials and loss mechanisms for electromagnetic wave absorption. Carbon 2024, 219, 118834. [Google Scholar] [CrossRef]

- Yang, H.; Ye, T.; Lin, Y.; Zhu, J.; Wang, F. Microwave absorbing properties of the ferrite composites based on graphene. J. Alloys Compd. 2016, 683, 567–574. [Google Scholar] [CrossRef]

- He, P.; Hou, Z.-L.; Zhang, K.-L.; Li, J.; Yin, K.; Feng, S.; Bi, S. Lightweight ferroferric oxide nanotubes with natural resonance property and design for broadband microwave absorption. J. Mater. Sci. 2017, 52, 8258–8267. [Google Scholar] [CrossRef]

- Hu, R.; Pan, D.; Xu, X.; Xiao, B.; Wang, H. Tunable natural resonances via synergistic effects of two phases in Fex(CoyNi1-y)100-x for multi-band microwave absorption. J. Mater. 2023, 9, 90–98. [Google Scholar]

- Yang, Y.; Xu, C.-L.; Qiao, L.; Li, X.-H.; Li, F.-S. Microwave Magnetic Properties and Natural Resonance of ε-Co Nanoparticles. Chin. Phys. Lett. 2010, 27, 057501. [Google Scholar] [CrossRef]

- Yuan, M.; Weible, A.H.; Azadi, F.; Li, B.; Cui, J.; Lv, H.; Che, R.; Wang, X. Advancements in high-entropy materials for electromagnetic wave absorption. Mater. Horiz. 2025, 12, 1033–1057. [Google Scholar] [CrossRef] [PubMed]