Numerical Study of the Combustion-Flow-Thermo-Pyrolysis Process in an Innovative Externally Heated Oil Shale Retort

Abstract

1. Introduction

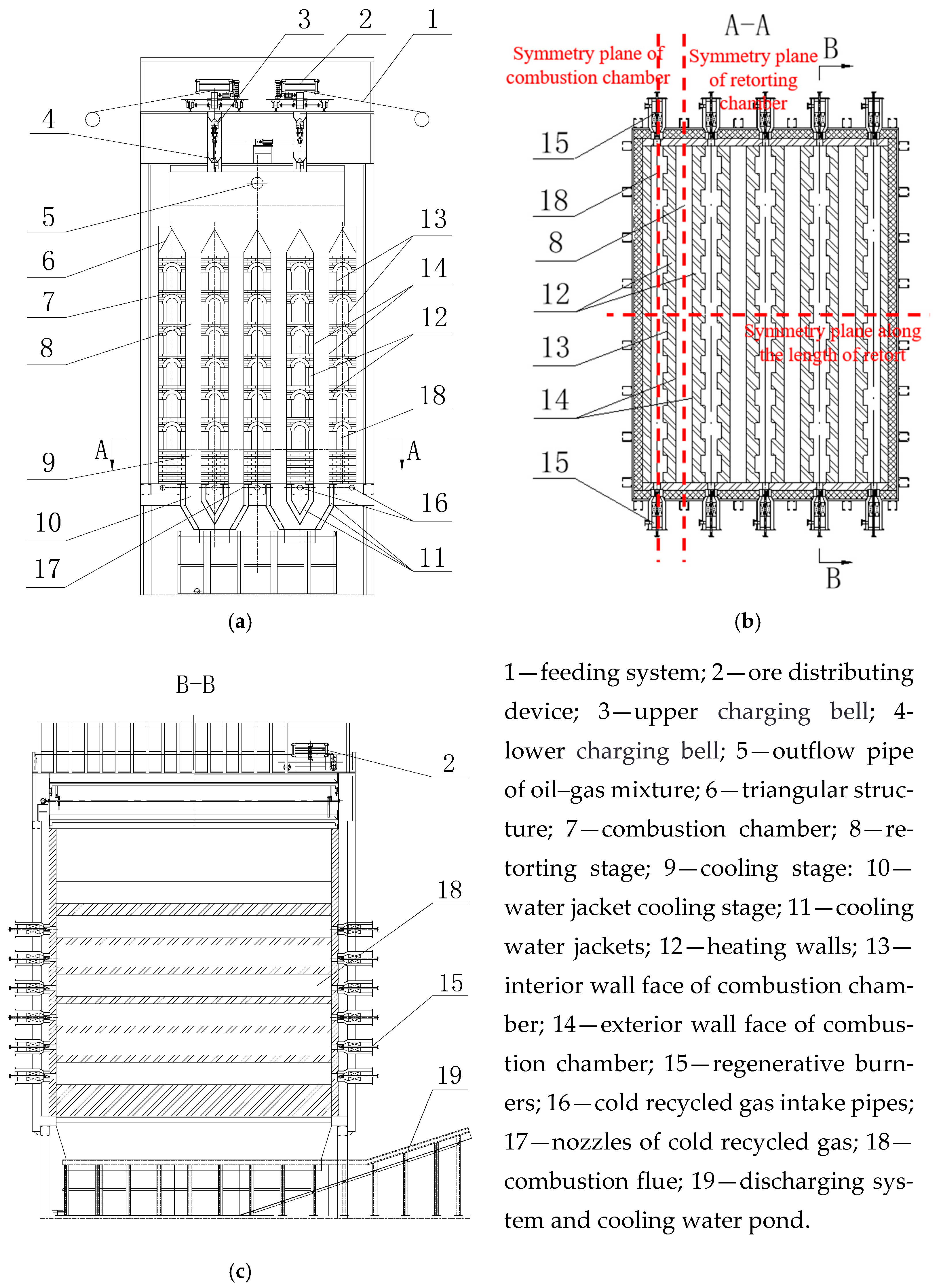

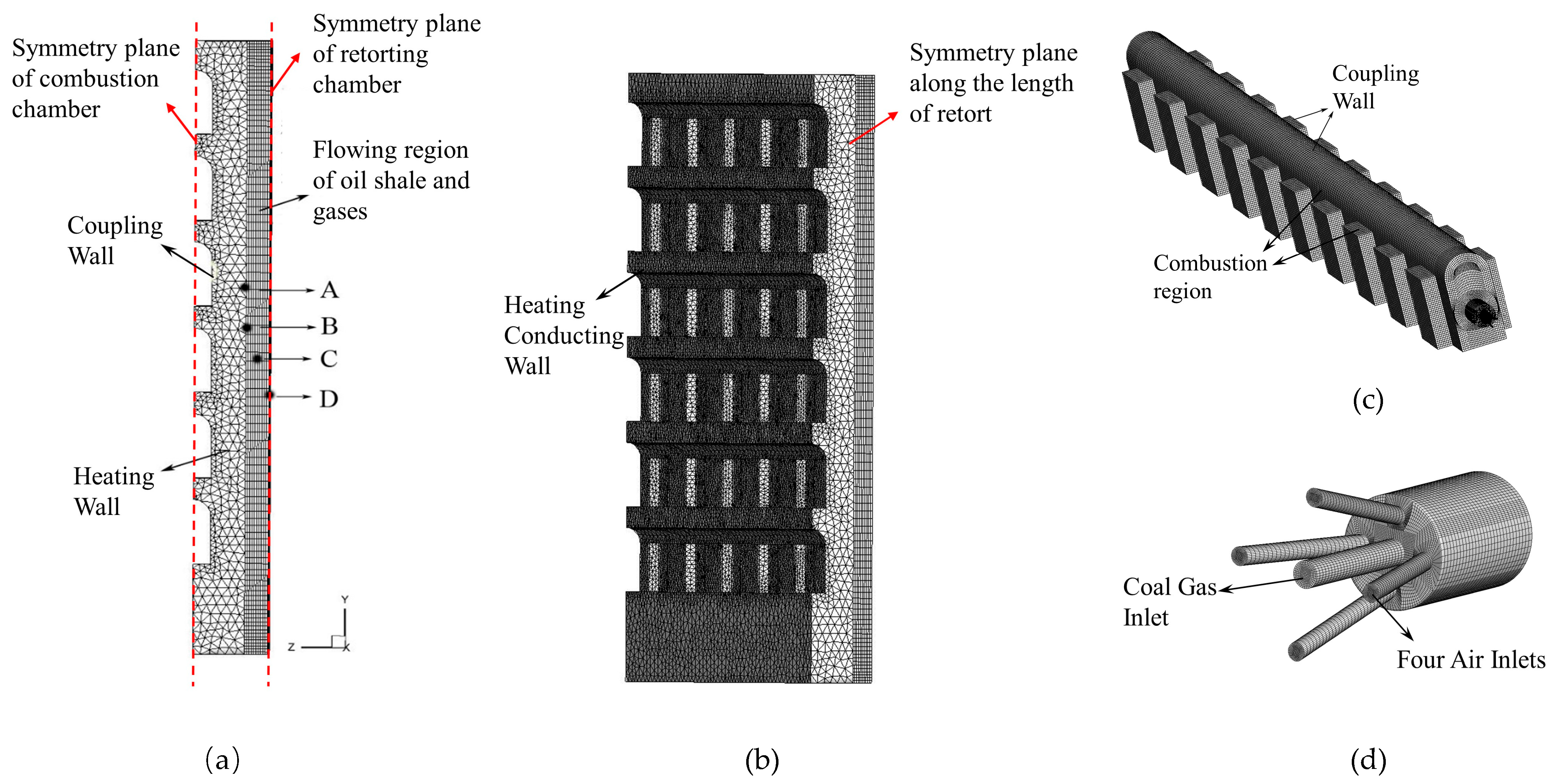

2. Structure of the Externally Heated Oil Shale Retort Battery

3. Mathematical Model

3.1. Governing Equations in the Combustion Flues

- (1)

- Non-premixed combustion modelwhere is the average of the mixed score, the unit is percent. is the mass source term, E is the reaction activation energy, B represents the volume of retort gas consumed per hour, R is the molar gas constant, the subscript fuel represents fuel, and ox represents oxygen.

- (2)

- Radiation heat transfer modelwhere I is the total radiation intensity, is the absorption coefficient, is the scattering coefficient, is the position vector, is the direction vector, is the component of , is the refraction coefficient, is the scattering direction vector, is the Stefan–Boltzmann constant, , T is the thermodynamic temperature, is the solid angle, is the phase function which represents the spatial distribution characteristics of inward scattering.

3.2. Governing Equations in the Retorting Chambers

- (1)

- The governing equations of gases:

- (2)

- The governing equations of oil shale:

- (3)

- Oil shale pyrolysis model:

4. Results and Discussion

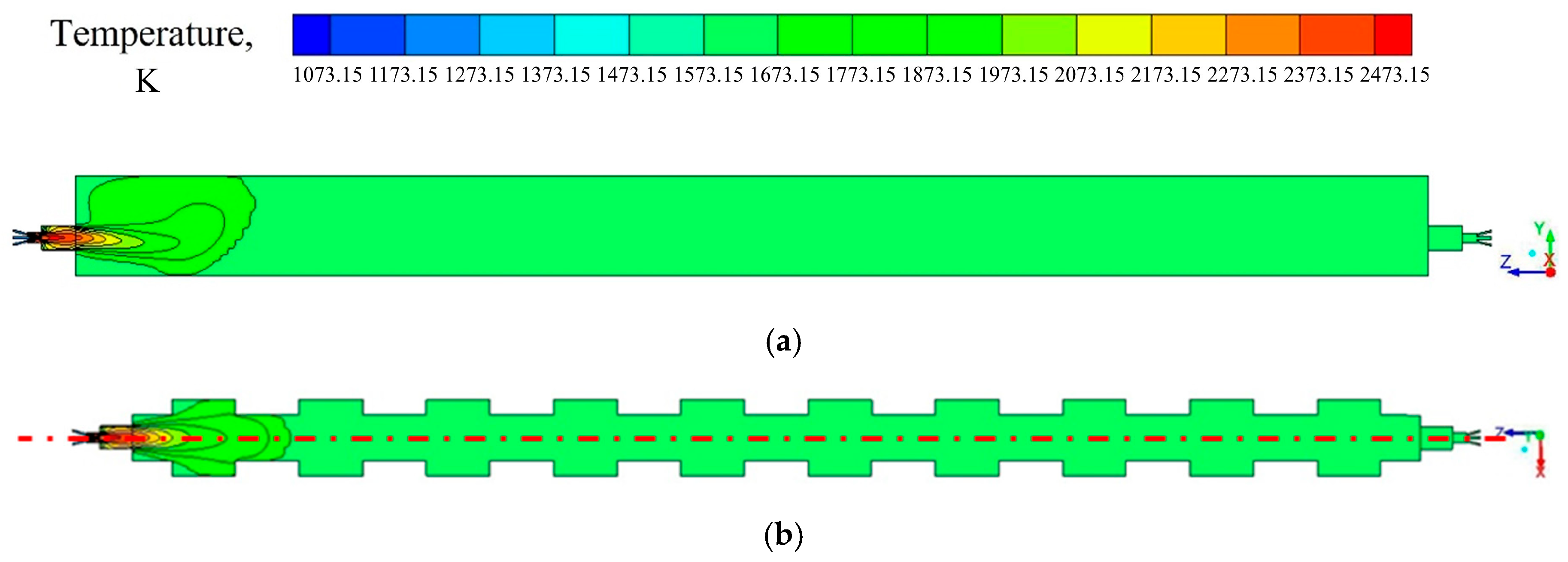

4.1. The Combustion Process in the Combustion Flues

4.2. The Flowing, Heat Transfer, and Pyrolysis Processes in the Retorting Chamber

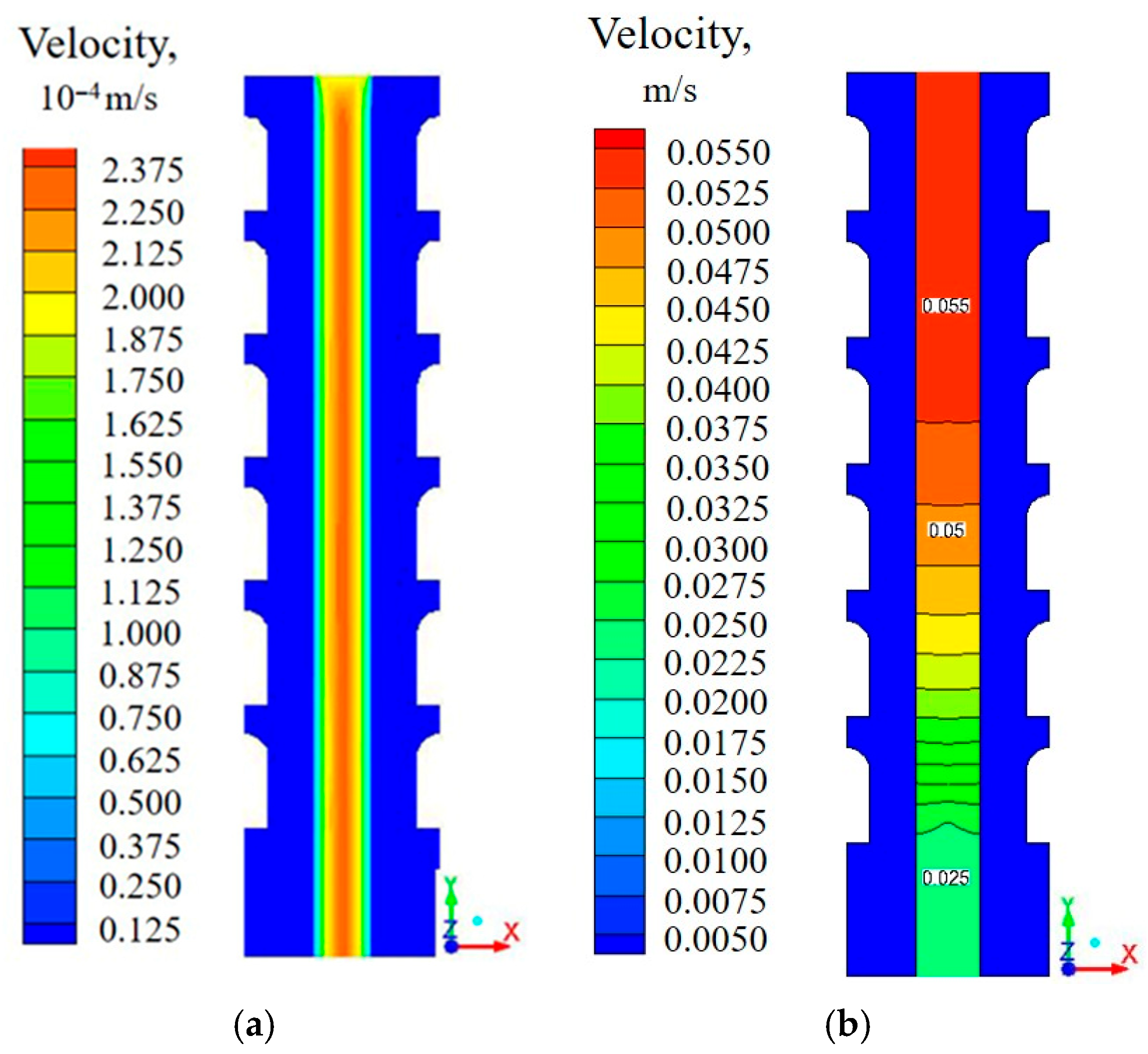

4.2.1. Flowing Characteristics

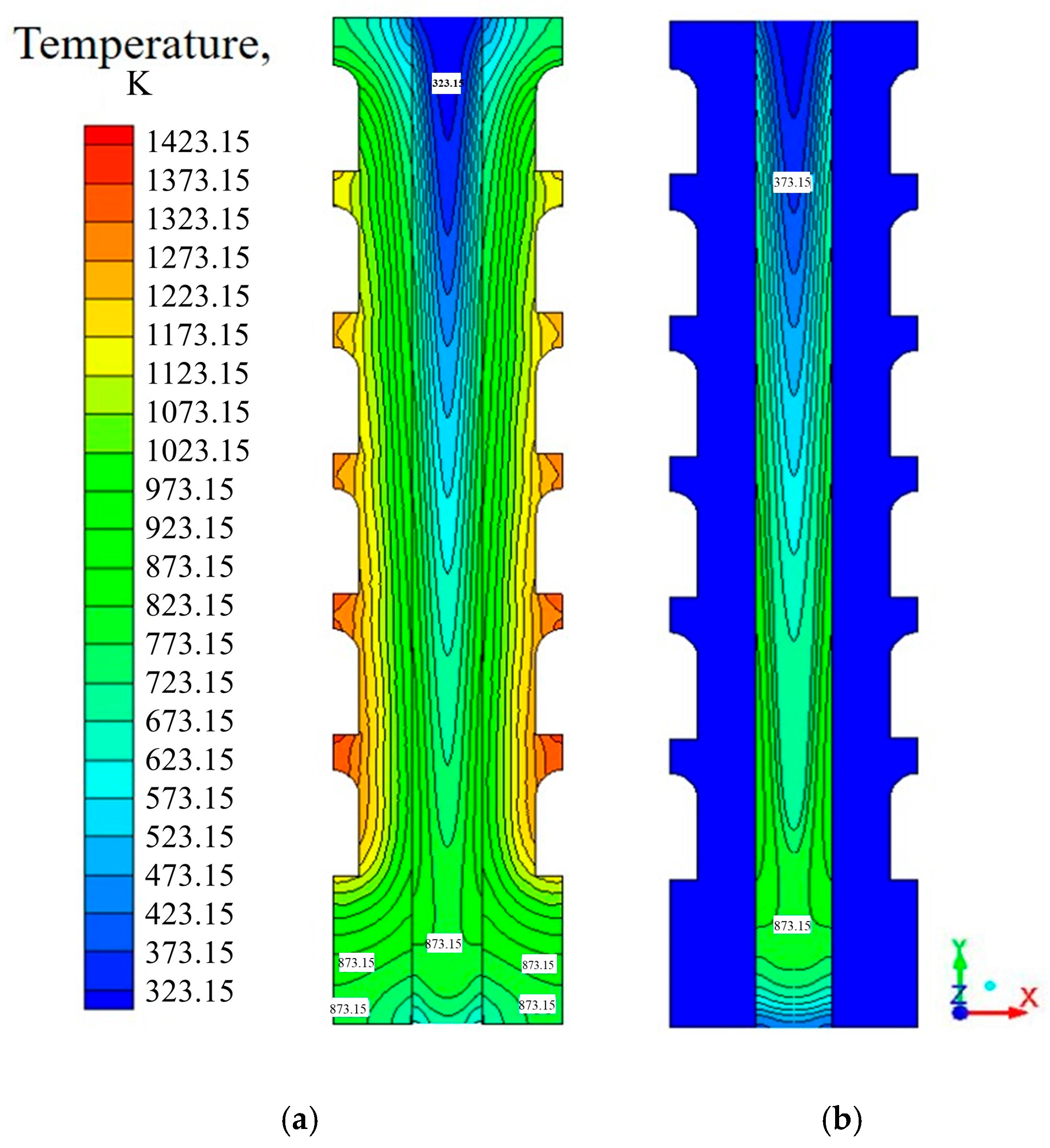

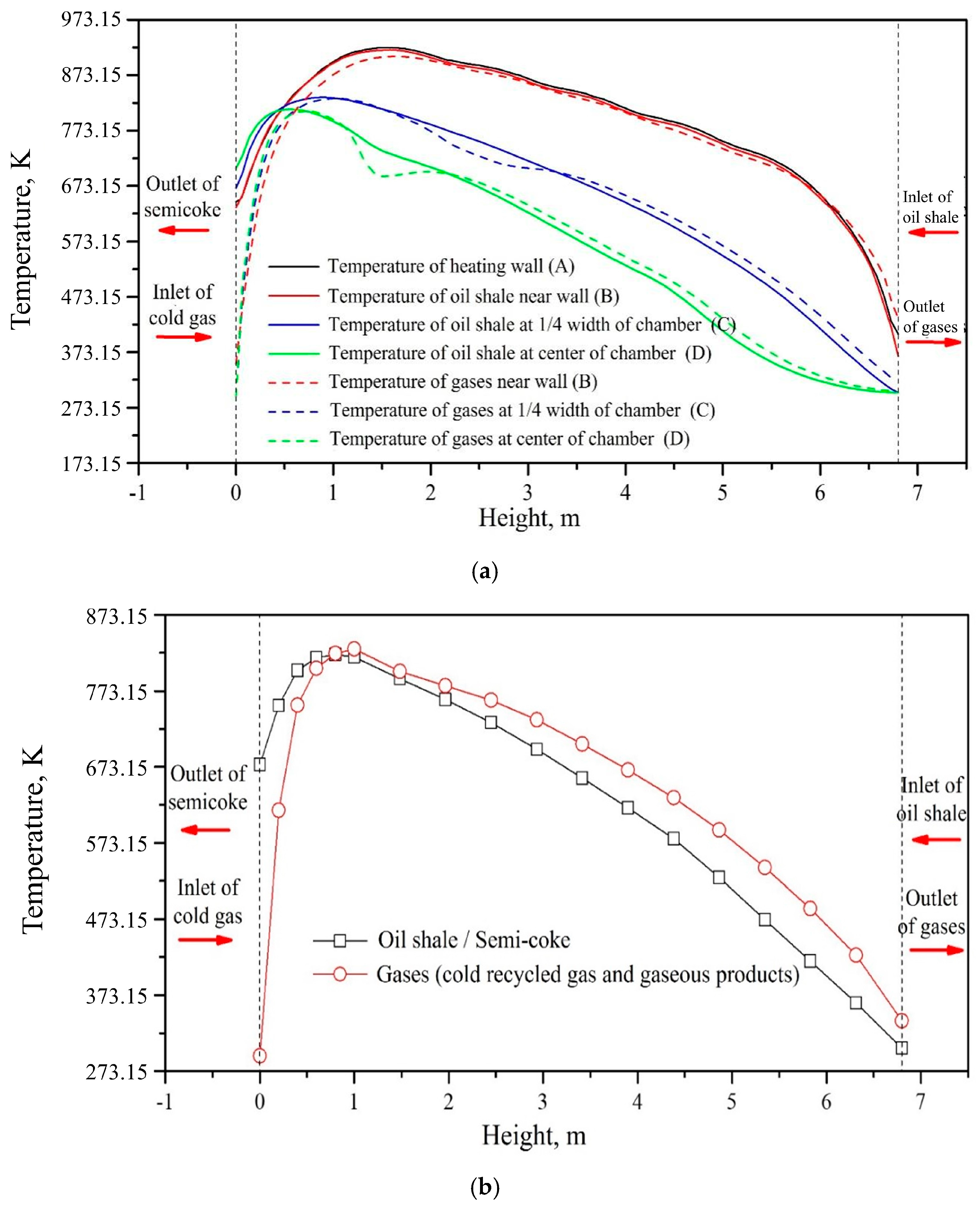

4.2.2. Temperature Distribution

4.2.3. Oil Shale Pyrolysis Reaction

5. Conclusions

- (1)

- Horizontally, the velocity of oil shale particles demonstrates a gradual increase from the retort wall regions to the central regions, attributed to the viscous drag between particles and the wall. The velocity of gases has a similar pattern to that of oil shale.

- (2)

- The temperature distribution in the combustion flues of the externally heated oil shale retort furnace is relatively uniform. Additionally, the flue gas temperature is about 1623.15 K. The fuel self-sufficiency rate of this externally heated oil shale retort can reach 82.83%.

- (3)

- The oil shales pyrolyze gradually from the region near the wall to the core region of the retorting chamber and pyrolyze completely at the bottom of the retorting zone. The final mass-weighted average pyrolysis temperature of oil shale is 821.05 K, and the outlet temperature of semi-coke cooled by cold recycled gas is 676.35 K, which are in agreement with the design requirements.

- (4)

- The gaseous products are mainly generated during their downward movement to the bottom of the retorting stage. The theoretical oil and gas yield could reach 100% of the Fischer oil yield of oil shale.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chen, Z.; Tian, Y.; Lai, D.; Zhan, J.-H.; Han, Z.; Xu, G.; Gao, S. Oil shale pyrolysis in a moving bed with internals enhanced by rapid preheating in a heated drop tube. Energy Convers. Manag. 2020, 224, 113358. [Google Scholar] [CrossRef]

- Lai, D.; Zhang, G.; Xu, G. Characterization of oil shale pyrolysis by solid heat carrier in moving bed with internals. Fuel Process. Technol. 2017, 158, 191–198. [Google Scholar] [CrossRef]

- Yang, S.; Wang, H.; Zheng, J.; Pan, Y.; Ji, C. Comprehensive review: Study on heating rate characteristics and coupling simulation of oil shale pyrolysis. J. Anal. Appl. Pyrolysis 2024, 177, 106289. [Google Scholar] [CrossRef]

- Qian, J.; Li, S.; Guo, S.; Ding, F. Oil Shale Distillation and Refining Technology; China Petrochemical Press: Beijing, China, 2014. (In Chinese) [Google Scholar]

- Ma, Y.; Xiang, Q.; Ding, K. Development of oil shale at home and abroad. World Pet. Ind. 2024, 31, 16–25. (In Chinese) [Google Scholar]

- Lai, D.; Chen, Z.; Shi, Y.; Lin, L.; Zhan, J.; Gao, S.; Xu, G. Pyrolysis of oil shale by solid heat carrier in an innovative moving bed with internals. Fuel 2015, 159, 943–951. [Google Scholar] [CrossRef]

- Yang, Q.; Qian, Y.; Kraslawski, A.; Zhou, H.; Yang, S. Advanced exergy analysis of an oil shale retorting process. Appl. Energy 2016, 165, 405–415. [Google Scholar] [CrossRef]

- He, J.; Wang, Q. Development and application of Estonia Galoter technology. J. Northeast. Dianli Univ. 2016, 36, 76–80. (In Chinese) [Google Scholar]

- Li, W.; Deng, J.; Yu, C. Development of lignite pyrolysis with solid heat carrier. Coal Chem. Ind. 2012, 158, 1–5. (In Chinese) [Google Scholar]

- Templado, J.L.; Ribas, J.; Lopera, J.M.; Rodríguez, H.d.A.; Lopez, J.J.F. Capacitive Charge-Level Measurement System for Coke Ovens. IEEE Trans. Ind. Appl. 2023, 59, 7839–7847. [Google Scholar] [CrossRef]

- Lin, L.; Zhang, C.; Li, H.; Lai, D.; Xu, G. Pyrolysis in indirectly heated fixed bed with internals: The first application to oil shale. Fuel Process. Technol. 2015, 138, 147–155. [Google Scholar] [CrossRef]

- Lin, L.; Lai, D.; Guo, E.; Zhang, C.; Xu, G. Oil shale pyrolysis in indirectly heated fixed bed with metallic plates of heating enhancement. Fuel 2016, 163, 48–55. [Google Scholar] [CrossRef]

- Xu, H. Semi-Industrial Experimental Study on Externally Heated Dry Distillation of Oil Shale. Master’s Thesis, Jilin University, Changchun, China, 2012. (In Chinese). [Google Scholar]

- Lu, H.; Pan, L.; Guo, Y.; Xiong, Q.; Dai, F.; Wang, S. Experimental investigation of the characteristics and transformation mechanism of Jimsar oil shale and derived shale oil. Processes 2023, 11, 411. [Google Scholar] [CrossRef]

- Da Silva, B.P.; Saccol, F.; Pedrazzi, C.; Caetano, N.R. Technical and Economic Viability for the Briquettes Manufacture. Defect Diffus. Forum 2017, 380, 218–226. [Google Scholar] [CrossRef]

- Pan, L.; Lu, H.; Dai, F.; Pei, S.; Wu, Q.; Huang, J. Numerical study of the flow, heat transfer and pyrolysis process in the gas full circulation oil shale retort. Oil Shale 2021, 38, 317–337. [Google Scholar] [CrossRef]

- Zhang, A.Q.; Feng, Y.H.; Zhang, X.X.; Wang, M.D.; Yang, J.F.; Xu, Y. Decoupling simulation of thermal processes in coupled combustion andcoking chambers of a coke oven. ISIJ Int. 2013, 53, 995–1001. [Google Scholar] [CrossRef]

- He, J.; Yang, X.; Li, X.; Cao, W.; Xu, H.; Yin, Q.; Jiang, X.; Liu, B. Comparative study on the molecular evolution of changqing petroleum coke during air and pure oxygen combustion: A ReaxFF method analysis. J. Clean. Prod. 2024, 452, 142104. [Google Scholar] [CrossRef]

- Smolka, J.; Slupik, L.; Fic, A.; Nowak, A.J.; Kosyrczyk, L. 3-D coupled CFD model of a periodic operation of a heating flue and coke ovens in a coke oven battery. Fuel 2016, 165, 94–104. [Google Scholar] [CrossRef]

- Pan, L.; Dai, F.; Tian, Y.; Zhang, F. Experimental investigation of the sphericity of irregularly shaped oil shale particle groups. Adv. Powder Technol. 2015, 26, 66–72. [Google Scholar] [CrossRef]

- Jin, K.; Feng, Y.; Zhang, X.; Wang, M.; Yang, J.; Ma, X. Simulation of transport phenomena in coke oven with staging combustion. Appl. Therm. Eng. 2013, 58, 354–362. [Google Scholar] [CrossRef]

- Modest, M. Radiative Heat Transfer, 2nd ed.; Academic Press: San Diego, CA, USA, 2003. [Google Scholar]

- Alazmi, B.; Vafai, K. Analysis of variants within the porous media transport models. J. Heat Transf. 2000, 122, 303–312. [Google Scholar] [CrossRef]

- Wang, F.; Shuai, Y.; Tan, H.; Zhang, X.; Mao, Q. Heat transfer analyses of porous media receiver with multi-dish collector by coupling MCRT and FVM method. Sol. Energy 2013, 93, 158–168. [Google Scholar] [CrossRef]

- Wang, F.; Shuai, Y.; Wang, Z.; Leng, Y.; Tan, H. Thermal and chemical reaction performance analyses of steam methane reforming in porous media solar thermochemical reactor. Int. J. Hydrogen Energy 2014, 39, 718–730. [Google Scholar] [CrossRef]

- Jiang, P.X.; Ren, Z.P.; Wang, B.X. Numerical simulation of forced convection heat transfer in porous plate channels using thermal equilibrium and nonthermal equilibrium models. Numer. Heat Transf. Part A Appl. 1999, 35, 99–113. [Google Scholar] [CrossRef]

- Lin, W.; Feng, Y.; Zhang, X. Numerical study of volatiles production, fluid flow and heat transfer in coke ovens. Appl. Therm. Eng. 2015, 81, 353–358. [Google Scholar] [CrossRef]

- Gamrat, S.; Poraj, J.; Bodys, J.; Smolka, J.; Adamczyk, W. Influence of external flue gas recirculation on gas combustion in a coke oven heating system. Fuel Process. Technol. 2016, 152, 430–437. [Google Scholar] [CrossRef]

- Xiong, Q.; Lu, H.; Pan, L.; Dai, F.; Wang, S. Characteristics of Shichanggou oil shale and its pyrolysis semi coke. Sci. Technol. Eng. 2023, 23, 8650–8659. (In Chinese) [Google Scholar]

- Yuan, Q.; Pan, L.; Lu, H.; Guo, Y.; Dai, F.; Wang, S. Physical characteristics of combustion ash in Shichanggou oil shale. Sci. Technol. Eng. 2023, 23, 8201–8211. (In Chinese) [Google Scholar]

- Lu, H.; Pan, L.; Guo, Y.; Zhou, S.; Xiong, Q.; Dai, F.; Pei, S.; Huang, J. Simulation investigation of the particle flow behavior in the gas full circulation oil shale retort. J. Pet. Sci. Eng. 2022, 215, 110674. [Google Scholar] [CrossRef]

- Ying, W.F. Mathematical & Physical Simulation of COREX Pre-Reduction Shaft Furnace. Ph.D. Thesis, Northeastern University, Shengyang, China, 2013. (In Chinese). [Google Scholar]

- Zhang, X.S.; Zou, Z.S.; Luo, Z.G. Influence of CGD structure on burden descending behavior in COREX shaft furnace. Metall. Res. Technol. 2019, 116, 304. [Google Scholar] [CrossRef]

| Number of Layers (from Top to Bottom) | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| Fuel (m3/h) | 12.00 | 12.50 | 13.00 | 13.00 | 13.50 | 13.50 |

| Air (m3/h) | 99.60 | 103.75 | 107.90 | 107.90 | 112.05 | 112.05 |

| Heat flux of heating wall (103 W/m2) | 3.17 | 3.30 | 3.43 | 3.43 | 3.56 | 3.56 |

| Oil Shale Treating Capacity (103 kg/d) | Yield of Semi-Coke (103 kg/d) | Yield of Gaseous Products (103 kg/d) |

|---|---|---|

| 75 | 64.7 | 10.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, L.; Mei, Y.; Pan, L. Numerical Study of the Combustion-Flow-Thermo-Pyrolysis Process in an Innovative Externally Heated Oil Shale Retort. Symmetry 2025, 17, 1055. https://doi.org/10.3390/sym17071055

Zhao L, Mei Y, Pan L. Numerical Study of the Combustion-Flow-Thermo-Pyrolysis Process in an Innovative Externally Heated Oil Shale Retort. Symmetry. 2025; 17(7):1055. https://doi.org/10.3390/sym17071055

Chicago/Turabian StyleZhao, Lixin, Yingxue Mei, and Luwei Pan. 2025. "Numerical Study of the Combustion-Flow-Thermo-Pyrolysis Process in an Innovative Externally Heated Oil Shale Retort" Symmetry 17, no. 7: 1055. https://doi.org/10.3390/sym17071055

APA StyleZhao, L., Mei, Y., & Pan, L. (2025). Numerical Study of the Combustion-Flow-Thermo-Pyrolysis Process in an Innovative Externally Heated Oil Shale Retort. Symmetry, 17(7), 1055. https://doi.org/10.3390/sym17071055