Parameter Calibration and Experimental Validation of Fermented Grain Particles During the Loading Process Based on the Discrete Element Model

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Materials and Fundamental Parameters

2.2. JKR Contact Model

2.3. Particle Discrete Element Modeling and Parameter Settings

2.3.1. Discrete Element Modeling of Particle

2.3.2. Simulation Parameter Settings

2.4. Angle of Repose for Fermented Grain Particle

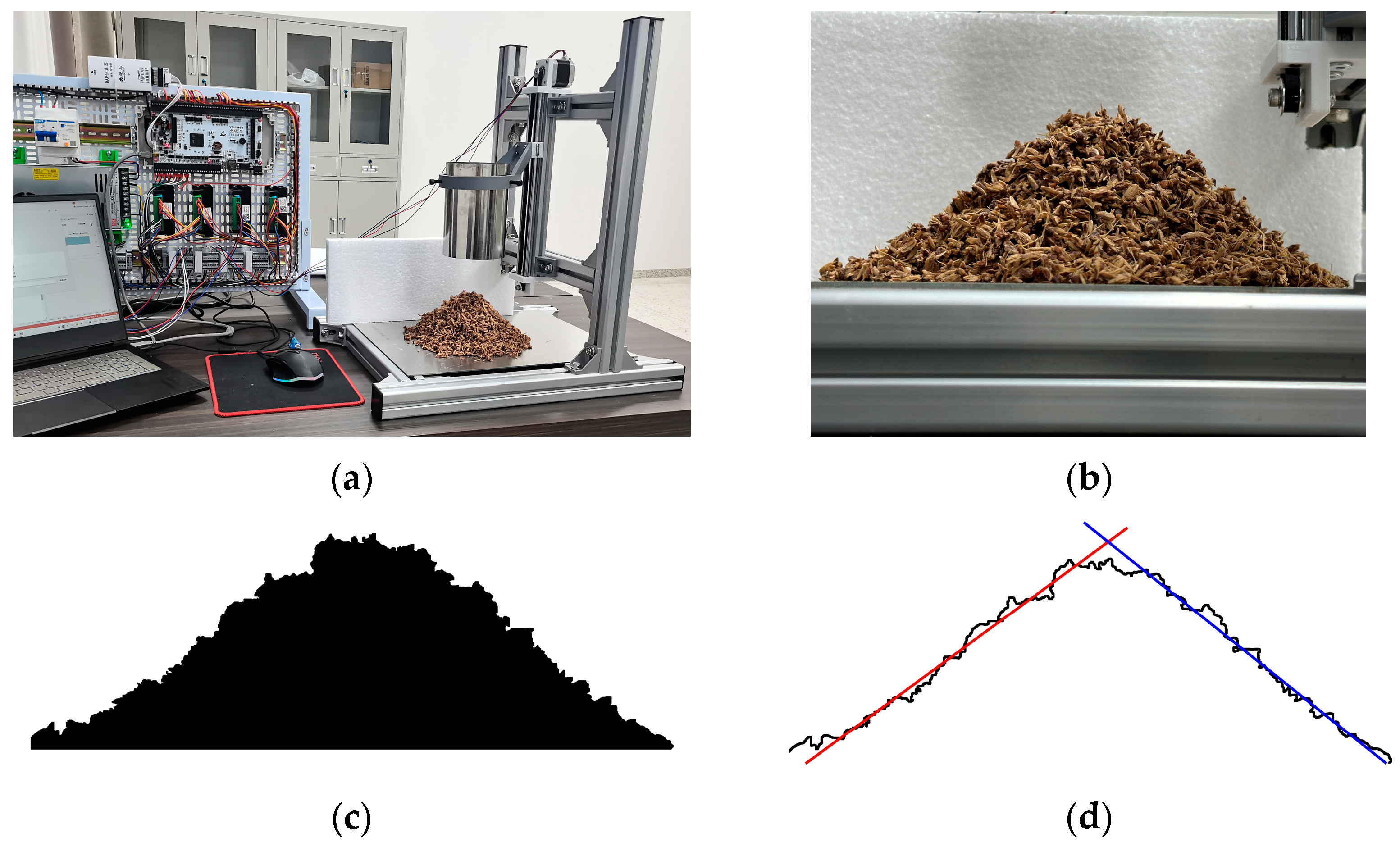

2.4.1. Angle of Repose Physical Experiment

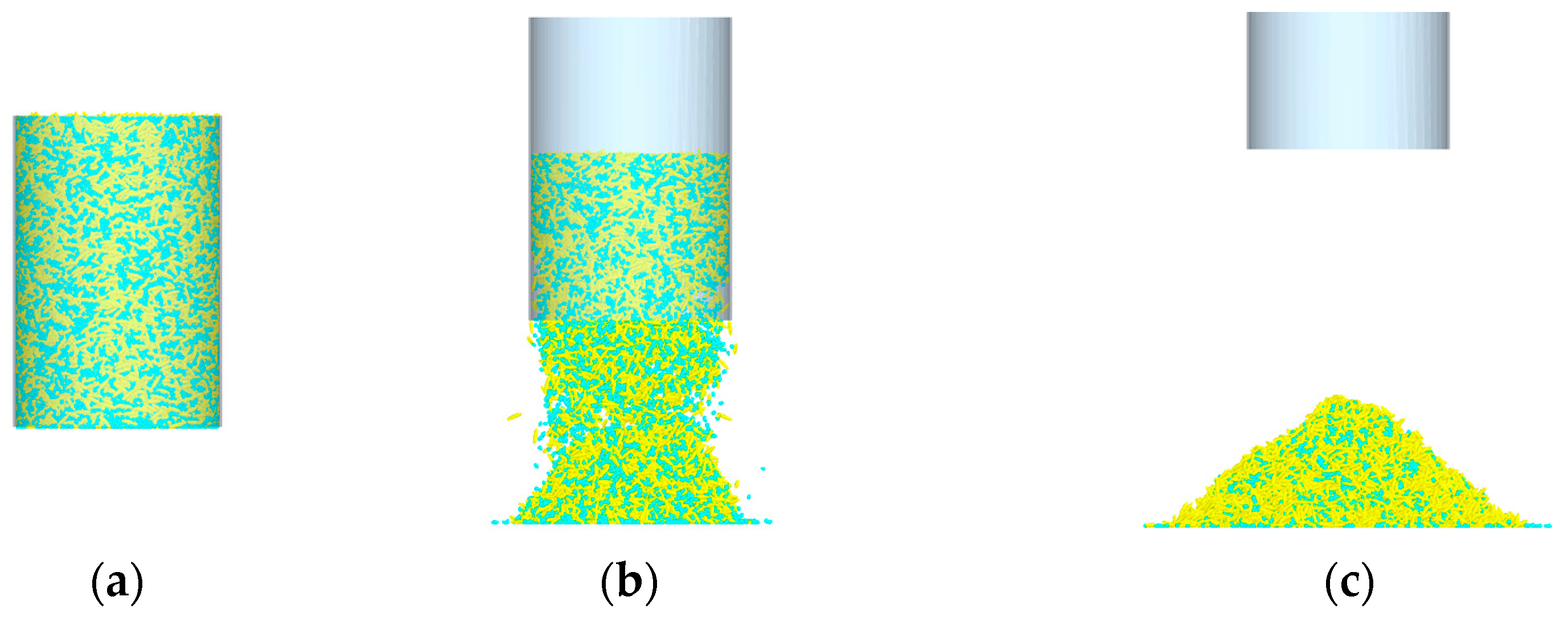

2.4.2. Simulation Deposition Test

3. Experiment and Result Analysis

3.1. Plackett–Burman Design

3.1.1. Plackett–Burman Design and Results

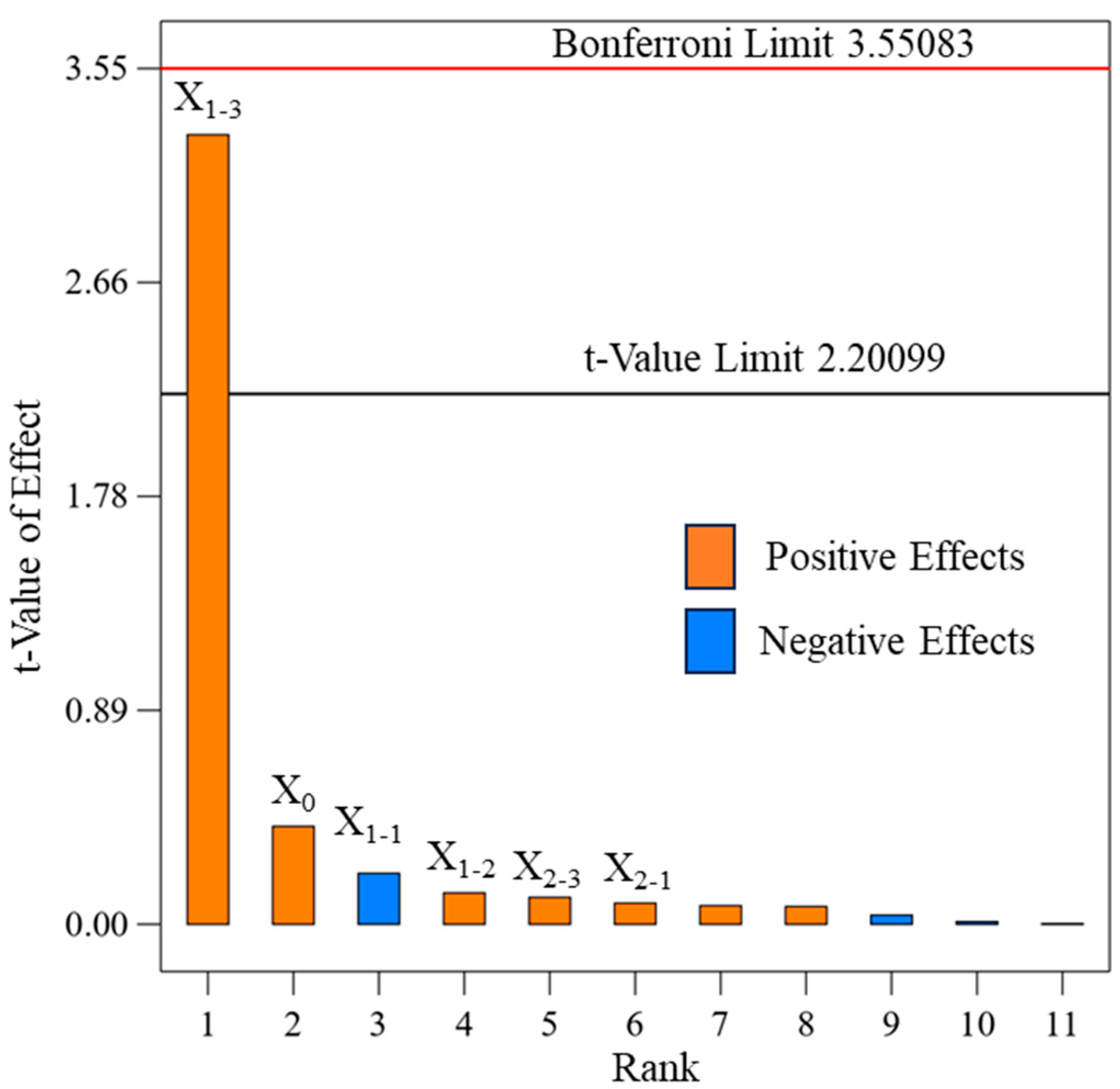

3.1.2. Analysis of Plackett-Burman Test Results

3.2. Steepest Ascent Experiment

3.3. Box–Behnken Design

3.3.1. Box–Behnken Design and Regression Model

3.3.2. Regression Model Interaction Response Analysis

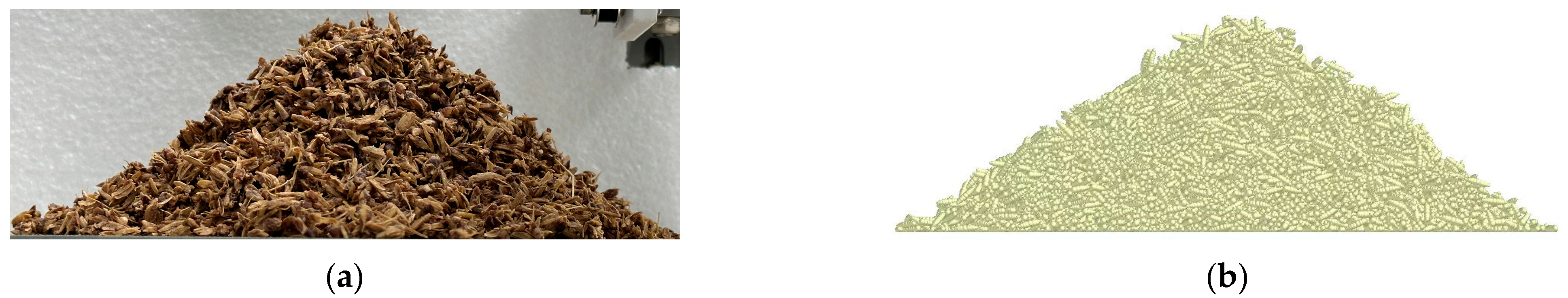

3.4. Validation Experiment

4. Discussion

- (1)

- Although the JKR model exhibits significant advantages in characterizing the interactions between highly cohesive particles, its computational cost remains a crucial factor that cannot be overlooked in practical applications. This model requires real-time coupled calculations of contact deformation and surface energy effects, leading to a substantial increase in computational complexity. In this study, considering that the rice husks are modeled using the multi-sphere assembly method and the large number of particles involved, in order to effectively improve the computational efficiency, we adopted the GPU parallel computing technology. Additionally, constructing the rice husk particles with a simplified hollow geometry model can reduce the computational memory usage by approximately 30%, significantly optimizing the computational performance. However, this simplified approach may cause the model to fail to fully consider the potential impact of the actual fiber structure of rice husks on the particle packing behavior.

- (2)

- This study focused on fermented grains from a single distillery; however, the generalizability of our model to other bio-materials and industrial contexts warrants careful consideration. While the Hertz–Mindlin with JKR contact model effectively captured the cohesive behavior of the specific fermented grains, its applicability may vary with different fermentation substrates, grain shapes, and moisture levels. For other fermentation substrates, materials with distinct physical properties (e.g., different surface energy, elasticity, and particle size distributions) may require re-calibration of model parameters. For instance, grains with higher moisture content typically exhibit stronger inter-particle adhesion, which could affect the accuracy of the current model.

5. Conclusions

- (1)

- A DEM of the fermented grains particle system was established using a multi-sphere clumping strategy. Specifically addressing the thin-walled structure of rice husks, a hollow geometric model was developed to construct its DEM representation, enabling the three-dimensional model to better approximate their true characteristics.

- (2)

- Three significant contact parameters—the surface energy, inter-particle collision restitution coefficient, and rolling friction coefficient—were identified via Plackett–Burman experimental design. Specifically, an 11-run gradient experimental design within the steepest ascent test framework was employed to determine optimal parameter ranges. The quadratic regression model constructed using Box–Behnken response surface methodology achieved a coefficient of determination (R2) of 0.9981 and a coefficient of variation (CV) as low as 0.34%.

- (3)

- The optimal solution was determined through parameter calibration: surface energy of 0.0429 J/m2, collision restitution coefficient of 0.183, and rolling friction coefficient of 0.216. The relative error of the angle of repose between physical experiments and simulation results was only 1.08%, with model validation errors significantly lower than the industry standard (<5%).

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jin, G.; Zhu, Y.; Xu, Y. Mystery behind Chinese liquor fermentation. Trends Food Sci. Technol. 2017, 63, 18–28. [Google Scholar] [CrossRef]

- Qiao, L.; Wang, J.; Wang, R.; Zhang, N.; Zheng, F. A review on flavor of Baijiu and other world-renowned distilled liquors. Food Chem. X 2023, 20, 100870. [Google Scholar] [CrossRef]

- Li, X.; Zhang, J.; Xue, Y.; Qiu, L. Classification of hops image based on ResNet-ConvLSTM and research of intelligent liquor picking system. Measurement 2022, 194, 110955. [Google Scholar] [CrossRef]

- Liu, X.; Gong, S.; Hua, X.; Chen, T.; Zhao, C. Research on temperature detection method of liquor distilling pot feeding operation based on a compressed algorithm. Sci. Rep. 2024, 14, 13292. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.; Chen, J.; Zhou, K.; Pang, Z. Industrial Robot Contouring Control Based on Non-Uniform Rational B-Spline Curve. Symmetry 2022, 14, 2533. [Google Scholar] [CrossRef]

- He, S.; Qian, C.; Jiang, Y.; Qin, W.; Huang, Z.; Huang, D.; Wang, Z.; Zang, Y. Design and optimization of the seed feeding device with DEM-CFD coupling approach for rice and wheat. Comput. Electron. Agric. 2024, 219, 108814. [Google Scholar] [CrossRef]

- Zhang, S.; Tekeste, M.Z.; Li, Y.; Gaul, A.; Zhu, D.; Liao, J. Scaled-up rice grain modelling for DEM calibration and the validation of hopper flow. Biosyst. Eng. 2020, 194, 196–212. [Google Scholar] [CrossRef]

- Fan, J.; Wang, H.; Sun, K.; Zhang, L.; Wang, L.; Zhao, J.; Yu, J. Experimental verification and simulation analysis of a multi-sphere modelling approach for wheat seed particles based on the discrete element method. Biosyst. Eng. 2024, 245, 135–151. [Google Scholar] [CrossRef]

- Ding, X.; Wang, B.; He, Z.; Shi, Y.; Li, K.; Cui, Y.; Yang, Q. Fast and precise DEM parameter calibration for Cucurbita ficifolia seeds. Biosyst. Eng. 2023, 236, 258–276. [Google Scholar] [CrossRef]

- Zhao, L.; Zhou, H.; Xu, L.; Song, S.; Zhang, C.; Yu, Q. Parameter calibration of coconut bran substrate simulation model based on discrete element and response surface methodology. Powder Technol. 2022, 395, 183–194. [Google Scholar] [CrossRef]

- Chen, Z.; Duan, A.; Liu, Y.; Zhao, H.; Dai, C.; Hu, S.; Lei, X.; Hu, J.; Chen, L. Discrete element contact model and parameter calibration of sticky particles and agglomerates. J. Terramechanics 2024, 116, 100998. [Google Scholar] [CrossRef]

- Balevičius, R.; Sielamowicz, I.; Mróz, Z.; Kačianauskas, R. Investigation of wall stress and outflow rate in a flat-bottomed bin: A comparison of the DEM model results with the experimental measurements. Powder Technol. 2011, 214, 322–336. [Google Scholar] [CrossRef]

- Xia, R.; Li, B.; Wang, X.; Li, T.; Yang, Z. Measurement and calibration of the discrete element parameters of wet bulk coal. Measurement 2019, 142, 84–95. [Google Scholar] [CrossRef]

- Chen, P.; Jia, F.; Han, Y.; Meng, X.; Li, A.; Chu, Y.; Zhao, H. Study on the segregation of brown rice and rice husks mixture in inclined chute flow. Powder Technol. 2022, 404, 117393. [Google Scholar] [CrossRef]

- Peiris, K.H.S.; Bean, S.R.; Tilley, M.; Jagadish, S.V.K. Analysis of sorghum content in corn-sorghum flour bioethanol feedstock by near infrared spectroscopy. J. Near Infrared Spectrosc. 2020, 28, 267–274. [Google Scholar] [CrossRef]

- Shi, J.; Shan, Z.; Yang, H. Research on the macro- and meso-mechanical properties of frozen sand mold based on Hertz-Mindlin with Bonding model. Particuology 2024, 88, 176–191. [Google Scholar] [CrossRef]

- Berry, N.; Zhang, Y.; Haeri, S. Contact models for the multi-sphere discrete element method. Powder Technol. 2023, 416, 118209. [Google Scholar] [CrossRef]

- Hærvig, J.; Kleinhans, U.; Wieland, C.; Spliethoff, H.; Jensen, A.; Sørensen, K.; Condra, T. On the adhesive JKR contact and rolling models for reduced particle stiffness discrete element simulations. Powder Technol. 2017, 319, 472–482. [Google Scholar] [CrossRef]

- Zhou, J.; Zhang, L.; Hu, C.; Li, Z.; Tang, J.; Mao, K.; Wang, X. Calibration of wet sand and gravel particles based on JKR contact model. Powder Technol. 2022, 397, 117005. [Google Scholar] [CrossRef]

- Elskamp, F.; Kruggel-Emden, H.; Hennig, M.; Teipel, U. A strategy to determine DEM parameters for spherical and non-spherical particles. Granul. Matter 2017, 19, 46. [Google Scholar] [CrossRef]

- Kruggel-Emden, H.; Rickelt, S.; Wirtz, S.; Scherer, V. A study on the validity of the multi-sphere Discrete Element Method. Powder Technol. 2008, 188, 153–165. [Google Scholar] [CrossRef]

- Gao, W.; Feng, Y.T.; Wang, C. A coupled isogeometric/multi-sphere discrete element approach for the contact interaction between irregular particles and structures. Powder Technol. 2023, 430, 118971. [Google Scholar] [CrossRef]

- Tahmasebi, P. A state-of-the-art review of experimental and computational studies of granular materials: Properties, advances, challenges, and future directions. Prog. Mater. Sci. 2023, 138, 101157. [Google Scholar] [CrossRef]

- Wan, Z.; Yang, S.; Hu, J.; Wang, H. DEM analysis of flow dynamics of cohesive particles in a rotating drum. Adv. Powder Technol. 2024, 35, 104379. [Google Scholar] [CrossRef]

- Scheffler, O.C.; Coetzee, C. DEM calibration for simulating bulk cohesive materials. Comput. Geotech. 2023, 161, 105476. [Google Scholar] [CrossRef]

- Rong, W.; Feng, Y.; Schwarz, P.; Yurata, T.; Witt, P.; Li, B.; Song, T.; Zhou, J. Sensitivity analysis of particle contact parameters for DEM simulation in a rotating drum using response surface methodology. Powder Technol. 2020, 362, 604–614. [Google Scholar] [CrossRef]

- Zhang, J.; Ding, W.; Wang, S.; Ha, X.; Zhang, L.; Zhao, Y.; Wu, W.; Zhao, M.; Zou, G.; Chen, Y. Pollution characteristics of microplastics in greenhouse soil profiles with the long-term application of organic compost. Resour. Environ. Sustain. 2024, 17, 100165. [Google Scholar] [CrossRef]

- Gong, F.; Hu, M.; Bao, A.; Li, D.; Gao, T.; Wang, C. Parameter Calibration and Significance Analysis of Rice Straw based on Hertz-Mindlin Model. J. Southwest Univ. (Nat. Sci. Ed.) 2022, 44, 186–196. [Google Scholar]

- Yang, G.; Zhang, F.; Zheng, L.; Wang, Z.; Kong, M.; Zhang, X. Tuber Physical Characteristics and Calibration of Discrete Element Simulation Parameters of Pinellia ternata. J. Agric. Sci. Technol. 2022, 24, 99–108. [Google Scholar]

- Müller, D.; Fimbinger, E.; Brand, C. Algorithm for the determination of the angle of repose in bulk material analysis. Powder Technol. 2021, 383, 598–605. [Google Scholar] [CrossRef]

- Kajiyama, S.; Nakata, Y.; Nakase, H. Proposal of Sidewall Velocity-Controlled Cylindrical Angle of Repose Measurement Apparatus. Geotech. Test. J. 2025, 48, 229–242. [Google Scholar] [CrossRef]

- Al-Hashemi, H.M.B.; Al-Amoudi, O.S.B. A review on the angle of repose of granular materials. Powder Technol. 2018, 330, 397–417. [Google Scholar] [CrossRef]

- Tang, X.; Liu, S.; Xiang, Q.; Cheng, J.; He, H.; Xue, B. Facial Expression Recognition Based on Dual-Channel Fusion with Edge Features. Symmetry 2022, 14, 2651. [Google Scholar] [CrossRef]

- Ding, X.; Wei, Y.; Yan, Z.; Zhu, Y.; Cao, D.; Li, K.; He, Z.; Cui, Y. Simulation and Experiment of the Spiral Digging End-Effector for Hole Digging in Plug Tray Seedling Substrate. Agronomy 2022, 12, 779. [Google Scholar] [CrossRef]

- Xie, C.; Yang, J.; Wang, B.; Zhuo, P.; Li, C.; Wang, L. Parameter calibration for the discrete element simulation model of commercial organic fertilizer. Int. Agrophys. 2021, 35, 107–117. [Google Scholar] [CrossRef]

| EDEM Parameters | Materials | Value | Materials | Value |

|---|---|---|---|---|

| Density/(kg/m3) | Particle | 853 | Steel | 7930 |

| Poisson’s Ratio | 0.32 | 0.29 | ||

| Shear Modulus/Pa | 5 × 107 | 7.7 × 1010 | ||

| Coefficient of Restitution | Particle–Particle | 0.15–0.35 | Particle–Steel | 0.15–0.35 |

| Coefficient of Static Friction | 0.8–1.2 | 0.73 | ||

| Coefficient of Rolling Friction | 0.1–0.25 | 0.1–0.25 | ||

| Surface Energy/(J/m2) | 0.02–0.05 | / |

| Symbol | Parameters | Parameter Level | ||

|---|---|---|---|---|

| Low Level | High Level | |||

| X0 | Particle–Particle | Surface energy/(J/m2) | 0.02 | 0.05 |

| X1-1 | Coefficient of restitution | 0.15 | 0.35 | |

| X1-2 | Coefficient of static friction | 0.8 | 1.2 | |

| X1-3 | Coefficient of rolling friction | 0.1 | 0.25 | |

| X2-1 | Particle–Steel | Coefficient of restitution | 0.15 | 0.35 |

| X2-3 | Coefficient of rolling friction | 0.1 | 0.25 | |

| NO. | X0 | X1-1 | X1-2 | X1-3 | X2-1 | X2-3 | Resting Angle/° |

|---|---|---|---|---|---|---|---|

| 1 | 0.05 | 0.35 | 0.8 | 0.1 | 0.15 | 0.25 | 23.48 |

| 2 | 0.02 | 0.35 | 1.2 | 0.1 | 0.35 | 0.25 | 22.62 |

| 3 | 0.05 | 0.35 | 0.8 | 0.25 | 0.35 | 0.25 | 41.09 |

| 4 | 0.05 | 0.15 | 1.2 | 0.25 | 0.15 | 0.25 | 43.36 |

| 5 | 0.02 | 0.15 | 1.2 | 0.1 | 0.35 | 0.25 | 23.31 |

| 6 | 0.02 | 0.15 | 0.8 | 0.1 | 0.15 | 0.1 | 22.47 |

| 7 | 0.02 | 0.35 | 0.8 | 0.25 | 0.35 | 0.1 | 38.77 |

| 8 | 0.05 | 0.15 | 0.8 | 0.1 | 0.35 | 0.1 | 24.25 |

| 9 | 0.05 | 0.35 | 1.2 | 0.1 | 0.15 | 0.1 | 23.11 |

| 10 | 0.02 | 0.15 | 0.8 | 0.25 | 0.15 | 0.25 | 38.83 |

| 11 | 0.05 | 0.15 | 1.2 | 0.25 | 0.35 | 0.1 | 42.05 |

| 12 | 0.02 | 0.35 | 1.2 | 0.25 | 0.15 | 0.1 | 38.53 |

| NO. | Sum of Squares | Standardization Effect | F | p | Significance Sort |

|---|---|---|---|---|---|

| X0 | 13.67 | 2.135 | 28.57 | 0.0031 | 2 |

| X1-1 | 3.71 | −1.112 | 7.75 | 0.0387 | 3 |

| X1-2 | 1.39 | 0.682 | 2.91 | 0.1486 | 4 |

| X1-3 | 890.79 | 17.231 | 1861.42 | <0.0001 | 1 |

| X2-1 | 0.44 | 0.385 | 0.93 | 0.3793 | 6 |

| X2-3 | 1.03 | 0.585 | 2.15 | 0.2029 | 5 |

| R2 = 0.9974, R2adj = 0.9942, CV = 2.17%, Adeq Precision = 39.0522 | |||||

| NO. | X0 | X1-1 | X1-2 | X1-3 | X2-1 | X2-3 | Resting Angle/° | Relative Error/% |

|---|---|---|---|---|---|---|---|---|

| 1 | 0.02 | 0.35 | 1.0 | 0.1 | 0.25 | 0.175 | 22.73 | 37.58 |

| 2 | 0.023 | 0.33 | 1.0 | 0.115 | 0.25 | 0.175 | 24.72 | 32.11 |

| 3 | 0.026 | 0.31 | 1.0 | 0.13 | 0.25 | 0.175 | 26.01 | 28.57 |

| 4 | 0.029 | 0.29 | 1.0 | 0.145 | 0.25 | 0.175 | 27.75 | 23.79 |

| 5 | 0.032 | 0.27 | 1.0 | 0.16 | 0.25 | 0.175 | 30.09 | 17.36 |

| 6 | 0.035 | 0.25 | 1.0 | 0.175 | 0.25 | 0.175 | 31.29 | 14.07 |

| 7 | 0.038 | 0.23 | 1.0 | 0.19 | 0.25 | 0.175 | 33.36 | 8.38 |

| 8 | 0.041 | 0.21 | 1.0 | 0.205 | 0.25 | 0.175 | 35.17 | 3.41 |

| 9 | 0.044 | 0.19 | 1.0 | 0.22 | 0.25 | 0.175 | 37.02 | 1.67 |

| 10 | 0.047 | 0.17 | 1.0 | 0.235 | 0.25 | 0.175 | 40.34 | 10.79 |

| 11 | 0.05 | 0.15 | 1.0 | 0.25 | 0.25 | 0.175 | 42.08 | 15.57 |

| NO. | X0 | X1-1 | X1-3 | Resting Angle/° | Relative Error/% |

|---|---|---|---|---|---|

| 1 | 0.044 | 0.19 | 0.22 | 37.07 | 1.8 |

| 2 | 0.044 | 0.19 | 0.22 | 36.98 | 1.56 |

| 3 | 0.044 | 0.19 | 0.22 | 36.94 | 1.39 |

| 4 | 0.041 | 0.19 | 0.235 | 40.01 | 9.88 |

| 5 | 0.047 | 0.19 | 0.205 | 35.78 | 1.74 |

| 6 | 0.044 | 0.21 | 0.205 | 35.53 | 2.42 |

| 7 | 0.044 | 0.17 | 0.235 | 40.12 | 10.18 |

| 8 | 0.047 | 0.21 | 0.22 | 37.22 | 2.22 |

| 9 | 0.041 | 0.17 | 0.22 | 36.85 | 1.2 |

| 10 | 0.041 | 0.19 | 0.205 | 35.29 | 3.08 |

| 11 | 0.047 | 0.17 | 0.22 | 37.61 | 3.29 |

| 12 | 0.041 | 0.21 | 0.22 | 36.74 | 0.9 |

| 13 | 0.044 | 0.21 | 0.235 | 39.78 | 9.25 |

| 14 | 0.044 | 0.17 | 0.205 | 35.66 | 2.07 |

| 15 | 0.047 | 0.19 | 0.235 | 40.51 | 11.25 |

| Source | Sum of Squares | F | p |

|---|---|---|---|

| Model | 44.30 | 288.69 | <0.0001 ** |

| X0 | 0.62 | 36.46 | 0.0018 * |

| X1-1 | 0.12 | 6.90 | 0.0467 * |

| X1-3 | 41.22 | 2418.02 | <0.0001 ** |

| X0X1-1 | 0.02 | 1.15 | 0.3326 |

| X0X1-3 | 0.00 | 0.00 | 0.9709 |

| X1-1X1-3 | 0.01 | 0.65 | 0.4578 |

| X02 | 0.05 | 2.95 | 0.1466 |

| X1-12 | 0.00 | 0.02 | 0.9072 |

| X1-32 | 2.27 | 133.18 | <0.0001 ** |

| Residual | 0.0852 | ||

| Lack of fit | 0.0764 | 5.74 | 0.1519 |

| Pure Error | 0.0089 | ||

| R2 = 0.9981, R2adj = 0.9946, CV = 0.3484%, Adeq Precision = 47.8178 | |||

| DEM Parameters | Particle–Particle | Particle–Steel |

|---|---|---|

| Coefficient of restitution | 0.183 | 0.25 |

| Coefficient of static friction | 1.0 | 0.73 |

| Coefficient of rolling friction | 0.216 | 0.175 |

| Surface energy/J/m2 | 0.0429 | / |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Chen, T.; Gong, S.; Xu, H.; Zhao, C. Parameter Calibration and Experimental Validation of Fermented Grain Particles During the Loading Process Based on the Discrete Element Model. Symmetry 2025, 17, 729. https://doi.org/10.3390/sym17050729

Liu X, Chen T, Gong S, Xu H, Zhao C. Parameter Calibration and Experimental Validation of Fermented Grain Particles During the Loading Process Based on the Discrete Element Model. Symmetry. 2025; 17(5):729. https://doi.org/10.3390/sym17050729

Chicago/Turabian StyleLiu, Xiaolian, Taotao Chen, Shaopeng Gong, Hairui Xu, and Chunjiang Zhao. 2025. "Parameter Calibration and Experimental Validation of Fermented Grain Particles During the Loading Process Based on the Discrete Element Model" Symmetry 17, no. 5: 729. https://doi.org/10.3390/sym17050729

APA StyleLiu, X., Chen, T., Gong, S., Xu, H., & Zhao, C. (2025). Parameter Calibration and Experimental Validation of Fermented Grain Particles During the Loading Process Based on the Discrete Element Model. Symmetry, 17(5), 729. https://doi.org/10.3390/sym17050729