Structural Damage Identification Using Data Fusion and Optimization of the Self-Adaptive Differential Evolution Algorithm

Abstract

1. Introduction

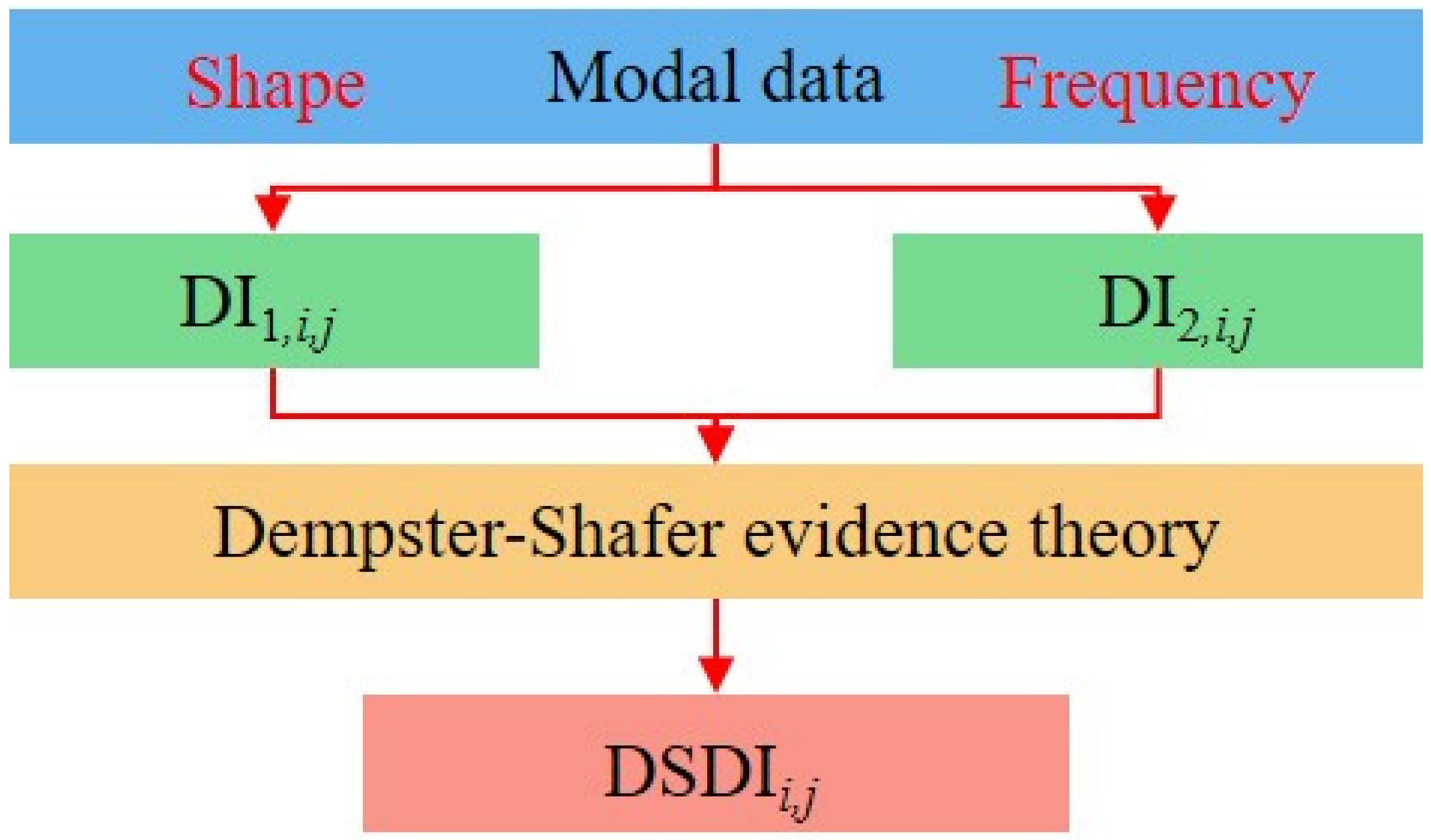

2. Basic Concepts and Definition of Damage Indicators

2.1. Curvature Modal

2.2. Definition of Damage Indicators

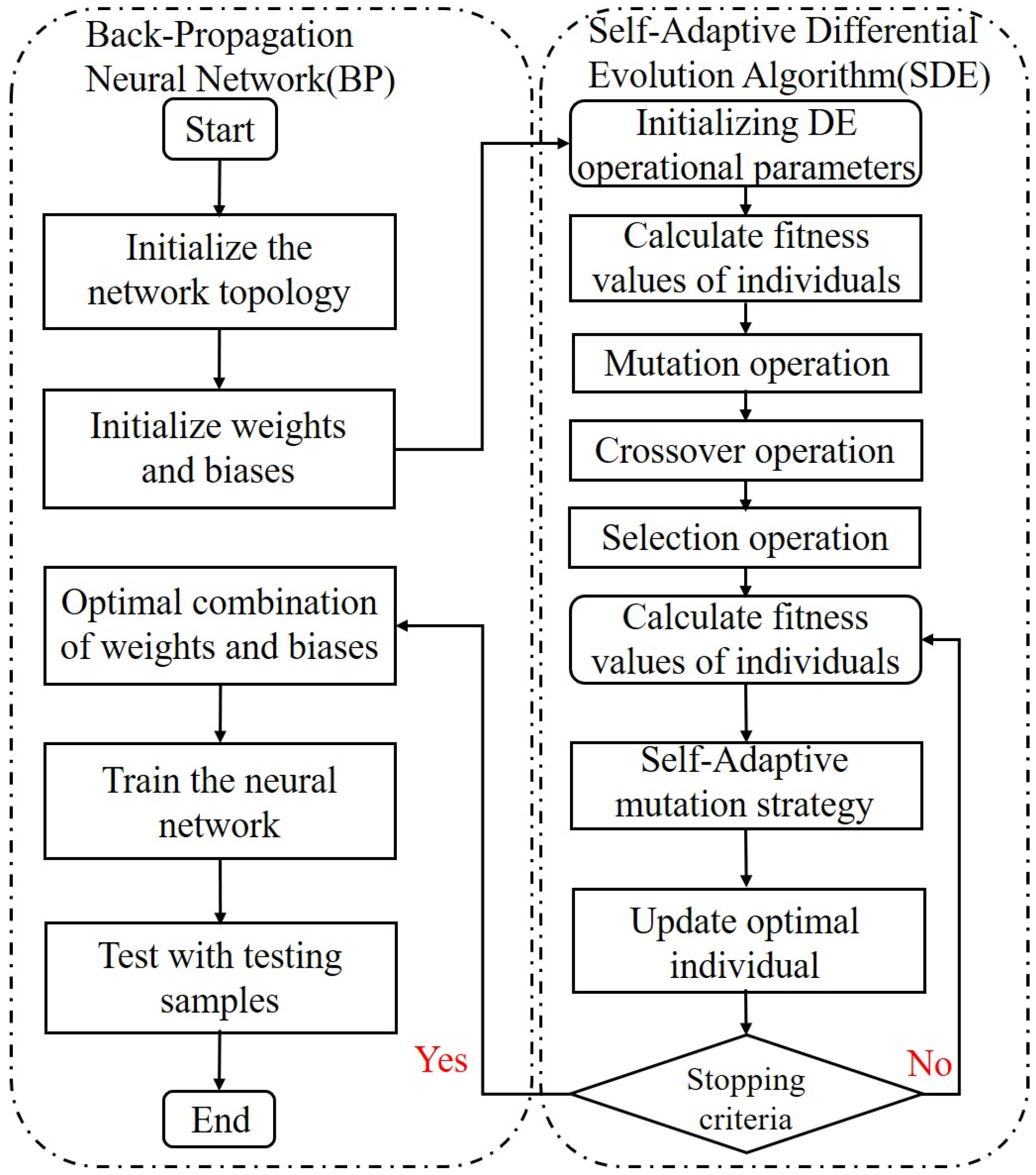

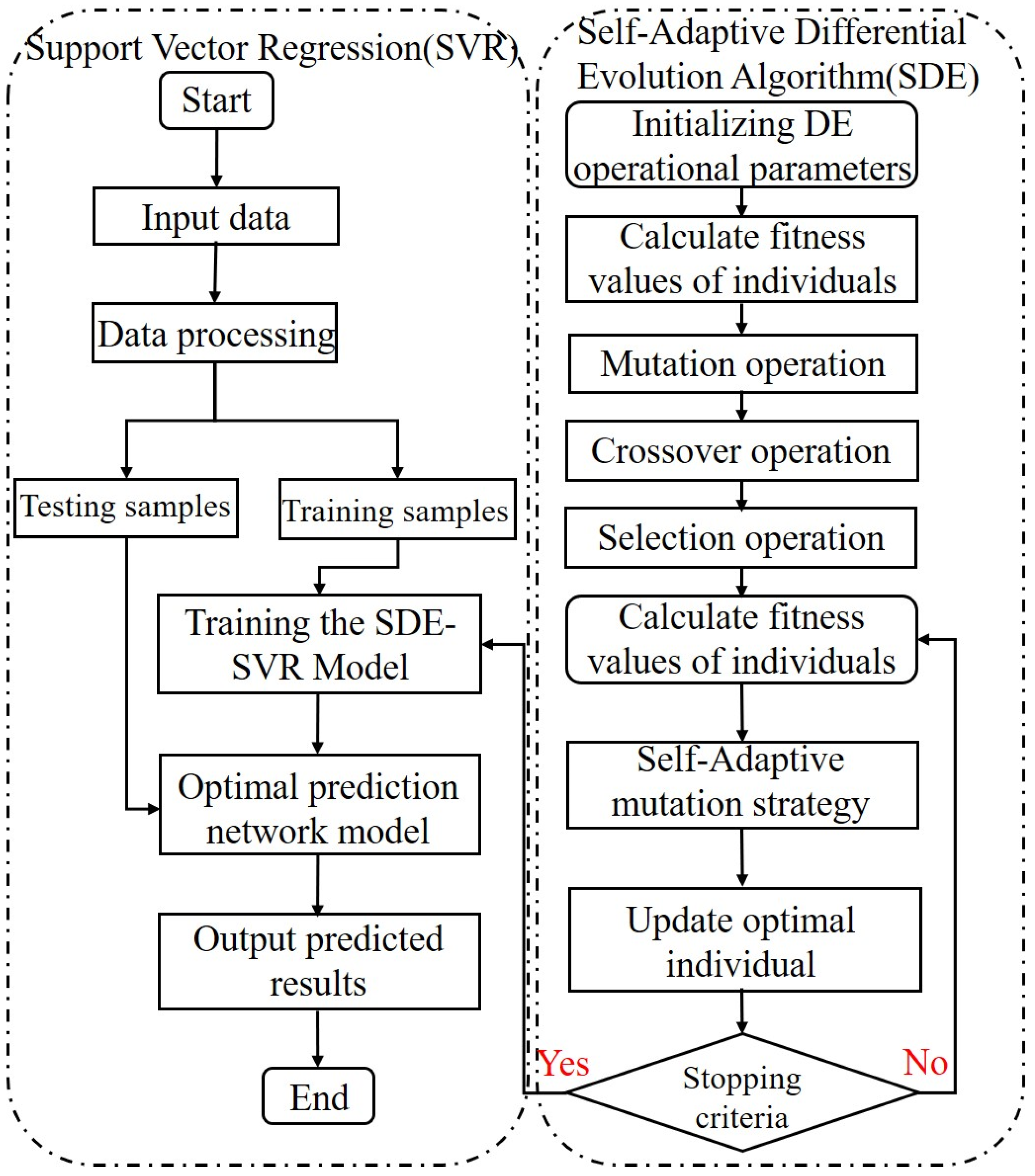

2.3. Optimizing the BP and SVR Using a Self-Adaptive Differential Evolution Algorithm

2.3.1. Backpropagation Neural Network

2.3.2. Support Vector Regression Method

2.3.3. The Differential Evolution Algorithm

2.3.4. The SDE-BP and SDE-SVR Algorithms

3. Surrogate Model of a Simply Supported Beam

4. Damage Identification of a Simply Supported Beam

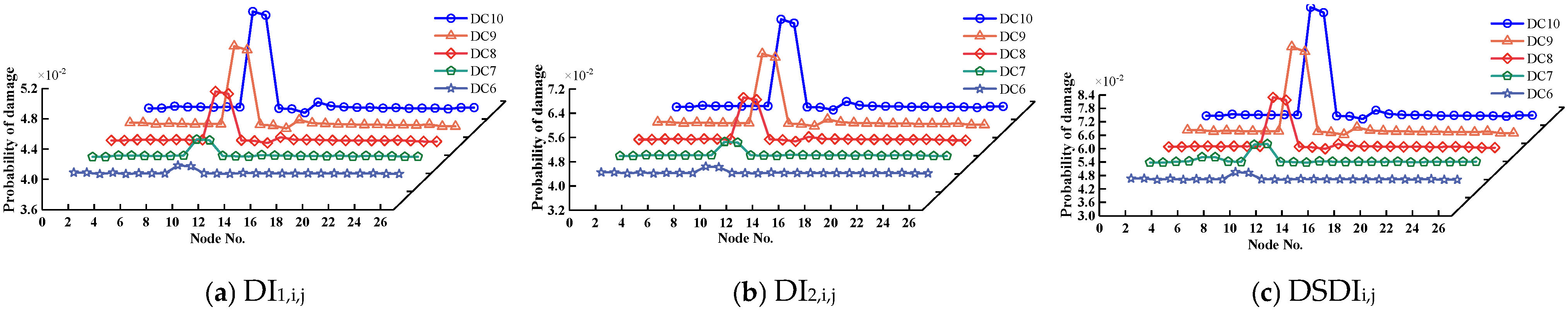

4.1. Damage Localization of a Simply Supported Beam

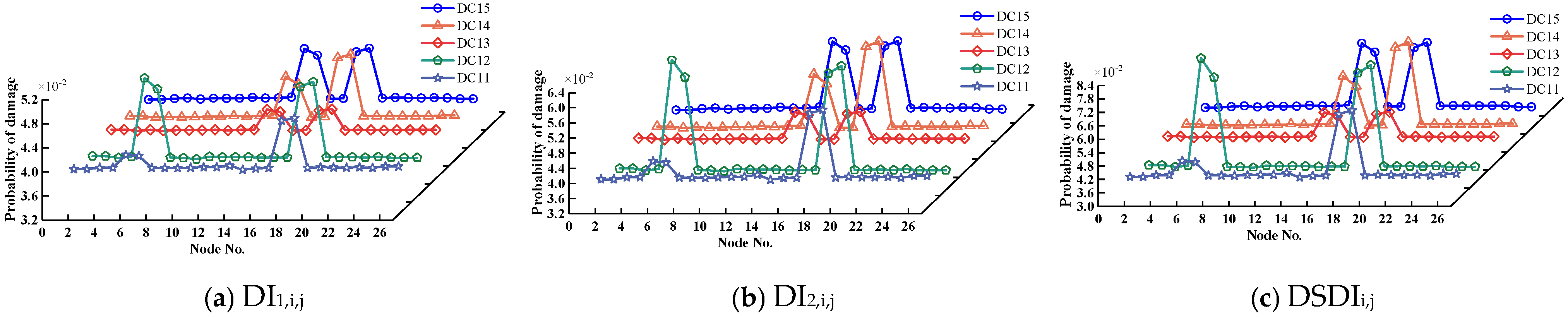

- (1)

- Single Damage Scenarios: The indicators DI1,i,j, DI2,i,j, and DSDIi,j accurately identify the damage location, with the peak value occurring at the damage site. As the damage increases, the severity also rises proportionally. All three indicators effectively reflect the severity of the damage qualitatively.

- (2)

- Comparing Damage Locations: When the same level of damage occurs at different locations, the peak values at each damage site are nearly identical. The DSDIi,j indicator exhibits the largest peak, followed by DI2,i,j, with DI1,i,j showing the smallest peak. All indicators provide an initial assessment of the relative damage levels at the affected elements.

- (3)

- Multiple Damage Scenarios: In cases of multiple damage scenarios, when different elements undergo varying or identical levels of damage, the damage indicators remain unaffected by the different damage levels or units.

- (4)

- Comparison with Curvature Mode Indicators: When comparing the damage identification results, DI1,i,j, DI2,i,j, and DSDIi,j all outperform the curvature mode indicators. They effectively address the large errors near displacement mode inflection points and the lower stability of higher-order curvature modes compared to lower-order modes, demonstrating superior performance in damage identification.

- (5)

- Integration Using D-S Evidence Theory: After integrating multi-source information with D-S evidence theory, the peak values of the damage locations are significantly enhanced, and interference from non-damaged locations is effectively suppressed. This integration substantially improves the accuracy of damage identification. It overcomes the limited sensitivity of the first two indicators in detecting minor damage and constructs the high-accuracy DSDIi,j indicator, providing a more reliable reference for structural damage identification.

4.2. Influence of Measurement Noise

- (1)

- Noise Impact on Damage Indicators: As shown in Figure 8c and Figure 10a, after introducing noise to nodes 5 and 6 in Condition 11, the peak probabilities of the damage identification indicators (DI1,i,j, DI2,i,j, and DSDIi,j) at the damage locations slightly decrease, while the peak probabilities at non-damaged locations increase. This suggests that noise negatively affects the performance of the indicators in damage recognition.

- (2)

- Comparison of Indicators’ Noise Robustness: As depicted in Figure 10a,b, for indicator DI1,i,j, the peak values at nodes 5 and 6 in Condition 11 before noise introduction are 0.039805 and 0.039625, respectively. After adding 1% noise, these values decrease to 0.039284 and 0.039427, respectively. For indicator DI2,i,j, under the same condition, the peak values before noise addition are 0.041058 and 0.040685, respectively, and, after adding noise, the values become 0.040687 and 0.040517. Therefore, the noise robustness of DI2,i,j is stronger than that of DI1,i,j, although both indicators exhibit consistent damage recognition performance.

- (3)

- Impact of D-S Data Fusion: As shown in Figure 10c,d, compared to before fusion, the DSDIi,j indicator after D-S data fusion exhibits a higher peak probability at the damage location under the same damage and noise conditions, with less sensitivity to noise interference.

4.3. Damage Quantification of a Simply Supported Beam

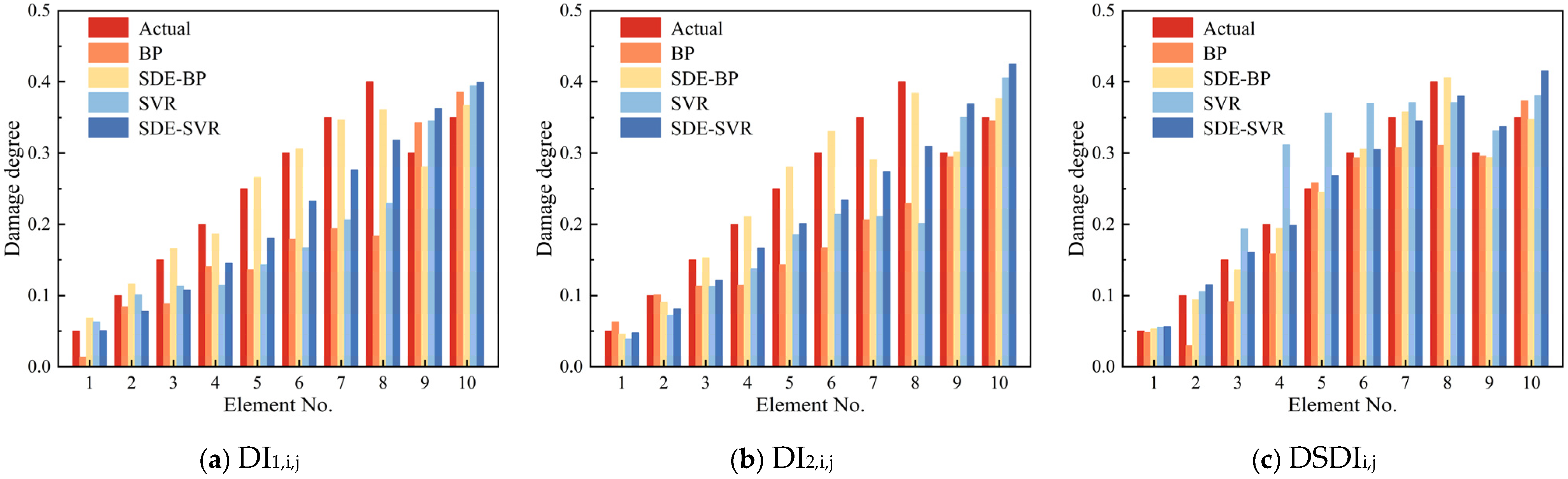

- (1)

- The performance of the BP and SDE-BP algorithms on the damage identification indices DI1,i,j, DI2,i,j, and the data fusion index DSDIi,j demonstrates that SDE-BP significantly outperforms BP. Specifically, the accuracy of SDE-BP for DI1,i,j increased from 63.55% to 89.95%, with the MAE and RMSE reduced to 0.01926 and 0.02576, respectively. For DI2,i,j, accuracy improved to 92.26%, with the MAE and RMSE decreasing to 0.01662 and 0.01815. For DSDIi,j, accuracy reached 96.54%, with the MAE and RMSE reduced to 0.00628 and 0.00693. Similar enhancements were observed in SVR neural networks following SDE optimization, confirming the generalized efficacy of the SDE framework for algorithmic improvement.

- (2)

- A comparison of predicted and actual damage severity values using BP and SVR reveals significant fluctuations in relative error, indicating suboptimal prediction performance. However, after SDE optimization, the relative error stabilizes considerably, further validating the effectiveness of the SDE optimization algorithm.

- (3)

- A comprehensive comparative evaluation of six machine learning architectures (SDE-BP, SDE-SVR, DE-BP, DE-SVR, BP, SVR) reveals that the proposed SDE-BP framework demonstrates superior predictive capability across all evaluation metrics (DI1,i,j, DI2,i,j, DSDIᵢ,ⱼ), achieving peak accuracy values of 89.98%, 92.26%, and 96.54%, respectively. Although optimization occasionally results in lower accuracy for different indicators, the optimized algorithm generally outperforms the SDE pre-optimized version in terms of accuracy when evaluated on the same indicator.

- (4)

- The adaptive mutation operator in SDE enables dynamic balance between global exploration and local exploitation. This contrasts with DE’s fixed mutation strategy, which exhibits slower convergence and higher probability of premature convergence to suboptimal solutions.

- (5)

- SDE-SVR achieves convergence in 21 iterations (RMSE = 0.02685) compared to DE-SVR’s 25 iterations (RMSE = 0.04958), representing 16.00% faster convergence rate and 5.67% higher final accuracy (88.57% vs. 83.55%). These metrics collectively demonstrate significantly enhanced optimization efficiency through SDE implementation.

- (1)

- The SDE-optimized models (SDE-BP and SDE-SVR) exhibit superior performance in terms of the MAE and RMSE. Specifically, SDE-BP achieves an exceptionally low MAE of 0.00628 and RMSE of 0.00693, whereas XGBoost yields significantly higher errors (MAE = 0.03041, RMSE = 0.02315), indicating reduced accuracy in damage identification. Regarding classification accuracy, SDE-BP attains 96.54%, outperforming CNN (90.35%) and LSTM (91.57%). Although CNN and LSTM improve upon XGBoost, their longer training times remain a drawback.

- (2)

- In terms of training time, SDE-BP completes training in just 360.83 s, substantially faster than LSTM (520.89 s) and the CNN (480.73 s). SDE-SVR also performs efficiently, requiring 380.42 s for training and just 0.18 s for prediction, striking a favorable balance between accuracy and computational cost. In contrast, the CNN and LSTM demand significantly higher computational resources, with training times of 480.73 s and 520.89 s, respectively.

4.4. Sensitivity Analysis and Computational Efficiency

4.4.1. Sensitivity Analysis

4.4.2. Computational Efficiency and Accuracy

5. Experimental Validation

5.1. Experimental Setup

5.2. Experimental Results

- (1)

- The damage identification indicators DI1,i,j, DI2,i,j, and DSDIi,j can accurately detect varying levels of damage at different locations on the experimental beam, including single, two-point, and multi-point damage scenarios. Furthermore, the damage severity is positively correlated with the peak value.

- (2)

- After D-S data fusion, the peak value probability at the damage locations increased, while the peak interference at non-damaged locations decreased. At non-damaged positions, fluctuations in the peak value were observed to varying extents, possibly due to environmental factors, measurement errors, or other influencing variables. However, these fluctuations did not significantly affect the damage identification accuracy.

6. Conclusions

- (1)

- The proposed indicators DI1,i,j, DI2,i,j, and DSDIi,j accurately identify single-location and multi-location damage on the simply supported beam. Compared to the first two indicators, the fused indicator DSDIi,j demonstrates superior recognition performance and robustness.

- (2)

- The accuracy of the damage identification improves, and the error rate decreases with the use of SDE-optimized BP and SVR algorithms, enabling the high-precision prediction of damage levels on the simply supported beam.

- (3)

- The damage identification indicators DI1,i,j, DI2,i,j, and DSDIi,j accurately detect varying damage levels under different conditions, with peak values positively correlated to damage severity. The experimental results confirm that the proposed method performs effectively in the engineering context of the simply supported beam.

- (1)

- Extend this method to truss and continuous beam bridges, focusing on optimizing sensor networks for complex geometries, recalibrating modal weights for boundary condition sensitivity, and improving computational efficiency for large-scale systems.

- (2)

- Validate the adaptability of the proposed method. Although this study centers on steel beams, its reliance on stiffness-dependent curvature modes and adaptive optimization principles suggests broader applicability to concrete and composite structures.

- (3)

- Validate the feasibility of implementing our method in real-time SHM systems.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yan, A.; Golinval, J.C. Structural Damage Localization by Combining Flexibility and Stiffness Methods. Eng. Struct. 2005, 27, 1752–1761. [Google Scholar] [CrossRef]

- Yang, Q.W.; Sun, B.X. Structural Damage Identification Based on Best Achievable Flexibility Change. Appl. Math. Modell. 2011, 35, 5217–5224. [Google Scholar] [CrossRef]

- Lee, E.T.; Eun, H.C. Damage Identification of a Frame Structure Model Based on the Response Variation Depending on Additional Mass. Eng. Comput. 2015, 31, 737–747. [Google Scholar] [CrossRef]

- Hou, J.; Li, Z.; Zhang, Q.; Jankowski, Ł.; Zhang, H. Local Mass Addition and Data Fusion for Structural Damage Identification Using Approximate Models. Int. J. Struct. Stab. Dyn. 2020, 20, 2050124. [Google Scholar] [CrossRef]

- Pandey, A.K.; Biswas, M.; Samman, M.M. Damage Detection from Changes in Curvature Mode Shapes. J. Sound Vib. 1991, 145, 321–332. [Google Scholar] [CrossRef]

- Ren, X.; Meng, Z. Damage Identification for Timber Structure Using Curvature Mode and Wavelet Transform. Structures 2024, 60, 105798. [Google Scholar] [CrossRef]

- Huang, T.; Liang, T.; Chen, L. A Comparative Analysis of Damage Identification Methods Based on Multi-Channel Data Fusion and Convolutional Neural Network for Frame Structures. Structures 2024, 61, 106076. [Google Scholar] [CrossRef]

- Jaramillo, V.H.; Ottewill, J.R.; Dudek, R.; Lepiarczyk, D.; Pawlik, P. Condition Monitoring of Distributed Systems Using Two-Stage Bayesian Inference Data Fusion. Mech. Syst. Signal Proc. 2017, 87, 91–110. [Google Scholar] [CrossRef]

- Sadeghi, F.; Yu, Y.; Zhu, X.; Li, J. Damage Identification of Steel-Concrete Composite Beams Based on Modal Strain Energy Changes Through General Regression Neural Network. Eng. Struct. 2021, 244, 112824. [Google Scholar] [CrossRef]

- Li, M.; Jia, D.; Wu, Z.; Qiu, S.; He, W. Structural Damage Identification Using Strain Mode Differences by the iFEM Based on the Convolutional Neural Network (CNN). Mech. Syst. Signal Proc. 2022, 165, 108289. [Google Scholar] [CrossRef]

- Miao, B.; Wang, M.; Yang, S.; Luo, Y.; Yang, C. An Optimized Damage Identification Method of Beam Using Wavelet and Neural Network. Engineering 2020, 12, 748. [Google Scholar] [CrossRef]

- Ghiasi, R.; Torkzadeh, P.; Noori, M. A Machine-Learning Approach for Structural Damage Detection Using Least Square Support Vector Machine Based on a New Combinational Kernel Function. Struct. Health Monit. 2016, 15, 302–316. [Google Scholar] [CrossRef]

- Yan, B.; Cui, Y.; Zhang, L.; Zhang, C.; Yang, Y.; Bao, Z.; Ning, G. Beam Structure Damage Identification Based on BP Neural Network and Support Vector Machine. Math. Prob. Eng. 2014, 2014, 850141. [Google Scholar] [CrossRef]

- Dessi, D.; Camerlengo, G. Damage Identification Techniques via Modal Curvature Analysis: Overview and Comparison. Mech. Syst. Signal Proc. 2015, 52, 181–205. [Google Scholar] [CrossRef]

- Guyon, I.; Elisseeff, A. An Introduction to Variable and Feature Selection. J. Mach. Learn. Res. 2003, 3, 1157–1182. [Google Scholar] [CrossRef]

- Dempster, A.P. Upper and Lower Probabilities Induced by a Multivalued Mapping. Ann. Math. Stat. 1967, 38, 325–339. [Google Scholar] [CrossRef]

- Bao, Y.; Li, H.; An, Y.; Ou, J. Dempster–Shafer Evidence Theory Approach to Structural Damage Detection. Struct. Health Monit. 2012, 11, 13–26. [Google Scholar] [CrossRef]

- Storn, R.; Price, K. Differential Evolution—A Simple and Efficient Heuristic for Global Optimization over Continuous Spaces. J. Glob. Optim. 1997, 11, 341–359. [Google Scholar] [CrossRef]

- Pant, M.; Zaheer, H.; Garcia-Hernandez, L.; Abraham, A. Differential Evolution: A Review of More Than Two Decades of Research. Eng. Appl. Artif. Intell. 2020, 90, 103479. [Google Scholar] [CrossRef]

- Wang, L.; Zeng, Y.; Chen, T. Back Propagation Neural Network with Adaptive Differential Evolution Algorithm for Time Series Forecasting. Expert Syst. Appl. 2015, 42, 855–863. [Google Scholar] [CrossRef]

- Leema, N.; Nehemiah, H.K.; Kannan, A. Neural Network Classifier Optimization Using Differential Evolution with Global Information and Back Propagation Algorithm for Clinical Datasets. Appl. Soft Comput. 2016, 49, 834–844. [Google Scholar] [CrossRef]

- Ding, Y.; Yao, X.; Wang, S.; Zhao, X. Structural Damage Assessment Using Improved Dempster-Shafer Data Fusion Algorithm. Earthq. Eng. Eng. Vibr. 2019, 18, 395–408. [Google Scholar] [CrossRef]

- Fan, W.; Qiao, P. Vibration-Based Damage Identification Methods: A Review and Comparative Study. Struct. Health Monit. 2011, 10, 83–111. [Google Scholar] [CrossRef]

| Damage Condition | Damage Element No. | Damage Index | Damage Degree (%) |

|---|---|---|---|

| 1, 2, 3, 4, 5 | 5 | DI1,i,j, DI2,i,j, DSDIi,j | 10, 15, 20, 30, 40 |

| 6, 7, 8, 9, 10 | 9 | DI1,i,j, DI2,i,j, DSDIi,j | 5, 10, 25, 35, 40 |

| 11, 12 | 5–17 | DI1,i,j, DI2,i,j, DSDIi,j | 10–30, 40–40 |

| 13, 14, 15 | 13–17 | DI1,i,j, DI2,i,j, DSDIi,j | 15–15, 25–35, 30–30 |

| 16, 17 | 9–13–17 | DI1,i,j, DI2,i,j, DSDIi,j | 10–20–30, 15–25–35 |

| 18, 19, 20 | 9–13–21 | DI1,i,j, DI2,i,j, DSDIi,j | 15–15–15, 25–25–25, 40–40–40 |

| Frequency | 1st-Order Frequency | 2nd-Order Frequency | 3rd-Order Frequency | |

|---|---|---|---|---|

| Damage Condition | ||||

| Non-DC | 1.7468 | 7.0401 | 16.0408 | |

| DC1 | 1.7428 | 6.9855 | 15.8230 | |

| DC2 | 1.7415 | 6.9707 | 15.7840 | |

| DC3 | 1.7400 | 6.9543 | 15.7410 | |

| Damage Condition | Damage Element No. | Damage Degree (%) |

|---|---|---|

| 1–8 | 5 | 5, 10, 15, 20, 25, 30, 35, 40 |

| 9–16 | 9 | 5, 10, 15, 20, 25, 30, 35, 40 |

| 17–24 | 13 | 5, 10, 15, 20, 25, 30, 35, 40 |

| 25–32 | 17 | 5, 10, 15, 20, 25, 30, 35, 40 |

| 41 | 5–17 | 10–30 |

| 42 | 5–17 | 25–35 |

| 44 | 9–13–17 | 10–20–30 |

| 45 | 9–13–17 | 15–25–35 |

| Damage Condition | Damaged Element No. | Damage Degree (%) |

|---|---|---|

| 33–40 | 21 | 5, 10, 15, 20, 25, 30, 35, 40 |

| 43 | 9–13 | 30–30 |

| 46 | 9–13–21 | 35–35–35 |

| Damage Index | BP Algorithm | SVR Algorithm | ||||

|---|---|---|---|---|---|---|

| MAE | RMSE | Accuracy Rate | MAE | RMSE | Accuracy Rate | |

| DI1,i,j | 0.08582 | 0.10536 | 63.55% | 0.07004 | 0.09364 | 73.23% |

| DI2,i,j | 0.07013 | 0.09363 | 73.23% | 0.06408 | 0.08763 | 74.69% |

| DSDIi,j | 0.03475 | 0.04545 | 81.82% | 0.04293 | 0.05695 | 80.95% |

| Damage Index | DE-BP Algorithm | DE-SVR Algorithm | ||||

|---|---|---|---|---|---|---|

| MAE | RMSE | Accuracy Rate | MAE | RMSE | Accuracy Rate | |

| DI1,i,j | 0.05901 | 0.07082 | 76.93% | 0.06145 | 0.07217 | 75.26% |

| DI2,i,j | 0.04351 | 0.06867 | 81.34% | 0.04496 | 0.06921 | 79.68% |

| DSDIi,j | 0.03982 | 0.04603 | 85.29% | 0.04054 | 0.04958 | 83.55% |

| Damage Index | SDE-BP Algorithm | SDE-SVR Algorithm | ||||

|---|---|---|---|---|---|---|

| MAE | RMSE | Accuracy Rate | MAE | RMSE | Accuracy Rate | |

| DI1,i,j | 0.01926 | 0.02576 | 89.98% | 0.04245 | 0.05176 | 82.56% |

| DI2,i,j | 0.01662 | 0.01815 | 92.26% | 0.04081 | 0.04892 | 84.34% |

| DSDIi,j | 0.00628 | 0.00693 | 96.54% | 0.02036 | 0.02685 | 88.57% |

| Algorithms | DSDIi,j | ||||

|---|---|---|---|---|---|

| MAE | RMSE | Accuracy Rate | Training Time (s) | Prediction Time (s) | |

| XGBoost | 0.02315 | 0.03041 | 86.92% | 250.25 | 0.12 |

| CNN | 0.01987 | 0.02458 | 90.35% | 480.73 | 0.22 |

| LSTM | 0.01894 | 0.02372 | 91.57% | 520.89 | 0.35 |

| SDE-SVR | 0.02036 | 0.02685 | 88.57% | 380.42 | 0.18 |

| SDE-BP | 0.00628 | 0.00693 | 96.54% | 360.83 | 0.15 |

| Model | Training Time (s) | Prediction Time (s) | Accuracy Rate |

|---|---|---|---|

| BP | 121.73 | 0.10 | 81.82% |

| SVR | 135.26 | 0.11 | 80.95% |

| SDE-BP | 360.83 | 0.15 | 96.54% |

| SDE-SVR | 380.42 | 0.18 | 88.57% |

| Damage Condition | Location of Damage and Depth of Cut | Damage Degree (%) |

|---|---|---|

| DC1 | Non-Damage Condition | 0 |

| DC2 | 30 cm and cut 2.5 cm | 50 |

| DC3 | 50 cm and cut 2 cm, 125 cm and cut 2.5 cm | 40, 50 |

| DC4 | 45 cm, 87.5 cm, 130 cm and cut 2 cm | 40, 40, 40 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Xiang, C.; Patelli, E.; Zhao, H. Structural Damage Identification Using Data Fusion and Optimization of the Self-Adaptive Differential Evolution Algorithm. Symmetry 2025, 17, 465. https://doi.org/10.3390/sym17030465

Li Y, Xiang C, Patelli E, Zhao H. Structural Damage Identification Using Data Fusion and Optimization of the Self-Adaptive Differential Evolution Algorithm. Symmetry. 2025; 17(3):465. https://doi.org/10.3390/sym17030465

Chicago/Turabian StyleLi, Yajun, Changsheng Xiang, Edoardo Patelli, and Hua Zhao. 2025. "Structural Damage Identification Using Data Fusion and Optimization of the Self-Adaptive Differential Evolution Algorithm" Symmetry 17, no. 3: 465. https://doi.org/10.3390/sym17030465

APA StyleLi, Y., Xiang, C., Patelli, E., & Zhao, H. (2025). Structural Damage Identification Using Data Fusion and Optimization of the Self-Adaptive Differential Evolution Algorithm. Symmetry, 17(3), 465. https://doi.org/10.3390/sym17030465