Study on Cross-Section Transition Form and Stability of Super-Large Variable-Span Tunnel

Abstract

1. Introduction

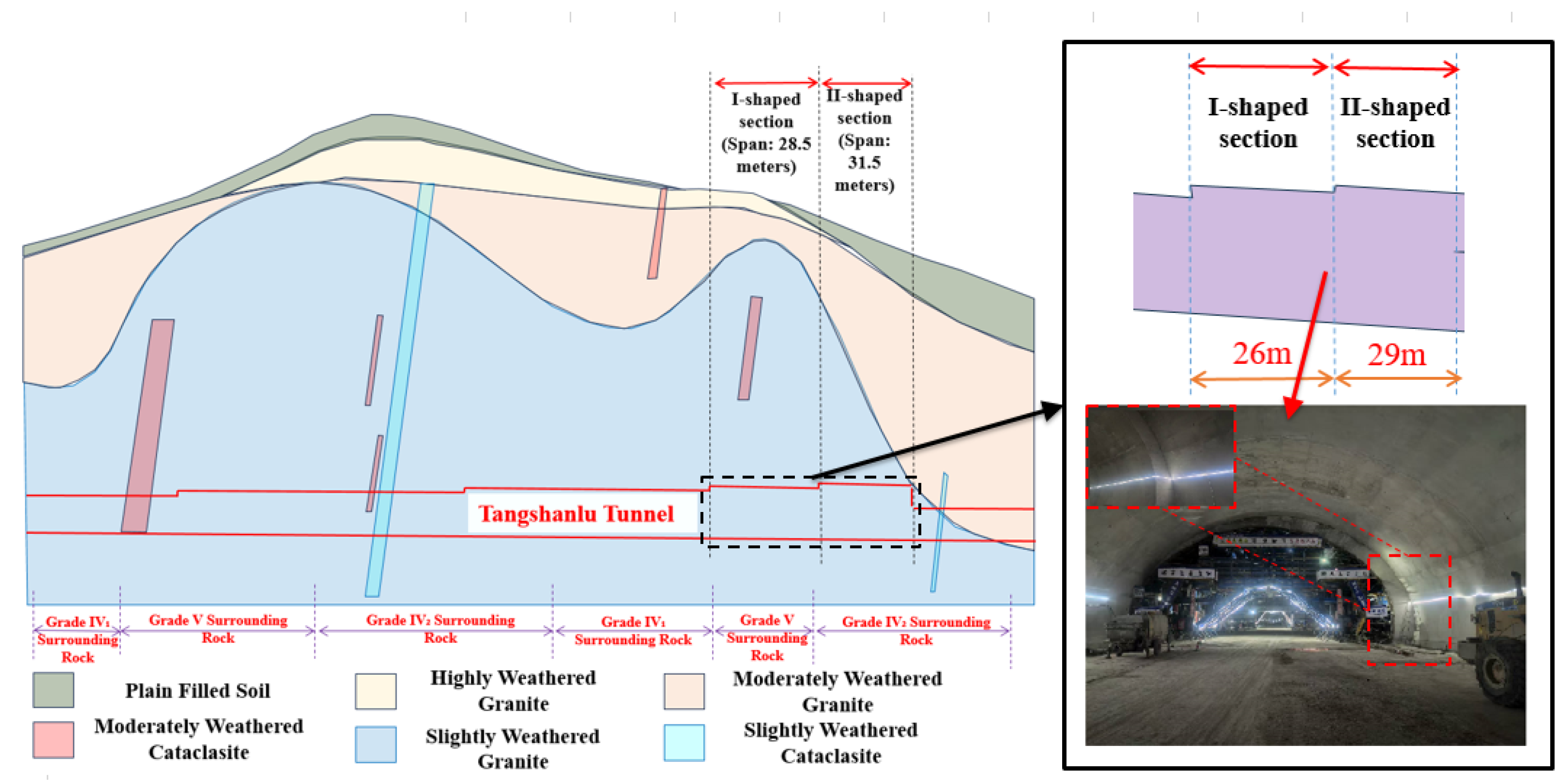

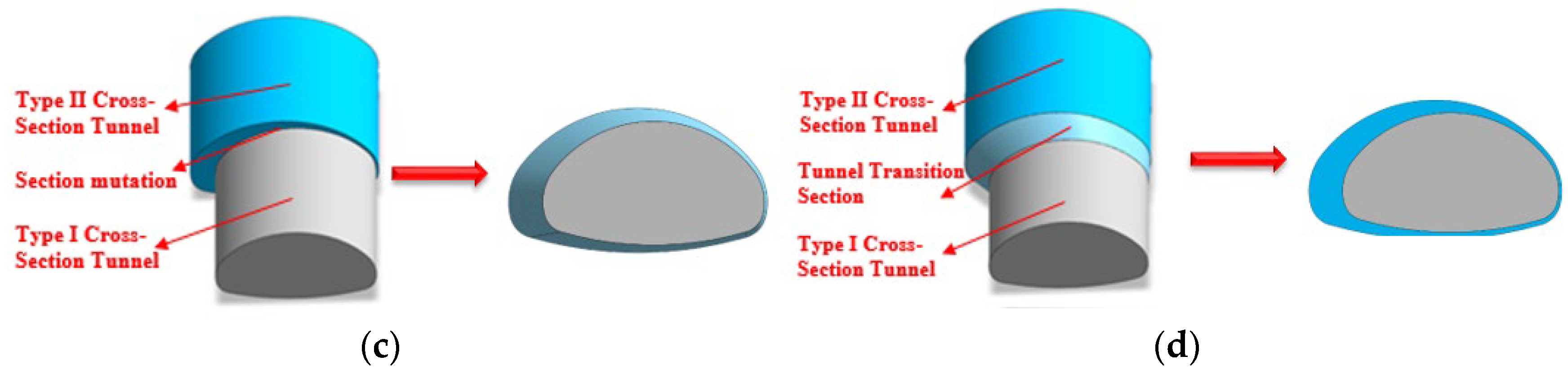

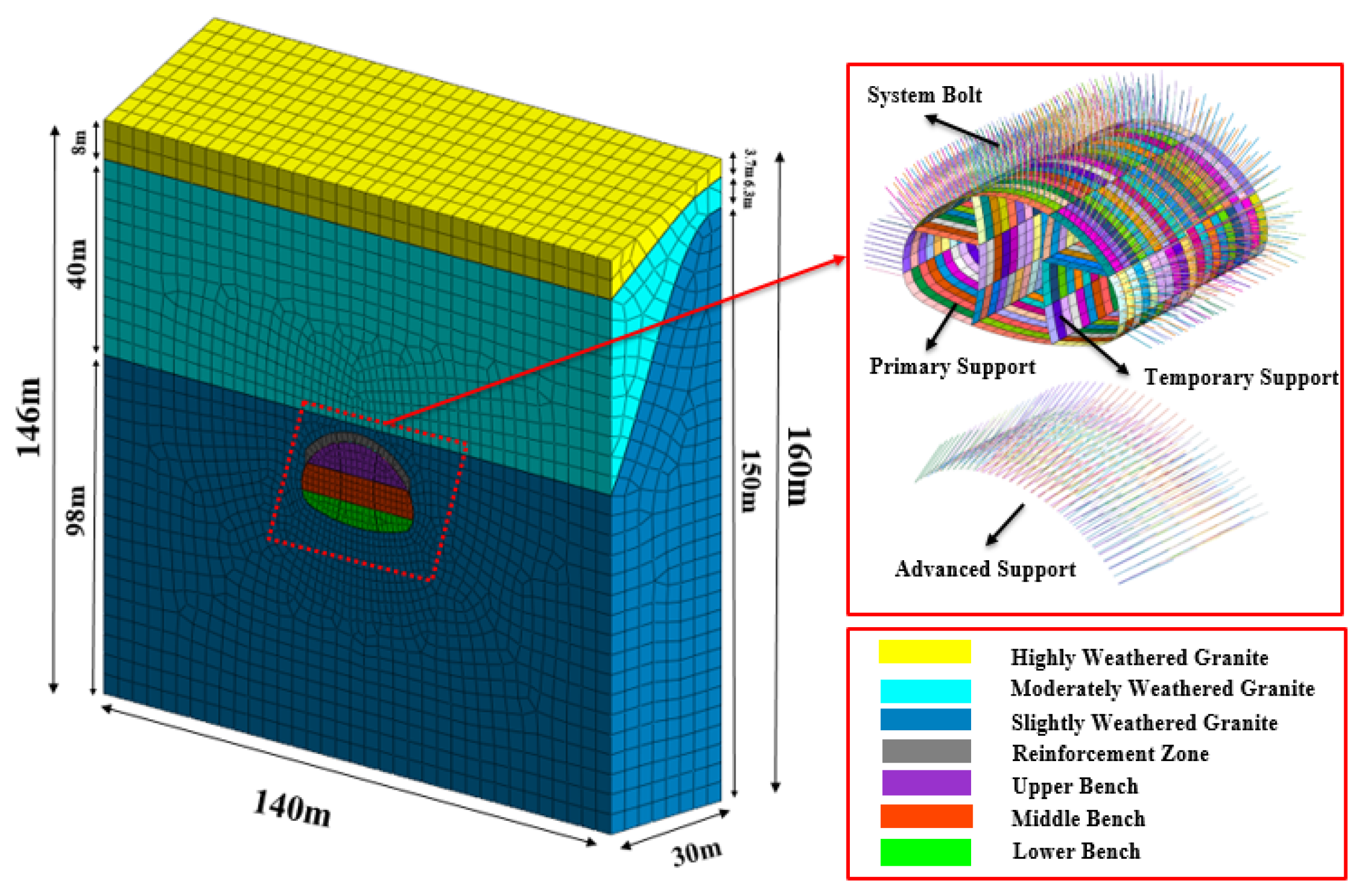

2. Project Introduction

2.1. Project Overview

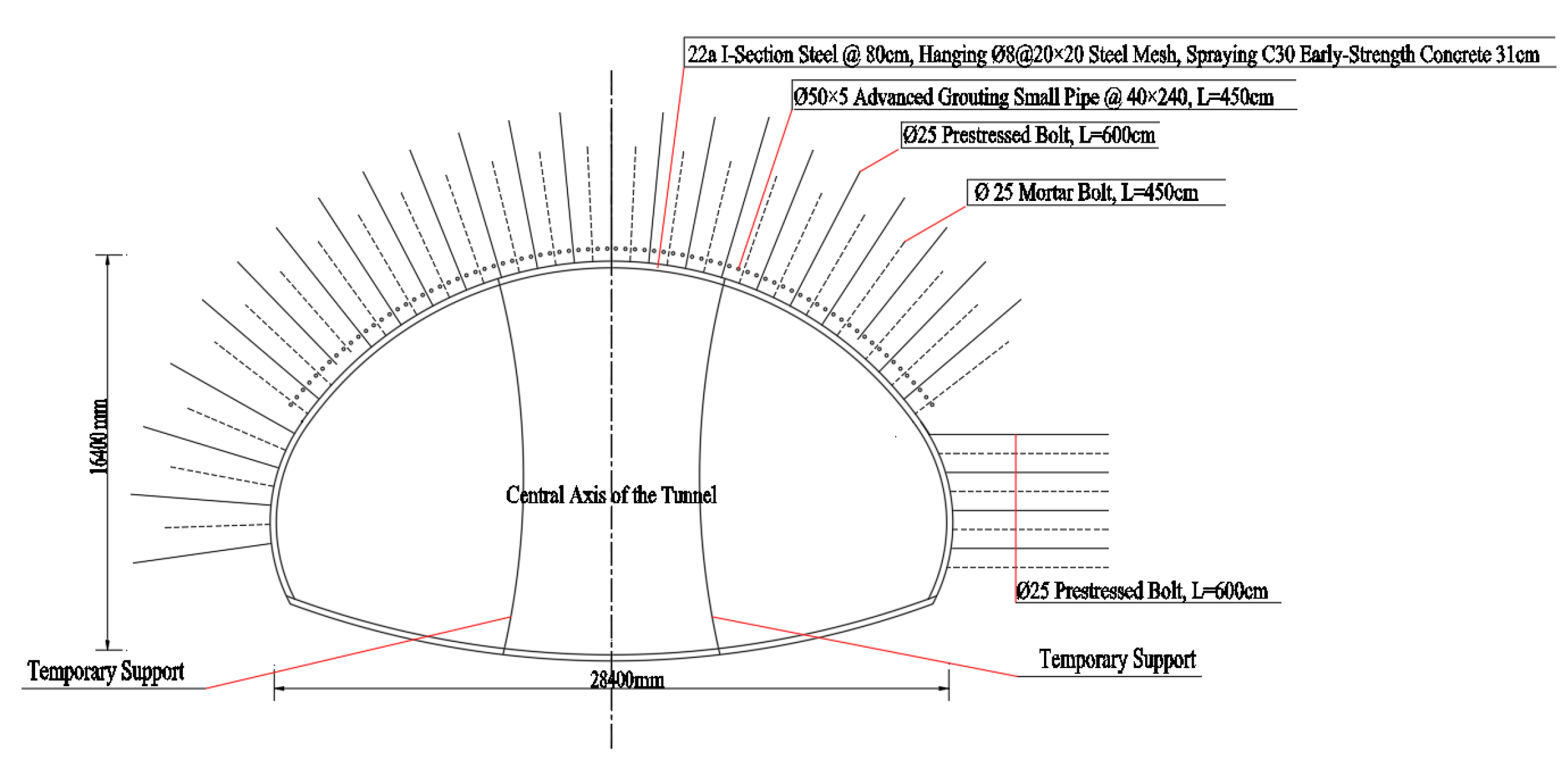

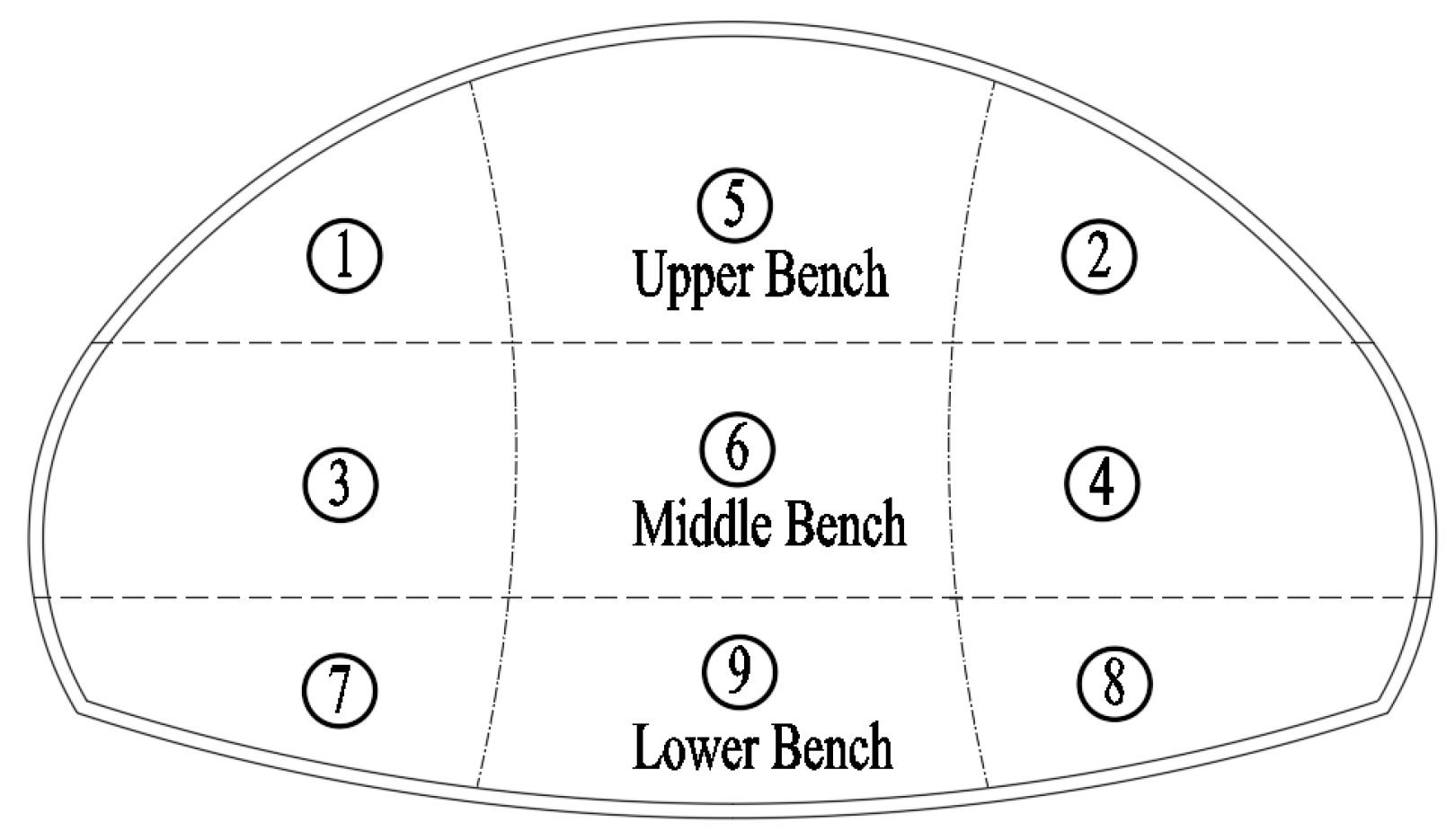

2.2. Overview of Supporting Structure and Excavation Method

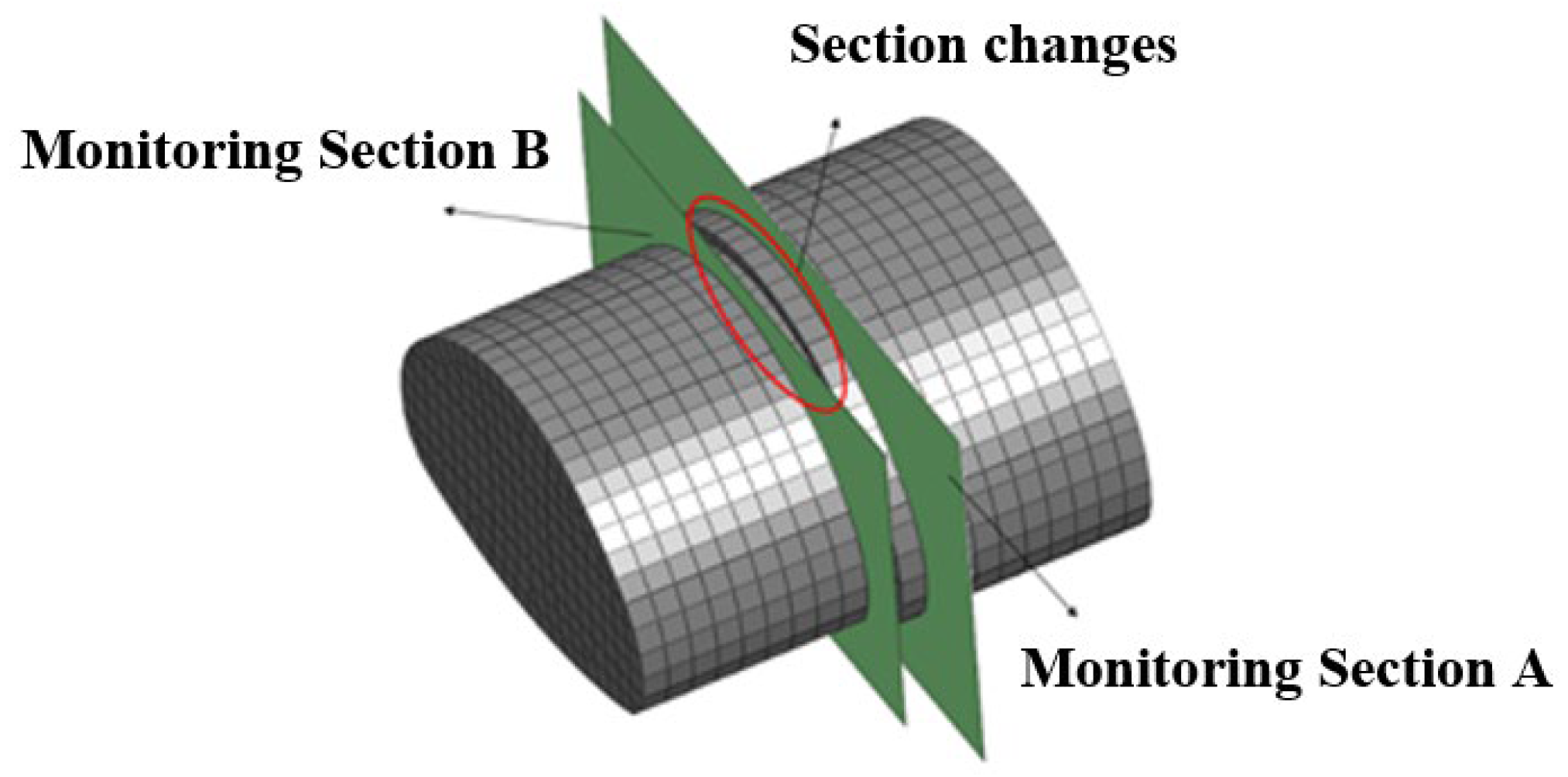

3. Establishment of Numerical Model

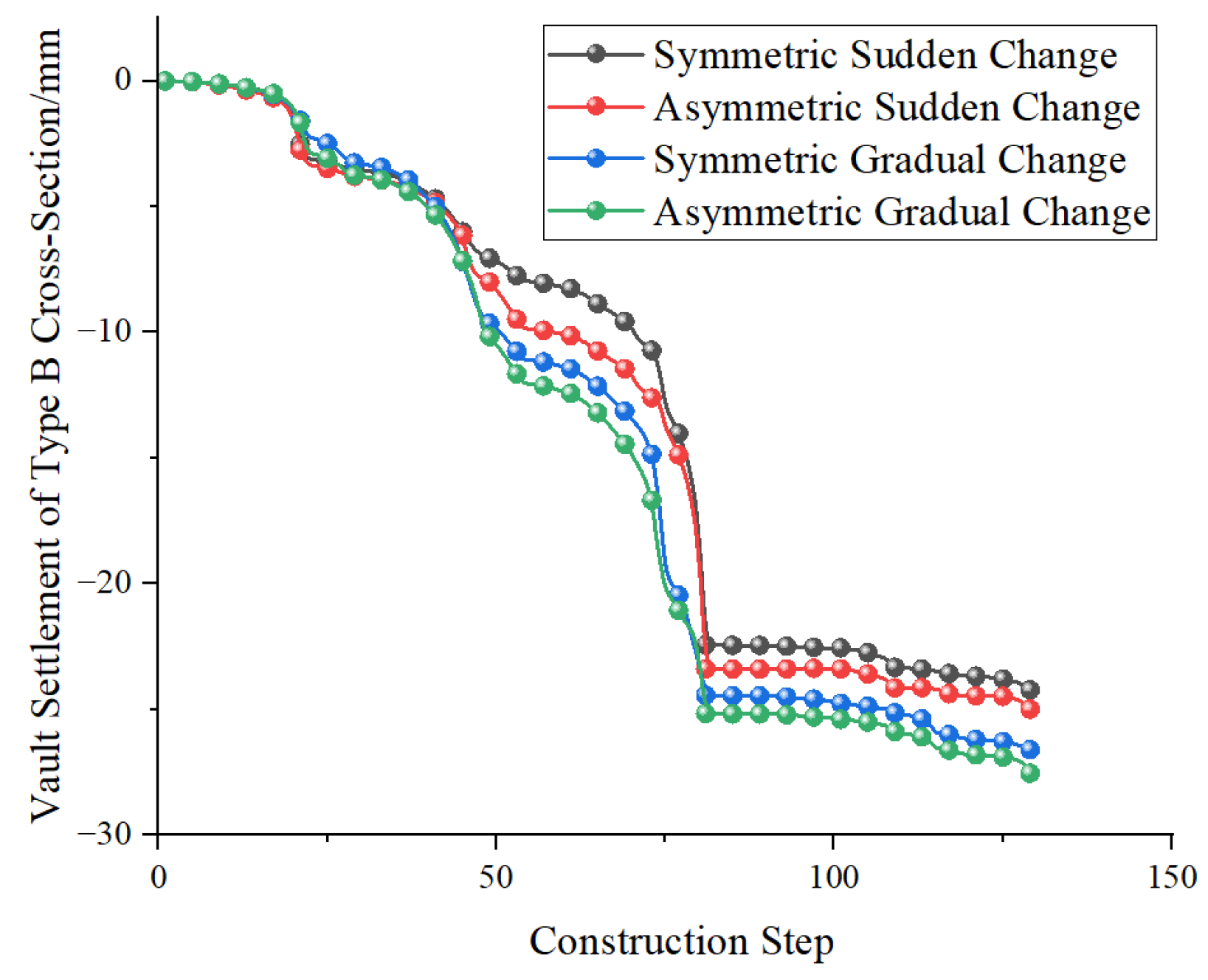

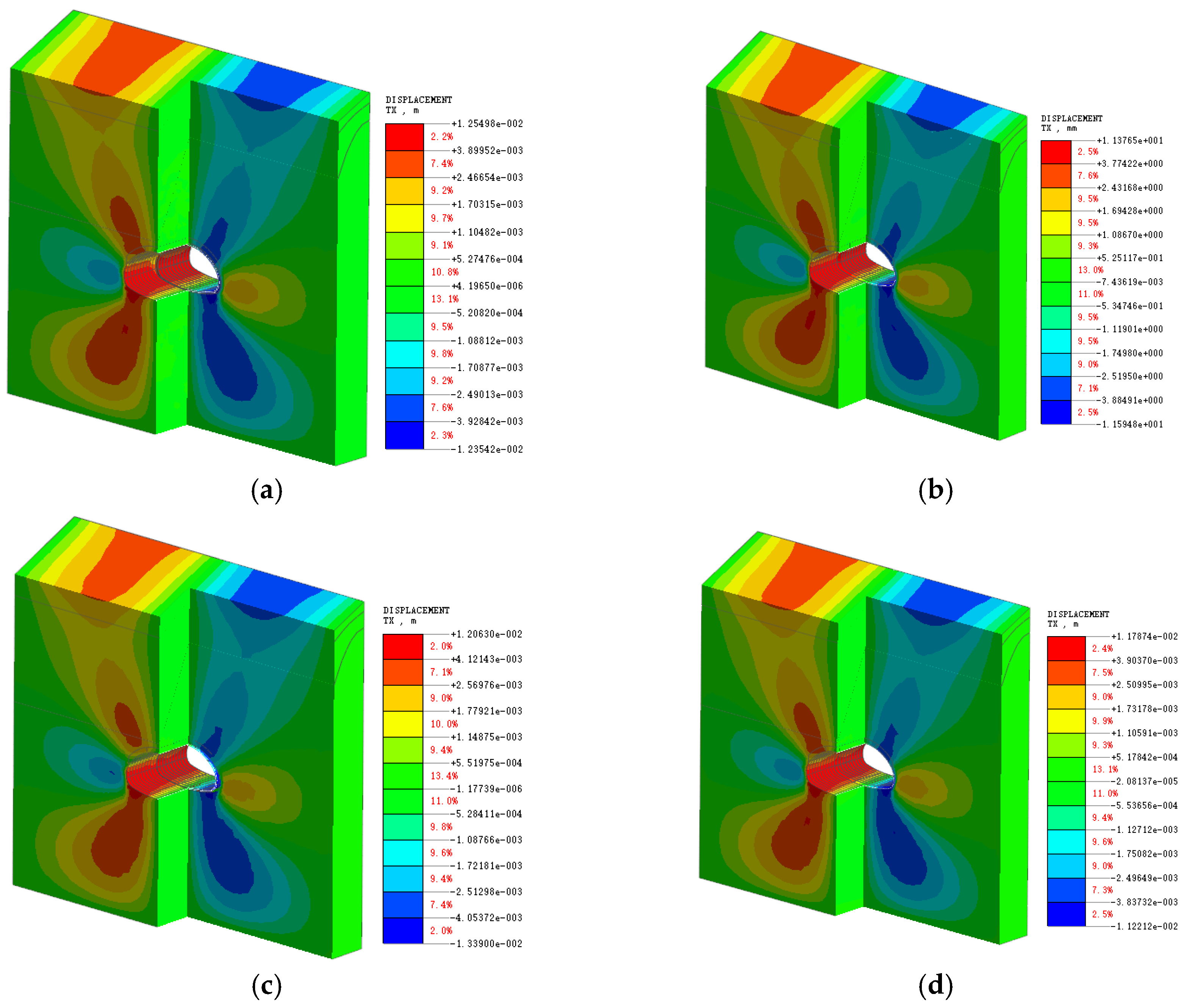

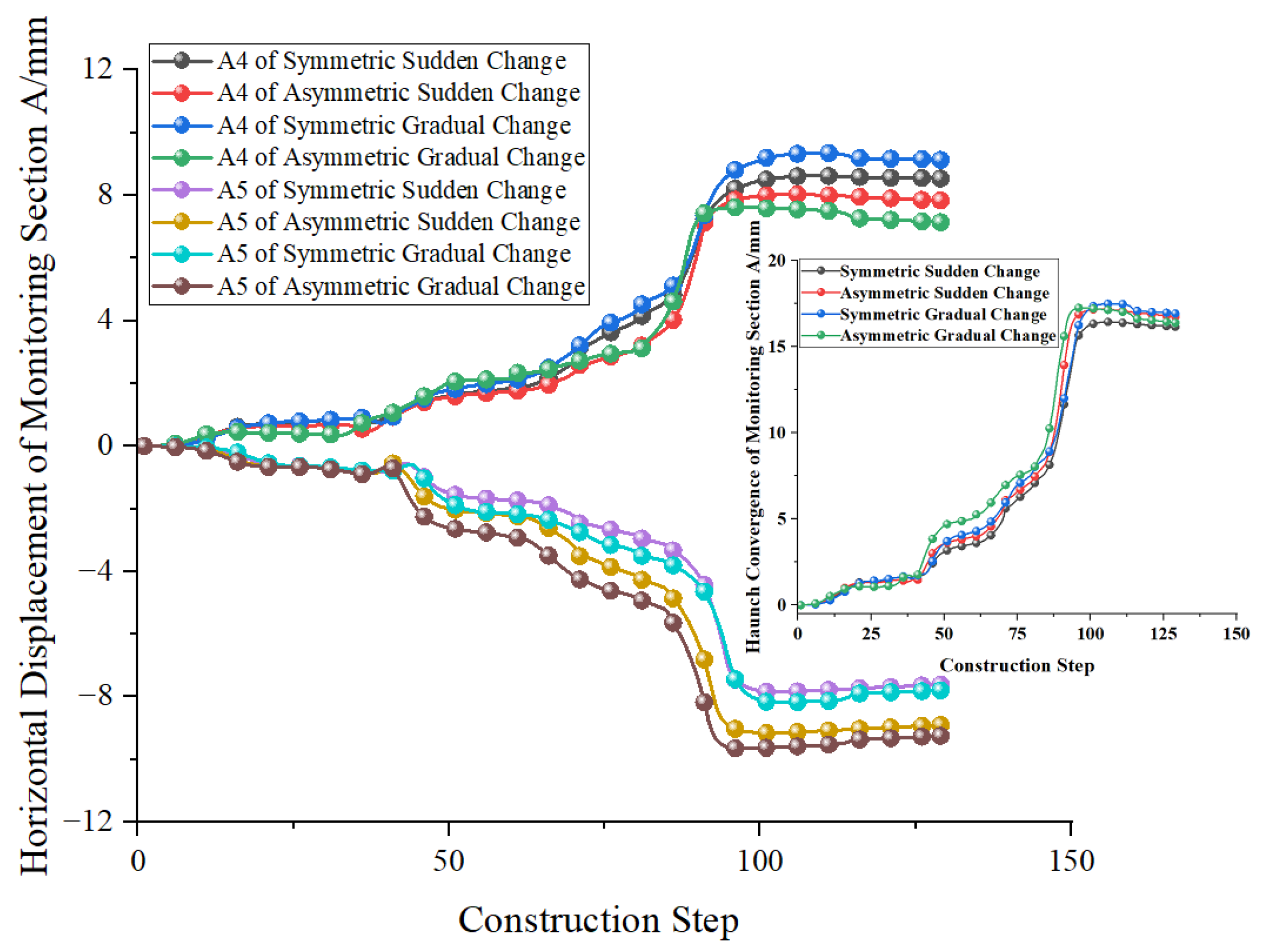

4. Comparative Analysis of Numerical Simulation

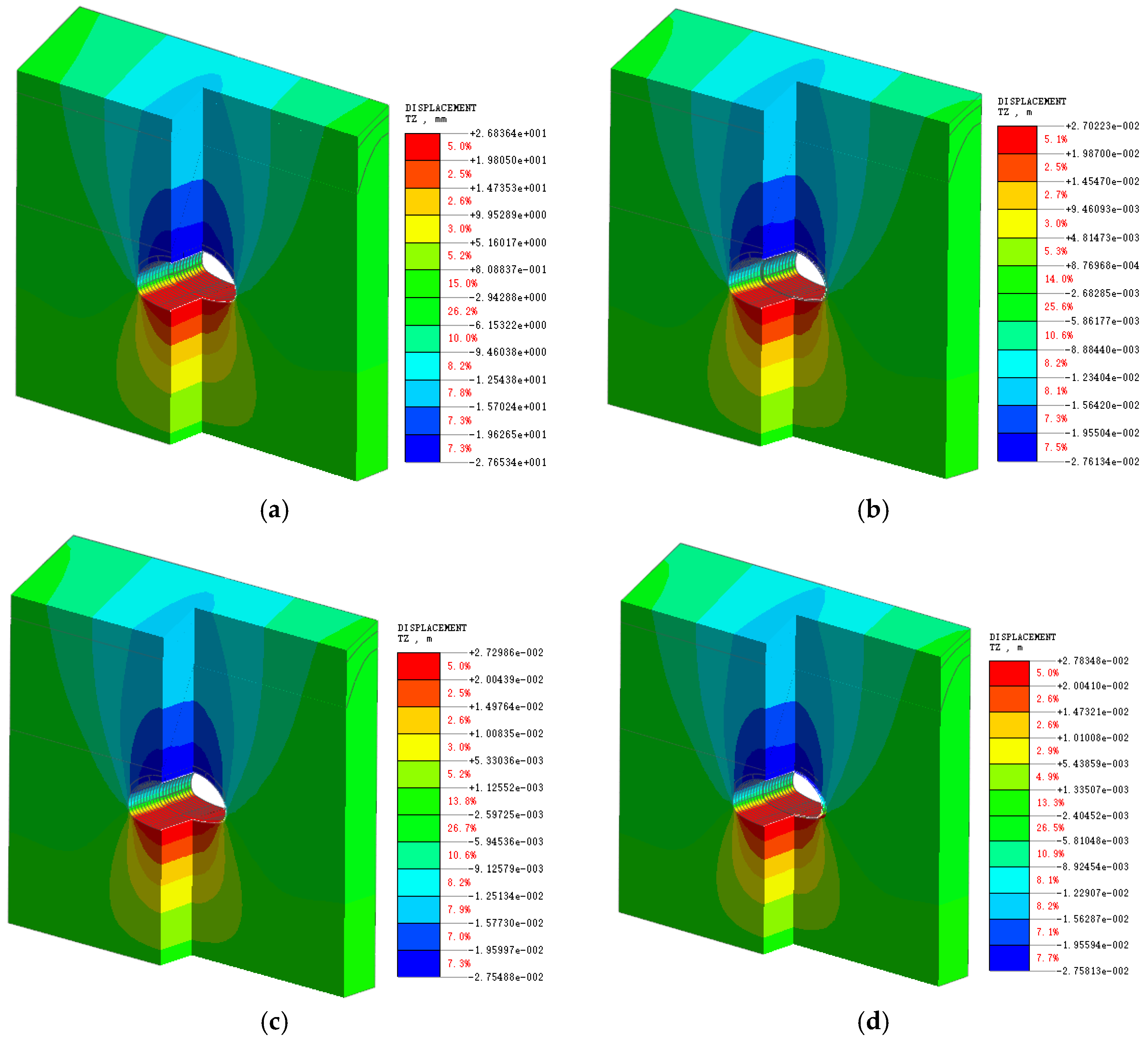

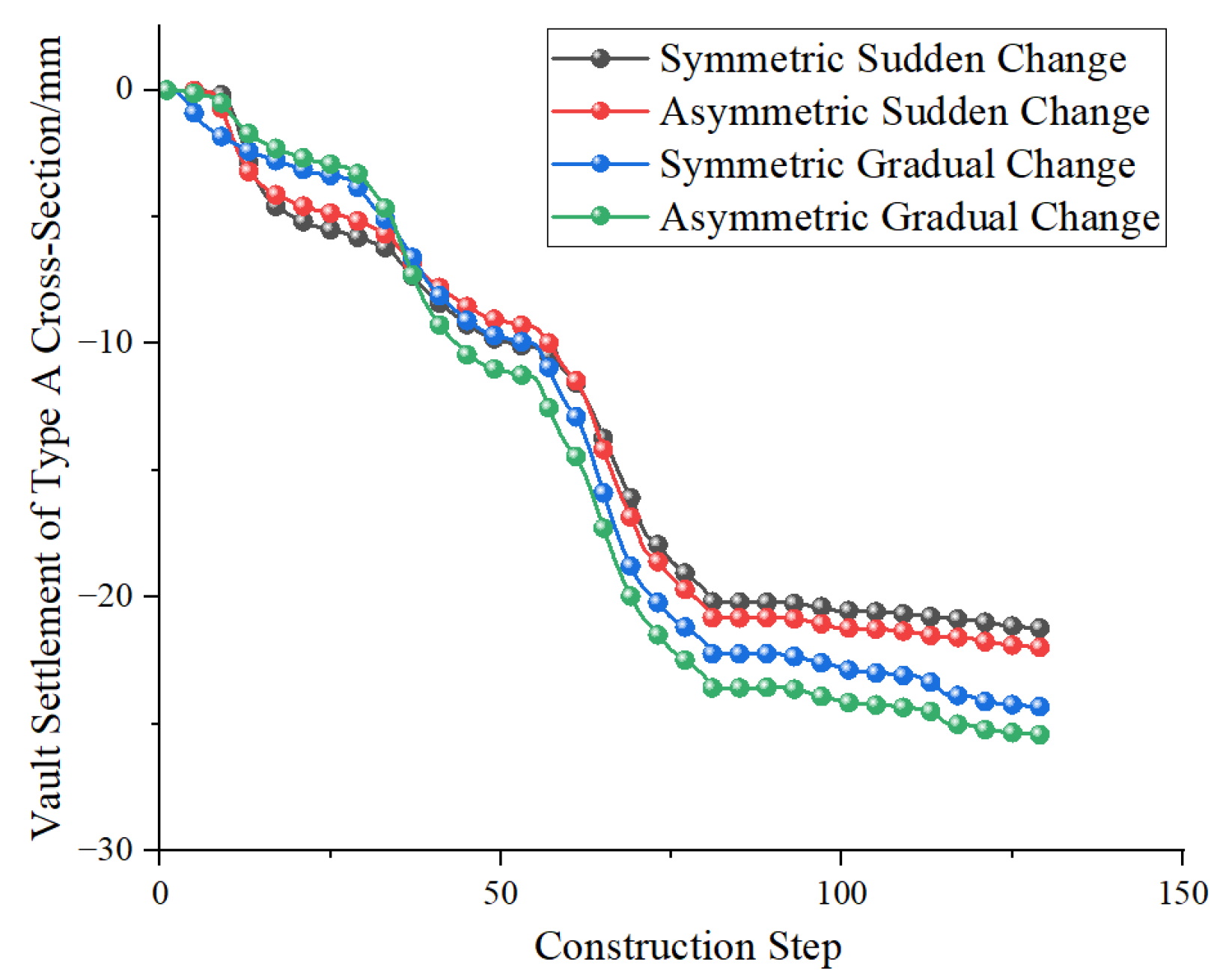

4.1. Analysis of Surrounding Rock Displacement

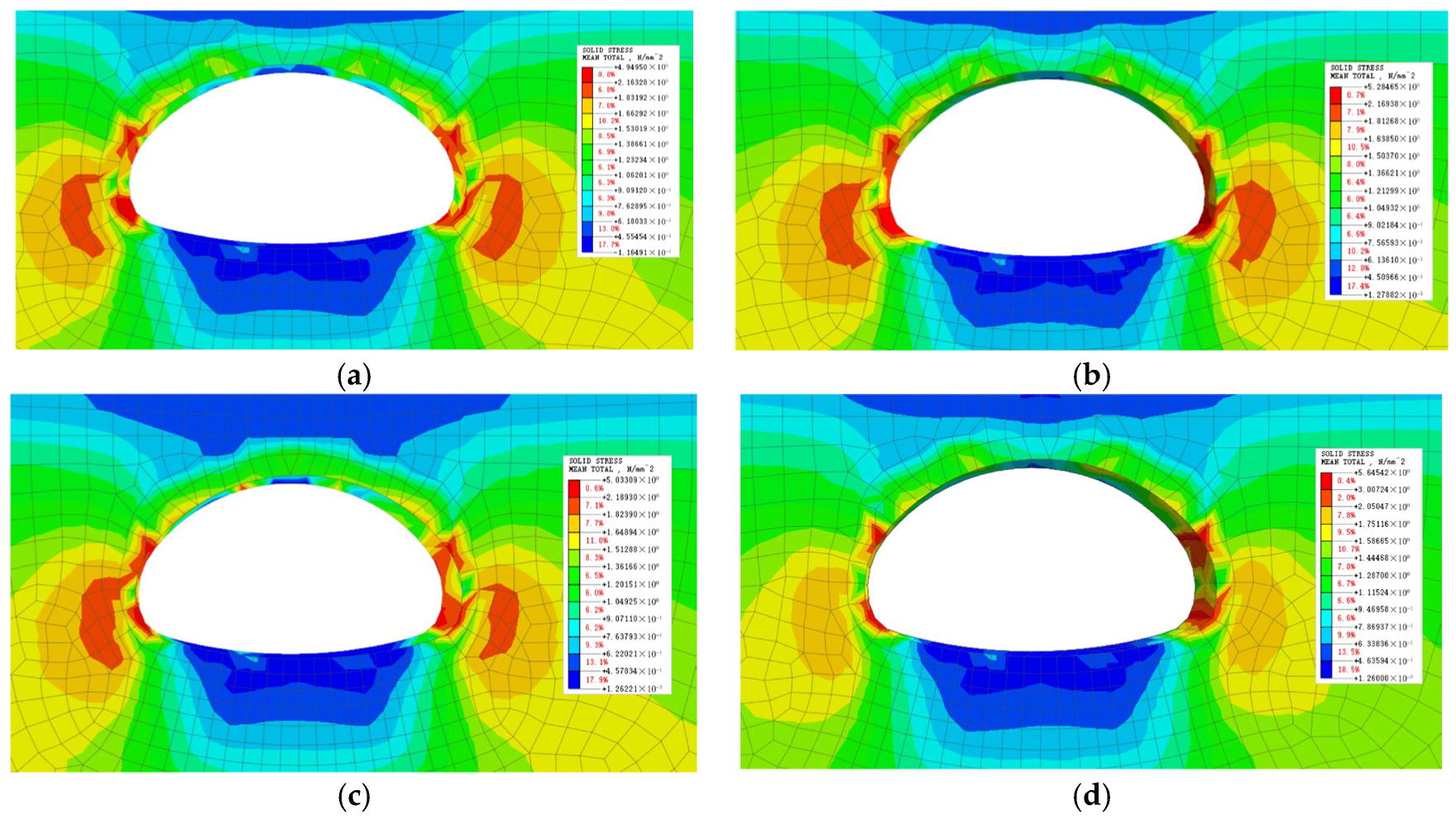

4.2. Surrounding Rock Stress Analysis

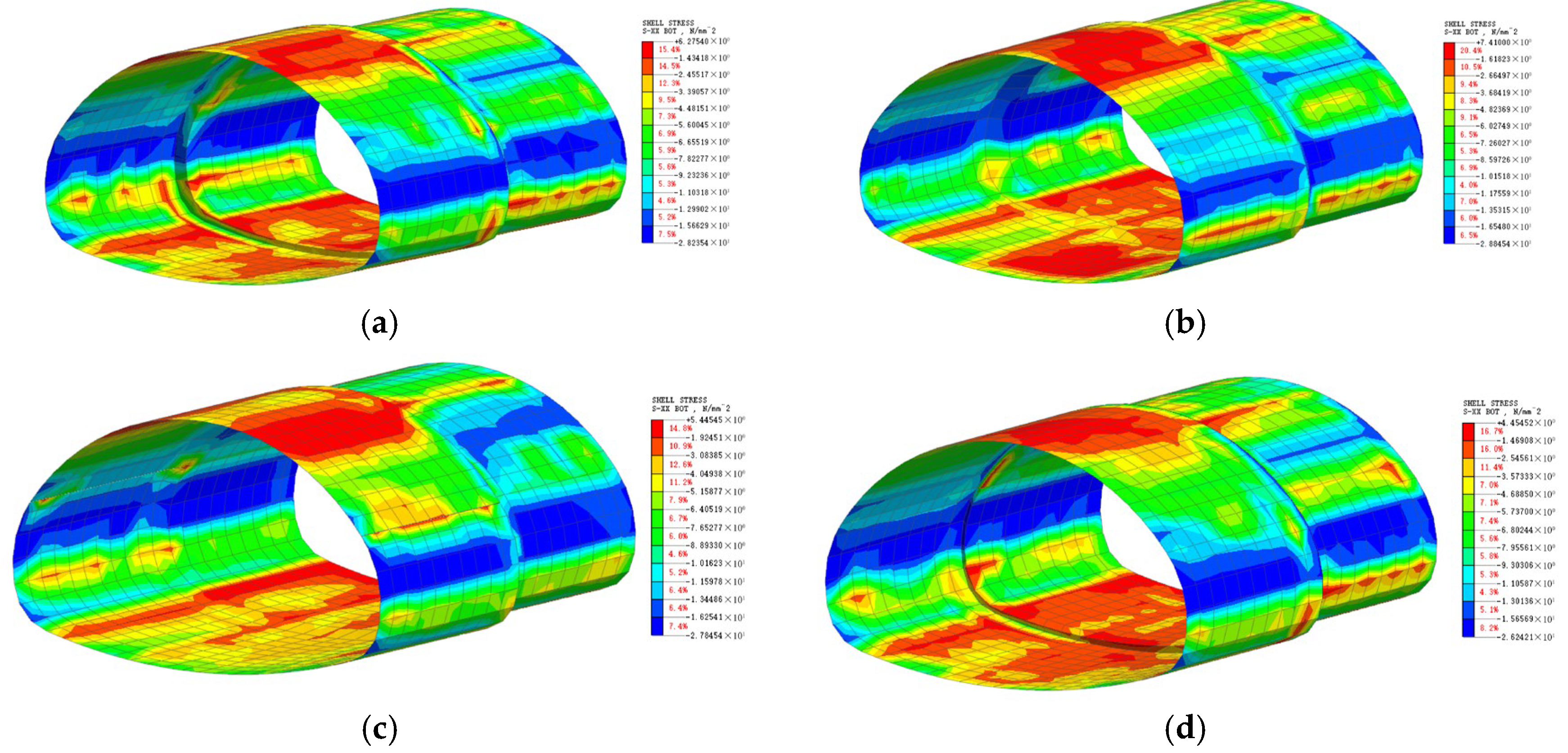

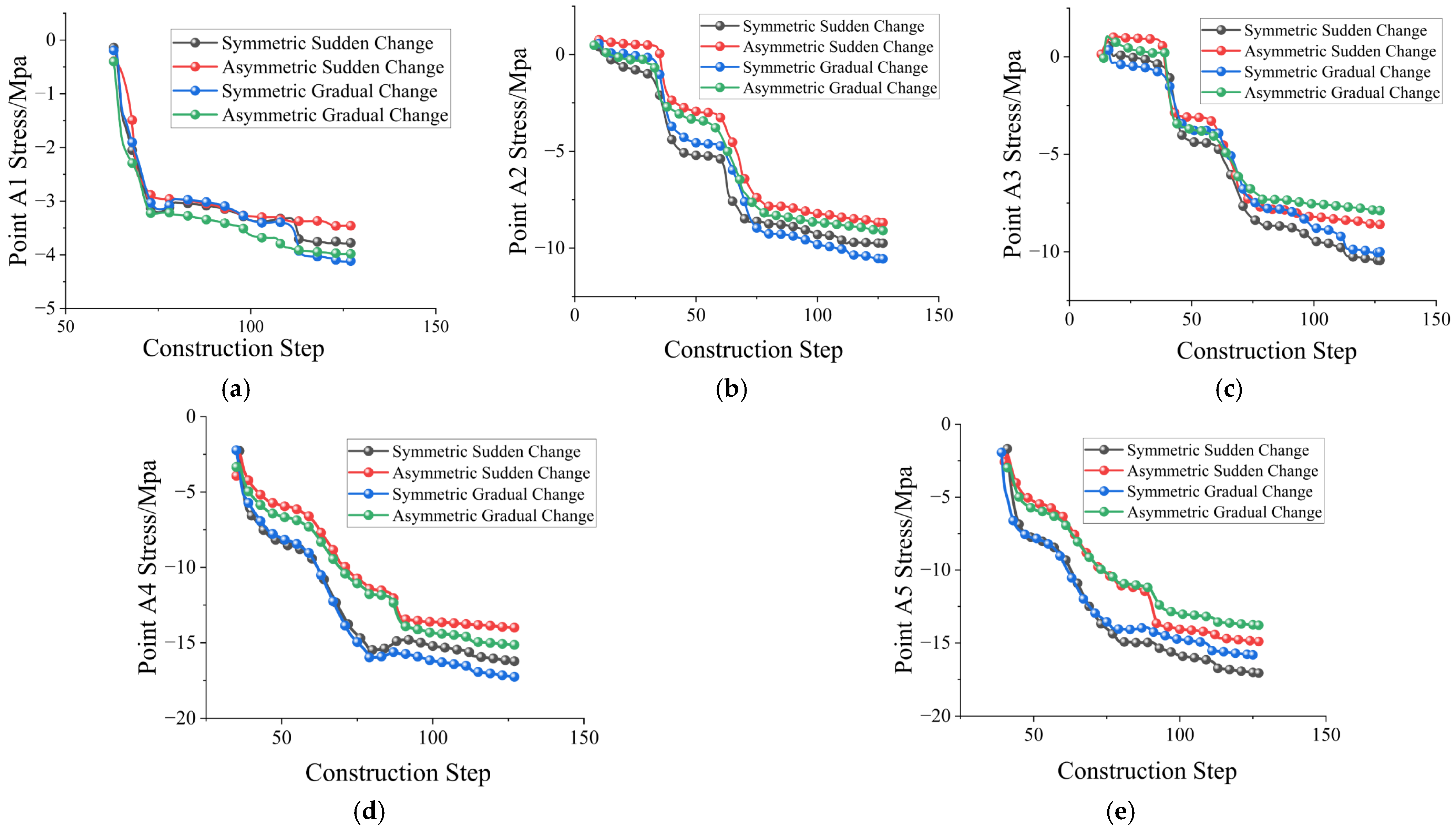

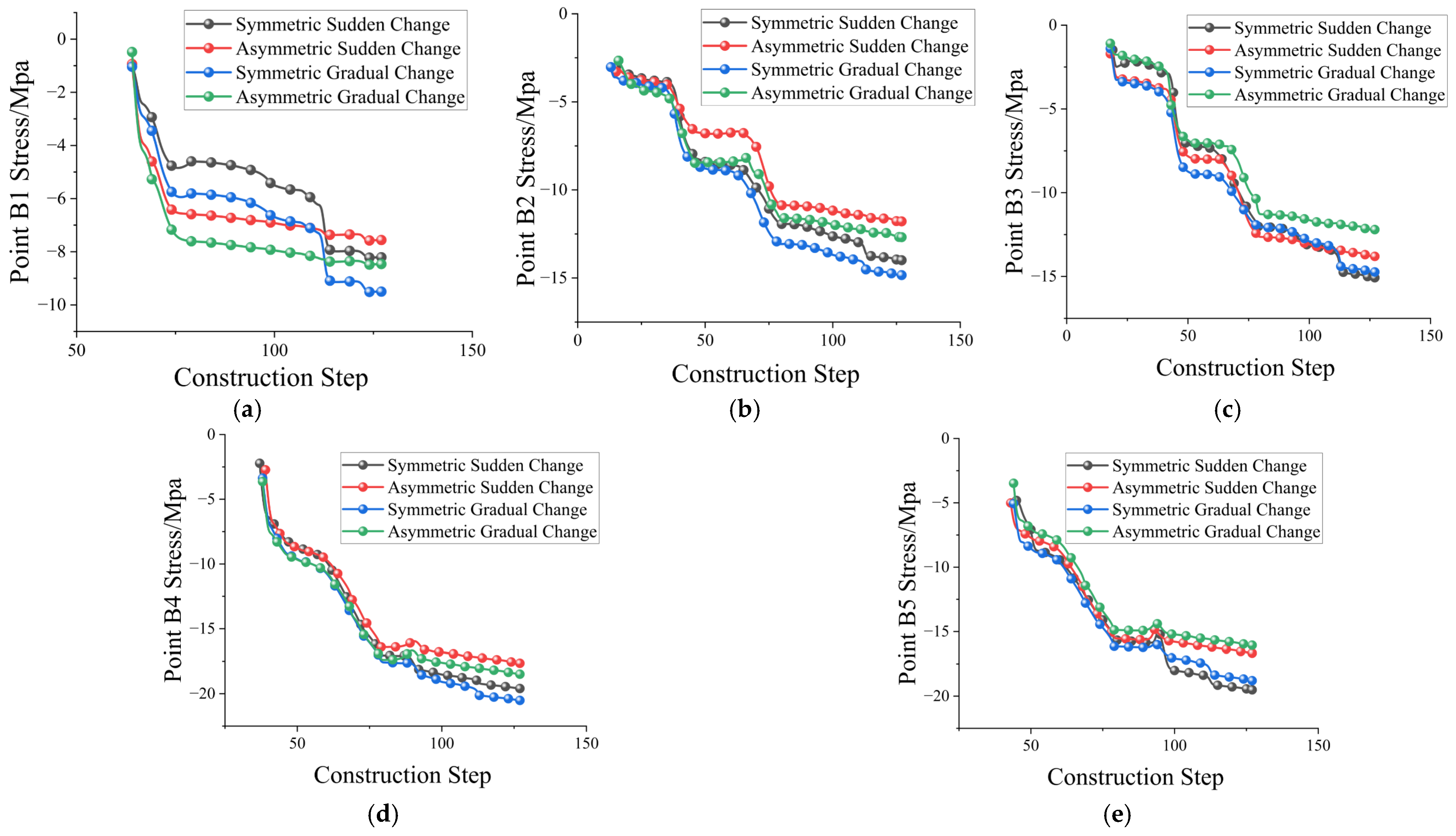

4.3. Initial Support Stress Analysis

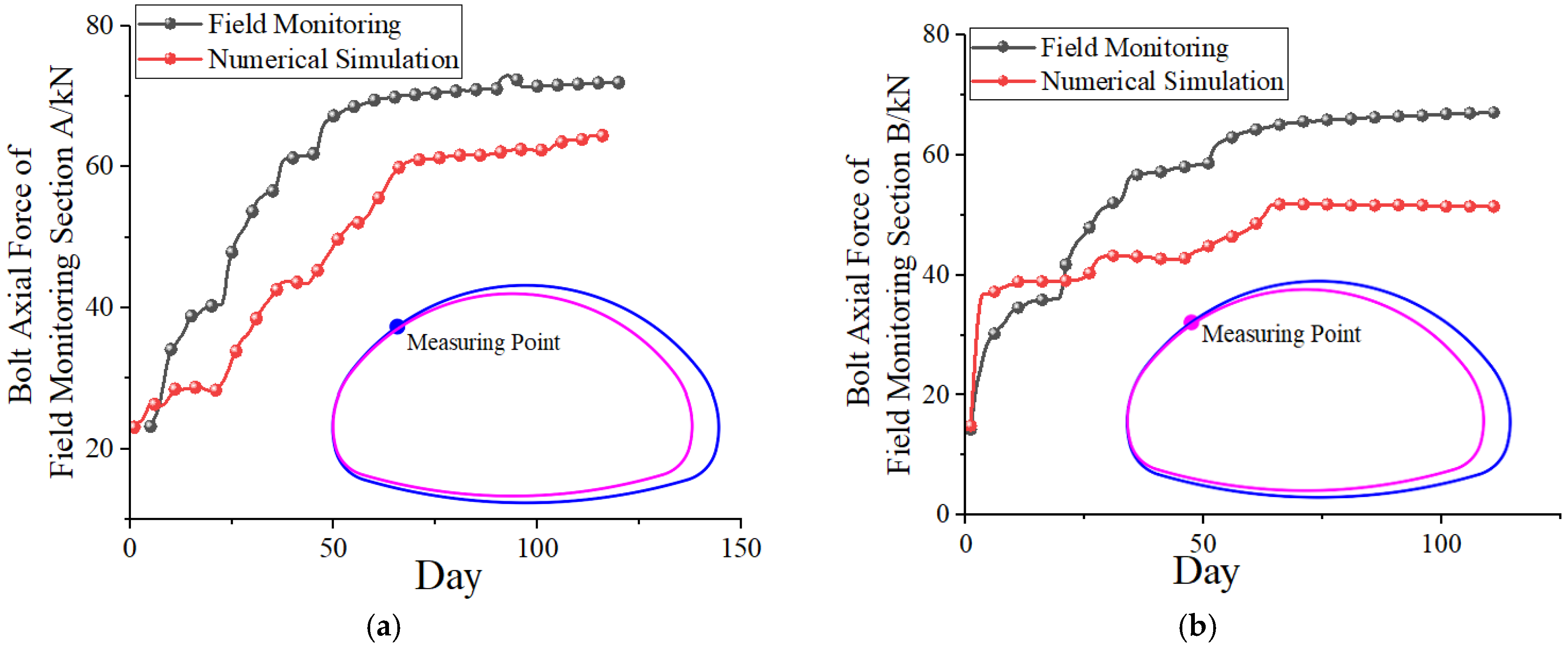

4.4. Analysis of Bolt Axial Force

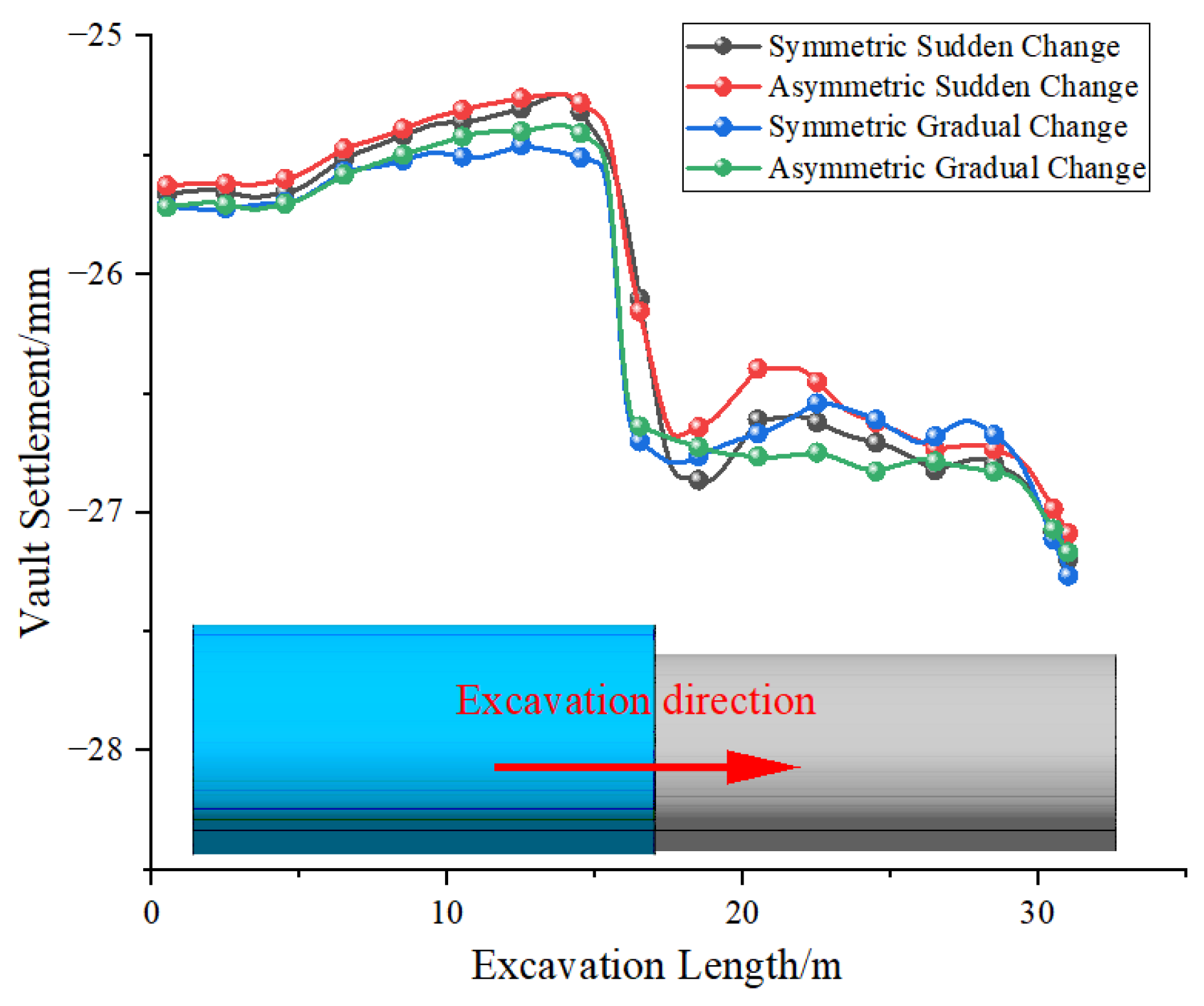

5. Field Monitoring and Result Analysis

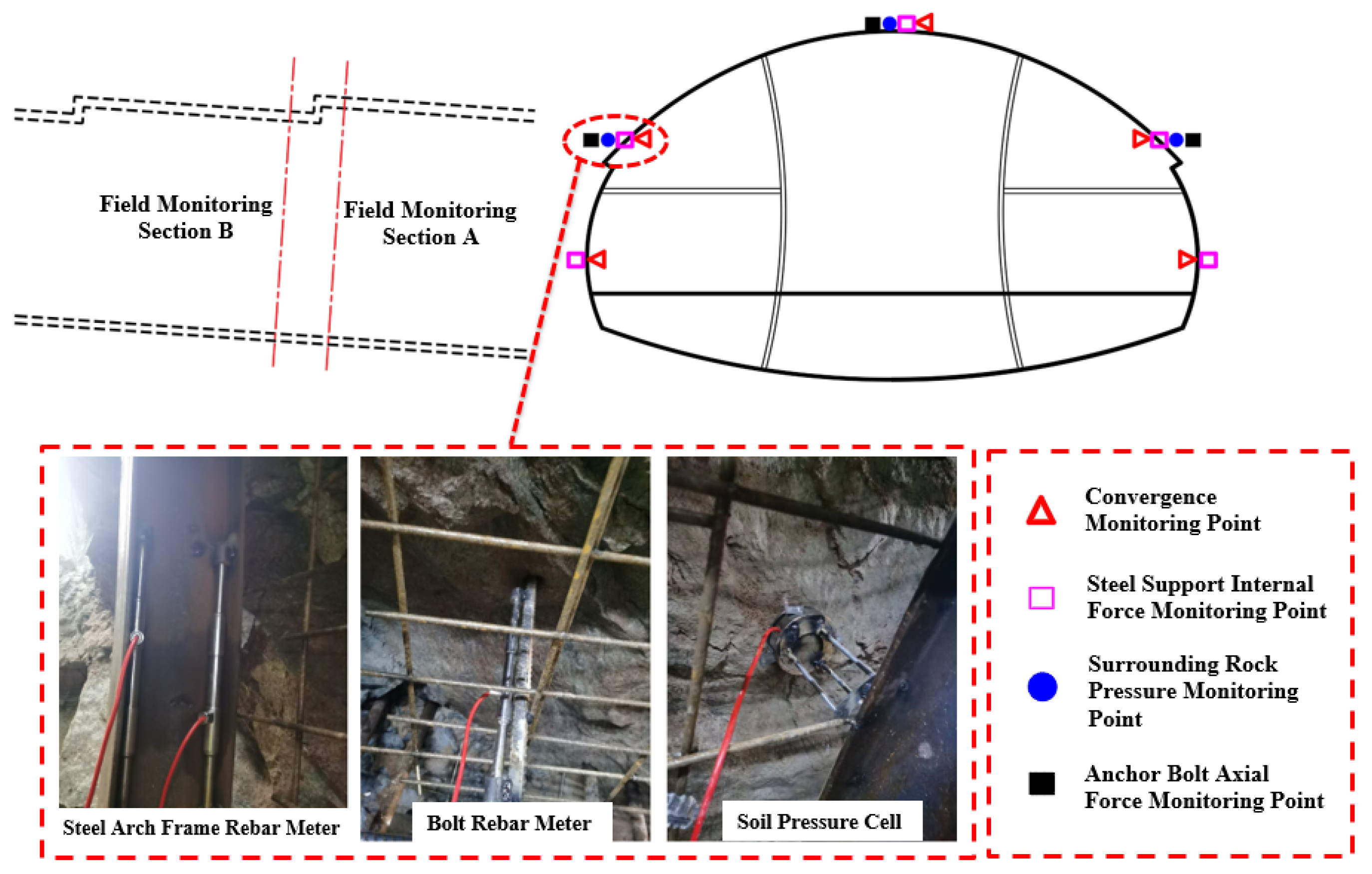

5.1. Monitoring Scheme

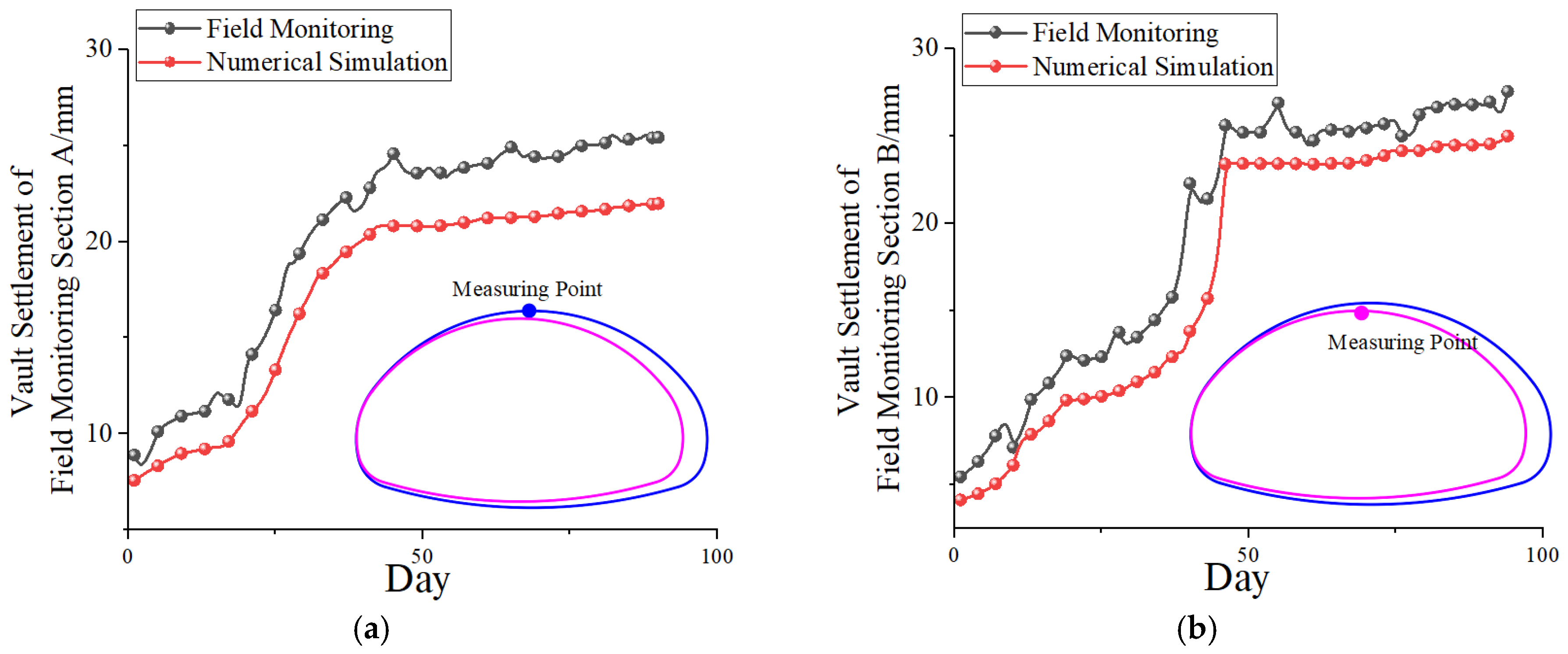

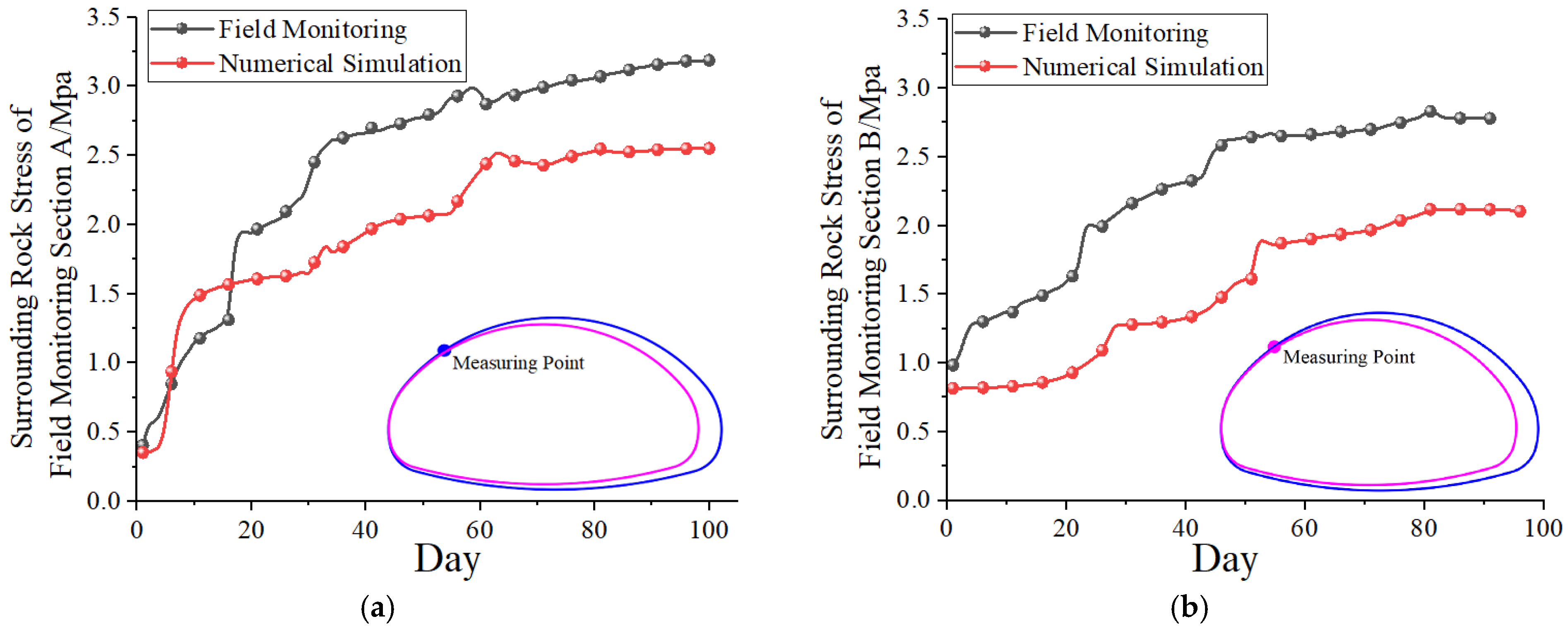

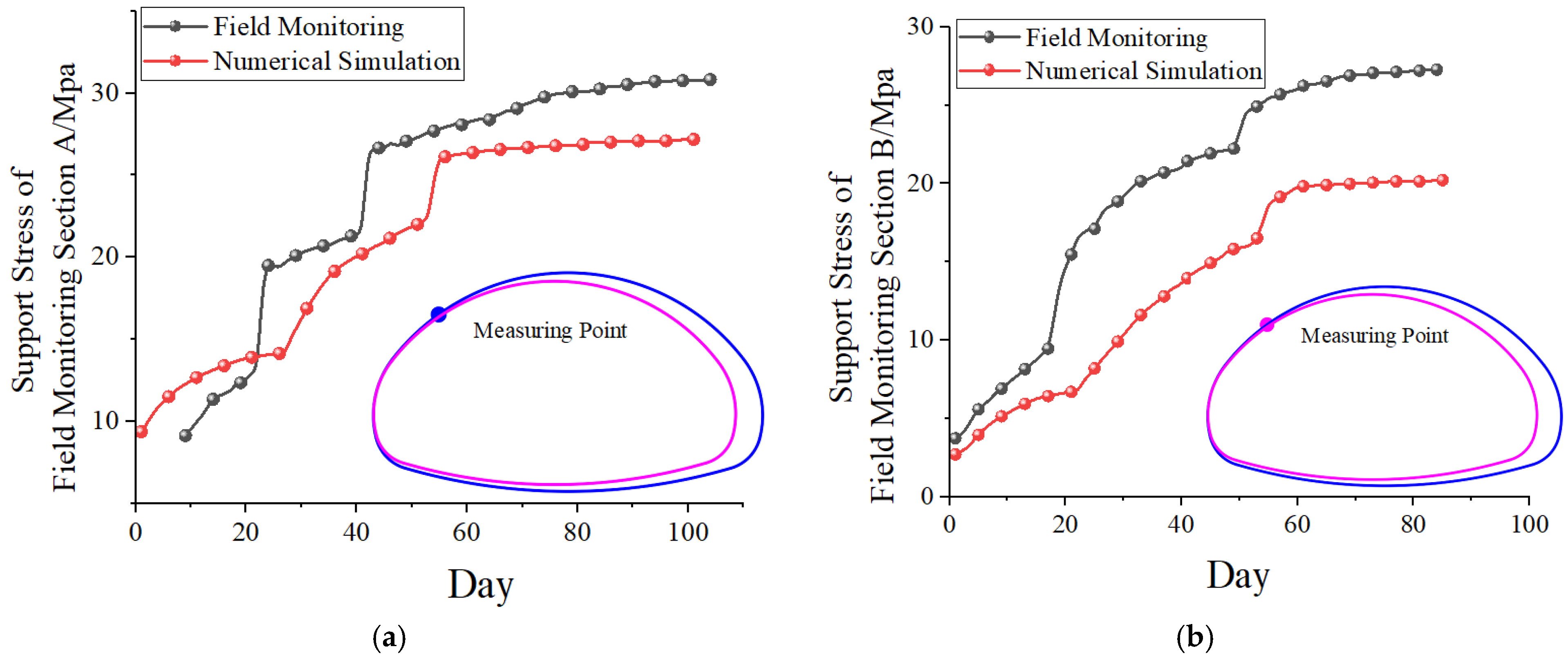

5.2. Monitoring Result Analysis

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yu, Y.H.; Yan, B. Present Situation and Development Trend of Underground Space in Megacity in China. Chin. J. Undergr. Space Eng. 2021, 17, 1–7. [Google Scholar]

- Zhang, Z.; Lin, C.; Li, J.; Dong, Y.; Shen, Y. Development status and prospect of highway tunnel rehabilitation and expansion in China. Tunn. Constr. 2022, 42, 570. [Google Scholar]

- Yan, J. Development trends in world tunneling technology: Safe, economical, green and artistic. Tunn. Constr. 2021, 41, 693. [Google Scholar]

- Yan, J.X. Achievements and Challenges of Tunneling Technology in China over Past 40 Years. Tunn. Constr. 2019, 39, 537–544. [Google Scholar]

- Guo, D.P.; Liu, Y.Q.; Huang, X. Analysis on Sensitivity of Construction Mode and Supporting Structre Parameters of Variable Cross-section Tunnel. Subgrade Eng. 2025, 3, 175–181. [Google Scholar]

- Zhao, H.; Zhang, G.L.; Li, S.T.; Liu, Y.; Ren, X.L.; Kong, L.W.; Wang, R.; Qiu, D.C.; Zhang, H.X. Study on the Dynamic Response of Rock Mechanics and Numerical Simulation of Excavation Sequence Optimization in Ultra-large Span Variable Section Tunnels: Taking Suzhou Changjiang Road South Extension Project-Qizishan Tunnel Project as an Example. Sci. Technol. Ind. 2024, 24, 227–238. [Google Scholar]

- Ou, J. Construction Optimization Study of Double Sidewall Heading Method for Shallow Buried Oversized Variable Section Tunnel. Railw. Constr. Technol. 2024, 3, 120–123. [Google Scholar]

- Tian, S.M.; Wang, W.; Gong, J.F. Development and prospect of railway tunnels in China (including statistics of railway tunnels in China by the end of 2020). Tunn. Constr. 2021, 41, 308. [Google Scholar]

- Yang, C.Z.; Wu, Y.J.; Wang, W.; Tang, Y.Q. Analysis on Influence of Special Effect on Excavation of Soft Rock Tunnel with Large Cross Section. Chin. J. Undergr. Space Eng. 2021, 17, 511–519. [Google Scholar]

- Zhu, N.K.; Chen, Y.S.; Jia, J.L. Numerical Simulation of Excavation Stability of Large Section Tunnel. J. Taiyuan Univ. 2021, 39, 1–6. [Google Scholar]

- Qi, H.; Shang, C.S.; Hu, C.; Jiang, Y.S.; Wu, F.M.; Jiang, H. Study on stability of rock supporting structure during construction of super—Large cross—Section tunnel. Yangtze River 2020, 51, 135–141. [Google Scholar]

- He, X.; Li, Y. Analysis of stress disturbed zone of tunnel and its influence factors. J. Railw. Sci. Eng. 2019, 16, 2782–2790. [Google Scholar]

- Yu, H.; Liu, G.H. Strain Softening Model of Rock Under Multiaxial Stress State Based on Drucker-prager Criterion. Bull. Sci. Technol. 2020, 36, 45–52. [Google Scholar]

- Jia, X.T.; Li, Q.; He, W.K. On the Analysis of the Prevention of Common Geological Disasters in Large Cross-Section Tunnel Construction. Shanxi Archit. 2012, 38, 216–217. [Google Scholar]

- Zhao, B.J. Study on Construction Method of Forked Tunnel with Large and Multi Section. Master’s Thesis, Beijing Jiaotong University, Beijing, China, 2019. [Google Scholar]

- Zhao, G. Excavation Technology for Large Section Interworking Tunnel of Variable Cross Section. Railw. Constr. Technol. 2015, 3, 87–91. [Google Scholar]

- Ren, D.P. Construction Technology of Variable Cross⁃section for Three⁃line Bifurcation and Large⁃span Section of Railway Tunnel. Railw. Eng. 2021, 61, 105–108. [Google Scholar]

- Ma, J.H.; Zhao, J.Q.; Peng, J.W.; Wu, R.J.; Wang, X.X.; Guo, Y.X. Study on displacement and stress characteristics of criss-cross tunnel with different size and support optimization. J. Taiyuan Univ. Technol. 2024, 1–10. Available online: https://link.cnki.net/urlid/14.1220.N.20240616.1556.002 (accessed on 19 November 2025).

- Hong, J.; Guo, H.M.; Zhang, J.R.; Chen, L.J. Study of Structure Selection and Construction Method for Three-line Transition Section at Exit of Xinkaotang Tunnel. Tunn. Constr. 2016, 36, 953–959. [Google Scholar]

- Yan, M.C.; Zeng, P.; He, Z.S.; Yang, X.A. Research on Construction Technology of Variable Section Section of Super Large Section Tunnel. Railw. Eng. 2015, 497, 43–45. [Google Scholar]

- Sun, S.; Jiang, Z.; Li, L.; Qiu, D. Model test and numerical verification of surrounding rock stability of super-large-span and variable-section tunnels. Tunn. Undergr. Space Technol. 2024, 153, 106020. [Google Scholar] [CrossRef]

- Fan, S.; Song, Z.; Li, X.; Zhang, Y.; Liu, L. Investigation into the large deformation mechanism and control technology of variable cross-section tunnel in layered mudstone stratum. Buildings 2022, 13, 110. [Google Scholar] [CrossRef]

- Song, S.; Li, S.; Liang, Y.; Huo, R.; Song, Z.; Miao, Z.; Song, Z. Study on construction mechanical effect and optimization of large-span variable cross-section of railway tunnel. Buildings 2023, 13, 2859. [Google Scholar] [CrossRef]

- Li, H.Y. Research on Construction Technology of Subway Crossing Tunnel in Variable Cross-Section and Soft Flow Plastic Stratum. Master’s Thesis, Central South University, Changsha, China, 2007. [Google Scholar]

- Zeng, W.H.; Peng, X.F.; Zhang, L.; Hu, E.L.; Yang, W.B. Mechanical Characteristics of Super-Large Variable-Section Tunnel. Chin. J. Undergr. Space Eng. 2022, 18, 2062−2071+2079. [Google Scholar]

- Fang, G.; Ding, C.L.; Jia, R.Z.; Wu, C. Mechanical Properties Analysis of Large Cross-section Tunnel with Variable Cross-Section. Mod. Tunn. Technol. 2018, 55, 258–263. [Google Scholar]

- Lu, R. Research on Construction Method Optimization and Support Countermeasures of Large Span Variable Section Bifurcation Tunnel. Master’s Thesis, University of Jinan, Jinan, China, 2023. [Google Scholar]

- Ayasrah, M.M.; Qiu, H.; Zhang, X. Influence of Cairo Metro Tunnel Excavation on Pile Deep Foundation of the Adjacent Underground Structures: Numerical Study. Symmetry 2021, 13, 426. [Google Scholar] [CrossRef]

- Huang, L.-H.; Chen, Q.-N. Study on Stability of Underground Cavern in Variable cross Section Based on Nonlinear. J. Hunan Inst. Eng. 2012, 22, 61–64. [Google Scholar]

- Fu, J.N. Comparison and Selection of Construction Scheme for Variable Section Tunnel in Interval Crossing Section Based on Numerical Analysis. Railw. Constr. Technol. 2019, 308, 104–108. [Google Scholar]

- Li, T.; Wang, Y.B.; Yu, Z.W.; Liu, B. Prediction of soil movement and settlement of excavated surface soil of variable section tunnel. J. Cent. South Univ. (Sci. Technol.) 2020, 51, 433–444. [Google Scholar]

- Tai, Q.M.; Zhang, D.L.; Wang, J.C.; Sun, Z.Y.; Li, A. Analysis on pressure arch evolution law of high-speed railway tunnel under unfavourable rock conditions. J. Beijing Jiaotong Univ. 2015, 39, 62–68. [Google Scholar] [CrossRef]

- Gere, J.M.; Goodno, B.J. Mechanics of Materials, 8th ed.; Cengage Learning: Boston, MA, USA, 2012. [Google Scholar]

| Stratum | Density /kN/m3 | Elastic Modulus /GPa | Poisson Ratio | Internal Friction Angle | Cohesion /kPa |

|---|---|---|---|---|---|

| Highly Weathered Granit | 22.5 | 0.5 | 0.25 | 28 | 50 |

| Moderately Weathered Granite | 24 | 5 | 0.23 | 35 | 500 |

| Slightly Weathered Granite | 25.8 | 22 | 0.23 | 40 | 1600 |

| Name of The Material | Material Type | Elastic Modulus/GPa | Density/kN/m3 | Poisson Ratio | Thickness/m |

|---|---|---|---|---|---|

| Initial Support | Plate Element | 28 | 25 | 0.2 | 0.31 |

| Temporary Support | Plate Element | 28 | 25 | 0.2 | 0.25 |

| II-shaped section Strengthening Support | Plate Element | 28 | 25 | 0.2 | 0.26 |

| Mortar Anchor | Implantable Truss | 206 | 78.5 | 0.25 | / |

| Advanced Support | Implantable Beam Element | 206 | 78.5 | 0.25 | / |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, C.; Gong, W.; Song, S.; Wang, R. Study on Cross-Section Transition Form and Stability of Super-Large Variable-Span Tunnel. Symmetry 2025, 17, 2036. https://doi.org/10.3390/sym17122036

Xie C, Gong W, Song S, Wang R. Study on Cross-Section Transition Form and Stability of Super-Large Variable-Span Tunnel. Symmetry. 2025; 17(12):2036. https://doi.org/10.3390/sym17122036

Chicago/Turabian StyleXie, Can, Wenbo Gong, Shuguang Song, and Rui Wang. 2025. "Study on Cross-Section Transition Form and Stability of Super-Large Variable-Span Tunnel" Symmetry 17, no. 12: 2036. https://doi.org/10.3390/sym17122036

APA StyleXie, C., Gong, W., Song, S., & Wang, R. (2025). Study on Cross-Section Transition Form and Stability of Super-Large Variable-Span Tunnel. Symmetry, 17(12), 2036. https://doi.org/10.3390/sym17122036