1. Introduction

Nanoparticles can be suspended to overcome the limited thermal conductivity of traditional heat-transfer fluids, resulting in nanofluids with much higher thermal conductivity for industrial applications. Increasing thermal conductivity ensures faster heat dissipation, reduces thermal damage, enhances heat-transfer efficiency, and fosters system reliability. By utilizing nanoparticles more effectively in nanofluid applications, thermal and energy system efficiency is improved, energy consumption is reduced, and sustainability is promoted [

1]. Ali et al. [

2] looked into the impact of varying the radius of copper nanoparticles on the flow of nanofluids under the combined influence of a magnetic field and porous media, aiming to optimize heat-transfer rates by analyzing effects on microrotation, velocity, and temperature profiles. Ref. [

3] demonstrated that, while the magnetic field resisted fluid flow, the addition of nanoparticles enhanced heat transfer, and that slip, viscosity variations, and magnetic effects were important factors in regulating thermal conductivity in porous materials. Sachin et al. [

4] used a nanofluid consisting of graphene oxide and aluminum oxide nanoparticles to investigate the effects of an inclined magnetic field on fluid flow over a stretching surface. They also analyzed several parameters to determine how they influence physical properties that are important in the biological, physical, and engineering sciences. The importance of mass flux due to a temperature gradient, heat flux resulting from a concentration gradient, and nanoparticle radius in the dynamics of a fluid exposed to an inclined magnetic field was examined by Shah et al. [

5]. A magnetic field and thermal radiation were considered in the flow and heat transfer of a nanofluid with fine particles flowing over a stretching surface [

6].

Peristalsis of Ree–Eyring non-Newtonian fluid is crucial for researching the rheological properties of biological fluids, such as blood, saliva, intracellular fluids, interstitial fluids, and intravascular fluids [

7]. The effects of different variables on fluid temperature and velocity, as well as the influence of thermal radiation and an inclined magnetic field on an MHD boundary layer across an exponentially stretching sheet, were investigated. The findings were consistent with previous similar studies [

8]. Srinivasulu et al. [

9] numerically examined the influence of an aligned magnetic field on Williamson nanofluid flow across a stretching surface with convective boundary conditions. Hayat et al. [

10] explored the effects of heat transfer and an inclined magnetic field on the flow of a third-grade fluid across an exponentially stretching surface. The impact of heat transfer and an inclined magnetic field on a stretching sheet with elastic deformation was also studied [

11]. For both Newtonian and non-Newtonian fluids, the study demonstrated that velocity profiles increased with Casson and stretching ratio parameters but decreased with increasing magnetic field parameters. In both fluid types, temperature profiles rose as the magnetic parameter, Prandtl number, and Eckert number increased [

12].

Using numerical techniques to assess velocity, temperature, skin friction, and the Nusselt number, Sudais [

13] examined the effects of a heat source and variable thermal conductivity on steady radiative MHD flow adjacent to a stagnation point over a nonconducting stretching sheet. The effects of radiation and different heat fluxes on EMHD nanofluid flow across a stretching sheet were investigated in the study by Ali et al. [

14]. In addition to improving the temperature field, the radiation parameter also improved the flow characteristics by increasing the velocity.

The mathematical model of entropy generation in convective magnetohydrodynamic flow of a Williamson nanofluid over a stretching sheet with suction and Cattaneo–Christov heat flux was numerically analyzed [

15]. With thermal radiation incorporated in the energy equation, the flow and heat transfer properties of a viscous nanofluid across a nonlinearly stretching sheet have been explored in the presence of thermal radiation and changeable wall temperature [

16]. A stretching surface with variable viscosity and convective conditions was used in the study by Mabood et al. [

17] to investigate the effects of thermal radiation and slip on MHD Casson nanofluid flow. Over a flat plate with convective heat flux and a non-uniform heat source/sink, the study evaluated the impact of temperature-dependent characteristics, partial slip, and thermal radiation on hydromagnetic flow and heat transfer [

18]. Anagandula et al. [

19] investigated velocity- and thermal-slip-affected Williamson fluid flow across a stretching sheet with radiation and an inclined magnetic field, and they discovered that greater radiation increased the temperature. Multiple slip effects on unsteady MHD flow with heat and mass transfer over a stretching sheet were examined by Mabood et al. [

20]. The research takes into account non-uniform sheet velocity, the Soret effect, thermal radiation, and a time-dependent magnetic field.

The study of convective magnetohydrodynamic (MHD) biofluid transport through a non-uniform duct is of interest because of its applications in biomedical devices and equipment [

21]. The peristaltic flow of a Jeffrey nanofluid along a vertical diverging channel under the influence of activation energy, heat generation, thermal radiation, and an inclined magnetic field has been analyzed [

22]. The study examined the impacts of cobalt ferrite, magnetic fields, and slip effects on the flow of a specific magnetic fluid over a stretching or shrinking surface, as well as their influence on heat transfer, flow stability, and friction [

23]. The effects of radiation, multiple slip, and an inclined magnetic field on the flow of a Williamson fluid over a stretching sheet were examined by Srinu et al. [

24]. The effects of velocity and thermal slip in MHD hybrid-nanofluid flow across a permeable, exponentially stretching or shrinking sheet were investigated by Patel et al. [

25], and it was demonstrated that these factors enhanced heat transfer and supported sustainable energy. The fluid velocity and boundary-layer thickness were affected by the Deborah number and velocity slip in the MHD flow and heat transfer of a Jeffrey nanoliquid over a stretching sheet [

26]. The slip-flow nanofluid over a permeable stretching sheet under magnetohydrodynamic forces was examined by Adel et al. [

27]. It was found that while the thermal boundary-layer thickness increased with higher slip velocity and magnetic parameters, the velocity boundary-layer thickness decreased. Using an RSM technique to optimize the heat-transfer properties of Casson hybrid-nanofluid flow across a porous, exponentially stretching surface [

28]. Baithalu et al. [

29] conducted a thorough RSM–ANOVA study to optimize shear and coupling stress analysis for magnetomicropolar dissipative nanofluid flow over a stretching surface.

The previously mentioned literature is still pertinent to research examining the significance of the nanoparticle radius under the simultaneous effects of a magnetic field and nonlinear thermal radiation. An exponential heat source and a higher-order boundary condition are also considered in the flow of a water-based tangent-hyperbolic fluid over a stretching sheet. The controlling partial differential equations were reduced using a similarity transformation, followed by their conversion into a set of nonlinear ordinary differential equations and their numerical solution using MATLAB (2021)’s BVP5C method.

The current study presents a novel aspect by using Response Surface Methodology (RSM)-based CCD design to optimize the thermal transmission rate. Systems employing micropolar hybrid nanofluids are optimized in the study’s results, which could be applied to various industrial and technical operations. Furthermore, combining RSM with ANOVA demonstrates an effective approach for clarifying the optimization of heat transfer when multiple components are involved. Tables and graphs illustrate the effects of various physical parameters on skin friction, temperature profiles, microrotation, dimensionless velocities, and the Nusselt number. Important information on the fluid’s flow properties and thermal behavior under different conditions is provided by the analysis results. In engineering applications where fluid dynamics and heat transfer are important, these findings can help optimize operations.

2. Model Description

This work investigates a two-dimensional, incompressible, viscous flow of a tangent-hyperbolic nanofluid over a stretching sheet with second-order slip and convective boundary conditions. The stretching surface, with a stretching velocity, runs along the x-axis. The transport phenomena of nonlinear convective and radiative micropolar nanofluid flow with varying nanoparticle radii have been taken into consideration. Additionally, the effects of an exponential heat source, inclined MHD, hydrodynamic slip, passive control of nanoparticles, and Arrhenius activation energy are taken into consideration. The sheet stretches linearly with the velocity

, where

a is a constant, while keeping the origin stationary [

Figure 1]. The fluid is a water-based

nanofluid. The controlling boundary-layer equations are developed using the boundary-layer approximations.

Refs. [

30,

31,

32,

33]

The problem mentioned above has a couple of boundary conditions [

34,

35]:

The acronyms listed below stand for the following terms: The effective heat capacity of the nanofluid is indicated by

.

is the material parameter representing the heat source coefficient, which depends on the exponential spatial.

denotes the spin gradient’s viscosity. The symbols used to represent fluid density, angular velocity (microrotation vector), micro-inertia, and viscosity vortex are

and

N. The Brownian diffusion coefficient is denoted by

. The heat transfer coefficient is denoted by

; the reaction rate is denoted by

; activation energy is denoted by

; the exponential index is denoted by

n; the fitted rate constant is denoted by

m;

is the heat sink coefficient that is thermally dependent

; and

is the Arrhenius function.

is the value of the parameter

for the boundary constant. The antisymmetric portion of the stress tensor vanishes at

, and turbulent boundary-layer flows occur at

. N = 0 occurs at the surface when

, where the microelements are unable to spin. The subsequent correspondence transforms can be utilized to alter Equations (2) to (6) in a set of differential equations [

36]:

represents the dimensionless coordinate.

together with various boundary conditions:

The resulting connection between the dynamic viscosities of the base fluid and the nanofluid was established by Gosukonda et al. [

37] and Graham [

38]:

The nanoparticle radius is denoted by the term

, the inter-particle spacing is denoted by

H, the Prandtl number is denoted by

, the Biot number is denoted by

, and the rendition parameter is denoted by

. The magnetic parameter is denoted by M, the similarity variable is denoted by

, the Schmidt number is denoted by

, the exponential space-dependent heat source parameter is denoted by

, the thermal heat source is denoted by

, the temperature ratio parameter is denoted by

, the reaction parameter is denoted by

, the dimensionless activation energy is denoted by

, the Weissenberg number is denoted by

W, the material parameter is denoted by

K and nanofluid’s thermophysical characteristics are shown in

Table 1.

4. Methodology and Validation

The highly nonlinear coupled ODE system with boundary condition (11) and Equations (7)–(10) can be solved using the BVP5C method function in the MATLAB solver. The BVP5C technique is often used to solve ODEs when the problem’s details are unknown in advance, and a flexible approach is needed to strike a compromise between accuracy and efficiency.

The following is the first guess strategy and solver setup:

For every dependent variable——over the computational domain, an initial mesh of 500 equally spaced points is generated for . The BVP5C solver refines the guesses iteratively until the residuals fall within the specified tolerance. The hypotheses are built on physically expected trends, such as exponential decline for temperature, concentration, and motile microbe density, and linear variation for velocity.

Tolerance and convergence criteria are as follows:

The solver iteratively updates the solution until the largest residual norm, , is less than over the entire domain. This ensures high numerical precision by setting the relative and absolute error tolerances to , confirming that further mesh refinement (up to 500 points) results in changes of less than 0.01 in the key output parameters—the skin-friction coefficient, Nusselt number, and Sherwood number.

Following sensitivity tests in which was varied from 6 to 9, the far-field boundary of = 7 was selected. It was found that, with minimal variation () in the calculated findings, the velocity, temperature, and concentration profiles all reached their asymptotic ambient values () beyond . This guarantees computational efficiency without compromising accuracy. Plotting the profiles and increasing until no discernible difference in the curves was seen allowed us to confirm the asymptotic nature of the profiles.

Now we set .

Accordingly, we have

The boundary conditions as

The final solution is obtained by calculating the variable values across the domain, and the level of accuracy is verified in

Table 2.

5. Concluding Results

The figures depict the effects of several important parameters on the velocity , microrotation , temperature , and concentration profiles in the presence of stimulating influences from inclined MHD and the nanoparticle radius .

Table 3 displays the variation of the skin-friction coefficient for different values of the velocity ratio parameter

, permeability parameter

, velocity slip,

and

, and the inclination angle

for two distinct particle diameters,

and

. The results demonstrate that

increases as W and K increase, suggesting that increased permeability and stronger stretching worsen surface shear stress. Conversely, greater values of the velocity slip parameter

result in a drop in

, indicating that microrotational effects reduce wall shear and counteract fluid motion. The sensitivity of friction to microrotation coupling is also demonstrated by the fact that a larger negative

raises Cf. Additionally, as the magnetic field inclination angle

increases from 45 to 90, cf decreases for all parameter combinations because the magnetic damping effect is stronger at higher inclinations. The higher particle diameter,

, yields considerably higher Cf values than

because larger particles have a thicker boundary layer and stronger momentum interaction.

The

Table 4 shows that the local Nusselt number

changes for two particle diameter ratios (

and

) for different values of

W,

,

,

, and

n. Given that

rises with increasing radiation parameter

and Biot number

, the results indicate enhanced heat transfer due to stronger radiative and convective effects. In contrast, when the power-law index

n or the microrotation parameter

rises,

falls, signifying a drop in temperature. Moreover, when the inclination angle

increases from 45 to 90,

decreases.

Figure 2a–d illustrate that the magnitude of the velocity distribution increases as the radius of the nanoparticle

increases from

to

. Consequently, the interphase and the nanoparticles are affected by the nanoparticle radius. In these nanofluids, the velocity increases as viscosity decreases with particle size. This explains why the velocity of the current transport phenomena increases with the radius of

. The impact of an increasing external magnetic flux, which is directly proportional to the angle (

), is also observed. According to

Figure 2a–d, lower velocities in the transport phenomena are achieved with increasing magnetic strength.

The impact of the Weissenberg number

W on the velocity field is shown in

Figure 2a. The velocity profile slightly decreases with increasing

W. The Weissenberg number is physically defined as the ratio of the fluid relaxation time to the characteristic process time. A decrease in the velocity field occurs due to the increasing resistance to fluid motion caused by a longer relaxation time as the Weissenberg number increases.

The relationship between the material parameter and the velocity profile is depicted in

Figure 2b. It is observed that the velocity profile decreases as a function of

K for nanoparticle radii

and

. Higher

K values are physically associated with lower viscosity and weaker rotation of the fluid’s particle moments. The material behavior changes without structural alteration due to its intrinsic properties. With higher

K values, it is evident that the fluid moves at a higher velocity near the wall and slows down as it moves away from it.

Figure 2c,d illustrate the effects of the first- and second-order slip parameters on the velocity field. The hydrodynamic boundary-layer thickness decreases, and the velocity field becomes smaller as the absolute values of

and

increase. In physical terms, an increase in the slip parameters decreases the thickness of the flow field and the velocity boundary layer because of the increased resistance to fluid motion.

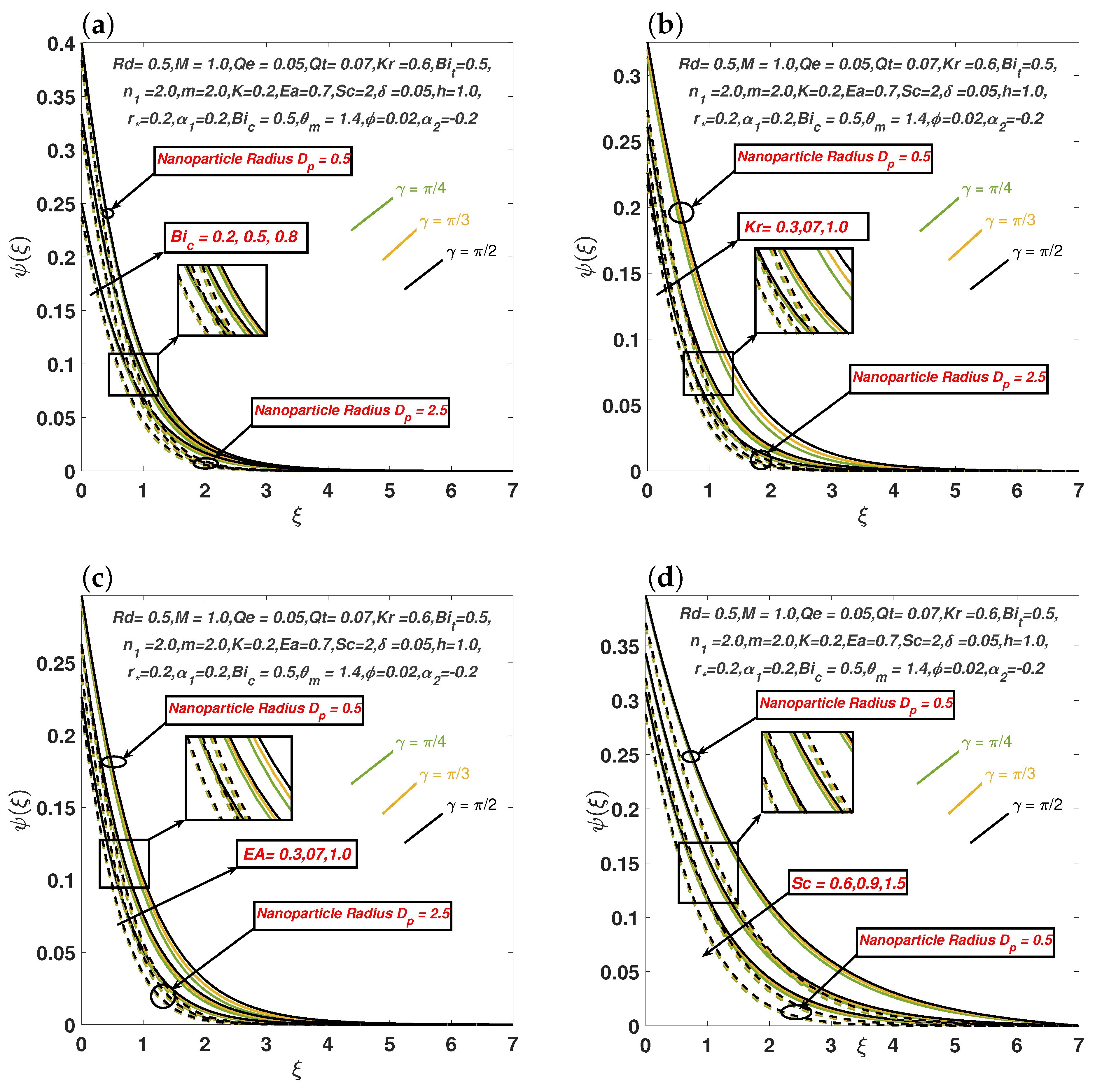

Figure 3a–d show that the microrotation distribution decreases as the radius of

nanoparticles increases from

to

, while the distribution pattern indicates enhanced fluid-layer activity with an increase in

from

to

in each profile. By increasing frictional heating between the fluid layers, the Lorentz drag physically releases energy as heat. This leads to a thickening of the thermal boundary layer. Additionally, the profile thickens as

W and

K increase, whereas the first-order and second-order slip parameters exhibit the opposite behavior.

Figure 4a–d show that as the particle radius

increases, the thermal boundary-layer thickness decreases. For

, the thermal boundary layer is significantly reduced, indicating a decline in the fluid-layer thermal properties with increasing

nanoparticle radius. However, the thermal layer thickens as

increases due to the parallel influence of MHD. Additionally, it is found that the fluid layers associated with

and

exhibit a rapidly growing thermal boundary layer. The temperature gradient increases as a result of stronger convective heating at the sheet, which is physically correlated with a larger

. With a greater temperature difference, the thermal influence can penetrate further into the quiescent fluid. As the fluid temperature increases with the Biot number, convective heat transfer is enhanced and the sheet’s thermal resistance decreases. The thermal boundary layer is found to be a highly significant increasing feature of the fluid layers for

and

.

Figure 5a,b illustrate how the concentration Biot number, chemical-reaction parameter

, nanoparticle radius

, and the stimulating influence of inclined MHD affect the concentration profile. The relationship between the Schmidt number (

) and the activation-energy parameter (

) with the concentration profile is shown in

Figure 5c,d. The

increases the profile, while a notable decrease is observed with

. Physically, the activation-energy parameter provides atoms or molecules with greater energy to interact, thereby intensifying the chemical reaction and enhancing the concentration profile.

6. Response Surface Methodology (RSM)

The interaction between pertinent attributes and the response variable is statistically investigated using RSM. RSM uses data from the central composite design to estimate the model for the dependent variable (Mahanthesh et al. [

42]). The heat transport of the

nanoliquid, represented as

, is selected as the dependent variable in this problem, and the independent variables are the magnetic parameter

, the nanoparticle radius

, the magnetic parameter

, and the radiation parameter

.

Table 5 displays the effective parameters and their levels. A generic model for the response variable, including interactive, quadratic, and linear terms, is expressed as follows:

Regression coefficients are represented by

(

i = 1 to 10). According to the CCD, the experimental plan and responses for the 20 runs are shown in

Table 6.

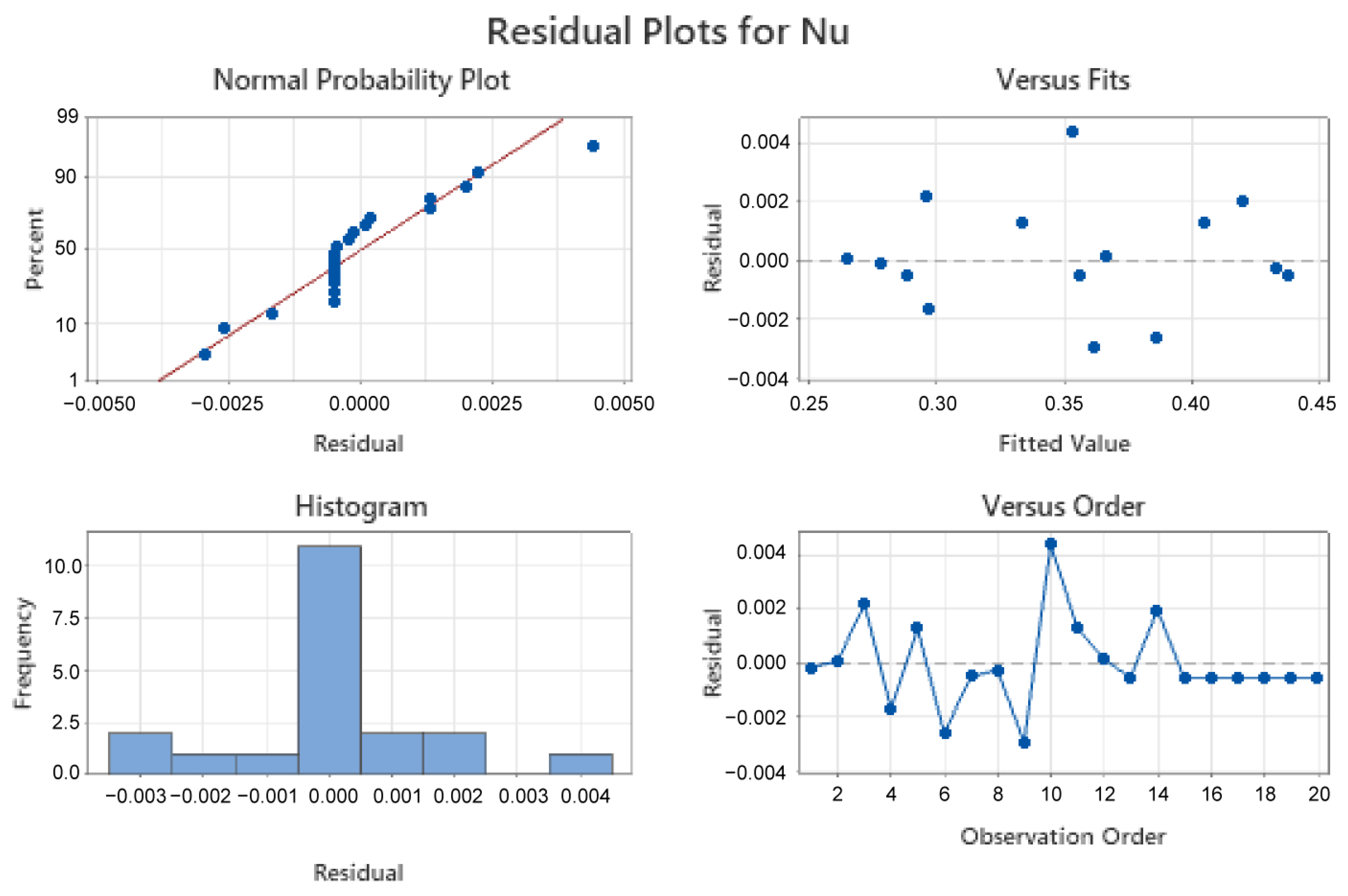

The estimated model’s efficiency is detailed in the ANOVA table (

Table 7). A parameter is deemed significant if its associated

p-value is less than 0.05 and its related F-value is larger than 1. See Areekara et al. [

43]. The quadratic terms in M and

, as well as the interaction term

, are found to be meaningless. These terms are, therefore, removed from the model. With a coefficient of determination (

) of 99.96, the model’s accuracy is increased. The uncoded version of the fitted quadratic model for

is provided by

The residual versus fitted plot shown in

Figure 6 is used to evaluate the estimated model’s dependability. The model’s accuracy is further increased by the fitted versus residual plot, which displays a maximum error of 0.010. By putting the third variable at the midpoint,

Figure 7 (contour plots) and

Figure 8 (surface plots) demonstrate that two independent factors can have an impact on the dependent variable simultaneously and make it clear that higher values of Rd and

and a lower

M, result in greater heat transfer.