1. Introduction

Hardware-in-the-Loop (HIL) testing technology, which integrates physical prototypes with numerical models, has proven indispensable for verification in fields such as aerospace and industrial control. It offers a high-precision and cost-effective approach for performance testing and control strategy validation of complex systems [

1]. In the field of aerospace engineering, Wang et al. [

2] developed a dual-satellite HIL testing experimental platform to address the technical challenges associated with inter-satellite laser interferometry in gravitational wave detection missions. By establishing a ground-based simulation environment, they successfully replicated in-orbit laser ranging and interferometric behaviors. Similarly, Du et al. [

3] focused on issues related to close-range spacecraft rendezvous, using an HIL testing system to validate strategies for improving angular navigation accuracy. Their work provided essential experimental support for the advancement of autonomous spacecraft rendezvous technology. In the industrial sector, HIL testing also plays a vital role. For instance, in precision tasks such as rotor assembly and bolt tightening, researchers have implemented HIL testing systems to optimize balance and preload distribution during assembly, thereby significantly improving the accuracy and efficiency of complex manufacturing processes [

4]. Collectively, these findings highlight the critical importance of HIL testing technology in the modeling and validation of complex systems.

Despite notable advancements in HIL testing technology across these domains, current research exhibits significant shortcomings in the critical step of initial attitude calibration. Such deficiencies impede the ability to meet the requirements of testing scenarios where convenience and efficiency are paramount, ultimately compromising the accuracy of subsequent dynamic simulations and even posing risks of equipment damage. In the context of missile system HIL testing, Hu et al. [

5] developed an experimental setup consisting of a three-degree-of-freedom motion platform and a servo-loading mechanism, enabling real-time detection and localization of failures in control surfaces and lifting surfaces. While their work advanced fault diagnosis during dynamic tests, it paid insufficient attention to attitude calibration in the initial testing phase and overlooked potential issues stemming from coordinate system misalignment. Similarly, Zhang et al. [

6] proposed a reinforcement learning-based HIL testing method to address balance optimization in fan rotor assembly. Yet, their approach also neglected the initial attitude calibration stage, potentially causing the phase angle adjustments of the blades to deviate from correct reference points. Furthermore, existing studies on initial attitude calibration have largely depended on external high-precision instruments—such as laser rangefinders, total stations, or dedicated calibration fixtures—to measure the attitude parameters of physical prototypes offline before importing them into numerical models [

7]. Although these methods can achieve high accuracy, they involve complex equipment setups that increase system cost and debugging complexity, while also limiting adaptability to dynamic adjustment needs. Therefore, the development of a convenient and reliable method for initial attitude calibration holds considerable theoretical and practical significance for enhancing HIL testing experiments.

This study employs a HIL test bench specifically designed for space docking mechanisms as the experimental platform. During the establishment of the initial coordinate system for HIL testing, the operator manually adjusts the pose of one docking mechanism to align it with its counterpart. This adjustment involves pushing, pulling, or rotating the end-effector of the target docking mechanism until the docking interfaces of both mechanisms achieve proper alignment. The entire alignment process consistently emphasizes the attainment of “goal symmetry”—a spatial pose alignment condition where the coordinate systems of the two docking mechanisms achieve either complete coincidence or mirror symmetry. This state represents the core objective of the initial attitude calibration procedure.

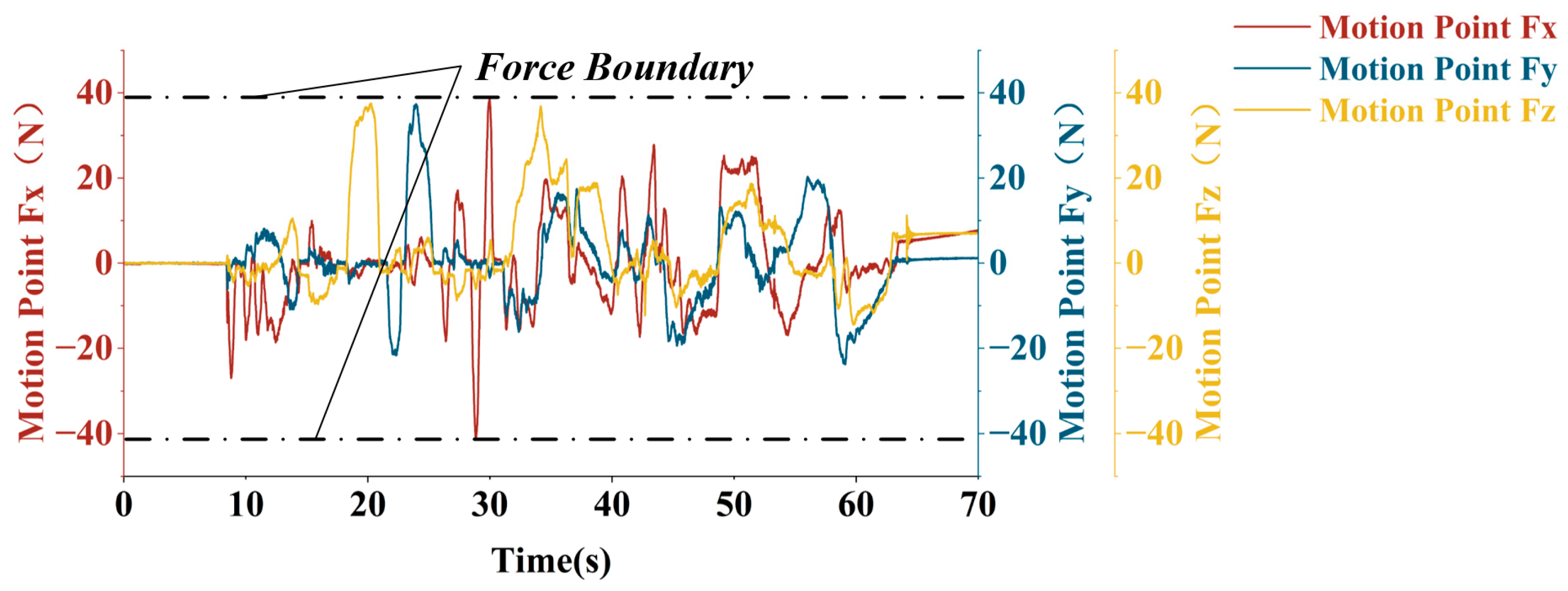

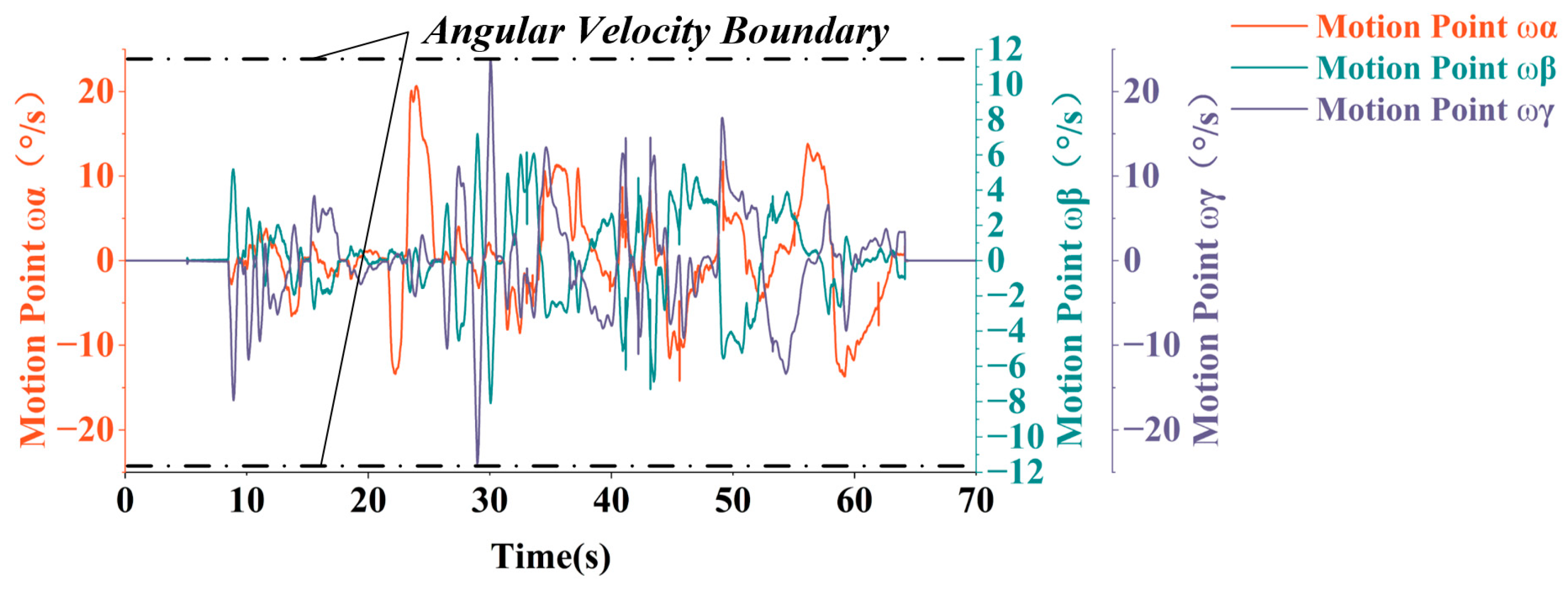

A 6-axis collaborative robotic arm equipped with a six-degree-of-freedom (6-DOF) force/torque sensor at its end-effector plays a critical role in the pose alignment process. It performs two primary functions: first, it acquires and transmits in real time the three-dimensional forces (Fx, Fy, Fz) and torques (Tx, Ty, Tz) generated during human–robot interaction, thereby providing accurate force/torque feedback for subsequent motion adjustments; second, it dynamically regulates its movement speed and acceleration based on the real-time force/torque signals. For instance, when the interaction force exceeds a predefined threshold, the robotic arm automatically and smoothly reduces its velocity from a higher initial value to a lower level while strictly constraining acceleration within a specified range to prevent inertial impact damage to the docking mechanism.

This dual-function design—integrating real-time sensing with dynamic adjustment—effectively reconstructs an ideal state of “interactive symmetry.” It ensures that during operator-guided traction, including fine corrections for minor pose deviations, the robotic arm’s motion response maintains high coordination with the operator’s input. The resulting motion remains smooth and jerk-free while exhibiting negligible delay, achieving close matching in both force transmission and kinematic correspondence.

The control strategy supporting this process is built upon an admittance control framework compliant with physical human–robot interaction standards. This framework not only maintains contact forces and interaction torques between the active and passive ends within a safe range—preventing structural damage to the docking mechanism and ensuring operator safety—but also guarantees smooth and continuous attitude trajectory throughout the alignment process, avoiding jerks or abrupt changes. These features collectively form a closed-loop control system that further facilitates the coordinated realization of both goal symmetry and interactive symmetry: while goal symmetry focuses on achieving precise pose alignment, interactive symmetry aims to establish a highly coordinated collaborative state between human and machine.

The proposed approach must address three fundamental challenges:

First, inherent time delays in command transmission, sensor filtering, and actuator response cause dynamic response mismatches, introducing significant phase deviations and lag. These delays can induce oscillatory behavior during attitude adjustments, increasing the risk of unintended collisions and complicating the calibration process, all of which must be managed under strict safety constraints.

Second, during the human-guided process for initial attitude calibration, the system is subjected to complex multi-source disturbances. These include measurement noise, robotic arm drive delays, parameter perturbations in the physical prototype, and environmental interference. These coupled, model-unknown uncertainties lead to deviations in the end-effector’s pose tracking, adversely affecting calibration accuracy and compromising the system’s robust stability. Consequently, effectively suppressing these disturbances without a precise model is crucial for ensuring reliable calibration.

Third, the manual guidance process must satisfy two conflicting requirements simultaneously—and these two requirements essentially serve to maintain ideal interactive symmetry between humans and machines, i.e., a smooth, force-matched, and lag-free collaborative relationship between the operator and the robotic arm: On one hand, it must strictly control the forces and torques of human–machine interaction within safety thresholds to prevent personnel injury or equipment damage, as excessive or asymmetric force/torque deviations would break the force balance in interactive symmetry and lead to risky collisions; on the other hand, it must ensure the robotic arm precisely tracks the operator’s low-frequency intentions without lag to achieve rapid calibration, since any response delay would disrupt the action synchronization in interactive symmetry and cause misalignment between the operator’s guidance intent and the robotic arm’s motion. This highlights the core challenge of balancing safety and tracking accuracy in dynamic human–machine interactions—and essentially, this balance is the key to safeguarding the stability of interactive symmetry throughout the calibration process.

To address these challenges, this paper incorporates time delays into the dynamic model and leverages the robustness of H∞ control theory, conducting targeted research as follows:

In various control system scenarios, control delays and system imbalances often lead to performance degradation and reduced stability; thus, the investigation of compensation strategies holds significant engineering importance. Existing scholars have proposed multiple delay compensation methods for different application scenarios: Ma et al. [

8] developed a novel vibration-absorbing wheel structure with time-delay feedback control for traditional wheel configurations, analyzed both delay-independent and delay-dependent stabilities of the system, and optimized the time-delay feedback control parameters using particle swarm optimization. This work provides a new technical path for vehicle vibration reduction systems, effectively mitigating the conflict between ride comfort and handling stability, and is of great significance for enhancing overall vehicle performance. Chan et al. [

9] proposed a robust adaptive nonlinear teleoperation system based on an improved extended active observer, an adaptive Smith predictor, and sliding mode control, aiming to address communication channel delays and uncertainties in nonlinear robot models. However, this method exhibits limited phase correction capability in high-frequency delay regions. For input time delays in nonholonomic differential-drive mobile robots, Baez-Hernandez et al. [

10] introduced a nonlinear extended form of the linear sub-predictor strategy to estimate future system states over h time steps. Based on Lyapunov-Krasovskii functional analysis, they proved that increasing the number of sub-predictors in the observation chain can effectively handle large time delays. By incorporating the predicted future states into the control law, closed-loop system stability was achieved. Finally, real-time experiments and numerical simulations verified the effectiveness of the prediction strategy.

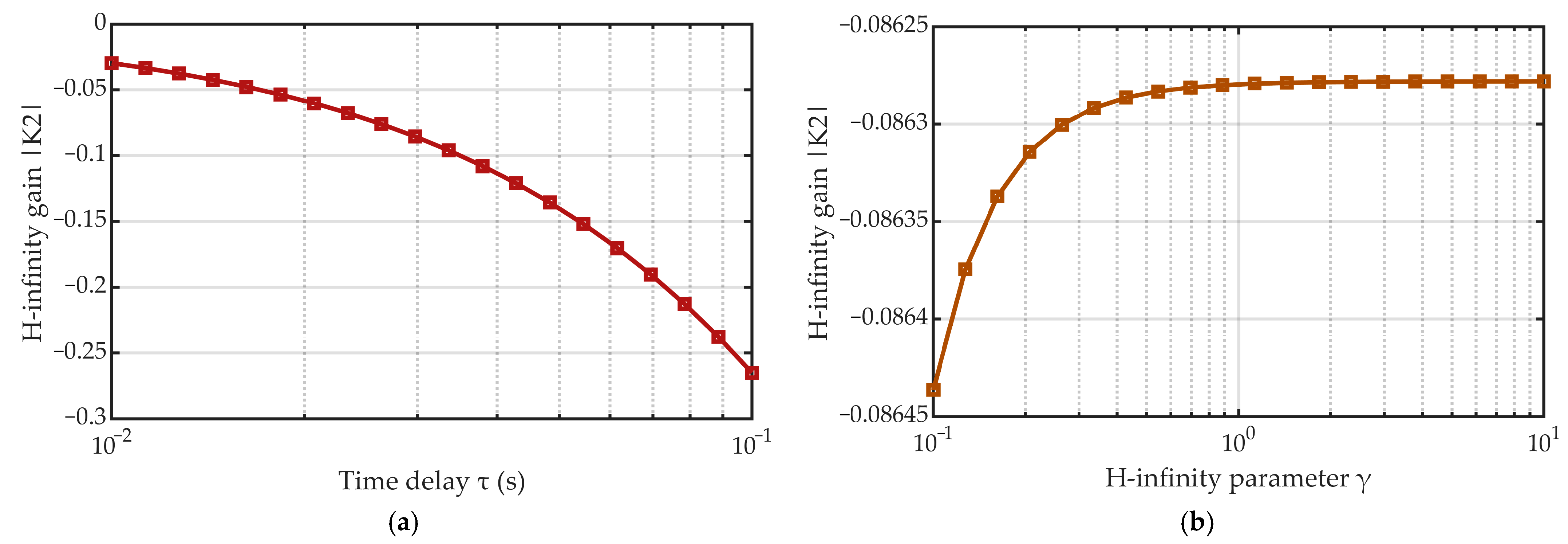

To overcome these limitations, this paper integrates inherent delays from command transmission, filtering, and actuation into the dynamic model. Pure delay terms are transformed into linear state-space representations using the Padé approximation, accurately capturing the dynamic coupling between delays, attitude deviations, and interaction forces/moments. This provides a precise foundation for designing an H∞ controller capable of robust delay compensation.

- 2.

Robustness against multi-source uncertainties:

The H∞ control framework aims to minimize the influence of disturbances on system outputs and ensure control precision under uncertain conditions, with its strong robustness well-documented: Zhang et al. [

11] proposed a robust, H∞-based fault-tolerant control strategy for hexacopter unmanned aerial vehicles operating in environments with random network delays, model uncertainties, and compound sensor-actuator failures. This work provides theoretical support and design references for the stable operation of UAV systems under faults in complex network environments, offering valuable insights for developing high-reliability flight control systems. Gu et al. [

12] tackled the control problem of nonlinear quarter-car suspension systems subjected to coupled parameter uncertainties, external disturbances, and hydraulic actuator delays by proposing a finite-time robust control strategy integrating sliding mode control and backstepping. This strategy provides new design ideas for finite-time control of nonlinear delayed systems and verifies its engineering applicability in the typical mechatronic system of quarter-car suspensions. For systems with uncertain input delays, Zheng et al. [

13] proposed a robust H∞ stabilization method: time-scale transformation was first applied to convert the uncertain delayed system into one with only deterministic delays, after which the Chebyshev spectral continuous-time approximation method and augmented matrix were further employed to transform it into a delay-free form, thereby simplifying subsequent control design. Similarly, Zhang et al. [

14] proposed an adaptive H∞ robust control strategy based on neural networks for vibration control of offshore platforms under wave-induced disturbances, input delays, and parameter perturbations, providing a new approach for low-cost and high-reliability vibration control of platforms in complex marine environments. Li et al. [

15] established a state-space model of the locomotive grid-side rectifier in the dq-coordinate system and addressed system nonlinearity using the state feedback ex-act linearization method, proposing a novel H∞ control strategy for rectifiers. This study provides a solution for stability control of train-grid systems with simple parameter tuning and excellent dynamic characteristics, significantly enhancing the operational reliability of high-speed railways. Targeting the stability issue of electric vehicle bidirectional wireless charging systems under load variation and coil misalignment, Li et al. [

16] conducted systematic research based on H∞ robust control theory: a mixed-sensitivity H∞ controller was designed, and the robust stability and robust performance of the system were rigorously verified using the structured singular value method. This significantly improved the system’s dynamic response and output stability under parameter perturbations and external disturbances, delivering a reliable control solution for efficient and stable bidirectional energy interaction between electric vehicles and the power grid.

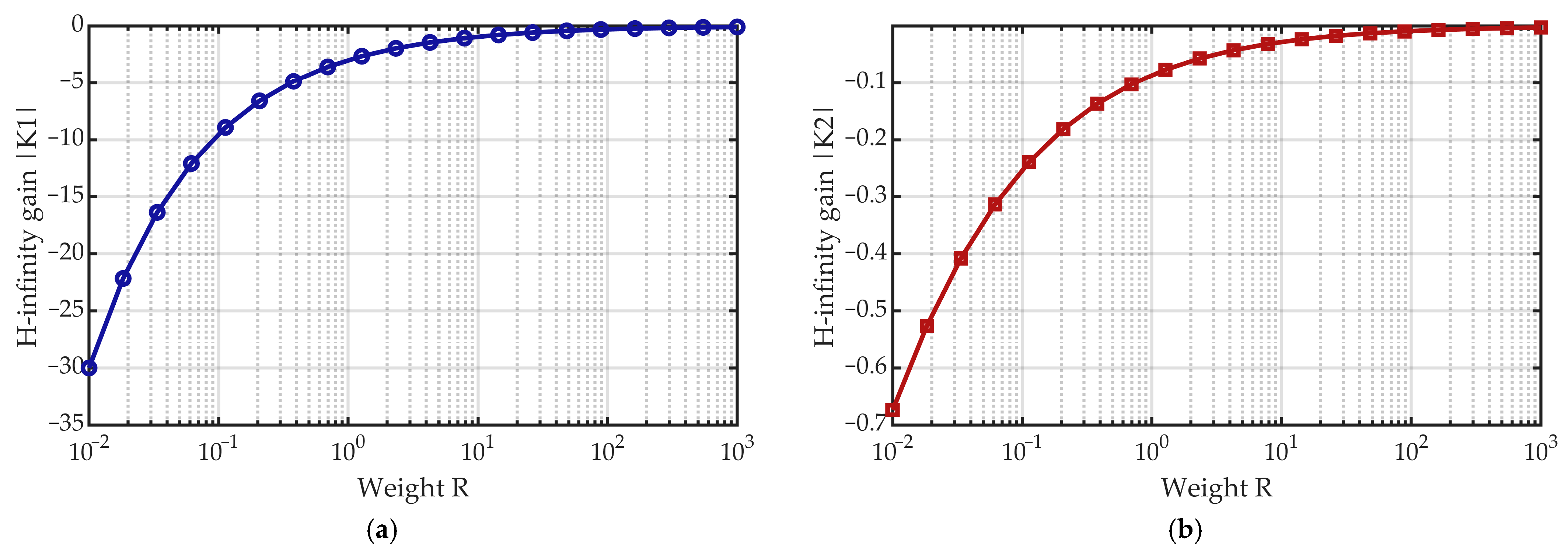

In this work, an augmented system model is constructed within the H∞ framework. The operator’s traction intent is treated as the reference input, six-dimensional force/torque signals as the output, and multi-source uncertainties as generalized disturbances. By constraining the H∞ norm of the closed-loop transfer function, the maximum amplification of sensor noise and environmental disturbances on tracking errors and interaction forces is limited. This theoretically guarantees robust stability against unknown disturbances, ensuring reliable operation in complex environments and mitigating instability risks.

- 3.

Balancing safety and rapidity in human–robot interaction:

The inherent randomness of physical interaction and the complexity of intent recognition make it challenging to distinguish intentional guidance from unintentional disturbances, particularly when operational speed is critical. Traditional compliance-based strategies often struggle to simultaneously guarantee safety and rapid response. Haddadin et al. [

17] implemented passive compliance control for a ball-handling task, but the lack of active force control and slow response render it unsuitable for scenarios requiring both safety constraints and high-speed operation. Lopes and Almeida [

18] integrated a Robot Collision Immunity Device to enable compliant assembly; however, the need for offline tuning of impedance parameters limits its adaptability to dynamically changing high-speed processes. Zhang et al. [

19] applied fuzzy impedance control to achieve flexible assembly by adjusting control gains through empirical rules, yet this method exhibits insufficient suppression of high-frequency disturbances and may fail to maintain stability under high-speed conditions, potentially compromising both safety and performance.

This paper proposes that the limitations of traditional methods in balancing safety and rapidity can be overcome through the frequency-domain shaping capabilities of H∞ control. The requirements for intent tracking and high-frequency disturbance attenuation are formulated as H∞ performance objectives. By constraining the H∞ norm of the closed-loop system, amplification of high-frequency disturbances is suppressed, enabling stable and rapid attitude adjustment. Furthermore, a value function within a game-theoretic framework is designed, and the Riccati equation is solved under this framework to harmonize agile tracking with force/torque safety constraints—this process embodies Symmetric Optimization, essentially seeking an optimal, balanced (symmetry-equivalent) solution between the conflicting demands of control objective (tracking accuracy) and safety constraint (force/torque limits). This avoids control performance degradation due to excessive conservatism or slow response, ensures accurate interpretation of operator intent while enabling both safe and efficient execution, and thereby effectively resolves the trade-off between safety and operational rapidity in human–robot interaction.

2. Establishment of Initial Attitude Calibration Model

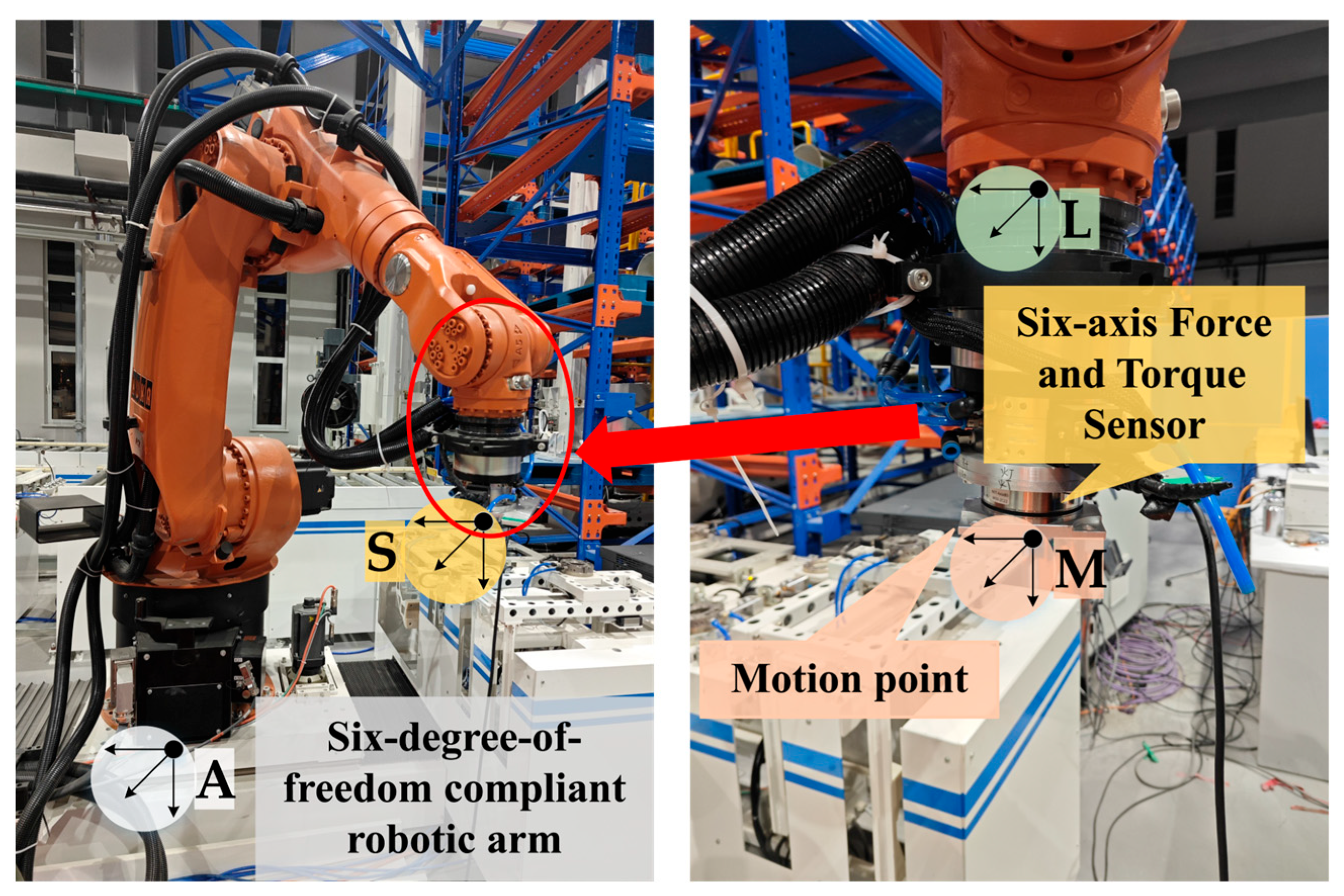

To accurately characterize the human–robot interaction dynamics during operator-guided manual positioning for initial pose calibration, a force-position coupling model must be established between the operator and the manipulator’s end-effector. We employ a Cartesian coordinate frame attached to the end-effector to quantitatively analyze the relationship between force feedback and positional deviation across all six degrees of freedom. The experimental setup is depicted in

Figure 1.

A motion point and a six-axis force/torque (F/T) sensor are mounted on the manipulator end-effector. The world coordinate frame {A} serves as the global reference. We define three key frames on the end-effector: the tool frame {L}, the force sensor frame {S} (from which F/T data is acquired), and the motion point frame {M}. For analysis, all force sensor data are transformed into the {M} frame.

The initial state of the model is defined when the operator’s hand engages with the robotic end-effector’s motion point, and the corresponding mathematical model is established. In this state, the operation point coincides with the origin of the manipulator’s end-effector coordinate frame, and the relationship between the applied force and the resultant positional deviation along any coordinate axis is described by the following linear model:

In the linear model,

denotes the current operating time of the system,

represents the current coordinate of the operating point along a given axis of the world coordinate system, and

represents the force component along each axis of the world coordinate system.

denotes the current positional coordinate of the end-effector of the manipulator along each axis of the world coordinate system and corresponds to the position input command received by the manipulator before time

.

is the gain coefficient that relates the deviation

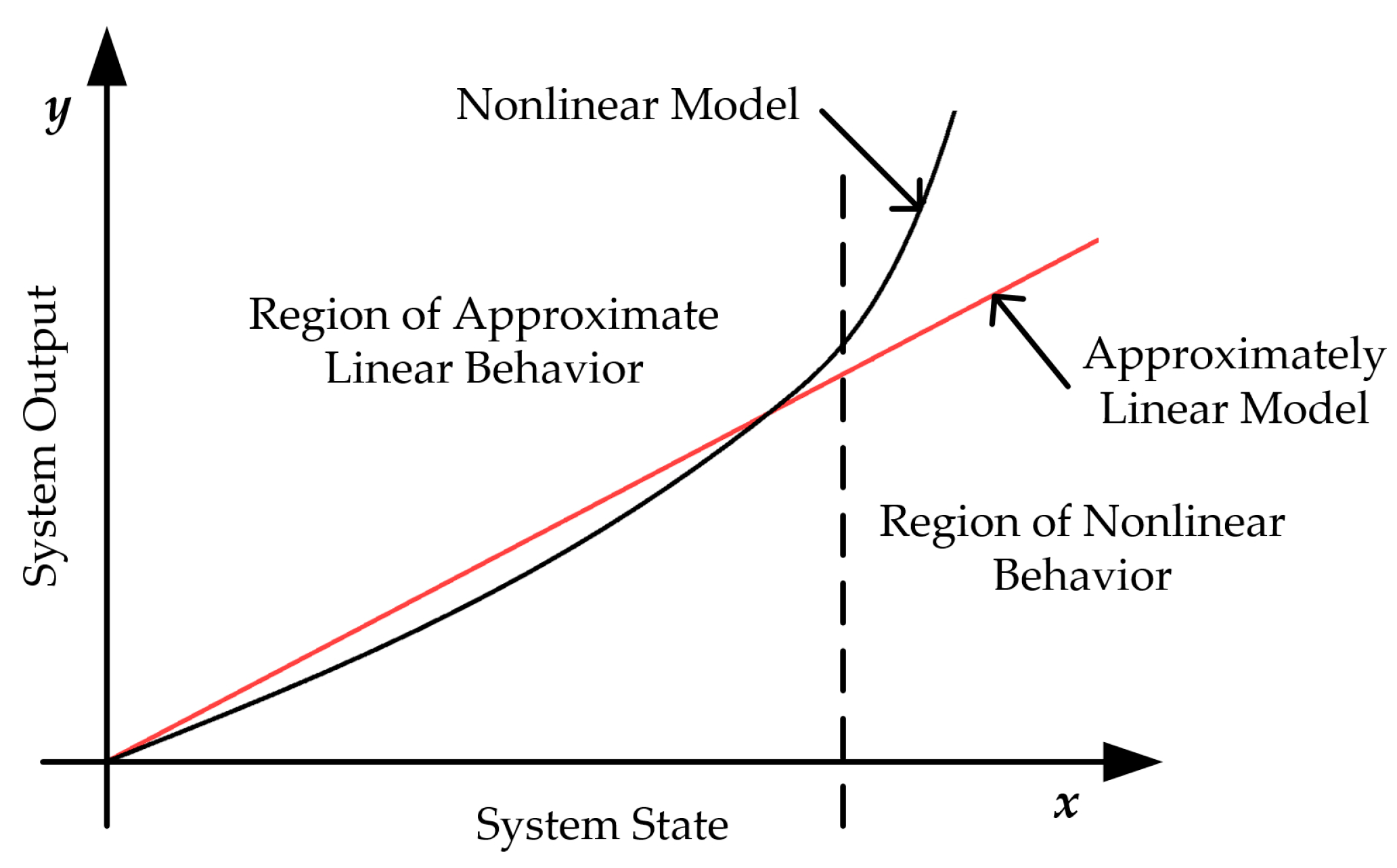

between the operating point of the operator and the position of the end-effector of the manipulator in each direction to the magnitude of the measured force component. The model operates under two core assumptions: first, the positional deviation between the operator’s operating point and the manipulator’s end-effector remains sufficiently small under normal operating forces; second, this deviation is linearly proportional to the force applied to the end-effector. The model and controller design presented in this work are developed and validated within the small-deviation linear regime, as confirmed by the experimental results. Under normal operating conditions, the interaction forces and torques remain bounded. A detailed discussion on the potential implications of nonlinear effects beyond this operational range is provided in

Appendix A.

Equation (1) is formulated in the manipulator’s end-effector coordinate frame for computational efficiency. This approach allows the force components measured by the force/torque sensor to be used directly, eliminating the need for additional coordinate transformations.

The torque component experienced along each axis of the manipulator end-effector coordinate system satisfies the functional relationship shown in Equation (2):

where

is the torque,

is the transformation coefficient between torque and angle difference, and

is the spatial rotational angle difference about the axis of torque. This equation governs the general relationship between angle and torque. Within the linear regime where angular changes are small, it shares the same form as Equation (1), but with a non-fixed axis of rotation. Our force/torque sensor can directly measure the torque components about the three coordinate axes (X, Y, Z). Consequently, by decomposing the rotational angles onto these three axes, we obtain three separate equations, each describing a rotation about a fixed axis.

where

denotes the current rotational angle of the operating point on the specified axis in the world coordinate system and

denotes the torque components on each axis of the world coordinate system.

denotes the current rotational angles of the end-effector of the robotic arm about each axis in the world coordinate system. This corresponds to the positional input commands received by the robotic arm prior to time

.

is the gain coefficient used to correlate the angular deviation

between the control point of the operator and the end-effector of the robotic arm in each direction, with the magnitude of the measured torque components.

Equation (1) is the force component of the system equation, and Equation (2) is the torque component of the system equation. Due to the identical dynamics across all six degrees of freedom, a uniform state-space model is applied to each. This allows the design of independent state-feedback controllers tailored to each degree of freedom’s dynamic parameters. The outputs from all six controllers are then combined into a composite command

to achieve compliant robot motion. In this framework, each state vector

and

consists of the positional (or angular) deviation and its derivative:

The system input

is defined as the rate of change in the robot’s posture at the current moment:

The Padé approximation method posits that, under conditions where system delay exists, the current attitude change rate of the robot satisfies the following relationship between the received command signal and the actual attitude:

Therefore, the system state can be expressed as Equation (7). Consequently, the rate of change in the system state is as follows:

Accordingly, the rate of change in the system state is as follows:

Thus, the state-space representation of the system is established as follows:

where

This section examines the physical significance of the system output , which represents the interaction force/torque between the operator and the manipulator end-effector. The disturbance input models the external influence exerted by the operator on the system. Mathematically, is formulated as a function of the kinematic state—specifically, the velocity and acceleration—of the operating point. The impact of the operator on both system stability and dynamic response will be analyzed in the subsequent sections.

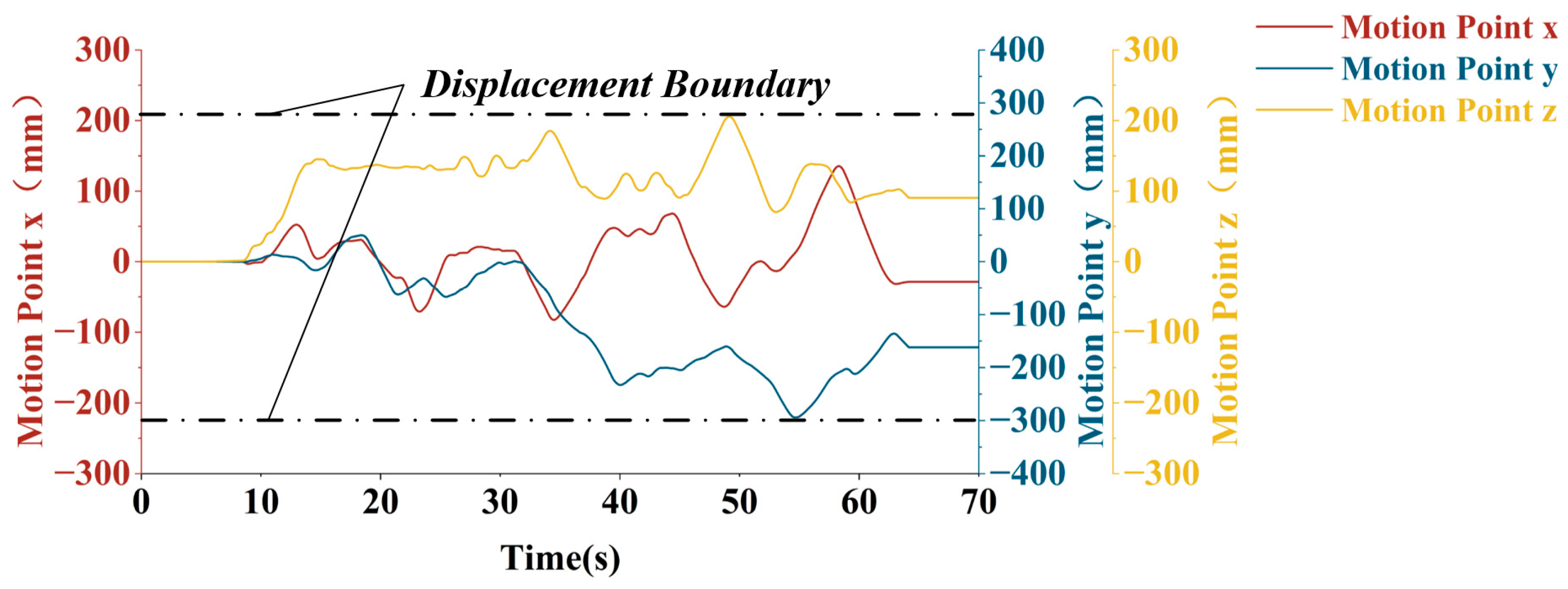

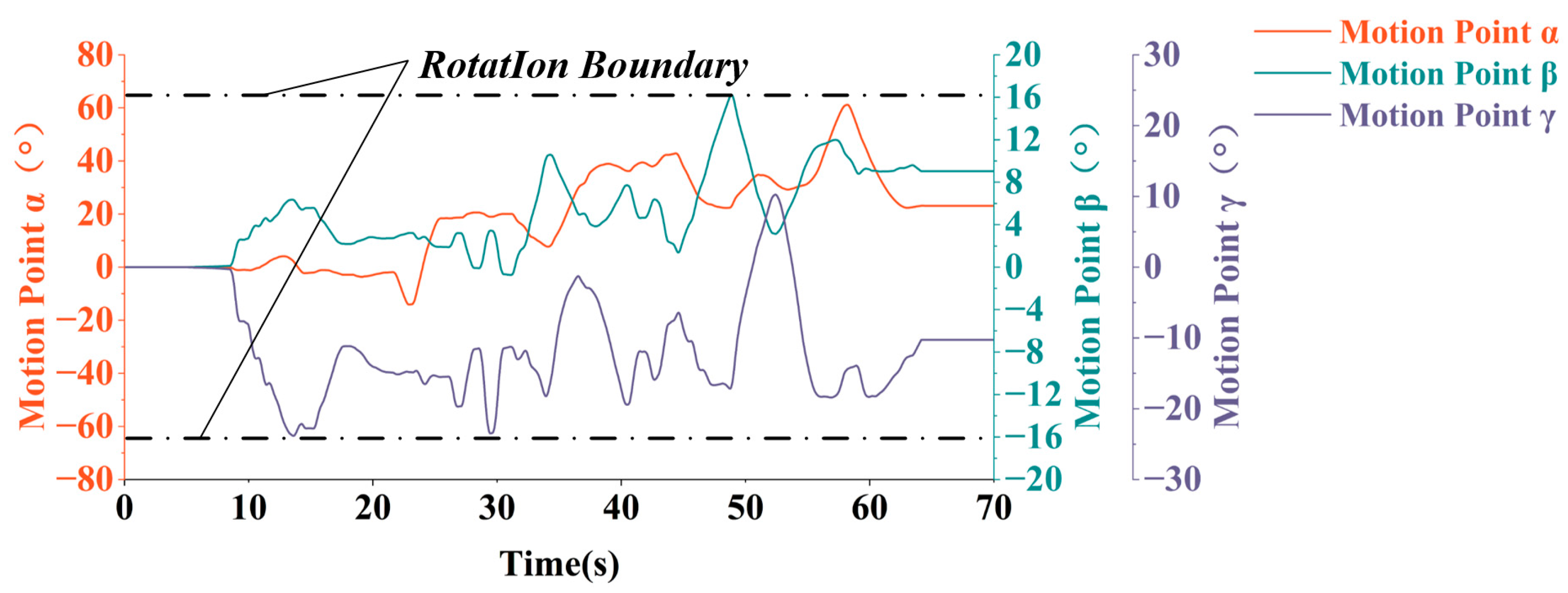

Remark 1. During real-time control execution, the system input corresponding to all degrees of freedom is calculated concurrently and synthesized to produce the translational velocity command vector and the rotational velocity command vector for the robot end-effector. A rate-limiting strategy, defined by Equations (11) and (12), is implemented to constrain the rate of change in the commands: In this study, and are defined as the maximum linear velocity and maximum linear acceleration, respectively, that are permissible for the manipulator end-effector.