1. Introduction

The pursuit of superior firing accuracy is inherently a problem of controlling initial disturbances and symmetry. For a projectile to strike its target precisely, its muzzle exit velocity and attitude are the decisive factors. Chamber pressure directly influences the projectile’s velocity, while the muzzle’s vibrational characteristics—often exhibiting asymmetric patterns due to gravity—can alter the forces acting on the projectile during the critical exit phase. This leads to variations in the initial conditions of the external trajectory, thereby compromising firing accuracy.

The influence of peak chamber pressure on the amplitude of muzzle initial disturbance is well-known. While this effect might be limited under controlled, ambient temperature conditions, it becomes profoundly exacerbated during rapid firing. The heat accumulation raises the barrel temperature, inducing changes in material properties and generating a pronounced thermo–mechanical coupling effect. This thermal input breaks the thermodynamic and mechanical symmetry of the barrel system, leading to a complex, nonlinear dynamic response where the influence of chamber pressure on muzzle vibration becomes more intense and unpredictable.

Scholarly investigations into interior ballistics have systematically examined the interplay between chamber pressure dynamics, shock wave behavior, bullet–barrel interactions, and thermal effects on weapon performance. Research developments reveal three interconnected domains of advancement: in interior ballistics and pressure management, studies by Degirmenci [

1] and Verberne [

2] established fundamental relationships between propellant characteristics and combustion dynamics, while Chen [

3] demonstrated active pressure control through segmented chamber designs. Qiu’s [

4] symmetric venting mechanism achieved optimal recoil reduction (31.80%) with minimal velocity loss (1.30%), with Guo [

5] providing critical insights into abnormal pressure conditions. The projectile–barrel interaction research has identified gravity-induced vibrations (Liu [

6]) and rifling wear effects (Shen [

7]) as primary factors affecting exit symmetry. Advanced diagnostic methods developed by Zhang [

8] enabled direct in-bore observation, while Hruschka [

9] and Doig [

10] characterized complex transonic aerodynamics during muzzle exit. Thermodynamic studies consistently identify heat accumulation as the fundamental constraint on sustained firing performance. Dai [

11], Yang [

12], and Chen [

13] documented thermal degradation mechanisms ranging from barrel softening to projectile material phase changes, while Hussain’s team [

14,

15,

16] developed predictive thermal models. Complementary research by Huang [

17], Gai [

18], Chen [

19], and Xu [

20] quantified thermo–mechanical coupling effects, with Wei [

21] and Hua [

22] providing structural performance benchmarks under thermal loading.

Although these studies have provided valuable insights, they have often overlooked the nonlinear coupling effect of chamber pressure on muzzle vibration during the in-bore motion and its consequent impact on projectile attitude symmetry. Furthermore, the specific influence of chamber pressure variation on the asymmetric vibrational response of a heated barrel remains scarcely explored. The muzzle vibration at the moment of exit is undoubtedly a critical factor that disrupts the symmetry of the projectile’s launch attitude and thus degrades accuracy.

Therefore, studying this coupling mechanism is imperative. Based on the aforementioned considerations, this study employs a 5.8 mm rifle to establish a thermo–mechanically coupled bullet–barrel interaction model using the nonlinear finite element method. By integrating actual pressure data, we aim to decipher the nonlinear correlation between chamber pressure and the symmetry-breaking vibrational response of the muzzle under continuous firing conditions. The findings are expected to provide new theoretical insights into accuracy degradation and a novel optimization strategy based on controlling dynamic asymmetry.

2. Chamber Pressure Test Experiment

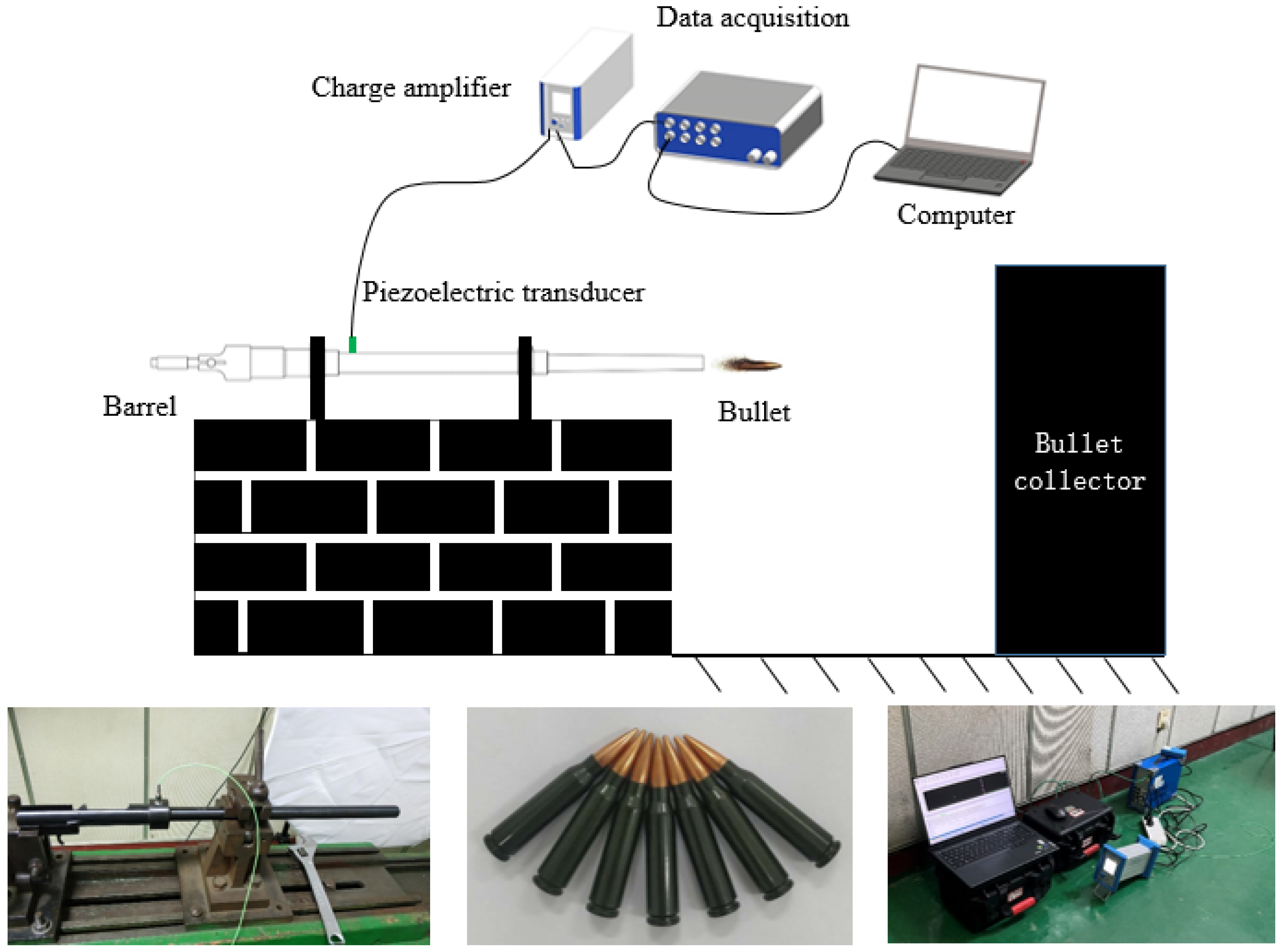

The chamber pressure is measured directly using a piezoelectric system. The experimental setup, schematized in

Figure 1, is equipped with a piezoelectric sensor, a charge amplifier, a data acquisition card, and a computer. In this configuration, the pressure signal is first converted to a charge signal by the sensor, then transformed into a voltage signal via the charge amplifier, and finally recorded by the data acquisition card. All experiments are conducted using a 5.8 mm ballistic rifle and standard 5.8 mm general-purpose ammunition.

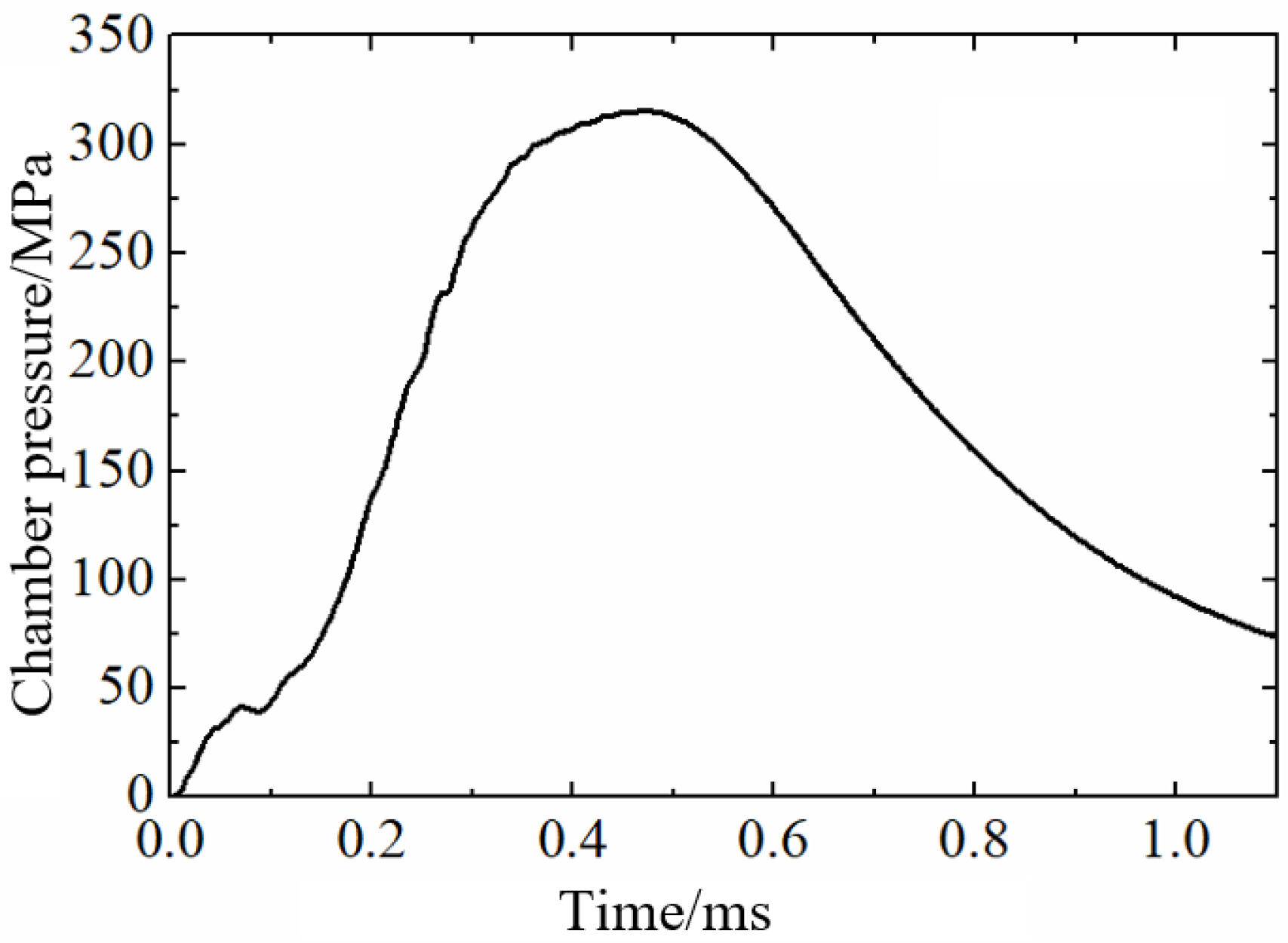

The measured chamber pressure curve is shown in

Figure 2. The peak pressure is recorded as 320 MPa. This curve will be converted to obtain the pressure curve acting on boattail. It will serve as the driving force for the projectile’s in-bore motion.

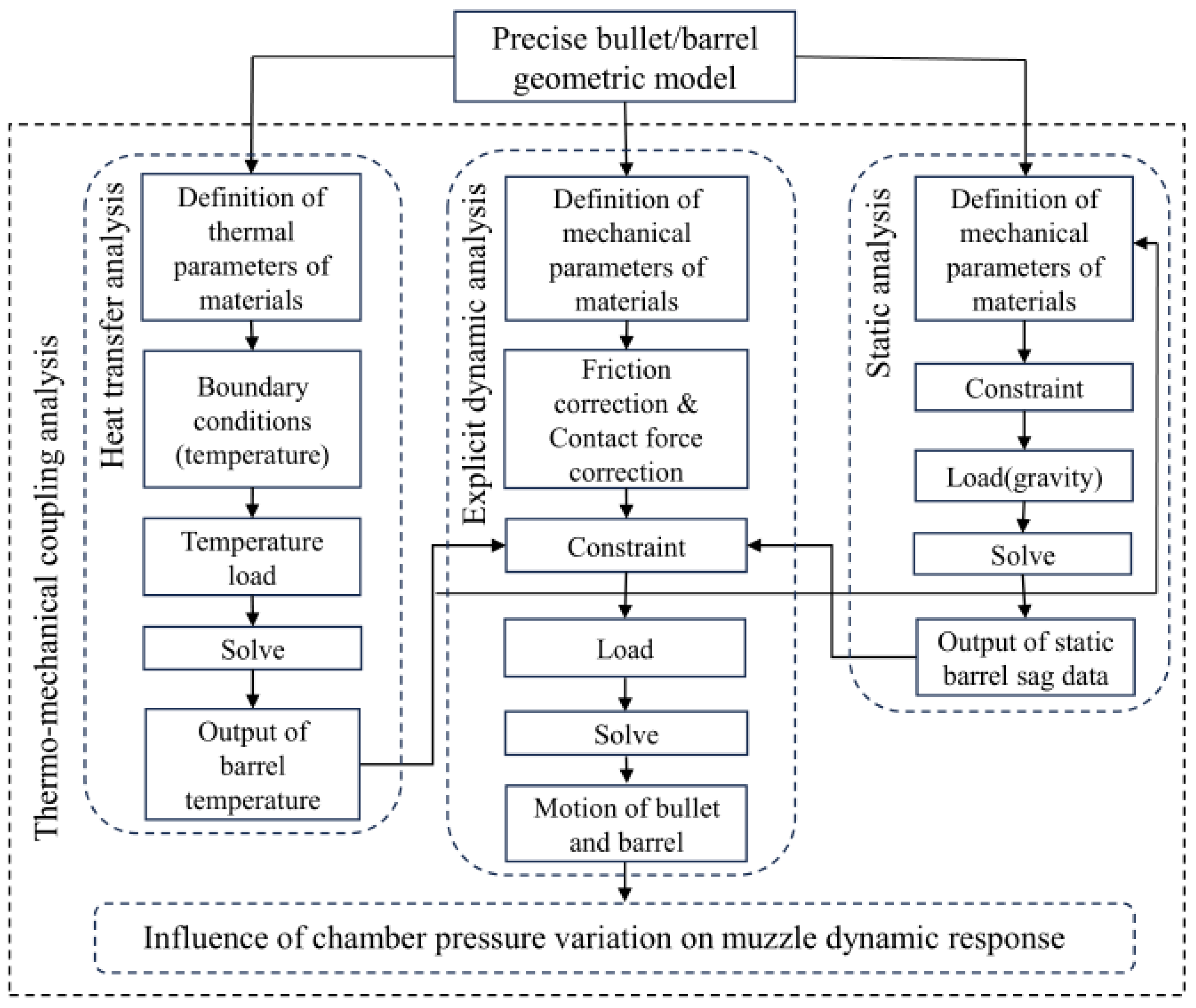

3. Thermo–Mechanical Coupling Modeling Method

To accurately simulate projectile motion and barrel dynamic response, a partitioned coupling numerical method is adopted. A thermo–mechanical coupled dynamic interaction model between the bullet and the barrel is established using the Abaqus simulation platform. The analysis process is shown in

Figure 3. It consists of three interrelated computational modules:

- (1)

Transient Heat Transfer Analysis Module

A barrel temperature evolution model is developed based on heat conduction theory. Thermal accumulation during continuous firing is considered. Material thermal properties (thermal conductivity, specific heat capacity) and thermal boundary conditions are defined. The temperature field of the barrel under continuous firing conditions is computed.

- (2)

Static Structural Analysis Module

Considering the combined effects of the temperature and gravity, the static sag data of the barrel is output by defining material parameters, temperature and motion boundary conditions, and applying gravity loads.

- (3)

Explicit Dynamics Module

Results from the previous two modules are integrated as constraints. Friction and contact force models are modified. The motion of the projectile in a heated barrel is simulated, and the projectile trajectory and muzzle vibration characteristics are analyzed.

3.1. Geometric Modeling and Meshing

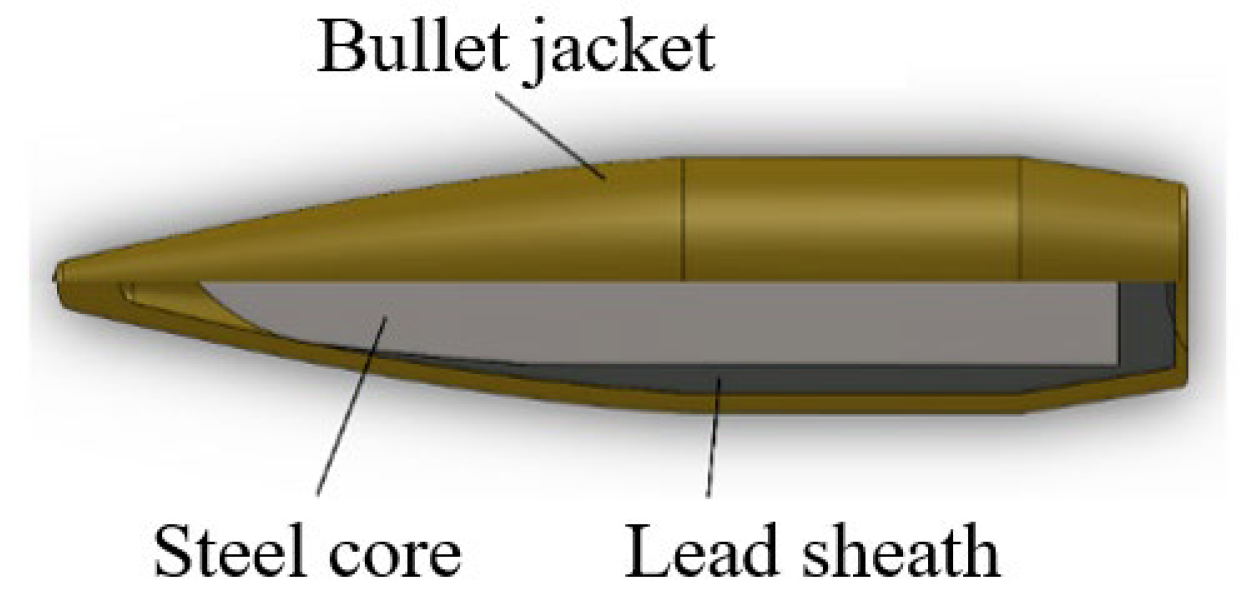

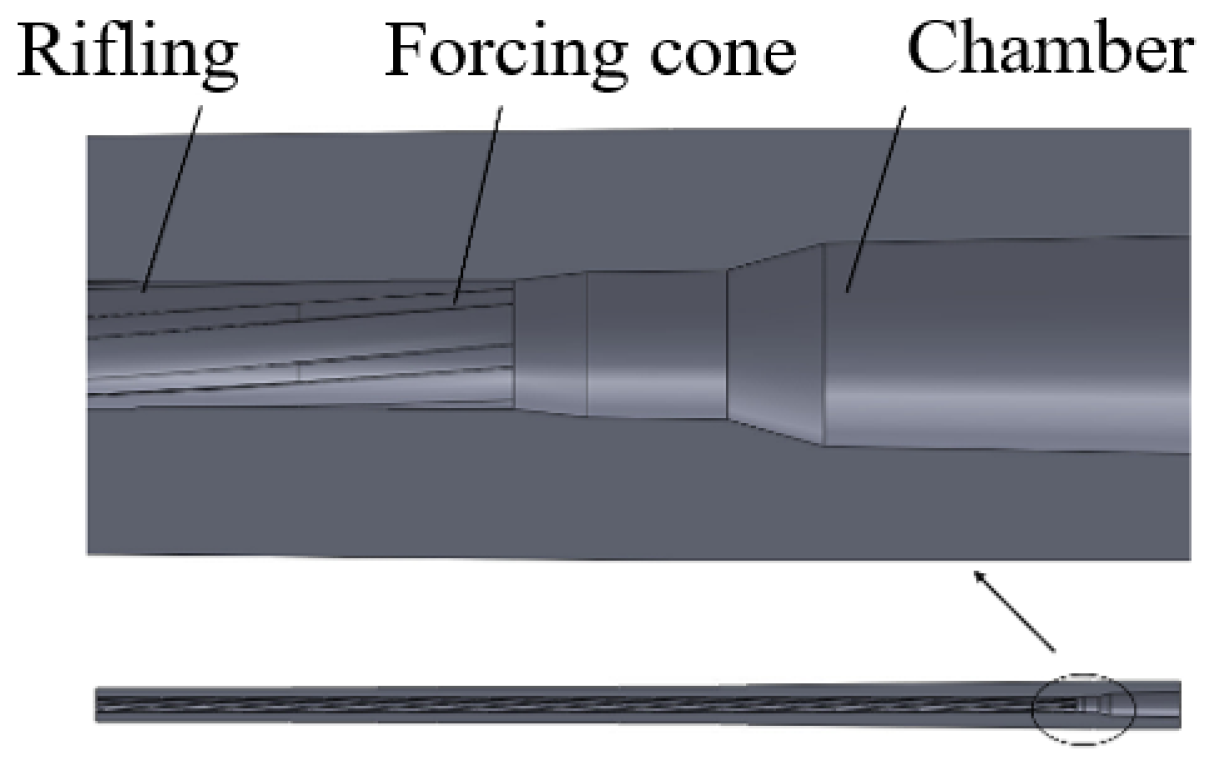

The study objects consist of a 5.8 mm general-purpose cartridge and a 5.8 mm automatic rifle. Cross-sectional schematic diagrams of their geometric models are shown in

Figure 4 and

Figure 5.

The projectile is designed with a typical three-component structure (copper jacket/lead sheath/steel core). The barrel model retains key features (rifling, forcing cone, etc.). Non-essential structures (threads, barrel bands, etc.) are simplified.

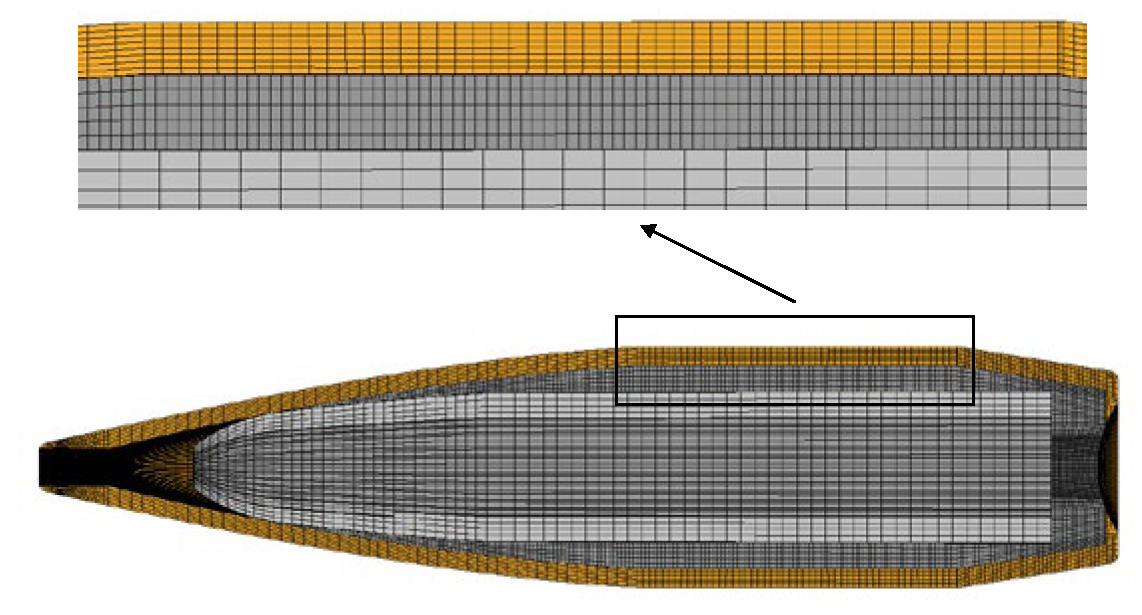

Preprocessing is performed using HyperMesh. Discretization is mainly carried out with C3D8RT elements (8-node thermally coupled hexahedral elements). Sectional mesh diagrams of the bullet and barrel are shown in

Figure 6 and

Figure 7.

3.2. Basic Assumption

To simplify the computational model, the following reasonable assumptions are made:

- (1)

The material is assumed to be isotropic, and its thermophysical parameters (specific heat capacity, thermal conductivity, elastic modulus, and Poisson’s ratio, etc.) are considered to be temperature-dependent;

- (2)

Frictional heating and heat conduction effects are taken into account;

- (3)

Initial deformation caused by the self-weight of the barrel is considered;

- (4)

The influence of air resistance in front of the projectile is neglected.

3.3. Material Constitutive Model

During its in-bore motion, the projectile is subjected to instantaneous high-temperature and high-pressure gas. The jacket undergoes high strain rates, material temperature rise, thermal softening, and strain hardening. These nonlinear mechanical states are experienced. The copper jacket material is specified as H90. The barrel material is designated as 30CrMnSiMoVA. Temperature-dependent material parameters are adopted for the barrel. The Johnson–Cook constitutive model is selected for the jacket material. It is used to describe the thermoviscoplastic behavior. The material parameters are provided in

Table 1,

Table 2 and

Table 3, respectively.

The Johnson–Cook constitutive model can be expressed as follows:

where

is the equivalent stress,

is the equivalent plastic strain,

is the equivalent plastic strain rate;

A is the yield stress;

B is the hardening modulus;

C is the strain rate sensitivity coefficient;

m is the thermal softening exponent;

n is the work hardening exponent;

is the reference strain rate;

T* is the homologous temperature.

where

Troom is the reference temperature,

Tmelt is the melting temperature of the material.

In

Table 1,

Table 2 and

Table 3, E is the elastic modulus,

is Poisson’s ratio,

is the material density, c is the specific heat capacity,

is the thermal conductivity,

is the coefficient of thermal expansion.

The Johnson–Cook failure criterion describes the damage degree through the damage parameter

D, which can be expressed as:

where ∆

εp is the equivalent plastic strain increment;

εf is the material failure strain.

The material failure strain

εf can be expressed as follows:

where

D1~

D5 are the damage parameters;

σ* is the ratio of pressure to equivalent stress

σeff.

The failure model characterizes material degradation through accumulated damage, describing the reduction in material stiffness. The element damage is defined as follows:

where

D is the damage parameter, its value ranges from 0 to 1, Initially,

D = 0, Material failure occurs when

D = 1; ∆

εp is the plastic strain increment within a single time step.

3.4. Boundary Condition

The boundary conditions of the thermo–mechanically coupled bullet/barrel dynamic response model include constraints, thermal boundary conditions, and loads.

3.4.1. Constraint

To accurately simulate the actual constraints of the weapon system, the following treatments are applied in the model: the breech end of the barrel is rigidly connected to a ground reference point using multipoint constraints (MPC). Initial sagging deformation due to gravity is retained. These approaches ensure both the rationality of the constraints and accurately capture the initial stress state of the barrel before firing.

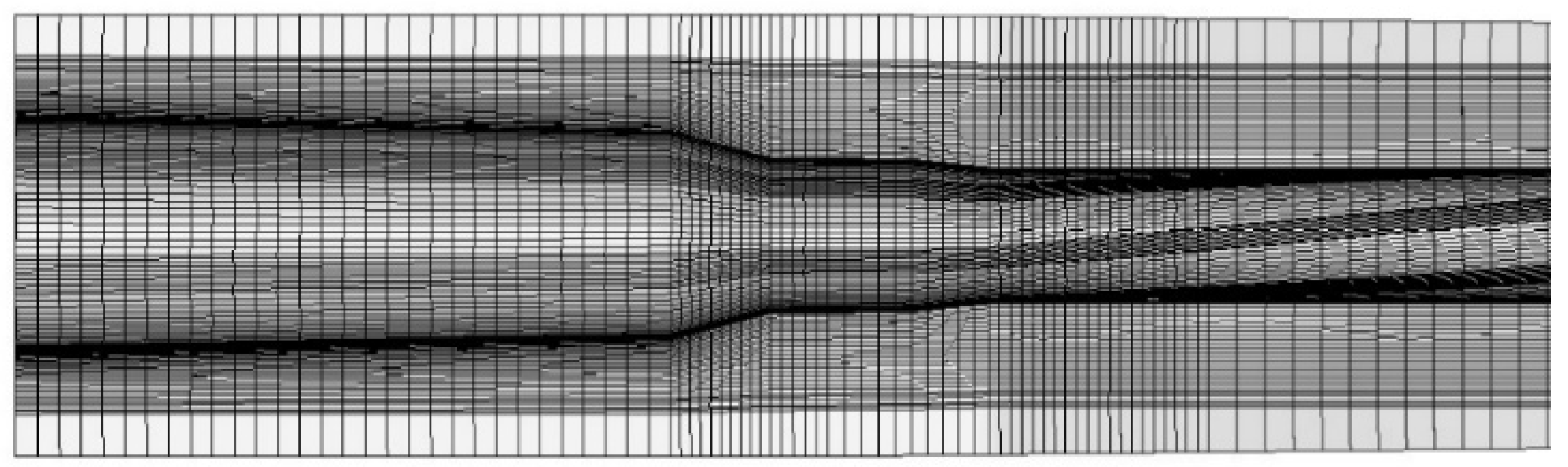

3.4.2. Thermal Boundary Condition

During the model construction process, the thermo–mechanical coupling effect under actual firing conditions is fully considered. First, the three-dimensional temperature distribution field of the barrel after 90 rounds of continuous firing is obtained through numerical simulation (as shown in

Figure 8). This temperature field is imported as an initial condition into the finite element model.

3.4.3. Loads

The driving force for projectile motion in this thermo–mechanical coupled bullet–barrel interaction model is derived from measured chamber pressure converted using Equation (7). The variation in measured chamber pressure over time is shown in

Figure 2.

where

is the propellant mass,

M is the projectile mass,

is the secondary work coefficient.

3.5. Contact

To address the complex contact issues in the thermo–mechanical coupling of the bullet–barrel system, a finite element model is developed based on the Abaqus general contact algorithm. The model primarily handles three key contact pairs: lead sheath–jacket, steel core–lead sheath, and jacket–barrel inner wall. For contact parameters, the normal behavior is defined using a hard contact criterion to describe pressure–overclosure relationships. The tangential behavior is modeled with a penalty friction formulation. To accurately simulate thermo–mechanical coupling effects, a thermal contact algorithm is incorporated. The frictional heat generation coefficient is set to 0.9 to quantify heat generation from friction. Contact thermal resistance parameters are configured to characterize heat transfer between dissimilar materials. This integrated modeling approach, considering both mechanical and thermal coupling, significantly improves the simulation accuracy of bullet–barrel interaction under high temperature and pressure conditions.

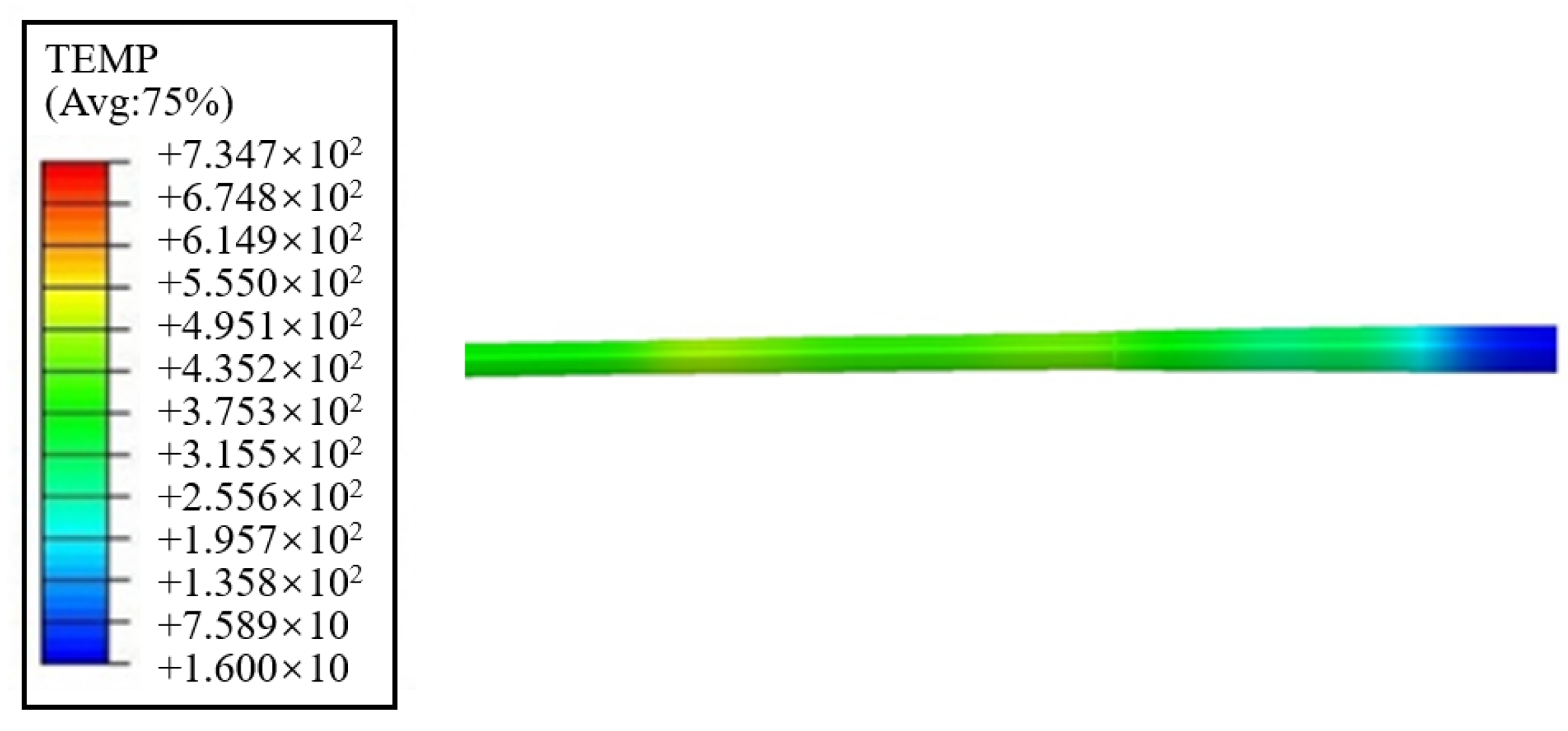

3.6. Grid Independence Verification

The thermo–mechanical coupled bullet/barrel interaction finite element model is discretized using hexahedral elements, which generally provide superior quality metrics compared to tetrahedral elements. To ensure a balance between computational efficiency and numerical accuracy, three mesh densities are applied to the barrel for grid independence verification. The mesh sizes are determined based on the minimum geometric feature size of the barrel structure to adequately resolve critical regions.

As shown in

Table 4, the computation time increased significantly with higher mesh density, while a clear loss of accuracy is observed when coarse mesh is used. When the mesh is refined from 0.87 million to 1.74 million elements, the calculated initial velocity increases noticeably from 875.9 m/s to 880.2 m/s. Further refinement to 3.48 million elements resulted in only a 0.1% change in velocity, indicating convergence of the solution. However, the simulation time more than doubled. Therefore, a mesh scheme with 1.74 million elements for the barrel is adopted. This approach effectively reduced computation time while maintaining numerical accuracy.

4. Model Verification

To validate the thermo–mechanical coupled bullet/barrel interaction finite element model, the in-bore travel distance, muzzle velocity, and surface morphology of the projectile are numerically calculated and compared with experimental results.

Due to the extremely short duration and difficulty in direct observation of the bullet/barrel interaction process, direct validation of the model is challenging. However, muzzle velocity and recovered projectile markings can reflect energy conversion and dynamic behavior during firing. Accurate prediction of these two parameters by the finite element model will indicate high reliability in simulating the actual firing dynamics. Although not comprehensive, this approach remains an effective method for model validation [

12,

17].

The experimental setup for muzzle velocity measurement and projectile soft recovery is shown in

Figure 9.

A 5.8 mm automatic rifle and 5.8 mm general-purpose ammunition are used. The muzzle velocity is measured using a system composed of light screens, a timer, and a power supply. Polyurethane foam blocks are employed as the recovery medium. The distance between the light screens is set to 2 m, and the recovery device is placed 10 m from the muzzle. Shooting is performed handheld.

For this projectile muzzle velocity test, a total of 20 rounds of 5.8 mm general-purpose ammunition are fired continuously. The test is conducted with 20 rounds, which is in accordance with the group size specified for rifle and machine gun cartridges in the national military standard. The arithmetic mean of the projectile muzzle velocities is calculated, resulting in an average experimental muzzle velocity of 899.8 m/s. Through the thermo–mechanical coupled finite element analysis, the in-bore motion time is determined to be 0.973 ms, the total travel distance is 435 mm, and the computed muzzle velocity is 880.2 m/s. Compared with the experimental average velocity of 899.8 m/s, the error is 2.2%. These results demonstrate the accuracy of the thermo–mechanical coupled model in simulating the in-bore motion of the projectile. This minor discrepancy is well within the expected range for such complex simulations. This error can be attributed to several potential sources. Firstly, the simulation employed experimentally measured chamber pressure data as the driving force input. It is possible that limitations in the pressure measurement instrumentation or methodology led to a slight underestimation of the actual pressure. This would result in a marginally lower propelling force in the model, consequently contributing to the lower computed muzzle velocity. Secondly, a slight overestimation of the barrel-projectile friction coefficient in the simulation could have increased the frictional energy loss. The close agreement, despite these potential minor deviations, confirms the model’s strong predictive capability.

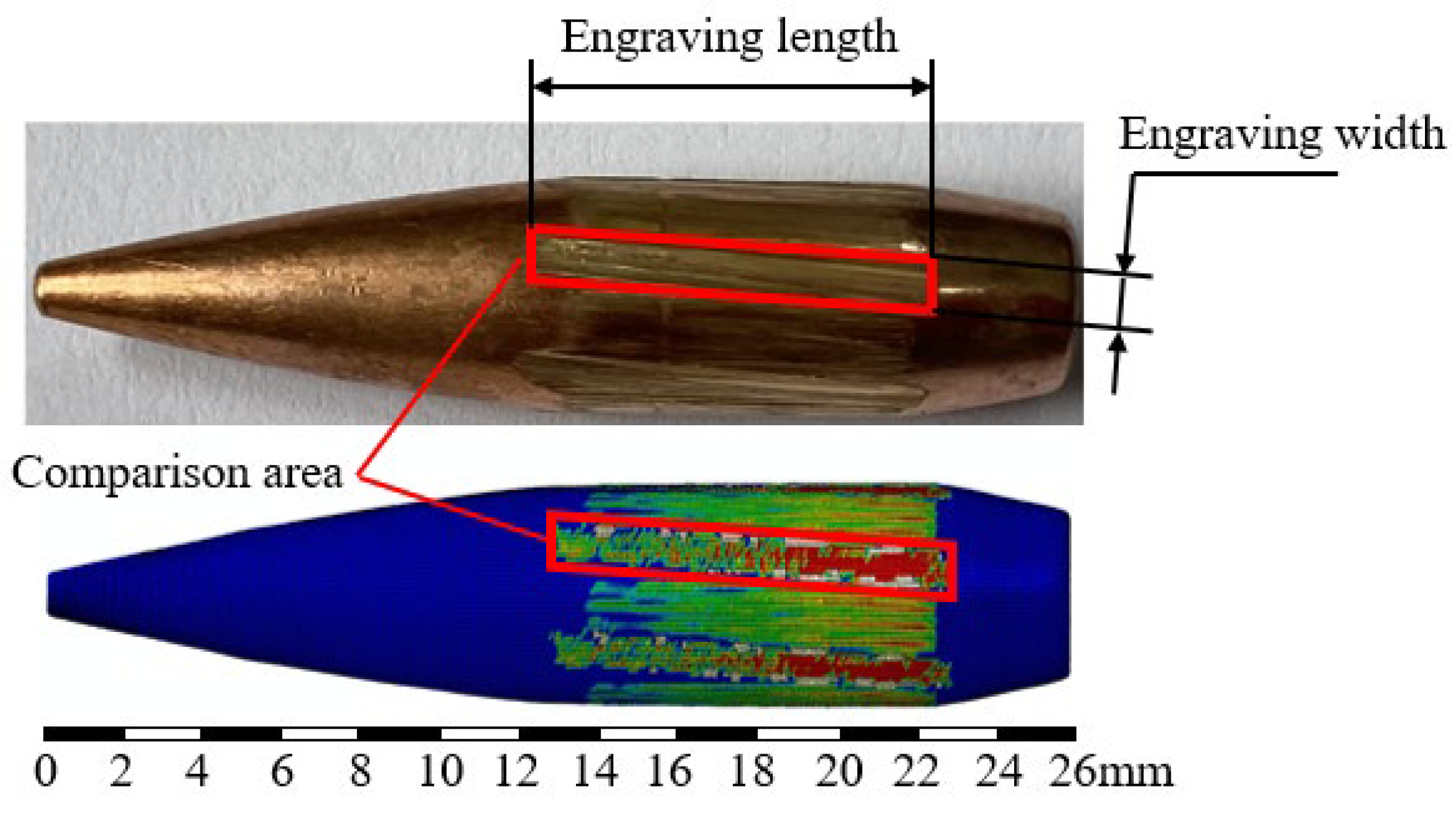

The projectiles recovered in the soft recovery test show no surface scratches and no deformation. A comparison between the scratches on the projectile surface at muzzle exit simulated by the thermo–mechanical coupled bullet–barrel interaction finite element model and the actual surface morphology obtained from the test is shown in

Figure 10. The comparisons of scratch length and width are presented in

Table 5. The errors in scratch dimensions are all less than 5%.

In summary, the comparison between the calculated results (projectile muzzle velocity and surface engraving characteristics) and experimental data demonstrates that the thermal–structural coupled bullet–barrel interaction finite element model is accurate and reliable, and can correctly represent the projectile’s travel and behavior within the barrel.

5. Influence of Chamber Pressure Variation on Muzzle Dynamic Response

Chamber pressure serves as the driving force for the projectile’s in-bore motion and plays a critical role in both the projectile movement and barrel dynamics. During actual firing, variations in propellant charge and ambient temperature can cause significant changes in the pressure curve. Changes in chamber pressure not only alter the projectile’s in-bore motion but also affect the movement of the barrel, particularly at the muzzle, further influencing firing accuracy.

This section investigates the influence of different chamber pressures on the muzzle motion state under the condition of a barrel temperature resulting from continuously firing 90 rounds. The chamber pressure of a barrel when firing a standard projectile with a standard propellant charge and according to standard firing specifications is defined as the standard chamber pressure. Based on the standard pressure, cases with 90%, 95%, 100%, 105%, and 110% of standard pressure are investigated at intervals of 5%. The muzzle motion during projectile travel is analyzed under these pressure conditions. A coordinate system is established to clearly describe the muzzle movement [

23].

5.1. Influence of Chamber Pressure Variation on Bullet Velocity

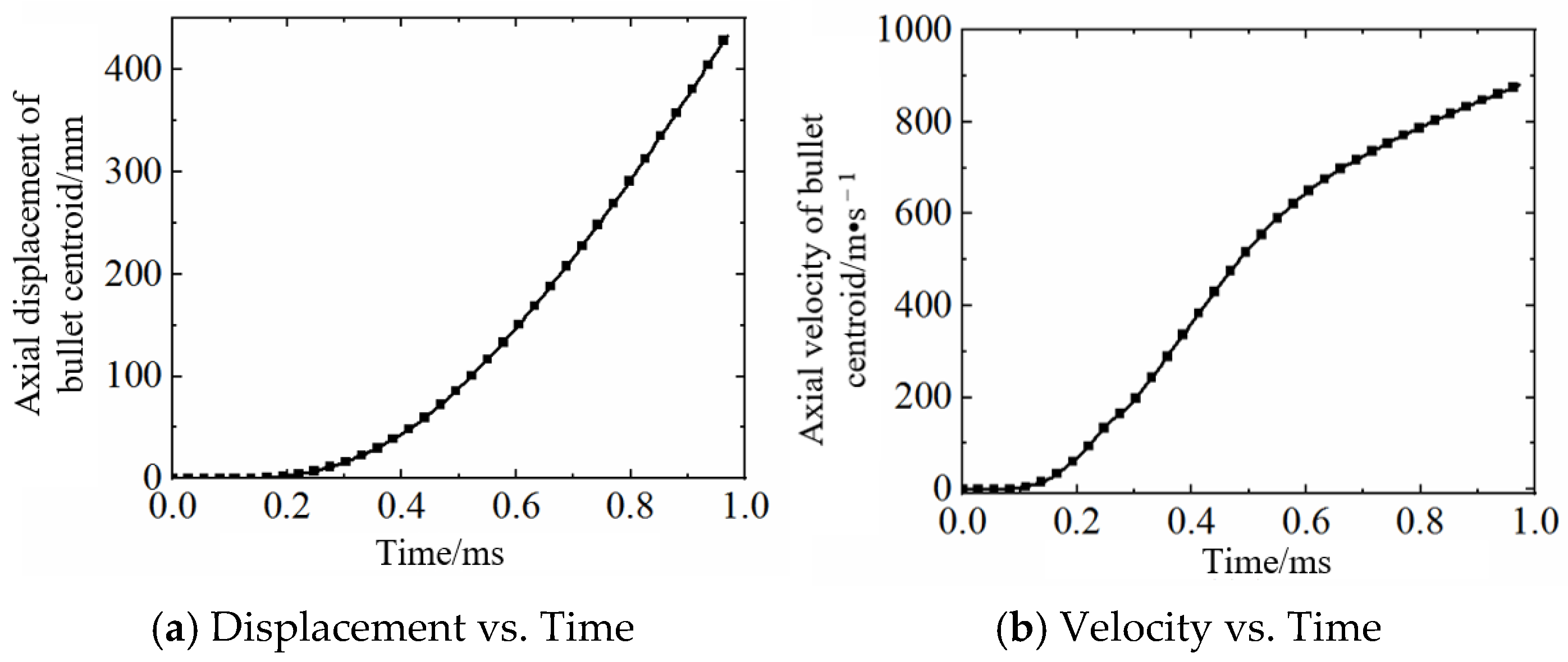

Through analysis using this thermo–mechanical coupled bullet/barrel interaction dynamic response model, the axial displacement and velocity of the projectile’s center of mass during in-bore motion under 100% standard chamber pressure are obtained. The results are shown in

Figure 11. The calculated interior ballistic duration is 0.973 ms. The total in-bore travel distance of the projectile is 435 mm. The muzzle velocity is computed as 880.2 m/s. Compared with the experimentally measured average muzzle velocity of 899.8 m/s, the error is 2.2%.

The calculated muzzle velocities of the projectile under five different chamber pressures are shown in

Table 6. A significant positive correlation between chamber pressure and muzzle velocity can be observed. The in-bore motion time of the projectile decreases with increasing pressure. This is consistent with the description of the relationship between chamber pressure and projectile initial velocity in the literature [

3].

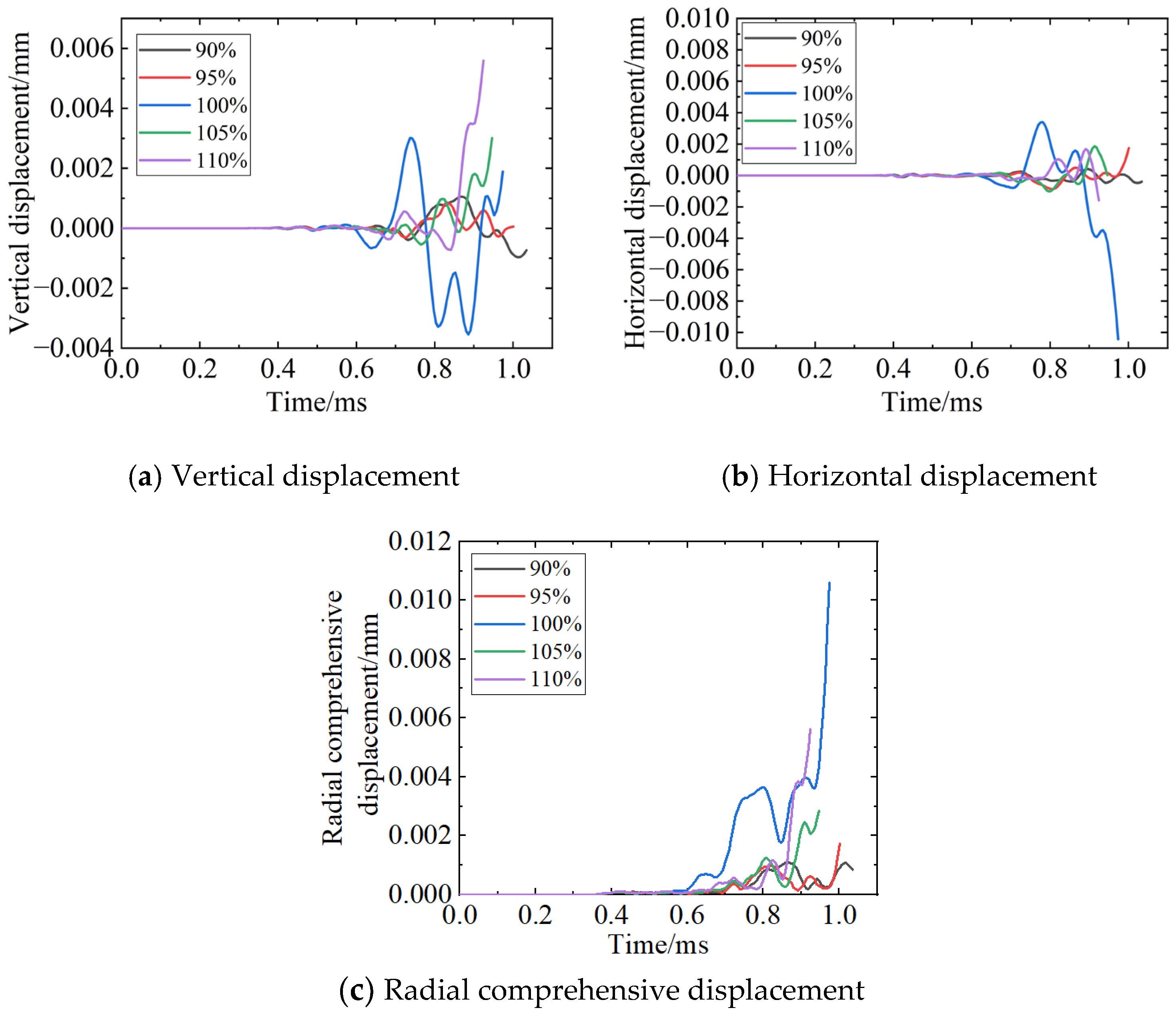

5.2. Influence of Chamber Pressure Variation on Muzzle Center Displacement

The temperature field of the barrel is under the condition of continuously firing 90 rounds. The curves of the muzzle center displacement (vertical, horizontal, and radial) over time under different chamber pressures are shown in

Figure 12, and the displacement values of the muzzle center at the moment when the projectile exits the muzzle are given in

Table 7.

As can be seen from

Figure 12, the displacement of the muzzle center hardly changes during the first 0.6 ms of the projectile’s engraving, after which it moves upward and to the right. An increase in chamber pressure amplifies the vertical displacement of the muzzle center, as the heightened pressure reduces the effect of gravity on the vertical movement of the muzzle center.

As can be seen from

Figure 12 and

Table 7, under the condition of a heated barrel with continuous firing of 90 projectiles, the maximum radial displacement at the center of the muzzle at the moment of projectile exit occurs at 100% standard chamber pressure (10.601 μm). And the horizontal displacement dominates in the radial composite displacement. In contrast, the minimum radial displacement at the center of the muzzle at the moment of projectile exit is observed at 90% standard chamber pressure (0.829 μm).

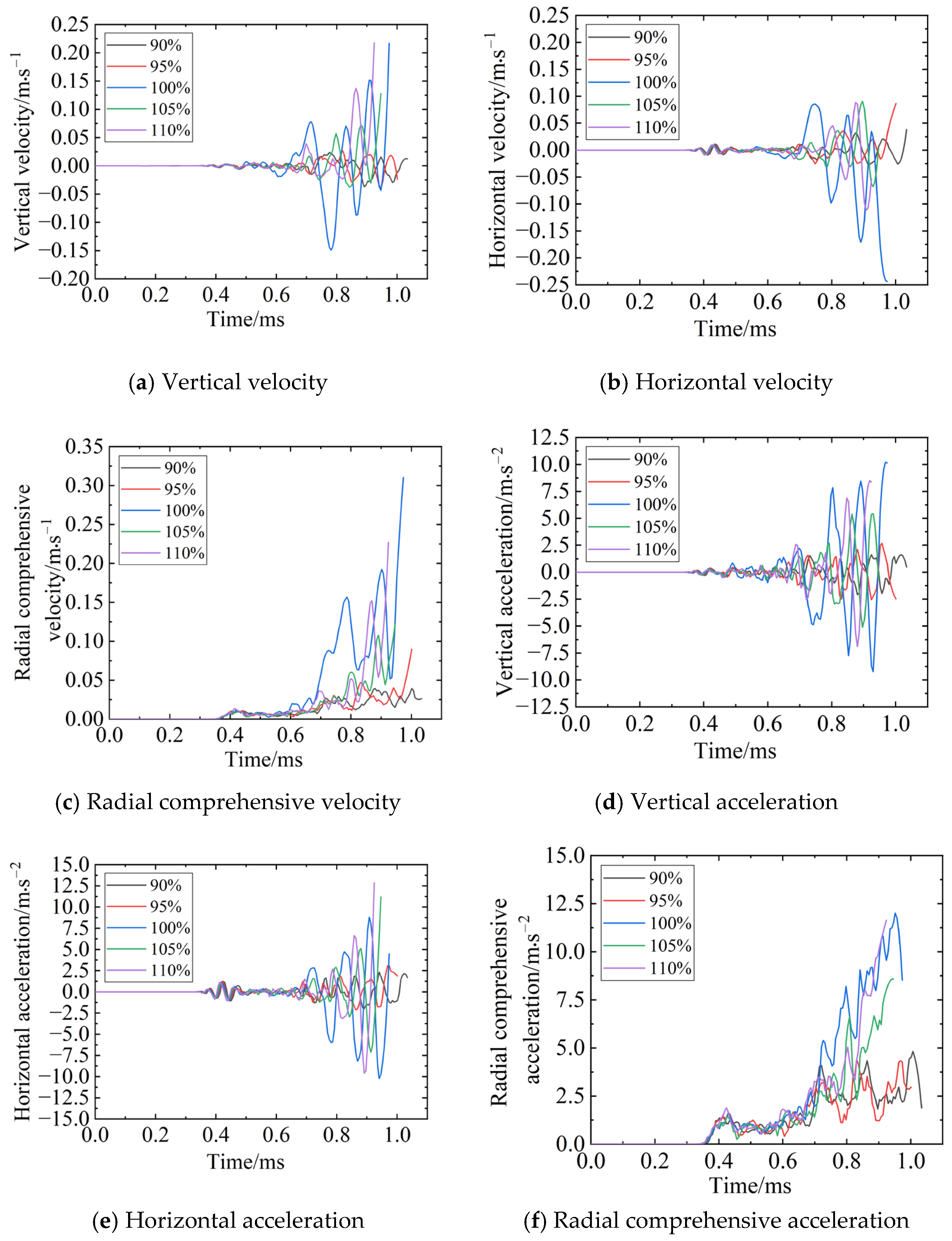

5.3. Influence of Chamber Pressure Variation on Muzzle Center Velocity and Acceleration

Figure 13 shows the time-varying curves of the muzzle center velocity and acceleration (vertical, horizontal, and radial) under different chamber pressures after continuously firing 90 rounds. The muzzle center velocity and acceleration values at the moment of projectile exit are listed in

Table 8.

As can be seen from

Figure 13 and

Table 8, under the heated barrel condition after 90 consecutive rounds, the maximum comprehensive radial velocity of the muzzle center at projectile exit (0.327 m/s) occurred at 100% standard chamber pressure. The minimum comprehensive radial velocity and acceleration (0.04 m/s and 1.742 m/s

2) are observed at 90% standard chamber pressure. It can be concluded from

Table 8 that as the chamber pressure increases, the horizontal acceleration of the muzzle center at projectile exit increases, as does the comprehensive radial acceleration.

5.4. Influence of Chamber Pressure Variation on Muzzle Plane Swing Angle and Angular Velocity

The temperature field of the barrel is under the condition of continuously firing 90 rounds. The time-varying curves of the muzzle plane swing angle and angular velocity (vertical, lateral, and comprehensive) under different chamber pressures are shown in

Figure 14. The values of the muzzle plane swing angle and angular velocity at the moment of projectile exit are listed in

Table 9.

As shown in

Figure 14 and

Table 9, under the heated barrel condition after continuously firing 90 projectiles; the maximum muzzle plane swing angle and angular velocity at projectile exit (0.192 mrad and 9.166 rad/s) are observed at 100% standard chamber pressure; and the minimum values (0.022 mrad and 0.413 rad/s) are recorded at 90% standard chamber pressure.

6. Discussion

6.1. Key Findings and Analysis

This study quantifies a critical anomalous phenomenon: under the thermal accumulation conditions induced by continuous firing, the standard (100%) chamber pressure elicits the most intense asymmetric muzzle vibration, rather than the higher (110% standard chamber pressure). This finding challenges the traditional linear perception framework, which typically assumes a monotonic relationship between load amplitude and structural response.

The performance degradation observed in this study closely correlates with several thermally activated mechanisms reported in the literature, thereby validating the reliability of our model. For instance, barrel material softening due to elevated temperatures [

13], thermal stripping of the copper jacket [

12], and degradation in the projectile jacket’s dynamic response [

17] are all documented factors contributing to accuracy loss under heat accumulation. However, the key advancement of this study lies in moving beyond these previously emphasized static or quasi-static degradation phenomena. We systematically reveal, for the first time, the nonlinear regulatory mechanism of pressure on dynamic symmetry under thermo–mechanical coupling conditions. By capturing the transient nonlinear dynamic interaction, we elucidate why the maximum disturbance occurs at a specific pressure level rather than at the peak pressure.

We postulate that this counterintuitive phenomenon stems from a nonlinear dynamic interaction between the pressure load and the barrel’s structural response. Under 100% standard chamber pressure conditions, the spectral characteristics of the pressure pulse likely couple with a specific natural frequency of the heated barrel, thereby exciting a strong resonant response. In contrast, under 110% of standard pressure conditions, the altered temporal characteristics of the pressure pulse shift the dominant excitation frequencies away from this critical resonance range. Furthermore, the increased pressure may enhance local structural stiffness variations or nonlinearities at key interfaces (e.g., projectile and rifling), consequently suppressing resonance to some extent or altering the energy transfer path. This confirms that the maximum dynamic response is not determined solely by the peak load amplitude but rather by a complex synergy between the load’s temporal-spectral characteristics and the structure’s inherent dynamic properties.

Another significant finding is that reducing the chamber pressure from 100% to 90% resulted in a dramatic reduction in muzzle motion parameters by 84% to 95%, as detailed in

Table 10. According to muzzle dynamics theory [

22], such pronounced suppression of muzzle disturbance directly contributes to improved shooting accuracy. This clearly demonstrates that under thermally compromised barrel conditions, lowering the chamber pressure can effectively mitigate nonlinear muzzle vibrations and enhance accuracy.

The traditional paradigm in army weapon design has long focused on maximizing kinetic energy advantage by increasing muzzle velocity and rate of fire. This study reveals a complementary, and in specific scenarios potentially superior, new pathway: prioritizing dynamic stability through pressure management to restore and maintain shooting accuracy under thermal stress. This signifies a paradigm shift from “energy priority” to “accuracy priority.” For example, in sustained firing scenarios for infantry fighting vehicles or fixed machine guns, compared to solutions requiring hardware modifications such as barrel cooling [

14] or material enhancement [

16], our strategy provides an immediate solution based on intelligent ballistic control without altering the mechanical structure, demonstrating significant practicality and cost-effectiveness.

6.2. Limitations and Future Research Directions

The primary limitation of this approach is the inherent trade-off with muzzle velocity, which may impact terminal ballistics and effective range. Furthermore, the conclusions are based on a model of a specific 5.8 mm caliber rifle, and their generalizability requires further validation across different weapon platforms.

Based on the findings of this study, we propose two key future research directions:

- (1)

Development of “Smart Adaptive” Interior Ballistic Systems: Aiming to achieve real-time dynamic adjustment of the pressure curve based on barrel temperature, realizing the paradigm shift from static design to dynamic control.

- (2)

Multi-Objective Optimization for System-Level Design: Conducting research on the trade-off between muzzle velocity and dynamic stability to seek Pareto optimal solutions, thereby systematically addressing the velocity-accuracy trade-off inherent in this approach and promoting the advancement of weapon design methodology.

7. Conclusions

This study reveals the nonlinear and asymmetric nature of the muzzle’s dynamic response under the thermo–mechanical coupling conditions of continuous firing. The key finding is that heat accumulation severely disrupts dynamic symmetry, and contrary to simple linear intuition, the maximum asymmetric vibration is excited by the standard (100%) chamber pressure, not the highest pressure.

Quantitative analysis demonstrates that strategically reducing the chamber pressure to 90% of the standard value can effectively suppress nonlinear vibrations, leading to a dramatic 84% to 95% reduction across all key kinematic parameters, thereby restoring the muzzle to a more symmetric and stable dynamic state.

In summary, this research not only quantifies and elucidates the intrinsic nonlinear correlation mechanism between chamber pressure and thermally induced asymmetric vibration but also demonstrates that “strategic pressure reduction” is an effective method for managing symmetry-breaking vibrations in a heated barrel. Ultimately, this work provides a new paradigm based on dynamic symmetry control for optimizing the accuracy of rapid-fire weapons, shifting the design focus from solely maximizing kinetic energy to the precise regulation of the symmetry of the launch event itself.

Author Contributions

Conceptualization, Z.W.; methodology, L.C.; software, L.C. and J.X.; validation, L.C. and J.S.; formal analysis, L.C.; investigation, L.C.; resources, Z.W. and J.S.; data curation, L.C.; writing—original draft preparation, L.C.; writing—review and editing, L.C.; funding acquisition, J.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China, grant number 52475108.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

The authors gratefully acknowledge the financial support from the National Natural Science Foundation of China (Grant No. 52475108).

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Degirmenci, E. Effects of grain size and temperature of double base solid propellants on internal ballistics performance. FUEL 2015, 146, 95–102. [Google Scholar] [CrossRef]

- Verberne, P.; Meguid, S.A. Dynamics of precision-guided projectile launch: Fluid–structure interaction. Acta Mech. 2021, 232, 1147–1161. [Google Scholar] [CrossRef]

- Chen, Z.J.; He, Z.; Ma, H.H. Experimental research on the launching system of auxiliary charge with filter cartridge structure. Def. Technol. 2024, 31, 41–48. [Google Scholar] [CrossRef]

- Qiu, M.; Si, P.; Song, J. Recoil Reduction Method of Gun with Side to Rear Jet Controlled by Piston Motion. Symmetry 2021, 13, 396. [Google Scholar] [CrossRef]

- Guo, Z. Analysis of the projectile motion was blocked in gun bore. IOP Conf. Ser. Earth Environ. Sci. 2021, 647, 012003. [Google Scholar]

- Liu, G.Q.; Xu, C.; Ding, C.J. Numerical calculation on the interaction between bullet and sniper rifle. J. Vib. Shock. 2017, 36, 1–7. [Google Scholar]

- Shen, C.; Zhou, K.D.; Lu, Y. Research on the influence of damaged barrel on interior ballistic performances and muz-zle-leaving state of bullet. Acta Armamentarii 2019, 40, 718–727. [Google Scholar]

- Zhang, F.; Zhang, R.; Xu, Q. The Test method of the Projectile’s Motion Attitude in the Semi-constraint Period. In Proceedings of the 2020 7th International Forum on Electrical Engineering and Automation (IFEEA), Hefei, China, 25–27 September 2020. [Google Scholar]

- Hruschka, R.; Klatt, D. In-pipe aerodynamic characteristics of a projectile in comparison with free flight for transonic Mach numbers. Shock Waves 2019, 29, 297–306. [Google Scholar] [CrossRef]

- Doig, G.; Wang, S.; Kleine, H. Aerodynamic analysis of projectiles in ground effect at near-sonic mach numbers. AIAA J. 2016, 54, 150–160. [Google Scholar] [CrossRef]

- Dai, C.; Cao, Y.F.; He, L. Cause analysis and result prediction of thermal dispersion for typical small caliber rifles. Acta Armamentarii 2024, 45, 885–892. [Google Scholar]

- Yang, Y.Z.; Zhang, X.Y.; Xu, C. The interaction between copper jacket projectile and barrel under different temperature based on thermo-mechanical coupling finite element model. J. Vib. Shock. 2020, 39, 44–51. [Google Scholar]

- Chen, J.; Wang, W.; Jin, P. Thermo-mechanical analysis of strength degradation of 30SiMn2MoVA gun barrel material during continuous shooting. Eng. Fail. Anal. 2022, 139, 106438. [Google Scholar] [CrossRef]

- Hussain, N.; Qayyum, F.; Pasha, R.A. Development of multi-physics numerical simulation model to investigate thermo-mechanical fatigue crack propagation in an autofrettaged gun barrel. Def. Technol. 2021, 17, 1579–1591. [Google Scholar] [CrossRef]

- Zieliński, M.; Koniorczyk, P.; Surma, Z. Numerical study of heat transfer in a gun barrel made of selected steels. Energies 2022, 15, 1868. [Google Scholar] [CrossRef]

- Susantez, C.; Caldeira, A.B. Heat transfer modelling and simulation of a 120 mm smoothbore gun barrel during interior ballistics. Def. Sci. J. 2022, 72, 30–39. [Google Scholar] [CrossRef]

- Huang, C.L.; Jiang, M.F.; Chen, L. Influence of the material of small-caliber bullet jacket on its motion in hot barrel. Acta Armamentarii 2022, 43, 2241–2251. [Google Scholar]

- Gai, Z.Y.; Zhou, K.D.; Lu, Y. Stress states of anisotropic material gun barrel by firing the projectiles with different jacket materials. Acta Armamentarii 2024, 45, 4119–4132. [Google Scholar]

- Chen, L.; Xie, K.; Lu, D.B. Influence of thermal physical properties on muzzle motion parameters under heated barrel condition. Trans. Beijing Inst. Technol. 2025, 45, 185–194. [Google Scholar]

- Xu, H.; Huang, C.L.; Wang, X.K. Theoretical and experimental study of projectile dynamic engraving resistance. Acta Armamentarii 2022, 43, 2263–2273. [Google Scholar]

- Wei, Z.; Cheng, Y.; Wang, Z. Simulation study on the impact response of barrels with different rifling profiles during bullet engraving. Model. Simul. Eng. 2022, 2022, 6407452. [Google Scholar] [CrossRef]

- Hua, H.L.; Liao, Z.Q.; Zhang, X.Y. Muzzle dynamic characteristics analysis and its matching for firing accuracy improvement. J. Vib. Shock. 2017, 36, 29–33. [Google Scholar]

- Rui, X.T. Launch Dynamics of Multibody System, 1st ed.; National Defense Industry Press: Beijing, China, 1995. [Google Scholar]

Figure 1.

Pressure test diagram of 5.8 mm ballistic gun.

Figure 1.

Pressure test diagram of 5.8 mm ballistic gun.

Figure 2.

Bore pressure test result diagram.

Figure 2.

Bore pressure test result diagram.

Figure 3.

Thermo–mechanical coupling analysis flowchart.

Figure 3.

Thermo–mechanical coupling analysis flowchart.

Figure 4.

The 5.8 mm bullet geometric model.

Figure 4.

The 5.8 mm bullet geometric model.

Figure 5.

Semi-profile sketch of the geometric model of a 5.8 mm automatic rifle barrel.

Figure 5.

Semi-profile sketch of the geometric model of a 5.8 mm automatic rifle barrel.

Figure 6.

Semi-section grid diagram of bullet.

Figure 6.

Semi-section grid diagram of bullet.

Figure 7.

Semi-section grid diagram of the barrel.

Figure 7.

Semi-section grid diagram of the barrel.

Figure 8.

Barrel temperature field under 90 rounds of continuous shooting.

Figure 8.

Barrel temperature field under 90 rounds of continuous shooting.

Figure 9.

Schematic diagram of test device and test site.

Figure 9.

Schematic diagram of test device and test site.

Figure 10.

Comparison of soft recovery projectile and simulation.

Figure 10.

Comparison of soft recovery projectile and simulation.

Figure 11.

Time history of bullet centroid axial displacement and velocity.

Figure 11.

Time history of bullet centroid axial displacement and velocity.

Figure 12.

Influence of different chamber pressure on the center displacement of muzzle.

Figure 12.

Influence of different chamber pressure on the center displacement of muzzle.

Figure 13.

Influence of different chamber pressure on the velocity and acceleration of muzzle center.

Figure 13.

Influence of different chamber pressure on the velocity and acceleration of muzzle center.

Figure 14.

Influence of different chamber pressure on the swing angle and angular velocity of the muzzle plane.

Figure 14.

Influence of different chamber pressure on the swing angle and angular velocity of the muzzle plane.

Table 1.

Mechanical and thermodynamic parameters of H90.

Table 1.

Mechanical and thermodynamic parameters of H90.

| Parameter Type | Value |

|---|

| Elastic and thermal | E/GPa | | ρ/(kg·m−3) | c/(J·kg−1·K−1) | λ/(W·m−1·K−1) |

| 112 | 0.31 | 8730 | 375 | 110 |

| Plastic | A/MPa | B/MPa | C | n | m | Tm/K | |

| 112 | 505 | 0.09 | 0.42 | 1.68 | 1082 | 1 |

| Damage failure | D1 | D2 | D3 | D4 | D5 |

| 0.54 | 4.89 | −3.03 | 0.014 | 1.12 |

Table 2.

Mechanical and thermodynamic parameters of lead sheath.

Table 2.

Mechanical and thermodynamic parameters of lead sheath.

| Parameter Type | Value |

|---|

| Elastic and thermal | E/GPa | | ρ/(kg·m−3) | c/(J·kg−1·K−1) | λ/(W·m−1·K−1) |

| 17 | 0.42 | 11,340 | 130 | 207 |

| Plastic | A/MPa | B/MPa | C | n | m | Tm/K | |

| 8 | 110 | 0.09 | 0.52 | 1.1 | 760 | 1 |

Table 3.

Mechanical and thermodynamic parameters of 30CrMnSiMoV2A.

Table 3.

Mechanical and thermodynamic parameters of 30CrMnSiMoV2A.

| Temperature/°C | E/GPa | | λ/(W·m−1·K−1) | c/(J·kg−1·K−1) | |

|---|

| 16 | 211 | 0.27 | 48 | 523 | 1.7 × 10−5 |

| 200 | 202 | 0.295 | 42 | 567 |

| 400 | 190 | 0.303 | 36 | 611 |

| 600 | 180 | 0.311 | 30 | 779 |

| 800 | 162 | 0.344 | 24 | 946 |

Table 4.

Grid independence verification.

Table 4.

Grid independence verification.

| Element Type | Barrel Element Numbers/Million | Initial Velocity/m·s−1 | Simulation Time/h |

|---|

| C3D8RT | 0.87 | 875.9 (0.5%) | 7.8 |

| 1.74 | 880.2 | 15.6 |

| 3.48 | 881.4 (0.1%) | 31.5 |

Table 5.

Comparison of soft recovery projectile denting with simulation results.

Table 5.

Comparison of soft recovery projectile denting with simulation results.

| Value | Average of Experiment Results | Calculation Results | Error/% |

|---|

| Length/mm | 9.98 | 9.92 | 0.6 |

| Width/mm | 0.95 | 0.92 | 3.2 |

Table 6.

Bullet initial velocity at varying chamber pressures.

Table 6.

Bullet initial velocity at varying chamber pressures.

| Group | Time/ms | Initial Velocity/m·s−1 |

|---|

| 90% | 1.034 | 806.6 |

| 95% | 1.001 | 843.7 |

| 100% | 0.973 | 880.2 |

| 105% | 0.946 | 916.4 |

| 110% | 0.924 | 952.7 |

Table 7.

Displacement of muzzle center at the moment of bullet exit barrel.

Table 7.

Displacement of muzzle center at the moment of bullet exit barrel.

| Group | Time of Bullet Exit/ms | Vertical Displacement of Muzzle Center/×10−3 mm | Horizontal Displacement of Muzzle Center/×10−3 mm | Radial Comprehensive Displacement of Muzzle Center/×10−3 mm |

|---|

| 90% | 1.034 | −0.727 | −0.399 | 0.829 |

| 95% | 1.001 | 0.053 | 1.758 | 1.759 |

| 100% | 0.973 | 1.894 | −10.43 | 10.601 |

| 105% | 0.946 | 3.014 | 0.003 | 3.014 |

| 110% | 0.924 | 5.600 | 1.585 | 5.819 |

Table 8.

Velocity and acceleration of muzzle center at the moment of bullet exit barrel.

Table 8.

Velocity and acceleration of muzzle center at the moment of bullet exit barrel.

| Group | Time of Bullet Exit/ms | Velocity of Muzzle Center/m·s−1 | Acceleration of Muzzle Center/m·s−2 |

|---|

| Vertical | Horizontal | Comprehensive | Vertical | Horizontal | Comprehensive |

|---|

| 90% | 1.034 | 0.012 | 0.038 | 0.040 | 0.480 | 1.675 | 1.742 |

| 95% | 1.001 | −0.024 | 0.087 | 0.090 | −2.485 | 1.856 | 3.102 |

| 100% | 0.973 | 0.217 | −0.244 | 0.327 | 10.134 | 4.486 | 11.083 |

| 105% | 0.946 | 0.128 | 0.006 | 0.128 | −0.627 | 11.210 | 11.228 |

| 110% | 0.924 | 0.217 | −0.054 | 0.224 | 8.371 | 12.864 | 15.348 |

Table 9.

Swing angle and angular velocity of muzzle plane at the moment of bullet exit muzzle.

Table 9.

Swing angle and angular velocity of muzzle plane at the moment of bullet exit muzzle.

| Group | Time of Bullet Exit/ms | Swing angle of Muzzle Plane/mrad | Swing Angle Velocity of Muzzle Plane/rad·s−1 |

|---|

| Vertical | Horizontal | Comprehensive | Vertical | Horizontal | Comprehensive |

|---|

| 90% | 1.034 | 0.018 | 0.013 | 0.022 | 0.413 | 0.013 | 0.413 |

| 95% | 1.001 | 0.006 | 0.021 | 0.022 | −0.415 | 2.279 | 2.316 |

| 100% | 0.973 | −0.107 | −0.159 | 0.192 | −3.333 | −8.539 | 9.166 |

| 105% | 0.946 | −0.078 | 0.078 | 0.110 | −3.636 | −2.049 | 4.174 |

| 110% | 0.924 | −0.139 | 0.084 | 0.162 | −3.565 | −4.229 | 5.531 |

Table 10.

Kinematic state comparison when bullet exit muzzle under varying chamber pressures.

Table 10.

Kinematic state comparison when bullet exit muzzle under varying chamber pressures.

| Parameters | 100% Standard Chamber Pressure | 90% Standard Chamber Pressure | Decline |

|---|

| Radial comprehensive displacement of muzzle center/×10−3 mm | 10.601 | 0.829 | 92.18% |

| Radial comprehensive velocity/m·s−1 | 0.327 | 0.040 | 87.76% |

| Radial comprehensive acceleration/m·s−2 | 11.083 | 1.742 | 84.28% |

| Swing angle of muzzle plane/mrad | 0.192 | 0.022 | 88.54% |

| Swing angular velocity of muzzle plane/rad·s−1 | 9.166 | 0.413 | 95.49% |

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).