CFD-Based Design of an Asymmetric Twisted Flap Rudder for Lift Enhancement at Small Deflection Angles

Abstract

1. Introduction

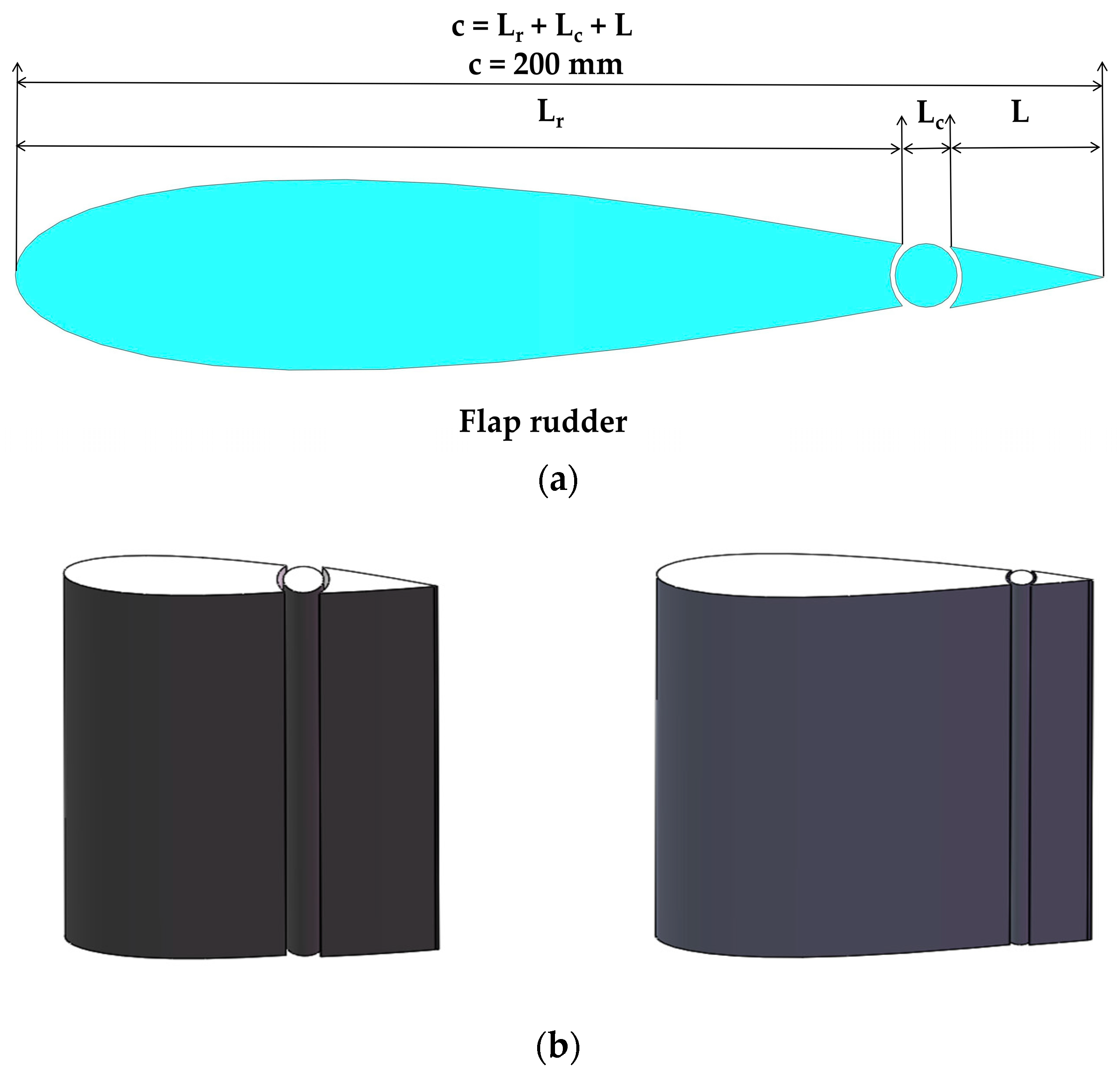

2. Rudder Modeling

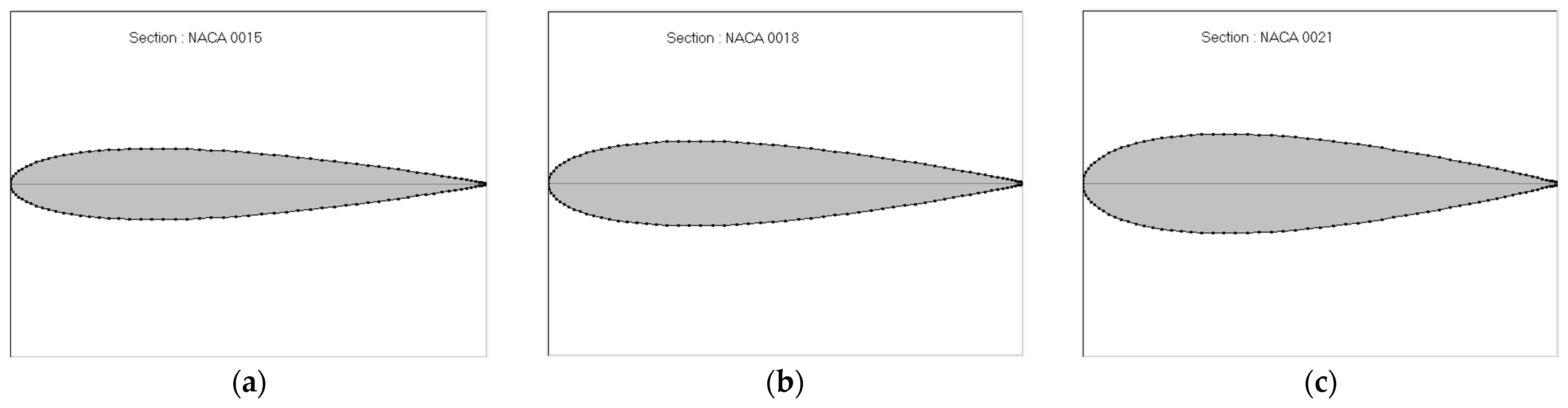

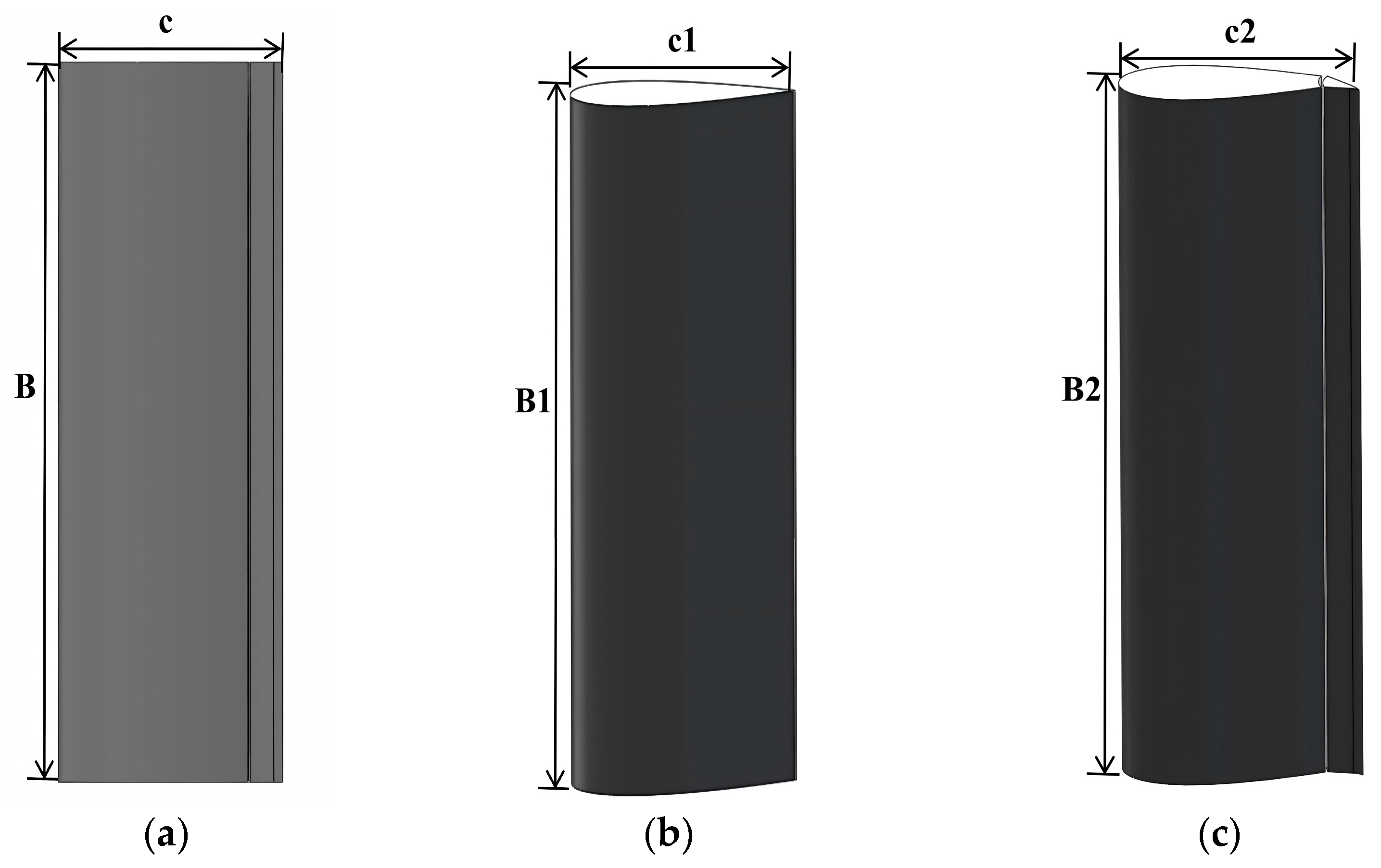

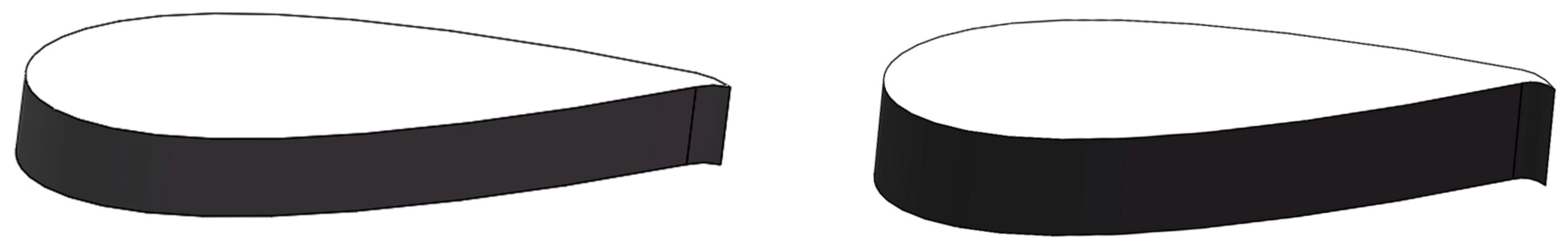

2.1. Rudder Selection

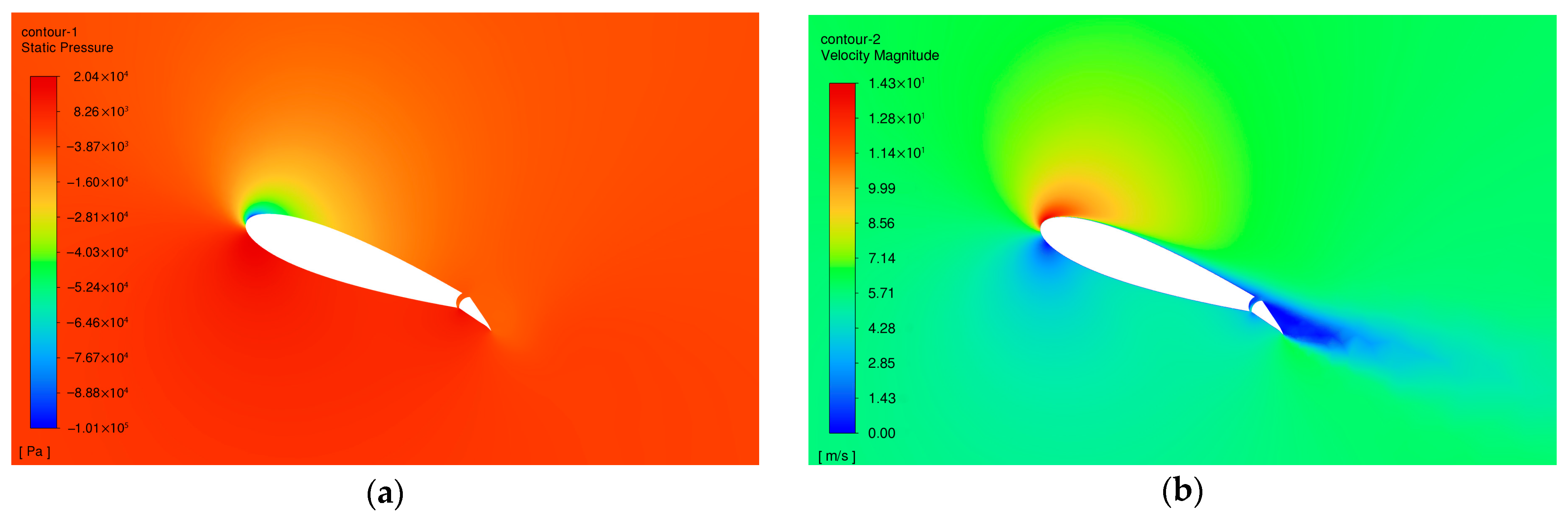

2.2. Simulation Model Establishment

2.3. Numerical Mode

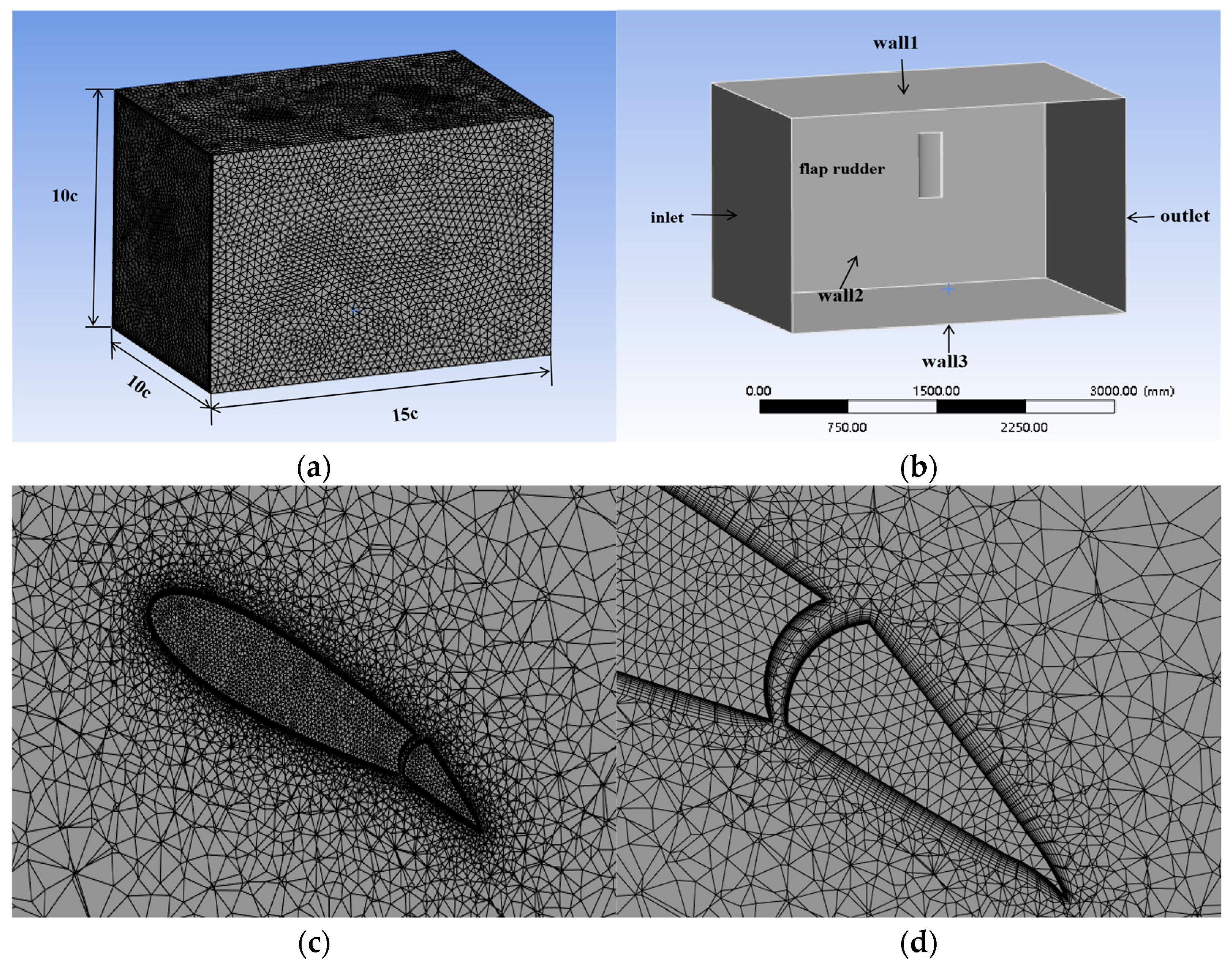

3. Mesh Generation for Flap Rudder

4. Result Analysis

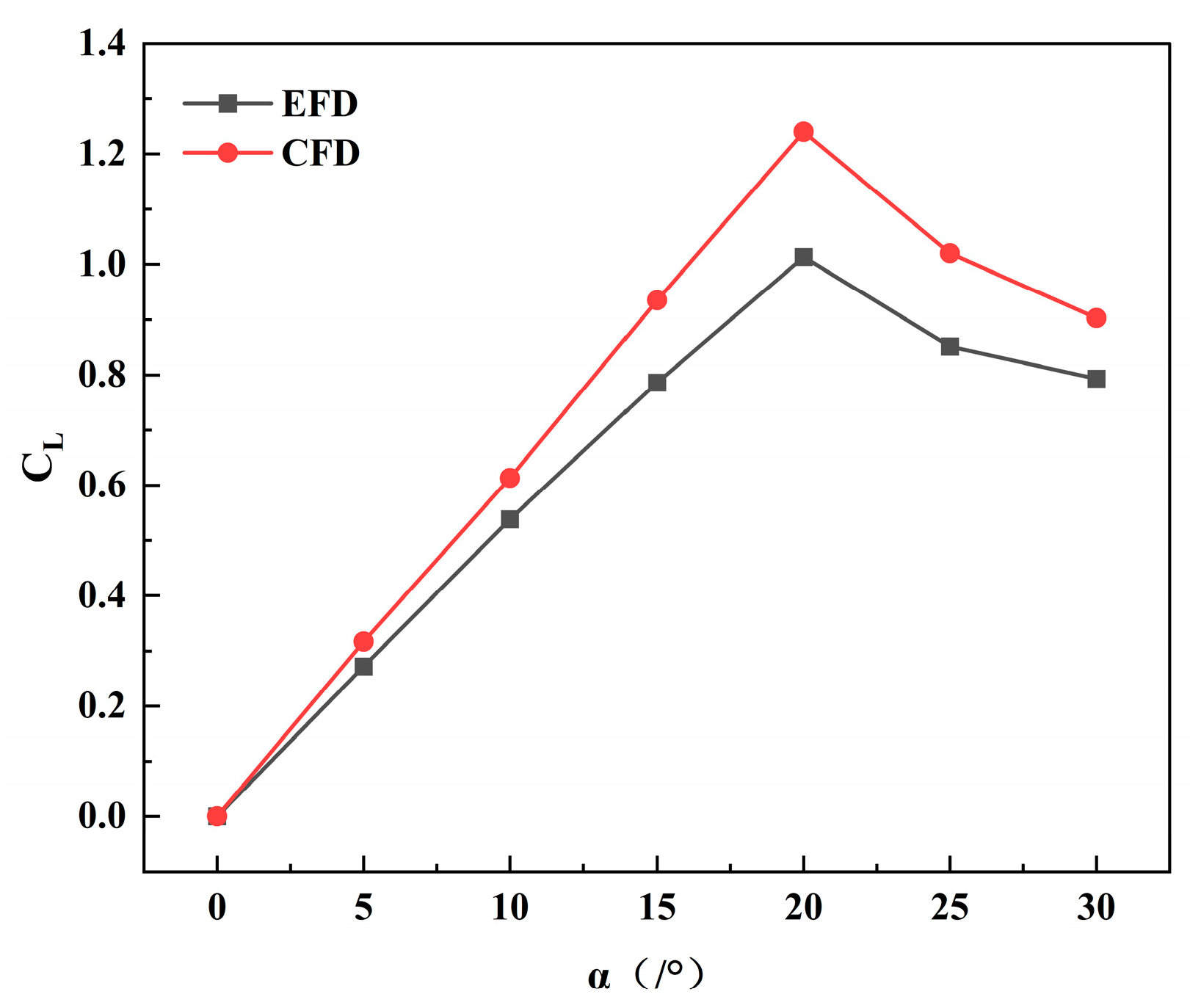

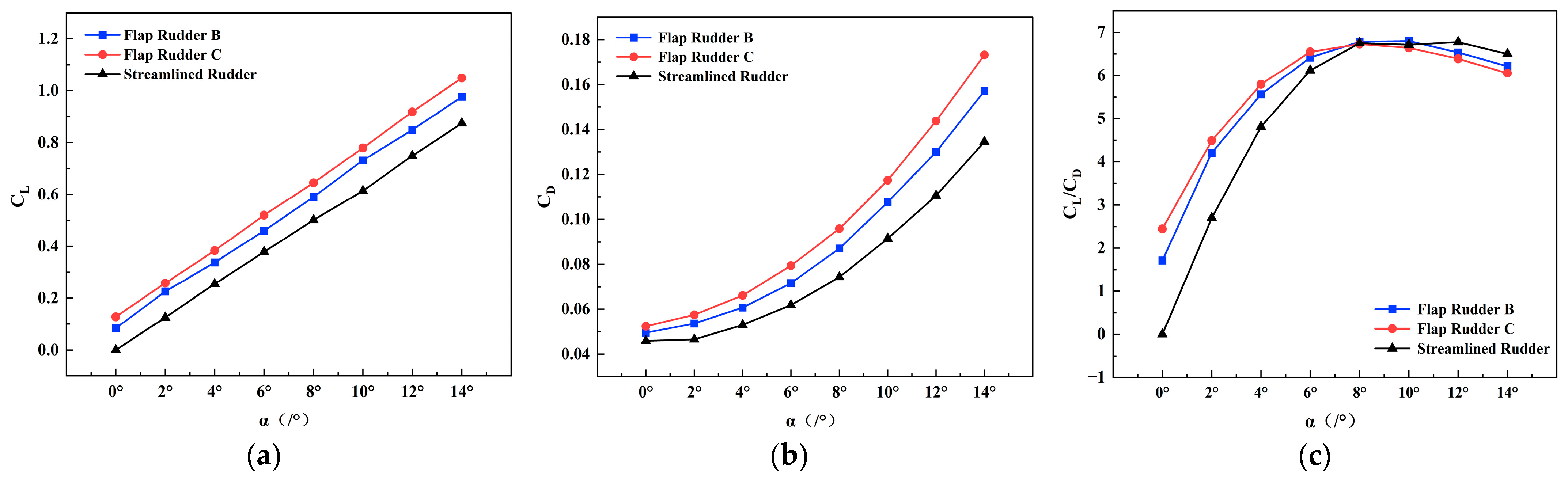

4.1. Case Study

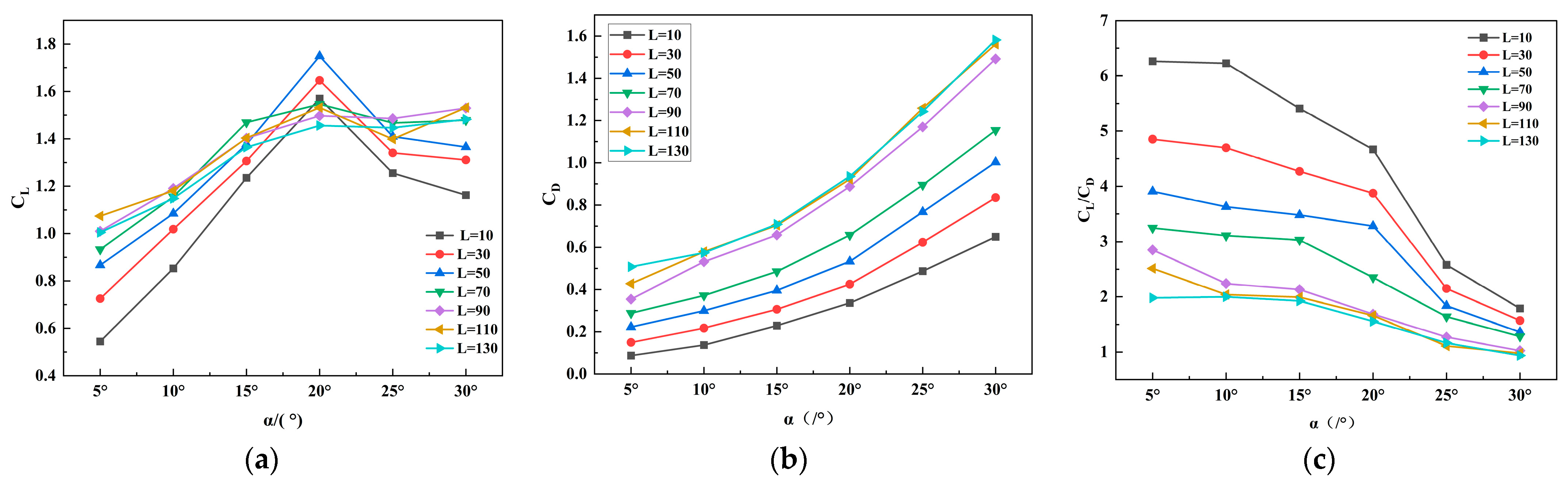

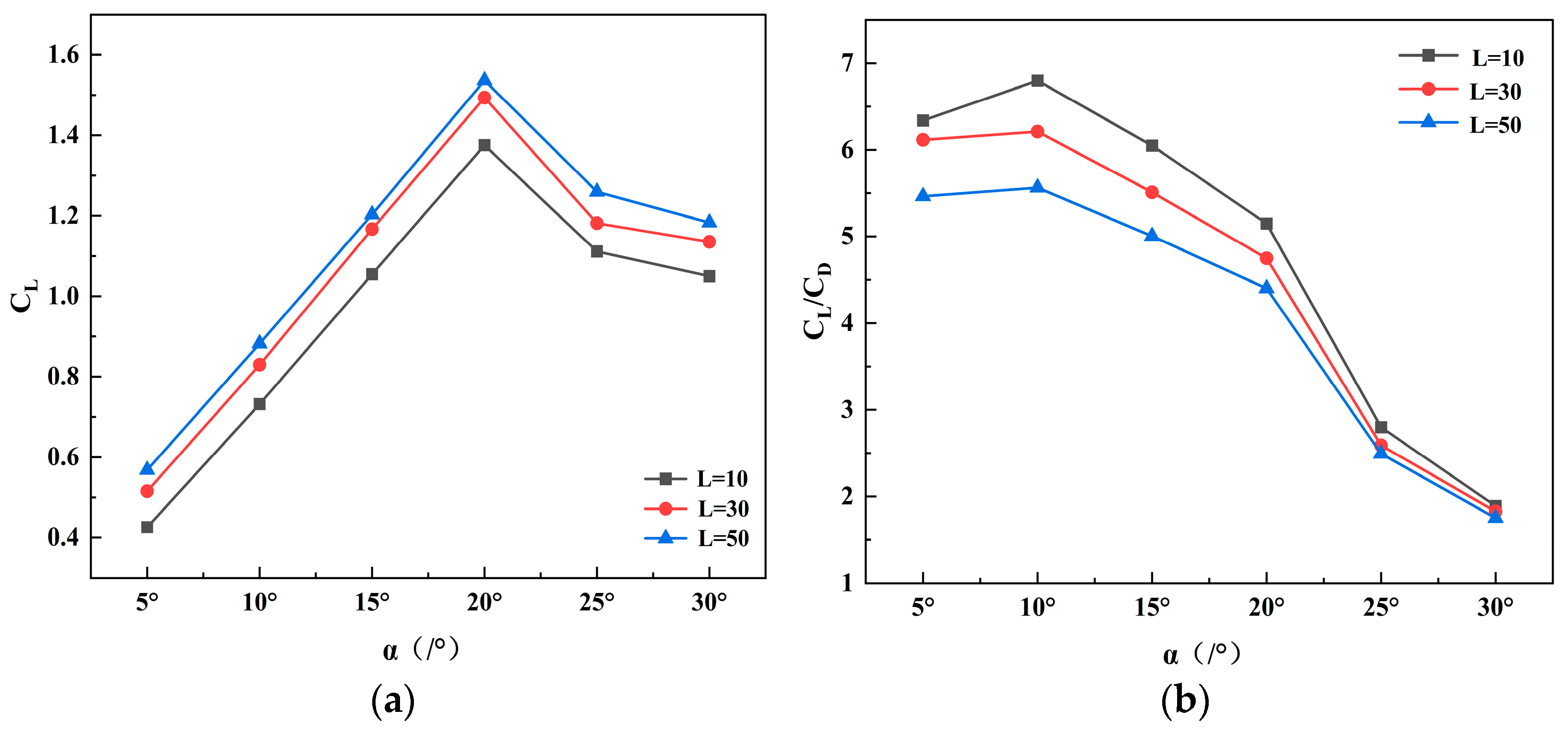

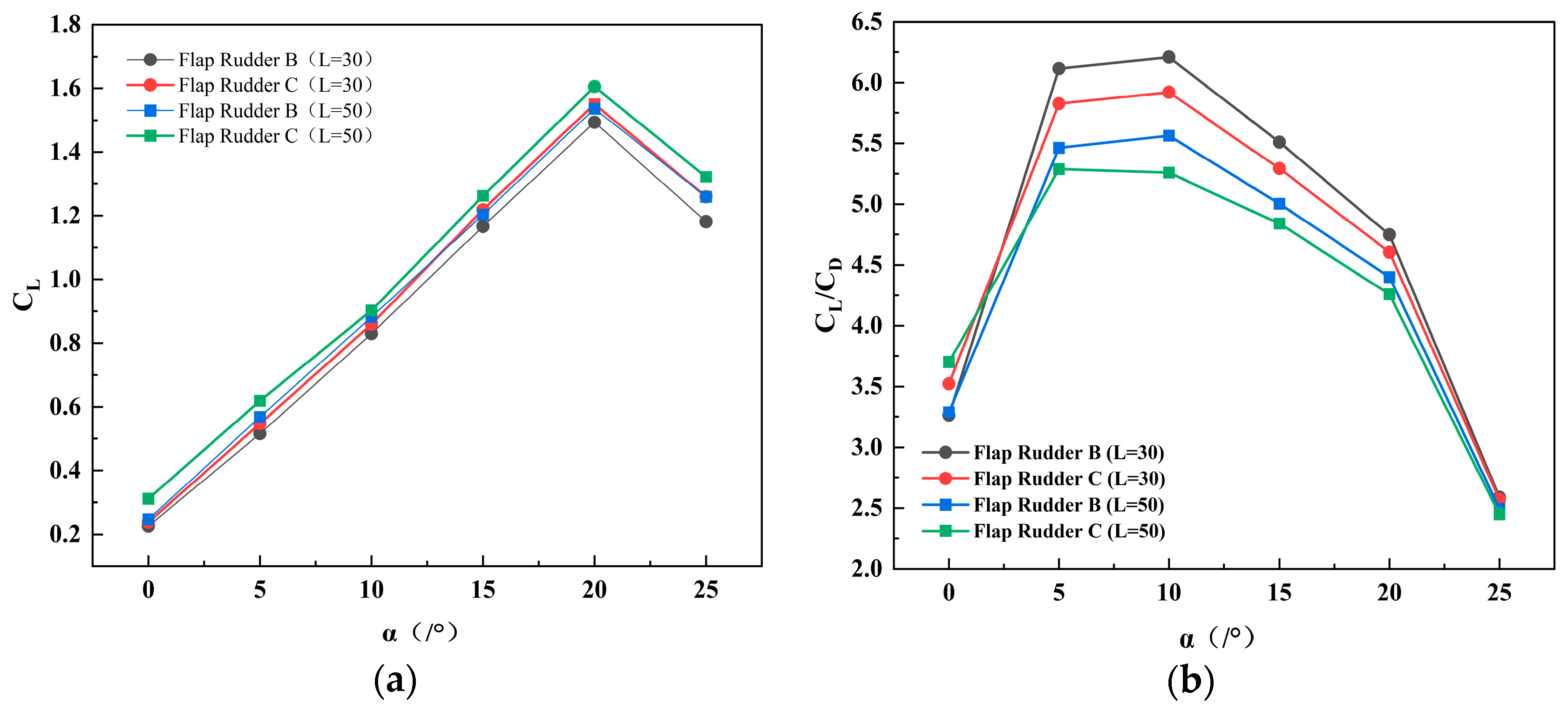

4.2. Influence of Flap Size on the Hydrodynamic Performance of the Flap Rudder

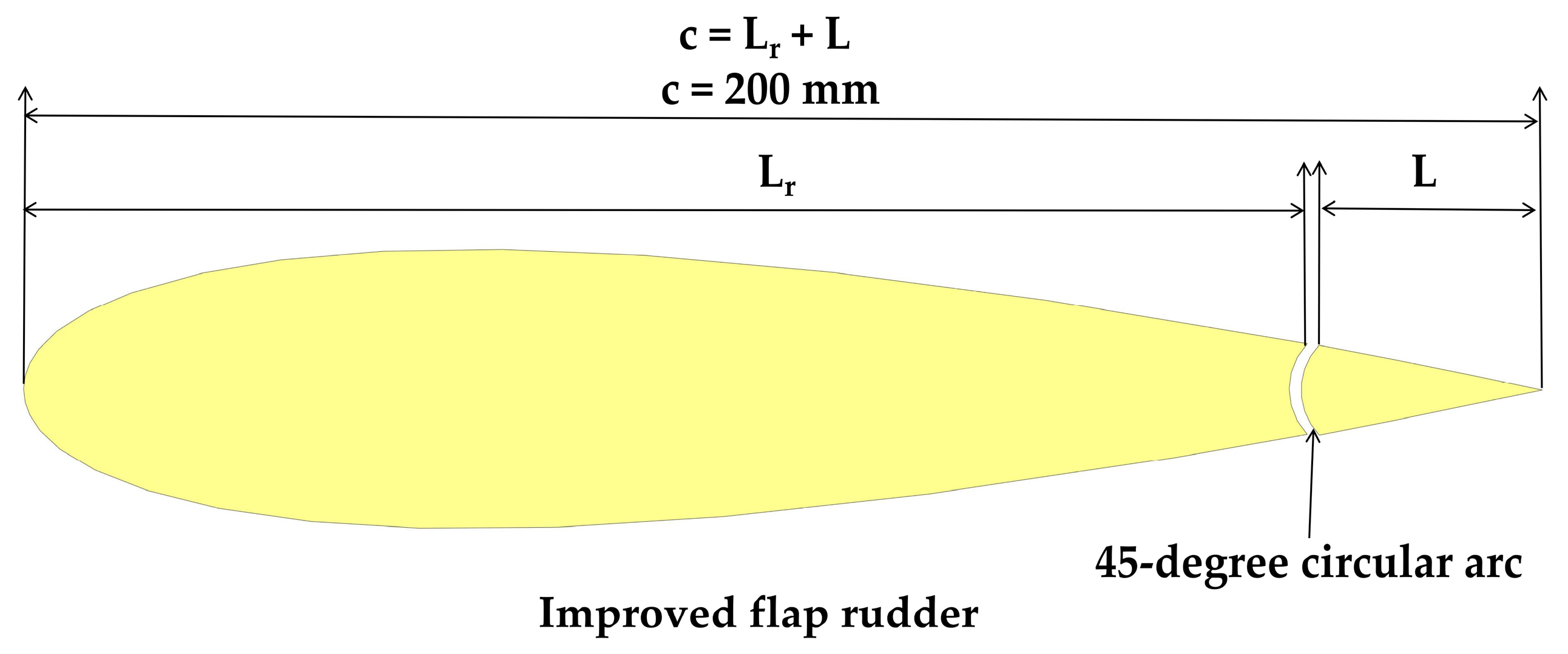

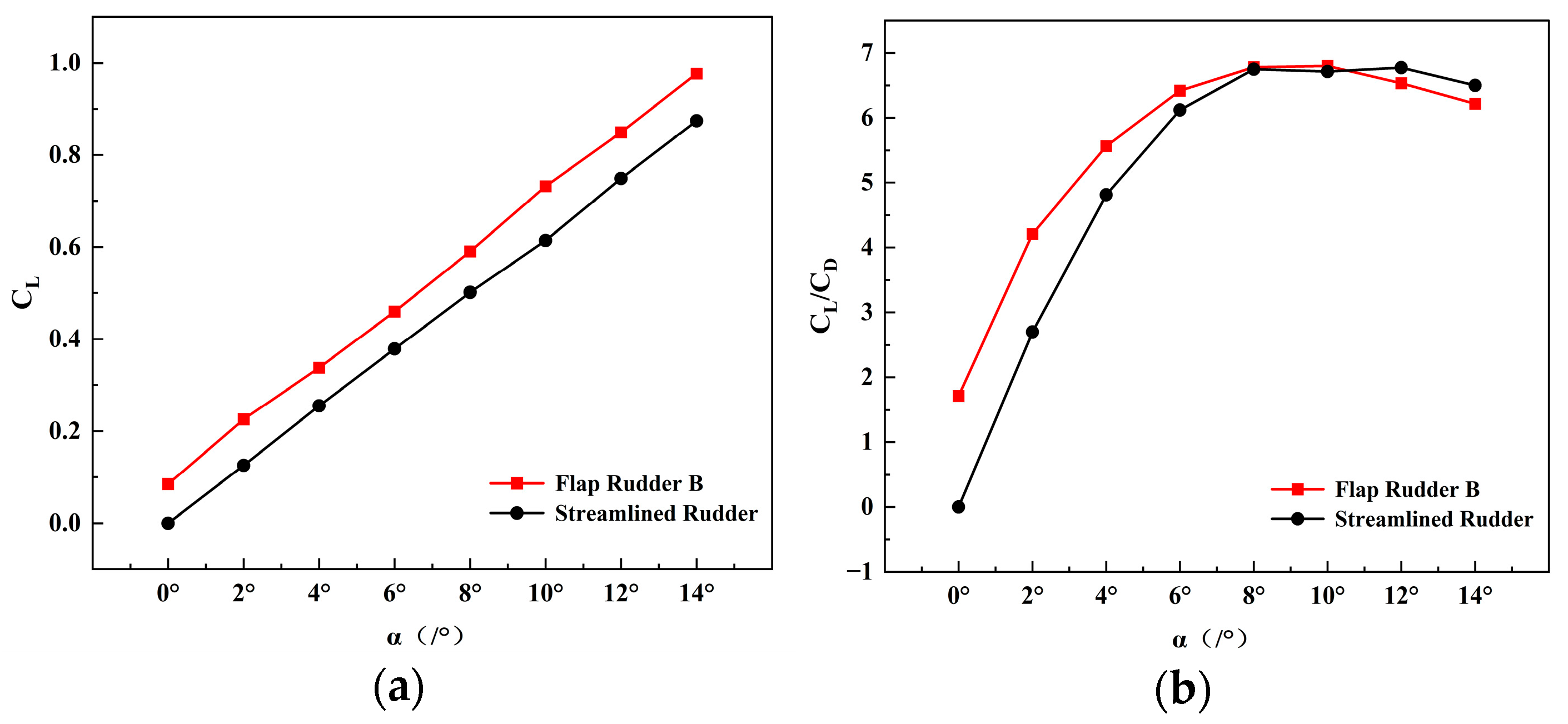

4.3. Improved Flap Rudder Design

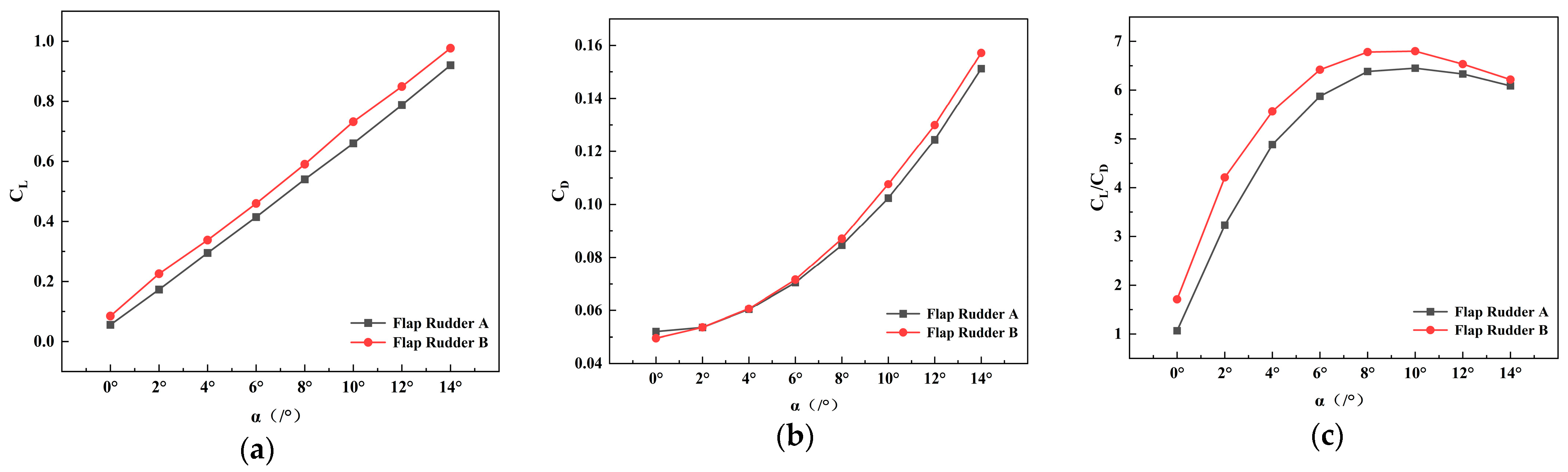

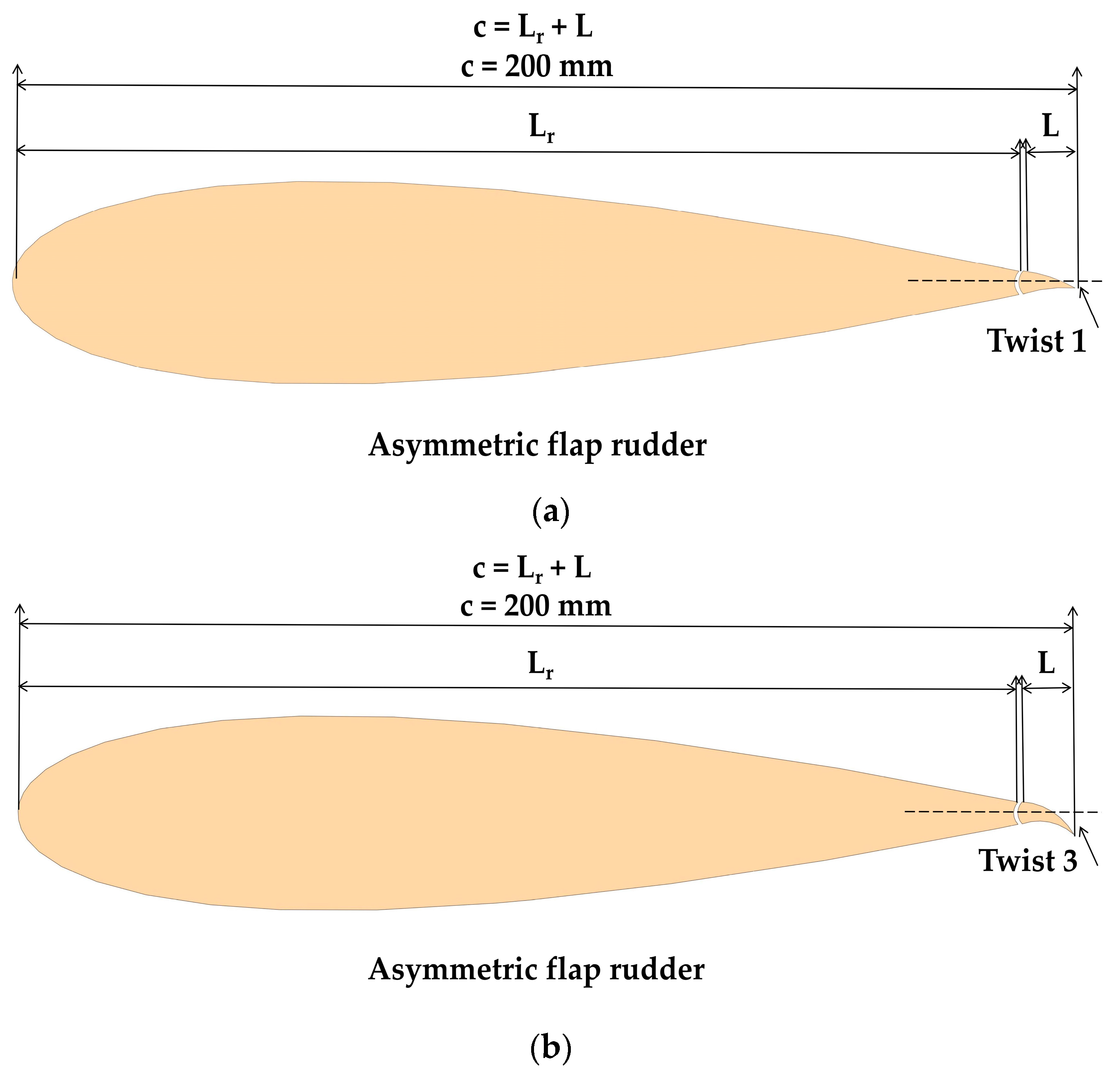

4.4. Design of an Aft-Asymmetric Flap Rudder with Trailing-Edge Twist

4.5. Performance Analysis of Coupled Rotation Between Main Rudder and Flap in Flap Rudder C

5. Conclusions

- At a deflection angle of 5°, the lift coefficient is 0.3167 for the streamlined rudder, 0.4261 for the conventional flap rudder, and 0.4599 for the asymmetric flap configuration. This corresponds to an increase of about 45% compared with the streamlined rudder and roughly 7.93% relative to the conventional flap rudder. The lift-to-drag ratios are 5.559, 5.87, and 6.342, reflecting improvements of 14% and 7.99%, respectively. These results indicate that the asymmetric configuration provides a notable enhancement in low-angle hydrodynamic performance compared with the baseline designs.

- Despite the improvements at low deflection angles, the asymmetric configuration exhibits limitations at large deflection angles, where drag increases and the lift-to-drag ratio can drop below that of the streamlined rudder. Further investigations are needed to enhance flap rudder performance under high-angle conditions.

- The selection of flap rudder geometries in this study was primarily guided by the maximization of the lift-to-drag ratio. For flap lengths of L = 30 and L = 50, simulations indicate that the asymmetric configuration consistently improves hydrodynamic performance. However, additional research is required to optimize the relative proportion between the flap and the asymmetric section, as well as to determine the optimal twist intensity of the asymmetric flap.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CFD | Computational Fluid Dynamics |

| UAVs | Unmanned Aerial Vehicles |

| CAS | Chinese Academy of Sciences |

| AUV | Autonomous Underwater Vehicle |

| RANS | Reynolds-averaged Navier–Stokes |

| FD | Drag force |

| FL | Lift force |

| FR | Resultant force |

| FN | Normal force |

| FT | Tangential force |

| CL | Lift coefficient |

| CD | Drag coefficient |

| CN | Normal force coefficient |

| CT | Tangential force coefficient |

| α | Angle of attack |

| θ | Flap deflection angle |

| c | Rudder chord length |

| B | Rudder height |

| L | Flap length |

| SA | Projected area of the flap rudder |

| ρ | Water density |

| V | Inflow velocity |

| N-S | Navier–Stokes |

| SST | Shear-Stress Transport |

| k | Turbulent kinetic energy |

| ω | Specific dissipation rate |

| Pk | Generating term of turbulent kinetic energy k |

| μt | Eddy viscosity |

| P | Pressure |

| μ | Hydrodynamic viscous coefficient |

| gi | Mass force |

References

- Agarwala, N. Monitoring the Ocean Environment Using Robotic Systems: Advancements, Trends, and Challenges. Mar. Technol. Soc. J. 2020, 54, 42–60. [Google Scholar] [CrossRef]

- Kabanov, A.; Kramar, V. Marine Internet of Things Platforms for Interoperability of Marine Robotic Agents: An Overview of Concepts and Architectures. J. Mar. Sci. Eng. 2022, 10, 1279. [Google Scholar] [CrossRef]

- Fang, S.; Tian, C.; Zhang, Y.; Xu, C.; Ding, T.; Wang, H.; Xia, T. Aerodynamic Analysis of Rigid Wing Sail Based on CFD Simulation for the Design of High-Performance Unmanned Sailboats. Mathematics 2024, 12, 2481. [Google Scholar] [CrossRef]

- Malmek, K.; Larsson, L.; Werner, S.; Ringsberg, J.W.; Bensow, R.; Finnsgård, C. Rapid aerodynamic method for predicting the performance of interacting wing sails. Ocean Eng. 2024, 293, 116596. [Google Scholar] [CrossRef]

- Xu, J.; Zhao, J.; Chang, J. Effect of Different Voltage Frequencies of Plasma Actuators on Wind Turbine Blade Lift and Rudder Efficiency. Processes 2025, 13, 1032. [Google Scholar] [CrossRef]

- Mei, Y.; Gao, J.; Lin, J.; Song, X. An AUV stability estimation method by considering rudder design parameters. Ocean Eng. 2024, 313, 119358. [Google Scholar] [CrossRef]

- Zhang, D.; Chiodi, A.M.; Zhang, C.; Foltz, G.R.; Cronin, M.F.; Mordy, C.W.; Cross, J.; Cokelet, E.D.; Zhang, J.A.; Meinig, C.; et al. Observing Extreme Ocean and Weather Events Using: Innovative Saildrone Uncrewed Surface Vehicles. Oceanography 2023, 36, 70–77. [Google Scholar] [CrossRef]

- Sun, Z.; Feng, A.; Yu, J.; Zhao, W.; Huang, Y. Development of autonomous sailboat sails and future perspectives: A review. Renew. Sustain. Energy Rev. 2025, 207, 114918. [Google Scholar] [CrossRef]

- Yang, A.; Jiancheng, Y.; Jin, Z. Autonomous sailboat design: A review from the performance perspective. Ocean Eng. 2021, 238, 109753. [Google Scholar] [CrossRef]

- An, Y.; Hu, F.; Chen, K.; Yu, J. Optimising General Configuration of Wing-Sailed Autonomous Sailing Monohulls Using Bayesian Optimisation and Knowledge Transfer. J. Mar. Sci. Eng. 2023, 11, 703. [Google Scholar] [CrossRef]

- Liu, H.; Yang, Y.; Yin, S. Study on the Turning Characteristics and Influencing Factors of the Unmanned Sailboat. J. Mar. Sci. Eng. 2024, 12, 1374. [Google Scholar] [CrossRef]

- Lina, K.; Hongyu, L.; Xin, S.; Xin, S.; Zongsheng, W.; Yu, Z.; Weizhuang, M. Effect of chord length ratio on aerodynamic performance of two-element wing sail. Ocean Eng. 2023, 287, 115946. [Google Scholar] [CrossRef]

- Dhomé, U.; Hillenbrand, A.; Kuttenkeuler, J.; Rolleberg, N. Unsteady pressure measurements at sea on the rigid wings of a model wind propelled ship. Part A: Measurement system development. Ocean Eng. 2025, 331, 121229. [Google Scholar] [CrossRef]

- Wang, B.; Huang, T.; Sun, Z.; Li, Z.; Zhao, Y.; Wang, Y.; Zhang, D.; Qian, P. Influence of hull geometry on self-propulsion performance of vector-propelled streamlined AUV with a ducted propeller. Ocean Eng. 2025, 338, 121959. [Google Scholar] [CrossRef]

- Liu, J.; Hekkenberg, R.; Zhao, B. RANS study on hydrodynamic characteristics of flapped rudders. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Madrid, Spain, 17–22 June 2018; American Society of Mechanical Engineers: New York, NY, USA, 2018; p. V11BT12A002. [Google Scholar]

- Troll, M.; Das, T.K.; Shi, W.; Jia, L.; Li, C. Experimental analysis of a high-lift flap rudder with leading-edge tubercles. Ocean Eng. 2025, 340, 122208. [Google Scholar] [CrossRef]

- Lu, S.; Li, F.; Liu, J.; Liu, Z. Case studies on the impact of flap rudders on ship maneuverings. In Proceedings of the 2021 6th International Conference on Transportation Information and Safety (ICTIS), Wuhan, China, 22–24 October 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 998–1003. [Google Scholar]

- Hao, Z.; Li, K.; Liu, G.; Liu, S. Optimizing the Hydrodynamic Performance of Unmanned Sailboats by Adjusting the Structure of the Keel and Rudder. J. Mar. Sci. Eng. 2025, 13, 414. [Google Scholar] [CrossRef]

- Liu, J.; Hekkenberg, R. Sixty years of research on ship rudders: Effects of design choices on rudder performance. Ships Offshore Struct. 2017, 12, 495–512. [Google Scholar] [CrossRef]

- Whicker, L.F.; Fehlner, L.F. Free-Stream Characteristics of a Family of Low-Aspect-Ratio, All-Movable Control Surfaces for Application to Ship Design; David Taylor Model Basin: Washington, DC, USA, 1958. [Google Scholar]

- Abbott, I.H.; Von Doenhoff, A.E. Theory of Wing Sections: Including a Summary of Airfoil Data; Courier Corporation: Chelmsford, MA, USA, 2012. [Google Scholar]

- Thieme, H. Design of Ship Rudders (zur Formgebung Von Schiffsrudern); David Taylor Model Basin: Washington, DC, USA, 1965. [Google Scholar]

- Molland, A.F.; Turnock, S.R. Marine Rudders and Control Surfaces: Principles, Data, Design and Applications; Elsevier: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Ahmed, T.; Amin, M.T.; Islam, S.R.; Ahmed, S. Computational study of flow around a NACA 0012 wing flapped at different flap angles with varying Mach numbers. Glob. J. Res. Eng. 2014, 13, 4–16. [Google Scholar]

- Tasif, T.H.; Rahman, M.H.; Fazle, A.B.; Karim, M.M. Numerical prediction of flow past a marine rudder. Procedia Eng. 2017, 194, 59–66. [Google Scholar] [CrossRef]

- Guo, C.; Hu, W.; Huang, S. Using RANS to simulate the interaction and overall performance of propellers and rudders with thrust fins. J. Mar. Sci. Appl. 2010, 9, 323–327. [Google Scholar] [CrossRef]

- Moshfeghi, M.; Song, Y.J.; Xie, Y.H. Effects of near-wall grid spacing on SST-K-ω model using NREL Phase VI horizontal axis wind turbine. J. Wind Eng. Ind. Aerodyn. 2012, 107, 94–105. [Google Scholar] [CrossRef]

- Clara, I.; d’Adamo, A.; Stefano, F.; Giovanni, D.I.; Krassimirov, K.V. A wall-adapted zonal URANS/LES methodology for the scale-resolving simulation of engine flows. Int. J. Engine Res. 2022, 23, 1732–1747. [Google Scholar]

- Gao, H.; Xu, H.; Ma, Y.; Liu, Y.; Liang, X. Simulation study on the hydrodynamic characteristics and stability of an Open-Frame underwater towed body. Ocean Eng. 2025, 337, 121902. [Google Scholar] [CrossRef]

- Hou, L.; Han, Y.; Wang, R. Optimization design about end plates of ship rudder based on hydrodynamic numerical simulations. Brodogradnja 2025, 76, 76404. [Google Scholar] [CrossRef]

- Lee, M.; Park, G.; Park, C.; Kim, C. Improvement of Grid Independence Test for Computational Fluid Dynamics Model of Building Based on Grid Resolution. Adv. Civ. Eng. 2020, 2020, 8827936. [Google Scholar] [CrossRef]

- Molland, A.F.; Turnock, S.R. Wind Tunnel Tests on the Influence of Propeller Loading on Ship Rudder Performance: Four Quadrant Operation, Low and Zero Speed Operation. 1993. Available online: https://eprints.soton.ac.uk/46044/ (accessed on 11 July 2025).

- Liu, J.-l.; Hekkenberg, R. 3D RANS simulations of shallow water effects on rudder hydrodynamic characteristics. In Proceedings of the Proceedings 2016 International Conference on Maritime Technology, Harbin, China, 16–18 July 2016; pp. 35–39. [Google Scholar]

- Wang, X.; Qian, W.; Zhao, T.; He, L.; Chen, H.; Sun, H.; Tian, Y.; Cui, J. Fast Prediction of Airfoil Aerodynamic Characteristics Based on a Combined Autoencoder. Symmetry 2024, 16, 791. [Google Scholar] [CrossRef]

- Albert, H.F. On Quasisympletic Formulation and Formal Integration of Classical Fluid Dynamic Conservation Laws. ZAMM-J. Appl. Math. Mech./Z. Angew. Math. Mech. 2001, 81, 17–29. [Google Scholar] [CrossRef]

| Number of Grids (No.) | Lift Coefficient CL of Flap Rudder | Drag Coefficient CD of Flap Rudder |

|---|---|---|

| 6.56 × 105 | 1.116 | 0.194 |

| 12.3 × 105 | 1.110 | 0.191 |

| 17.3 × 105 | 1.111 | 0.190 |

| 27.5 × 105 | 1.113 | 0.189 |

| 35.3 × 105 | 1.113 | 0.189 |

| 45.5 × 105 | 1.113 | 0.189 |

| Flow field velocity | 6 m/s |

| α | 0°, 5°, 10°, 15°, 20°, 25°, 30° |

| The viscosity equation | SST k-ω |

| Fluid domain materials | water |

| Calculate the reference area | The flap rudder’s projected area in the Y-direction |

| Calculate the reference length | 0.2 m |

| Report definition | Lift coefficient, drag coefficient, lift force, drag force |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Tian, C.; Ding, T.; Xu, C.; Ye, J.; Gong, A.; Liu, M. CFD-Based Design of an Asymmetric Twisted Flap Rudder for Lift Enhancement at Small Deflection Angles. Symmetry 2025, 17, 1613. https://doi.org/10.3390/sym17101613

Wang H, Tian C, Ding T, Xu C, Ye J, Gong A, Liu M. CFD-Based Design of an Asymmetric Twisted Flap Rudder for Lift Enhancement at Small Deflection Angles. Symmetry. 2025; 17(10):1613. https://doi.org/10.3390/sym17101613

Chicago/Turabian StyleWang, Huimin, Cunwei Tian, Tianci Ding, Changbin Xu, Jiaqi Ye, Aijiao Gong, and Mingfei Liu. 2025. "CFD-Based Design of an Asymmetric Twisted Flap Rudder for Lift Enhancement at Small Deflection Angles" Symmetry 17, no. 10: 1613. https://doi.org/10.3390/sym17101613

APA StyleWang, H., Tian, C., Ding, T., Xu, C., Ye, J., Gong, A., & Liu, M. (2025). CFD-Based Design of an Asymmetric Twisted Flap Rudder for Lift Enhancement at Small Deflection Angles. Symmetry, 17(10), 1613. https://doi.org/10.3390/sym17101613