Practical Prescribed Tracking Control of n-DOF Robotic Manipulator with Uncertainties via Friction Compensation Approach

Abstract

1. Introduction

1.1. Background and Motivation

- (1)

- Achieving the control objectives efficiently and precisely.

- (2)

- Robustness against uncertain dynamics and external disturbances.

- (3)

- Easy implementation and tuning in engineering practice.

1.2. Related Work

- (1)

- It cannot promptly capture abrupt perturbations, such as friction mutations resulting from velocity reversal [12].

- (2)

- High constant gains may bring peak values if the initial position error is significant.

1.3. Contribution and Outline

- (1)

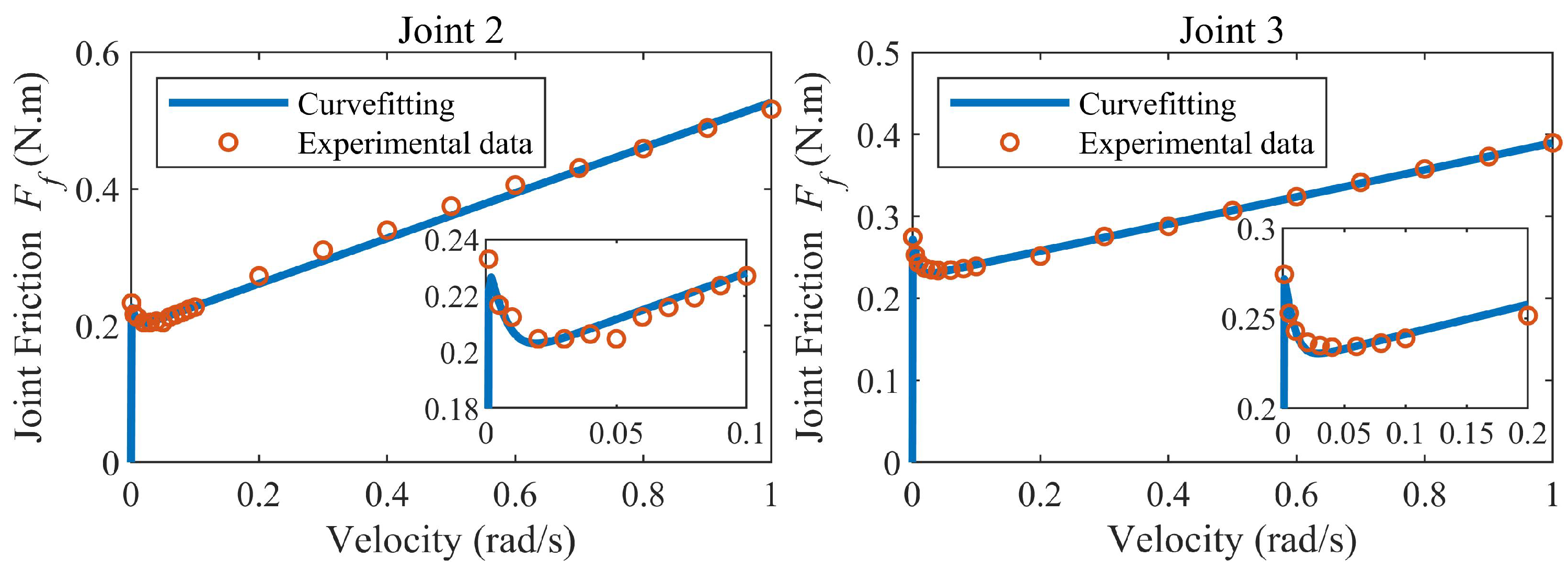

- A continuously differentiable non-linear friction model is introduced to mitigate the adverse effects of the friction, thereby augmenting observer estimation and overall tracking performance. In addition, a practical way of identifying friction parameters is presented.

- (2)

- (3)

2. Problem Formulation and Preliminaries

2.1. Dynamic Model and Problem Formulation

2.2. Error Transformation

3. Practical Tracking Control Design

3.1. Continuously Differentiable Friction Model

3.2. VGFESO Design

3.3. Controller Design and Stability Analysis

4. Numerical Simulation

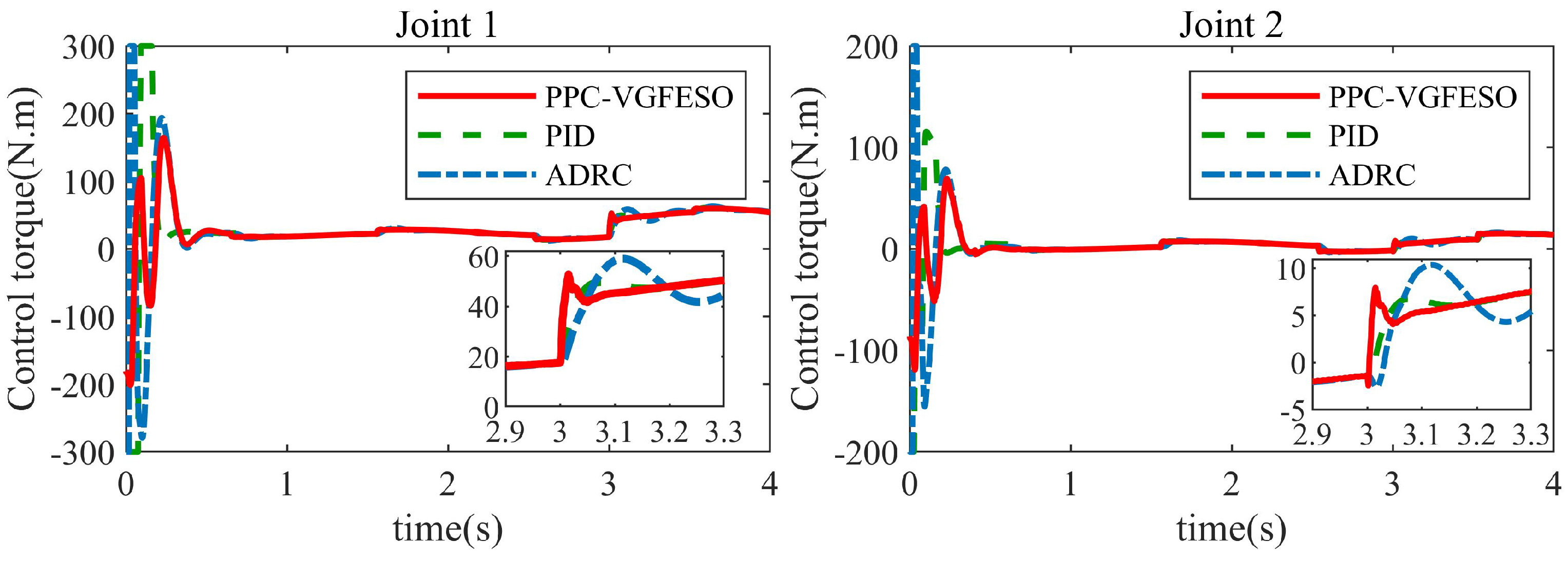

- (1)

- PPC-VGFESO: This is the controller (26) designed in this paper. The PPF parameters are set as , , , , . The controller parameters are set as , , , , , , , , . The nominal friction model is selected as .

- (2)

- ADRC [22]: The control law can be expressed aswhere is the estimation of state by LESO. The controller parameters are set as , , , , , . To compare with VGFESO, the parameter of LESO is also chosen as .

- (3)

- Proportional-integral-derivative (PID): A PID controller is defined as . Its gains are , , , , , and , which are adjusted through trial and error to balance steady-state and transient performance.

- (1)

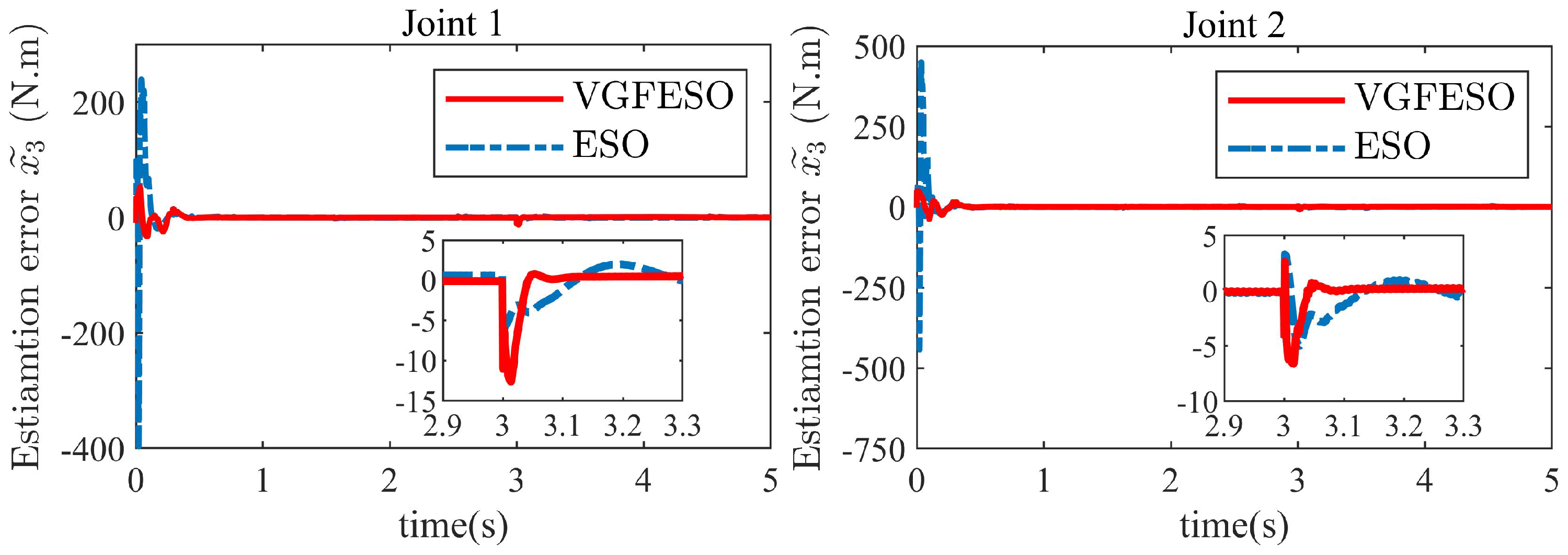

- The rapid disturbance estimation by VGFESO and effective compensation, as shown in Figure 3;

- (2)

- The steady-state performance is strictly constrained by the PPF.

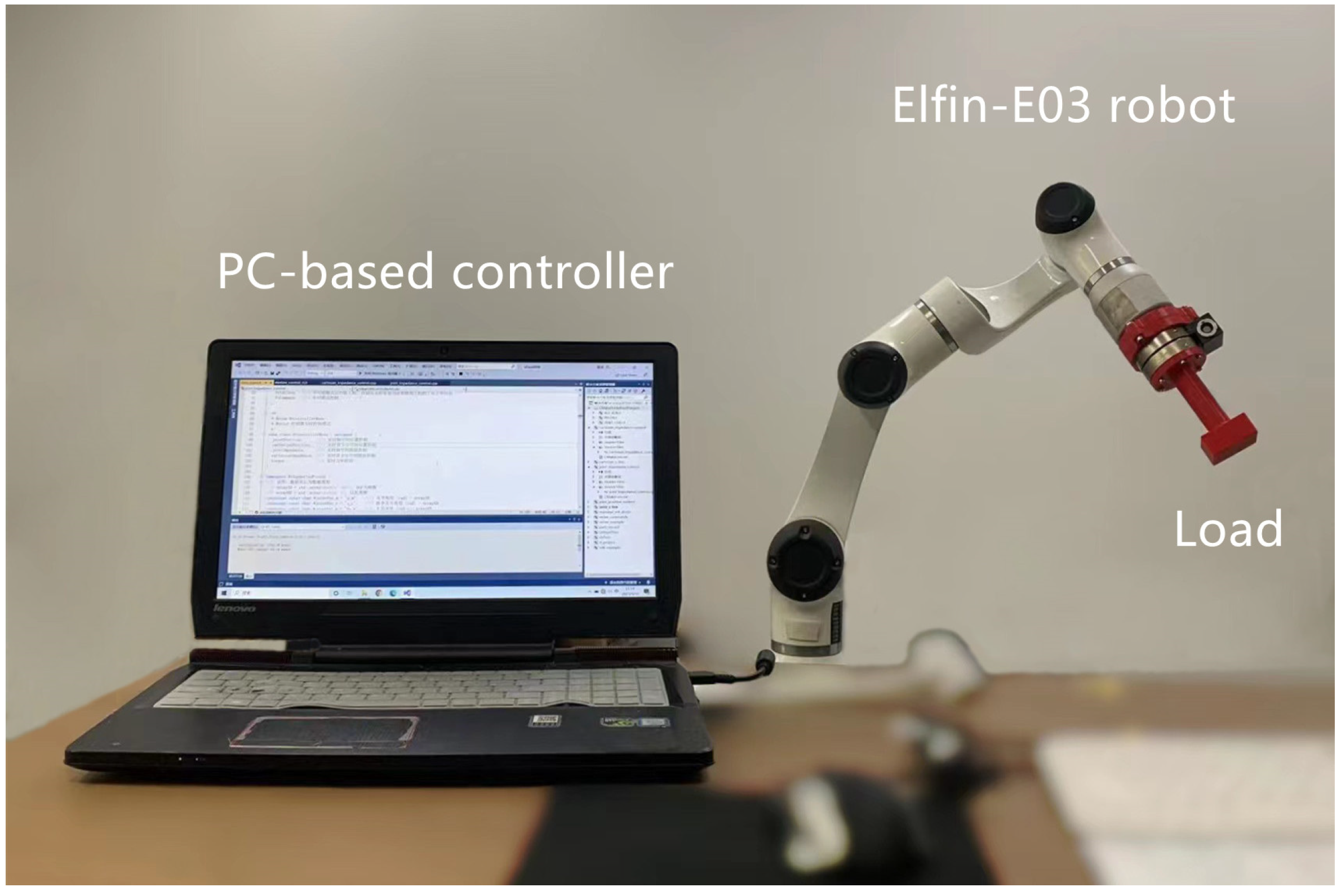

5. Experiment Verification

5.1. Experiment Setup

5.2. Friction Parameter Identification

5.3. Comparative Experimental Results

5.3.1. Trajectory Tracking in Joint Space

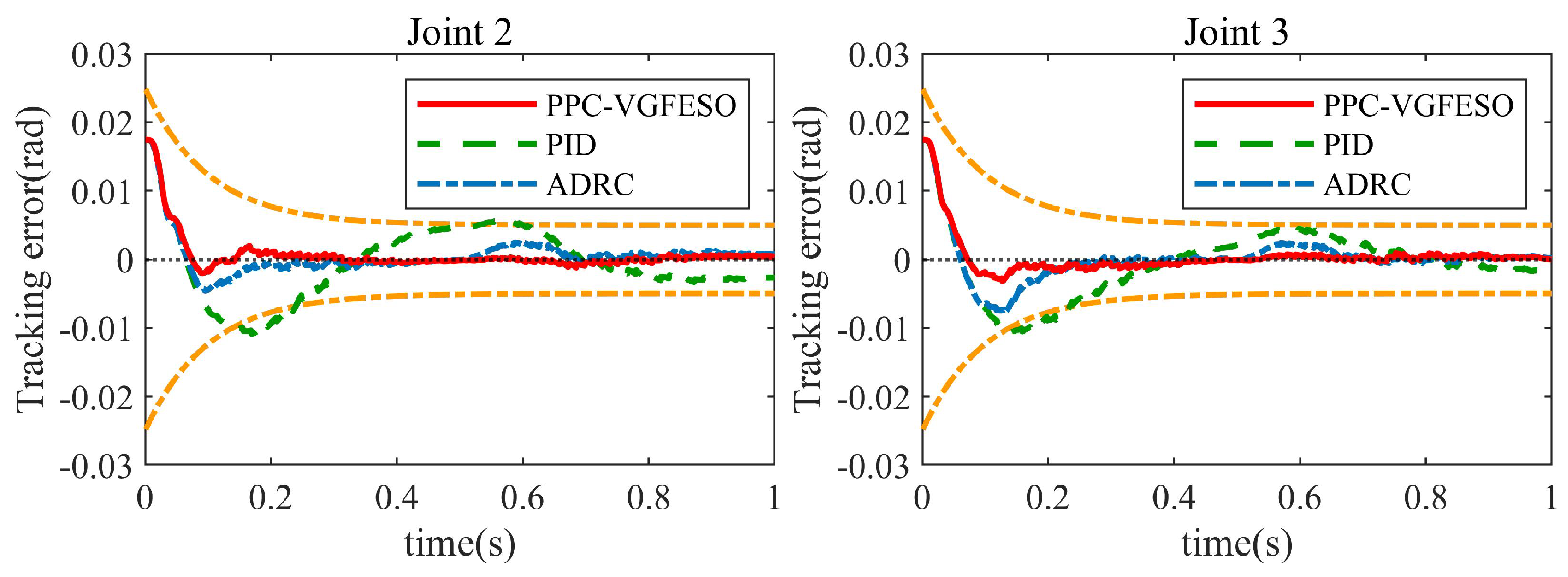

- Case 1—Low-frequency sinusoidal signal tracking and no load: In this experiment, the reference trajectory is , and the robot operates without a load. The initial angular position of each joint is set to 0.0175 rad (1°), and the initial velocity is zero. Figure 7 and Figure 8 present the experimental results. The proposed method exhibits faster convergence and smaller steady-state error than the PID and ADRC controllers. It effectively keeps tracking errors within predefined performance boundaries while successfully addressing abrupt friction changes.

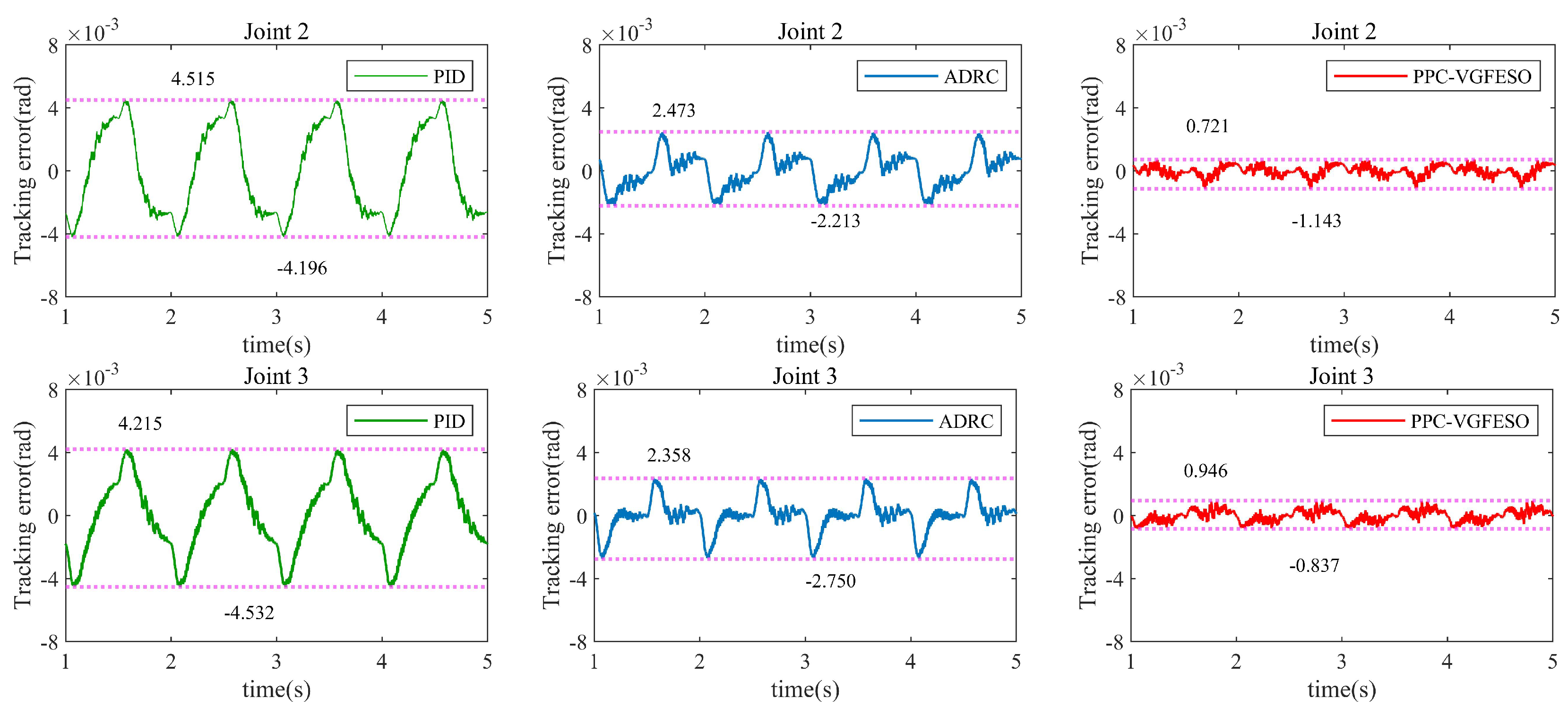

- Case 2—Doubled frequency sinusoidal signal tracking and 1 kg load: A higher frequency sinusoidal trajectory signal is employed, with a 1 kg load added to the end. Importantly, the controller parameters remain unchanged from Case 1. The analysis of the experimental results, as shown in Figure 9 and Figure 10, reveals that the proposed PPC-VGFESO maintains satisfactory tracking performance, demonstrating its robustness. In contrast, the overall tracking performance of the PID algorithm deteriorated significantly, while the convergence speed of the ADRC algorithm decreased, accompanied by more pronounced fluctuations in tracking errors. These results highlight the effectiveness of the proposed method.

5.3.2. Trajectory Tracking in Cartesian Space

- Case 3—Low speed and no load: The velocity of the end effector is set at 300 mm/s, with an acceleration of 600 mm/s2 and a jerk of 4000 mm/s3.

- Case 4—Doubled speed and no load: The velocity of the end effector is doubled to 600 mm/s, with an acceleration of 1200 mm/s2 and a jerk of 8000 mm/s3.

- Case 5—Doubled speed and 1 kg load: The velocity, acceleration, and jerk remain the same as in Case 4, with a 1 kg load added.

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Liang, X.; Yao, Z.; Deng, W.; Yao, J. Adaptive control of n-link hydraulic manipulators with gravity and friction identification. Nonlinear Dyn. 2023, 111, 19093–19109. [Google Scholar] [CrossRef]

- Pezzato, C.; Ferrari, R.; Corbato, C.H. A novel adaptive controller for robot manipulators based on active inference. IEEE Robot. Autom. Lett. 2020, 5, 2973–2980. [Google Scholar] [CrossRef]

- Xiao, B.; Cao, L.; Xu, S.; Liu, L. Robust tracking control of robot manipulators with actuator faults and joint velocity measurement uncertainty. IEEE/ASME Trans. Mechatron. 2020, 25, 1354–1365. [Google Scholar] [CrossRef]

- Su, Y.; Zheng, C.; Mercorelli, P. Robust approximate fixed-time tracking control for uncertain robot manipulators. Mech. Syst. Signal. Process. 2020, 135, 106379. [Google Scholar] [CrossRef]

- Prakash, R.; Behera, L.; Mohan, S.; Jagannathan, S. Dual-Loop Optimal Control of a Robot Manipulator and Its Application in Warehouse Automation. IEEE Trans. Autom. Sci. Eng. 2022, 19, 262–279. [Google Scholar] [CrossRef]

- Xin, L.; Wang, Y.; Fu, H. Omnidirectional Mobile Robot Dynamic Model Identification by NARX Neural Network and Stability Analysis Using the APLF Method. Symmetry 2020, 12, 1430. [Google Scholar] [CrossRef]

- Santos, L.; Cortesão, R. Computed-Torque Control for Robotic-Assisted Tele-Echography Based on Perceived Stiffness Estimation. IEEE Trans. Autom. Sci. Eng. 2018, 15, 1337–1354. [Google Scholar] [CrossRef]

- Gao, J.; Kang, E.; He, W.; Qiao, H. Adaptive model-based dynamic event-triggered output feedback control of a robotic manipulator with disturbance. ISA Trans. 2022, 122, 63–78. [Google Scholar] [CrossRef]

- Gao, Z. Scaling and bandwidth-parameterization based controller tuning. In Proceedings of the 2003 American Control Conference, Denver, CO, USA, 4–6 June 2003; Volume 6, pp. 4989–4996. [Google Scholar]

- Patelski, R.; Dutkiewicz, P. On the stability of ADRC for manipulators with modelling uncertainties. ISA Trans. 2020, 102, 295–303. [Google Scholar] [CrossRef]

- Jin, X.; Lv, H.; He, Z.; Li, Z.; Wang, Z.; Ikiela, N.V.O. Design of Active Disturbance Rejection Controller for Trajectory-Following of Autonomous Ground Electric Vehicles. Symmetry 2023, 15, 1786. [Google Scholar] [CrossRef]

- Chen, C.; Zhang, C.; Hu, T.; Ni, H.; Luo, W. Model-assisted extended state observer-based computed torque control for trajectory tracking of uncertain robotic manipulator systems. Int. J. Adv. Robot. 2018, 15, 1729881418801738. [Google Scholar] [CrossRef]

- Ran, M.; Li, J.; Xie, L. A new extended state observer for uncertain nonlinear systems. Automatica 2021, 131, 109772. [Google Scholar] [CrossRef]

- Zhou, X.; Li, X. Trajectory tracking control for electro-optical tracking system based on fractional-order sliding mode controller with super-twisting extended state observer. ISA Trans. 2021, 117, 85–95. [Google Scholar] [CrossRef] [PubMed]

- Qian, D.; Zhang, G.; Wang, J.; Wu, Z. Second-Order Sliding Mode Formation Control of Multiple Robots by Extreme Learning Machine. Symmetry 2019, 11, 1444. [Google Scholar] [CrossRef]

- Chertopolokhov, V.; Andrianova, O.; Hernandez-Sanchez, A.; Mireles, C.; Poznyak, A.; Chairez, I. Averaged sub-gradient integral sliding mode control design for cueing end-effector acceleration of a two-link robotic arm. ISA Trans. 2023, 133, 134–146. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Chen, Y.; Wu, Y.; He, B.; Miao, Z.; Zhang, H.; Wang, Y. Hybrid Force/Position Control for Switchable Unmanned Aerial Manipulator Between Free Flight and Contact Operation. IEEE Trans. Autom. Sci. Eng. 2023, 1–15. [Google Scholar] [CrossRef]

- Bechlioulis, C.P.; Rovithakis, G.A. Robust adaptive control of feedback linearizable MIMO nonlinear systems with prescribed performance. IEEE Trans. Autom. Control 2008, 53, 2090–2099. [Google Scholar] [CrossRef]

- Zhang, C.; Wu, J.; Ahn, C.K.; Fei, Z.; Wei, C. Learning observer and performance tuning-based robust consensus policy for multiagent systems. IEEE Sens. J. 2021, 16, 431–439. [Google Scholar] [CrossRef]

- Yang, Y.; Tan, J.; Yue, D. Prescribed performance control of one-DOF link manipulator with uncertainties and input saturation constraint. IEEE/CAA J. Autom. Sin. 2018, 6, 148–157. [Google Scholar] [CrossRef]

- Ding, Y.; Wang, Y.; Chen, B. Fault-tolerant control of an aerial manipulator with guaranteed tracking performance. Int. J. Robust Nonlinear Control 2022, 32, 960–986. [Google Scholar] [CrossRef]

- Stanković, M.R.; Manojlović, S.M.; Simić, S.M.; Mitrović, S.T.; Naumović, M.B. FPGA system-level based design of multi-axis ADRC controller. Mechatronics 2016, 40, 146–155. [Google Scholar] [CrossRef]

- Spong, M.W. An historical perspective on the control of robotic manipulators. Annu. Rev. Control Robot. Auton. Syst. 2022, 5, 1–31. [Google Scholar] [CrossRef]

- Na, J.; Chen, Q.; Ren, X.; Guo, Y. Adaptive prescribed performance motion control of servo mechanisms with friction compensation. IEEE Trans. Ind. Electron. 2013, 61, 486–494. [Google Scholar] [CrossRef]

- Makkar, C.; Dixon, W.; Sawyer, W.; Hu, G. A new continuously differentiable friction model for control systems design. In Proceedings of the 2005 IEEE/ASME International Conference on Advanced Intelligent Mechatronics, Monterey, CA, USA, 24–28 July 2005; IEEE: Piscataway, NJ, USA, 2005; pp. 600–605. [Google Scholar]

- Han, J. From PID to active disturbance rejection control. IEEE Trans. Ind. Electron. 2009, 56, 900–906. [Google Scholar] [CrossRef]

- Guo, B.; Zhao, Z. On convergence of tracking differentiator. Int. J. Control 2011, 84, 693–701. [Google Scholar] [CrossRef]

- Yao, J.; Jiao, Z.; Ma, D.; Yan, L. High-accuracy tracking control of hydraulic rotary actuators with modeling uncertainties. IEEE/ASME Trans. Mechatron. 2013, 19, 633–641. [Google Scholar] [CrossRef]

- Storn, R.; Price, K. Differential evolution-a simple and efficient heuristic for global optimization over continuous spaces. J. Glob. Optim. 1997, 11, 341. [Google Scholar] [CrossRef]

- Hussain, M.; Rehan, M.; Ahn, C.K.; Tufail, M. Robust antiwindup for one-sided Lipschitz systems subject to input saturation and applications. IEEE Trans. Ind. Electron. 2018, 65, 9706–9716. [Google Scholar] [CrossRef]

- Qu, Z.; Dawson, D.M.; Lim, S.Y.; Dorsey, J.F. A new class of robust control laws for tracking of robots. Int. J. Rob. Res. 1994, 13, 355–363. [Google Scholar]

| Symbol | Definition | Value |

|---|---|---|

| , | Mass of links 1 and 2 | 4 kg, 2 kg |

| , | Length of links 1 and 2 | 0.5 m, 0.25 m |

| , | Distance to the centers of mass of links 1 and 2 | 0.25 m, 0.15 m |

| , | Inertia tensors of links 1 and 2 | 1 kg·m2, 0.8 kg·m2 |

| g | Gravity acceleration | 9.8 m/s2 |

| Parameters | ||||||

|---|---|---|---|---|---|---|

| Joint 2 | 0.0386 | 1500 | 99.0837 | 0.1970 | 1500 | 0.3320 |

| Joint 3 | 0.0510 | 1800 | 79.7978 | 0.2248 | 1800 | 0.1648 |

| Controller | Parameters |

|---|---|

| PPC-VGFESO | |

| ADRC | |

| PID |

| 300 mm/s, No Load | 600 mm/s, No Load | 600 mm/s, 1 kg Load | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Controller | PID | ADRC | PPC-VGFESO | PID | ADRC | PPC-VGFESO | PID | ADRC | PPC-VGFESO |

| 1.3109 | 1.0259 | 0.5168 | 1.6132 | 1.4208 | 0.7996 | 1.6893 | 1.5230 | 0.9948 | |

| 0.5777 | 0.4698 | 0.1797 | 0.8421 | 0.7202 | 0.2472 | 0.8678 | 0.7481 | 0.2725 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, C.; Du, F.; Chen, B.; Chen, D.; He, W.; Chen, Q.; Zhang, C.; Wu, J.; Wang, J. Practical Prescribed Tracking Control of n-DOF Robotic Manipulator with Uncertainties via Friction Compensation Approach. Symmetry 2024, 16, 423. https://doi.org/10.3390/sym16040423

Chen C, Du F, Chen B, Chen D, He W, Chen Q, Zhang C, Wu J, Wang J. Practical Prescribed Tracking Control of n-DOF Robotic Manipulator with Uncertainties via Friction Compensation Approach. Symmetry. 2024; 16(4):423. https://doi.org/10.3390/sym16040423

Chicago/Turabian StyleChen, Chao, Fuxin Du, Bin Chen, Detong Chen, Weikai He, Qiang Chen, Chengxi Zhang, Jin Wu, and Jihe Wang. 2024. "Practical Prescribed Tracking Control of n-DOF Robotic Manipulator with Uncertainties via Friction Compensation Approach" Symmetry 16, no. 4: 423. https://doi.org/10.3390/sym16040423

APA StyleChen, C., Du, F., Chen, B., Chen, D., He, W., Chen, Q., Zhang, C., Wu, J., & Wang, J. (2024). Practical Prescribed Tracking Control of n-DOF Robotic Manipulator with Uncertainties via Friction Compensation Approach. Symmetry, 16(4), 423. https://doi.org/10.3390/sym16040423