Temperature Effects on Critical Energy Release Rate for Aluminum and Titanium Alloys

Abstract

1. Introduction

2. Theory and Methods

2.1. Theroy of Energy Release Rate

2.2. Simulation Material Model

2.3. Critical Energy Release Rate Calculated from Element Deletion Method

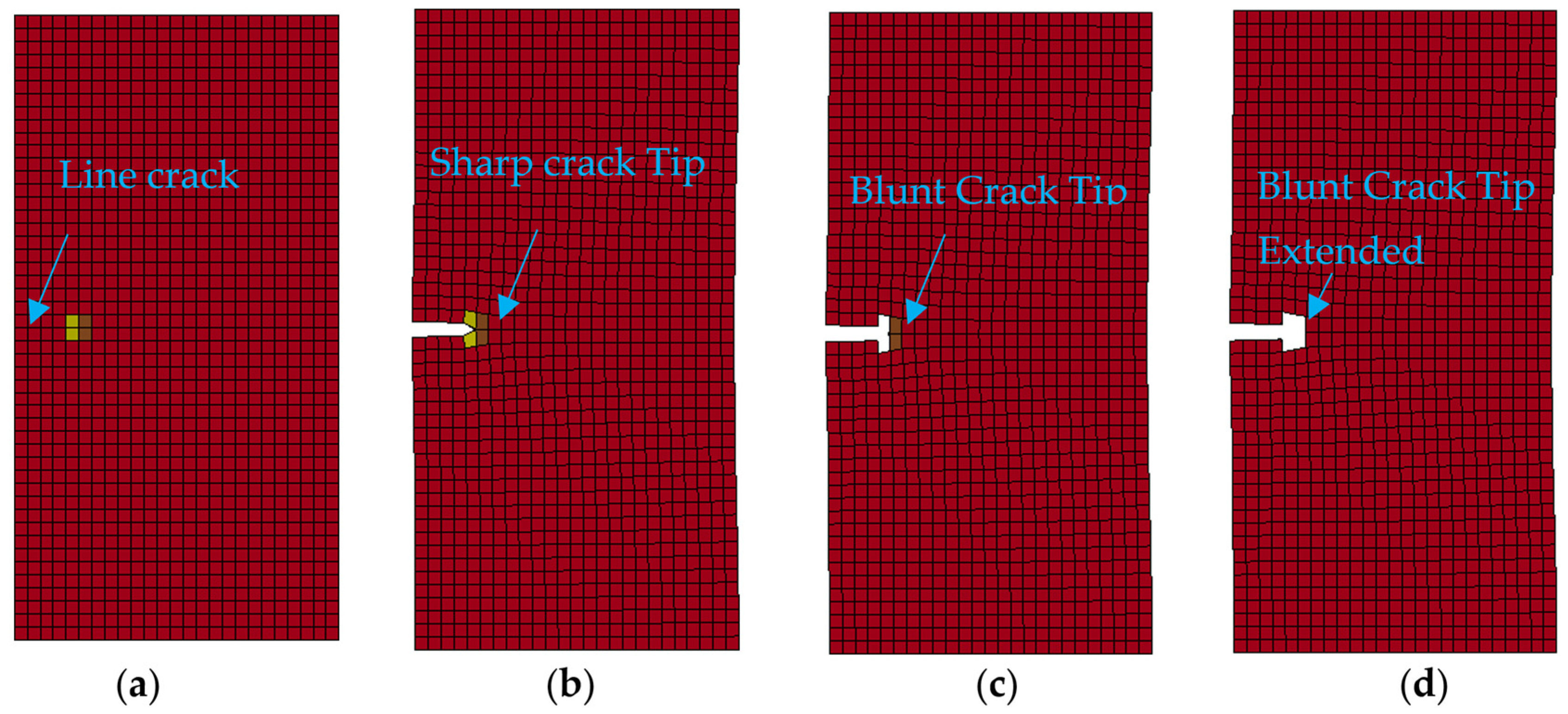

2.3.1. Critical Energy Release Rate from Element Deletion Method

2.3.2. Element Deletion Method Result

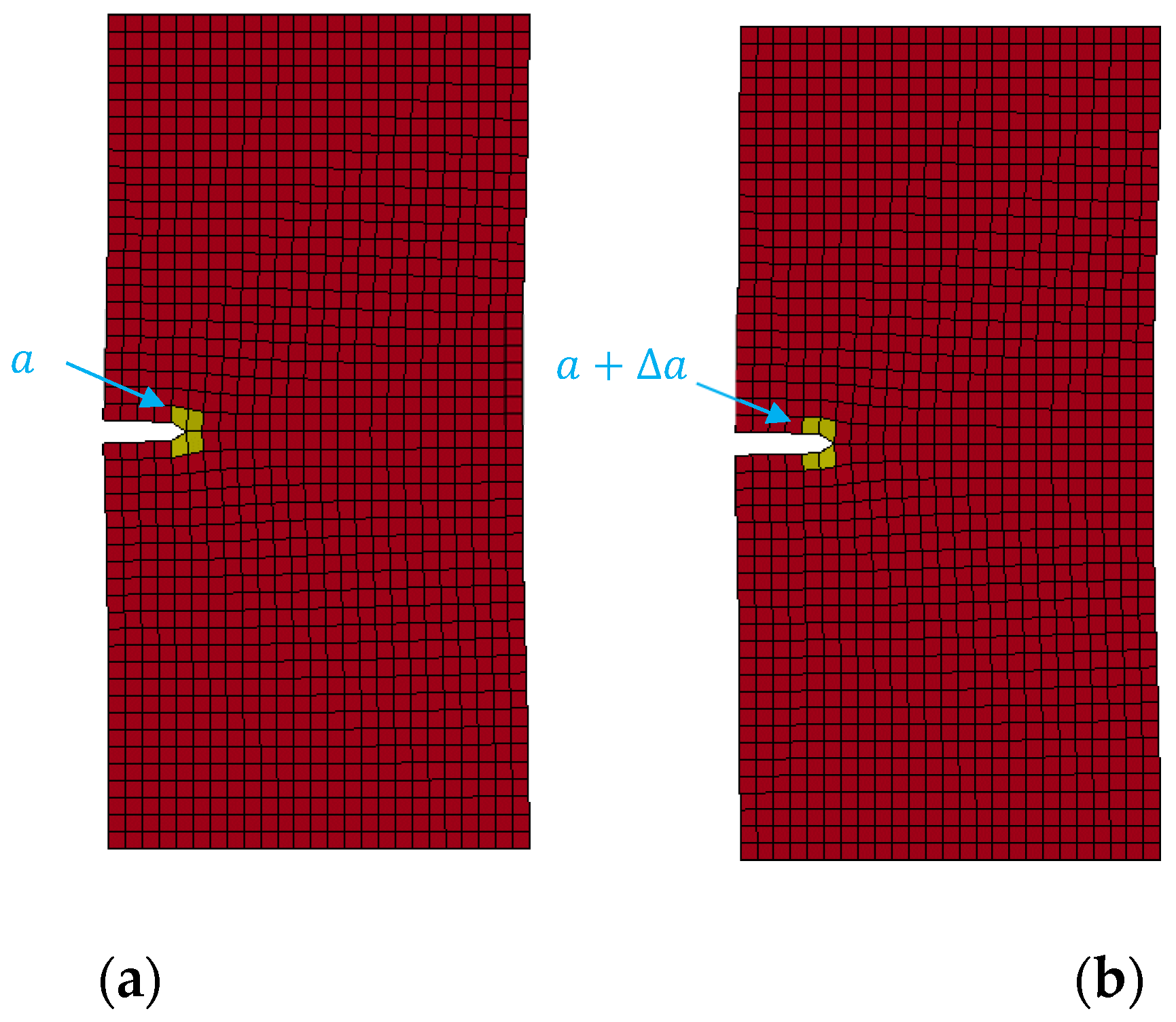

2.3.3. Critical Energy Release Rate from Virtual Crack Opening Method

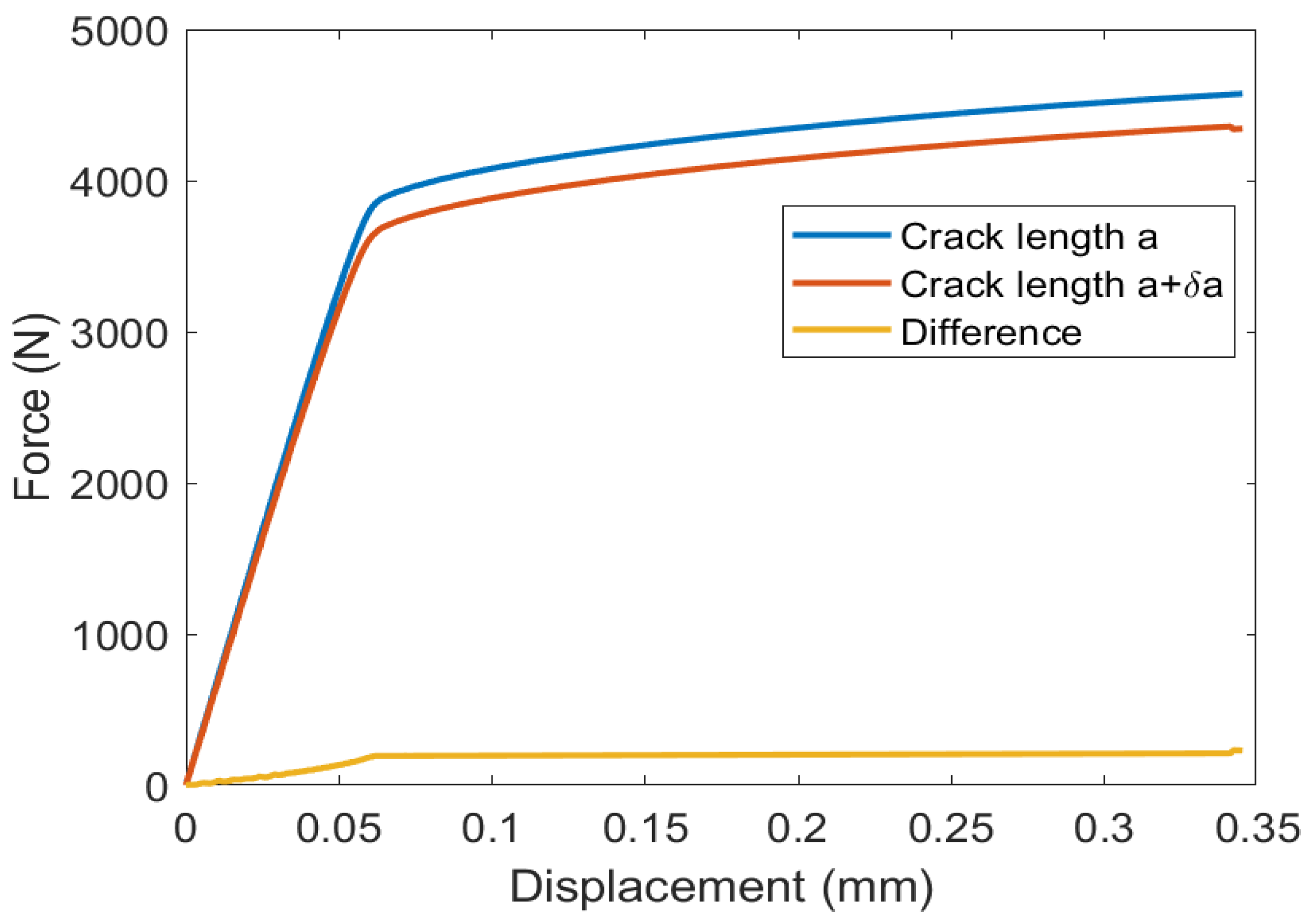

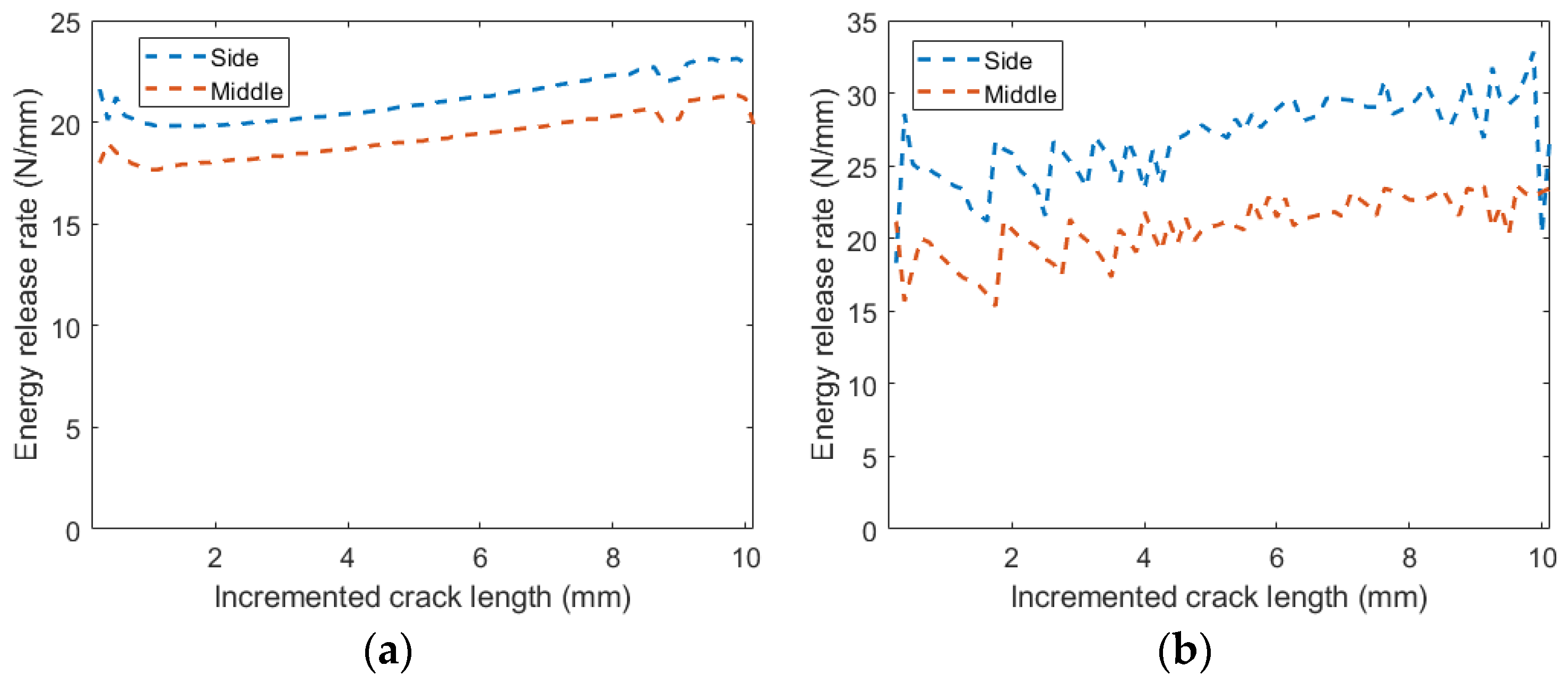

2.3.4. Virtual Crack Opening Method Result

2.3.5. Critical Energy Release Rate Comparison and Verification

2.4. Critical Energy Release Rate Comparison of Verification

3. Results

3.1. Temperature Dependency of Critical Energy Release Rate

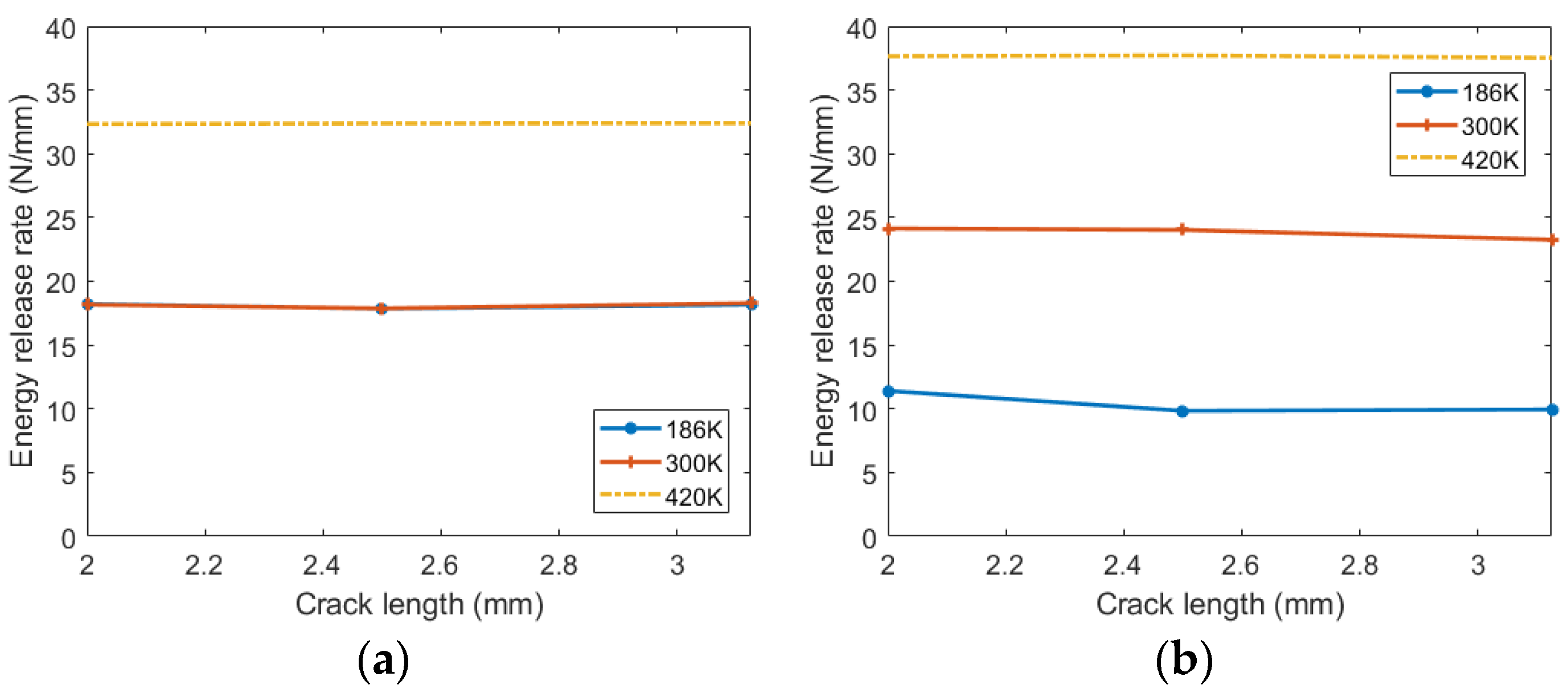

3.2. Dynamic Crack Size Dependency of Critical Energy Release Rate

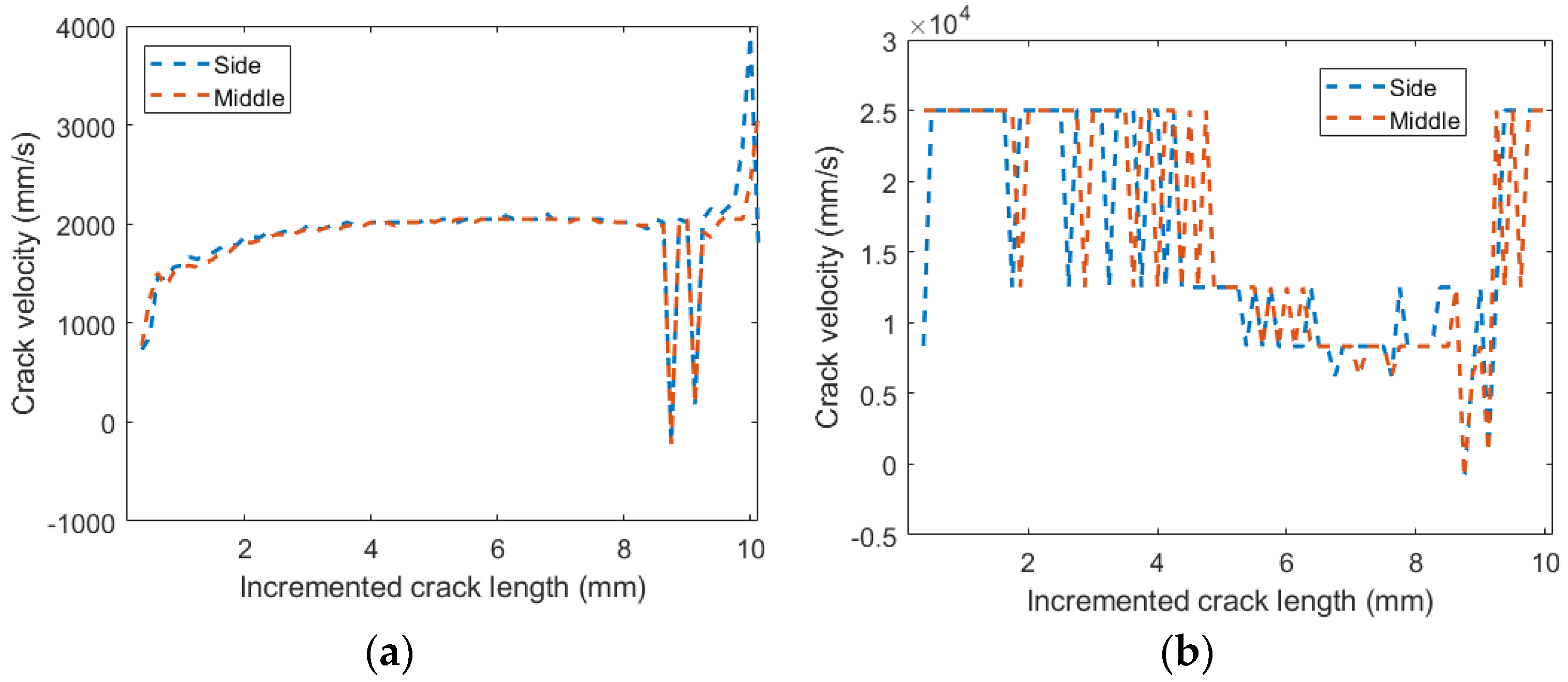

3.3. Crack Speed in Dynamic Crack Popogation

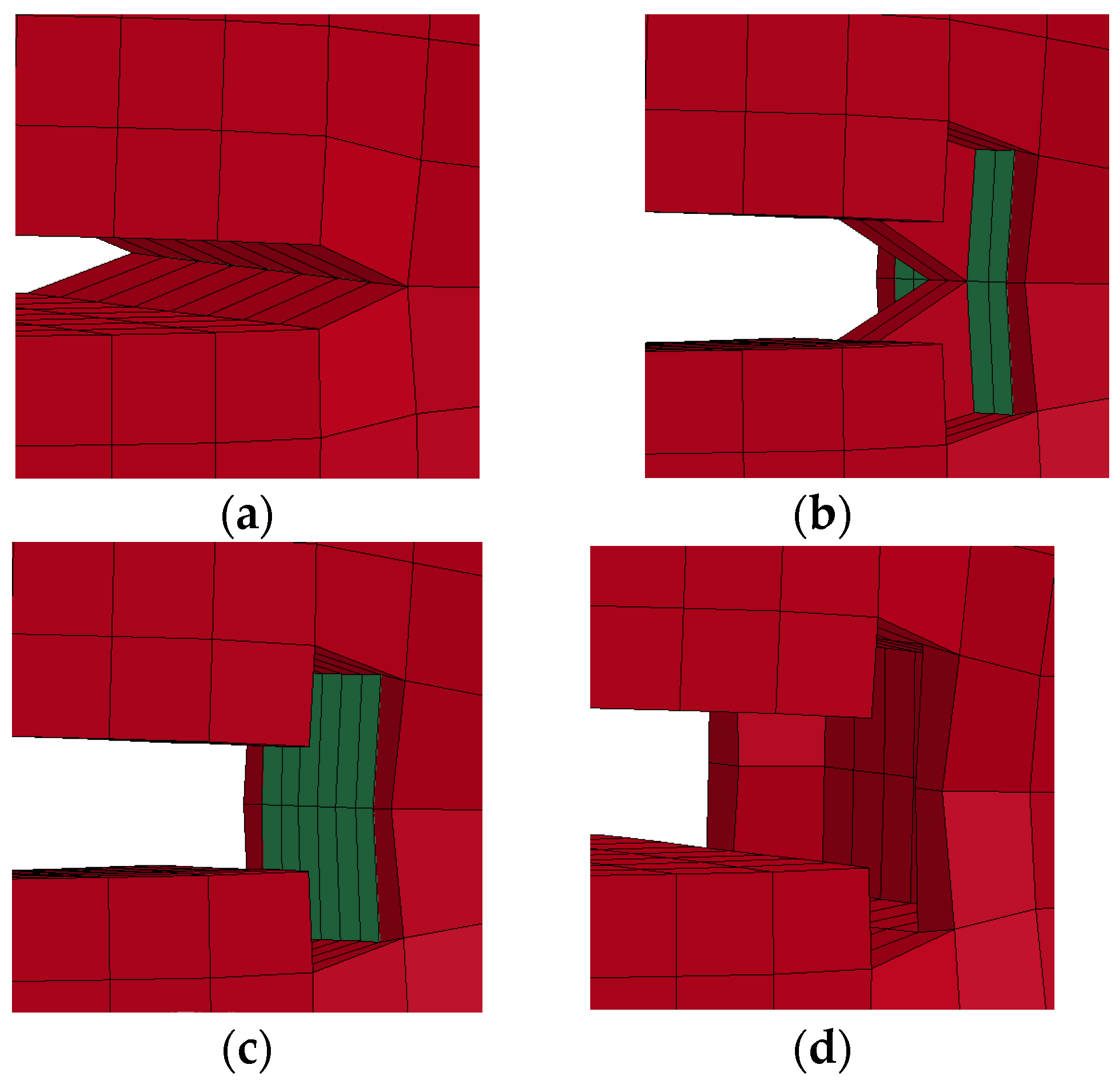

3.4. Crack Tip Profile at Critical Time

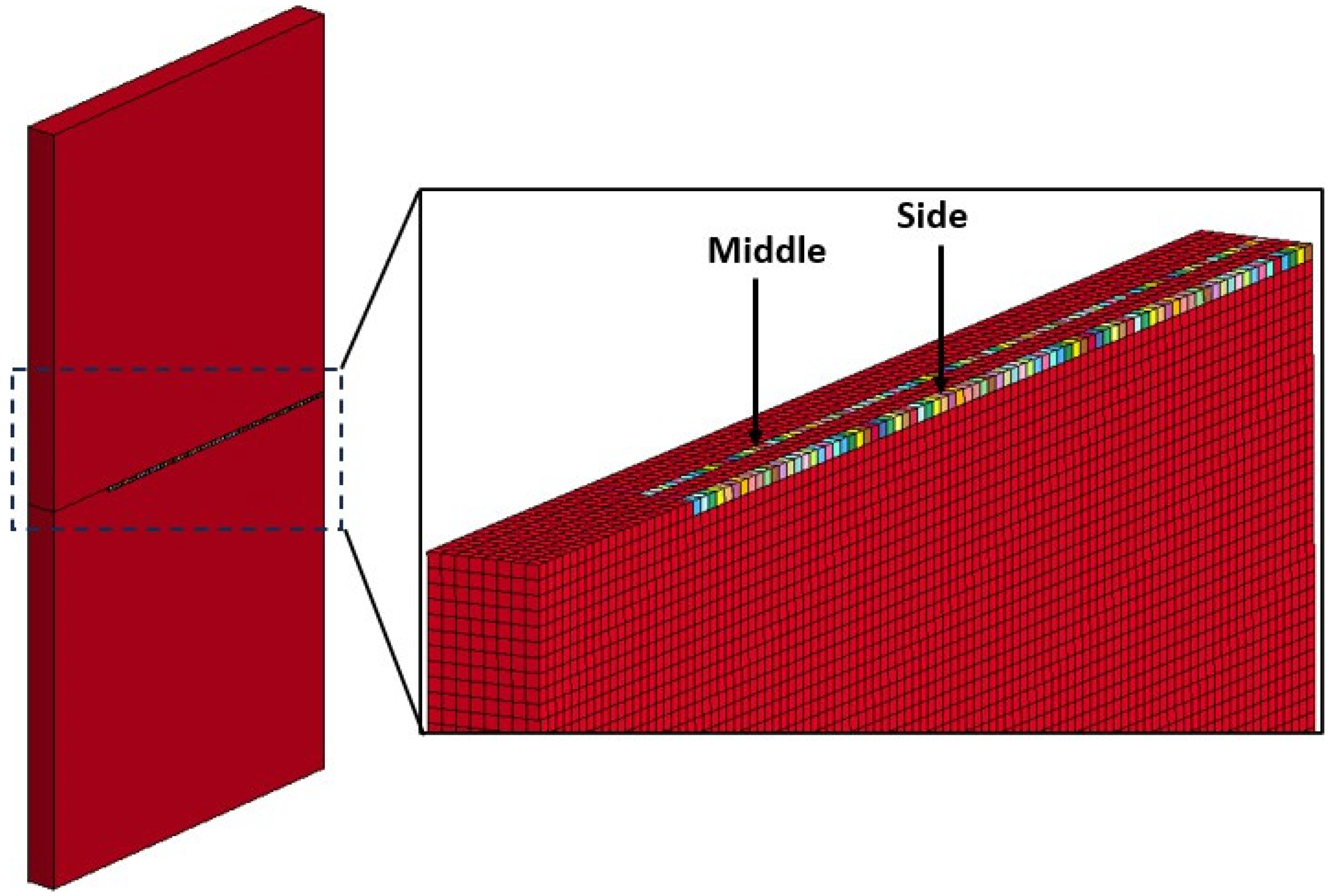

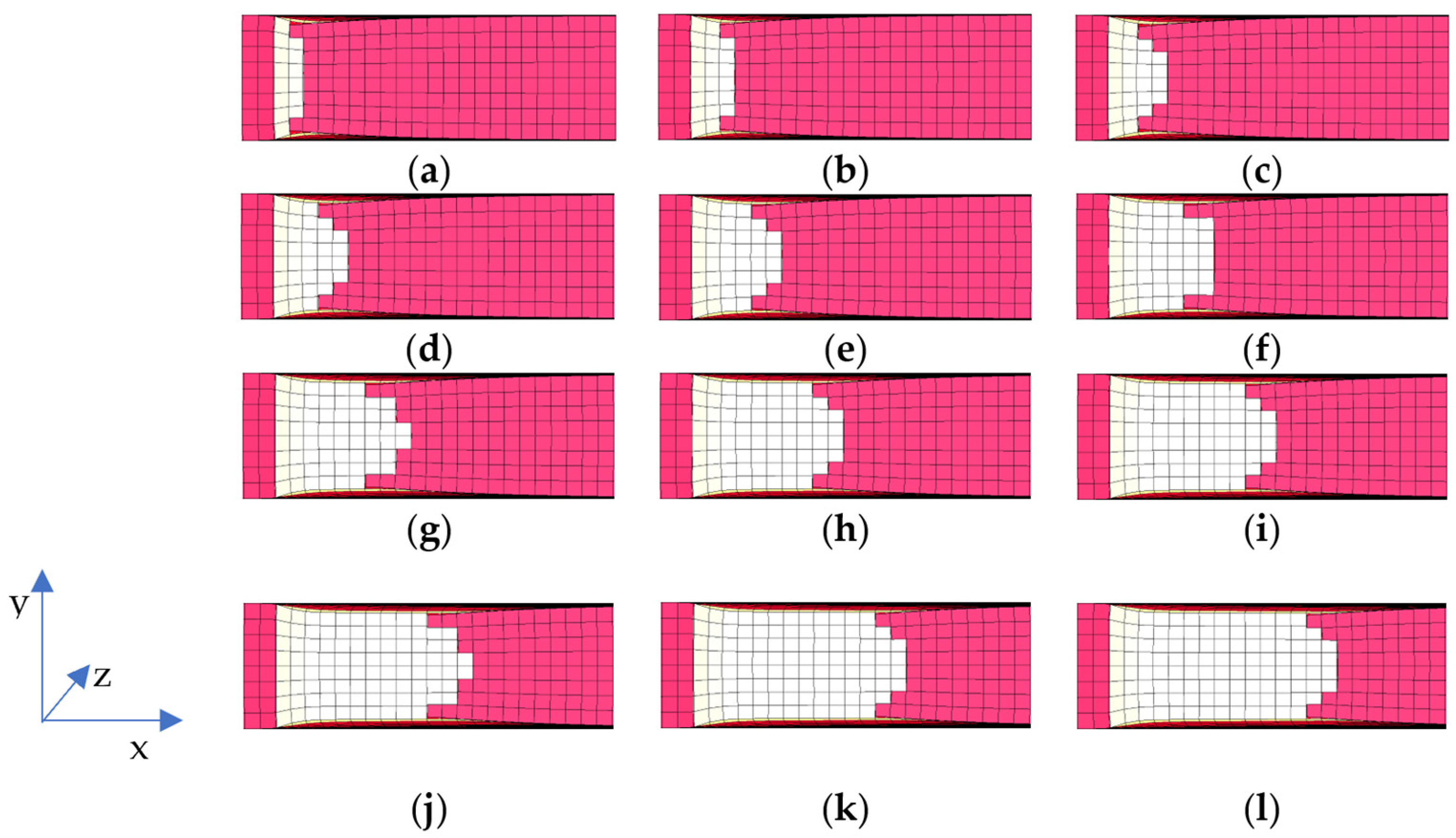

3.5. Crack Front Profile during Propagation

3.6. Initial Crack Size Dependency of Critical Energy Release Rate

4. Discussion

5. Conclusions and Future Work

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Haight, S.; Wang, L.; Bois, P.D.; Carney, K.; Kan, C.-D. Development of a Titanium Alloy ti-6al-4v Material Model Used in ls-Dyna, DOT/FAA/TC-15/23. 2015. Available online: https://www.tc.faa.gov/its/worldpac/techrpt/tc15-23.pdf (accessed on 1 December 2023).

- Park, C.-K.; Carney, K.; Bois, P.D.; Cordasco, D.; Aluminum, C.-D.K. 2024-T351 Input Parameters for *MAT_224 in LS-DYNA, DOT/FAA/TC-19/41 2020. Available online: https://www.tc.faa.gov/its/worldpac/techrpt/tc19-41-p1.pdf (accessed on 1 December 2023).

- McDanels, S.; Mayeaux, B.; Russell, R.; Collins, T.; Jerman, G.; Shah, S.; Piascik, R. An overview of the space shuttle Columbia accident from recovery through reconstruction. J. Fail. Anal. Prev. 2006, 6, 82–91. [Google Scholar] [CrossRef]

- Cikanek, H., III. Characteristics of space shuttle main engine failures. In Proceedings of the 23rd Joint Propulsion Conference, San Diego, CA, USA, 29 June–2 July 1987; p. 1939. [Google Scholar] [CrossRef]

- Inglis, C.E. Stresses in a plate due to the presence of cracks and sharp corners. Trans. Inst. Naval. Archit. 1913, 55, 219–241. [Google Scholar]

- Wang, L. Energy Release Rate in Fracture Mechanics. Ph.D. Thesis, The George Washington University, Washington, DC, USA, 2015. [Google Scholar] [CrossRef]

- Irwin, G.R. Analysis of stresses and strains near the end of a crack traversing a plate. J. Appl. Mech. 1957, 24, 361–364. [Google Scholar] [CrossRef]

- Rice, J.R. A path independent integral and the approximate analysis of strain concentration by notches and cracks. J. Appl. Mech. 1968, 35, 379–386. [Google Scholar] [CrossRef]

- Long, T.; Wang, L.; Kan, C.-D.; Lee, J.D. Numerical verification of energy release rate and J-Integral in large strain formulation. Forces Mech. 2023, 11, 100202. [Google Scholar] [CrossRef]

- Hallquist, J.O. Ls-dyna keyword user’s manual. Livermore Softw. Technol. Corp. 2007, 970, 299–800. [Google Scholar]

- Griffith, A.A. VI. the phenomena of rupture and flow in solids, Philosophical transactions of the royal society of London. Ser. A Contain. Pap. A Math. Phys. Character 1921, 221, 163–198. [Google Scholar] [CrossRef]

- Rhee, S.K. Surface energies of silicate glasses calculated from their wettability data. J. Mater. Sci. 1977, 12, 823–824. [Google Scholar] [CrossRef]

- Available online: https://www.fracturemechanics.org/griffith.html (accessed on 1 December 2023).

- Sun, C.-T.; Jin, Z. Fracture Mechanics; Academic Press: New York, NY, USA, 2011. [Google Scholar]

- Anderson, T.L. Fracture Mechanics: Fundamentals and Applications; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Janssen, M.; Zuidema, J.; Wanhill, R. Fracture Mechanics: Fundamentals and Applications; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar]

- Zou, Z.; Reid, S.; Soden, P.; Li, S. Measurement of the critical energy release rate Giic for filament wound grp pipes. Compos. Part A Appl. Sci. Manuf. 2001, 32, 271–280. [Google Scholar] [CrossRef]

- Oyen-Tiesma, M.; Cook, R.F. Technique for estimating fracture resistance of cultured neocartilage. J. Mater. Sci. Mater. Med. 2001, 12, 327–332. [Google Scholar] [CrossRef]

- Giner, E.; Belda, R.; Arango, C.; Vercher-Martínez, A.; Taranc, J.E.; Fuenmayor, F.J. Calculation of the critical energy release rate Gc of the cement line in cortical bone combining experimental tests and finite element models. Eng. Fract. Mech. 2017, 184, 168–182. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, X.; Lee, J.D. An atomistic methodology of energy re- lease rate for graphene at nanoscale. J. Appl. Phys. 2014, 115, 114314. [Google Scholar] [CrossRef]

- D’Amico, F.; Carbone, G.; Foglia, M.; Galietti, U. Moving cracks in viscoelastic materials: Temperature and energy-release-rate measurements. Eng. Fract. Mech. 2013, 98, 315–325. [Google Scholar] [CrossRef]

- Zhang, H.; Ravi-Chandar, K. On the dynamics of localization and fragmentation-iv. expansion of al 6061-o tubes. Int. J. Fract. 2010, 163, 41–65. [Google Scholar] [CrossRef]

- Margerit, P.; Weisz-Patrault, D.; Ravi-Chandar, K.; Constantinescu, A. Tensile and ductile fracture properties of as-printed 316l stainless steel thin walls obtained by directed energy deposition. Addit. Manuf. 2021, 37, 101664. [Google Scholar] [CrossRef]

- Zhang, H.; Ravi-Chandar, K. Dynamic fragmentation of ductile materials. J. Phys. D Appl. Phys. 2009, 42, 214010. [Google Scholar] [CrossRef]

- Landis, C.M.; Ravi-Chandar, K.; Hughes, T.J. Texas Univ at Austin Austin United States. In An Integrated Experimental and Modeling Study of Ductile Fracture; Defense Technical Information Center: Ft. Belvoir, VA, USA, 2017. [Google Scholar]

- Cui, Y.; Xiang, D.; Shu, L.; Liao, Z.; Zhang, Z.; Liu, W. Effects of impact speeds, fall postures and cortical thicknesses on femur fracture by incremental element deletion based finite element analysis. Authorea 2021, preprints. [Google Scholar] [CrossRef]

- Li, Y.; Luo, M.; Gerlach, J.; Wierzbicki, T. Prediction of shear-induced fracture in sheet metal forming. J. Mater. Process. Technol. 2010, 210, 1858–1869. [Google Scholar] [CrossRef]

- Liu, J.; Bai, Y.; Xu, C. Evaluation of ductile fracture models in finite element simulation of metal cutting processes. J. Manuf. Sci. Eng. 2014, 136, 011010. [Google Scholar] [CrossRef]

- Adewole, K.K.; Bull, S.J. Prediction of the fracture performance of defect-free steel bars for civil engineering applications using finite element simulation. Constr. Build. Mater. 2013, 41, 9–14. [Google Scholar] [CrossRef]

- Wang, L.; Dicecca, F.; Haight, S.; Carney, K.; DuBois, P.; Emmerling, W.; Kan, C. Test and simulation comparison using titanium material models based on mat224. In Proceedings of the 14th International LS-DYNA Users Conference, Detroit, MI, USA, 12–14 June 2016; pp. 1–17. [Google Scholar]

- Seidt, J.D.; Park, C.-K.; Buyuk, M.; Lowe, R.L.; Wang, L.; Carney, K.S.; Bois, P.D.; Gilat, A.; Kan, C.-D. An experimental investigation of the influence of the state of stress on the ductile fracture of 2024-t351 aluminum. J. Eng. Mater. Technol. 2022, 144, 041006. [Google Scholar] [CrossRef]

- Pretorius, C.C.; Mostert, R.J.; Ramjee, S. The crack growth resistance behaviour of aluminium alloy 2024-T3 at slow strain rates after exposure to standard corrosive environments. J. S. Afr. Inst. Min. Metall. 2021, 121, 151–158. [Google Scholar] [CrossRef]

- Griffis, C.; Yoder, G. Initial crack extension in two intermediate-strength aluminum alloys. J. Eng. Mater. Technol. 1976, 98, 152–158. [Google Scholar] [CrossRef]

- Ojo, S.A. Use of Compact Specimens to Determine Fracture Tough-Ness and Fatigue Crack Growth Anisotropy of Ded Additive Manufactured ti-6al-4v. Ph.D. Thesis, University of Akron, Akron, OH, USA, 2020. [Google Scholar] [CrossRef]

- Menouillard, T.; Belytschko, T. Analysis and computations of oscillating crack propagation in a heated strip. Int. J. Fract. 2011, 167, 57–70. [Google Scholar] [CrossRef]

- Belhouari, M.; Benkheira, A.; Madani, K.; Campilho, R.; Gong, X. Effect of temperature on the energy release rate variation in repaired laminate composites. J. Fail. Anal. Prev. 2023, 23, 420–435. [Google Scholar] [CrossRef]

- Freund, L. Dynamic Fracture Mechanics; Cambridge University Press: New York, NY, USA, 1990. [Google Scholar]

- Zhang, Z.Y.; Duan, Z.; Zhou, F.H. Velocity-toughening and crack speed oscillations in the dynamic fracture of PMMA plates. Appl. Mech. Mater. 2014, 566, 298–304. [Google Scholar] [CrossRef]

- Mahanta, B.; Tripathy, A.; Vishal, V.; Singh, T.; Ranjith, P. Effects of strain rate on fracture toughness and energy re- lease rate of gas shales. Eng. Geol. 2017, 218, 39–49. [Google Scholar] [CrossRef]

- Kroon, M. Energy release rates in rubber during dynamic crack propagation. Int. J. Solids Struct. 2014, 51, 4419–4426. [Google Scholar] [CrossRef][Green Version]

- Ekhtiyari, A.; Alderliesten, R.; Shokrieh, M.M. Loading rate dependency of strain energy release rate in mode i delamination of composite laminates. Theor. Appl. Fract. Mech. 2021, 112, 102894. [Google Scholar] [CrossRef]

- Balden, V.; Nurick, G. Numerical simulation of the post-failure motion of steel plates subjected to blast loading. Int. J. Impact Eng. 2005, 32, 14–34. [Google Scholar] [CrossRef]

- Zhu, Y.; Liu, K.; Wen, Y.; Cui, G.; Niu, W.; Wang, Y.; Cao, Y.; Xu, C. Experimental and numerical study on the ballistic performance of ultrahigh molecular weight polyethylene laminate. Polym. Compos. 2021, 42, 5168–5198. [Google Scholar] [CrossRef]

| Method | Virtual Crack Opening | Element Deletion |

|---|---|---|

| Temperature (K) | 186 | 300 | 420 | 537 |

|---|---|---|---|---|

| of aluminum AA2024-T351 (N/mm) | 17.8517 | 17.8683 | 32.3792 | 102.4848 |

| of titanium Ti-6Al-4V (N/mm) | 9.8381 | 24.0282 | 37.7108 | 44.6406 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Long, T.; Wang, L.; Lee, J.D.; Kan, C.-D. Temperature Effects on Critical Energy Release Rate for Aluminum and Titanium Alloys. Symmetry 2024, 16, 142. https://doi.org/10.3390/sym16020142

Long T, Wang L, Lee JD, Kan C-D. Temperature Effects on Critical Energy Release Rate for Aluminum and Titanium Alloys. Symmetry. 2024; 16(2):142. https://doi.org/10.3390/sym16020142

Chicago/Turabian StyleLong, Teng, Leyu Wang, James D. Lee, and Cing-Dao Kan. 2024. "Temperature Effects on Critical Energy Release Rate for Aluminum and Titanium Alloys" Symmetry 16, no. 2: 142. https://doi.org/10.3390/sym16020142

APA StyleLong, T., Wang, L., Lee, J. D., & Kan, C.-D. (2024). Temperature Effects on Critical Energy Release Rate for Aluminum and Titanium Alloys. Symmetry, 16(2), 142. https://doi.org/10.3390/sym16020142