Frequency Up-Conversion for Vibration Energy Harvesting: A Review

Abstract

:1. Introduction

2. Energy Conversion Mechanisms

2.1. Piezoelectric Transduction

2.2. Electromagnetic Transduction

2.3. Electrostatic Transduction

3. Frequency Up-Conversion Principles

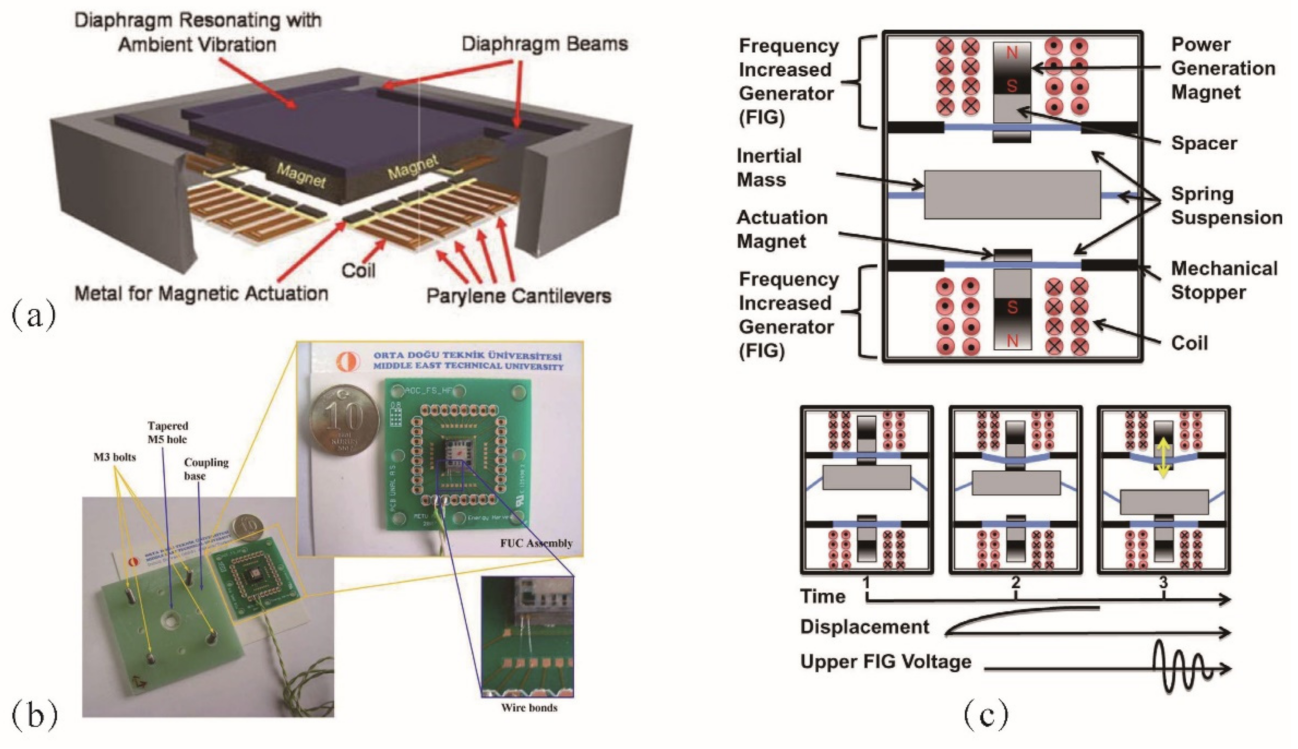

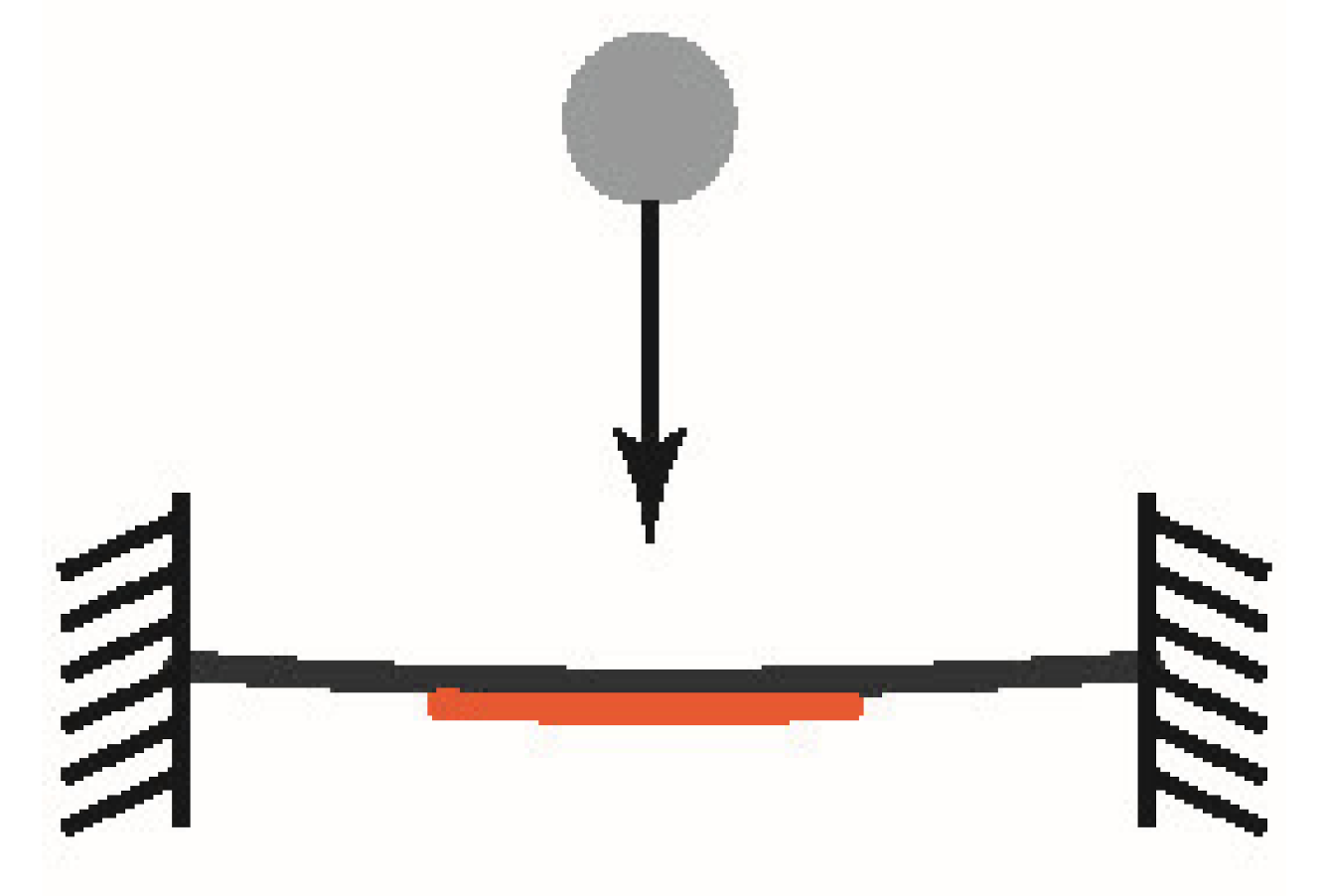

3.1. Impact-Based Approach

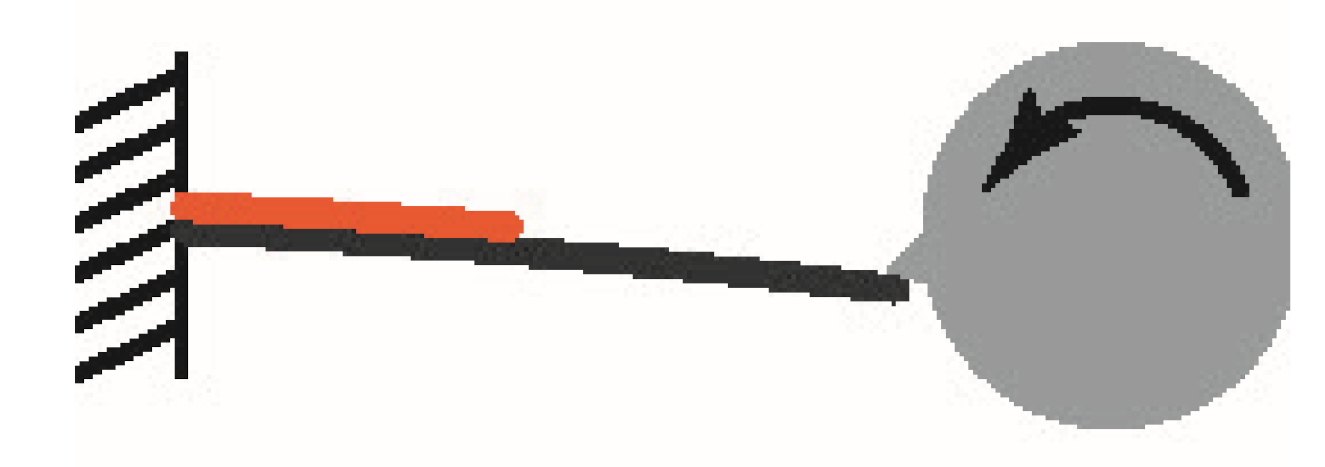

3.2. Plucking-Based Approach

3.3. Snap-Through-Based Approach

4. Impact-Based Energy Harvesters

5. Plucking-Based Energy Harvesters

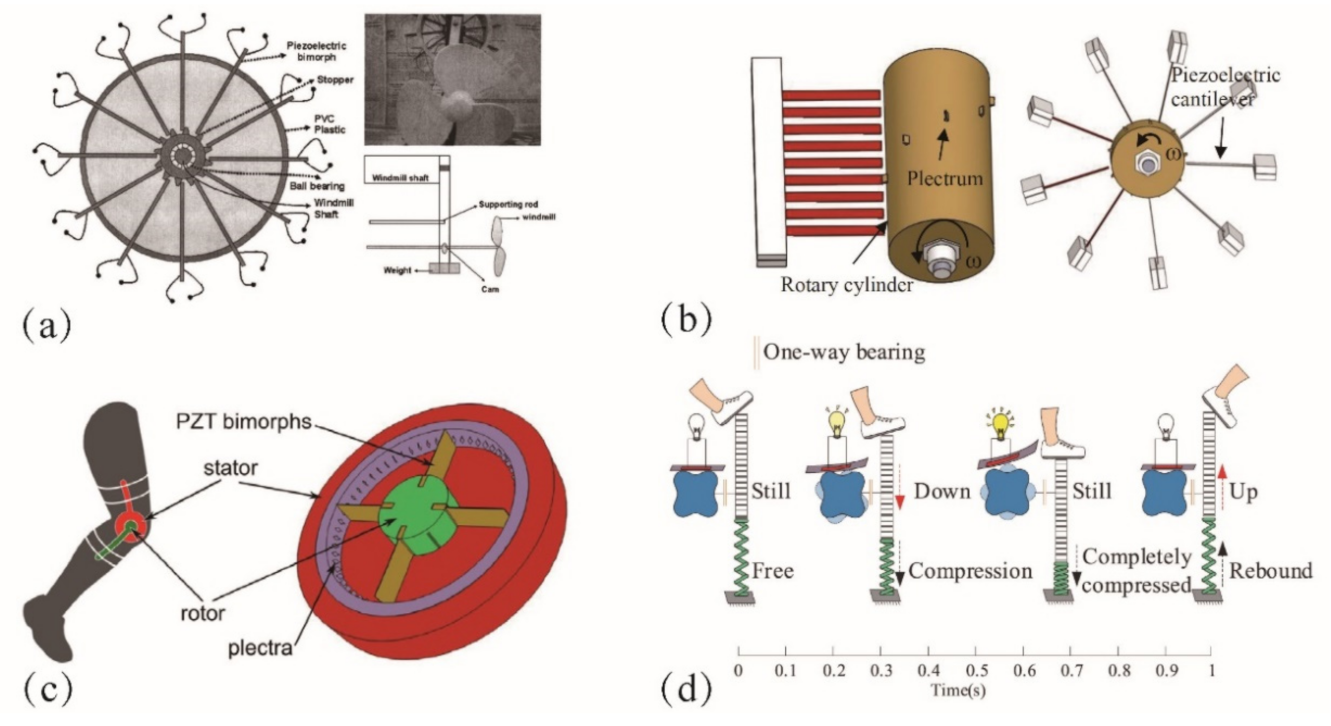

5.1. Mechanical Plucking

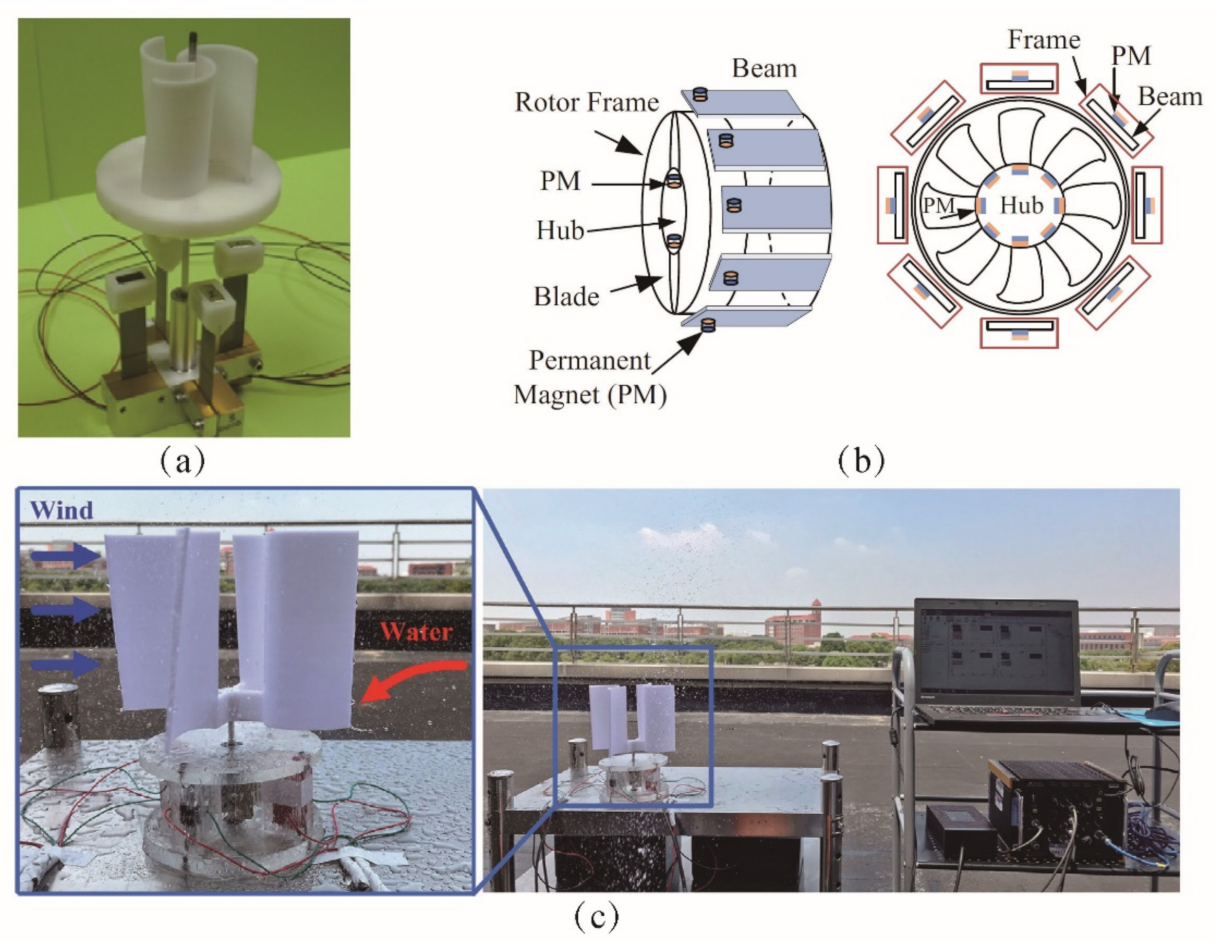

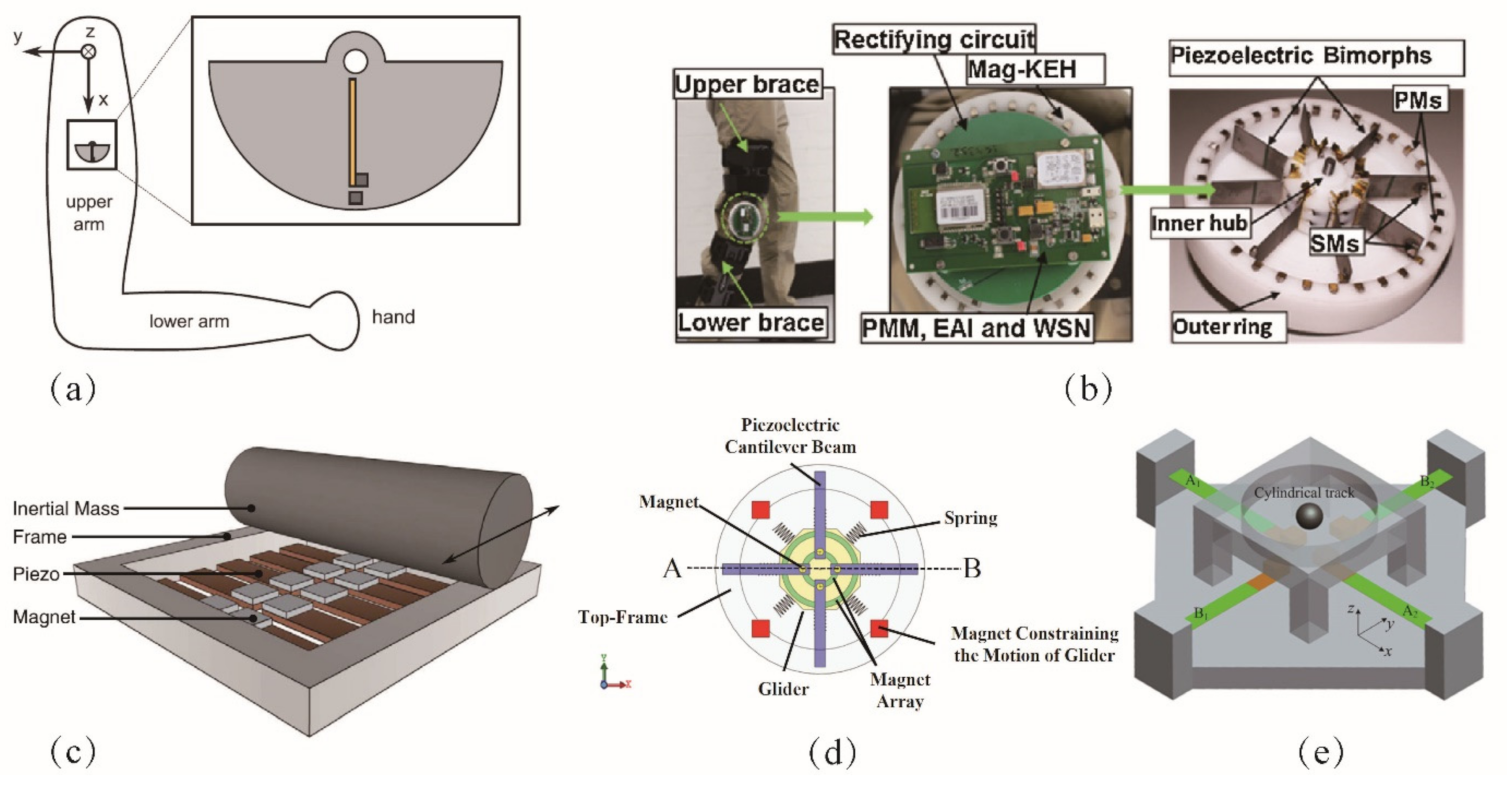

5.2. Magnetic Plucking

6. Snap-Through Based Energy Harvesters

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zachariah, T.; Adkins, J.; Dutta, P. Browsing the Web of Connectable Things. In Proceedings of the EWSN, Lyon, France, 17–19 February 2020; pp. 49–60. [Google Scholar]

- Raghunathan, V.; Kansal, A.; Hsu, J.; Friedman, J.; Srivastava, M. Design considerations for solar energy harvesting wireless embedded systems. In Proceedings of the IPSN 2005, Fourth International Symposium on Information Processing in Sensor Networks, Boise, ID, USA, 15 April 2005; pp. 457–462. [Google Scholar]

- Lu, X.; Wang, P.; Niyato, D.; Kim, D.I.; Han, Z. Wireless networks with RF energy harvesting: A contemporary survey. IEEE Commun. Surv. Tutor. 2014, 17, 757–789. [Google Scholar] [CrossRef] [Green Version]

- Kishore, R.A.; Priya, S. A review on low-grade thermal energy harvesting: Materials, methods and devices. Materials 2018, 11, 1433. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wei, C.; Jing, X. A comprehensive review on vibration energy harvesting: Modelling and realization. Renew. Sustain. Energy Rev. 2017, 74, 1–18. [Google Scholar] [CrossRef]

- Harne, R.L.; Zhang, C.; Li, B.; Wang, K. An analytical approach for predicting the energy capture and conversion by impulsively-excited bistable vibration energy harvesters. J. Sound Vib. 2016, 373, 205–222. [Google Scholar] [CrossRef]

- Li, X.; Tang, H.; Liang, J.; Tang, L. Exploring the magnetic plucking motion towards a transient-motion-powered IoT sensor node. In Proceedings of the Active and Passive Smart Structures and Integrated Systems XIV, Online, 27 April–9 May 2020; p. 113761U. [Google Scholar]

- Akita, I.; Okazawa, T.; Kurui, Y.; Fujimoto, A.; Asano, T. A feedforward noise reduction technique in capacitive MEMS accelerometer analog front-end for ultra-low-power IoT applications. IEEE J. Solid-State Circuits 2019, 55, 1599–1609. [Google Scholar] [CrossRef]

- Khalid, S.; Raouf, I.; Khan, A.; Kim, N.; Kim, H.S. A review of human-powered energy harvesting for smart electronics: Recent progress and challenges. Int. J. Precis. Eng. Manuf. Green Technol. 2019, 6, 821–851. [Google Scholar] [CrossRef]

- Liu, H.; Zhong, J.; Lee, C.; Lee, S.-W.; Lin, L. A comprehensive review on piezoelectric energy harvesting technology: Materials, mechanisms, and applications. Appl. Phys. Rev. 2018, 5, 041306. [Google Scholar] [CrossRef]

- Wang, J.; Geng, L.; Ding, L.; Zhu, H.; Yurchenko, D. The state-of-the-art review on energy harvesting from flow-induced vibrations. Appl. Energy 2020, 267, 114902. [Google Scholar] [CrossRef]

- Adkins, J.; Ghena, B.; Dutta, P. SIGNPOST: Enabling City-Scale Sensing for Citizens and Scientists. GetMobile Mob. Comput. Commun. 2019, 22, 23–26. [Google Scholar] [CrossRef]

- Yeager, D.J.; Sample, A.P.; Smith, J.R. WISP: A passively powered UHF RFID tag with sensing and computation. In RFID Handbook; CRC Press: Bocraton, FL, USA, 2017; pp. 261–276. [Google Scholar]

- Sigrist, L.; Stricker, N.; Bernath, D.; Beutel, J.; Thiele, L. Thermoelectric energy harvesting from gradients in the Earth surface. IEEE Trans. Ind. Electron. 2019, 67, 9460–9470. [Google Scholar] [CrossRef] [Green Version]

- Roundy, S.; Wright, P.K.; Rabaey, J. A study of low level vibrations as a power source for wireless sensor nodes. Comput. Commun. 2003, 26, 1131–1144. [Google Scholar] [CrossRef]

- Hu, G.; Tang, L.; Banerjee, A.; Das, R. Metastructure with piezoelectric element for simultaneous vibration suppression and energy harvesting. J. Vib. Acoust. 2017, 139. [Google Scholar] [CrossRef]

- Li, X.; Teng, L.; Tang, H.; Chen, J.; Wang, H.; Liu, Y.; Fu, M.; Liang, J. ViPSN: A vibration-powered iot platform. IEEE Internet Things J. 2020, 8, 1728–1739. [Google Scholar] [CrossRef]

- Wang, J.; Tang, L.; Zhao, L.; Hu, G.; Song, R.; Xu, K. Equivalent circuit representation of a vortex-induced vibration-based energy harvester using a semi-empirical lumped parameter approach. Int. J. Energy Res. 2020, 44, 4516–4528. [Google Scholar] [CrossRef]

- Hu, G.; Tang, L.; Liang, J.; Lan, C.; Das, R. Acoustic-Elastic Metamaterials and Phononic Crystals for Energy Harvesting: A Review. Smart Mater. Struct. 2021, 8, 085025. [Google Scholar] [CrossRef]

- Hu, G.; Tang, L.; Das, R.; Marzocca, P. A two-degree-of-freedom piezoelectric energy harvester with stoppers for achieving enhanced performance. Int. J. Mech. Sci. 2018, 149, 500–507. [Google Scholar] [CrossRef]

- Daqaq, M.F.; Masana, R.; Erturk, A.; Dane Quinn, D. On the role of nonlinearities in vibratory energy harvesting: A critical review and discussion. Appl. Mech. Rev. 2014, 66, 040801. [Google Scholar] [CrossRef]

- Remick, K.; Quinn, D.D.; McFarland, D.M.; Bergman, L.; Vakakis, A. High-frequency vibration energy harvesting from impulsive excitation utilizing intentional dynamic instability caused by strong nonlinearity. J. Sound Vib. 2016, 370, 259–279. [Google Scholar] [CrossRef] [Green Version]

- Guyomar, D.; Badel, A.; Lefeuvre, E.; Richard, C. Toward energy harvesting using active materials and conversion improvement by nonlinear processing. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2005, 52, 584–595. [Google Scholar] [CrossRef] [Green Version]

- Lefeuvre, E.; Badel, A.; Richard, C.; Guyomar, D. Piezoelectric energy harvesting device optimization by synchronous electric charge extraction. J. Intell. Mater. Syst. Struct. 2005, 16, 865–876. [Google Scholar] [CrossRef]

- Lefeuvre, E.; Badel, A.; Richard, C.; Petit, L.; Guyomar, D. A comparison between several vibration-powered piezoelectric generators for standalone systems. Sens. Actuators A Phys. 2006, 126, 405–416. [Google Scholar] [CrossRef]

- Liang, J.; Liao, W.-H. Impedance modeling and analysis for piezoelectric energy harvesting systems. IEEE/ASME Trans. Mechatron. 2011, 17, 1145–1157. [Google Scholar] [CrossRef]

- Sari, I.; Balkan, T.; Kulah, H. A wideband electromagnetic micro power generator for wireless microsystems. In Proceedings of the TRANSDUCERS 2007-2007 International Solid-State Sensors, Actuators and Microsystems Conference, Lyon, France, 10–14 June 2007; pp. 275–278. [Google Scholar]

- Zou, H.-X.; Zhao, L.-C.; Gao, Q.-H.; Zuo, L.; Liu, F.-R.; Tan, T.; Wei, K.-X.; Zhang, W.-M. Mechanical modulations for enhancing energy harvesting: Principles, methods and applications. Appl. Energy 2019, 255, 113871. [Google Scholar] [CrossRef]

- Brennan, M.; Gatti, G. Harvesting energy from time-limited harmonic vibrations: Mechanical considerations. J. Vib. Acoust. 2017, 139, 051019. [Google Scholar] [CrossRef]

- Yang, G.; Stark, B.H.; Hollis, S.J.; Burrow, S.G. Challenges for energy harvesting systems under intermittent excitation. IEEE J. Emerg. Sel. Top. Circuits Syst. 2014, 4, 364–374. [Google Scholar] [CrossRef]

- Roundy, S.; Wright, P.K. A piezoelectric vibration based generator for wireless electronics. Smart Mater. Struct. 2004, 13, 1131. [Google Scholar] [CrossRef] [Green Version]

- Roundy, S.; Leland, E.S.; Baker, J.; Carleton, E.; Reilly, E.; Lai, E.; Otis, B.; Rabaey, J.M.; Wright, P.K.; Sundararajan, V. Improving power output for vibration-based energy scavengers. IEEE Pervasive Comput. 2005, 4, 28–36. [Google Scholar] [CrossRef]

- Harne, R.L.; Wang, K. A review of the recent research on vibration energy harvesting via bistable systems. Smart Mater. Struct. 2013, 22, 023001. [Google Scholar] [CrossRef]

- Wang, Z.L. Triboelectric nanogenerators as new energy technology for self-powered systems and as active mechanical and chemical sensors. ACS Nano 2013, 7, 9533–9557. [Google Scholar] [CrossRef]

- Khan, F.U. Review of non-resonant vibration based energy harvesters for wireless sensor nodes. J. Renew. Sustain. Energy 2016, 8, 044702. [Google Scholar] [CrossRef]

- Shaikh, F.K.; Zeadally, S. Energy harvesting in wireless sensor networks: A comprehensive review. Renew. Sustain. Energy Rev. 2016, 55, 1041–1054. [Google Scholar] [CrossRef]

- Wang, Z.L. Nanogenerators, self-powered systems, blue energy, piezotronics and piezo-phototronics—A recall on the original thoughts for coining these fields. Nano Energy 2018, 54, 477–483. [Google Scholar] [CrossRef]

- Bai, Y.; Jantunen, H.; Juuti, J. Energy harvesting research: The road from single source to multisource. Adv. Mater. 2018, 30, 1707271. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ahmad, M.M.; Khan, N.M.; Khan, F.U. Review of frequency up-conversion vibration energy harvesters using impact and plucking mechanism. Int. J. Energy Res. 2021, 45, 15609–15645. [Google Scholar] [CrossRef]

- Li, Z.; Yan, Z.; Luo, J.; Yang, Z. Performance comparison of electromagnetic energy harvesters based on magnet arrays of alternating polarity and configuration. Energy Convers. Manag. 2019, 179, 132–140. [Google Scholar] [CrossRef]

- Li, Z.; Liu, Y.; Yin, P.; Peng, Y.; Luo, J.; Xie, S.; Pu, H. Constituting abrupt magnetic flux density change for power density improvement in electromagnetic energy harvesting. Int. J. Mech. Sci. 2021, 198, 106363. [Google Scholar] [CrossRef]

- Hu, G.; Zhao, C.; Yang, Y.; Li, X.; Liang, J. Triboelectric energy harvesting using an origami-inspired structure. Appl. Energy 2022, 306, 118037. [Google Scholar] [CrossRef]

- Zhao, C.; Yang, Y.; Upadrashta, D.; Zhao, L. Design, modeling and experimental validation of a low-frequency cantilever triboelectric energy harvester. Energy 2021, 214, 118885. [Google Scholar] [CrossRef]

- Hu, G.; Tang, L.; Liang, J.; Das, R. Modelling of a cantilevered energy harvester with partial piezoelectric coverage and shunted to practical interface circuits. J. Intell. Mater. Syst. Struct. 2019, 30, 1896–1912. [Google Scholar] [CrossRef]

- Peng, Y.; Xu, Z.; Wang, M.; Li, Z.; Peng, J.; Luo, J.; Xie, S.; Pu, H.; Yang, Z. Investigation of frequency-up conversion effect on the performance improvement of stack-based piezoelectric generators. Renew. Energy 2021, 172, 551–563. [Google Scholar] [CrossRef]

- Meitzler, A.; Tiersten, H.; Warner, A.; Berlincourt, D.; Couqin, G.; Welsh, F., III. 176-1987-IEEE Standard on Piezoelectricity. Standards Committee of the IEEE Ultrasonics, Ferroelectrics, and Frequency Control Society. 1988. Available online: https://docplayer.net/62806764-Ieee-standard-on-piezoelectricity.html (accessed on 26 December 2021).

- Tao, K.; Tang, L.; Wu, J.; Lye, S.W.; Chang, H.; Miao, J. Investigation of multimodal electret-based MEMS energy harvester with impact-induced nonlinearity. J. Microelectromech. Syst. 2018, 27, 276–288. [Google Scholar] [CrossRef]

- Wu, C.; Wang, A.C.; Ding, W.; Guo, H.; Wang, Z.L. Triboelectric nanogenerator: A foundation of the energy for the new era. Adv. Energy Mater. 2019, 9, 1802906. [Google Scholar] [CrossRef]

- Li, H.; Tian, C.; Deng, Z.D. Energy harvesting from low frequency applications using piezoelectric materials. Appl. Phys. Rev. 2014, 1, 041301. [Google Scholar] [CrossRef] [Green Version]

- Yang, Y.; Shen, Q.; Jin, J.; Wang, Y.; Qian, W.; Yuan, D. Rotational piezoelectric wind energy harvesting using impact-induced resonance. Appl. Phys. Lett. 2014, 105, 053901. [Google Scholar] [CrossRef]

- Halim, M.A.; Khym, S.; Park, J. Frequency up-converted wide bandwidth piezoelectric energy harvester using mechanical impact. J. Appl. Phys. 2013, 114, 044902. [Google Scholar] [CrossRef]

- Halim, M.A.; Park, J.Y. Piezoelectric energy harvester using impact-driven flexible side-walls for human-limb motion. Microsyst. Technol. 2018, 24, 2099–2107. [Google Scholar] [CrossRef]

- Priya, S. Modeling of electric energy harvesting using piezoelectric windmill. Appl. Phys. Lett. 2005, 87, 184101. [Google Scholar] [CrossRef]

- Pozzi, M.; Zhu, M. Plucked piezoelectric bimorphs for knee-joint energy harvesting: Modelling and experimental validation. Smart Mater. Struct. 2011, 20, 055007. [Google Scholar] [CrossRef] [Green Version]

- Tan, Y.; Lu, G.; Cong, M.; Wang, X.; Ren, L. Gathering energy from ultra-low-frequency human walking using a double-frequency up-conversion harvester in public squares. Energy Convers. Manag. 2020, 217, 112958. [Google Scholar] [CrossRef]

- Zhao, L.-C.; Zou, H.-X.; Yan, G.; Liu, F.-R.; Tan, T.; Zhang, W.-M.; Peng, Z.-K.; Meng, G. A water-proof magnetically coupled piezoelectric-electromagnetic hybrid wind energy harvester. Appl. Energy 2019, 239, 735–746. [Google Scholar] [CrossRef]

- Kulah, H.; Najafi, K. Energy scavenging from low-frequency vibrations by using frequency up-conversion for wireless sensor applications. IEEE Sens. J. 2008, 8, 261–268. [Google Scholar] [CrossRef]

- Fan, K.; Chang, J.; Pedrycz, W.; Liu, Z.; Zhu, Y. A nonlinear piezoelectric energy harvester for various mechanical motions. Appl. Phys. Lett. 2015, 106, 223902. [Google Scholar] [CrossRef]

- Kuang, Y.; Ruan, T.; Chew, Z.J.; Zhu, M. Energy harvesting during human walking to power a wireless sensor node. Sens. Actuators A: Phys. 2017, 254, 69–77. [Google Scholar] [CrossRef]

- Ando, B.; Baglio, S.; Marletta, V.; Pistorio, A.; Bulsara, A.R. Performance investigation of a nonlinear energy harvester with random vibrations and subthreshold deterministic signals. IEEE Trans. Instrum. Meas. 2017, 66, 992–1001. [Google Scholar] [CrossRef]

- Dauksevicius, R.; Kleiva, A.; Grigaliunas, V. Analysis of magnetic plucking dynamics in a frequency up-converting piezoelectric energy harvester. Smart Mater. Struct. 2018, 27, 085016. [Google Scholar] [CrossRef]

- Umeda, M.; Nakamura, K.; Ueha, S. Analysis of the transformation of mechanical impact energy to electric energy using piezoelectric vibrator. Jpn. J. Appl. Phys. 1996, 35, 3267. [Google Scholar] [CrossRef]

- Renaud, M.; Fiorini, P.; van Schaijk, R.; Van Hoof, C. Harvesting energy from the motion of human limbs: The design and analysis of an impact-based piezoelectric generator. Smart Mater. Struct. 2009, 18, 035001. [Google Scholar] [CrossRef]

- Yuksek, N.; Feng, Z.; Almasri, M. Broadband electromagnetic power harvester from vibrations via frequency conversion by impact oscillations. Appl. Phys. Lett. 2014, 105, 113902. [Google Scholar] [CrossRef]

- He, X.; Teh, K.S.; Li, S.; Dong, L.; Jiang, S. Modeling and experimental verification of an impact-based piezoelectric vibration energy harvester with a rolling proof mass. Sens. Actuators A Phys. 2017, 259, 171–179. [Google Scholar] [CrossRef]

- Zhang, X.; Gao, S.; Li, D.; Jin, L.; Wu, Q.; Liu, F. Frequency up-converted piezoelectric energy harvester for ultralow-frequency and ultrawide-frequency-range operation. Appl. Phys. Lett. 2018, 112, 163902. [Google Scholar] [CrossRef]

- Halim, M.A.; Park, J.Y. Theoretical modeling and analysis of mechanical impact driven and frequency up-converted piezoelectric energy harvester for low-frequency and wide-bandwidth operation. Sens. Actuators A Phys. 2014, 208, 56–65. [Google Scholar] [CrossRef]

- Janphuang, P.; Lockhart, R.A.; Isarakorn, D.; Henein, S.; Briand, D.; de Rooij, N.F. Harvesting energy from a rotating gear using an AFM-like MEMS piezoelectric frequency up-converting energy harvester. J. Microelectromech. Syst. 2014, 24, 742–754. [Google Scholar] [CrossRef]

- Kathpalia, B.; Tan, D.; Stern, I.; Erturk, A. An experimentally validated model for geometrically nonlinear plucking-based frequency up-conversion in energy harvesting. Smart Mater. Struct. 2017, 27, 015024. [Google Scholar] [CrossRef] [Green Version]

- Fang, S.; Fu, X.; Du, X.; Liao, W.-H. A music-box-like extended rotational plucking energy harvester with multiple piezoelectric cantilevers. Appl. Phys. Lett. 2019, 114, 233902. [Google Scholar] [CrossRef]

- Fu, X.; Liao, W.-H. Modeling and analysis of piezoelectric energy harvesting with dynamic plucking mechanism. J. Vib. Acoust. 2019, 141, 031002. [Google Scholar] [CrossRef]

- Fang, S.; Fu, X.; Liao, W.-H. Asymmetric plucking bistable energy harvester: Modeling and experimental validation. J. Sound Vib. 2019, 459, 114852. [Google Scholar] [CrossRef]

- Li, X.; Tang, H.; Hu, G.; Zhao, B.; Liang, J. ViPSN-pluck: A Transient-motion-powered Motion Detector. IEEE Internet Things J. 2021, 9, 3372–3382. [Google Scholar] [CrossRef]

- Riemer, R.; Shapiro, A. Biomechanical energy harvesting from human motion: Theory, state of the art, design guidelines, and future directions. J. Neuroeng. Rehabil. 2011, 8, 22. [Google Scholar] [CrossRef] [Green Version]

- Pozzi, M.; Aung, M.S.; Zhu, M.; Jones, R.K.; Goulermas, J.Y. The pizzicato knee-joint energy harvester: Characterization with biomechanical data and the effect of backpack load. Smart Mater. Struct. 2012, 21, 075023. [Google Scholar] [CrossRef]

- Kuang, Y.; Zhu, M. Design study of a mechanically plucked piezoelectric energy harvester using validated finite element modelling. Sens. Actuators A Phys. 2017, 263, 510–520. [Google Scholar] [CrossRef]

- Liu, H.; Tay, C.J.; Quan, C.; Kobayashi, T.; Lee, C. A scrape-through piezoelectric MEMS energy harvester with frequency broadband and up-conversion behaviors. Microsyst. Technol. 2011, 17, 1747–1754. [Google Scholar] [CrossRef]

- Liu, H.; Lee, C.; Kobayashi, T.; Tay, C.J.; Quan, C. Piezoelectric MEMS-based wideband energy harvesting systems using a frequency-up-conversion cantilever stopper. Sens. Actuators A Phys. 2012, 186, 242–248. [Google Scholar] [CrossRef]

- Gu, L.; Livermore, C. Impact-driven, frequency up-converting coupled vibration energy harvesting device for low frequency operation. Smart Mater. Struct. 2011, 20, 045004. [Google Scholar] [CrossRef]

- Gu, L. Low-frequency piezoelectric energy harvesting prototype suitable for the MEMS implementation. Microelectron. J. 2011, 42, 277–282. [Google Scholar] [CrossRef]

- Lin, Z.; Zhang, Y. Dynamics of a mechanical frequency up-converted device for wave energy harvesting. J. Sound Vib. 2016, 367, 170–184. [Google Scholar] [CrossRef]

- Dechant, E.; Fedulov, F.; Chashin, D.V.; Fetisov, L.Y.; Fetisov, Y.K.; Shamonin, M. Low-frequency, broadband vibration energy harvester using coupled oscillators and frequency up-conversion by mechanical stoppers. Smart Mater. Struct. 2017, 26, 065021. [Google Scholar] [CrossRef]

- Chen, W.; Mo, J.; Xiang, Z.; Wang, A.; Liu, Q.; Qian, H. A new concept of frequency-excitation-up conversion to improve the yield of linear piezoelectric generators. Sens. Actuators A Phys. 2021, 325, 112712. [Google Scholar] [CrossRef]

- Li, P.; Xu, N.; Gao, C. A Multi-Mechanisms Composite Frequency Up-Conversion Energy Harvester. Int. J. Precis. Eng. Manuf. 2020, 21, 1781–1788. [Google Scholar] [CrossRef]

- Sari, I.; Balkan, T.; Külah, H. An electromagnetic micro power generator for low-frequency environmental vibrations based on the frequency upconversion technique. J. Microelectromech. Syst. 2009, 19, 14–27. [Google Scholar] [CrossRef]

- Galchev, T.; Kim, H.; Najafi, K. Micro power generator for harvesting low-frequency and nonperiodic vibrations. J. Microelectromech. Syst. 2011, 20, 852–866. [Google Scholar] [CrossRef] [Green Version]

- Galchev, T.; Aktakka, E.E.; Najafi, K. A piezoelectric parametric frequency increased generator for harvesting low-frequency vibrations. J. Microelectromech. Syst. 2012, 21, 1311–1320. [Google Scholar] [CrossRef]

- Tien, C.M.T.; Goo, N.S. Use of a piezo-composite generating element for harvesting wind energy in an urban region. Aircr. Eng. Aerosp. Technol. 2010, 82, 376–381. [Google Scholar] [CrossRef]

- Luong, H.T.; Goo, N.S. Use of a magnetic force exciter to vibrate a piezocomposite generating element in a small-scale windmill. Smart Mater. Struct. 2012, 21, 025017. [Google Scholar] [CrossRef]

- Wang, J.; Yurchenko, D.; Hu, G.; Zhao, L.; Tang, L.; Yang, Y. Perspectives in flow-induced vibration energy harvesting. Appl. Phys. Lett. 2021, 119, 100502. [Google Scholar] [CrossRef]

- Lu, H.; Zhu, J. A comparative study of microactuators driven by electric and magnetic principles. In Proceedings of the Australasian Universities Power Engineering Conference, Brisbane, Australia, 26–29 September 2004; p. 79. [Google Scholar]

- Kan, J.; Fan, C.; Wang, S.; Zhang, Z.; Wen, J.; Huang, L. Study on a piezo-windmill for energy harvesting. Renew. Energy 2016, 97, 210–217. [Google Scholar] [CrossRef]

- Karami, M.A.; Farmer, J.R.; Inman, D.J. Parametrically excited nonlinear piezoelectric compact wind turbine. Renew. Energy 2013, 50, 977–987. [Google Scholar] [CrossRef]

- Rezaei-Hosseinabadi, N.; Tabesh, A.; Dehghani, R.; Aghili, A. An efficient piezoelectric windmill topology for energy harvesting from low-speed air flows. IEEE Trans. Ind. Electron. 2014, 62, 3576–3583. [Google Scholar]

- Rezaei-Hosseinabadi, N.; Tabesh, A.; Dehghani, R. A topology and design optimization method for wideband piezoelectric wind energy harvesters. IEEE Trans. Ind. Electron. 2015, 63, 2165–2173. [Google Scholar] [CrossRef]

- Fu, H.; Yeatman, E.M. A miniaturized piezoelectric turbine with self-regulation for increased air speed range. Appl. Phys. Lett. 2015, 107, 243905. [Google Scholar] [CrossRef] [Green Version]

- Wickenheiser, A.; Garcia, E. Broadband vibration-based energy harvesting improvement through frequency up-conversion by magnetic excitation. Smart Mater. Struct. 2010, 19, 065020. [Google Scholar] [CrossRef]

- Ramezanpour, R.; Nahvi, H.; Ziaei-Rad, S. Electromechanical behavior of a pendulum-based piezoelectric frequency up-converting energy harvester. J. Sound Vib. 2016, 370, 280–305. [Google Scholar] [CrossRef]

- Shu, Y.; Wang, W.; Chang, Y. Electrically rectified piezoelectric energy harvesting induced by rotary magnetic plucking. Smart Mater. Struct. 2018, 27, 125006. [Google Scholar] [CrossRef]

- Xue, T.; Roundy, S. On magnetic plucking configurations for frequency up-converting mechanical energy harvesters. Sens. Actuators A Phys. 2017, 253, 101–111. [Google Scholar] [CrossRef] [Green Version]

- Fu, H.; Zhou, S.; Yeatman, E.M. Exploring coupled electromechanical nonlinearities for broadband energy harvesting from low-frequency rotational sources. Smart Mater. Struct. 2019, 28, 075001. [Google Scholar] [CrossRef]

- Pillatsch, P.; Yeatman, E.M.; Holmes, A.S. A piezoelectric frequency up-converting energy harvester with rotating proof mass for human body applications. Sens. Actuators A Phys. 2014, 206, 178–185. [Google Scholar] [CrossRef]

- Pillatsch, P.; Yeatman, E.; Holmes, A. Magnetic plucking of piezoelectric beams for frequency up-converting energy harvesters. Smart Mater. Struct. 2013, 23, 025009. [Google Scholar] [CrossRef]

- Pillatsch, P.; Yeatman, E.M.; Holmes, A.S.; Wright, P.K. Wireless power transfer system for a human motion energy harvester. Sens. Actuators A Phys. 2016, 244, 77–85. [Google Scholar] [CrossRef] [Green Version]

- Fu, H.; Yeatman, E.M. A methodology for low-speed broadband rotational energy harvesting using piezoelectric transduction and frequency up-conversion. Energy 2017, 125, 152–161. [Google Scholar] [CrossRef] [Green Version]

- Fu, H.; Yeatman, E.M. Effective piezoelectric energy harvesting using beam plucking and a synchronized switch harvesting circuit. Smart Mater. Struct. 2018, 27, 084003. [Google Scholar] [CrossRef] [Green Version]

- Fu, H.; Yeatman, E.M. Rotational energy harvesting using bi-stability and frequency up-conversion for low-power sensing applications: Theoretical modelling and experimental validation. Mech. Syst. Signal Processing 2019, 125, 229–244. [Google Scholar] [CrossRef]

- Kuang, Y.; Yang, Z.; Zhu, M. Design and characterisation of a piezoelectric knee-joint energy harvester with frequency up-conversion through magnetic plucking. Smart Mater. Struct. 2016, 25, 085029. [Google Scholar] [CrossRef]

- Pillatsch, P.; Yeatman, E.; Holmes, A. A scalable piezoelectric impulse-excited energy harvester for human body excitation. Smart Mater. Struct. 2012, 21, 115018. [Google Scholar] [CrossRef]

- Fan, K.; Chang, J.; Chao, F.; Pedrycz, W. Design and development of a multipurpose piezoelectric energy harvester. Energy Convers. Manag. 2015, 96, 430–439. [Google Scholar] [CrossRef]

- Jiang, H.; Kiziroglou, M.E.; Yates, D.C.; Yeatman, E.M. A motion-powered piezoelectric pulse generator for wireless sensing via FM transmission. IEEE Internet Things J. 2014, 2, 5–13. [Google Scholar] [CrossRef]

- Chung, T.-K.; Wang, C.-M.; Yeh, P.-C.; Liu, T.-W.; Tseng, C.-Y.; Chen, C.-C. A three-axial frequency-tunable piezoelectric energy harvester using a magnetic-force configuration. IEEE Sens. J. 2014, 14, 3152–3163. [Google Scholar] [CrossRef] [Green Version]

- Lo, Y.; Chen, C.; Shu, Y.; Lumentut, M. Broadband piezoelectric energy harvesting induced by mixed resonant modes under magnetic plucking. Smart Mater. Struct. 2021, 30, 105026. [Google Scholar] [CrossRef]

- Fakeih, E.; Almansouri, A.S.; Kosel, J.; Younis, M.I.; Salama, K.N. A Wideband Magnetic Frequency Up-Converter Energy Harvester. Adv. Eng. Mater. 2021, 23, 2001364. [Google Scholar] [CrossRef]

- Jiang, W.-A.; Chen, L.-Q. Snap-through piezoelectric energy harvesting. J. Sound Vib. 2014, 333, 4314–4325. [Google Scholar] [CrossRef]

- Jung, S.-M.; Yun, K.-S. Energy-harvesting device with mechanical frequency-up conversion mechanism for increased power efficiency and wideband operation. Appl. Phys. Lett. 2010, 96, 111906. [Google Scholar] [CrossRef]

- Speciale, A.; Ardito, R.; Baù, M.; Ferrari, M.; Ferrari, V.; Frangi, A.A. Snap-through buckling mechanism for frequency-up conversion in piezoelectric energy harvesting. Appl. Sci. 2020, 10, 3614. [Google Scholar] [CrossRef]

- Panigrahi, S.R.; Bernard, B.P.; Feeny, B.F.; Mann, B.P.; Diaz, A.R. Snap-through twinkling energy generation through frequency up-conversion. J. Sound Vib. 2017, 399, 216–227. [Google Scholar] [CrossRef] [Green Version]

- Han, D.; Yun, K.-S. Piezoelectric energy harvester using mechanical frequency up conversion for operation at low-level accelerations and low-frequency vibration. Microsyst. Technol. 2015, 21, 1669–1676. [Google Scholar] [CrossRef]

- Chamanian, S.; Zangabad, R.P.; Zarbakhsh, P.; Bahrami, M.; Khodaei, M. Wideband capacitive energy harvester based on mechanical frequency-up conversion. In Proceedings of the 2012 IEEE Sensors Applications Symposium Proceedings, Brescia, Italy, 7–9 February 2012; pp. 1–4. [Google Scholar]

- Xie, Z.; Xiong, J.; Zhang, D.; Wang, T.; Shao, Y.; Huang, W. Design and experimental investigation of a piezoelectric rotation energy harvester using bistable and frequency up-conversion mechanisms. Appl. Sci. 2018, 8, 1418. [Google Scholar] [CrossRef] [Green Version]

| Mechanisms | Methodologies | Frequency Ranges | Representative Designs | References | Applications * | Features |

|---|---|---|---|---|---|---|

| Impact | Mechanical impact | 1–50 Hz |  | Yang et al. [50] Halim et al. [51] Halim et al. [52] |

|

|

| Plucking | Mechanical plucking | 10–50 Hz |  | Priya et al. [53] Pozzi et al. [54] Tan et al. [55] |

|

|

| Magnetic plucking | 10–100 Hz |  | Zhao et al. [56] Kulah et al. [57] Fan et al. [58] Kuang et al. [59] |

| ||

| Snap-through | 1–30 Hz |  | Ando et al. [60] |

|

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Hu, G.; Guo, Z.; Wang, J.; Yang, Y.; Liang, J. Frequency Up-Conversion for Vibration Energy Harvesting: A Review. Symmetry 2022, 14, 631. https://doi.org/10.3390/sym14030631

Li X, Hu G, Guo Z, Wang J, Yang Y, Liang J. Frequency Up-Conversion for Vibration Energy Harvesting: A Review. Symmetry. 2022; 14(3):631. https://doi.org/10.3390/sym14030631

Chicago/Turabian StyleLi, Xin, Guobiao Hu, Zhenkun Guo, Junlei Wang, Yaowen Yang, and Junrui Liang. 2022. "Frequency Up-Conversion for Vibration Energy Harvesting: A Review" Symmetry 14, no. 3: 631. https://doi.org/10.3390/sym14030631

APA StyleLi, X., Hu, G., Guo, Z., Wang, J., Yang, Y., & Liang, J. (2022). Frequency Up-Conversion for Vibration Energy Harvesting: A Review. Symmetry, 14(3), 631. https://doi.org/10.3390/sym14030631