Interfacial Surface Properties of Compression Moulded Hydrolysed Polyvinyl Acetate (PVAc) Using Different Release Materials

Abstract

1. Introduction

2. Materials and Methods

2.1. Compression Moulding

2.2. Release Material

2.3. Production of Surfaces with a Range of Hydrophobicities

2.4. Surface Hydrophobicities: Dynamic Contact Angle of Surfaces (Wilhemy Plate Method)

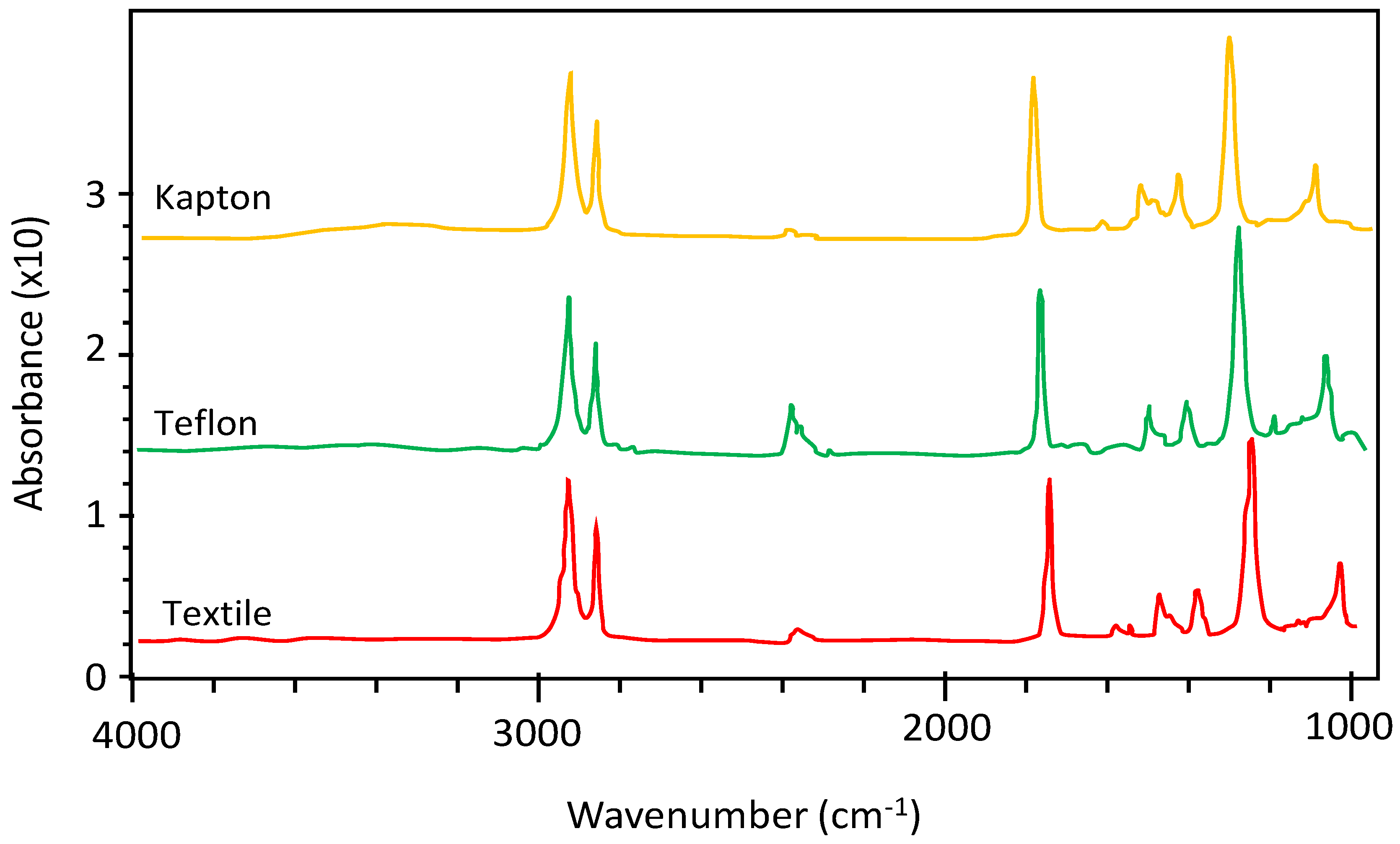

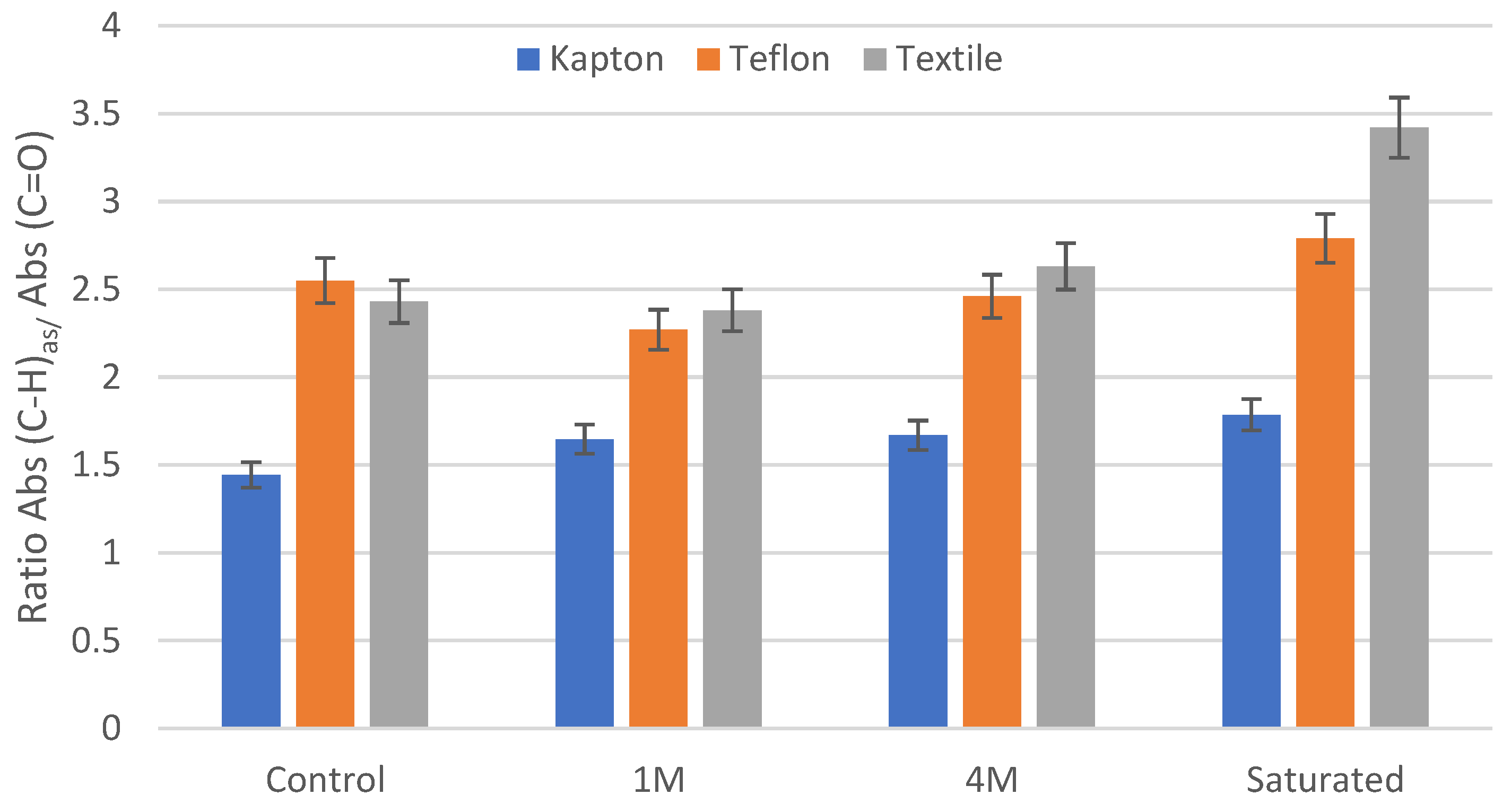

2.5. Attenuated Total Reflection Fourier Transformation Infra-Red (ATR-FTIR)

2.6. Determination of Surface Roughness and Topography Using Atomic Force Microscopy (AFM)

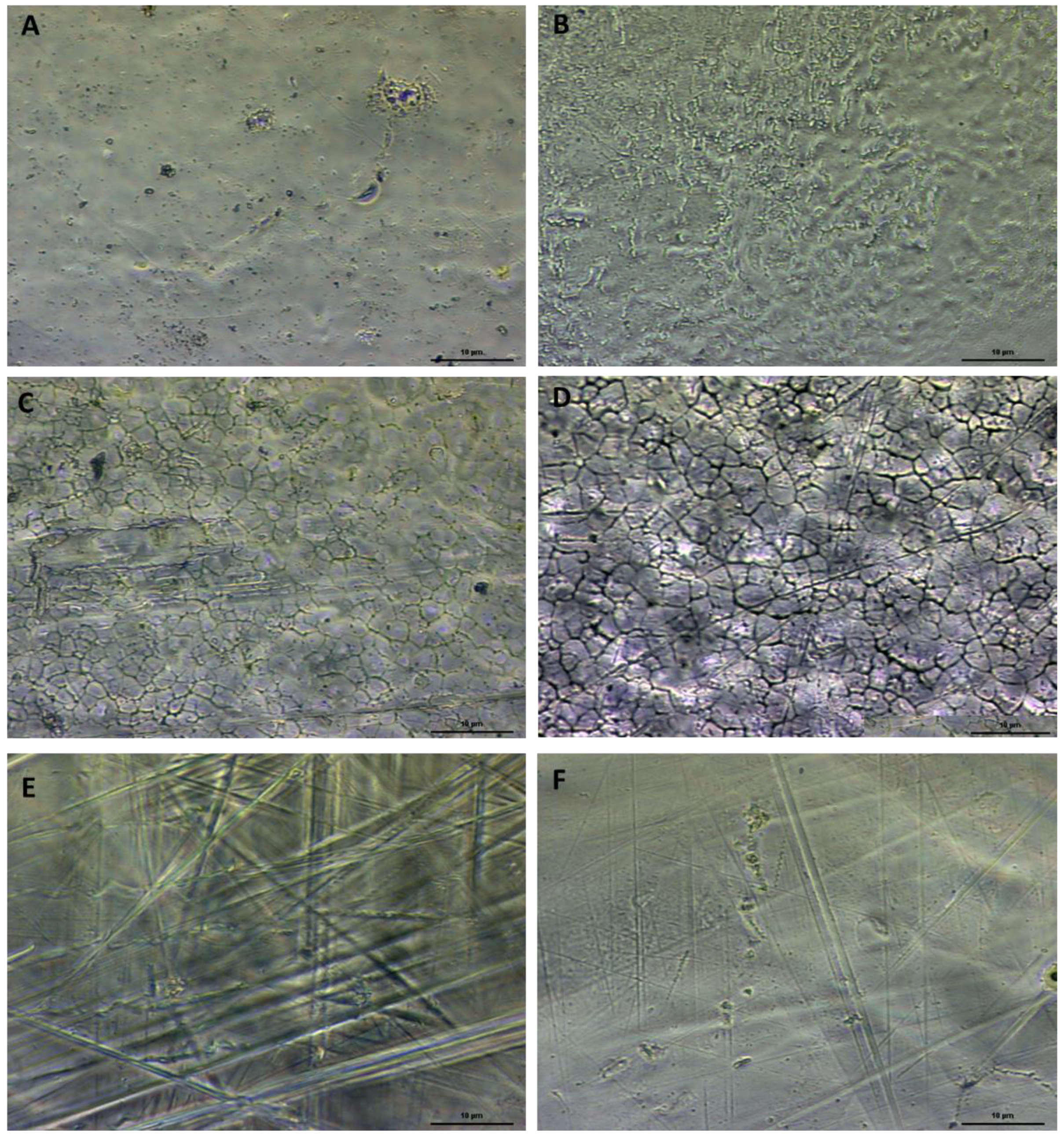

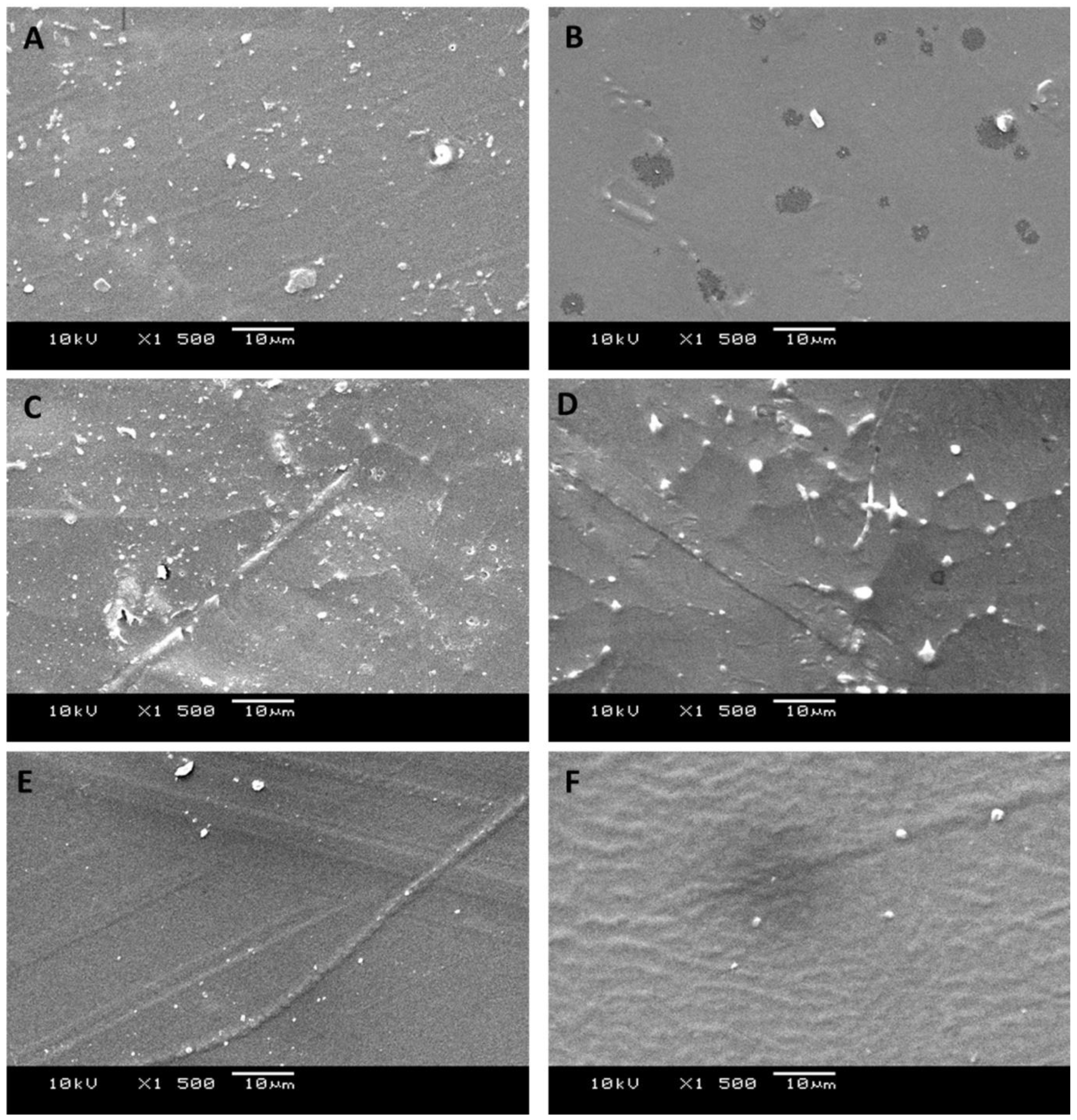

2.7. Scanning Electron Microscopy (SEM)

2.8. Statistical Analysis

3. Results

4. Discussion

4.1. Surface Analysis and Hydrolysis

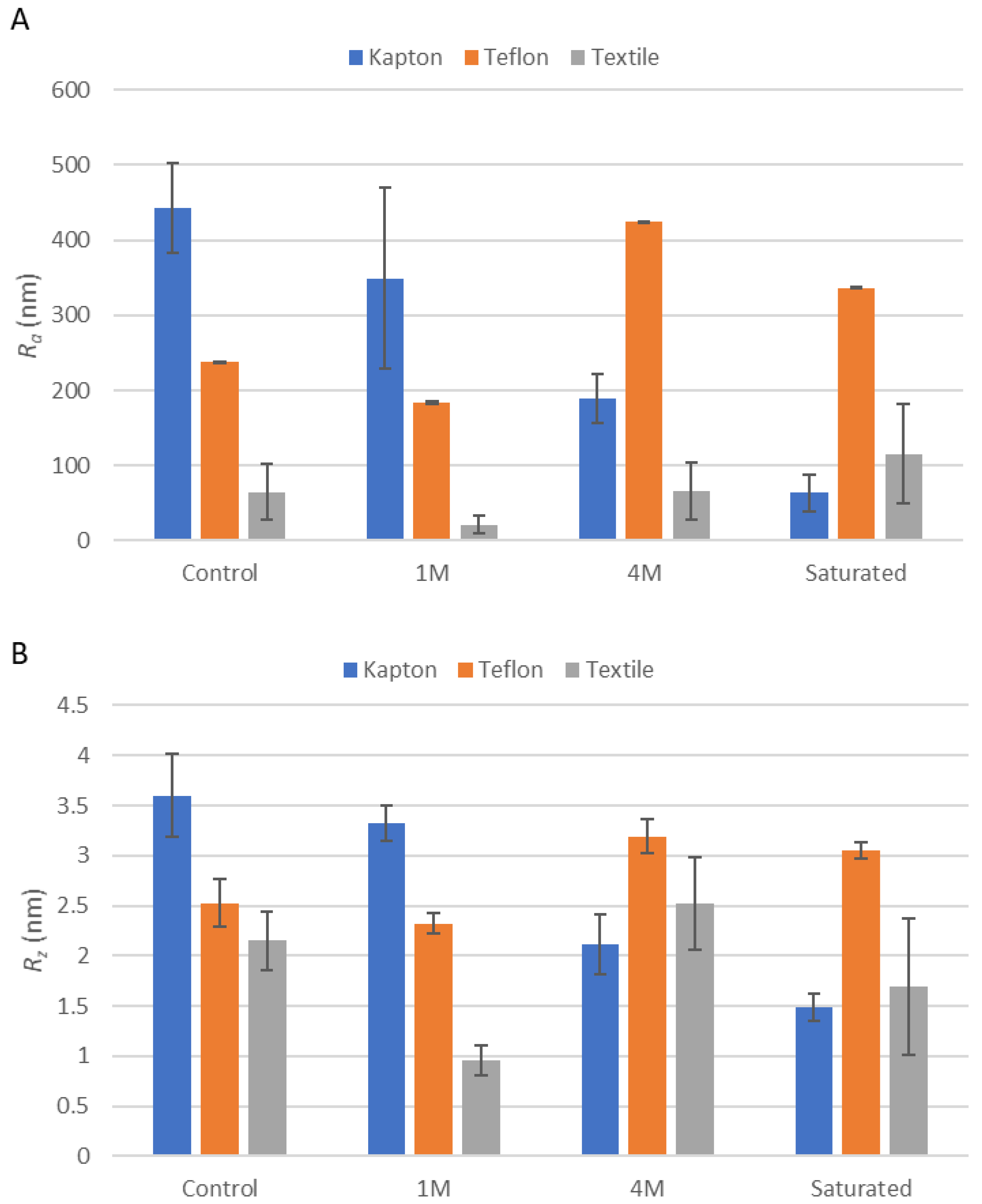

4.2. Surface Topography

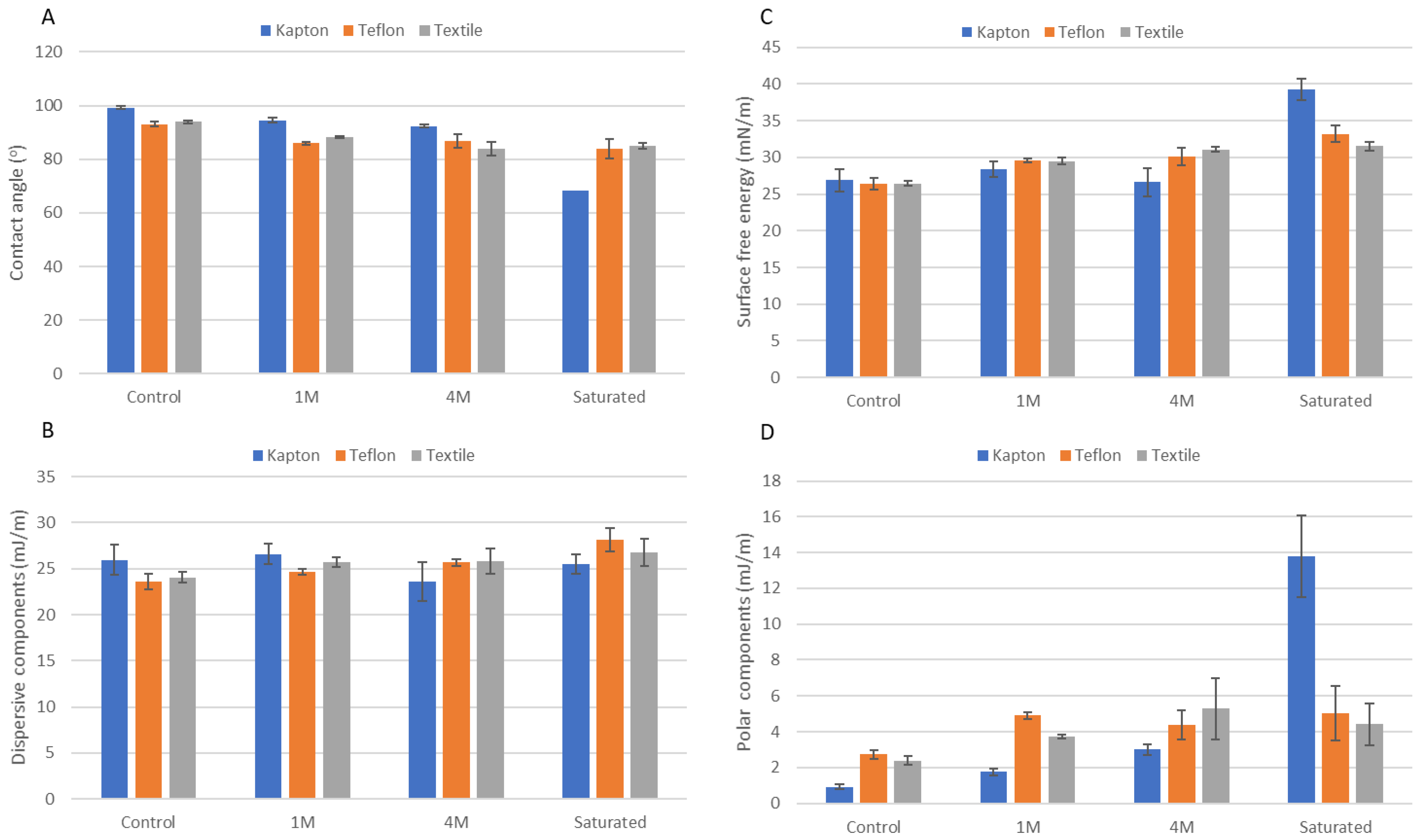

4.3. Surface Physicochemistry

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Razumova, L.L.; Veretennikova, A.A.; Zaikov, G.Y.; Volf, L.A. Degradation of polyvinyl alcohol surgical thread. Polym. Sci. U.S.S.R. 1983, 25, 2418–2425. [Google Scholar] [CrossRef]

- Webb, M. Methods and materials for filling losses on lacquer objects. J. Am. Inst. Conserv. 1998, 37, 117–133. [Google Scholar] [CrossRef]

- Montero, J.; Vitale, P.; Weber, S.; Bleckmann, M.; Paetzold, K. Indirect Additive Manufacturing of resin components using polyvinyl alcohol sacrificial moulds. Procedia CIRP 2020, 91, 388–395. [Google Scholar] [CrossRef]

- Apicella, A.; Barbato, A.; Garofalo, E.; Incarnato, L.; Scarfato, P. Effect of PVOH/PLA + Wax Coatings on Physical and Functional Properties of Biodegradable Food Packaging Films. Polymers 2022, 14, 935. [Google Scholar] [CrossRef] [PubMed]

- Jain, N.; Singh, V.K.; Chauhan, S. A review on mechanical and water absorption properties of polyvinyl alcohol based composites/films. J. Mech. Behav. Mater. 2017, 26, 213–222. [Google Scholar] [CrossRef]

- Finley, J.H. Spectrophotometric determination of alcohol in paper coatings. Anal. Chem. 1961, 33, 1925–1927. [Google Scholar] [CrossRef]

- Byrne, D.; Boeije, G.; Croft, I.; Hüttmann, G.; Luijkx, G.; Meier, F.; Parulekar, Y.; Stijntjes, G. Biodegradability of polyvinyl alcohol based film used for liquid detergent capsules. Tenside Surfactants Detetergents 2021, 58, 2. [Google Scholar] [CrossRef]

- Van Etten, E.A.; Ximenes, E.S.; Tarasconi, L.T.; Garcia, I.T.S.; Forte, M.M.C.; Boudinov, H. Insulating characteristics of polyvinyl alcohol for integrated electronics. Thin Solid Film. 2014, 568, 111–116. [Google Scholar] [CrossRef]

- Vetter, P.; Ohmura, Y.; Uchida, T. Study of memory alignment of nematic liquid crystals on polyvinyl alcohol coatings. Jpn. J. Appl. Phys. 1993, 32, L1239. [Google Scholar] [CrossRef]

- Schaper, C.D.; Miahnahri, A. Polyvinyl alcohol templates for low cost, high resolution, complex printing. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. Process. Meas. Phenom. 2004, 22, 3323. [Google Scholar] [CrossRef]

- Burnett, C.L. Polyvinyl Alcohol. Int. J. Toxicol. 2017, 36, 2. [Google Scholar] [CrossRef]

- Sakurada, I. Polyvinyl Alcohol Fibers; Marcel Dekker: New York, NY, USA; Basel, Switzerland, 1985. [Google Scholar]

- Kaity, S.; Isaac, J.; Ghosh, A. Interpenetrating polymer network of locust bean gum-poly (vinyl alcohol) for controlled release drug delivery. Carbohydr. Polym. 2013, 94, 456–467. [Google Scholar] [CrossRef] [PubMed]

- Hyon, S.H.; Cha, W.I.; Ikada, Y.; Kita, M.; Ogura, Y.; Honda, Y. Poly (vinyl alcohol) hydrogels as soft contact lens material. J. Biomater. Sci. Polym. Ed. 1994, 5, 397–406. [Google Scholar] [CrossRef] [PubMed]

- Muggli, D.S.; Burkoth, A.K.; Anseth, K.S. Crosslinked polyanhydrides for use in orthopedic applications: Degradation behavior and mechanics. J. Biomed. Mater. Res. 1999, 46, 271–278. [Google Scholar] [CrossRef]

- Thong, C.C.; Teo, D.C.L.; Ng, C.K. Application of polyvinyl alcohol (PVA) in cement-based composite materials: A review of its engineering properties and microstructure behaviour. Constr. Build. Mater. 2016, 107, 172–180. [Google Scholar] [CrossRef]

- Aruldass, S. Hydrolysis of polyvinyl acetate into polyvinyl alcohol. Res. Commun. Eng. Sci. Technol. 2019, 3, 10. [Google Scholar]

- Brydson, J.A. Plastics Materials, 4th ed.; Butterworth Scientific: London, UK, 1985; p. 355. ISBN 0-408-00538. [Google Scholar]

- Gaaz, T.S.; Sulong, A.B.; Akhtar, M.N.; Kadhum, A.A.; Mohamad, A.B.; Al-Amiery, A.A. Properties and applications of polyvinyl alcohol, halloysite nanotubes and their nanocomposites. Molecules 2015, 19, 22833–22847. [Google Scholar] [CrossRef]

- Kuraray. Basic Physical Properties of PVOH. Available online: https://www.kuraray-poval.com/fileadmin/technical_information/brochures/poval/kuraray_poval_basic_physical_properties_web.pdf (accessed on 25 August 2022).

- Saunders, K.J. Organic Polymer Chemistry; Chapman and Hall: London, UK, 1985; p. 111. ISBN 0-412-10580. [Google Scholar]

- Chihani, T.; Bergmark, P.; Flodin, P.; Hjertberg, T. Surface properties of an anhydride-epoxy resin cured against different mould surfaces. J. Adhes. Technol. 1993, 7, 569–582. [Google Scholar] [CrossRef]

- Chihani, T.; Bergmark, P.; Flodin, P. Surface modification of ethylene copolymers molded against different mold surfaces. Part 2. Changes at the outermost surface. J. Adhes. Technol. 1993, 7, 327–341. [Google Scholar] [CrossRef]

- Chihani, T.; Chihani, P.; Flodin, P.; Hjettberg, T. Modification of epoxy surfaces with different polyvinylalcohol polymers. J. Appl. Polym. Sci. 1993, 50, 1343–1350. [Google Scholar] [CrossRef]

- Kavousanakis, M.E.; Chamakos, N.T.; Papathanasiou, A.G. Connection of intrinsic wettability and surface topography with the apparent wetting behavior and adhesion properties. J. Phys. Chem. C 2015, 119, 15056–15066. [Google Scholar] [CrossRef]

- Liauw, C.M.; Deisenroth, T.; Preuss, A.; Verran, J.; Whitehead, K.A. The effect of polyvinyl acetate and polyvinyl alcohol on the attachment, adhesion and retention of fungal spores. J. Polym. Environ. 2020, 28, 1450–1464. [Google Scholar] [CrossRef]

- dos Reis, E.F.; Campos, F.S.; Lage, A.P.; Leite, R.C.; Heneine, L.G.; Vasconcelos, W.L.; Lobato, Z.I.P.; Mansur, H.S. Synthesis and characterization of Poly (Vinyl Alcohol) hydrogels and hybrids for rMPB70 protein adsorption. Mater. Res. 2006, 9, 185–191. [Google Scholar] [CrossRef]

- Roberts, J.J.; Martens, P.J. Chapter 9 Engineering biosynthetic cell encapsulation systems. In Biosynthetic Polymers for Medical Applications; Woodhead Publishing Series in Biomaterials; Woodhead Publishing: Cambridge, UK, 2016; pp. 205–239. [Google Scholar]

- Guvendiren, M.; Purcell, B.; Burdick, J.A. Chapter 9.22 Photopolymerizable systems. Polym. Sci. A Compr. Ref. 2012, 9, 413–438. [Google Scholar]

- Whitehead, K.A.; Verran, J. The effect of surface topography on the retention of microorganisms: A review. Food Bioprod. Process. 2006, 84, 253–259. [Google Scholar] [CrossRef]

- Yuan, Y.; Hays, M.P.; Hardwidge, P.R.; Kim, J. Surface characteristics influencing bacterial adhesion to polymeric substrates. RSC Adv. 2017, 7, 14254–14261. [Google Scholar] [CrossRef]

- Whitehead, K.A.; Verran, J. The Effect of Substratum Properties on the Survival of Attached Microorganisms on Inert Surfaces. In Marine and Industrial Biofouling; Flemming, H.-C., Venkatesan, R., Murthy, P.S., Cooksey, K., Eds.; Springer Series on Biofilms Springer: Cham, Germany, 2009; pp. 13–33. [Google Scholar]

- Lee, H.; Mensire, R.; Cohen, R.E.; Rubner, M.F. Strategies for hydrogen bonding based layer-by-layer assembly of poly (vinyl alcohol) with weak polyacids. Macromolecules 2011, 45, 347–355. [Google Scholar] [CrossRef]

- Fujii, K.; Nakagaito, A.N.; Takagi, H.; Yonekura, D. Sulfuric acid treatment of halloysite nanoclay to improve the mechanical properties of PVA/halloysite transparent composite films. Compos. Interfaces 2014, 21, 319–327. [Google Scholar] [CrossRef]

- Lvov, Y.; Abdullayev, E. Functional polymer-clay nanotube composites with sustained release of chemical agents. Prog. Polym. Sci. 2013, 38, 1690–1719. [Google Scholar] [CrossRef]

- Zhou, W.Y.; Guo, B.; Liu, M.; Liao, R.; Rabie, A.B.; Jia, D. Poly (vinyl alcohol)/halloysite nanotubes bionanocomposite films: Properties and in vitro osteoblasts and fibroblasts response. J. Biomed. Mater. Res. A 2010, 93, 1574–1587. [Google Scholar] [CrossRef]

- Jang, J.; Lee, D.K. Plasticizer effect on the melting and crystallization behavior of polyvinyl alcohol. Polymer 2003, 44, 8139–8146. [Google Scholar] [CrossRef]

- Fernandes, E.M.; Pires, R.A.; Mano, J.F.; Reis, R.L. Bionanocomposites from lignocellulosic resources: Properties, applications and future trends for their use in the biomedical field. Prog. Polym. Sci. 2013, 38, 1415–1441. [Google Scholar] [CrossRef]

- Jayasekara, R.; Harding, I.; Bowater, I.; Christie, G.B.; Lonergan, G.T. Preparation, surface modification and characterisation of solution cast starch PVA blended films. Polym. Test. 2004, 23, 17–27. [Google Scholar] [CrossRef]

- Heuschmid, F.F.; Schuster, P.; Lauer, B.; Fabian, E.; Leibold, E.; Ravenzwaay, B.V. Polyethylene glycol-polyvinyl alcohol grafted copolymer: Study of the bioavailability after oral administration to rats. Food Chem. Toxicol. 2013, 51, S3–S6. [Google Scholar] [CrossRef]

- Ebnesajjad, S. Introduction to fluoropolymers. In Applied Plastics Engineering Handbook; Kutz, M., Ed.; Elsevier: New York, NY, USA, 2011; pp. 49–60. [Google Scholar]

- Henry, B.J.; Carlin, J.P.; Hammerschmidt, J.A.; Buck, R.C.; Buxton, L.W.; Fiedler, H.; Seed, J.; Hernandez, O. A critical review of the application of polymer of low concern and regulatory criteria to fluoropolymers. Integr. Environ. Assess. Manag. 2018, 14, 316–334. [Google Scholar] [CrossRef]

- Sajid, M.; Ilyas, M. PTFE-coated non-stick cookware and toxicity concerns: A perspective. Environ. Sci. Pollut. Res. Int. 2017, 24, 23436–23440. [Google Scholar] [CrossRef]

- Artto, H.; Soda, R. Pyrolysis products of polytetrafluoroethylene and polyfluoroethylenepropylene with reference to inhalation toxicity. Annu. Occup. Hyg. 1977, 20, 247–253. [Google Scholar]

- Encinas, N.; Pantoja, M.; Abenojar, J.; Martínez, M.A. Control of wettability of polymers by surface roughness modification. J. Adhes. Sci. Technol. 2010, 24, 1869–1883. [Google Scholar] [CrossRef]

| Min Valley Depth (µm) | Max Valley Depth (µm) | Min Valley Width (µm) | Max Valley Width (µm) | Min Peak Height (µm) | Max Peak Height (µm) | Min Peak Width (µm) | Max Peak Width (µm) | |

|---|---|---|---|---|---|---|---|---|

| Kapton control | 0.5 | 32 | 1 | 49 | 1.25 | 17 | 1.5 | 45 |

| Kapton 1M | 0.75 | 14 | 1.25 | 23 | 1 | 10 | 2 | 9 |

| Kapton 4M | 2 | 60 | 4 | 31 | 1 | 70 | 3 | 50 |

| Kapton Conc. | 0.75 | 6 | 2 | 29 | 0.75 | 10 | 3 | 19 |

| Teflon control | 0.25 | 6 | 0.5 | 20 | 1 | 25 | 2 | 21 |

| Teflon 1M | 2 | 16 | 3 | 24 | 1 | 6 | 2 | 6 |

| Teflon 4M | 1 | 6 | 1 | 16 | 0.5 | 8 | 0.5 | 17 |

| Teflon Conc. | 0.25 | 36 | 0.75 | 16 | 1 | 19 | 1 | 19 |

| Textile control | 0.5 | 12 | 1 | 42 | 1.5 | 16 | 2 | 30 |

| Textile 1M | 1.5 | 12 | 0.5 | 50 | 0.75 | 14 | 1 | 2 |

| Textile 4M | 0.5 | 4 | 1.5 | 20 | 0.5 | 6 | 1.5 | 12 |

| Textile Conc. | 0.25 | 8 | 0.5 | 10 | 0.5 | 14 | 1.25 | 25 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Whitehead, K.A.; Amin, M.; Deisenroth, T.; Liauw, C.M.; Verran, J. Interfacial Surface Properties of Compression Moulded Hydrolysed Polyvinyl Acetate (PVAc) Using Different Release Materials. Symmetry 2022, 14, 2063. https://doi.org/10.3390/sym14102063

Whitehead KA, Amin M, Deisenroth T, Liauw CM, Verran J. Interfacial Surface Properties of Compression Moulded Hydrolysed Polyvinyl Acetate (PVAc) Using Different Release Materials. Symmetry. 2022; 14(10):2063. https://doi.org/10.3390/sym14102063

Chicago/Turabian StyleWhitehead, Kathryn A., Mohsin Amin, Ted Deisenroth, Christopher M. Liauw, and Joanna Verran. 2022. "Interfacial Surface Properties of Compression Moulded Hydrolysed Polyvinyl Acetate (PVAc) Using Different Release Materials" Symmetry 14, no. 10: 2063. https://doi.org/10.3390/sym14102063

APA StyleWhitehead, K. A., Amin, M., Deisenroth, T., Liauw, C. M., & Verran, J. (2022). Interfacial Surface Properties of Compression Moulded Hydrolysed Polyvinyl Acetate (PVAc) Using Different Release Materials. Symmetry, 14(10), 2063. https://doi.org/10.3390/sym14102063