Modeling Test and Numerical Simulation of Vertical Bearing Performance for Rigid-Flexible Composite Pouch Piles with Expanded Bottom (RFCPPEB)

Abstract

:1. Introduction

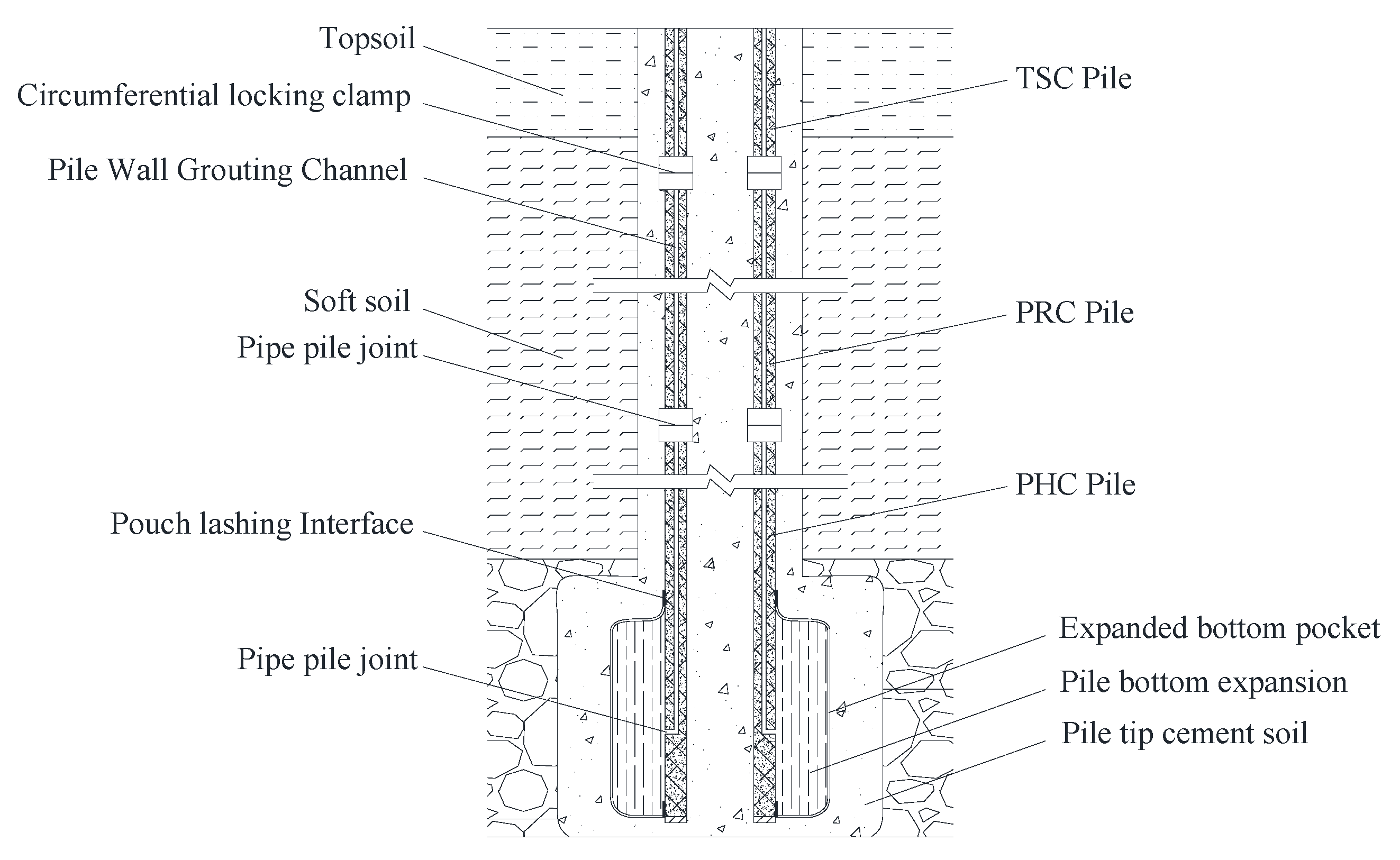

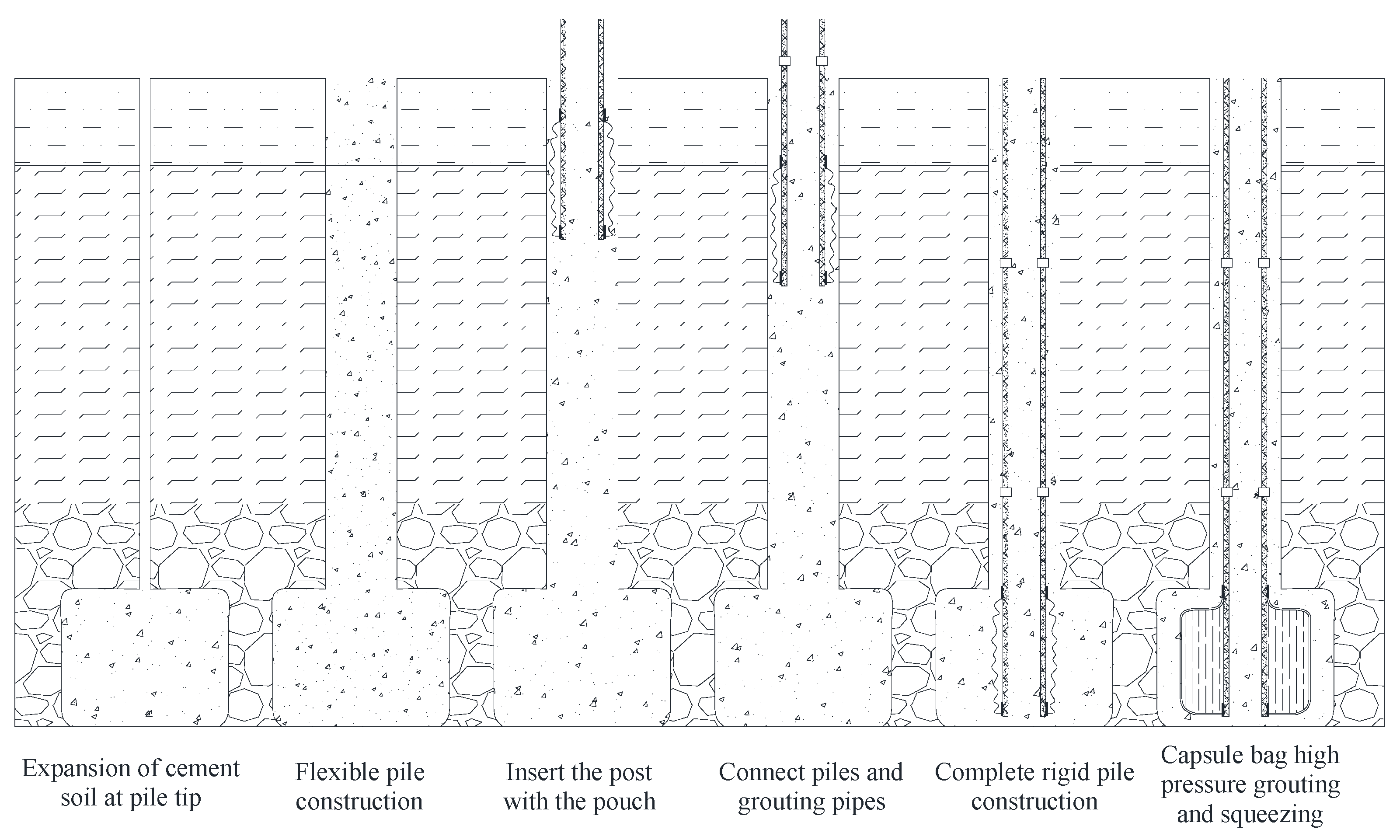

2. Technology of RFCPPEB

3. Design Procedures for Laboratory Tests

3.1. Testing Materials

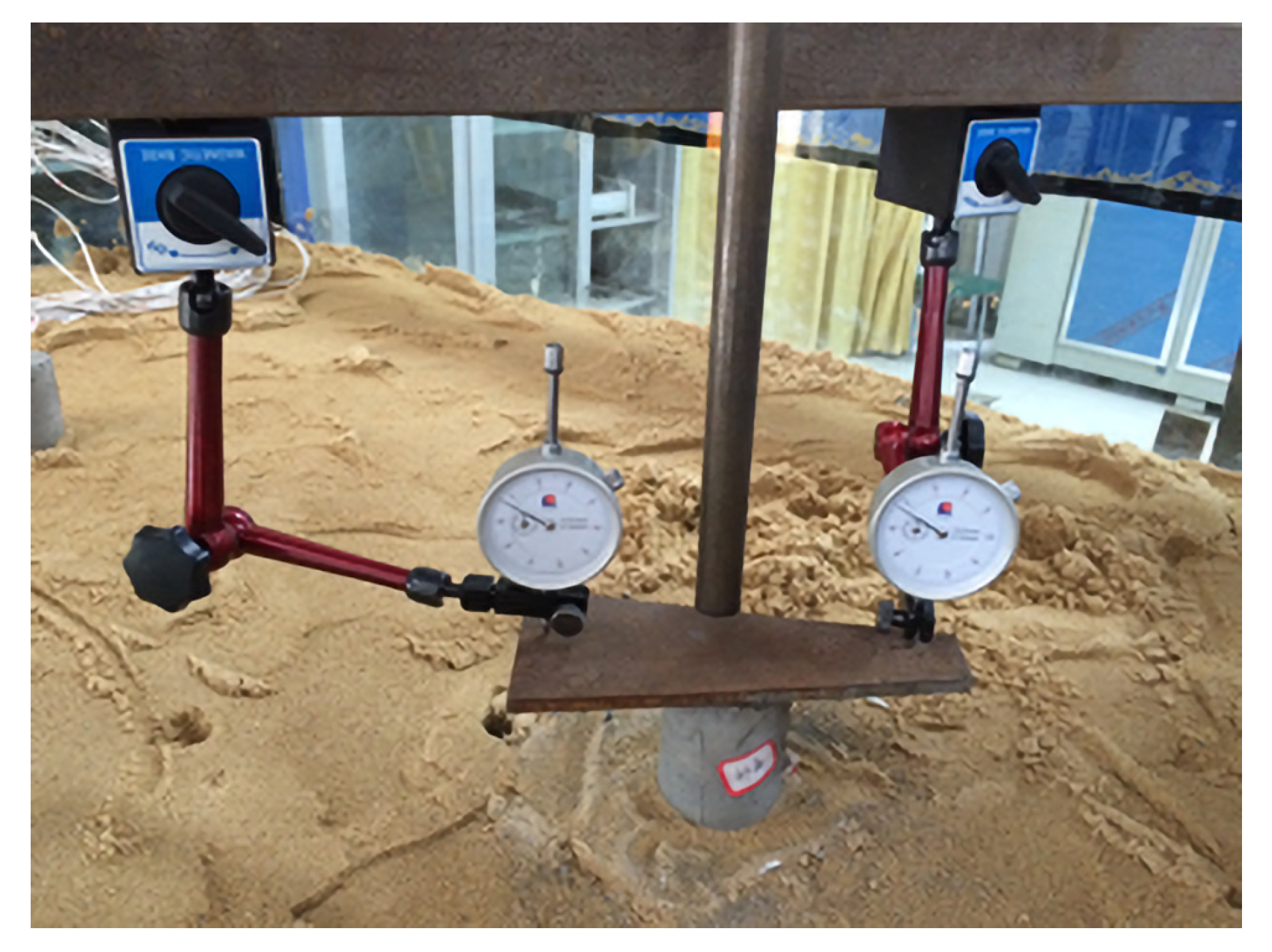

3.2. Modeling Box and Loading Device

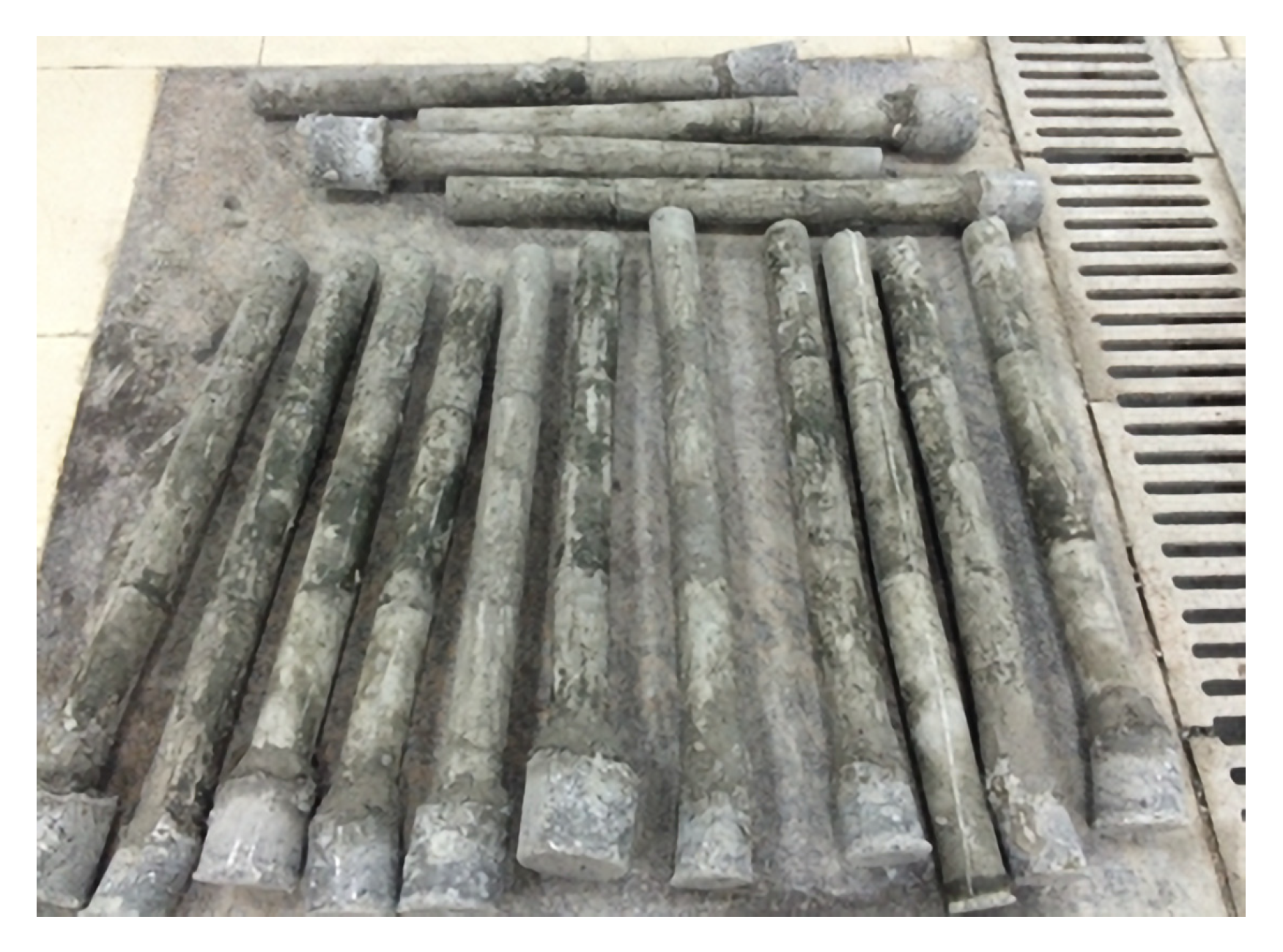

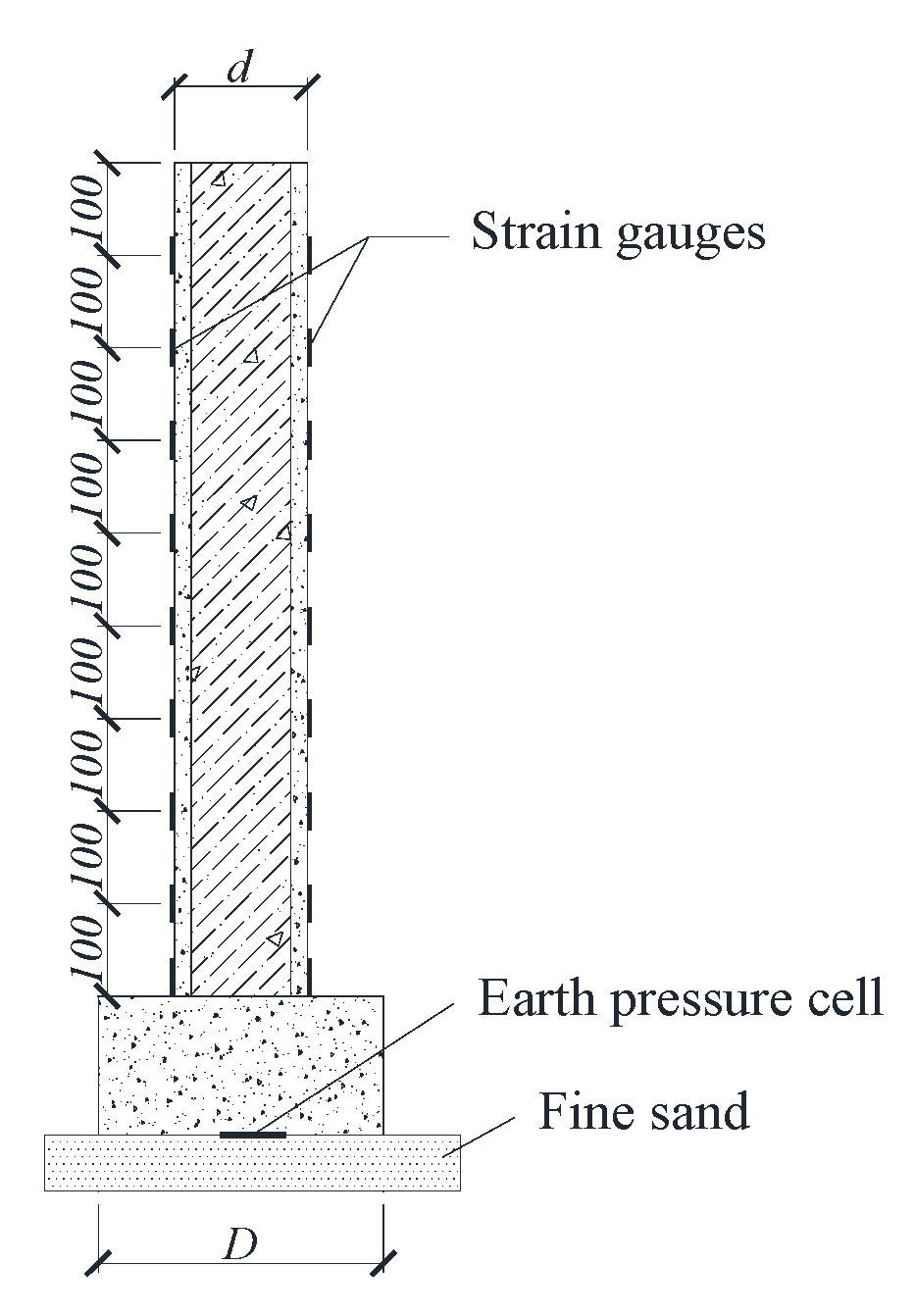

3.3. Model Pile Manufacturing and Measuring Points

3.4. Methods Used during Testing

4. Results and Discussion

4.1. Results of Modeling Test for Rigid Bottom-Expanded Piles

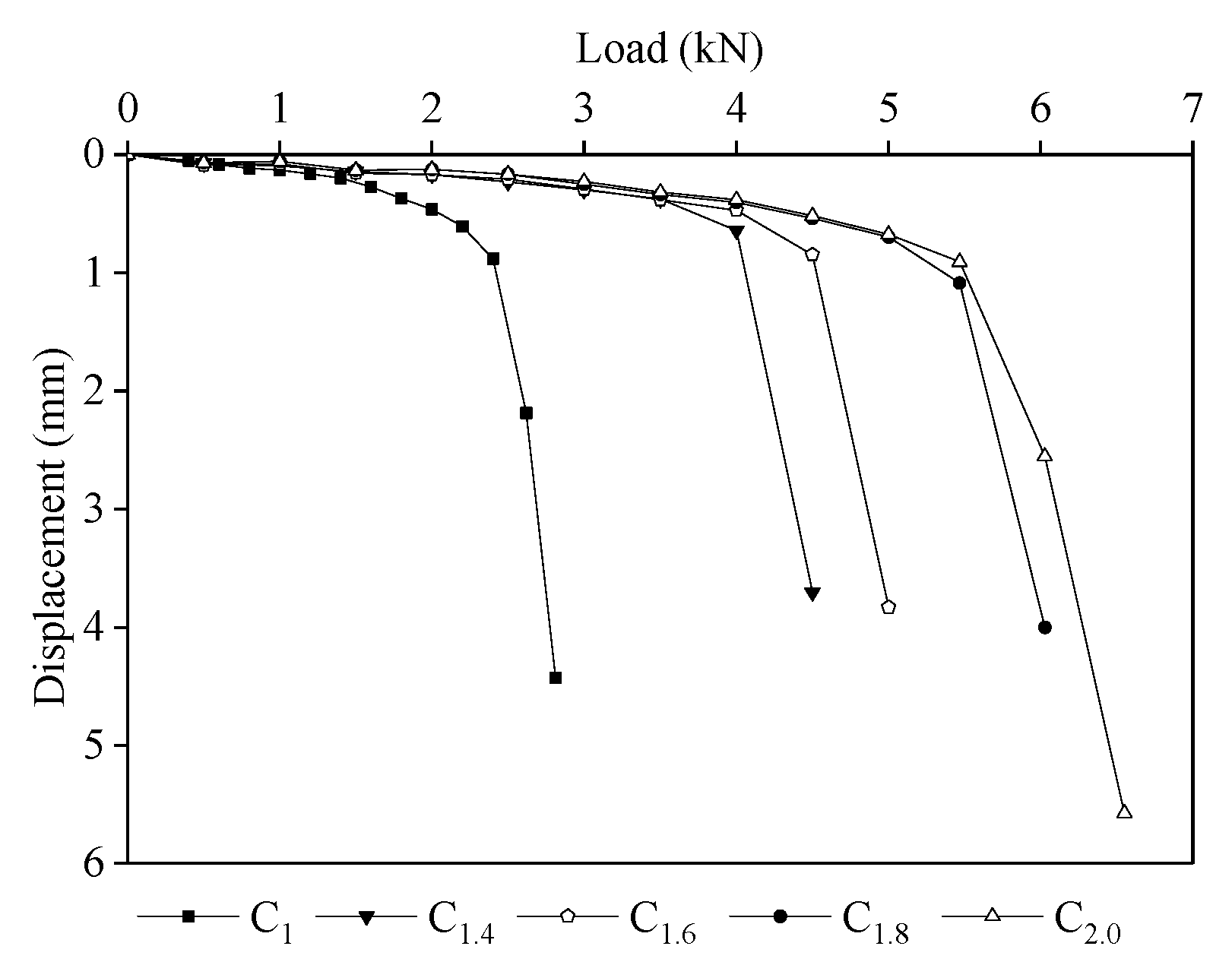

4.1.1. Load and Settlement Relationship

4.1.2. Pile Axial Force

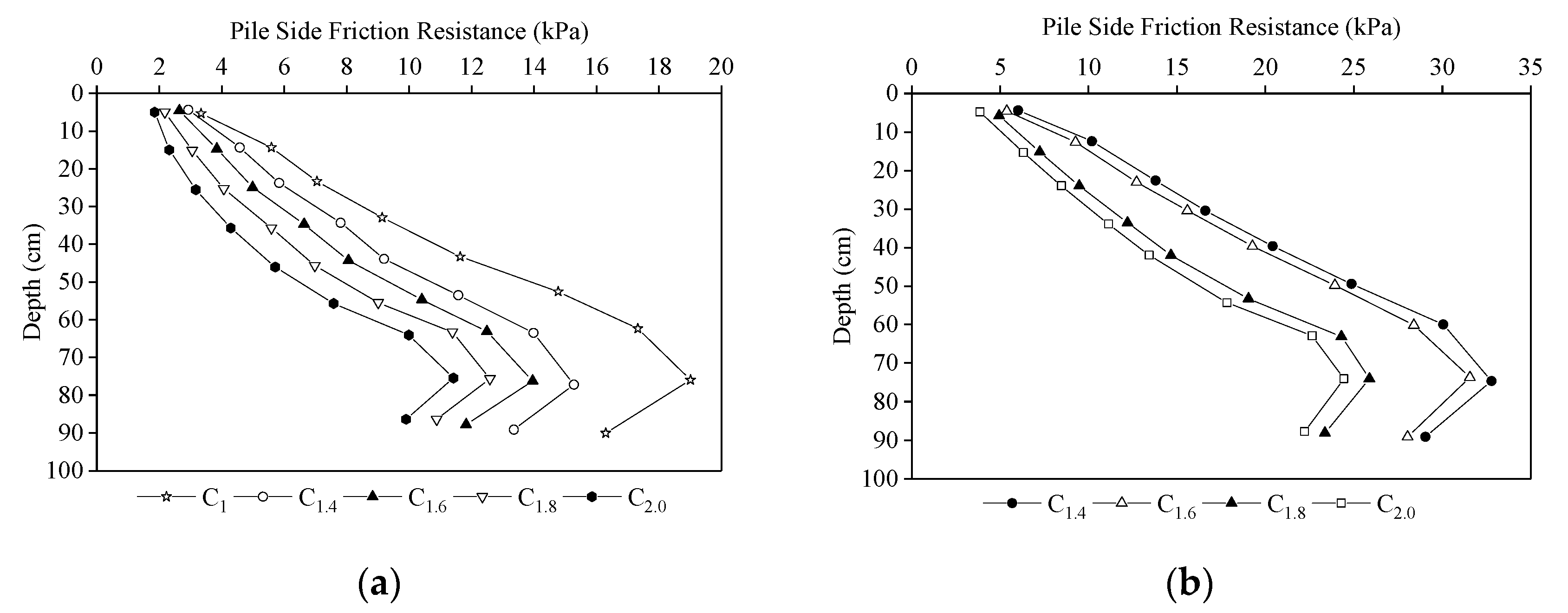

4.1.3. Shaft Resistance

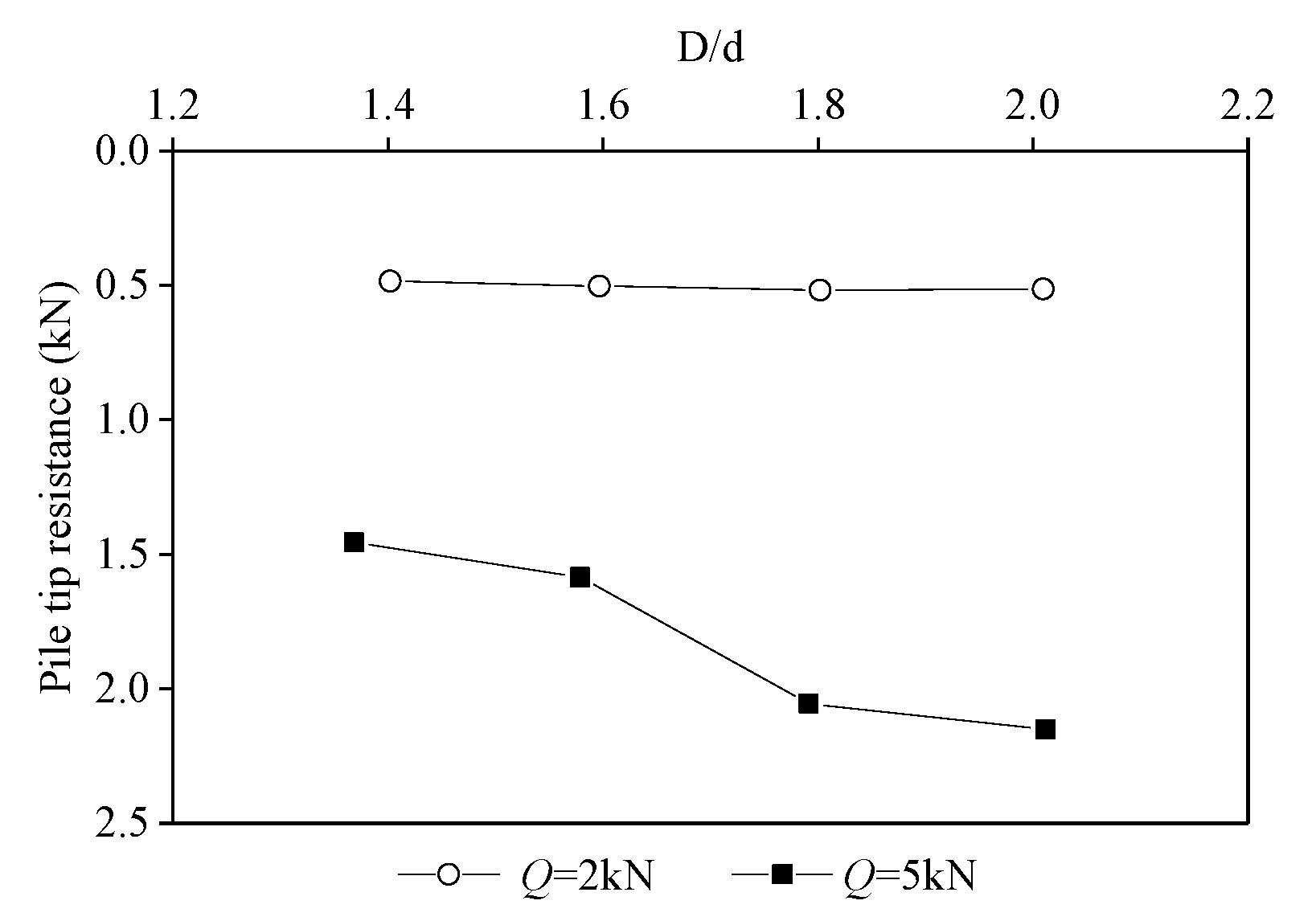

4.1.4. Pile Tip Resistance and Load Sharing Ratio

4.2. Results of Modeling Test for RFCPPEB

4.2.1. Load Settlement Curves (Q–S Curves)

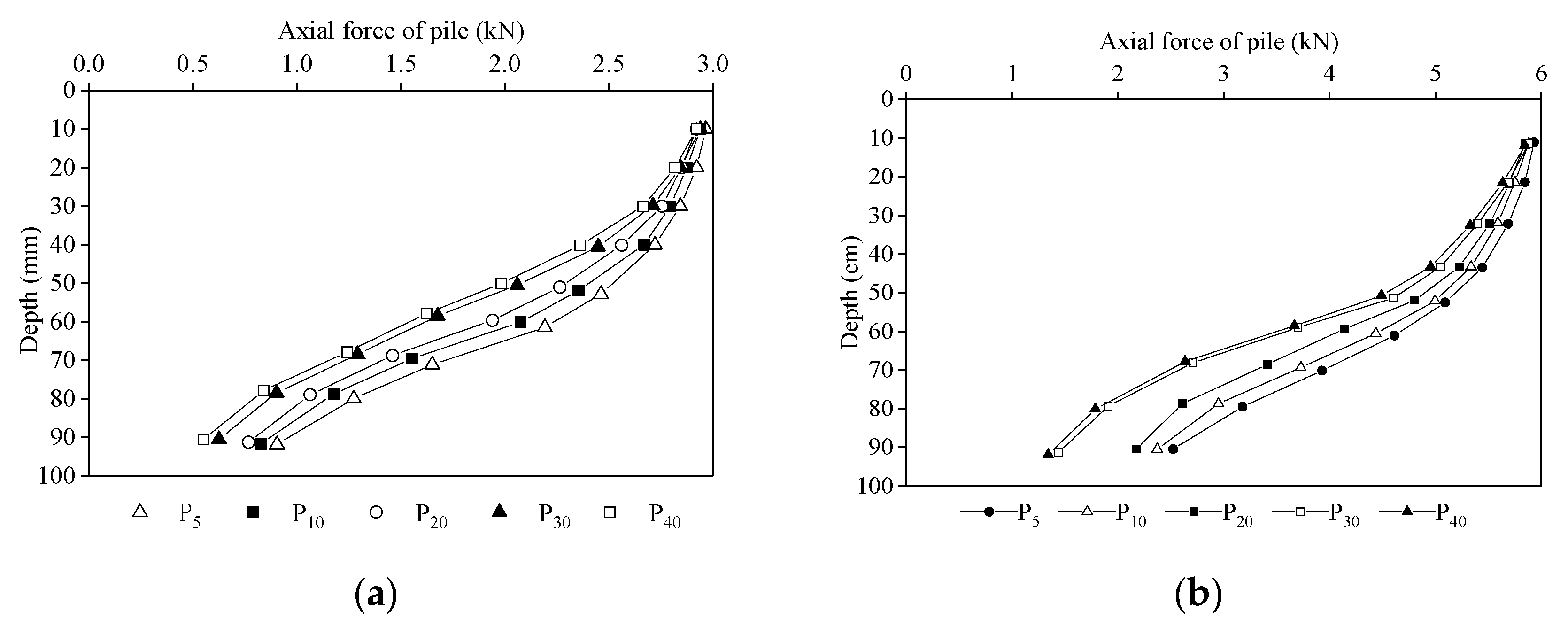

4.2.2. Axial Force of the Pile

4.2.3. Shaft Resistance

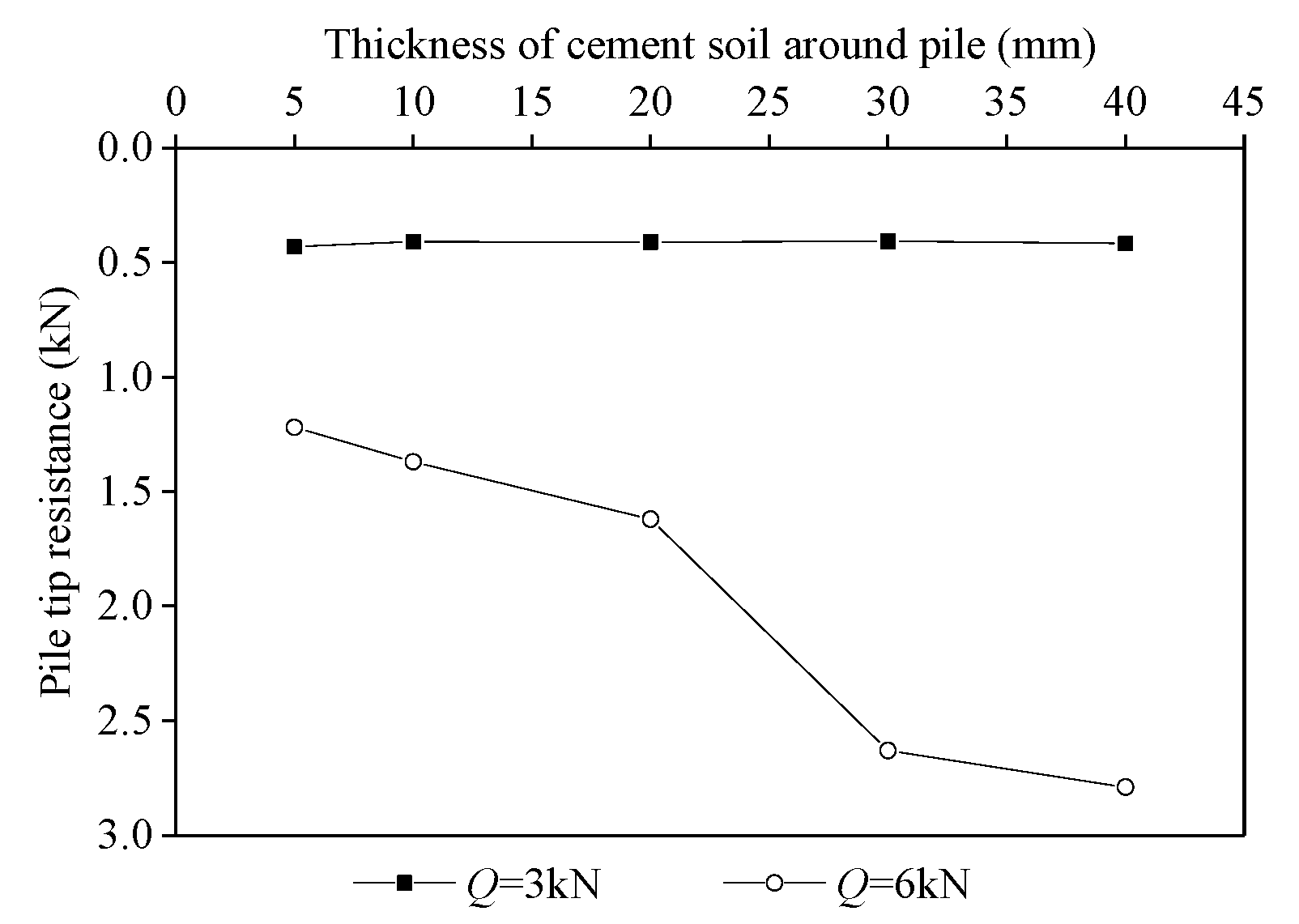

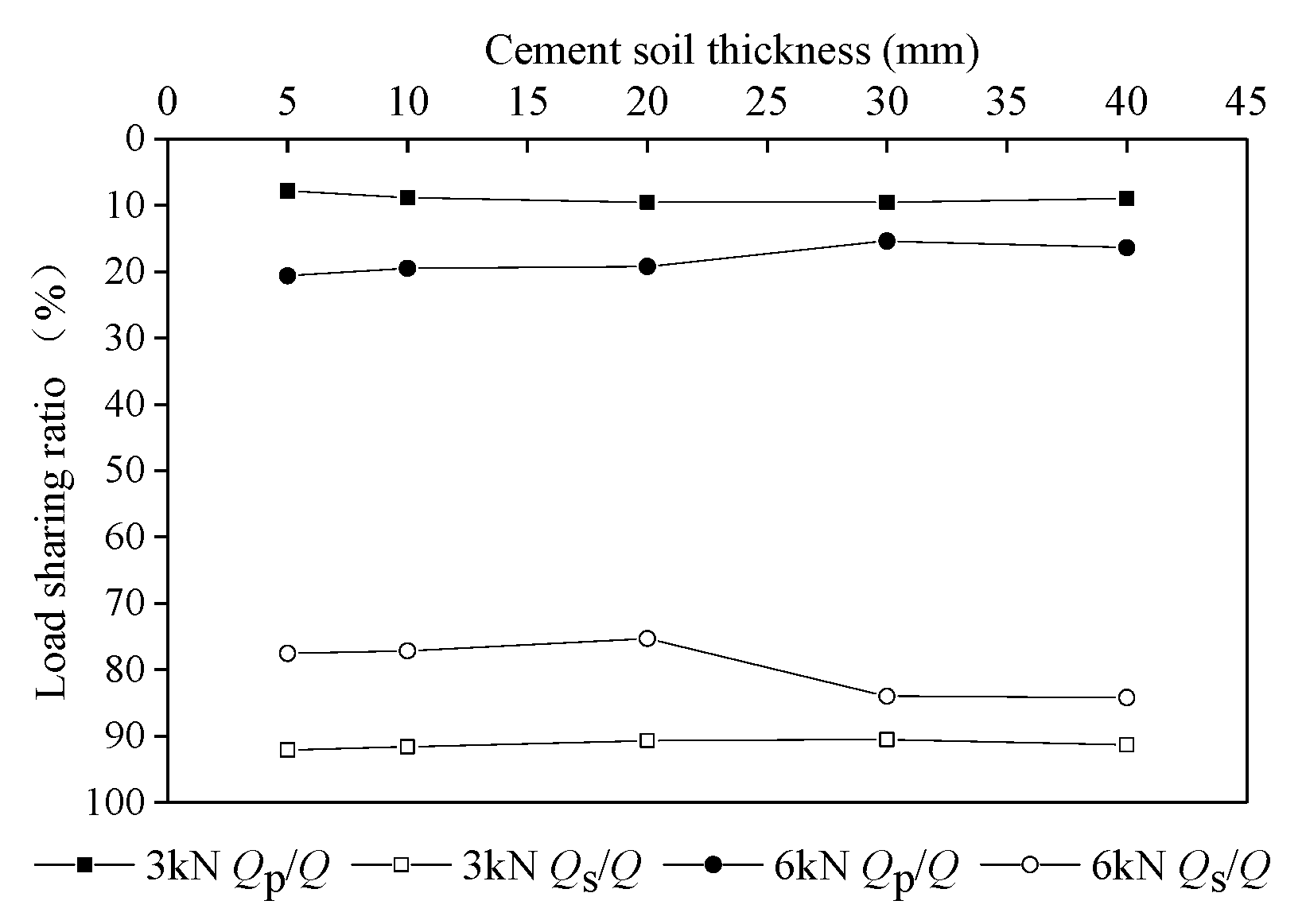

4.2.4. Pile Tip Resistance and Load Sharing Ratio

5. Numerical Modeling

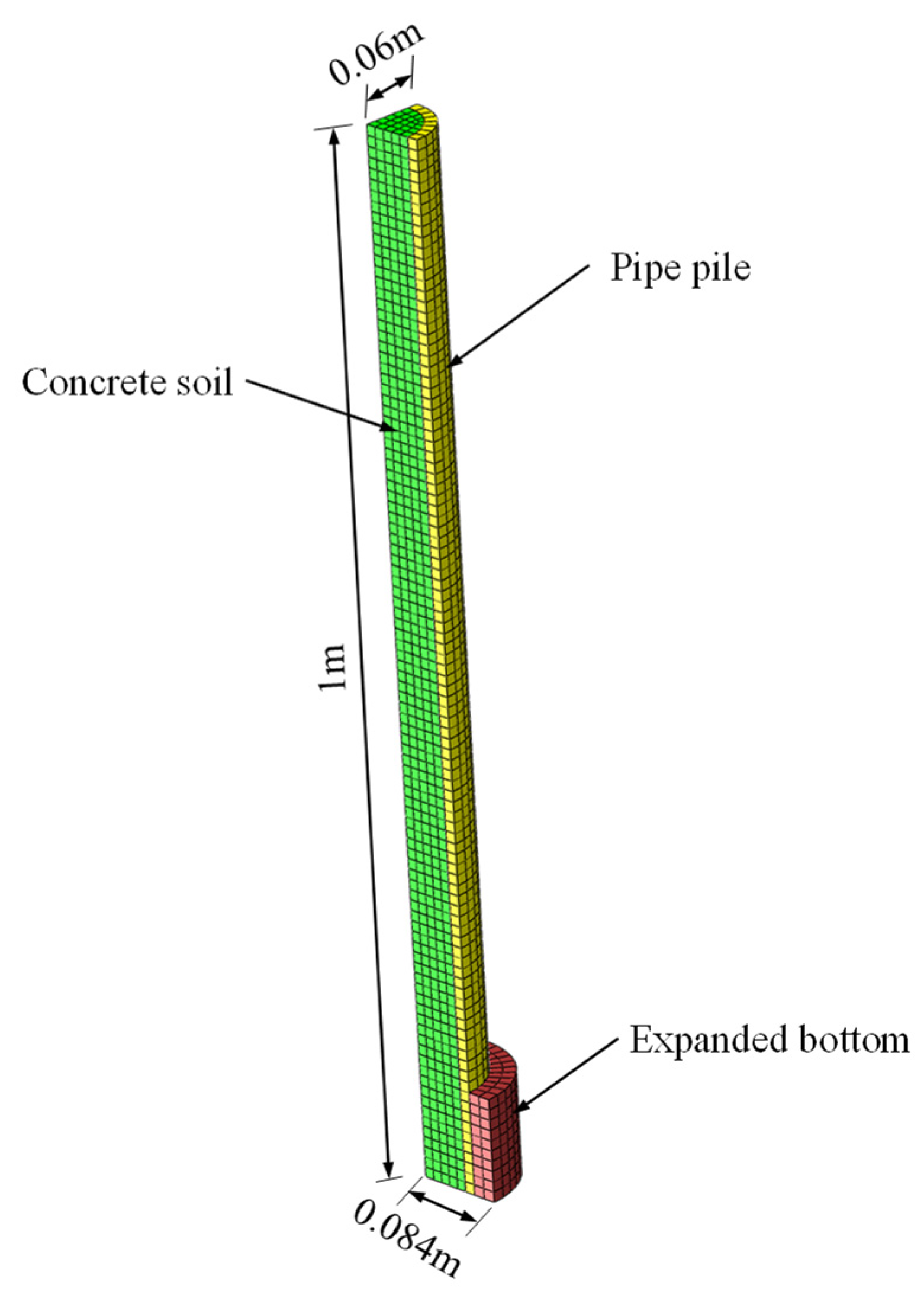

5.1. Basic Assumptions and Simplified Calculation

- It was assumed that the boundary of the pile and soil displayed the no-node displacement. This means that the regularity of the analysis is not affected by the pile and soil relationships.

- The rigid pile with expanded bottom was a line elastomer.

- The soil and cemented soil were homogeneous, continuous, and isotropic elastic–plastic solids.

- It was assumed that the load was borne by the top surface of the rigid pile with expanded bottom.

5.2. Establishment of Finite Element Model

5.3. Reliability Validation of the Numerical Model

5.4. Simulation Results of RFCPPEB

6. Conclusions

- The bearing capacity of the rigid piles with expanded bottom was better than that of the pipe piles. When the bottom expansion ratio (D/d) was increased, the bearing capacity of bottom-expanded piles was significantly increased at D/d = 1.4 and D/d = 1.8 compared to that of D/d = 1.0, reaching 1.67 and 2.29 times, respectively, while for D/d = 1.6 and D/d = 2.0, the ultimate bearing capacity remained unchanged. Besides, D/d = 1.8 was the favorable range for the ultimate bearing capacity of the rigid piles with expanded bottom that reduced the consumption of cement. Part of the load of the rigid pile with expanded bottom was borne by the expanded bottom. Moreover, with the increase in the expanded bottom diameter, the ultimate bearing capacity of the pile tip was increased, and such increase was most obvious when D/d = 1.8.

- Shaft resistance played an important role in the bearing process of the rigid piles with expanded bottom and RFCPPEB. The pile body was mainly destroyed by the shearing of the soil around piles. Hence, improving the shaft resistance could effectively enhance the bearing capacity of the pile foundation.

- The increases in the shaft resistance of RFCPPEB and thickness of the cemented soil showed a nonlinear growth, and the maximum shaft resistance was approximately 75 cm from the pile top. It had a linear relationship under the relatively small load, but the increase was small. The maximum shaft resistance of P10 and P20 was increased and the shaft resistance started to play its role. The maximum shaft resistance of P30 rose significantly compared with that of P20, indicating that when the thickness of the cemented soil was 0.5 of the pile diameter, the shaft resistance had the best performance. However, when the thickness of the cemented soil exceeded this value, it was of little significance to improve the shaft resistance and pile tip resistance.

- The soil pressure at the pile tip of RFCPPEB was smaller than that of the rigid piles with expanded bottom. The soil pressure at the pile tip was proportional to the pile top load under the relatively small load. The load ratio of the shaft resistance QS/Q for P5, P10, P20, P30, and P40 piles were 77.5%, 77.1%, 75.3%, 84.0%, and 84.2% respectively. When the pile top load was large, the soil pressure at the pile tip of RFCPPEB was decreased in the form of half of the quadratic curve. It reached the most reasonable position at the maximum slope of the quadratic curve when the thickness of the cemented soil was slightly greater than 0.5 times the diameter of the pipe pile. Relatively small thickness for the cemented soil led to poor effects. When thickness exceeded a certain value, the effect on the ultimate bearing capacity of the pile foundation was not obvious.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhou, H.; Liu, H.; Li, Y.; Ding, X. Limit lateral resistance of XCC pile group in undrained soil. Acta Geotech. 2019, 15, 1673–1683. [Google Scholar] [CrossRef]

- Liu, F.; Yi, J.; Cheng, P.; Yao, K. Numerical simulation of set-up around shaft of XCC pile in clay. Geomech. Eng. 2020, 21, 489–501. [Google Scholar]

- Zhou, H.; Yuan, J.; Liu, H.; Kong, G. Analytical model for evaluating XCC pile shaft capacity in soft soil by incorporating penetration effects. Soils Found. 2018, 58, 1093–1112. [Google Scholar] [CrossRef]

- Wang, X.-Q.; Chen, Y.-H.; Lin, F.; Lü, X.-Y.; Zhang, T. Evaluation of ultimate bearing capacity of Y-shaped vibro-pile. J. Central South Univ. Technol. 2008, 15, 186–194. [Google Scholar] [CrossRef]

- Ren, L.W.; Guo, W.D.; Yang, Q.W. Analysis on bearing performance of Y-shaped piles under compressive and tensile loading. Proc. Inst. Civ. Eng. Geotech. Eng. 2020, 173, 58–69. [Google Scholar] [CrossRef]

- Lv, Y.; Ng, C.W.; Lam, S.Y.; Liu, H.; Ding, X. Comparative study of Y-shaped and circular floating piles in consolidating clay. Can. Geotech. J. 2016, 53, 1483–1494. [Google Scholar] [CrossRef]

- Murphy, G.; Doherty, P.; Cadogan, D.; Gavin, K. Field experiments on instrumented winged monopiles. Proc. Inst. Civ. Eng. Geotech. Eng. 2016, 169, 227–239. [Google Scholar] [CrossRef]

- Zhou, J.-J.; Wang, K.-H.; Gong, X.-N.; Zhang, R.-H. Bearing capacity and load transfer mechanism of a static drill rooted nodular pile in soft soil areas. J. Zhejiang Univ. A 2013, 14, 705–719. [Google Scholar] [CrossRef] [Green Version]

- Zhou, J.-J.; Gong, X.-N.; Wang, K.-H.; Zhang, R.-H. A field study on the behavior of static drill rooted nodular piles with caps under compression. J. Zhejiang Univ. A 2015, 16, 951–963. [Google Scholar] [CrossRef] [Green Version]

- Zhou, J.J.; Gong, X.N.; Wang, K.H.; Zhang, R.H. Performance of static drill rooted nodular piles under compression. J. Zhejiang Univ. 2014, 48, 835–842. [Google Scholar]

- Zhou, J.J.; Gong, X.N.; Wang, K.H.; Zhang, R.H.; Yan, T.L. A model test on the behavior of a static drill rooted nodular pile under compression. Mar. Georesour. Geotechnol. 2016, 34, 293–301. [Google Scholar] [CrossRef]

- Zhou, J.J.; Gong, X.N.; Wang, K.H.; Zhang, R.H. Shaft capacity of the pre-bored grouted planted pile in dense sand. Acta Geotech. 2018, 13, 1227–1239. [Google Scholar] [CrossRef]

- Zhou, J.-J.; Yu, J.-L.; Gong, X.-N.; Yan, T.-L. Field tests on behavior of pre-bored grouted planted pile and bored pile embedded in deep soft clay. Soils Found. 2020, 60, 551–561. [Google Scholar] [CrossRef]

- Chao, G.; Lu, Z. Frost heaving of foundation pit for seasonal permafrost areas. Mag. Civ. Eng. 2019, 86, 61–71. [Google Scholar]

- Zheng, J.J.; Lu, S.Q.; Cao, W.Z.; Jing, D. Numerical simulation of composite rigid-flexible pile-supported retaining wall under the action of high-filled expansive soil. Rock Soil Mech. 2019, 40, 395–402. (In Chinese) [Google Scholar]

- Liu, K.F.; Cao, L.L.; Hu, Y.; Xu, J.P. Model test on the deformation behavior of geogrid supported by rigid-flexible piles under static load. In Proceedings of the GeoShanghai International Conference, Singapore, 27–30 May 2018; pp. 338–346. [Google Scholar]

- Liu, K.F.; Hu, Y.; Zhu, Y.J.; Wang, H. Effect of Flexible Pile on Rigid Flexible Pile Composite Foundation with Geogrid Reinforced Cushion. Adv. Mater. Res. 2014, 1065, 119–122. [Google Scholar] [CrossRef]

- Wang, X.Q.; Zhang, T.; Qi, C.G.; Cui, Y.L.; Zhang, S.M.; Chen, H.S. Field Test on Mechanical Behaviors of Coaxial Rigid-flexible Compound Pile Reinforced Embankment. China J. Highw. Transp. 2016, 29, 13–20. [Google Scholar]

- Zhang, H.D.; Wang, Q.H.; Lei, Z.G. Technology and application of jg soil-cement-pile strengthened pile in industrial projects. J. Eng. Geol. 2008, 16, 373–376. (In Chinese) [Google Scholar]

- Liu, H.L.; Ren, L.W.; Zheng, H.; Xiao, Y.Z. Full-scale model test on load transfer mechanism for jet grouting soil-cement-pile strengthened pile. Rock Soil Mech. 2010, 31, 1395–1401. (In Chinese) [Google Scholar]

- Ren, L.W.; Lu, C.C.; Zhang, J.W.; Xiao, Y.; Zhang, M.X. Model test on uplift bearing behavior of JPP pile under different combinations. Tumu Jianzhu Yu Huanjing Gongcheng J. Civ. 2018, 40, 94–101. (In Chinese) [Google Scholar]

- Zhou, D.Q.; Wang, X.L.; Guo, C.Y.; Zhou, J.J.; Wang, K. Research and application of hydraulic fracturing borehole bag sealing technology. IOP Conf. Ser. Earth Environ. Sci. 2021, 781, 022008. [Google Scholar] [CrossRef]

- Li, B.; Wang, F.; Fang, H.; Yang, K.J.; Zhang, X.J.; Ji, Y.T. Experimental and numerical study on polymer grouting pretreatment technology in void and corroded concrete pipes. Tunn. Undergr. Space Technol. 2021, 113, 103842. [Google Scholar] [CrossRef]

- Yang, W.S.; Yang, C.L. Creative Grouting Method Used in Blocking Water Inflow in a Shaft Wall. Int. Mine Water Assoc. Congr. Mine Water-Manag. Chall. 2011, 129–131. [Google Scholar]

- Fu, J.H.; Li, X.L.; Wang, Z.M. A novel sealing material and a bag-grouting sealing method for underground CBM drainage in China. Constr. Build. Mater. 2021, 299, 124016. [Google Scholar] [CrossRef]

- Wang, D.; Cao, J. The Experimental Research on the Bag-Grouting-Pile Composite Foundation in Coastal Soft Foundation Treatment. Appl. Mech. Mater. 2013, 275, 1411–1414. [Google Scholar] [CrossRef]

- Xu, Z.; Zhu, Z.J.; Fan, Y.X.; Li, K.X.; Chen, X.; Jiang, Q.C.; Liu, R.T. Field Test Research on Film Bag Grouting in Strongly Weathered Stratum Overlying Subway. IOP Conf. Ser. Earth Environ. Sci. 2020, 570, 052054. [Google Scholar] [CrossRef]

- Li, Q.; Wu, Z.; Zhang, D. Soil Compaction Effect of Bagged Grouting Piles in Saturated Soft Clay Subgrade. J. Southwest Jiaotong Univ. 2018, 53, 1026–1032. [Google Scholar]

- JGJ. JGJ 106-2014. Technical Code for Testing of Building Foundation Piles; China Architecture and Building Press: Beijing, China, 2014; pp. 13–16. (In Chinese) [Google Scholar]

- Cui, Y.L.; Qi, C.G.; Zheng, J.H.; Wang, X.Q.; Zhang, S.M. Field test research on post-grouting effect for super-long cast-in-place bored pile in thick soft foundation. Geotech. Geol. Eng. 2021, 39, 4833–4842. [Google Scholar] [CrossRef]

| Soil Type | Density, ρ (g/cm3) | Internal Angle of Friction, φ | Cohesion, c (kPa) | Compression Modulus, Es MPa | Water Content (%) |

|---|---|---|---|---|---|

| Sand | 1.51 | 39.0 | 0.0 | 17.42 | 2.795 |

| Clay | 1.92 | 28.2 | 24.7 | 4.69 | 28.30 |

| Test Group | Pile No. | Type | Cement Grade | Grade of Cemented Soil around Pile | L (m) | d (mm) | D (mm) | h (mm) |

|---|---|---|---|---|---|---|---|---|

| 1 | C1 | Rigid expanded bottom pile | P42.5 | - | 1 | 60 | 60 | 0 |

| C1.4 | 1 | 60 | 84 | 0 | ||||

| C1.6 | 1 | 60 | 96 | 0 | ||||

| C1.8 | 1 | 60 | 108 | 0 | ||||

| C2.0 | 1 | 60 | 120 | 0 | ||||

| 2 | P5 | RFCPPEB | P32.5 | 1 | 60 | 108 | 5 | |

| P10 | 1 | 60 | 108 | 10 | ||||

| P20 | 1 | 60 | 108 | 20 | ||||

| P30 | 1 | 60 | 108 | 30 | ||||

| P40 | 1 | 60 | 108 | 40 |

| Tested Pile | C1 | C1.4 | C1.6 | C1.8 | C2.0 |

|---|---|---|---|---|---|

| Ultimate bearing capacity (kN) | 2.4 | 4.0 | 4.0 | 5.5 | 5.7 |

| Ratio to ultimate bearing capacity of pile C1 | 1.00 | 1.67 | 1.67 | 2.29 | 2.38 |

| The concrete amount of the pile body (cm3) | 2826.0 | 3097.3 | 3266.8 | 3459.1 | 3673.8 |

| Ratio to pile body concrete amount of pile C1 | 1.00 | 1.10 | 1.16 | 1.22 | 1.30 |

| Concrete ultimate bearing capacity per unit volume of pile (N/cm3) | 0.85 | 1.29 | 1.22 | 1.59 | 1.55 |

| Ratio to concrete ultimate bearing capacity per unit volume of pile C1 | 1.00 | 1.52 | 1.44 | 1.87 | 1.82 |

| Methods | Tested Pile | |||||

|---|---|---|---|---|---|---|

| C1.8 | P5 | P10 | P20 | P30 | P40 | |

| Ultimate bearing capacity of each pile (kN) | 5.5 | 5.7 | 6.0 | 6.2 | 7.5 | 7.7 |

| Comparison of the ultimate bearing capacity of each pile with C1.8 (kN) | 0 | +0.2 | +0.5 | +0.7 | +2 | +2.2 |

| Ratio of the increased bearing capacity of each pile to the ultimate bearing capacity of C1.8 | 0 | 3.6% | 9.1% | 12.7% | 36.4% | 40.0% |

| Ratio of the cemented soil thickness around piles to the pile diameter | - | 1/12 | 1/6 | 1/3 | 1/2 | 2/3 |

| Cemented soil content around piles (m3) | 0 | 0.0007 | 0.0014 | 0.0029 | 0.0047 | 0.0065 |

| Ratio of the cemented soil content around pile P5 | - | 1.00 | 2.00 | 4.14 | 6.71 | 9.29 |

| Bearing capacity provided by the cemented soil per unit volume around piles (kN/m3) | - | 285.7 | 357.1 | 241.4 | 425.5 | 338.5 |

| Ratio of the ultimate bearing capacity provided by cemented soil per unit volume around pile P5 | - | 1.00 | 1.25 | 0.84 | 1.49 | 1.18 |

| Materials | Quality Density (kg/mm3) | Elastic Modulus Es (MPa) | Poisson’s Ratio | Cohesion c (kPa) | Internal Friction Angle φ (°) |

|---|---|---|---|---|---|

| Sandy soil | 1.51 × 10−6 | 10 | 0.18 | 35 | 30 |

| Cemented soil | 2.15 × 10−6 | 150 | 0.30 | 300 | 18 |

| C30 cement | 2.5 × 10−6 | 30,000 | 0.23 | / | / |

| Tested Pile | Pile Type for the Rigid Pile with Expanded Bottom | d (mm) | l (m) | D (mm) | h (mm) |

|---|---|---|---|---|---|

| H0 | C1.4 | 60 | 1 | 84 | 0 |

| H25 | 84 | 25 | |||

| H30 | 84 | 30 | |||

| H35 | 84 | 35 | |||

| H40 | 84 | 40 | |||

| I0 | C1.6 | 60 | 1 | 96 | 0 |

| I25 | 96 | 25 | |||

| I30 | 96 | 30 | |||

| I35 | 96 | 35 | |||

| I40 | 96 | 40 | |||

| J0 | C1.8 | 60 | 1 | 108 | 0 |

| J25 | 108 | 25 | |||

| J30 | 108 | 30 | |||

| J35 | 108 | 35 | |||

| J40 | 108 | 40 | |||

| K0 | C2.0 | 60 | 1 | 120 | 0 |

| K25 | 120 | 25 | |||

| K30 | 120 | 30 | |||

| K35 | 120 | 35 | |||

| K40 | 120 | 40 |

| Thickness of Cemented Soil, h | 25 mm | 30 mm | 35 mm | 40 mm | |

|---|---|---|---|---|---|

| Pile Type | |||||

| C1.4 | 6.5 kN | 7.0 kN | 7.5 kN | 7.5 kN | |

| C1.6 | 7.0 kN | 7.5 kN | 8.5 kN | 8.5 kN | |

| C1.8 | 7.5 kN | 8.0 kN | 9.5 kN | 9.5 kN | |

| C2.0 | 7.5 kN | 8.0 kN | 9.5 kN | 9.5 kN | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Que, Y.; Wang, K.; Diao, H.; Cui, Y.; Li, Q.; Li, D. Modeling Test and Numerical Simulation of Vertical Bearing Performance for Rigid-Flexible Composite Pouch Piles with Expanded Bottom (RFCPPEB). Symmetry 2022, 14, 107. https://doi.org/10.3390/sym14010107

Wang X, Que Y, Wang K, Diao H, Cui Y, Li Q, Li D. Modeling Test and Numerical Simulation of Vertical Bearing Performance for Rigid-Flexible Composite Pouch Piles with Expanded Bottom (RFCPPEB). Symmetry. 2022; 14(1):107. https://doi.org/10.3390/sym14010107

Chicago/Turabian StyleWang, Xinquan, Yichen Que, Kangyu Wang, Hongguo Diao, Yunliang Cui, Qing Li, and Dongliang Li. 2022. "Modeling Test and Numerical Simulation of Vertical Bearing Performance for Rigid-Flexible Composite Pouch Piles with Expanded Bottom (RFCPPEB)" Symmetry 14, no. 1: 107. https://doi.org/10.3390/sym14010107

APA StyleWang, X., Que, Y., Wang, K., Diao, H., Cui, Y., Li, Q., & Li, D. (2022). Modeling Test and Numerical Simulation of Vertical Bearing Performance for Rigid-Flexible Composite Pouch Piles with Expanded Bottom (RFCPPEB). Symmetry, 14(1), 107. https://doi.org/10.3390/sym14010107